Nutritionally Enriched Muffins from Roselle Calyx Extract Using Response Surface Methodology

Abstract

1. Introduction

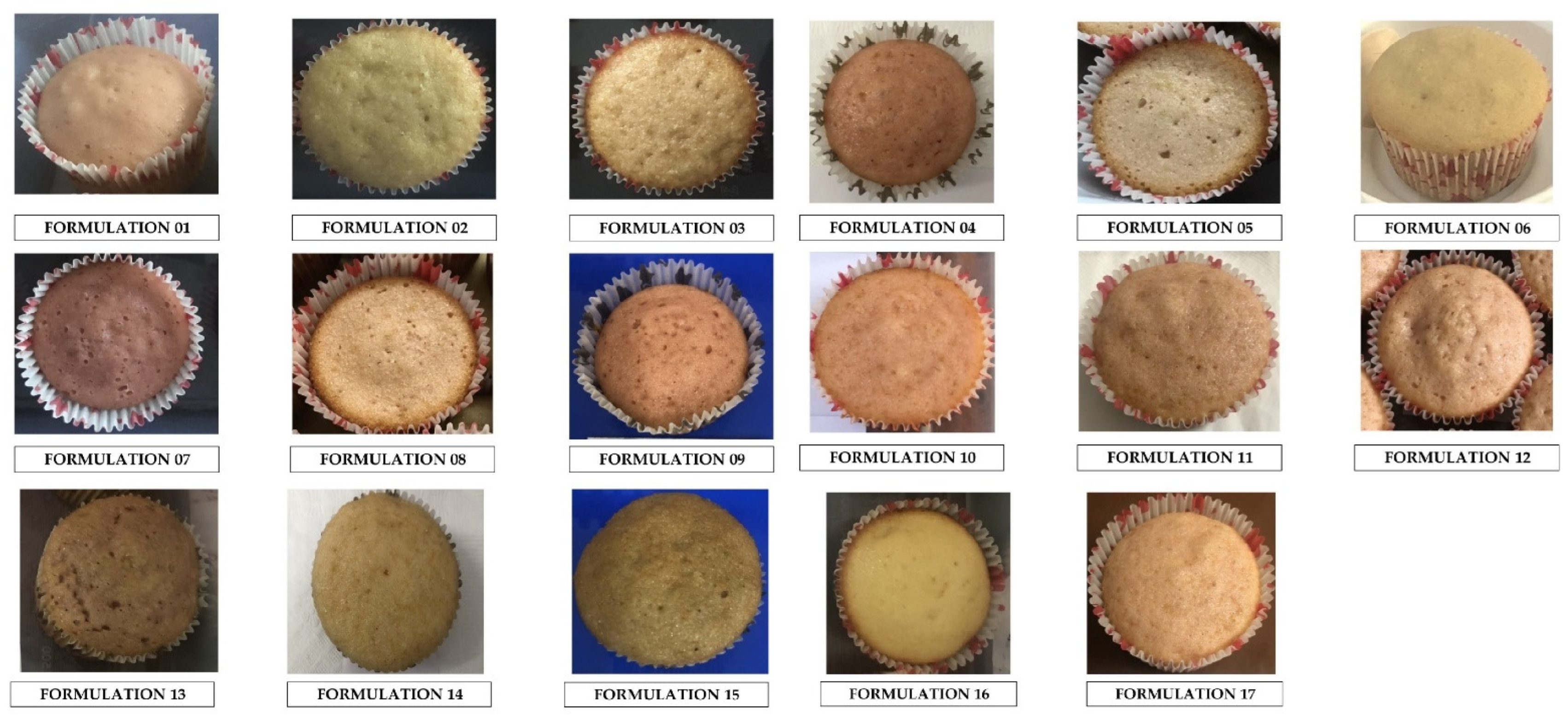

2. Results

2.1. Effect of Factors on Muffin Responses

2.2. Optimization

2.3. Sensory and Physicochemical Characteristics

2.4. Phytochemical Characteristics of Batter and Optimized Muffin

2.5. Microbial Shelf-Life

3. Materials and Methods

3.1. Chemicals

3.2. Raw Materials

3.3. Design of the Experiment

3.4. Roselle Calyx Extract Preparation

3.5. Muffin Preparation

3.6. Optimization

3.7. Sensory Analysis

3.8. Physicochemical Analysis

3.8.1. Proximate

3.8.2. Texture Profile Analysis

3.8.3. PH Measurement

3.8.4. Color Measurement

3.9. Phythochemical Analysis

3.9.1. Total Phenolic Content

3.9.2. Total Anthocyanin Content

3.9.3. DPPH Radical Scavenging

3.9.4. Ascorbic Acid Content

3.10. Microbial Shelf-Life

3.11. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thomford, N.E.; Senthebane, D.A.; Rowe, A.; Munro, D.; Seele, P.; Maroyi, A.; Dzobo, K. Natural products for drug discovery in the 21st century: Innovations for novel drug discovery. Int. J. Mol. Sci. 2018, 19, 1578. [Google Scholar] [CrossRef]

- Kroyer, G.T. Red clover extract as antioxidant active and functional food ingredient. Innov. Food Sci. Emerg. Technol. 2004, 5, 101–105. [Google Scholar] [CrossRef]

- Blunt, J.W.; Carroll, A.R.; Copp, B.R.; Davis, R.A.; Keyzers, R.A.; Prinsep, M.R. Marine natural products. Nat. Prod. Rep. 2018, 35, 8–53. [Google Scholar] [CrossRef]

- Havey, A.L. Natural products in drug discovery. Drug Discov. Today 2008, 13, 894–901. [Google Scholar] [CrossRef]

