By-Product Revalorization: Cava Lees Can Improve the Fermentation Process and Change the Volatile Profile of Bread

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sourdough Formulation and Bread-Making

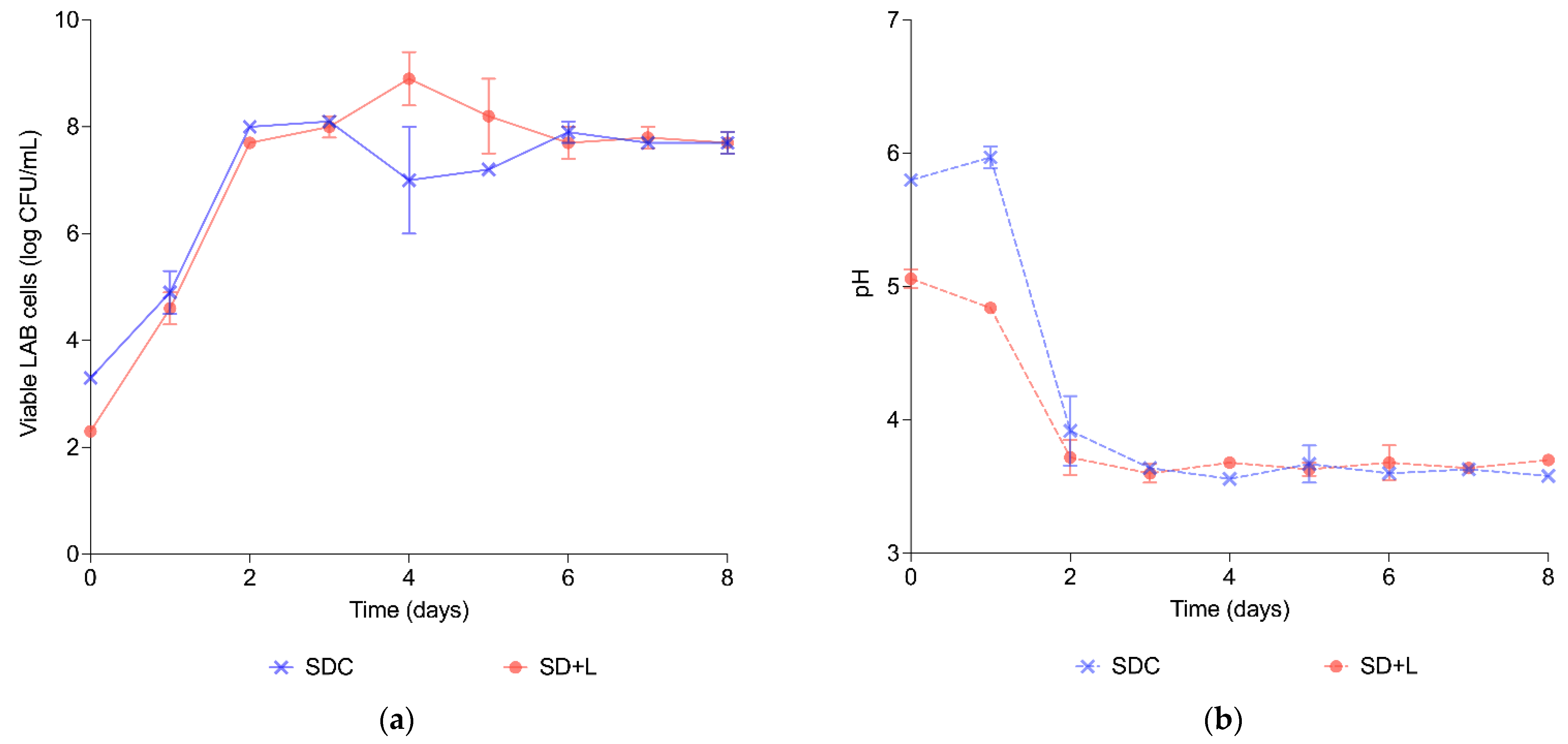

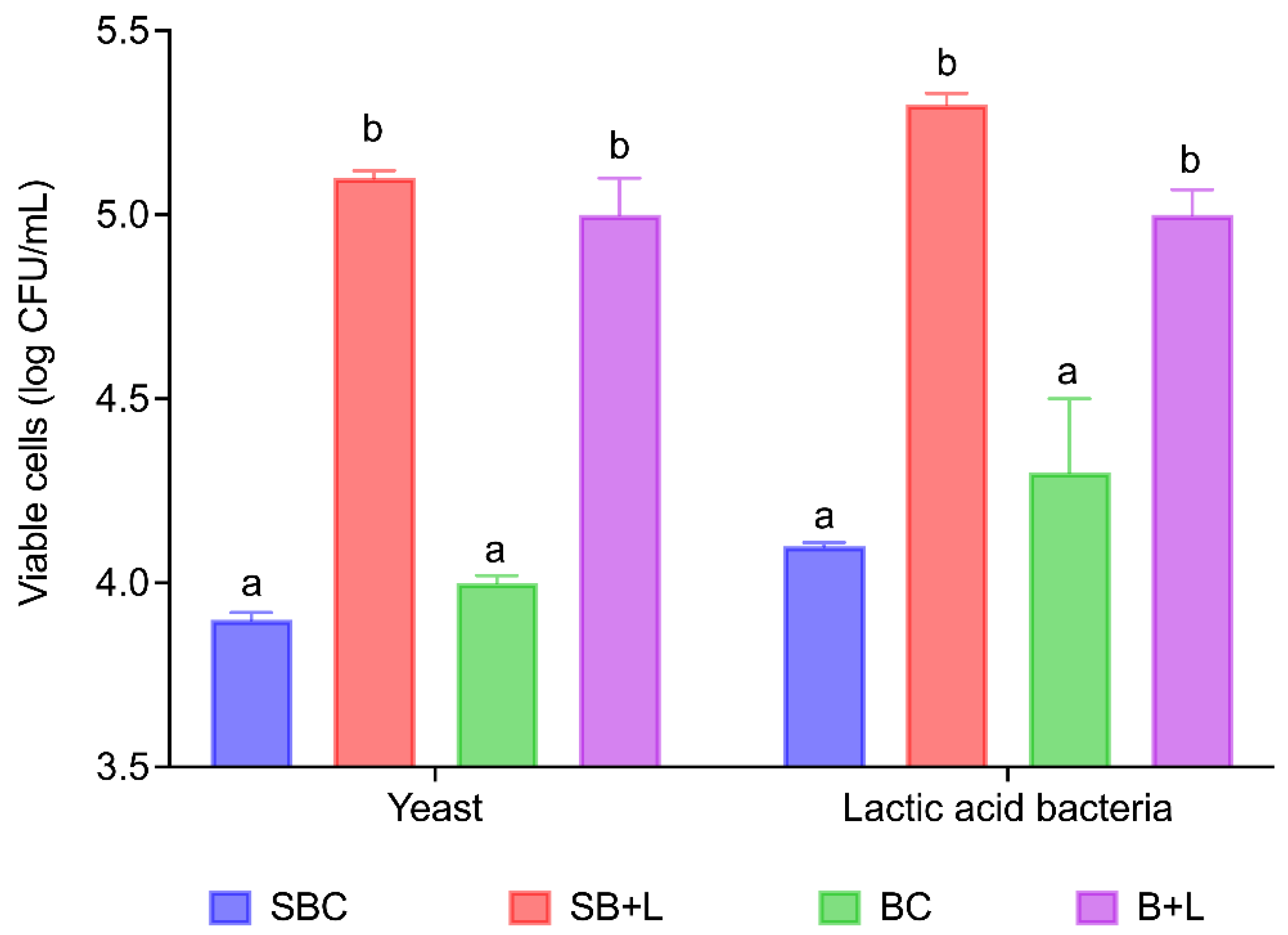

2.2. Microbial Populations and Fermentation Monitoring

2.3. Headspace Solid Phase Microextraction (HS-SPME)

2.4. Analysis of Volatile Compounds by Gas Chromatography—Mass Spectrometry (GC-MS)

2.5. Statistical Analysis

3. Results and Discussion

3.1. Microbial Populations and Fermentation Monitoring

3.2. Analysis of Volatile Compounds

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Caldeira, C.; De Laurentiis, V.; Corrado, S.; van Holsteijn, F.; Sala, S. Quantification of Food Waste per Product Group along the Food Supply Chain in the European Union: A Mass Flow Analysis. Resour. Conserv. Recycl. 2019, 149, 479–488. [Google Scholar] [CrossRef]

- Rivas, M.Á.; Casquete, R.; Córdoba, M.d.G.; Ruíz-Moyano, S.; Benito, M.J.; Pérez-Nevado, F.; Martín, A. Chemical Composition and Functional Properties of Dietary Fibre Concentrates from Winemaking By-Products: Skins, Stems and Lees. Foods 2021, 10, 1510. [Google Scholar] [CrossRef]

- De Iseppi, A.; Lomolino, G.; Marangon, M.; Curioni, A. Current and Future Strategies for Wine Yeast Lees Valorization. Food Res. Int. 2020, 137, 109352. [Google Scholar] [CrossRef]

- Chowdhary, P.; Gupta, A.; Gnansounou, E.; Pandey, A.; Chaturvedi, P. Current Trends and Possibilities for Exploitation of Grape Pomace as a Potential Source for Value Addition. Environ. Pollut. 2021, 278, 116796. [Google Scholar] [CrossRef]

