Preparation of Water-in-Oil Nanoemulsions Loaded with Phenolic-Rich Olive Cake Extract Using Response Surface Methodology Approach

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Phenolic-Rich Olive Cake Extract Used as the Aqueous Phase

2.3. Preparation of Water-in-Oil (W/O) Nanoemulsions

2.4. Characterization of W/O Nanoemulsions

2.5. Experimental Design

3. Results and Discussion

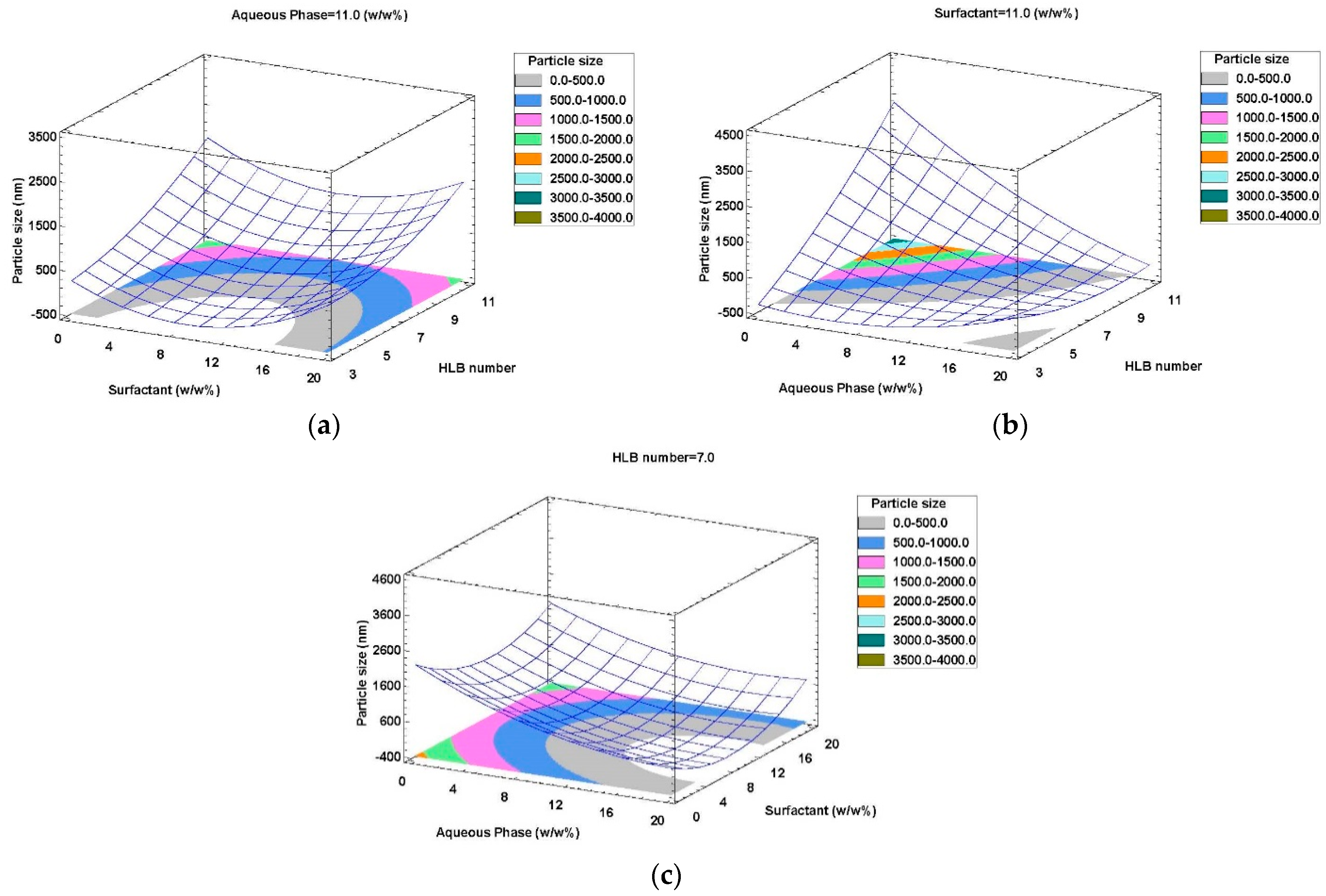

3.1. W/O Nanoemulsion Formulation

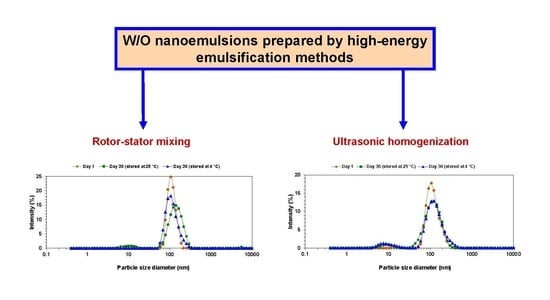

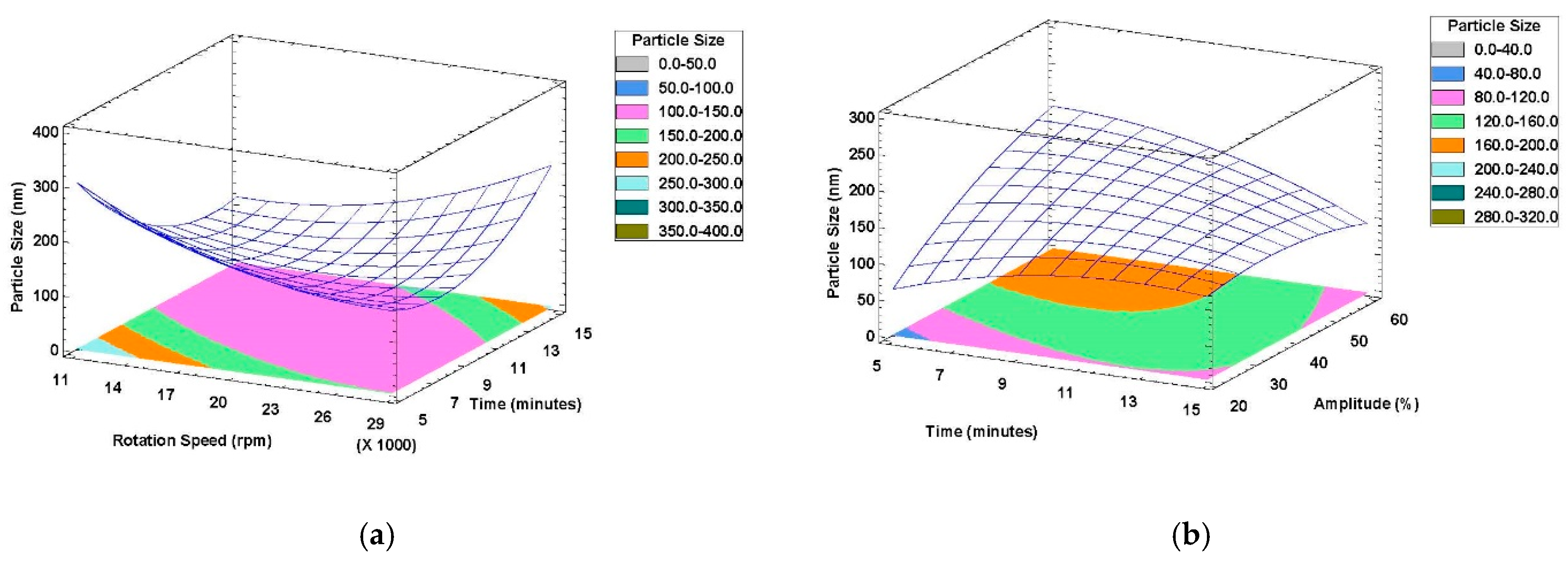

3.2. Effects of High-Energy Emulsification Methods on W/O Nanoemulsion Droplet Size

3.3. Characterization of Optimal W/O Nanoemulsion

4. Conclusions and Future Research Needs

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Maqtari, Q.A.; Ghaleb, A.D.S.; Mahdi, A.A.; Al-Ansi, W.; Noman, A.E.; Wei, M.; Yao, W. Stabilization of water-in-oil emulsion of Pulicaria jaubertii extract by ultrasonication: Fabrication, characterization, and storage stability. Food Chem. 2021, 350, 129249. [Google Scholar] [CrossRef]

- Cheng, C.; Gao, H.; McClements, D.J.; Zeng, H.; Ma, L.; Zou, L.; Miao, J.; Wu, X.; Tan, J.-N.; Liang, R.; et al. Impact of polysaccharide mixtures on the formation, stability and EGCG loading of water-in-oil high internal phase emulsions. Food Chem. 2022, 372, 131225. [Google Scholar] [CrossRef] [PubMed]

