Thermal and Dielectric Properties of Wolfberries as Affected by Moisture Content and Temperature Associated with Radio Frequency and Microwave Dehydrations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Measurements of True Density

2.3. Measurement of Thermal Properties

2.4. Measurement of Dielectric Properties

2.5. Statistical Analysis

3. Results and Discussion

3.1. Thermal Properties of Wolfberries

3.2. Dielectric Properties of Wolfberries

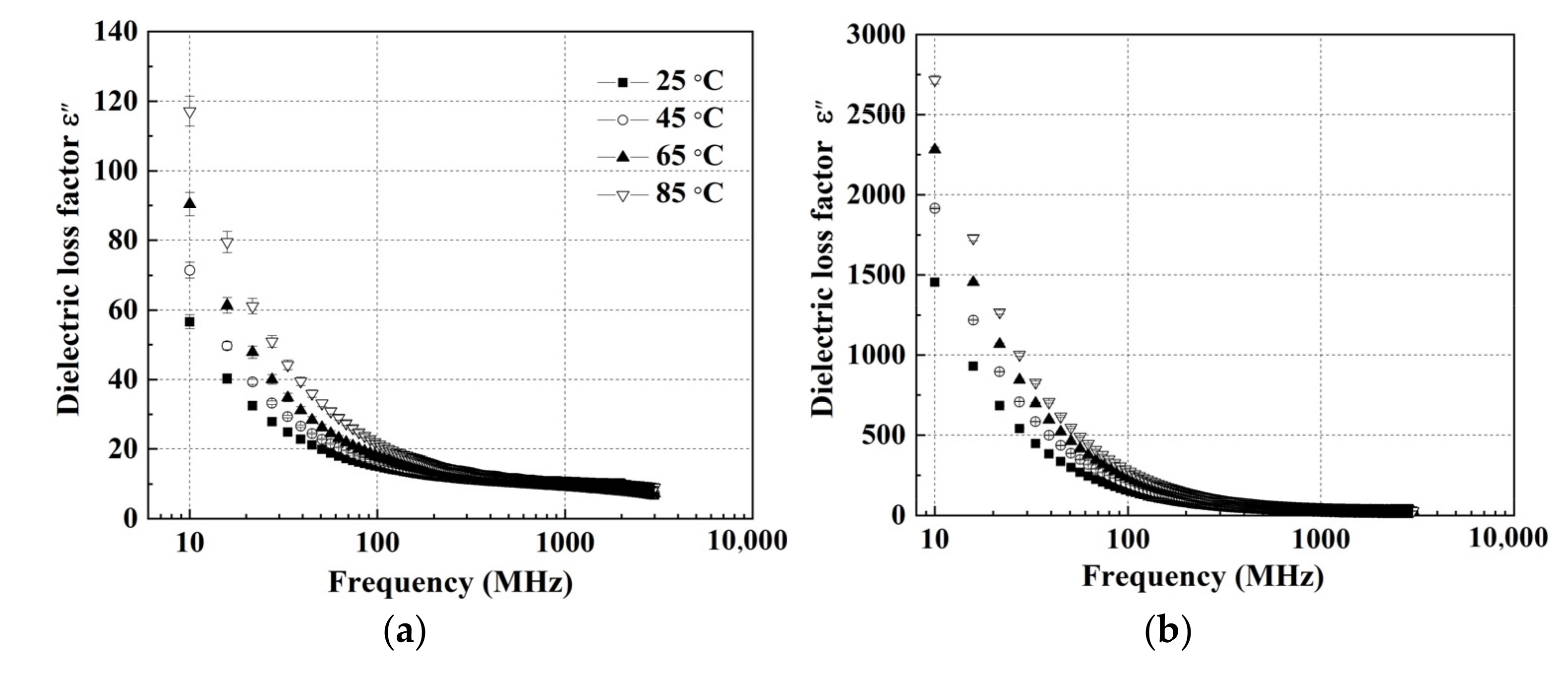

3.2.1. Frequency-Dependent DPs

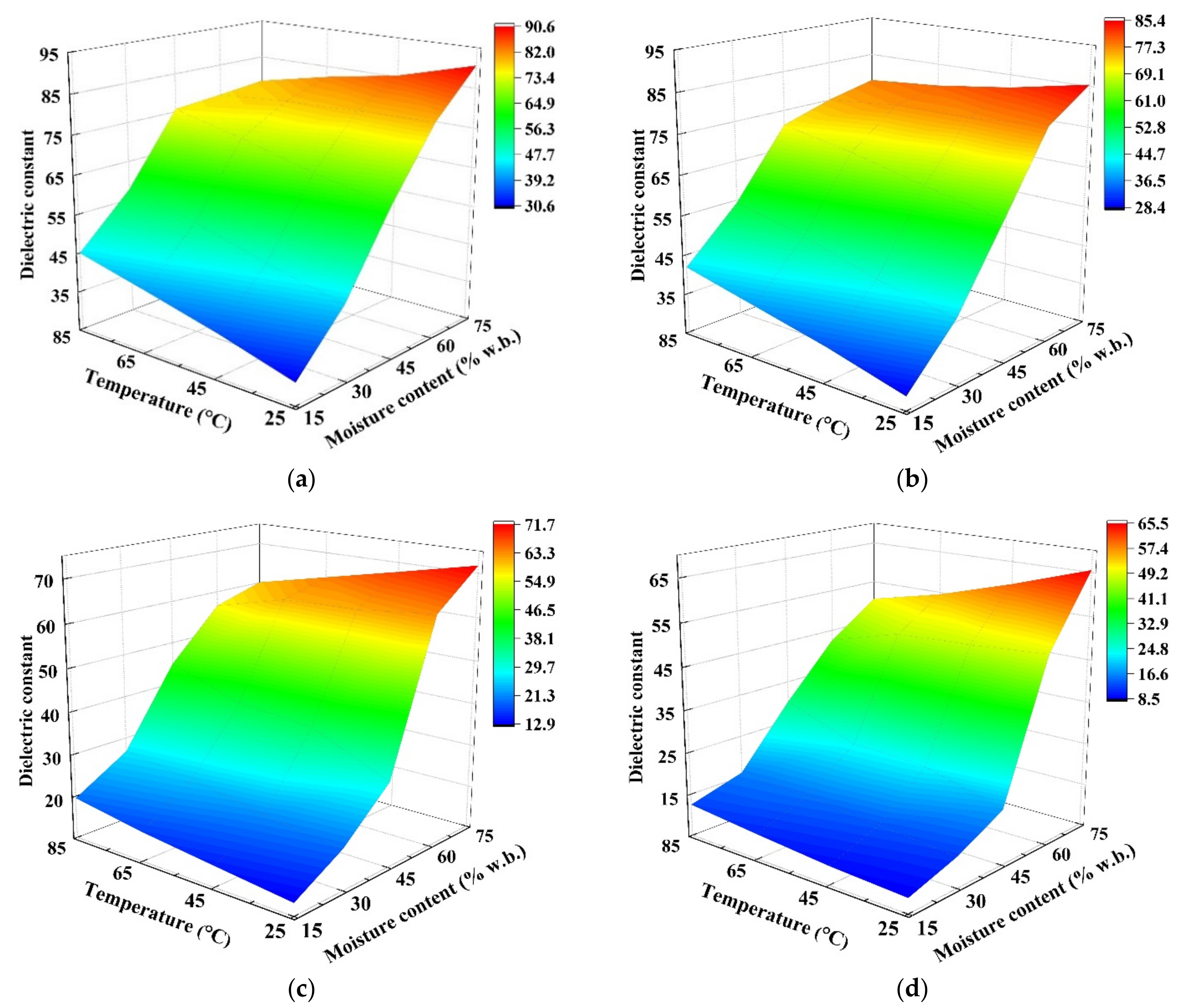

3.2.2. Moisture Content- and Temperature-Dependent DPs

3.2.3. Regression Models

3.3. Penetration Depth

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Konarska, A. Microstructural and histochemical characteristics of Lycium barbarum L. fruits used in folk herbal medicine and as functional food. Protoplasma 2018, 255, 1839–1854. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kulczynski, B.; Gramza-Michalowska, A. Goji berry (Lycium barbarum): Composition and health effects—A review. Pol. J. Food Nutr. Sci. 2016, 66, 67–75. [Google Scholar] [CrossRef]

- Masci, A.; Carradori, S.; Casadei, M.A.; Paolicelli, P.; Petralito, S.; Ragno, R.; Cesa, S. Lycium barbarum polysaccharides: Extraction, purification, structural characterisation and evidence about hypoglycaemic and hypolipidaemic effects. A review. Food Chem. 2018, 254, 377–389. [Google Scholar] [CrossRef] [PubMed]

