Exploring the Role of Acacia (Acacia seyal) and Cactus (Opuntia ficus-indica) Gums on the Dough Performance and Quality Attributes of Breads and Cakes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Isolation of Gums

2.2. Preparation of Wheat Flour-Gum Mixtures

2.3. Rapid Visco Analyzer Measurements (RVA)

2.4. Gel Texture

2.5. Dough-Mixing Properties Using Doughlab

2.6. Bread-Baking Procedure

2.7. Cake-Baking Procedure

2.8. Crumb Color of Bread and Cakes

2.9. Bread and Cake Firmness

2.10. Sensory Evaluation of Baked Products

2.11. Statistical Analyses

3. Results and Discussion

3.1. Dough Properties of Flour-Gum Mixtures

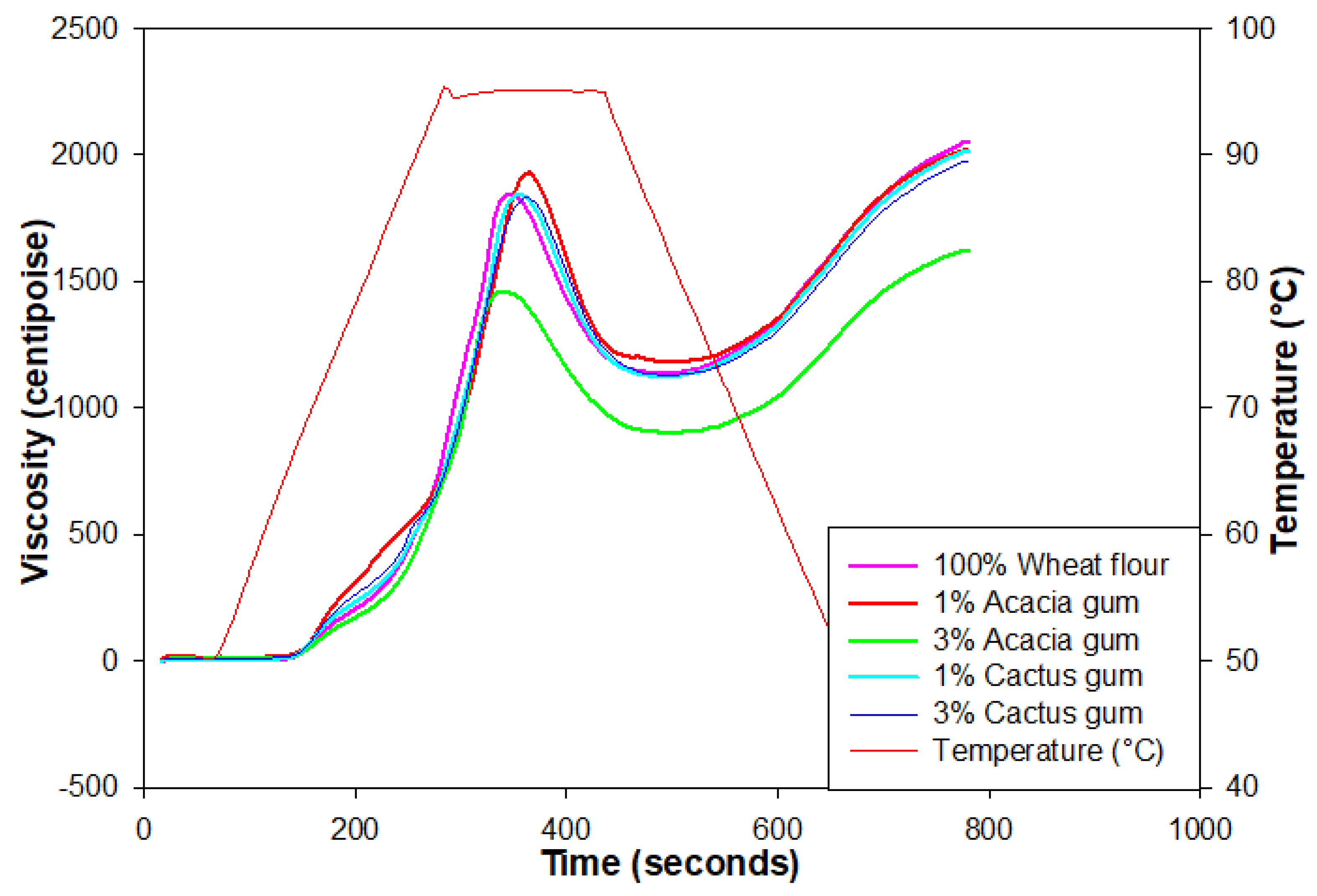

3.2. Pasting Properties of Flour–Gum Mixtures

3.3. Textural Properties of Flour-Gum Mixtures

3.4. Crumb-Color Profiles of Baked Products

3.5. Volume, Weight, and Specific Volume of Baked Products

3.6. Textural Attributes of Baked Products

3.7. Sensory Quality of Baked Products

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Awulachew, M. Gluten-Free Bread: A Review of Non-Gluten Component Characteristics Retain the Baking Quality and Viscoelastic Properties of Dough. Gl J Foo Sci Nutri GJFSN 2021, 122, 115–120. [Google Scholar]

- Gänzle, M.; Gobbetti, M. 12.1 Microbial Ecology of Sourdough. In Handbook on Sourdough Biotechnology; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 279. [Google Scholar]

- Itthivadhanapong, P.; Jantathai, S.; Schleining, G. Improvement of physical properties of gluten-free steamed cake based on black waxy rice flour using different hydrocolloids. J. Food Sci. Technol. 2016, 53, 2733–2741. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hojjatoleslami, M.; Azizi, M.H. Impact of tragacanth and xanthan gums on the physical and textural characteristics of gluten-free cake. Nutr. Food Sci. Res. 2015, 2, 29–37. [Google Scholar]

