Composition of Polysaccharides in Hull-Less Barley Sourdough Bread and Their Impact on Physical Properties of Bread

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Spontaneous Hull-Less Barley and Germinated Hull-Less Barley Sourdough Preparation

2.3. Bread Making

2.4. Determination of Polysaccharides

2.5. Wholegrain Barley and Wheat Sourdough Bread Technological Characteristics

2.6. Statistical Analysis

3. Results and Discussion

3.1. Starch, Total Dietary Fiber and Non-Starch Polysaccharides Composition in Flours and Breads

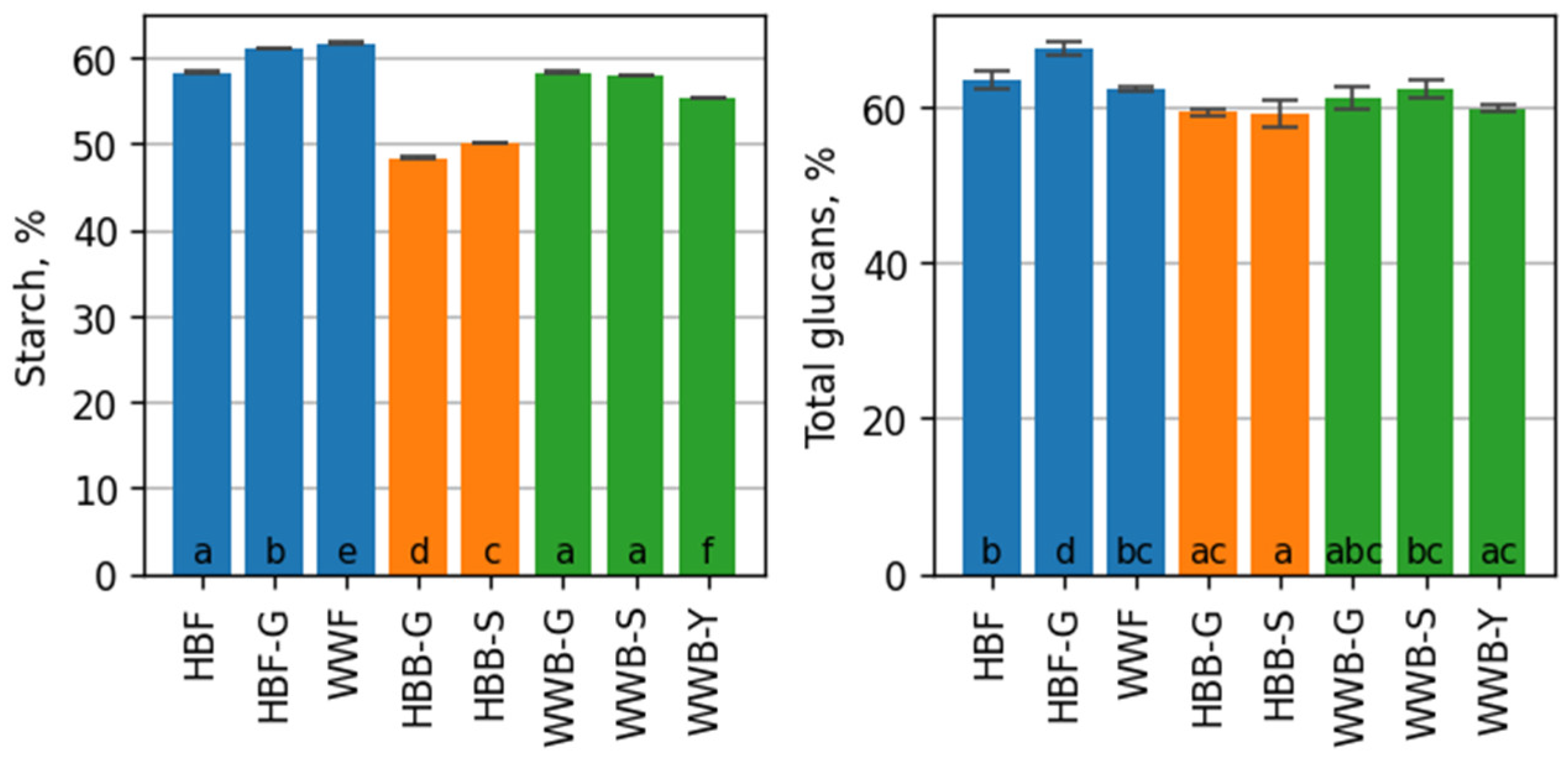

3.1.1. The Content of Starch and Total Glucans

3.1.2. Total Dietary Fiber and Non-Starch Polysaccharides Composition

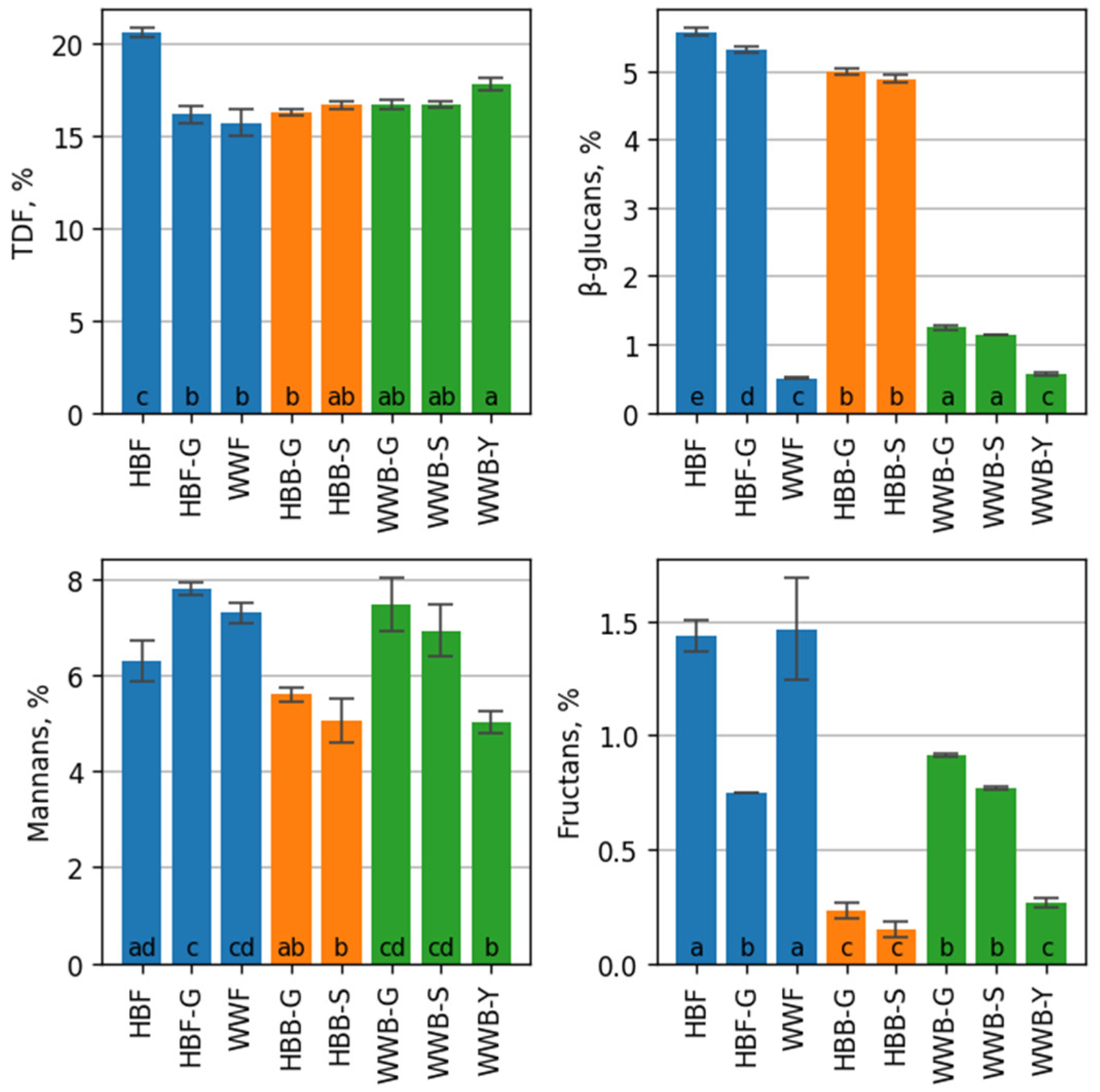

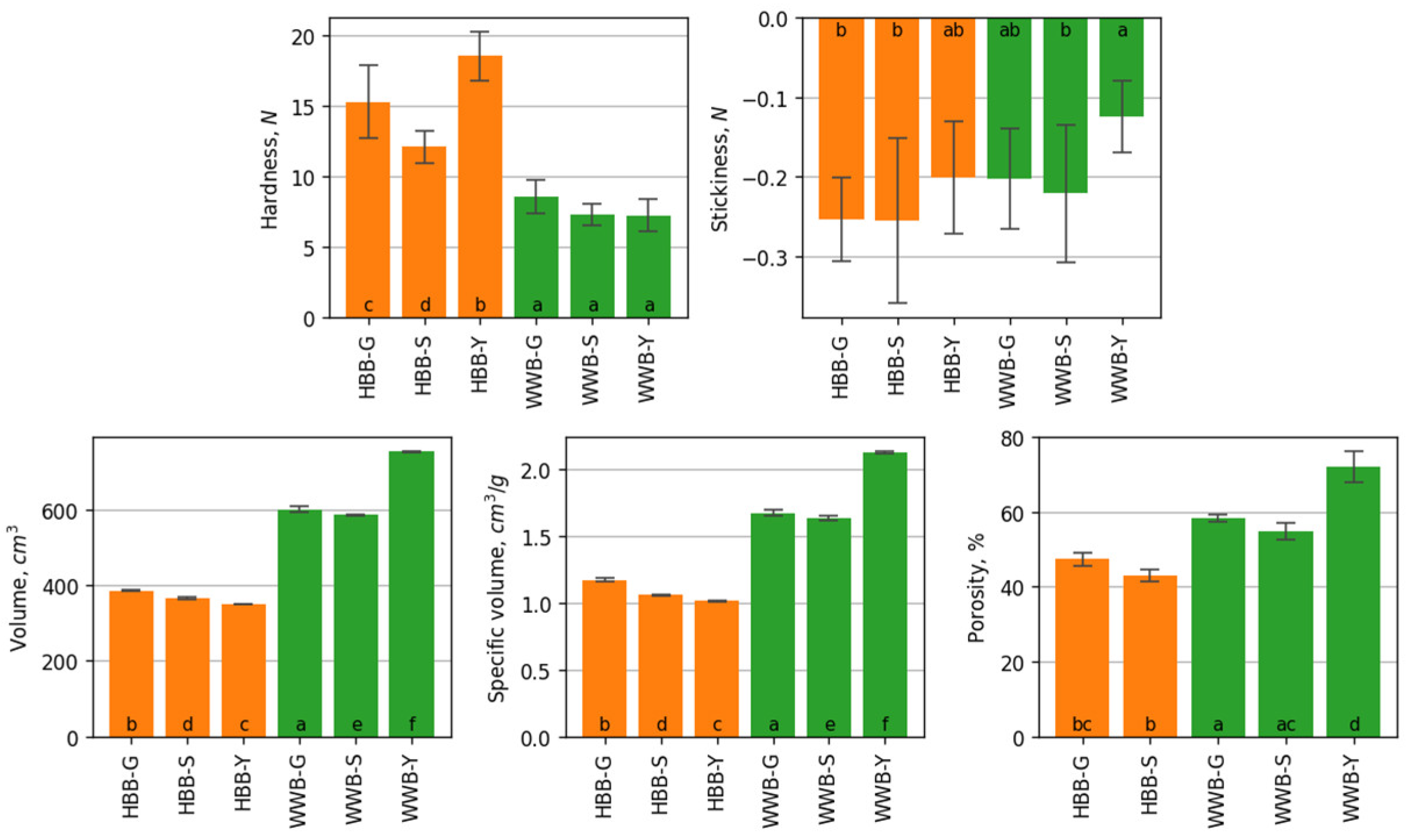

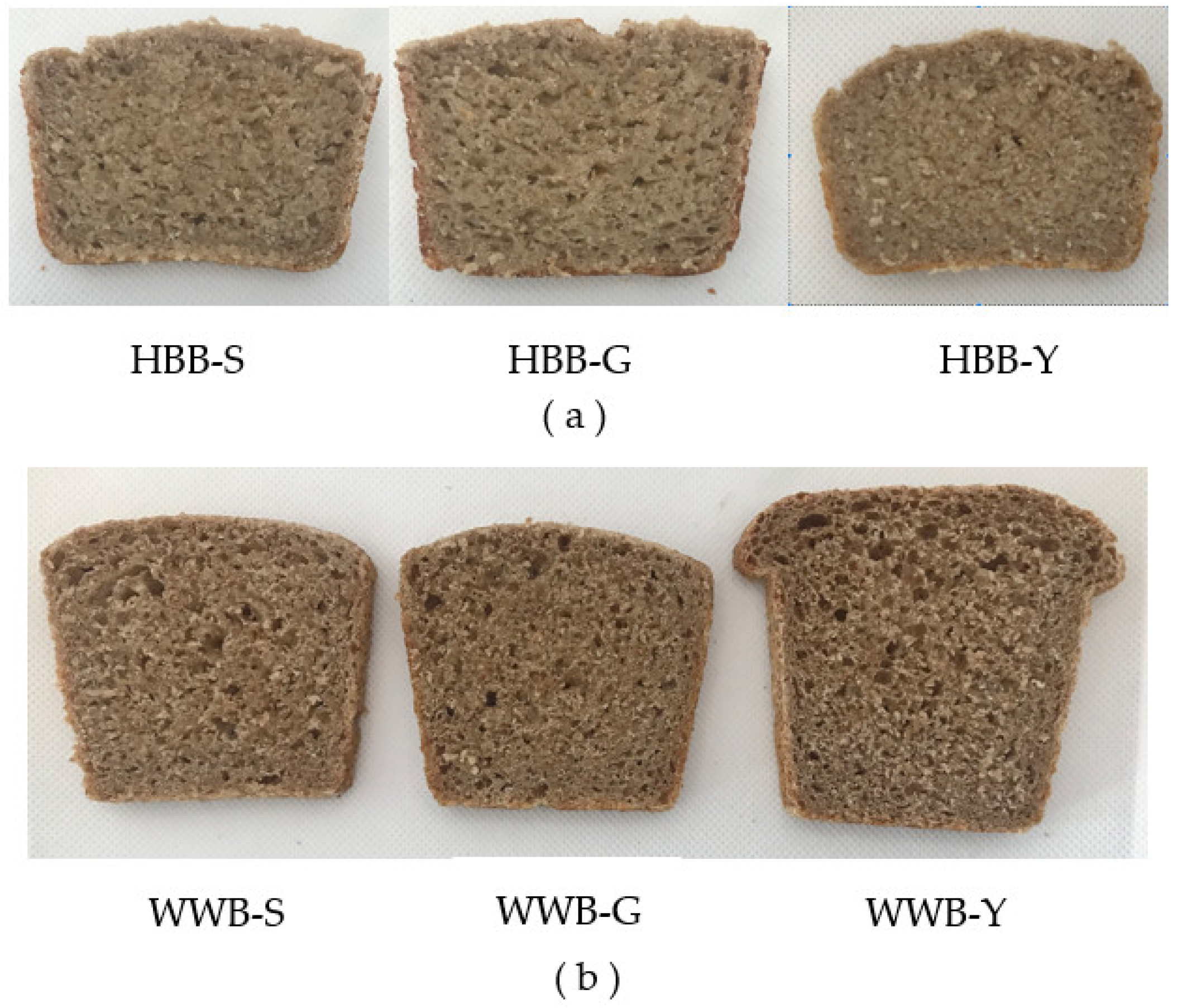