- Patsilinakos, A.; Ragno, R.; Carradori, S.; Petralito, S.; Cesa, S. Carotenoid content of Goji berries: CIELAB, HPLC-DAD analyses and quantitative correlation. Food Chem. 2018, 268, 49–56. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.J.; Liang, X.J.; Guo, S.J.; Li, Y.K.; Zhang, B.; Yin, Y.; An, W.; Cao, Y.L.; Zhao, J.H. Evaluation of nutrients and related environmental factors for wolfberry (Lycium barbarum) fruits grown in the different areas of China. Biochem. Syst. Ecol. 2019, 86, 103916. [Google Scholar]

- Yan, Y.M.; Ran, L.W.; Cao, Y.L.; Qin, K.; Zhang, X.; Luo, Q.; Jabbar, S.; Abid, M.; Zeng, X.X. Nutritional, Phytochemical characterization and antioxidant capacity of Ningxia wolfberry (Lycium barbarum L.). J. Chem. Soc. Pak. 2014, 36, 1079–1087. [Google Scholar]

- Cui, C.J.; Zhao, D.D.; Huang, J.; Hao, J.X. Progress on research and development of goji berry drying: A review. Int. J. Food Prop. 2022, 25, 435–449. [Google Scholar] [CrossRef]

- Sacilik, K.; Elicin, A.K. The thin layer drying characteristics of organic apple slices. J. Food Eng. 2006, 73, 281–289. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, M.; Mujumdar, A.S.; Lim, R.X. Comparison of drying characteristic and uniformity of banana cubes dried by pulse-spouted microwave vacuum drying, freeze drying and microwave freeze drying. J. Sci. Food Agric. 2014, 94, 1827–1834. [Google Scholar] [CrossRef]

- Ramaswamy, H.; Tang, J. Microwave and radio frequency heating. Food Sci Technol. Int. 2008, 14, 423–427. [Google Scholar] [CrossRef]

- Huang, Z.; Zhu, H.K.; Yan, R.J.; Wang, S.J. Simulation and prediction of radio frequency heating in dry soybeans. Biosyst. Eng. 2015, 129, 34–47. [Google Scholar] [CrossRef]

- Zhou, X.; Ramaswamy, H.; Qu, Y.T.; Xu, R.Z.; Wang, S.J. Radio frequency-vacuum drying of kiwifruits: Kinetics, uniformity, and product quality. Food Bioprocess Technol. 2018, 11, 2094–2109. [Google Scholar] [CrossRef]

- Wang, C.C.; Kou, X.X.; Zhou, X.; Li, R.; Wang, S.J. Effects of layer arrangement on heating uniformity and product quality after hot air assisted radio frequency drying of carrot. Innov. Food Sci. Emerg. Technol. 2021, 69, 102667. [Google Scholar] [CrossRef]

- Zhang, H.J.; Gong, C.T.; Wang, X.F.; Liao, M.J.; Yue, J.; Jiao, S.S. Application of hot air-assisted radio frequency as second stage drying method for mango slices. J. Food Process Eng. 2019, 42, 8. [Google Scholar] [CrossRef]

- Chen, L.; Subbiah, J.; Jones, D.; Zhao, Y.Y.; Jung, J. Development of effective drying strategy with a combination of radio frequency (RF) and convective hot-air drying for inshell hazelnuts and enhancement of nut quality. Innov. Food Sci. Emerg. Technol. 2020, 67, 102555. [Google Scholar] [CrossRef]

- Das, I.; Arora, A. Alternate microwave and convective hot air application for rapid mushroom drying. J. Food Eng. 2018, 223, 208–219. [Google Scholar] [CrossRef]

- Cuccurullo, G.; Giordano, L.; Metallo, A.; Cinquanta, L. Drying rate control in microwave assisted processing of sliced apples. Biosyst. Eng. 2018, 170, 24–30. [Google Scholar] [CrossRef]

- Mao, Y.X.; Wang, P.H.; Wu, Y.; Hou, L.X.; Wang, S.J. Effects of various radio frequencies on combined drying and disinfestation treatments for in-shell walnuts. LWT-Food Sci Technol. 2021, 144, 111246. [Google Scholar] [CrossRef]