- Jia, C.; Huang, W.; Ji, L.; Zhang, L.; Li, N.; Li, Y. Improvement of hydrocolloid characteristics added to angel food cake by modifying the thermal and physical properties of frozen batter. Food Hydrocoll. 2014, 41, 227–232. [Google Scholar] [CrossRef]

- Rodge, A.; Sonkamble, S.; Salve, R.; Hashmi, S. Effect of hydrocolloid (guar gum) incorporation on the quality characteristics of bread. J. Food Processing Technol. 2012, 3, 136. [Google Scholar] [CrossRef] [Green Version]

- Kohajdová, Z.; Karovičová, J. Application of hydrocolloids as baking improvers. Chem. Pap. 2009, 63, 26–38. [Google Scholar] [CrossRef]

- Ma, M.; Mu, T.; Sun, H.; Zhou, L. Evaluation of texture, retrogradation enthalpy, water mobility, and anti-staling effects of enzymes and hydrocolloids in potato steamed bread. Food Chem. 2022, 368, 130686. [Google Scholar] [CrossRef]

- Sharadanant, R.; Khan, K. Effect of hydrophilic gums on the quality of frozen dough: Electron microscopy, protein solubility, and electrophoresis studies. Cereal Chem. 2006, 83, 411–417. [Google Scholar] [CrossRef]

- Aboulnaga, E.; Ibrahim, F.Y.; Youssif, M.; Mohamed, A. Influence of various hydrocolloids addition on pan bread quality. J. Food Dairy Sci. 2018, 9, 339–346. [Google Scholar] [CrossRef]

- Barcenas, M.E.; Rosell, C.M. Effect of HPMC addition on the microstructure, quality and aging of wheat bread. Food Hydrocoll. 2005, 19, 1037–1043. [Google Scholar] [CrossRef]

- Nessrien, M.; Gadallah, M. Effect of adding different gums and emulsifiers on quality attributes and staling rate of microwave-baked cakes. Alex. J. Food Sci. Technol. 2011, 8, 1–12. [Google Scholar]

- Noorlaila, A.; Hasanah, H.N.; Asmeda, R.; Yusoff, A. The effects of xanthan gum and hydroxypropylmethylcellulose on physical properties of sponge cakes. J. Saudi Soc. Agric. Sci. 2020, 19, 128–135. [Google Scholar] [CrossRef]