- Gil-Chávez, G.J.; Villa, J.A.; Ayala-Zavala, J.F.; Heredia, J.B.; Sepulveda, D.; Yahia, E.M.; González-Aguilar, G.A. Technologies for extraction and production of bioactive compounds to be used as nutraceuticals and food ingredients: An overview. Compr. Rev. Food Sci. Food Saf. 2013, 12, 5–23. [Google Scholar] [CrossRef]

- Marak, S.; Shumilina, E.; Kaushik, N.; Falch, E.; Dikiy, A. Effect of Different Drying Methods on the Nutritional Value of Hibiscus sabdariffa Calyces as Revealed by NMR Metabolomics. Molecules 2021, 26, 1675. [Google Scholar] [CrossRef]

- Ali, B.H.; Wabel, N.A.; Blunden, G. Phytochemical, pharmacological and toxicological aspects of Hibiscus. Toxicol. Eval. Nat. Prod. Deriv. 2005, 19, 369–375. [Google Scholar] [CrossRef]

- González, C.S.; Balderas, F.T.V.; Regules, A.O.; Beltrán, J.A.G. Antioxidant properties and color of Hibiscus sabdariffa extracts. Cien. Inv. Agr. 2012, 39, 79–90. [Google Scholar] [CrossRef]

- Prabawati, N.B.; Oktavirina, V.; Palma, M.; Setyaningsih, W. Edible flowers: Antioxidant compounds and their functional properties. Horticulturae 2021, 7, 66. [Google Scholar] [CrossRef]

- Da-Costa-Rocha, I.; Bonnlaender, B.; Sievers, H.; Pischel, I.; Heinrich, M. Hibiscus sabdariffa L.—A phytochemical and pharmacological review. Food Chem. 2014, 165, 424–443. [Google Scholar] [CrossRef] [PubMed]

- Martins, N.; Roriz, C.L.; Morales, P.; Barros, L.; Ferreira, I.C. Food colorants: Challenges, opportunities, and current desires of agro-industries to ensure consumer expectations and regulatory practices. Trends Food Sci. Technol. 2016, 52, 1–15. [Google Scholar] [CrossRef]

- Shruti, V.H.; Ramachandra, C.T.; Nidoni, U.; Hiregoudar, S.; Naik, N.; Kurubar, A.R. Roselle (Hibiscus sabdariffa L.) as a source of natural colour: A review. Plant Arch. 2016, 16, 515–522. Available online: http://plantarchives.org/PDF%20162/515-522.pdf (accessed on 3 August 2022).