3.2. Physical Characteristics of Hull-Less Barley and Wholegrain Wheat Breads

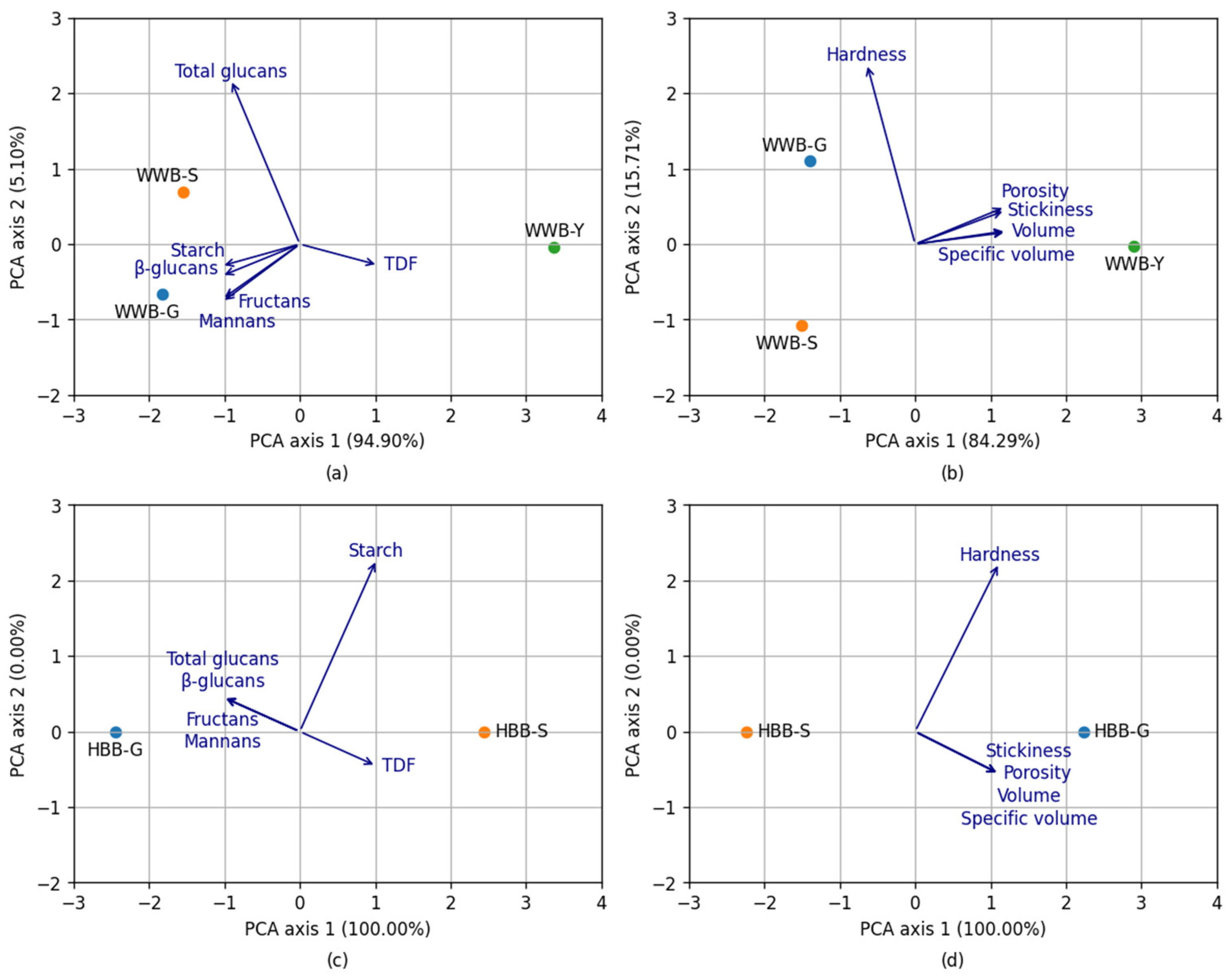

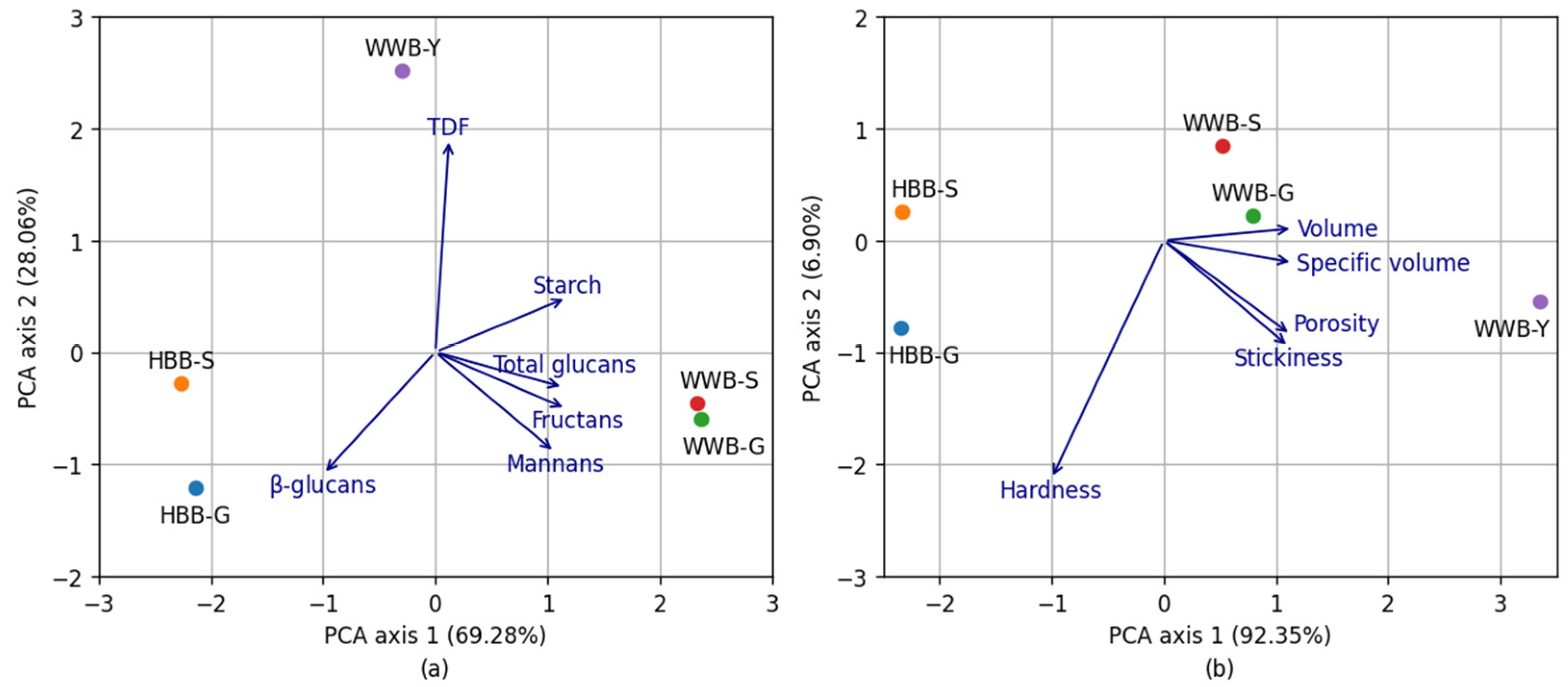

3.3. Relationship between Physical and Chemical Parameters of Breads

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Newman, C.W.; Newman, R.K. A Brief History of Barley Foods. Cereal Foods World 2006, 51, 4–7. [Google Scholar] [CrossRef]

- Šterna, V.; Zute, S.; Jakobsone, I. Grain Composition and Functional Ingredients of Barley Varieties Created in Latvia. Proc. Latv. Acad. Sci. Sect. B Nat. Exact Appl. Sci. 2015, 69, 158–162. [Google Scholar] [CrossRef]

- Baik, B.K.; Ullrich, S.E. Barley for Food: Characteristics, Improvement, and Renewed Interest. J. Cereal Sci. 2008, 48, 233–242. [Google Scholar] [CrossRef]