- Salehi, F. Effect of common and new gums on the quality, physical, and textural properties of bakery products: A review. J. Texture Stud. 2020, 51, 361–370. [Google Scholar] [CrossRef] [PubMed]

- Salehi, F.; Kashaninejad, M. Modeling of xanthan gum effect on textural properties of carrot cake. Iran. J. Food Sci. Technol. 2018, 75, 73–82. [Google Scholar]

- Turabi, E.; Sumnu, G.; Sahin, S. Quantitative analysis of macro and micro-structure of gluten-free rice cakes containing different types of gums baked in different ovens. Food Hydrocoll. 2010, 24, 755–762. [Google Scholar] [CrossRef]

- Feugang, J.M.; Konarski, P.; Zou, D.; Stintzing, F.C.; Zou, C. Nutritional and medicinal use of Cactus pear (Opuntia spp.) cladodes and fruits. Front. Biosci. 2006, 11, 2574–2589. [Google Scholar] [CrossRef] [PubMed]

- Sepúlveda, E.; Sáenz, C.; Aliaga, E.; Aceituno, C. Extraction and characterization of mucilage in Opuntia spp. J. Arid Environ. 2007, 68, 534–545. [Google Scholar] [CrossRef]

- Stintzing, F.C.; Carle, R. Cactus stems (Opuntia spp.): A review on their chemistry, technology, and uses. Mol. Nutr. Food Res. 2005, 49, 175–194. [Google Scholar] [CrossRef]

- Salehi, E.; Emam-Djomeh, Z.; Askari, G.; Fathi, M. Opuntia ficus indica fruit gum: Extraction, characterization, antioxidant activity and functional properties. Carbohydr. Polym. 2019, 206, 565–572. [Google Scholar] [CrossRef]

- Dick, M.; Dal Magro, L.; Rodrigues, R.C.; de Oliveira Rios, A.; Flôres, S.H. Valorization of Opuntia monacantha (Willd.) Haw. cladodes to obtain a mucilage with hydrocolloid features: Physicochemical and functional performance. Int. J. Biol. Macromol. 2019, 123, 900–909. [Google Scholar] [CrossRef]

- Manhivi, V.E.; Venter, S.; Amonsou, E.O.; Kudanga, T. Composition, thermal and rheological properties of polysaccharides from amadumbe (Colocasia esculenta) and cactus (Opuntia spp.). Carbohydr. Polym. 2018, 195, 163–169. [Google Scholar] [CrossRef] [PubMed]

- De Waal, H.; Louhaichi, M.; Taguchi, M.; Fouché, H.; De Wit, M. Development of a cactus pear agro-industry for the sub-Sahara Africa Region. In Proceedings of the International Workshop, University of the Free State, Bloemfontein, South Africa, 27–28 January 2015. [Google Scholar]

- Hussain, S.; Mohamed, A.A.; Alamri, M.S.; Ibraheem, M.A.; Qasem, A.A.A.; Alsulami, T.; Ababtain, I.A. Effect of Cactus (Opuntia ficus-indica) and Acacia (Acacia seyal) Gums on the Pasting, Thermal, Textural, and Rheological Properties of Corn, Sweet Potato, and Turkish Bean Starches. Molecules 2022, 27, 701. [Google Scholar] [CrossRef] [PubMed]

- Alamri, M.S.; Mohamed, A.; Hussain, S.; Al-Ruquie, I. Behri dates pits-enriched bread: Effect on dough rheology, bread quality, and shelf life. Ital. J. Food Sci. 2014, 26, 62–73. [Google Scholar]

- Dangi, P.; Chaudhary, N.; Khatkar, B. Rheological and microstructural characteristics of low molecular weight glutenin subunits of commercial wheats. Food Chem. 2019, 297, 124989. [Google Scholar] [CrossRef] [PubMed]

- AACC. Approved methods of the American association of cereal chemists. In Amer Assn of Cereal Chemists; AACC: Saint Paul, MN, USA, 2000; Volume 1. [Google Scholar]

