Accurate Identification and Quantification of Chinese Yam Powder Adulteration Using Laser-Induced Breakdown Spectroscopy

Abstract

:1. Introduction

2. Materials and Methods

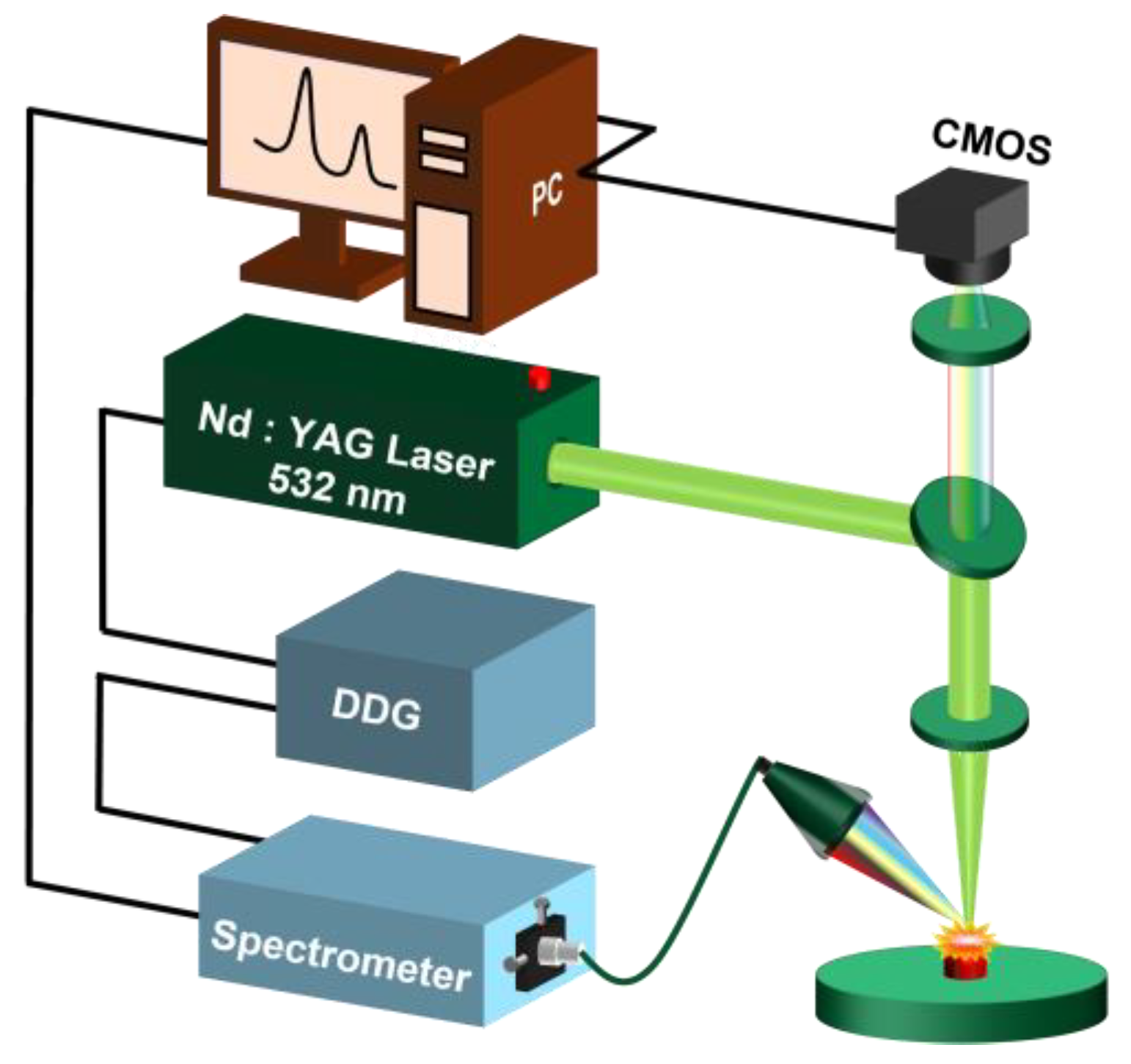

2.1. Experiment Setup

2.2. Sample Pretreatment

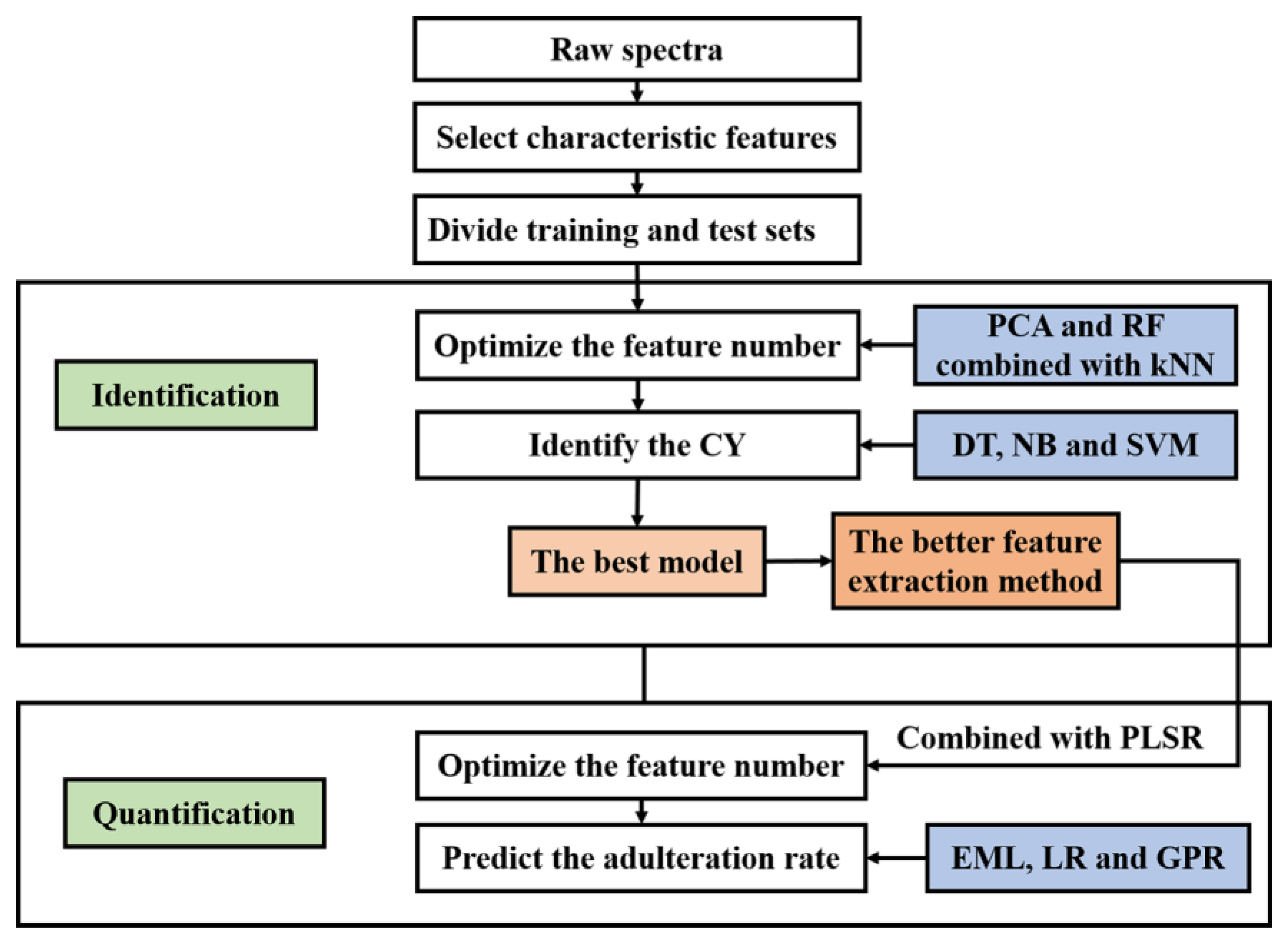

2.3. Algorithm Description

- Find the characteristic element peaks of CY LIBS spectra.

- Divide the training set and test set of LIBS spectra for classification samples randomly by the proportion 2:1.

- Use PCA and RF combined with kNN to optimize the number of inputs for identification, respectively.

- With the optimized features, train the DT, NB and SVM classifiers, and identify CY by different models, respectively.

- With the better feature extraction method, optimize the number of features combined with PLSR for quantification.

- Train the LR, EML and GPR models, and quantify CY adulteration by different models, respectively.

- For evaluation indexes, the recognition accuracy, the root-mean-square error (RMSE) and the correlation coefficient were used for identification and quantitation, respectively.