- Huang, Z.; Chen, Y.; Wang, S. Numerical studies on the electromagnetic and thermal performances of radio frequency disinfestation treatments for dried apricots. Postharvest Biol. Technol. 2020, 163, 111116. [Google Scholar] [CrossRef]

- Sosa-Morales, M.E.; Tiwari, G.; Wang, S.; Tang, J.; Garcia, H.S.; Lopez-Malo, A. Dielectric heating as a potential post-harvest treatment of disinfesting mangoes, Part I: Relation between dielectric properties and ripening. Biosyst. Eng. 2009, 103, 297–303. [Google Scholar] [CrossRef]

- Mykhailyk, V.; Lebovka, N. Specific heat of apple at different moisture contents and temperatures. J. Food Eng. 2014, 123, 32–35. [Google Scholar] [CrossRef] [Green Version]

- Guo, W.; Tiwari, G.; Tang, J.; Wang, S. Frequency, moisture and temperature-dependent dielectric properties of chickpea flour. Biosyst. Eng. 2008, 101, 217–224. [Google Scholar] [CrossRef]

- Nelson, S.O.; Trabelsi, S. Use of material dielectric properties in agricultural applications. J. Microwave Power E.E. 2016, 50, 237–268. [Google Scholar] [CrossRef]

- Jiao, S.; Johnson, J.A.; Tang, J.; Tiwari, G.; Wang, S. Dielectric properties of cowpea weevil, black-eyed peas and mung beans with respect to the development of radio frequency heat treatments. Biosyst. Eng. 2011, 108, 280–291. [Google Scholar] [CrossRef]

- Mao, Y.X.; Hao, Y.J.; Guan, X.Y.; Wang, P.H.; Wang, S.J. Temperature and moisture dependent dielectric and thermal properties of walnut components associated with radio frequency and microwave pasteurization. Foods. 2022, 11, 919. [Google Scholar] [CrossRef]

- Li, R.; Zhang, S.; Kou, X.X.; Ling, B.; Wang, S.J. Dielectric properties of almond kernels associated with radio frequency and microwave pasteurization. Sci. Rep. 2017, 7, 42452. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Zhou, L.Y.; Ling, B.; Wang, S.J. Dielectric properties of peanut kernels associated with microwave and radio frequency drying. Biosyst. Eng. 2016, 145, 108–117. [Google Scholar] [CrossRef]

- Zhou, X.; Li, R.; Lyng, J.G.; Wang, S.J. Dielectric properties of kiwifruit associated with a combined radio frequency vacuum and osmotic drying. J. Food Eng. 2018, 239, 72–82. [Google Scholar] [CrossRef]

- Zhu, X.H.; Guo, W.C.; Wu, X.L.; Wang, S.J. Dielectric properties of chestnut flour relevant to drying with radio-frequency and microwave energy. J. Food Eng. 2012, 113, 143–150. [Google Scholar] [CrossRef]

- Peng, J.; Tang, J.; Jiao, Y.; Bohnet, S.G.; Barrett, D.M. Dielectric properties of tomatoes assisting in the development of microwave pasteurization and sterilization processes. LWT-Food Sci. Technol. 2013, 54, 367–376. [Google Scholar] [CrossRef]

- Bon, J.; Vaquiro, H.; Benedito, J.; Telis-Romero, J. Thermophysical properties of mango pulp (Mangifera indica L. cv. Tommy Atkins). J. Food Eng. 2010, 97, 563–568. [Google Scholar] [CrossRef]

- Souza, M.A.; Bonomo, R.C.F.; Fontan, R.C.I.; Minim, L.A.; Coimbra, J.S.D. Thermophysical properties of pack fruit pulp affected by changes in moisture content and temperature. J. Food Process Eng. 2011, 34, 580–592. [Google Scholar] [CrossRef]

- Delgado, A.E.; Gallo, A.; DePiante, D.; Rubiolo, A. Thermal conductivity of unfrozen and frozen strawberry and spinach. J. Food Eng. 1997, 31, 137–146. [Google Scholar] [CrossRef]

- McKeown, M.S.; Trabelsi, S.; Tollner, E.W.; Nelson, S.O. Dielectric spectroscopy measurements for moisture prediction in Vidalia onions. J. Food Eng. 2012, 111, 505–510. [Google Scholar] [CrossRef]