- Alamri, M.S. Okra-gum fortified bread: Formulation and quality. J. Food Sci. Technol. 2014, 51, 2370–2381. [Google Scholar] [CrossRef] [Green Version]

- Mahmood, K.; Alamri, M.; Mohamed, A.; Hussain, S.; Abdu Qasem, A. Gum cordia: Physico-functional properties and effect on dough rheology and pan bread quality. Qual. Assur. Saf. Crops Foods 2015, 7, 569–579. [Google Scholar] [CrossRef]

- Wang, J.J.; Liu, G.; Huang, Y.-B.; Zeng, Q.-H.; Song, G.-S.; Hou, Y.; Li, L.; Hu, S.-Q. Role of N-terminal domain of HMW 1Dx5 in the functional and structural properties of wheat dough. Food Chem. 2016, 213, 682–690. [Google Scholar] [CrossRef]

- Chen, M.; Wang, L.; Qian, H.; Zhang, H.; Li, Y.; Wu, G.; Qi, X. The effects of phosphate salts on the pasting, mixing and noodle-making performance of wheat flour. Food Chem. 2019, 283, 353–358. [Google Scholar] [CrossRef]

- Alamri, M.S.; Mohamed, A.A.; Hussain, S.; Ibraheem, M.A.; Qasem, A.A.A.; Shamlan, G.; Hakeem, M.J.; Ababtain, I.A. Functionality of Cordia and Ziziphus Gums with Respect to the Dough Properties and Baking Performance of Stored Pan Bread and Sponge Cakes. Foods 2022, 11, 460. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, J.J.; Chen, Y.; Wei, N.; Hou, Y.; Bai, W.; Hu, S.-Q. Effect of water-soluble dietary fiber resistant dextrin on flour and bread qualities. Food Chem. 2020, 317, 126452. [Google Scholar] [CrossRef]

- Al-Dalain, S.Y.; Morsy, M.K. Effect of Pullulan and Hydrocolloids on Rheological Properties and Quality Parameters of Wheat-Soy Baladi Bread. Food Nutr. Sci. 2018, 9, 32–45. [Google Scholar] [CrossRef] [Green Version]

- Mahmood, K.; Alamri, M.S.; Abdellatif, M.A.; Hussain, S.; Qasem, A.A.A. Wheat flour and gum cordia composite system: Pasting, rheology and texture studies. Food Sci. Technol. 2018, 38, 691–697. [Google Scholar] [CrossRef] [Green Version]

- Singh, A.; Geveke, D.J.; Yadav, M.P. Improvement of rheological, thermal and functional properties of tapioca starch by using gum arabic. LWT 2017, 80, 155–162. [Google Scholar] [CrossRef]

- Shrivastava, M.; Yadav, R.B.; Yadav, B.S.; Dangi, N. Effect of incorporation of hydrocolloids on the physicochemical, pasting and rheological properties of colocasia starch. J. Food Meas. Charact. 2018, 12, 1177–1185. [Google Scholar] [CrossRef]

- Alamri, M.S.; Mohamed, A.A.; Hussain, S. Effects of alkaline-soluble okra gum on rheological and thermal properties of systems with wheat or corn starch. Food Hydrocoll. 2013, 30, 541–551. [Google Scholar] [CrossRef]

- Kiprop, V.J.; Omwamba, M.N.; Mahungu, S.M. Influence of Gum Arabic from Acacia Senegal var. kerensis on the Modifications of Pasting and Textural Properties of Cassava and Corn Starches. Food Nutr. Sci. 2021, 12, 1098–1115. [Google Scholar]

- Hussain, S.; Mohamed, A.A.; Alamri, M.S.; Ibraheem, M.A.; Qasem, A.A.A.; Shahzad, S.A.; Ababtain, I.A. Use of Gum Cordia (Cordia myxa) as a Natural Starch Modifier; Effect on Pasting, Thermal, Textural, and Rheological Properties of Corn Starch. Foods 2020, 9, 909. [Google Scholar] [CrossRef]