3. Results and Discussion

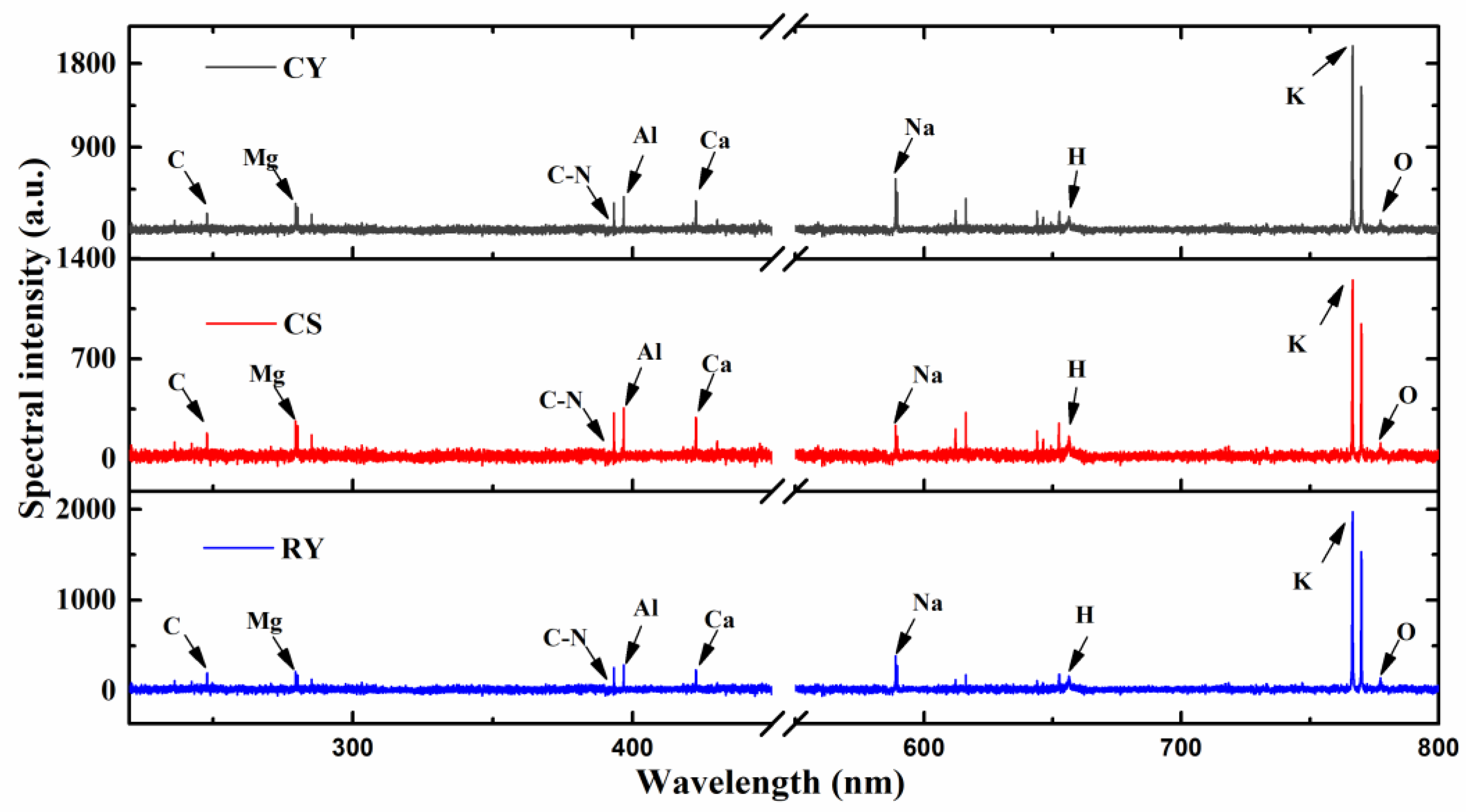

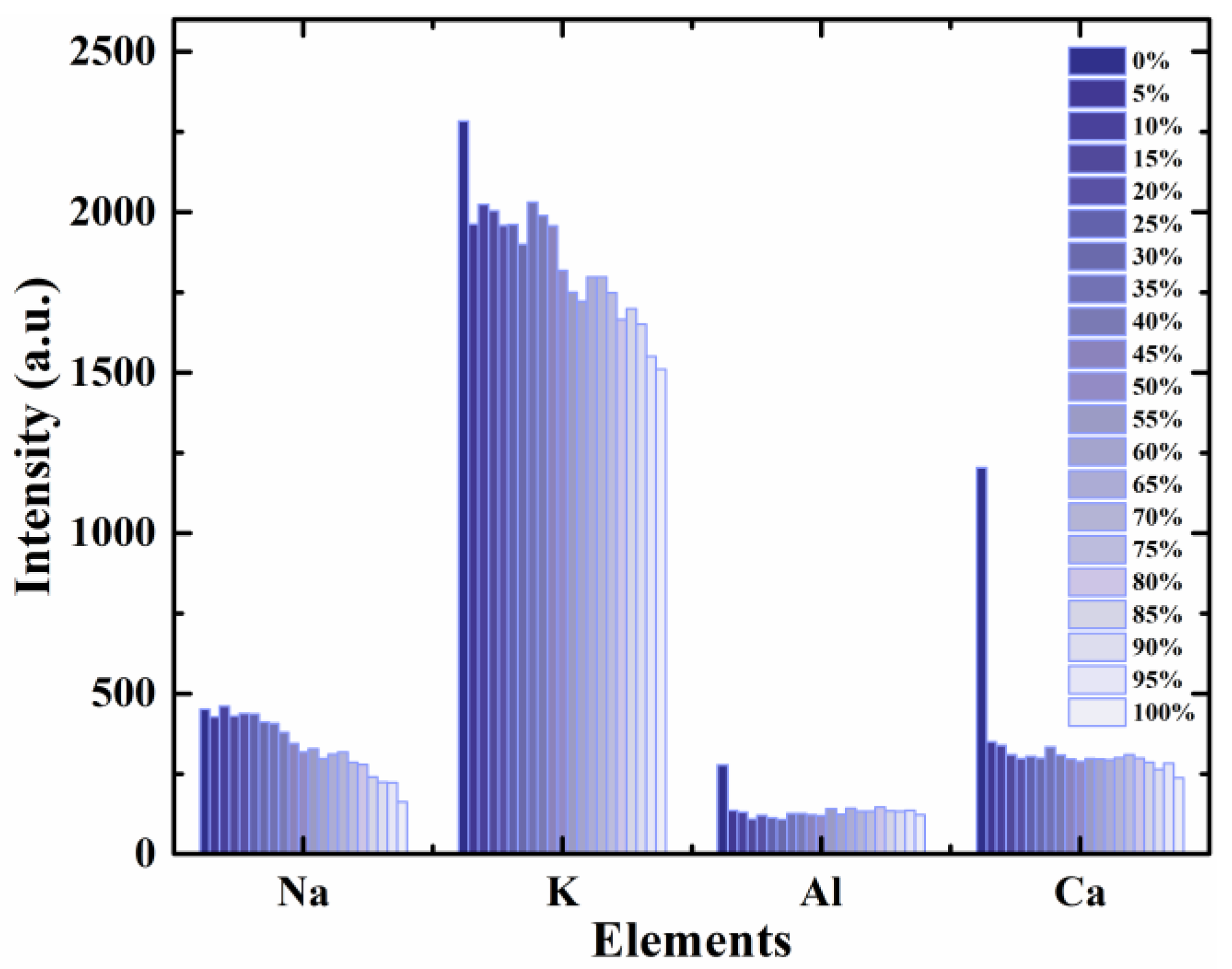

3.1. Spectral Analysis

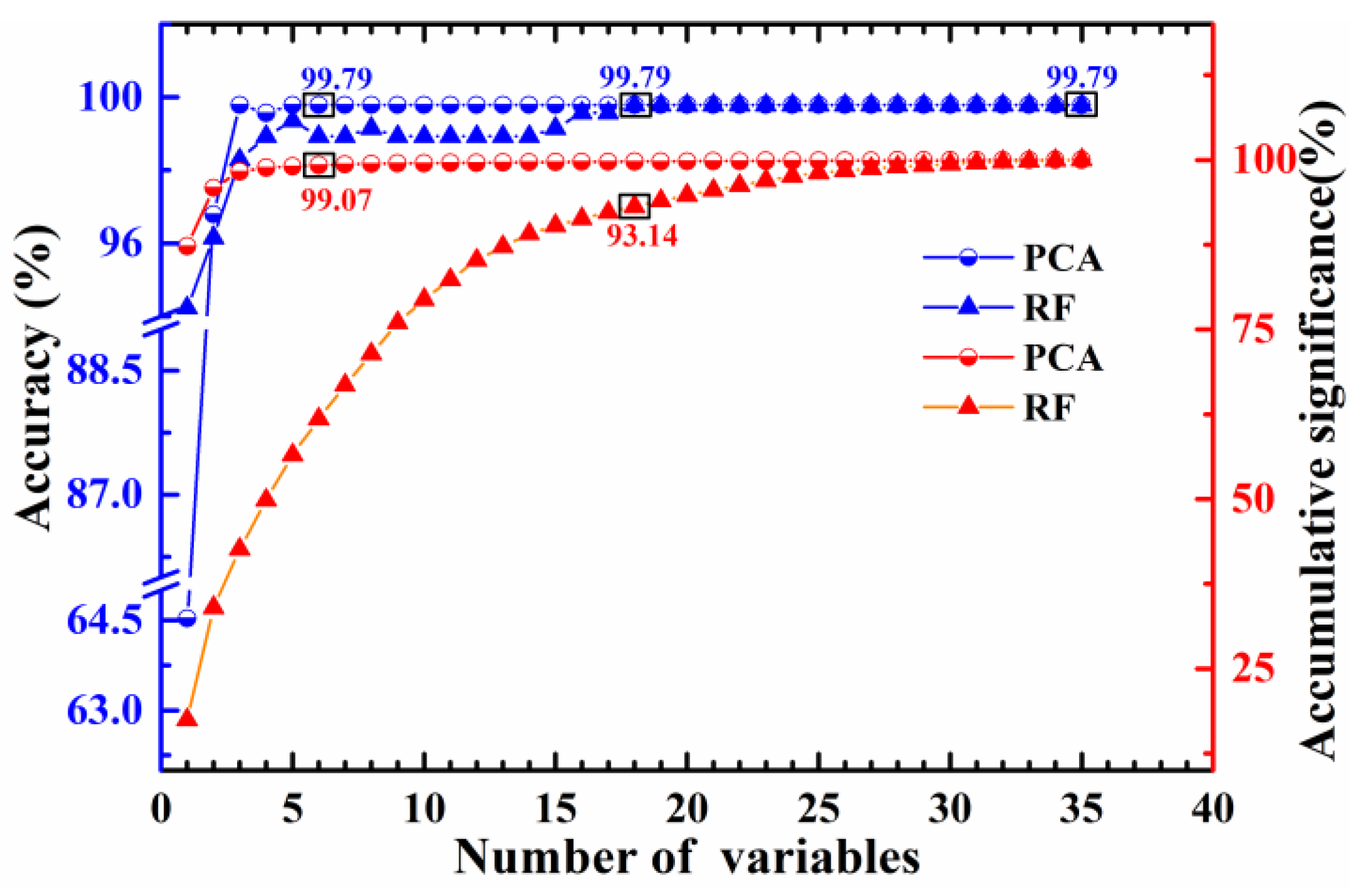

3.2. Identification of CY Adulteration