- Tudela, R.; Gallardo-Chacón, J.J.; Rius, N.; López-Tamames, E.; Buxaderas, S. Ultrastructural Changes of Sparkling Wine Lees during Long-Term Aging in Real Enological Conditions. FEMS Yeast Res. 2012, 12, 466–476. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hernández-Macias, S.; Comas-Basté, O.; Jofré, A.; Bover-Cid, S.; Latorre-Moratalla, M.L.; Vidal-Carou, M.C. Growth-Promoting Effect of Cava Lees on Lactic Acid Bacteria Strains: A Potential Revalorization Strategy of a Winery By-Product. Foods 2021, 10, 1636. [Google Scholar] [CrossRef] [PubMed]

- Gallardo-Chacón, J.; Vichi, S.; Urpi, P.; López-Tamames, E.; Buxaderas, S. Antioxidant Activity of Lees Cell Surface during Sparkling Wine Sur Lie Aging. Int. J. Food Microbiol. 2010, 143, 48–53. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Macias, S.; Ferrer-Bustins, N.; Comas-Basté, O.; Jofré, A.; Latorre-Moratalla, M.; Bover-Cid, S.; del Carmen Vidal-Carou, M. Revalorization of Cava Lees to Improve the Safety of Fermented Sausages. Foods 2021, 10, 1916. [Google Scholar] [CrossRef]

- Lafarga, T.; Gallagher, E.; Bademunt, A.; Viñas, I.; Bobo, G.; Villaró, S.; Aguiló-Aguayo, I. Bioaccessibility, Physicochemical, Sensorial, and Nutritional Characteristics of Bread Containing Broccoli Co-Products. J. Food Process. Preserv. 2019, 43, e13861. [Google Scholar] [CrossRef]

- Sayed Ahmad, B.; Talou, T.; Straumite, E.; Sabovics, M.; Kruma, Z.; Saad, Z.; Hijazi, A.; Merah, O. Protein Bread Fortification with Cumin and Caraway Seeds and By-Product Flour. Foods 2018, 7, 28. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Collar, C.; Rosell, C.M.; Muguerza, B.; Moulay, L. Breadmaking Performance and Keeping Behavior of Cocoa-Soluble Fiber-Enriched Wheat Breads. Food Sci. Technol. Int. 2009, 15, 79–87. [Google Scholar] [CrossRef]

- Pérez-Serradilla, J.A.; Luque de Castro, M.D. Role of Lees in Wine Production: A Review. Food Chem. 2008, 111, 447–456. [Google Scholar] [CrossRef]

- Kopsahelis, N.; Dimou, C.; Papadaki, A.; Xenopoulos, E.; Kyraleou, M.; Kallithraka, S.; Kotseridis, Y.; Papanikolaou, S.; Koutinas, A.A. Refining of Wine Lees and Cheese Whey for the Production of Microbial Oil, Polyphenol-rich Extracts and Value-added Co-products. J. Chem. Technol. Biotechnol. 2017, 93, 257–268. [Google Scholar] [CrossRef]

- Felix, M.; Martínez, I.; Sayago, A.; Recamales, M.Á.F. Wine Lees: From Waste to O/W Emulsion Stabilizer. Innov. Food Sci. Emerg. Technol. 2021, 74, 102810. [Google Scholar] [CrossRef]

- Martín-Garcia, A.; Riu-Aumatell, M.; López-Tamames, E. Revalorization of Cava (Spanish Sparkling Wine) Lees on Sourdough Fermentation. Fermentation 2022, 8, 133. [Google Scholar] [CrossRef]

- Martín-Garcia, A.; Riu-Aumatell, M.; López-Tamames, E. Influence of Process Parameters on Sourdough Microbiota, Physical Properties and Sensory Profile. Food Rev. Int. 2021, 1–15. [Google Scholar] [CrossRef]

- Gallardo-Chacón, J.; Vichi, S.; López-Tamames, E.; Buxaderas, S. Analysis of Sparkling Wine Lees Surface Volatiles by Optimized Headspace Solid-Phase Microextraction. J. Agric. Food Chem. 2009, 57, 3279–3285. [Google Scholar] [CrossRef]

- Paraskevopoulou, A.; Chrysanthou, A.; Koutidou, M. Characterisation of Volatile Compounds of Lupin Protein Isolate-enriched Wheat Flour Bread. Food Res. Int. 2012, 48, 568–577. [Google Scholar] [CrossRef]

- Harth, H.; Van Kerrebroeck, S.; De Vuyst, L. Impact of Process Conditions on the Microbial Community Dynamics and Metabolite Production Kinetics of Teff Sourdough Fermentations under Bakery and Laboratory Conditions. Food Sci. Nutr. 2018, 6, 1438–1455. [Google Scholar] [CrossRef]

- De Luca, L.; Aiello, A.; Pizzolongo, F.; Blaiotta, G.; Aponte, M.; Romano, R. Volatile Organic Compounds in Breads Prepared with Different Sourdoughs. Appl. Sci. 2021, 11, 1330. [Google Scholar] [CrossRef]

- Torrieri, E.; Pepe, O.; Ventorino, V.; Masi, P.; Cavella, S. Effect of Sourdough at Different Concentrations on Quality and Shelf Life of Bread. LWT-Food Sci. Technol. 2014, 56, 508–516. [Google Scholar] [CrossRef]