- da Silva Costa, R.A.; Bonomo, R.C.F.; Rodrigues, L.B.; Santos, L.S.; Veloso, C.M. Improvement of texture properties and syneresis of arrowroot (Maranta arundinacea) starch gels by using hydrocolloids (guar gum and xanthan gum). J. Sci. Food Agric. 2020, 100, 3204–3211. [Google Scholar] [CrossRef]

- Gunasekara, D.; Bulathgama, A.; Wickramasinghe, I. Comparison of Different Hydrocolloids on the Novel Development of Muffins from “Purple Yam” (Dioscorea alata) Flour in Sensory, Textural, and Nutritional Aspects. Int. J. Food Sci. 2021, 2021, 9970291. [Google Scholar] [CrossRef]

- Liu, G.; Wang, J.; Hou, Y.; Huang, Y.-B.; Wang, J.; Li, C.; Guo, S.; Li, L.; Hu, S.-Q. Characterization of wheat endoplasmic reticulum oxidoreductin 1 and its application in Chinese steamed bread. Food Chem. 2018, 256, 31–39. [Google Scholar] [CrossRef]

- Rathnayake, H.; Navaratne, S.; Navaratne, C. Porous crumb structure of leavened baked products. Int. J. Food Sci. 2018, 2018, 8187318. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rojas, J.A.; Rosell, C.M.; De Barber, C.B. Pasting properties of different wheat flour-hydrocolloid systems. Food Hydrocoll. 1999, 13, 27–33. [Google Scholar] [CrossRef]

- Mohamed, A.; Hussain, S.; Alamri, M.S.; Ibraheem, M.A.; Qasem, A.A.A.; Ababtain, I.A. Physicochemical Properties of Starch Binary Mixtures with Cordia and Ziziphus Gums. Processes 2022, 10, 180. [Google Scholar] [CrossRef]

- Matia-Merino, L.; Prieto, M.; Roman, L.; Gómez, M. The impact of basil seed gum on native and pregelatinized corn flour and starch gel properties. Food Hydrocoll. 2019, 89, 122–130. [Google Scholar] [CrossRef]

- Huang, S.; Chi, C.; Li, X.; Zhang, Y.; Chen, L. Understanding the structure, digestibility, texture and flavor attributes of rice noodles complexation with xanthan and dodecyl gallate. Food Hydrocoll. 2022, 127, 107538. [Google Scholar] [CrossRef]

| WA (%) | DDT (min) | Stability (min) | Softening (FU) | MTI (FU) | Quality Number | |

|---|---|---|---|---|---|---|

| Control (100% WF) | 61.47 ± 1.16 a | 1.60 ± 0.08 c | 5.70 ± 0.22 c | 91.67 ± 2.36 e | 35.67 ± 4.19 e | 61.23 ± 0.95 a |

| Acacia 1% | 59.93 ± 0.09 b | 5.50 ± 0.08 a | 6.53 ± 0.12 b | 105.67 ± 0.94 c | 64.67 ± 0.47 c | 53.00 ± 0.73 c |

| Acacia 3% | 58.63 ± 0.12 d | 5.57 ± 0.26 a | 7.40 ± 0.16 a | 99.67 ± 0.47 d | 52.33 ± 2.05 d | 56.43 ± 0.39 b |

| Cactus 1% | 59.50 ± 0.41 bc | 3.90 ± 0.08 b | 4.20 ± 0.16 d | 131.93 ± 2.15 b | 100.67 ± 4.19 b | 42.99 ± 0.74 d |

| Cactus 3% | 58.93 ± 0.09 c | 3.93 ± 0.09 b | 3.40 ± 0.08 e | 146.63 ± 1.73 a | 111.00 ± 2.94 a | 40.97 ± 1.19 e |

| PV (cP) | BD (cP) | FV (cP) | SB (cP) | PT (°C) | |

|---|---|---|---|---|---|

| Control (100% WF) | 1886 ± 35.26 a | 736 ± 21.79 a | 2056 ± 1.70 a | 905 ± 12.36 a | 69.40 ± 0.04 c |

| Acacia 1% | 1693 ± 4.97 b | 647 ± 9.46 c | 1860 ± 1.25 c | 815 ± 5.35 d | 83.68 ± 0.31 b |