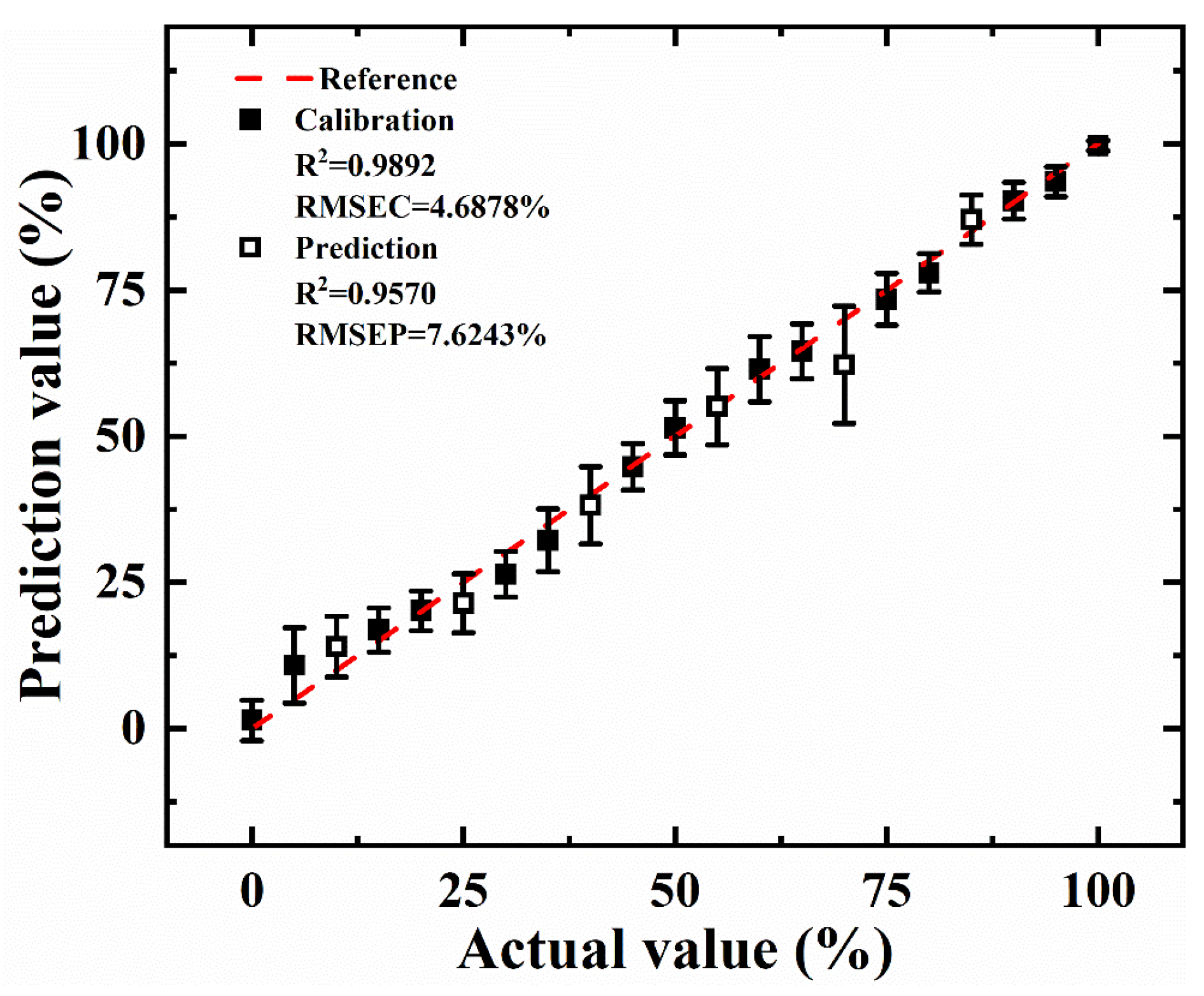

3.3. Quantification of the Adulterants in CY Powder

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Epping, J.; Laibach, N. An underutilized orphan tuber crop—Chinese yam: A review. Planta 2020, 252, 58. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.F.; Zhu, Q.; Wu, S. Preparation of oligosaccharides from Chinese yam and their antioxidant activity. Food Chem. 2015, 173, 1107–1110. [Google Scholar] [CrossRef] [PubMed]