- Colucci, G.; Santamaria-Echart, A.; Silva, S.C.; Fernandes, I.P.M.; Sipoli, C.C.; Barreiro, M.F. Development of water-in-oil emulsions as delivery vehicles and testing with a natural antimicrobial extract. Molecules 2020, 25, 2105. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Dong, J.; Chen, J.; Eastoe, J.; Li, X. Design and optimization of a new self-nanoemulsifying drug delivery system. J. Colloid Interface Sci. 2009, 330, 443–448. [Google Scholar] [CrossRef] [PubMed]

- Bhatti, H.S.; Khalid, N.; Uemura, K.; Nakajima, M.; Kobayashi, I. Formulation and characterization of food grade water-in-oil emulsions encapsulating mixture of essential amino acids. Eur. J. Lipid Sci. Technol. 2017, 119, 1600202. [Google Scholar] [CrossRef]

- Prichapan, N.; McClements, D.J.; Klinkesorn, U. Iron encapsulation in water-in-oil emulsions: Effect of ferrous sulfate concentration and fat crystal formation on oxidative stability. J. Food Sci. 2018, 83, 309–317. [Google Scholar] [CrossRef]

- Gomes, A.; Costa, A.L.R.; Perrechil, F.D.A.; Cunha, R.L. Role of the phases composition on the incorporation of gallic acid in O/W and W/O emulsions. J. Food Eng. 2016, 168, 205–214. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Q.; Pan, Y.; Jia, X.; Li, J.; Zhang, M.; Yin, L. Review on the stability mechanism and application of water-in-oil emulsions encapsulating various additives. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1660–1675. [Google Scholar] [CrossRef]