| Acacia 3% | 1453 ± 6.55 c | 568 ± 9.46 d | 1593 ± 25.77 d | 705 ± 9.90 e | 84.07 ± 0.65 a |

| Cactus 1% | 1854 ± 7.04 a | 732 ± 4.85 a | 2004 ± 9.84 b | 881 ± 8.99 b | 68.53 ± 0.02 d |

| Cactus 3% | 1847 ± 11.02 a | 702 ± 0.70 b | 1991 ± 13.10 b | 848 ± 0.47 c | 68.54 ± 0.01 d |

| Hardness (N) | Gumminess (N) | Chewiness (N.mm) | Springiness (mm) | Cohesiveness | Adhesiveness (mJ) | |

|---|---|---|---|---|---|---|

| Control (100% WF) | 61.00 ± 0.65 b | 30.00 ± 0.38 ab | 297 ± 1.88 a | 10.00 ± 0.07 a | 0.49 ± 0.01 b | 0.83 ± 0.05 a |

| Acacia 1% | 55.10 ± 0.81 c | 28.59 ± 0.47 b | 284 ± 3.55 b | 9.95 ± 0.04 a | 0.52 ± 0.02 a | 0.87 ± 0.05 a |

| Acacia 3% | 41.33 ± 0.47 d | 22.04 ± 0.23 d | 216 ± 2.22 c | 9.80 ± 0.01 b | 0.53 ± 0.01 a | 0.70 ± 0.02 b |

| Cactus 1% | 63.33 ± 0.45 a | 31.04 ± 0.73 a | 303 ± 5.85 a | 9.75 ± 0.04 b | 0.49 ± 0.02 b | 0.60 ± 0.06 c |

| Cactus 3% | 57.00 ± 0.72 c | 26.78 ± 0.08 c | 262 ± 0.80 c | 9.80 ± 0.02 b | 0.47 ± 0.01 c | 0.70 ± 0.01 b |