- Mengesha, W.A.; Demissew, S.; Fay, M.F.; Smith, R.J.; Nordal, I.; Wilkin, P. Genetic diversity and species delimitation in the cultivated and wild Guinea yams (Dioscorea spp.) from Southwest Ethiopia as determined by AFLP (amplified fragment length polymorphism) markers. Genet. Resour. Crop Evol. 2013, 60, 1365–1375. [Google Scholar] [CrossRef]

- Meng, X.L.; Wang, B.; Lv, C.Z.; Hu, C.; He, M.J.; Zhang, S.S. Quantification of Chinese yam processing methods based on pyrolysis characteristics and its relation to Maillard reaction. Chin. Herb. Med. 2020, 12, 56–66. [Google Scholar] [CrossRef]

- Hayes, A. Stress relaxation behaviour of a highly calcareous soil amended with long-term application of three organic manures. J. Acoust. Soc. Am. 2010, 85, 1935–1945. [Google Scholar]

- Cui, Y.; Sun, T.; Li, Q. Quality analysis on Shandong special sampling inspection of Dioscoreae rhizoma decoction pieces. J. Pharm. Res. 2021, 40, 312–315. [Google Scholar]

- Ma, H.-L.; Wang, J.W.; Chen, Y.-J.; Lai, Z.T. Rapid authentication of starch adulterations in ultrafine granular powder of Shanyao by near-infrared spectroscopy coupled with chemometric methods. Food Chem. 2017, 215, 108–115. [Google Scholar] [CrossRef]

- Gu, Y.H.; Li, Y.; Tian, Y.; Yuan, L. Study on the multivariate quantitative analysis method for steel alloy elements using LIBS. Spectrosc. Spectr. Anal. 2014, 34, 2244–2249. [Google Scholar]

- Kwon, H.J.; Choi, S.H.; Yoo, C.S.; Choi, H.Y.; Park, Y.D. Development of an analytical method for yam saponins using HPLC with pulsed amperometric detection at different column temperatures. J. Sep. Sci. 2014, 36, 690–698. [Google Scholar] [CrossRef]

- Tsai, W.Y.; Jheng, Y.J.; Chen, K.H.; Lin, K.W.; Lin, K.C. Molecular cloning, structural analysis and mass spectrometric identification of native dioscorins of various yam species. J. Sci. Food Agric. 2013, 93, 761–770. [Google Scholar] [CrossRef]

- Alamu, E.O.; Nuwamanya, E.; Cornet, D.; Meghar, K.; Adesokan, M.; Tran, T.; Belalcazar, J.; Desfontaines, L.; Davrieux, F. Near-infrared spectroscopy applications for high-throughput phenotyping for cassava and yam: A review. Intern. J. Food Sci. Technol. 2021, 56, 1491–1501. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Nie, P.; Shao, Y.; He, Y.; Sun, D. Fsat adulterant quantification in Chinese yam powder using visible, near and mid-infrared spectroscopy. In Proceedings of the CIGR XVIIth World Congress Canada, Québec City, QC, Canada, 10–17 June 2010. [Google Scholar]

- David, C.; Chaffee. LIBS continues to evolve. Opt. Photonics News 2017, 28, 42–49. [Google Scholar]

- Blevins, L.G.; Shaddix, C.R.; Sickafoose, S.M.; Walsh, P.M. Laser-induced breakdown spectroscopy at high temperatures in industrial boilers and furnaces. Appl. Opt. 2003, 42, 6107–6118. [Google Scholar] [CrossRef]

- Noll, R.; Fricke-Begemann, C.; Brunk, M.; Connemann, S.; Meinhardt, C.; Scharun, M.; Sturm, V.; Makowe, J.; Gehlen, C. Laser-induced breakdown spectroscopy expands into industrial applications. Spectrochim. Acta Part B At. Spectrosc. 2014, 93, 41–51. [Google Scholar] [CrossRef]

- Wang, Q.; Xiangli, W.; Chen, X.; Zhang, J.; Teng, G.; Cui, X.; Idrees, B.S.; Wei, K. Primary study of identification of parathyroid gland based on laser-induced breakdown spectroscopy. Biomed. Opt. Express 2021, 12, 1999–2014. [Google Scholar] [CrossRef]

- Zhang, D.; Zhao, Z.; Zhang, S.; Chen, F.; Sheng, Z.; Deng, F.; Zeng, Q.; Guo, L. Accurate identification of soluble solid content in citrus by indirect laser-induced breakdown spectroscopy with its leaves. Microchem. J. 2021, 169, 106530. [Google Scholar] [CrossRef]

- Stefas, D.; Gyftokostas, N.; Kourelias, P.; Nanou, E.; Tananaki, C.; Kanelis, D.; Liolios, V.; Kokkinos, V.; Bouras, C.; Couris, S. Honey discrimination based on the bee feeding by Laser Induced Breakdown Spectroscopy. Food Control 2022, 134, 108770. [Google Scholar] [CrossRef]

- Sezer, B.; Bjelak, A.; Velioglu, H.M.; Boyaci, I.H. Identification of meat species in processed meat products by using protein based laser induced breakdown spectroscopy assay. Food Chem. 2022, 372, 131245. [Google Scholar] [CrossRef]