- Ritzoulis, C.; Petridis, D.; Derlikis, E.M.; Fytianos, K.; Asteriou, P. Utilization of inverse water-in-oil emulsions as fat replacers in frankfurter model sausages: Influence of fat emulsion content on the organoleptic and mechanical properties. J. Texture Stud. 2010, 41, 62–74. [Google Scholar] [CrossRef]

- Luo, S.-Z.; Hu, X.-F.; Pan, L.-H.; Zheng, Z.; Zhao, Y.-Y.; Cao, L.-L.; Pang, M.; Hou, Z.-G.; Jiang, S.-T. Preparation of camellia oil-based W/O emulsions stabilized by tea polyphenol palmitate: Structuring camellia oil as a potential solid fat replacer. Food Chem. 2019, 276, 209–217. [Google Scholar] [CrossRef]

- Pintado, T.; Muñoz-González, I.; Salvador, M.; Ruiz-Capillas, C.; Herrero, A.M. Phenolic compounds in emulsion gel-based delivery systems applied as animal fat replacers in frankfurters: Physico-chemical, structural and microbiological approach. Food Chem. 2021, 340, 128095. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Elias, R.J. Antioxidant and pro-oxidant activity of (−)-epigallocatechin-3-gallate in food emulsions: Influence of pH and phenolic concentration. Food Chem. 2013, 138, 1503–1509. [Google Scholar] [CrossRef] [PubMed]