- Katsi, P.; Kosma, I.S.; Michailidou, S.; Argiriou, A.; Badeka, A.V.; Kontominas, M.G. Characterization of Artisanal Spontaneous Sourdough Wheat Bread from Central Greece: Evaluation of Physico-Chemical, Microbiological, and Sensory Properties in Relation to Conventional Yeast Leavened Wheat Bread. Foods 2021, 10, 635. [Google Scholar] [CrossRef]

- Pico, J.; Bernal, J.; Gómez, M. Wheat Bread Aroma Compounds in Crumb and Crust: A Review. Food Res. Int. 2015, 75, 200–215. [Google Scholar] [CrossRef] [PubMed]

- Pétel, C.; Onno, B.; Prost, C. Sourdough Volatile Compounds and Their Contribution to Bread: A Review. Trends Food Sci. Technol. 2017, 59, 105–123. [Google Scholar] [CrossRef]

- Calvert, M.D.; Madden, A.A.; Nichols, L.M.; Haddad, N.M.; Lahne, J.; Dunn, R.R.; McKenney, E.A. A Review of Sourdough Starters: Ecology, Practices, and Sensory Quality with Applications for Baking and Recommendations for Future Research. PeerJ 2021, 9, e11389. [Google Scholar] [CrossRef] [PubMed]

- Torrens, J.; Rlu-Aumatell, M.; Vichi, S.; López-Tamames, E.; Buxaderas, S. Assessment of Volatile and Sensory Profiles between Base and Sparkling Wines. J. Agric. Food Chem. 2010, 58, 2455–2461. [Google Scholar] [CrossRef] [PubMed]

- The Good Scents Company Information System. Flavor, Fragrance, Food and Cosmetics Ingredients Information. Available online: http://www.thegoodscentscompany.com/ (accessed on 29 January 2021).

- Odor Detection Thresholds & References. Available online: http://www.leffingwell.com/odorthre.htm (accessed on 30 January 2021).

- Hansen, Å.; Hansen, B. Flavour of Sourdough Wheat Bread Crumb. Z. Lebensm.-Unters. Forsch. 1996, 202, 244–249. [Google Scholar] [CrossRef]

- Debonne, E.; Van Schoors, F.; Maene, P.; Van Bockstaele, F.; Vermeir, P.; Verwaeren, J.; Eeckhout, M.; Devlieghere, F. Comparison of the Antifungal Effect of Undissociated Lactic and Acetic Acid in Sourdough Bread and in Chemically Acidified Wheat Bread. Int. J. Food Microbiol. 2020, 321, 108551. [Google Scholar] [CrossRef]

- Birch, A.N.; Petersen, M.A.; Arneborg, N.; Hansen, Å.S. Influence of Commercial Baker’s Yeasts on Bread Aroma Profiles. Food Res. Int. 2013, 52, 160–166. [Google Scholar] [CrossRef]

- Liu, T.; Li, Y.; Yang, Y.; Yi, H.; Zhang, L.; He, G. The Influence of Different Lactic Acid Bacteria on Sourdough Flavor and a Deep Insight into Sourdough Fermentation through RNA Sequencing. Food Chem. 2020, 307, 125529. [Google Scholar] [CrossRef]

- Ripari, V.; Cecchi, T.; Berardi, E. Microbiological Characterisation and Volatiles Profile of Model, Ex-Novo, and Traditional Italian White Wheat Sourdoughs. Food Chem. 2016, 205, 297–307. [Google Scholar] [CrossRef]

- Bianchi, F.; Careri, M.; Chiavaro, E.; Musci, M.; Vittadini, E. Gas Chromatographic–Mass Spectrometric Characterisation of the Italian Protected Designation of Origin “Altamura” Bread Volatile Profile. Food Chem. 2008, 110, 787–793. [Google Scholar] [CrossRef]

- Kaseleht, K.; Paalme, T.; Mihhalevski, A.; Sarand, I. Analysis of Volatile Compounds Produced by Different Species of Lactobacilli in Rye Sourdough Using Multiple Headspace Extraction. Int. J. Food Sci. Technol. 2011, 46, 1940–1946. [Google Scholar] [CrossRef]

- De Souza Nascimento, A.M.; Fagundes de Souza, J.; dos Santos Lima, M.; Pereira, G.E. Volatile Profiles of Sparkling Wines Produced by the Traditional Method from a Semi-Arid Region. Beverages 2018, 4, 103. [Google Scholar] [CrossRef] [Green Version]

- Jagatić Korenika, A.-M.; Preiner, D.; Tomaz, I.; Jeromel, A. Volatile Profile Characterization of Croatian Commercial Sparkling Wines. Molecules 2020, 25, 4349. [Google Scholar] [CrossRef]