- Huang, W.; Guo, L.; Kou, W.; Zhang, D.; Hu, Z.; Chen, F.; Chu, Y.; Cheng, W. Identification of adulterated milk powder based on convolutional neural network and laser-induced breakdown spectroscopy. Microchem. J. 2022, 176, 107190. [Google Scholar] [CrossRef]

- Zhang, S.; Hu, Z.; Zhao, Z.; Chen, F.; Tang, Y.; Sheng, Z.; Zhang, D.; Zhang, Z.; Jin, H.; Pu, H. Quantitative analysis of mineral elements in hair and nails using calibration-free laser-induced breakdown spectroscopy. Optik 2021, 242, 167067. [Google Scholar] [CrossRef]

- Nan, S.; Wang, P.T.; Zhu, Q.L.; Sun, J.Y.; Zhang, H.Y.; Liu, X.Y.; Cao, T.X.; Xin, C.; Huang, Y.J.; Zhou, Q.H. Comprehensive characterization of yam tuber nutrition and medicinal quality of Dioscorea opposita and D. alata from different geographic groups in China. J. Integr. Agric. 2020, 19, 2839–2848. [Google Scholar]

- Elmaz, F.; Yücel, Ö.; Mutlu, A.Y. Predictive modeling of biomass gasification with machine learning-based regression methods. Energy 2020, 191, 116541. [Google Scholar] [CrossRef]

- Chu, Y.; Chen, T.; Chen, F.; Tang, Y.; Tang, S.; Jin, H.; Guo, L.; Feng Lu, Y.; Zeng, X. Discrimination of nasopharyngeal carcinoma serum using laser-induced breakdown spectroscopy combined with an extreme learning machine and random forest method. J. Aanl. At. Spectrom. 2018, 33, 2083–2088. [Google Scholar] [CrossRef]

- Rao, A.P.; Jenkins, P.R.; Auxier II, J.D.; Shattan, M.B. Comparison of machine learning techniques to optimize the analysis of plutonium surrogate material via a portable LIBS device. J. Anal. At. Spectrom. 2021, 36, 399–406. [Google Scholar] [CrossRef]

- Yangli, X.; Liuwei, M.; Xiaojing, C.; Xi, C.; Laijin, S.; Leiming, Y.; Wen, S.; Huang, G. A strategy to significantly improve the classification accuracy of LIBS data: Application for the determination of heavy metals in Tegillarca granosa. Plasma Sci. Technol. 2021, 23, 085503. [Google Scholar]

- Menking Hoggatt, K.; Arroyo, L.; Curran, J.; Trejos, T. Novel LIBS method for micro-spatial chemical analysis of inorganic gunshot residues. J. Chemom. 2021, 35, e3208. [Google Scholar] [CrossRef]

- Chu, Y.W.; Chen, F.; Sheng, Z.; Zhang, D.; Guo, L. Blood cancer diagnosis using ensemble learning based on random subspace method in laser-induced breakdown spectroscopy. Biomed. Opt. Express 2020, 11, 4191–4202. [Google Scholar] [CrossRef]

- Tao, M. Gaussian process regression for multivariate spectroscopic calibration. Chemom. Intell. Lab. Syst. 2007, 87, 59–71. [Google Scholar]

- Braga, J.W.B.; Trevizan, L.C.; Nunes, L.C. Comparison of univariate and multivariate calibration for the determination of micronutrients in pellets of plant materials by laser induced breakdown spectrometry. Spectrochim. Acta Part B At. Spectrosc. 2010, 65, 66–74. [Google Scholar] [CrossRef]

- Shen, M.; Hao, Z.; Li, X.; Li, C.; Guo, L.; Tang, Y.; Yang, P.; Zeng, X.; Lu, Y. New spectral reduction algorithm for echelle spectrometer in laser-induced breakdown spectroscopy. Opt. Express 2018, 26, 34131–34141. [Google Scholar] [CrossRef]

- Zhang, Z.; Xie, C. Analysis on the Characteristics of Inorganic Elements in Dioscorea opposita Thunb. Spec. Wild Econ. Anim. Plant Res. 2003, 1, 41–44. [Google Scholar]

- Subbarao, G.; Ito, O.; Berry, W.; Wheeler, R. Sodium—A functional plant nutrient. Crit. Rev. Plant Sci. 2003, 22, 391–416. [Google Scholar]

- Lyu, C.; Yang, J.; Wang, T.; Kang, C.; Wang, S.; Wang, H.; Wan, X.; Zhou, L.; Zhang, W.; Huang, L. A field trials-based authentication study of conventionally and organically grown Chinese yams using light stable isotopes and multi-elemental analysis combined with machine learning algorithms. Food Chem. 2020, 343, 128506. [Google Scholar] [CrossRef]

- Soetan, K.O.; Olaiya, C.O.; Oyewole, O.E. The importance of mineral elements for humans, domestic animals and plants: A review. Afr. J. Food Sci. 2009, 4, 200–222. [Google Scholar]