- Abou-Arab, A.A.; Abu-Salem, F.M.; Abou-Arab, E.A. Physico-chemical properties of natural pigments (anthocyanin) extracted from Roselle calyces (Hibiscus subdariffa). J. Am. Sci. 2011, 7, 445–456. Available online: http://www.americanscience.org/ (accessed on 3 August 2022).

- Sanz, T.; Salvador, A.; Baixauli, R.; Fiszman, S.M. Evaluation of four types of resistant starch in muffins. II. Effects in texture, colour and consumer response. Eur. Food Res. Technol. 2009, 229, 197–204. [Google Scholar] [CrossRef]

- Martínez-Cervera, S.; Sanz, T.; Salvador, A.; Fiszman, S.M. Rheological, textural, and sensorial properties of low-sucrose muffins reformulated with sucralose/polydextrose. LWT—Food Sci. Technol. 2012, 45, 213–220. [Google Scholar] [CrossRef]

- Liu, R.H. Health-promoting components of fruits and vegetables in the diet. Adv. Nutr. 2013, 4, 384S–392S. [Google Scholar] [CrossRef]

- Rothwell, J.A.; Medina-Remón, A.; Pérez-Jiménez, J.; Neveu, V.; Knaze, V.; Slimani, N.; Scalbert, A. Effects of food processing on polyphenol contents: A systematic analysis using Phenol-Explorer data. Mol. Nutr. Food Res. 2015, 59, 160–170. [Google Scholar] [CrossRef]

- Blessington, T.; Nzaramba, M.N.; Scheuring, D.C.; Hale, A.L.; Reddivari, L.; Miller, J.C. Cooking methods and storage treatments of potato: Effects on carotenoids, antioxidant activity, and phenolics. Am. J. Potato Res. 2010, 87, 479–491. [Google Scholar] [CrossRef]

- Xu, X.; Li, W.; Lu, Z.; Beta, T.; Hydamaka, A.W. Phenolic content, composition, antioxidant activity, and their changes during domestic cooking of potatoes. J. Agric. Food Chem. 2009, 57, 10231–10238. [Google Scholar] [CrossRef]

- Doerry, W.T. Breadmaking Technology; American Institute of Baking: New York, NY, USA, 1995; pp. 156–159. [Google Scholar]

- Gilbert, R.J.; De Louvois, J.; Donovan, T.; Little, C.; Nye, K.; Ribeiro, C.D.; Bolton, F.J. Guidelines for the microbiological quality of some ready-to-eat foods sampled at the point of sale. PHLS Advisory Committee for Food and Dairy Products. Commun. Dis. Public Health 2000, 3, 163–167. Available online: https://www.mb-labs.com/wp-content/uploads/2014/08/Micro-Limits-Ready-to-Eat-Foods.pdf (accessed on 3 August 2022).

- Carl, A.B. Confectionery products—Cakes and pastries. In Encyclopedia of Food Microbiology; Batt, C.A., Ed.; Academic Press: London, UK, 2014; pp. 500–502. [Google Scholar]

- Poliński, S.; Topka, P.; Tańska, M.; Kowalska, S.; Czaplicki, S.; Szydłowska-Czerniak, A. Effect of Grinding Process Parameters and Storage Time on Extraction of Antioxidants from Ginger and Nutmeg. Molecules 2022, 27, 7395. [Google Scholar] [CrossRef]

- Demirok, N.T.; Yıkmış, S. Combined Effect of Ultrasound and Microwave Power in Tangerine Juice Processing: Bioactive Compounds, Amino Acids, Minerals, and Pathogens. Processes 2022, 10, 2100. [Google Scholar] [CrossRef]