- Papuc, C.; Goran, G.V.; Predescu, C.N.; Nicorescu, V.; Stefan, G. Plant polyphenols as antioxidant and antibacterial agents for shelf-life extension of meat and meat products: Classification, structures, sources, and action mechanisms. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1243–1268. [Google Scholar] [CrossRef] [Green Version]

- Manzanares, P.; Ruiz, E.; Ballesteros, M.; Negro, M.J.; Gallego, F.J.; López-Linares, J.C.; Castro, E. Residual biomass potential in olive tree cultivation and olive oil industry in Spain: Valorization proposal in a biorefinery context. Span. J. Agric. Res. 2017, 15, e0206. [Google Scholar] [CrossRef] [Green Version]

- Suárez, M.; Romero, M.-P.; Ramo, T.; Macià, A.; Motilva, M.-J. Methods for preparing phenolic extracts from olive cake for potential application as food antioxidants. J. Agric. Food Chem. 2009, 57, 1463–1472. [Google Scholar] [CrossRef]

- Niknam, S.M.; Kashaninejad, M.; Escudero, I.; Sanz, M.T.; Beltrán, S.; Benito, J.M. Valorization of olive mill solid residue through ultrasound-assisted extraction and phenolics recovery by adsorption process. J. Clean. Prod. 2021, 316, 128340. [Google Scholar] [CrossRef]

- Fang, Z.; Bhandari, B. Encapsulation of polyphenols—A review. Trends Food Sci. Technol. 2010, 21, 510–523. [Google Scholar] [CrossRef]

- McClements, D.J. Encapsulation, protection, and release of hydrophilic active components: Potential and limitations of colloidal delivery systems. Adv. Colloid Interface Sci. 2015, 219, 27–53. [Google Scholar] [CrossRef]

- Lu, W.; Kelly, A.L.; Miao, S. Emulsion-based encapsulation and delivery systems for polyphenols. Trends Food Sci. Technol. 2016, 47, 1–9. [Google Scholar] [CrossRef]

- Gadkari, P.V.; Shashidhar, M.; Balaraman, M. Delivery of green tea catechins through oil-in-water (O/W) nanoemulsion and assessment of storage stability. J. Food Eng. 2017, 199, 65–76. [Google Scholar] [CrossRef]

- Gutiérrez, G.; Matos, M.; Benito, J.M.; Coca, J.; Pazos, C. Preparation of HIPEs with controlled droplet size containing lutein. Colloids Surf. A Physicochem. Eng. Asp. 2014, 442, 111–122. [Google Scholar] [CrossRef]

- Ye, Q.; Li, T.; Li, J.; Liu, L.; Dou, X.; Zhang, X. Development and evaluation of tea polyphenols loaded water in oil emulsion with zein as stabilizer. J. Drug Deliv. Sci. Technol. 2020, 56, 101528. [Google Scholar] [CrossRef]

- Niknam, S.M.; Escudero, I.; Benito, J.M. Formulation and preparation of water-in-oil-in-water emulsions loaded with a phenolic-rich inner aqueous phase by application of high energy emulsification methods. Foods 2020, 9, 1411. [Google Scholar] [CrossRef] [PubMed]

- Matos, M.; Gutiérrez, G.; Coca, J.; Pazos, C. Preparation of water-in-oil-in-water (W1/O/W2) double emulsions containing trans-resveratrol. Colloids Surf. A Physicochem. Eng. Asp. 2014, 442, 69–79. [Google Scholar] [CrossRef]