- Mir, S.A.; Manickavasagan, A.; Shah, M.A. (Eds.) Whole Grain; CRC Press: Boca Raton, FL, USA, 2019; Volume 6. [Google Scholar]

- Yang, W.; Huang, G. Extraction Methods and Activities of Natural Glucans. Trends Food Sci. Technol. 2021, 112, 50–57. [Google Scholar] [CrossRef]

- Torbica, A.; Radosavljević, M.; Belović, M.; Djukić, N.; Marković, S. Overview of Nature, Frequency and Technological Role of Dietary Fibre from Cereals and Pseudocereals from Grain to Bread. Carbohydr. Polym. 2022, 290, 119470. [Google Scholar] [CrossRef] [PubMed]

- Verma, D.K.; Patel, A.R.; Thakur, M.; Singh, S.; Tripathy, S.; Srivastav, P.P.; Chávez-González, M.L.; Gupta, A.K.; Aguilar, C.N. A Review of the Composition and Toxicology of Fructans, and Their Applications in Foods and Health. J. Food Compos. Anal. 2021, 99, 103884. [Google Scholar] [CrossRef]

- Belitz, H.-D.; Grosch, W.; Schieberle, P. Food Chemistry; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar] [CrossRef]

- Ispiryan, L.; Kuktaite, R.; Zannini, E.; Arendt, E.K. Fundamental Study on Changes in the FODMAP Profile of Cereals, Pseudo-Cereals, and Pulses during the Malting Process. Food Chem. 2021, 343, 128549. [Google Scholar] [CrossRef]

- Verhertbruggen, Y.; Falourd, X.; Sterner, M.; Guillon, F.; Girousse, C.; Foucat, L.; Le Gall, S.; Chateigner-Boutin, A.L.; Saulnier, L. Challenging the Putative Structure of Mannan in Wheat (Triticum aestivum) Endosperm. Carbohydr. Polym. 2019, 224, 115063. [Google Scholar] [CrossRef]

- Wang, Y.X.; Li, L.Y.; Zhang, T.; Wang, J.Q.; Huang, X.J.; Hu, J.L.; Yin, J.Y.; Nie, S.P. Fractionation, Physicochemical and Structural Characterization of Polysaccharides from Barley Water-Soluble Fiber. Food Hydrocoll. 2021, 113, 106539. [Google Scholar] [CrossRef]

- Comino, P.; Shelat, K.; Collins, H.; Lahnstein, J.; Gidley, M.J. Separation and Purification of Soluble Polymers and Cell Wall Fractions from Wheat, Rye and Hull Less Barley Endosperm Flours for Structure-Nutrition Studies. J. Agric. Food Chem. 2013, 61, 12111–12122. [Google Scholar] [CrossRef]

- Singh, S.; Singh, G.; Arya, S.K. Mannans: An Overview of Properties and Application in Food Products. Int. J. Biol. Macromol. 2018, 119, 79–95. [Google Scholar] [CrossRef] [PubMed]

- Verspreet, J.; Dornez, E.; van den Ende, W.; Delcour, J.A.; Courtin, C.M. Cereal Grain Fructans: Structure, Variability and Potential Health Effects. Trends Food Sci. Technol. 2015, 43, 32–42. [Google Scholar] [CrossRef]

- Ispiryan, L.; Zannini, E.; Arendt, E.K. Characterization of the FODMAP-Profile in Cereal-Product Ingredients. J. Cereal Sci. 2020, 92, 102916. [Google Scholar] [CrossRef]

- Loponen, J.; Gänzle, M.G. Use of Sourdough in Low FODMAP Baking. Foods 2018, 7, 96. [Google Scholar] [CrossRef] [PubMed]

- Tokuşoğlu, Ö.; Hall, C.A. Fruit and Cereal Bioactives: Sources, Chemistry, and Applications; Taylor & Francis, CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Pejcz, E.; Czaja, A.; Wojciechowicz-Budzisz, A.; Gil, Z.; Spychaj, R. The Potential of Naked Barley Sourdough to Improve the Quality and Dietary Fibre Content of Barley Enriched Wheat Bread. J. Cereal Sci. 2017, 77, 97–101. [Google Scholar] [CrossRef]