- Barba, F.J.; Rajha, H.N.; Debs, E.; Abi-Khattar, A.M.; Khabbaz, S.; Dar, B.N.; Louka, N. Optimization of Polyphenols’ Recovery from Purple Corn Cobs Assisted by Infrared Technology and Use of Extracted Anthocyanins as a Natural Colorant in Pickled Turnip. Molecules 2022, 27, 5222. [Google Scholar] [CrossRef] [PubMed]

- Vo, T.P.; Duong, N.H.N.; Phan, T.H.; Mai, T.P.; Nguyen, D.Q. Optimized Cellulase-Hydrolyzed Deoiled Coconut Cake Powder as Wheat Flour Substitute in Cookies. Foods 2022, 11, 2709. [Google Scholar] [CrossRef] [PubMed]

- Turabi, E.; Sumnu, G.; Sahin, S. Optimization of baking of rice cakes in infrared–microwave combination oven by response surface methodology. Food Bioprocess Technol. 2008, 1, 64–73. [Google Scholar] [CrossRef]

- Sanchez, H.D.; Osella, C.A.; De La Torre, M.A. Use of response surface methodology to optimize gluten-free bread fortified with soy flour and dry milk. Food Sci. Technol. Int. 2004, 10, 5–9. [Google Scholar] [CrossRef]

- Kurek, M.A.; Moczkowska-Wyrwisz, M.; Wyrwisz, J.; Karp, S. Development of Gluten-Free Muffins with β-Glucan and Pomegranate Powder Using Response Surface Methodology. Foods 2021, 10, 2551. [Google Scholar] [CrossRef]

- Noordin, M.Y.; Venkatesh, V.C.; Sharif, S.; Elting, S.; Abdullah, A. Application of response surface methodology in describing the performance of coated carbide tools when turning AISI 1045 steel. J. Mater. Process. Technol. 2004, 145, 46–58. [Google Scholar] [CrossRef]

- Siti Faridah, M.A.; Hasmadi, M.; Lee, J.A.; Nurul, S.R. Physicochemical and organoleptic evaluation of muffin partially substituted with roselle calyces (Hibiscus sabdariffa) powder. Borneo Sci. 2014, 35, 10–17. Available online: http://borneoscience.ums.edu.my/wp-content/uploads/2016/03/physicochemical-and-organoleptic-evaluation-of-muffin-partially-substituted-with-roselle-calyces-hibiscus-sabdariffa.-l-powder.pdf (accessed on 4 August 2022).

- Everitt, M. Consumer-Targeted Sensory Quality. In Global Issues in Food Science and Technology; Academic Press: London, UK, 2009; pp. 117–128. [Google Scholar] [CrossRef]

- Krinsky, N.I.; Beecher, G.R.; Burk, R.F.; Chan, A.C.; Erdman, J.J.; Jacob, R.A.; Traber, M.G. Dietary reference intakes for vitamin C, vitamin E, selenium, and carotenoids. Inst. Med. 2000, 19, 95–185. Available online: https://www.ncbi.nlm.nih.gov/books/NBK225480/ (accessed on 4 August 2022).

- Rodríguez-García, J.; Sahi, S.S.; Hernando, I. Functionality of lipase and emulsifiers in low-fat cakes with inulin. LWT–Food Sci. Technol. 2014, 58, 173–182. [Google Scholar] [CrossRef]

- Xu, Q.; Li, B.; Wang, D.; Luo, L.; Liu, G.; Zhou, Y. Microencapsulation and stability analysis of blueberry anthocyanins. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Xi’an, China, 15–16 December 2018; IOP Publishing: Bristol, UK, 2019; Volume 252, p. 052133. [Google Scholar]

- Rodriguez, M.V.; Medina, L.M.; Jordano, R. Prolongation of shelf life of sponge cakes using modified atmosphere packaging. Acta Aliment. 2002, 31, 191–196. [Google Scholar] [CrossRef]

- Rafeeda. Simple Vanilla Muffins—The Big Sweet Tooth. 2019. Available online: https://www.thebigsweettooth.com/simple-vanilla-muffins/ (accessed on 17 July 2021).