- Al Faruq, A.; Zhang, M.; Bhandari, B.; Azam, S.M.R.; Khatun, M.H.A. New understandings of how dielectric properties of fruits and vegetables are affected by heat-induced dehydration: A review. Drying Technol. 2019, 37, 1780–1792. [Google Scholar] [CrossRef]

- Jiang, H.; Shen, Y.B.; Zhen, L.Y.; Li, W.H.; Zhang, Q.G. Evaluation of strawberries dried by radio frequency energy. Dry. Technol. 2018, 37, 312–321. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the Association of Official Analytical Chemists; AOAC: Rockville, MD, USA, 1990. [Google Scholar]

- Xie, L.; Zheng, Z.A.; Mujunndar, A.S.; Fang, X.M.; Wang, J.; Zhang, Q.; Ma, Q.; Xiao, H.W.; Liu, Y.H.; Gao, Z.J. Pulsed vacuum drying (PVD) of wolfberry: Drying kinetics and quality attributes. Dry. Technol. 2018, 36, 1501–1514. [Google Scholar] [CrossRef]

- Guan, X.Y.; Ramaswamy, H.; Zhang, B.H.; Lin, B.Y.; Hou, L.X.; Wang, S.J. Influence of moisture content, temperature and heating rate on germination rate of watermelon seeds. Sci. Hortic. 2020, 272, 109528. [Google Scholar] [CrossRef]

- Lin, B.Y.; Wang, S.J. Dielectric properties, heating rate, and heating uniformity of wheat flour with added bran associated with radio frequency treatments. Innov. Food Sci. Emerg. Technol. 2020, 60, 102290. [Google Scholar] [CrossRef]

- Zhang, S.; Huang, Z.; Wang, S.J. Improvement of radio frequency (RF) heating uniformity for peanuts with a new strategy using computational modeling. Innov. Food Sci. Emerg. Technol. 2017, 41, 79–89. [Google Scholar] [CrossRef]

- Sahin, S.; Sumnu, S.G. Physical Properties of Foods; Springer: New York, NY, USA, 2006. [Google Scholar]

- Jiao, Y.; Tang, J.; Wang, S.J.; Koral, T. Influence of dielectric properties on the heating rate in free-running oscillator radio frequency systems. J. Food Eng. 2014, 120, 197–203. [Google Scholar] [CrossRef]

- Ling, B.; Guo, W.; Hou, L.; Li, R.; Wang, S. Dielectric properties of pistachio kernels as influenced by frequency, temperature, moisture and salt content. Food Bioprocess Technol. 2015, 8, 420–430. [Google Scholar] [CrossRef]

- Chen, Y.X.; He, J.L.; Li, F.; Tang, J.M.; Jiao, Y. Model food development for tuna (Thunnus Obesus) in radio frequency and microwave tempering using grass carp mince. J. Food Eng. 2020, 292, 110267. [Google Scholar] [CrossRef]

- Gezahegn, Y.A.; Tang, J.; Sablani, S.S.; Pedrow, P.D.; Hong, Y.K.; Lin, H.; Tang, Z. Dielectric properties of water relevant to microwave assisted thermal pasteurization and sterilization of packaged foods. Innov. Food Sci. Emerg. Technol. 2021, 74, 102837. [Google Scholar] [CrossRef]

- Barba, A.A.; Lamberti, G. Dielectric properties of pineapple as function of temperature and water content. Int. J. Food Sci. Technol. 2013, 48, 1334–1338. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, M.; Mujumdar, A.S.; Jiang, H. Effect of salt and sucrose content on dielectric properties and microwave freeze drying behavior of re-structured potato slices. J. Food Eng. 2011, 106, 290–297. [Google Scholar] [CrossRef]

- Tang, J.; Feng, H.; Lau, M. Advances in agricultural engineering. In Microwave Heating in Food Processing; Young, X., Tang, J., Eds.; World Scientific Publishing Co Pte Ltd.: New York, NY, USA, 2002; pp. 1–43. [Google Scholar]

- Metaxas, A.C.; Meredith, R.J. Industrial Microwave Heating; Pereginus: London, UK, 1988. [Google Scholar]