- Ubeda, C.; Callejón, R.M.; Troncoso, A.M.; Peña-Neira, A.; Morales, M.L. Volatile Profile Characterisation of Chilean Sparkling Wines Produced by Traditional and Charmat Methods via Sequential Stir Bar Sorptive Extraction. Food Chem. 2016, 207, 261–271. [Google Scholar] [CrossRef]

- Siepmann, F.B.; Sousa de Almeida, B.; Waszczynskyj, N.; Spier, M.R. Influence of Temperature and of Starter Culture on Biochemical Characteristics and the Aromatic Compounds Evolution on Type II Sourdough and Wheat Bread. LWT-Food Sci. Technol. 2019, 108, 199–206. [Google Scholar] [CrossRef]

- Benucci, I.; Cerreti, M.; Maresca, D.; Mauriello, G.; Esti, M. Yeast Cells in Double Layer Calcium Alginate–Chitosan Microcapsules for Sparkling Wine Production. Food Chem. 2019, 300, 125174. [Google Scholar] [CrossRef]

| Code | Wheat Flour | Water | Dough 1 | Cava Lees |

|---|---|---|---|---|

| SDC | 100 | 100 | 100 | - |

| SD+L | 100 | 100 | 100 | 5 2 |

| Code 1 | Wheat Flour | Water | Sourdough | Baker’s Yeast | Salt | Cava Lees |

|---|---|---|---|---|---|---|

| SBC | 500 | 285 | 150 | 4 | 10 | - |

| SB+L | 500 | 285 | 150 | 4 | 10 | - |

| BC | 500 | 285 | - | 4 | 10 | - |

| B+L | 500 | 285 | - | 4 | 10 | 25 |

| pH | SBC | SB+L | BC | B+L |

|---|---|---|---|---|

| t = 0 h | 5.48 ± 0.03 a | 5.00 ± 0.01 b | 5.76 ± 0.03 c | 4.97 ± 0.03 b |

| t = 2 h | 5.14 ± 0.02 a | 4.75 ± 0.04 b | 5.45 ± 0.02 c | 4.37 ± 0.03 d |

| Compound | CAS-Num. | Odor 1 | ODT 2 | SBC | SB+L | BC | B+L | |

|---|---|---|---|---|---|---|---|---|

| ACIDS | ||||||||

| 1 | Acetic acid | 64-19-7 | sharp pungent sour vinegar | - | 143.83 ± 1.63 a | 27.01 ± 8.74 b | 132.04 ± 0.06 a | 67.60 ± 16.22 c |

| 2 | Benzoic acid | 65-85-0 | faint balsam urine | na | nd | 6.83 ± 0.98 a | 3.89 ± 0.10 a | 8.52 ± 2.35 a |

| 3 | Decanoic acid | 334-48-5 | sweet waxy floral soapy clean | 1000 | nd | 5.09 ± 0.77 a | nd | 77.19 ± 2.62 b |

| 4 | Dodecanoic acid | 143-07-7 | sweet waxy floral soapy clean | 1000 | nd | nd | nd | 240.41 ± 83.22 |

| 5 | Hexadecanoic acid | 57-10-3 | slightly waxy fatty | 1000 | 7.26 ± 1.78 a | nd | 10.20 ± 1.03 a | 18.86 ± 2.66 b |

| 6 | Hexanoic acid | 142-62-1 | sour fatty sweat cheese | 300 | nd | 3.76 ± 0.49 a | 18.33 ± 0.33 b | 46.97 ± 5.34 c |

| 7 | Octanoic acid | 124-07-2 | fatty waxy rancid oily vegetable cheesy | 300 | 13.69 ± 2.56 a | nd | 11.13 ± 6.27 a | 173.53 ± 11.96 b |

| 8 | Isobutyric acid | 79-31-2 | acidic sour cheese dairy buttery rancid | 810 | nd | nd | 18.90 ± 6.30 a | 18.72 ± 9.86 a |

| 9 | Myristic acid | 544-63-8 | waxy fatty soapy coconut | 1000 | 28.54 ± 3.87 a | 12.51 ± 2.45 b | nd | 8.66 ± 1.53 b |

| TOTAL ACIDS | 193.32 ± 9.84 a | 55.20 ± 13.43 a | 194.49 ± 14.09 a | 660.46 ± 135.76 b | ||||

| ALCOHOLS | ||||||||

| 10 | Butyl alcohol | 71-36-3 | fusel oil sweet balsam whiskey | 50 | nd | nd | 10.32 ± 1.97 a | 11.61 ± 2.65 a |

| 11 | Isoamyl alcohol | 123-51-3 | fusel oil alcoholic whiskey fruity banana | 25–30 | 96.16 ± 7.30 a | 92.88 ± 6.19 a | 82.69 ± 4.57 a | 60.26 ± 5.17 b |

| 12 | 1-Dodecanol | 112-53-8 | earthy soapy waxy fatty honey coconut | na | nd | 4.76 ± 0.30 | nd | nd |