- Horwitz, W. Official Method of Analysis, 13th ed.; Association of Analytical Chemists: Washington, DC, USA, 1980. [Google Scholar]

- Jauharah, M.A.; Rosli, W.W.; Robert, S.D. Physicochemical and sensorial evaluation of biscuit and muffin incorporated with young corn powder. Sains Malays. 2014, 43, 45–52. Available online: http://journalarticle.ukm.my/6814/1/06_M.Z._Anis_Jauharah.pdf (accessed on 3 October 2022).

- Abdel-Moemin, A.R. Effect of Roselle calyces extract on the chemical and sensory properties of functional cupcakes. Food Sci. Hum. Wellness 2016, 5, 230–237. [Google Scholar] [CrossRef]

- Shirazi, O.U.; Khattak, M.M.A.K.; Shukri, N.A.M.; Nasyriq, M.N. Determination of total phenolic, flavonoid content and free radical scavenging activities of common herbs and spices. J. Pharmacogn. Phytochem. 2014, 3, 104–108. Available online: https://www.phytojournal.com/archives/2014/vol3issue3/PartB/29.1.pdf (accessed on 20 August 2022).

- Lee, J.; Durst, R.W.; Wrolstad, R.E.; Collaborators: Eisele, T.; Giusti, M.M.; Hach, J.; Hofsommer, H.; Koswig, S.; Krueger, D.A.; Kupina, S.; et al. Determination of total monomeric anthocyanin pigment content of fruit juices, beverages, natural colorants, and wines by the pH differential method: Collaborative study. J. AOAC Int. 2005, 88, 1269–1278. [Google Scholar] [CrossRef]

- Brad-Williams, W.; Cuvelier, M.E.; Berset, C.L.W.T. Use of a free radical method to evaluate antioxidant activity. LWT—Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

| Independent Variables | Dependent Variables | ||||||

|---|---|---|---|---|---|---|---|

| Codes | A | B | C | Response 1: Texture (Score) | Response 2: OAA (Score) | ||

| Formulation | Extract Volume (mL) | Citric Acid (g) | Sodium Bicarbonate (g) | Experimental Data | RSM Predicted Data | Experimental Data | RSM Predicted Data |