- Robert, P.; Zamorano, M.; González, E.; Silva-Weiss, A.; Cofrades, S.; Giménez, B. Double emulsions with olive leaves extract as fat replacers in meat systems with high oxidative stability. Food Res. Int. 2019, 120, 904–912. [Google Scholar] [CrossRef] [Green Version]

- Caporaso, N.; Genovese, A.; Burke, R.; Barry-Ryan, C.; Sacchi, R. Effect of olive mill wastewater phenolic extract, whey protein isolate and xanthan gum on the behaviour of olive O/W emulsions using response surface methodology. Food Hydrocoll. 2016, 61, 66–76. [Google Scholar] [CrossRef] [Green Version]

- Mehmood, T.; Ahmad, A.; Ahmed, A.; Ahmed, Z. Optimization of olive oil based O/W nanoemulsions prepared through ultrasonic homogenization: A response surface methodology approach. Food Chem. 2017, 229, 790–796. [Google Scholar] [CrossRef]

- Katsouli, M.; Polychniatou, V.; Tzia, C. Optimization of water in olive oil nano-emulsions composition with bioactive compounds by response surface methodology. LWT 2018, 89, 740–748. [Google Scholar] [CrossRef]

- Nishad, J.; Dutta, A.; Saha, S.; Rudra, S.G.; Varghese, E.; Sharma, R.R.; Tomar, M.; Kumar, M.; Kaur, C. Ultrasound-assisted development of stable grapefruit peel polyphenolic nano-emulsion: Optimization and application in improving oxidative stability of mustard oil. Food Chem. 2021, 334, 127561. [Google Scholar] [CrossRef]

- Sánchez Moral, P.; Ruiz Méndez, M.V. Production of pomace olive oil. Grasas Aceites 2006, 57, 47–55. [Google Scholar] [CrossRef]

- Gómez-Cruz, I.; Cara, C.; Romero, I.; Castro, E.; Gullón, B. Valorisation of exhausted olive pomace by an eco-friendly solvent extraction process of natural antioxidants. Antioxidants 2020, 9, 1010. [Google Scholar] [CrossRef]

- Alonso, L.; Roque, L.; Escudero, I.; Benito, J.M.; Sanz, M.T.; Beltrán, S. Solubilization of Span 80 niosomes by sodium dodecyl sulfate. ACS Sustain. Chem. Eng. 2016, 4, 1862–1869. [Google Scholar] [CrossRef]

- Roque, L.; Fernández, M.; Benito, J.M.; Escudero, I. Stability and characterization studies of Span 80 niosomes modified with CTAB in the presence of NaCl. Colloids Surf. A Physicochem. Eng. Asp. 2020, 601, 124999. [Google Scholar] [CrossRef]

- Shen, Q.; Zhang, B.; Xu, R.; Wang, Y.; Ding, X.; Li, P. Antioxidant activity in vitro of the selenium-contained protein from the Se-enriched Bifidobacterium animalis 01. Anaerobe 2010, 16, 380–386. [Google Scholar] [CrossRef] [PubMed]

- Regan, J.O.; Mulvihill, D.M. Water soluble inner aqueous phase markers as indicators of the encapsulation properties of water-in-oil-in-water emulsions stabilized with sodium caseinate. Food Hydrocoll. 2009, 23, 2339–2345. [Google Scholar] [CrossRef]

- Allende, D.; Cambiella, A.; Benito, J.M.; Pazos, C.; Coca, J. Destabilization-enhanced centrifugation of metalworking oil-in-water emulsions: Effect of demulsifying agents. Chem. Eng. Technol. 2008, 31, 1007–1014. [Google Scholar] [CrossRef]

- Rebolleda, S.; Sanz, M.T.; Benito, J.M.; Beltrán, S.; Escudero, I.; González-Sanjosé, M.L. Formulation and characterisation of wheat bran oil-in-water nanoemulsions. Food Chem. 2015, 167, 16–23. [Google Scholar] [CrossRef] [Green Version]