| 13 | 1-Hexanol | 111-27-3 | ethereal fusel oil fruity alcoholic sweet green | 250 | 88.78 ± 31.46 a | 37.95 ± 11.30 b | 76.65 ± 11.19 ab | 39.54 ± 7.10 b |

| 14 | 2-Ethyl-1-hexanol | 104-76-7 | citrus fresh floral oily sweet | na | 8.62 ± 3.20 a | 9.81 ± 4.44 a | 55.69 ± 9.96 b | 64.75 ± 1.08 b |

| 15 | 1-Octanol | 111-87-5 | waxy green orange aldehydic rose mushroom | 11–13 | 18.61 ± 8.18 a | 11.22 ± 2.88 a | 10.23 ± 2.45 a | 6.92 ± 2.57 a |

| 16 | 1-Octen-3-ol | 3391-86-4 | mushroom earthy green oily fungal raw chicken | 1 | 20.22 ± 2.36 a | 8.89 ± 0.87 b | 20.17 ± 1.25 a | 8.06 ± 0.96 b |

| 17 | 1-Pentanol | 71-41-0 | fusel oil sweet balsam | 400 | 13.85 ± 1.48 | nd | nd | nd |

| 18 | 2-Methyl-1-propanol | 78-83-1 | ethereal winey cortex | na | 8.79 ± 0.79 a | nd | 12.27 ± 0.84 b | nd |

| 19 | 2-Furanmethanol | 98-00-0 | alcoholic chemical musty sweet caramel bread coffee | na | 13.79 ± 5.67 a | 7.40 ± 2.44 a | 24.12 ± 4.04 b | 15.54 ± 1.78 ab |

| 20 | 7-Octen-4-ol | 53907-72-5 | - | na | 28.42 ± 5.87 | nd | nd | nd |

| 21 | 9-Decen-1-ol | 13019-22-2 | dewy rose waxy fresh clean aldehydic | na | 27.08 ± 3.27 a | 7.78 ± 0.86 b | 34.13 ± 5.97 a | 15.69 ± 3.48 b |

| 22 | Phenethyl alcohol | 60-12-8 | floral rose dried rose flower rose water | 75–110 | 253.45 ± 3.78 a | 100.51 ± 33.46 b | 102.35 ± 17.03 b | 130.47 ± 30.62 b |

| 23 | Benzyl alcohol | 100-51-6 | floral rose phenolic balsamic | 1000 | nd | nd | nd | 11.64 ± 1.27 |

| 24 | 2-Phenoxy-ethanol | 122-99-6 | mild rose balsam cinnamyl | na | nd | nd | 15.46 ± 5.11 a | 8.76 ± 2.48 a |

| 25 | Heptanol | 111-70-6 | musty leafy violet herbal green sweet woody peony | 0.3 | 22.69 ± 5.53 a | 12.77 ± 1.97 b | 24.61 ± 2.15 a | nd |

| 26 | Nonanol | 143-08-8 | fresh clean fatty floral rose orange dusty wet oily | 5 | 10.81 ± 1.48 a | nd | 19.48 ± 6.17 b | 21.54 ± 1.57 b |

| TOTAL ALCOHOLS | 611.27 ± 80.37 a | 293.97 ± 64.71 b | 488.17 ± 72.70 ac | 394.78 ± 60.73 bc | ||||

| ALDEHYDES | ||||||||

| 27 | (E)-2-Heptenal | 18829-55-5 | pungent green vegetable fresh fatty | 1.3 | 16.50 ± 2.36 a | 7.58 ± 3.29 a | 40.93 ± 20.65 ab | 13.21 ± 3.08 a |

| 28 | (E)-2-Nonenal | 18829-56-6 | fatty green cucumber aldehydic citrus | 0.08-0.1 | 27.29 ± 2.93 a | 10.85 ± 0.93 b | nd | 26.21 ± 3.28 a |

| 29 | (E)-2-Octenal | 2548-87-0 | fresh cucumber fatty green herbal banana waxy green leaf | 0.3 | 23.02 ± 2.44 a | 10.77 ± 3.39 b | 17.74 ± 1.86 ab | 12.81 ± 1.84 b |

| 30 | (E,E)-2,4-Decadienal | 25152-84-5 | oily cucumber melon citrus pumpkin nut meat | 0.07 | 10.46 ± 2.36 a | nd | 8.23 ± 0.94 a | 8.92 ± 0.64 a |

| 31 | (E,Z)-2,4-Decadienal | 25152-83-4 | fried fatty geranium green waxy | na | nd | nd | 24.70 ± 2.79 | nd |

| 32 | Benzaldehyde | 100-52-7 | strong sharp sweet bitter almond cherry | 35–350 | 41.90 ± 4.59 a | 43.46 ± 19.19 a | 24.36 ± 5.68 a | 88.66 ± 11.41 b |