| 01 | 27.5 | 2.5 | 1.0 | 6.36 ± 1.54 | 6.54 | 5.70 ± 1.78 | 5.88 |

| 02 | 5.0 | 1.0 | 1.7 | 6.63 ± 0.92 | 6.90 | 6.00 ± 1.11 | 6.14 |

| 03 | 27.5 | 1.7 | 1.7 | 6.93 ± 1.11 | 6.96 | 7.53 ± 0.97 | 7.56 |

| 04 | 50.0 | 2.5 | 1.7 | 6.60 ± 1.28 | 6.47 | 6.65 ± 1.25 | 6.50 |

| 05 | 27.5 | 1.0 | 1.0 | 7.23 ± 0.97 | 6.96 | 6.53 ± 1.27 | 6.35 |

| 06 | 5.0 | 1.7 | 2.5 | 6.46 ± 1.00 | 6.51 | 6.26 ± 0.94 | 6.30 |

| 07 | 50.0 | 1.7 | 2.5 | 6.63 ± 1.35 | 6.58 | 6.78 ± 0.99 | 6.99 |

| 08 | 27.5 | 2.5 | 2.5 | 7.13 ± 1.27 | 7.00 | 6.66 ± 1.24 | 6.59 |

| 09 | 50.0 | 1.7 | 1.0 | 6.63 ± 1.09 | 6.76 | 6.70 ± 1.08 | 6.66 |

| 10 | 27.5 | 1.7 | 1.7 | 6.88 ± 0.63 | 6.96 | 7.30 ± 0.83 | 7.56 |

| 11 | 27.5 | 1.7 | 1.7 | 7.23 ± 0.72 | 7.05 | 7.80 ± 0.80 | 7.56 |

| 12 | 27.5 | 1.7 | 1.7 | 7.00 ± 0.69 | 6.96 | 7.60 ± 0.77 | 7.56 |

| 13 | 50.0 | 1.0 | 1.7 | 7.20 ± 1.03 | 7.12 | 7.10 ± 0.99 | 7.07 |

| 14 | 5.0 | 1.7 | 1.0 | 6.96 ± 1.15 | 6.69 | 6.38 ± 1.32 | 6.17 |

| 15 | 27.5 | 1.0 | 2.5 | 7.23 ± 0.85 | 7.36 | 6.53 ± 0.93 | 6.60 |

| 16 | 5.0 | 2.5 | 1.7 | 6.46 ± 1.16 | 6.54 | 6.20 ± 1.12 | 6.23 |

| 17 | 27.5 | 1.7 | 1.7 | 6.76 ± 0.67 | 6.96 | 7.56 ± 0.62 | 7.56 |

| A | B | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Source | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value | Source | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value |

| Model | 1.01 | 9 | 0.1125 | 1.86 | 0.21 ** | Model | 5.62 | 9 | 0.6244 | 12.82 | <0.01 * |

| A-Extract Volume | 0.0378 | 1 | 0.0378 | 0.62 | 0.45 | A-Extract Volume | 0.7140 | 1 | 0.7140 | 14.66 | <0.01 |

| B-Citric Acid | 0.3784 | 1 | 0.3784 | 6.26 | 0.04 | B-Citric Acid | 0.1128 | 1 | 0.1128 | 2.32 | 0.17 |

| C-Sodium Bicarbonate | 0.0091 | 1 | 0.0091 | 0.15 | 0.70 | C-Sodium Bicarbonate | 0.1058 | 1 | 0.1058 | 2.17 | 0.18 |

| AB | 0.0462 | 1 | 0.0462 | 0.76 | 0.41 | AB | 0.1056 | 1 | 0.1056 | 2.17 | 0.18 |

| AC | 0.0625 | 1 | 0.0625 | 1.03 | 0.34 | AC | 0.0100 | 1 | 0.0100 | 0.20 | 0.66 |

| BC | 0.1482 | 1 | 0.1482 | 2.45 | 0.16 | BC | 0.2304 | 1 | 0.2304 | 4.73 | 0.06 |

| A² | 0.3242 | 1 | 0.3242 | 5.37 | 0.05 | A² | 0.8441 | 1 | 0.8441 | 17.33 | <0.01 |

| B² | 0.0067 | 1 | 0.0067 | 0.11 | 0.74 | B² | 1.63 | 1 | 1.63 | 33.52 | <0.01 |

| C² | 0.0007 | 1 | 0.0007 | 0.01 | 0.91 | C² | 1.42 | 1 | 1.42 | 29.10 | <0.01 |

| Residual | 0.4230 | 7 | 0.0604 | Residual | 0.3410 | 7 | 0.0487 | ||||

| Lack of Fit | 0.3012 | 3 | 0.1004 | 3.30 | 0.13 | Lack of Fit | 0.2133 | 3 | 0.0711 | 2.23 | 0.22 |

| Pure Error | 0.1218 | 4 | 0.0305 | Pure Error | 0.1277 | 4 | 0.0319 | ||||

| Cor Total | 1.44 | 16 | Cor Total | 5.96 | 16 | ||||||

| Fit Statistics | Std. Dev. | Mean | C.V% | R2 | Fit Statistics | Std. Dev. | Mean | C.V% | R2 | ||