- Peng, L.-C.; Liu, C.-H.; Kwan, C.-C.; Huang, K.-F. Optimization of water-in-oil nanoemulsions by mixed surfactants. Colloids Surf. A Physicochem. Eng. Asp. 2010, 370, 136–142. [Google Scholar] [CrossRef]

- Pimentel-Moral, S.; Rodríguez-Pérez, C.; Segura-Carretero, A.; Martínez-Férez, A. Development and stability evaluation of water-in-edible oils emulsions formulated with the incorporation of hydrophilic Hibiscus sabdariffa extract. Food Chem. 2018, 260, 200–207. [Google Scholar] [CrossRef]

- Hu, Y.-T.; Ting, Y.; Hu, J.-Y.; Hsieh, S.-L. Techniques and methods to study functional characteristics of emulsion systems. J. Food Drug Anal. 2017, 25, 16–26. [Google Scholar] [CrossRef]

- Khadem, B.; Sheibat-Othman, N. Theoretical and experimental investigations of double emulsion preparation by ultrasonication. Ind. Eng. Chem. Res. 2019, 58, 8220–8230. [Google Scholar] [CrossRef]

- Qian, C.; McClements, D.J. Formation of nanoemulsions stabilized by model food-grade emulsifiers using high-pressure homogenization: Factors affecting particle size. Food Hydrocoll. 2011, 25, 1000–1008. [Google Scholar] [CrossRef]

- Yukuyama, M.N.; Kato, E.T.M.; De Araujo, G.L.B.; Löbenberg, R.; Monteiro, L.M.; Lourenço, F.R.; Bou-Chacra, N.A. Olive oil nanoemulsion preparation using high-pressure homogenization and d-phase emulsification—A design space approach. J. Drug Deliv. Sci. Technol. 2019, 49, 622–631. [Google Scholar] [CrossRef]

- Anarjan, N.; Mirhosseini, H.; Baharin, B.S.; Tan, C.P. Effect of processing conditions on physicochemical properties of astaxanthin nanodispersions. Food Chem. 2010, 123, 477–483. [Google Scholar] [CrossRef]

- Gaikwad, S.G.; Pandit, A.B. Ultrasound emulsification: Effect of ultrasonic and physicochemical properties on dispersed phase volume and droplet size. Ultrason. Sonochem. 2008, 15, 554–563. [Google Scholar] [CrossRef]

- Rabelo, C.A.S.; Taarji, N.; Khalid, N.; Kobayashi, I.; Nakajima, M.; Neves, M.A. Formulation and characterization of water-in-oil nanoemulsions loaded with açaí berry anthocyanins: Insights of degradation kinetics and stability evaluation of anthocyanins and nanoemulsions. Food Res. Int. 2018, 106, 542–548. [Google Scholar] [CrossRef]

- Mortensen, A.; Aguilar, F.; Crebelli, R.; Di Domenico, A.; Dusemund, B.; Frutos, M.J.; Galtier, P.; Gott, D.; Gundert-Remy, U.; Leblanc, J.C.; et al. Re-evaluation of polyglycerol polyricinoleate (E 476) as a food additive. EFSA J. 2017, 15, 4743. [Google Scholar] [CrossRef] [Green Version]

- Wang, M.; Yan, W.; Zhou, Y.; Fan, L.; Liu, Y.; Li, J. Progress in the application of lecithins in water-in-oil emulsions. Trends Food Sci. Technol. 2021, 118, 388–398. [Google Scholar] [CrossRef]

- Balcaen, M.; Steyls, J.; Schoeppe, A.; Nelis, V.; Van der Meeren, P. Phosphatidylcholine-depleted lecithin: A clean-label low-HLB emulsifier to replace PGPR in w/o and w/o/w emulsions. J. Colloid Interface Sci. 2021, 581, 836–846. [Google Scholar] [CrossRef]