- Guo, W.C.; Wang, S.J.; Tiwari, G.; Johnson, J.A.; Tang, J. Temperature and moisture dependent dielectric properties of legume flour associated with dielectric heating. LWT Food Sci. Technol. 2010, 43, 193–201. [Google Scholar] [CrossRef]

| Moisture Content (w.b.) | True Density (g/cm3) |

|---|---|

| 15.2 ± 1.2% | 1.193 ± 0.019 a * |

| 30.3 ± 1.1% | 1.166 ± 0.004 ab |

| 45.3 ± 1.4% | 1.147 ± 0.012 b |

| 59.8 ± 1.8% | 1.126 ± 0.042 b |

| 75.1 ± 1.3% | 0.947 ± 0.004 c |

| Frequency (MHz) | Dielectric Properties | Equations |

|---|---|---|

| 27 | ε′ = 20.64 + 0.16T − 19.81M + 0.82TM + 330.70M2 − 1.77M2T − 227.30M3 | (4) |

| ε″ = 212.80 − 2.44T − 1295.00M + 13.38TM + 1962.00M2 | (5) | |

| 40 | ε′ = 25.10 − 0.14T − 82.66M + 0.83TM + 495.85M2−1.77M2T−356.02M3 | (6) |

| ε″ = 151.70 − 1.71T − 901.23M + 9.39TM + 1369.00M2 | (7) | |

| 915 | ε′ = −3.72 + 72.69M + 0.93TM−1.57M2T + 66.77M3 | (8) |

| ε″ = 1.54 − 0.04T + 54.95M + 0.33TM − 36.79M2 | (9) | |

| 2450 | ε′ = 30.99−276.90M + 0.91TM + 770.70M2−1.67M2T−438.21M3 | (10) |

| ε″ = −5.99 + 0.05T + 78.81M − 52.21M2 | (11) |

| Variance and R2 | 27 MHz (Equation (4)) | 40 MHz (Equation (6)) | 915 MHz (Equation (8)) | 2450 MHz (Equation (10)) | ||||

|---|---|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | |

| T | 7.246 | 0.0226 | 13.608 | 0.0042 | 0.995 | 0.3420 | 0.737 | 0.4109 |

| M | 215.363 | <0.0001 | 581.503 | <0.0001 | 169.904 | <0.0001 | 119.065 | <0.0001 |

| TM | 73.438 | <0.0001 | 160.598 | <0.0001 | 14.337 | 0.0036 | 5.007 | 0.0492 |

| T2 | 0.001 | 0.9799 | 0.157 | 0.7004 | 0.063 | 0.8069 | 0.019 | 0.8922 |

| M2 | 41.620 | <0.0001 | 116.886 | <0.0001 | 0.693 | 0.4247 | 25.166 | 0.0005 |

| T2M | 0.123 | 0.7335 | 0.0001 | 0.9905 | 0.041 | 0.8444 | 0.001 | 0.9765 |

| TM2 | 12.091 | 0.0059 | 27.172 | 0.0004 | 6.431 | 0.0296 | 6.215 | 0.0318 |

| T3 | 0.125 | 0.7307 | 0.183 | 0.6776 | 0.013 | 0.9122 | 0.020 | 0.8896 |

| M3 | 9.251 | 0.0124 | 51.168 | <0.0001 | 25.777 | 0.0005 | 11.137 | 0.0075 |

| Model | 191.722 | <0.0001 | 420.048 | <0.0001 | 91.154 | <0.0001 | 68.785 | <0.0001 |

| R2 | 0.994 | 0.997 | 0.988 | 0.984 | ||||

| Variance and R2 | 27 MHz (Equation (5)) | 40 MHz (Equation (7)) | 915 MHz (Equation (9)) | 2450 MHz (Equation (11)) | ||||

|---|---|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | |

| T | 55.004 | <0.0001 | 117.475 | <0.0001 | 59.110 | <0.0001 | 17.160 | 0.0010 |

| M | 789.362 | <0.0001 | 1199.657 | <0.0001 | 751.532 | <0.0001 | 532.508 | <0.0001 |

| TM | 73.609 | <0.0001 | 73.709 | <0.0001 | 25.173 | 0.0002 | 0.277 | 0.6070 |

| T2 | 0.077 | 0.7860 | 0.071 | 0.7938 | 0.050 | 0.8266 | 0.005 | 0.9459 |

| M2 | 99.675 | <0.0001 | 98.608 | <0.0001 | 20.259 | 0.0005 | 45.142 | <0.0001 |

| Model | 297.693 | <0.0001 | 297.904 | <0.0001 | 171.225 | <0.0001 | 119.018 | <0.0001 |