| 0.2458 | 6.84 | 3.59 | 0.70 | 0.2207 | 6.78 | 3.25 | 0.94 | ||||

| Components | Goal | Lower Limit | Upper Limit |

|---|---|---|---|

| A: Extract Volume | Maximize | 5.00 | 50.0 |

| B: Citric Acid | is in range | 1.00 | 2.50 |

| C: Sodium Bicarbonate | is in range | 1.00 | 2.50 |

| Texture | Maximize | 6.36 | 7.23 |

| Overall Acceptability | Maximize | 5.70 | 7.80 |

| Components | Optimum Value | |

| Extract Volume (mL) | 45.37 | |

| Citric acid (g) | 1.11 | |

| Sodium bicarbonate (g) | 1.67 | |

| Desirability of response value | 0.84 | |

| Response | Model Calculated value | Observed value |

| Texture | 7.13 | 8.31 |

| OAA | 7.27 | 8.30 |

| Parameters | Roselle Muffin | Control Muffin | p-Value (p < 0.05) |

|---|---|---|---|

| Sensory Parameters | |||

| Colour and Appearance | 7.85 ± 0.70 * | 7.36 ± 0.80 * | 0.01 |

| Aroma | 7.71 ± 0.66 ns | 7.70 ± 0.70 ns | 0.92 |

| Body and Texture | 8.21 ± 0.53 ** | 7.53 ± 0.89 ** | <<0.01 |

| Taste and Flavour | 8.18 ± 0.70 * | 7.76 ± 0.81 * | 0.03 |

| Overall Acceptability | 8.30 ± 0.68 ** | 7.68 ± 0.64 ** | <<0.01 |

| Proximate (per 100 g) | |||

| Moisture (%) | 21.66 ± 0.89 * | 20.86 ± 0.24 * | 0.29 |

| Ash (%) | 4.22 ± 0.41 ** | 2.11 ± 0.41 ** | <<0.01 |

| Fat (%) | 11.20 ± 0.16 ** | 13.6 ± 0.16 ** | <<0.01 |

| Protein (%) | 7.73 ± 0.12 ** | 8.33 ± 0.12 ** | <<0.01 |

| Total Carbohydrate (%) | 55.18 ± 1.24 ns | 55.09 ± 0.51 ns | 0.92 |

| pH | 5.26 ± 0.04 ** | 7.10 ± 0.08 ** | <<0.01 |

| Ascorbic acid, mg/100 g | 12.10 ± 0.89 | ND | - |

| Color Parameters | |||

| L* | 62.70 ± 0.19 ** | 68.84 ± 0.21 ** | <<0.01 |

| a* | 9.51 ± 0.01 ** | 5.21 ± 0.05 ** | <<0.01 |

| b* | 10.47 ± 0.06 ** | 14.88 ± 0.08 ** | <<0.01 |

| c* | 14.14 ± 0.05 ** | 15.77 ± 0.10 ** | <<0.01 |

| h0 | 47.75 ± 0.11 ** | 70.69 ± 0.06 ** | <<0.01 |

| Texture Parameters | |||

| Hardness, N | 865.38 ± 6.32 ** | 1720.84 ± 56.08 ** | <<0.01 |

| Springiness, % | 0.87 ± 0.01 ns | 0.89 ± 0.00 ns | 0.30 |

| Cohesiveness | 0.45 ± 0.00 * | 0.50 ± 0.01 * | 0.02 |

| Chewiness | 346.26 ± 1.71 ** | 780.11 ± 41.87 ** | <<0.01 |

| Roselle Muffin | Control Muffin | ||||

|---|---|---|---|---|---|

| Phytochemical Parameters | Batter | Muffin | Batter | Muffin | p-Value (p < 0.05) |

| TAC, mg cyanidin-3-glucoside (Cyn-3-glu/100 g) | 154.56 ± 3.40 ** | 126.63 ± 1.96 ** | ND | ND | <<0.01 |

| TPC, mg gallic acid (GA/100 g) | 19.74 ± 0.28 ** | 12.91 ± 0.69 ** | 3.12 ± 0.06 | ND | <<0.01 |