- Okuro, P.K.; Gomes, A.; Costa, A.L.R.; Adame, M.A.; Cunha, R.L. Formation and stability of W/O-high internal phase emulsions (HIPEs) and derived O/W emulsions stabilized by PGPR and lecithin. Food Res. Int. 2019, 122, 252–262. [Google Scholar] [CrossRef]

| Run | Independent Variables | Response Variables | |||||

|---|---|---|---|---|---|---|---|

| Aqueous Phase Content (X1, % w/w) | Surfactant Content (X2, % w/w) | HLB Number (X3) | Droplet Size (Y, nm) | PDI | |||

| Mean | SD | Mean | SD | ||||

| 1 | 2 | 20 | 11 | 3688 | 464 | 1 | 0 |

| 2 | 20 | 2 | 3 | 313.5 | 12.7 | 0.956 | 0.076 |

| 3 | 2 | 2 | 3 | 143.9 | 24.6 | 0.094 | 0.071 |

| 4 | 20 | 20 | 11 | 692.1 | 121.0 | 1 | 0 |

| 5 | 11 | 20 | 7 | 804.2 | 237.3 | 1 | 0 |

| 6 | 2 | 2 | 11 | 3856 | 589 | 1 | 0 |

| 7 | 20 | 20 | 3 | 1152 | 30 | 0.164 | 0.148 |

| 8 | 2 | 11 | 7 | 259.3 | 51.7 | 0.246 | 0.210 |

| 9 | 11 | 11 | 3 | 177.4 | 47.0 | 0.104 | 0.009 |

| 10 | 11 | 11 | 7 | 331.8 | 116.0 | 0.082 | 0.054 |

| 11 | 11 | 11 | 7 | 142.3 | 13.1 | 0.222 | 0.094 |

| 12 | 11 | 2 | 7 | 356.1 | 68.1 | 0.350 | 0.278 |

| 13 | 20 | 2 | 11 | 263.2 | 71.8 | 1 | 0 |

| 14 | 11 | 11 | 11 | 320.3 | 64.6 | 0.666 | 0.413 |

| 15 | 2 | 20 | 3 | 359.8 | 14.0 | 0.055 | 0.061 |

| 16 | 20 | 11 | 7 | 372.1 | 136.3 | 0.416 | 0.303 |

| Source | Regression Coefficients | F-Ratio | p-Value |

|---|---|---|---|

| c0 | −388.136 | - | - |

| c1 | 8.48871 | 169.34 | 0.0488 |

| c2 | −146.709 | 17.32 | 0.1501 |

| c3 | 244.208 | 248.00 | 0.0404 |

| c11 | 4.23006 | 17.24 | 0.1505 |

| c12 | 1.88194 | 10.35 | 0.1918 |

| c13 | −26.217 | 396.89 | 0.0319 |

| c22 | 7.49487 | 54.11 | 0.0860 |

| c23 | −2.75521 | 4.38 | 0.2837 |

| c33 | 17.2365 | 11.17 | 0.1851 |

| Run | Rotor-Stator Mixer | |||||

|---|---|---|---|---|---|---|

| Independent Variables | Response Variables | |||||

| Rotation Speed (X1, rpm) | Time (X2, min) | Droplet Size (Y, nm) | PDI | |||

| Mean | SD | Mean | SD | |||

| 1 | 20,000 | 10 | 105.8 | 10.3 | 0.255 | 0.045 |

| 2 | 20,000 | 5 | 223.5 | 26.8 | 0.425 | 0.238 |

| 3 | 29,000 | 15 | 280.7 | 29.0 | 0.571 | 0.093 |

| 4 | 29,000 | 10 | 133.2 | 6.6 | 0.166 | 0.107 |

| 5 | 20,000 | 10 | 105.0 | 4.7 | 0.192 | 0.224 |

| 6 | 11,000 | 15 | 138.4 | 2.2 | 0.187 | 0.043 |

| 7 | 29,000 | 5 | 136.4 | 6.1 | 0.175 | 0.016 |

| 8 | 11,000 | 10 | 148.5 | 30.0 | 0.323 | 0.044 |

| 9 | 11,000 | 5 | 286.9 | 15.2 | 0.556 | 0.150 |

| 10 | 20,000 | 15 | 112.6 | 4.4 | 0.185 | 0.020 |