| 33 | o-Tolualdehyde | 529-20-4 | cherry | na | nd | 4.57 ± 0.57 | nd | nd |

| 34 | Butanal | 123-72-8 | pungent cocoa musty green malty bready | 0.9–3.73 | nd | nd | nd | 2.39 ± 0.15 |

| 35 | Isovaleraldehyde | 590-86-3 | ethereal aldehydic chocolate peach fatty | 0.2–2 | nd | nd | nd | 2.05 ± 0.43 |

| 36 | Heptanal | 111-71-7 | fresh aldehydic fatty green herbal wine-lee ozone | 3 | 14.04 ± 7.68 a | 18.19 ± 1.69 a | nd | nd |

| 37 | Hexanal | 66-25-1 | fresh green fatty aldehydic grass leafy fruity sweaty | 4.5–5 | 56.11 ± 11.12 a | 32.86 ± 14.76 a | 105.01 ± 16.26 b | 53.56 ± 11.53 a |

| 38 | Nonanal | 124-19-6 | waxy aldehydic rose fresh orris orange peel fatty peely | 1 | nd | 8.88 ± 0.81 a | 15.04 ± 0.74 b | 21.80 ± 2.63 c |

| TOTAL ALDEHYDES | 189.68 ± 33.48 a | 137.16 ± 44.63 a | 236.01 ± 48.92 a | 229.61 ± 34.99 a | ||||

| KETONES | ||||||||

| 39 | Acetoin | 513-86-0 | sweet buttery creamy dairy milky fatty | 80 | 13.19 ± 6.75 a | 14.03 ± 9.11 a | 6.94 ± 0.97 a | 13.38 ± 3.59 a |

| 40 | 2-Nonanone | 821-55-6 | fresh sweet green weedy earthy herbal | 0.5–20 | nd | nd | nd | 4.78 ± 1.28 |

| 41 | 2-Octanone | 111-13-7 | earthy weedy natural woody herbal | 5 | 2.64 ± 0.45 a | nd | 4.87 ± 1.04 b | nd |

| 42 | 4-Methyl-2-pentanone | 108-10-1 | sharp solvent green herbal fruity dairy spice | na | 11.24 ± 3.49 a | nd | 14.52 ± 0.78 a | 11.26 ± 2.37 a |

| 43 | 2,3-Octanedione | 585-25-1 | dill asparagus cilantro herbal aldehydic earthy fatty cortex | na | nd | nd | 6.26 ± 1.08 | nd |

| 44 | Acetophenone | 98-86-2 | sweet pungent hawthorn mimosa almond acacia chemical | 6.5 | nd | nd | 5.64 ± 1.11 | nd |

| TOTAL KETONES | 27.07 ± 10.69 ab | 14.03 ± 9.11 b | 38.23 ± 4.98 a | 29.42 ± 7.24 ab | ||||

| ESTERS | ||||||||

| 45 | Isoamyl decanoate | 2306-91-4 | waxy banana fruity sweet cognac green | na | nd | 5.54 ± 0.83 a | nd | 175.37 ± 20.93 b |

| 46 | Phenethyl acetate | 103-45-7 | floral rose sweet honey fruity tropical | na | 6.20 ± 1.12 | nd | nd | nd |

| 47 | Hexyl acetate | 142-92-7 | fruity green apple banana sweet | 2 | nd | nd | nd | 12.77 ± 2.57 |

| 48 | L-Bornyl acetate | 5655-61-8 | sweet balsamic woody fresh pine needle herbal | na | nd | 6.23 ± 0.98 | nd | nd |

| 49 | Diethyl succinate | 123-25-1 | mild fruity cooked apple ylang | na | nd | nd | nd | 47.49 ± 6.39 |

| 50 | Ethyl decanoate | 628-97-7 | mild waxy fruity creamy milky balsamic greasy oily | >200 | 59.56 ± 3.91 a | 127.37 ± 13.90 b | nd | 220.30 ± 38.41 b |

| 51 | Ethyl 9-hexadecenoate | 54546-22-4 | - | na | nd | nd | nd | 23.95 ± 2.64 |

| 52 | Ethyl 9-decenoate | 67233-91-4 | fruity fatty | na | nd | nd | nd | 41.81 ± 2.93 |

| 53 | Ethyl hexanoate | 123-66-0 | sweet fruity pineapple waxy green banana | 1 | 9.67 ± 3.37 a | nd | 18.64 ± 3.78 b | 98.44 ± 3.07 c |

| 54 | Octyl acetate | 112-14-1 | green earthy mushroom herbal waxy | 1.2 | nd | nd | nd | 8.04 ± 1.26 |

| 55 | Ethyl nonadecanoate | 18281-04-4 | - | na | nd | nd | nd | 5.43 ± 1.02 |

| 56 | Isoamyl octanoate | 2035-99-6 | sweet oily fruity green soapy pineapple coconut | na | nd | nd | nd | 181.00 ± 17.83 |

| 57 | Ethyl octanoate | 106-32-1 | fruity wine waxy sweet apricot banana brandy pear | na | nd | nd | 28.72 ± 4.55 a | 965.31 ± 167.18 b |