| Antioxidant activity (%) | 27.30 ± 1.03 ** | 12.53 ± 0.13 ** | ND | ND | <<0.01 |

| Roselle Muffin | Control Muffin | |||

| Days | Total Plate Count | Yeast and Molds | Total Plate Count | Yeast and Molds |

|---|---|---|---|---|

| 01 | 2.4 × 103 | 4.1 × 103 | 3 × 102 | 2 × 102 |

| 03 | 1.8 × 104 | 1.5 × 104 | 3 × 102 | 5 × 102 |

| 06 | 5.4 × 104 | 4.9 × 104 | 7 × 103 | 3 × 103 |

| 09 | Uncountable | Uncountable | 5.7 × 104 | 4.5 × 104 |

| 12 | Visible mold growth | Visible mold growth | Uncountable | Uncountable |

| 15 | Visible mold growth | Visible mold growth | Visible mold growth | Visible mold growth |

| Codes | Independent Variables | Units | Minimum | Maximum |

|---|---|---|---|---|

| A | Extract Volume | mL | 5.00 | 50.00 |

| B | Citric Acid | g | 1.0000 | 2.50 |

| C | Sodium Bicarbonate | g | 1.0000 | 2.50 |

| Independent Variables | Dependent Variables | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Formulation | A: Extract Volume (mL) | B: Citric Acid (g) | C: Sodium Bicarbonate (g) | Milk Volume (mL) | Flour (g) | Sugar (g) | Butter (g) | Egg * (g) | Vanilla Extract (g) | Salt (g) |

| 1 | 27.5 | 2.5 | 1.0 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 2 | 5.0 | 1.0 | 1.7 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 3 | 27.5 | 1.7 | 1.7 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 4 | 50.0 | 2.5 | 1.7 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 5 | 27.5 | 1.0 | 1.0 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 6 | 5.0 | 1.7 | 2.5 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 7 | 50.0 | 1.7 | 2.5 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 8 | 27.5 | 2.5 | 2.5 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 9 | 50.0 | 1.7 | 1.0 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 10 | 27.5 | 1.7 | 1.7 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 11 | 27.5 | 1.7 | 1.7 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 12 | 27.5 | 1.7 | 1.7 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 13 | 50.0 | 1.0 | 1.7 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 14 | 5.0 | 1.7 | 1.0 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 15 | 27.5 | 1.0 | 2.5 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 16 | 5.0 | 2.5 | 1.7 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| 17 | 27.5 | 1.7 | 1.7 | 0 | 100 | 60 | 50 | 100 | 1 | 1 |

| Control | 0 | 0 | 0 | 50 | 100 | 60 | 50 | 100 | 1 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marak, S.; Kaushik, N.; Dikiy, A.; Shumilina, E.; Falch, E. Nutritionally Enriched Muffins from Roselle Calyx Extract Using Response Surface Methodology. Foods 2022, 11, 3982. https://doi.org/10.3390/foods11243982

Marak S, Kaushik N, Dikiy A, Shumilina E, Falch E. Nutritionally Enriched Muffins from Roselle Calyx Extract Using Response Surface Methodology. Foods. 2022; 11(24):3982. https://doi.org/10.3390/foods11243982

Chicago/Turabian StyleMarak, Sengnolotha, Nutan Kaushik, Alexander Dikiy, Elena Shumilina, and Eva Falch. 2022. "Nutritionally Enriched Muffins from Roselle Calyx Extract Using Response Surface Methodology" Foods 11, no. 24: 3982. https://doi.org/10.3390/foods11243982

APA StyleMarak, S., Kaushik, N., Dikiy, A., Shumilina, E., & Falch, E. (2022). Nutritionally Enriched Muffins from Roselle Calyx Extract Using Response Surface Methodology. Foods, 11(24), 3982. https://doi.org/10.3390/foods11243982