| L* | a* | b* | |

|---|---|---|---|

| Pan bread | |||

| Control (100% WF) | 75.39 ± 0.28 b | −7.05 ± 0.02 c | 17.31 ± 0.02 c |

| Acacia 1% | 74.54 ± 0.16 b | −6.89 ± 0.01 d | 17.58 ± 0.07 c |

| Acacia 3% | 72.75 ± 0.28 c | −6.48 ± 0.06 e | 17.97 ± 0.10 c |

| Cactus 1% | 78.27 ± 0.48 a | −7.33 ± 0.05 b | 18.75 ± 0.12 b |

| Cactus 3% | 78.77 ± 0.04 a | −7.68 ± 0.01 a | 20.65 ± 0.02 a |

| Sponge cake | |||

| Control (100% WF) | 71.53 ± 0.04 c | −9.28 ± 0.01 c | 26.66 ± 0.03 b |

| Acacia 1% | 71.21 ± 0.08 d | −9.39 ± 0.07 b | 26.12 ± 0.08 b |

| Acacia 3% | 69.63 ± 0.01 e | −9.65 ± 0.05 a | 29.48 ± 0.18 a |

| Cactus 1% | 71.94 ± 0.04 b | −9.15 ± 0.07 d | 25.40 ± 0.06 c |

| Cactus 3% | 73.45 ± 0.04 a | −9.21 ± 0.02 d | 25.23 ± 0.07 c |

| Loaf Volume (cm3) | Loaf Weight (g) | Specific Volume (cm3/g) | |

|---|---|---|---|

| Pan bread | |||

| Control (100% WF) | 771 ± 5.35 e | 326 ± 3.30 a | 2.37 ± 0.02 c |

| Cactus 1% | 801 ± 3.30 c | 317 ± 1.25 c | 2.52 ± 0.02 b |

| Cactus 3% | 821 ± 4.19 b | 320 ± 1.70 bc | 2.57 ± 0.01 a |

| Acacia 1% | 790 ± 4.50 d | 318 ± 1.63 c | 2.49 ± 0.03 b |

| Acacia 3% | 832 ± 2.05 a | 321 ± 2.49 ab | 2.59 ± 0.02 a |

| Sponge cake | |||

| Control (100% WF) | 749 ± 2.94 c | 286 ± 1.25 c | 2.62 ± 0.02 a |

| Cactus 1% | 732 ± 4.97 d | 289 ± 0.82 c | 2.53 ± 0.04 bc |

| Cactus 3% | 709 ± 3.30 e | 321 ± 3.74 a | 2.21 ± 0.03 e |

| Acacia 1% | 785 ± 4.08 b | 318 ± 2.05 ab | 2.47 ± 0.03 d |

| Acacia 3% | 811 ± 3.30 a | 315 ± 1.63 b | 2.57 ± 0.02 b |

| Firmness (g) 24 h | Springiness (%) 24 h | Firmness (g) 96 h | Springiness (%) 96 h | |

|---|---|---|---|---|

| Pan bread | ||||

| Control (100% WF) | 493.00 ± 16.38 a | - | 1070.57 ± 30.54 a | - |

| Cactus 1% | 232.58 ± 17.65 d | - | 357.88 ± 35.08 d | - |

| Cactus 3% | 256.25 ± 17.65 cd | - | 473.81 ± 24.23 bc | - |

| Acacia 1% | 282.03 ± 17.88 bc | - | 497.25 ± 15.90 b | - |

| Acacia 3% | 303.84 ± 6.16 b | - | 500.40 ± 35.40 b | - |

| Sponge cake | ||||

| Control (100% WF) | 234.29 ± 15.86 ab | 52.29 ± 1.18 b | 438.92 ± 30.74 a | 47.95 ± 0.86 b |

| Cactus 1% | 174.37 ± 5.91 c | 55.22 ± 0.47 a | 318.26 ± 8.65 c | 47.61 ± 1.01 b |

| Cactus 3% | 252.26 ± 27.76 a | 54.45 ± 0.41 a | 356.37 ± 8.21 b | 51.34 ± 0.93 a |

| Acacia 1% | 205.74 ± 15.17 b | 53.36 ± 0.10 ab | 305.20 ± 5.99 cd | 51.38 ± 0.18 a |

| Acacia 3% | 161.75 ± 10.32 c | 52.15 ± 1.65 b | 215.67 ± 5.42 e | 48.31 ± 0.56 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, S.; Alamri, M.S.; Mohamed, A.A.; Ibraheem, M.A.; Qasem, A.A.A.; Shamlan, G.; Ababtain, I.A. Exploring the Role of Acacia (Acacia seyal) and Cactus (Opuntia ficus-indica) Gums on the Dough Performance and Quality Attributes of Breads and Cakes. Foods 2022, 11, 1208. https://doi.org/10.3390/foods11091208

Hussain S, Alamri MS, Mohamed AA, Ibraheem MA, Qasem AAA, Shamlan G, Ababtain IA. Exploring the Role of Acacia (Acacia seyal) and Cactus (Opuntia ficus-indica) Gums on the Dough Performance and Quality Attributes of Breads and Cakes. Foods. 2022; 11(9):1208. https://doi.org/10.3390/foods11091208

Chicago/Turabian StyleHussain, Shahzad, Mohamed Saleh Alamri, Abdellatif A. Mohamed, Mohamed A. Ibraheem, Akram A. Abdo Qasem, Ghalia Shamlan, and Ibrahim A. Ababtain. 2022. "Exploring the Role of Acacia (Acacia seyal) and Cactus (Opuntia ficus-indica) Gums on the Dough Performance and Quality Attributes of Breads and Cakes" Foods 11, no. 9: 1208. https://doi.org/10.3390/foods11091208

APA StyleHussain, S., Alamri, M. S., Mohamed, A. A., Ibraheem, M. A., Qasem, A. A. A., Shamlan, G., & Ababtain, I. A. (2022). Exploring the Role of Acacia (Acacia seyal) and Cactus (Opuntia ficus-indica) Gums on the Dough Performance and Quality Attributes of Breads and Cakes. Foods, 11(9), 1208. https://doi.org/10.3390/foods11091208