| 58 | Phenethyl isobutyrate | 103-48-0 | floral fruity rose tea rose peach pastry | na | nd | nd | nd | 14.22 ± 2.49 |

| 59 | Ethyl myristate | 124-06-1 | sweet waxy violet orris | na | nd | nd | nd | 10.75 ± 7.36 |

| TOTAL ESTERS | 75.43 ± 8.76 a | 139.14 ± 15.71 a | 47.36 ± 8.33 a | 1804.88 ± 274.08 b | ||||

| TERPENES | ||||||||

| 60 | 𝛼-Terpinolene | 586-62-9 | fresh woody sweet pine citrus | 20 | nd | 8.71 ± 1.25 | nd | nd |

| 61 | Vitispirane | 66965-94-4 | floral fruity earthy woody | na | nd | 7.73 ± 0.43 a | nd | 25.03 ± 3.08 b |

| 62 | (E,E)-Farnesyl acetate | 4128-17-0 | oily waxy | na | nd | nd | nd | 44.88 ± 5.60 |

| 63 | dihydromyrcenol | 18479-58-8 | fresh citrus lime floral clean | na | 2.32 ± 0.13 | nd | nd | nd |

| 64 | Bornylene | 464-17-5 | - | na | nd | nd | 37.11 ± 6.92 | nd |

| 65 | d-Nerolidol | 142-50-7 | mild floral | na | nd | nd | nd | 13.66 ± 2.01 |

| 66 | DL-Limonene | 138-86-3 | citrus herbal terpene camphor | 10 | 5.39 ± 1.06 a | 9.43 ± 4.22 a | 23.34 ± 14.40 ab | 34.02 ± 2.30 b |

| 67 | Farnesol | 4602-84-0 | mild fresh sweet linden floral angelica | 2 | nd | nd | nd | 24.84 ± 6.21 |

| 68 | Nerolidol | 7212-44-4 | floral green waxy citrus woody | na | nd | nd | nd | 73.31 ± 8.75 |

| TOTAL TERPENES | 7.71 ± 1.19 a | 25.87 ± 5.90 ab | 60.45 ± 21.32 b | 215.74 ± 27.95 c | ||||

| MISCELANEOUS | ||||||||

| 69 | 2-Pentyl- furan | 3777-69-3 | fruity green earthy beany vegetable metallic | 6 | 22.82 ± 1.11 a | 59.05 ± 9.20 b | 54.47 ± 6.62 b | 46.31 ± 6.37 b |

| 70 | 2-Furancarboxaldehyde | 98-01-1 | sweet woody almond fragrant baked bread | na | 6.20 ± 3.68 a | 6.45 ± 0.91 a | nd | 19.55 ± 8.56 b |

| 71 | 1,1,6-Trimethyl-1,2-dihydronaphthalene (TDN) | 30364-38-6 | licorice | na | nd | 43.95 ± 16.26 a | nd | 196.29 ± 34.35 b |

| 72 | 4-Ethylguaiacol | 2785-89-9 | spicy smoky bacon phenolic clove | 50 | nd | nd | nd | 19.73 ± 6.59 |

| 73 | Styrene | 100-42-5 | sweet balsam floral plastic | 730 | nd | 103.69 ± 30.91 a | nd | 12.59 ± 0.89 b |

| 74 | 𝜸-Nonalactone | 104-61-0 | coconut creamy waxy sweet buttery oily | na | nd | nd | 15.80 ± 7.79 a | 15.10 ± 4.86 a |

| TOTAL MISCELANEOUS | 29.02 ± 4.79 a | 213.14 ± 57.28 b | 70.27 ± 14.41 a | 309.56 ± 61.62 b | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martín-Garcia, A.; Riu-Aumatell, M.; López-Tamames, E. By-Product Revalorization: Cava Lees Can Improve the Fermentation Process and Change the Volatile Profile of Bread. Foods 2022, 11, 1361. https://doi.org/10.3390/foods11091361

Martín-Garcia A, Riu-Aumatell M, López-Tamames E. By-Product Revalorization: Cava Lees Can Improve the Fermentation Process and Change the Volatile Profile of Bread. Foods. 2022; 11(9):1361. https://doi.org/10.3390/foods11091361

Chicago/Turabian StyleMartín-Garcia, Alba, Montserrat Riu-Aumatell, and Elvira López-Tamames. 2022. "By-Product Revalorization: Cava Lees Can Improve the Fermentation Process and Change the Volatile Profile of Bread" Foods 11, no. 9: 1361. https://doi.org/10.3390/foods11091361

APA StyleMartín-Garcia, A., Riu-Aumatell, M., & López-Tamames, E. (2022). By-Product Revalorization: Cava Lees Can Improve the Fermentation Process and Change the Volatile Profile of Bread. Foods, 11(9), 1361. https://doi.org/10.3390/foods11091361