| R2 | 0.991 | 0.991 | 0.984 | 0.977 | ||||

| Moisture Content (% w.b.) | T (°C) | Penetration Depth (cm) | |||

|---|---|---|---|---|---|

| 27 MHz | 40 MHz | 915 MHz | 2450 MHz | ||

| 15.1 | 25 | 38.84 ± 0.73 | 30.68 ± 0.59 | 2.16 ± 0.01 | 0.85 ± 0.00 |

| 45 | 34.36 ± 0.75 | 27.64 ± 0.42 | 2.13 ± 0.01 | 0.81 ± 0.02 | |

| 65 | 30.74 ± 0.87 | 25.21 ± 0.71 | 2.06 ± 0.01 | 0.79 ± 0.02 | |

| 85 | 25.51 ± 0.75 | 20.92 ± 0.57 | 1.99 ± 0.01 | 0.75 ± 0.01 | |

| 30.3 | 25 | 22.71 ± 1.38 | 18.55 ± 1.15 | 1.74 ± 0.12 | 0.61 ± 0.04 |

| 45 | 20.44 ± 0.24 | 16.83 ± 0.11 | 1.70 ± 0.06 | 0.60 ± 0.02 | |

| 65 | 18.70 ± 0.31 | 15.49 ± 0.26 | 1.56 ± 0.01 | 0.53 ± 0.00 | |

| 85 | 16.43 ± 0.12 | 13.73 ± 0.10 | 1.51 ± 0.00 | 0.51 ± 0.00 | |

| 45.3 | 25 | 11.75 ± 0.19 | 9.85 ± 0.16 | 1.33 ± 0.05 | 0.46 ± 0.02 |

| 45 | 9.60 ± 0.06 | 8.03 ± 0.04 | 1.31 ± 0.03 | 0.43 ± 0.01 | |

| 65 | 8.26 ± 0.01 | 6.87 ± 0.03 | 1.28 ± 0.02 | 0.42 ± 0.01 | |

| 85 | 7.52 ± 0.09 | 6.25 ± 0.09 | 1.26 ± 0.01 | 0.40 ± 0.00 | |

| 59.8 | 25 | 9.86 ± 0.02 | 8.37 ± 0.02 | 1.65 ± 0.02 | 0.59 ± 0.01 |

| 45 | 7.57 ± 0.09 | 6.32 ± 0.08 | 1.48 ± 0.01 | 0.56 ± 0.01 | |

| 65 | 5.97 ± 0.07 | 4.94 ± 0.06 | 1.31 ± 0.01 | 0.53 ± 0.00 | |

| 85 | 5.36 ± 0.18 | 4.42 ± 0.15 | 1.20 ± 0.04 | 0.48 ± 0.01 | |

| 75.1 | 25 | 5.80 ± 0.03 | 4.80 ± 0.02 | 1.69 ± 0.01 | 0.63 ± 0.00 |

| 45 | 4.97 ± 0.01 | 4.10 ± 0.01 | 1.45 ± 0.01 | 0.61 ± 0.00 | |

| 65 | 4.50 ± 0.02 | 3.69 ± 0.01 | 1.24 ± 0.01 | 0.56 ± 0.01 | |

| 85 | 4.09 ± 0.03 | 3.34 ± 0.03 | 1.06 ± 0.03 | 0.50 ± 0.01 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, S.; Liu, L.; Yu, H.; Guan, X.; Li, R.; Hou, L.; Ling, B.; Wang, S. Thermal and Dielectric Properties of Wolfberries as Affected by Moisture Content and Temperature Associated with Radio Frequency and Microwave Dehydrations. Foods 2022, 11, 3796. https://doi.org/10.3390/foods11233796

Bai S, Liu L, Yu H, Guan X, Li R, Hou L, Ling B, Wang S. Thermal and Dielectric Properties of Wolfberries as Affected by Moisture Content and Temperature Associated with Radio Frequency and Microwave Dehydrations. Foods. 2022; 11(23):3796. https://doi.org/10.3390/foods11233796

Chicago/Turabian StyleBai, Shunqin, Li Liu, Haibo Yu, Xiangyu Guan, Rui Li, Lixia Hou, Bo Ling, and Shaojin Wang. 2022. "Thermal and Dielectric Properties of Wolfberries as Affected by Moisture Content and Temperature Associated with Radio Frequency and Microwave Dehydrations" Foods 11, no. 23: 3796. https://doi.org/10.3390/foods11233796