| Ultrasonic Homogenizer | ||||||

| Time (X1, min) | Amplitude (X2, %) | Droplet Size (Y, nm) | PDI | |||

| Mean | SD | Mean | SD | |||

| 11 | 5 | 20 | 71.09 | 7.35 | 0.480 | 0.283 |

| 12 | 15 | 20 | 104.9 | 6.7 | 0.156 | 0.085 |

| 13 | 10 | 20 | 113.2 | 6.9 | 0.136 | 0.109 |

| 14 | 15 | 40 | 114.7 | 18.1 | 0.103 | 0.011 |

| 15 | 15 | 60 | 111.5 | 9.9 | 0.060 | 0.035 |

| 16 | 10 | 60 | 120.3 | 12.9 | 0.074 | 0.018 |

| 17 | 10 | 40 | 175.9 | 3.5 | 0.163 | 0.040 |

| 18 | 10 | 40 | 188.1 | 5.2 | 0.168 | 0.044 |

| 19 | 5 | 40 | 106.5 | 6.5 | 0.192 | 0.107 |

| 20 | 5 | 60 | 238.8 | 12.7 | 0.019 | 0.015 |

| Source | Rotor-Stator Mixer | Ultrasonic Homogenizer | ||||

|---|---|---|---|---|---|---|

| Regression Coefficients | F-Ratio | p-Value | Regression Coefficients | F-Ratio | p-Value | |

| c0 | 937.701 | - | - | −188.939 | - | - |

| c1 | −0.0362116 | 287.63 | 0.0375 | 31.4482 | 12.70 | 0.1742 |

| c2 | −89.7357 | 6900.01 | 0.0077 | 8.68788 | 65.80 | 0.0781 |

| c11 | 0.00000049 | 11380.94 | 0.0060 | −0.942343 | 17.40 | 0.1498 |

| c12 | 0.00162667 | 66978.00 | 0.0025 | −0.377775 | 76.71 | 0.0724 |

| c22 | 2.66829 | 32446.77 | 0.0035 | −0.0435214 | 9.50 | 0.1997 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niknam, S.M.; Kashaninejad, M.; Escudero, I.; Sanz, M.T.; Beltrán, S.; Benito, J.M. Preparation of Water-in-Oil Nanoemulsions Loaded with Phenolic-Rich Olive Cake Extract Using Response Surface Methodology Approach. Foods 2022, 11, 279. https://doi.org/10.3390/foods11030279

Niknam SM, Kashaninejad M, Escudero I, Sanz MT, Beltrán S, Benito JM. Preparation of Water-in-Oil Nanoemulsions Loaded with Phenolic-Rich Olive Cake Extract Using Response Surface Methodology Approach. Foods. 2022; 11(3):279. https://doi.org/10.3390/foods11030279

Chicago/Turabian StyleNiknam, Seyed Mehdi, Mansoore Kashaninejad, Isabel Escudero, María Teresa Sanz, Sagrario Beltrán, and José M. Benito. 2022. "Preparation of Water-in-Oil Nanoemulsions Loaded with Phenolic-Rich Olive Cake Extract Using Response Surface Methodology Approach" Foods 11, no. 3: 279. https://doi.org/10.3390/foods11030279

APA StyleNiknam, S. M., Kashaninejad, M., Escudero, I., Sanz, M. T., Beltrán, S., & Benito, J. M. (2022). Preparation of Water-in-Oil Nanoemulsions Loaded with Phenolic-Rich Olive Cake Extract Using Response Surface Methodology Approach. Foods, 11(3), 279. https://doi.org/10.3390/foods11030279