- Sezer, B.; Bilge, G.; Boyaci, I.H. Capabilities and limitations of LIBS in food analysis. TrAC Trends Anal. Chem. 2017, 97, 345–353. [Google Scholar] [CrossRef]

- Asumadu-Sarkodie, S.; Owusu, P.A. Recent evidence of the relationship between carbon dioxide emissions, energy use, GDP, and population in Ghana: A linear regression approach. Energy Sources Part B Econ. Plan. Policy 2017, 12, 495–503. [Google Scholar] [CrossRef]

- Peng, Y. A novel ensemble machine learning for robust microarray data classification. Comput. Biol. Med. 2006, 36, 553–573. [Google Scholar] [CrossRef]

- Bennett, B.N.; Martin, M.Z.; Leonard, D.N.; Garlea, E. Calibration curves for commercial copper and aluminum alloys using handheld laser-induced breakdown spectroscopy. Appl. Phys. B 2018, 124, 42. [Google Scholar] [CrossRef]

| Experiment Type | Sample Type | Preparation Method | Quantity |

|---|---|---|---|

| Qualitative | Training set and test set | Pure CY | 3 |

| Pure CS | 3 | ||

| Pure RY | 3 | ||

| Quantitative | Calibration set | 0%, 5%, 15%, 20%, 30%, 35%, 45%, 50%, 60%, 65%, 75%, 80%, 90%, 95%, 100% | 45 |

| Validation set | 10%, 25%, 40%, 55%, 70%, 85% | 18 |

| Element | Wavelength (nm) | Element | Wavelength (nm) |

|---|---|---|---|

| C-N | 386.19, 387.14, 388.34 | K | 404.41, 766.49, 769.90 |

| C | 247.86 | Na | 285.28, 589.00, 589.60, 819.48 |

| H | 656.29 | Mg | 279.55, 279.80, 280.27, 517.27, 518.36 |

| O | 777.19, 777.42, 777.54 | Al | 396.15 |

| Ca | 422.67, 442.54, 443.50, 443.57, 445.48, 445.59, 445.66, 558.88, 610.27, 612.22, 616.22, 643.91, 646.26, 649.38 | ||

| Sequence Number | Element Line (nm) | Sequence Number | Element Line (nm) |

|---|---|---|---|

| 1 | Na 589.00 * | 10 | Ca 443.50 |

| 2 | Na 589.60 | 11 | Ca 643.91 |

| 3 | K 769.90 * | 12 | K 404.41 |

| 4 | Mg 518.36 * | 13 | Ca 646.26 |

| 5 | Ca 616.22 * | 14 | Ca 445.48 |

| 6 | Al 396.15 * | 15 | O 777.54 |

| 7 | Mg 279.80 | 16 | O 777.19 |

| 8 | Ca 612.22 | 17 | Na 285.28 |

| 9 | Ca 610.27 | 18 | O 777.42 |

| Sequence Number | Element Line (nm) | Sequence Number | Element Line (nm) |

|---|---|---|---|

| 1 | Na 589.60 | 8 | Ca 643.91 |

| 2 | Na 589.00 # | 9 | K 766.50 |

| 3 | Na 819.48 | 10 | Ca 558.88 |

| 4 | K 404.41 | 11 | Ca 610.27 |

| 5 | K 769.90 # | 12 | Ca 612.22 |

| 6 | Al 396.15 # | 13 | Ca 422.67 |

| 7 | Ca 616.22 # |

| Models | Rc2 | RMSEC (%) | Rp2 | RMSEP (%) |

|---|---|---|---|---|

| EML | 0.9820 | 6.0730 | 0.9280 | 9.9885 |

| LR | 0.9451 | 10.4186 | 0.9541 | 8.2852 |

| GPR | 0.9892 | 4.6878 | 0.9570 | 7.6243 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Wang, Q.; Xu, X.; Chen, F.; Teng, G.; Wei, K.; Chen, G.; Cai, Y.; Guo, L. Accurate Identification and Quantification of Chinese Yam Powder Adulteration Using Laser-Induced Breakdown Spectroscopy. Foods 2022, 11, 1216. https://doi.org/10.3390/foods11091216

Zhao Z, Wang Q, Xu X, Chen F, Teng G, Wei K, Chen G, Cai Y, Guo L. Accurate Identification and Quantification of Chinese Yam Powder Adulteration Using Laser-Induced Breakdown Spectroscopy. Foods. 2022; 11(9):1216. https://doi.org/10.3390/foods11091216

Chicago/Turabian StyleZhao, Zhifang, Qianqian Wang, Xiangjun Xu, Feng Chen, Geer Teng, Kai Wei, Guoyan Chen, Yu Cai, and Lianbo Guo. 2022. "Accurate Identification and Quantification of Chinese Yam Powder Adulteration Using Laser-Induced Breakdown Spectroscopy" Foods 11, no. 9: 1216. https://doi.org/10.3390/foods11091216