- Mariotti, M.; Garofalo, C.; Aquilanti, L.; Osimani, A.; Fongaro, L.; Tavoletti, S.; Hager, A.S.; Clementi, F. Barley Flour Exploitation in Sourdough Bread-Making: A Technological, Nutritional and Sensory Evaluation. LWT-Food Sci. Technol. 2014, 59, 973–980. [Google Scholar] [CrossRef]

- Çakır, E.; Arici, M.; Durak, M.Z. Biodiversity and Techno-Functional Properties of Lactic Acid Bacteria in Fermented Hull-Less Barley Sourdough. J. Biosci. Bioeng. 2020, 130, 450–456. [Google Scholar] [CrossRef]

- Perri, G.; Rizzello, C.G.; Ampollini, M.; Celano, G.; Coda, R.; Gobbetti, M.; De Angelis, M.; Calasso, M. Bioprocessing of Barley and Lentil Grains to Obtain in Situ Synthesis of Exopolysaccharides and Composite Wheat Bread with Improved Texture and Health Properties. Foods 2021, 10, 1489. [Google Scholar] [CrossRef]

- Harth, H.; Van Kerrebroeck, S.; De Vuyst, L. Community Dynamics and Metabolite Target Analysis of Spontaneous, Backslopped Barley Sourdough Fermentations under Laboratory and Bakery Conditions. Int. J. Food Microbiol. 2016, 228, 22–32. [Google Scholar] [CrossRef]

- Gobbetti, M.; De Angelis, M.; Di Cagno, R.; Calasso, M.; Archetti, G.; Rizzello, C.G. Novel Insights on the Functional/Nutritional Features of the Sourdough Fermentation. Int. J. Food Microbiol. 2019, 302, 103–113. [Google Scholar] [CrossRef]

- Arora, K.; Ameur, H.; Polo, A.; Di Cagno, R.; Rizzello, C.G.; Gobbetti, M. Thirty Years of Knowledge on Sourdough Fermentation: A Systematic Review. Trends Food Sci. Technol. 2021, 108, 71–83. [Google Scholar] [CrossRef]

- İspirli, H.; Özmen, D.; Yılmaz, M.T.; Sağdıç, O.; Dertli, E. Impact of Glucan Type Exopolysaccharide (EPS) Production on Technological Characteristics of Sourdough Bread. Food Control 2020, 107, 106812. [Google Scholar] [CrossRef]

- Korcz, E.; Varga, L. Exopolysaccharides from Lactic Acid Bacteria: Techno-Functional Application in the Food Industry. Trends Food Sci. Technol. 2021, 110, 375–384. [Google Scholar] [CrossRef]

- Gobbetti, M.; Gänzle, M. Handbook on Sourdough Biotechnology; Springer: Boston, MA, USA, 2013. [Google Scholar] [CrossRef]

- Canesin, M.R.; Cazarin, C.B.B. Nutritional Quality and Nutrient Bioaccessibility in Sourdough Bread. Curr. Opin. Food Sci. 2021, 40, 81–86. [Google Scholar] [CrossRef]

- Kince, T.; Galoburda, R.; Klava, D.; Kruma, Z.; Aboltins, A.; Tomsone, L.; Sabovics, M.; Straumite, E.; Senhofa, S.; Blija, A. Effect of Processing on Microbial Safety, Total Phenolic Content and Radical Scavenging Activity of Germinated Hull-Less Barley Flakes. J. Food Agric. Environ. 2017, 15, 10–15. [Google Scholar]

- Reidzane, S.; Kruma, Z.; Kazantseva, J.; Traksmaa, A.; Klava, D. Determination of Technological Parameters and Characterization of Microbiota of the Spontaneous Sourdough Fermentation of Hull-Less Barley. Foods 2021, 10, 2253. [Google Scholar] [CrossRef] [PubMed]

- François, J.M. A Simple Method for Quantitative Determination of Polysaccharides in Fungal Cell Walls. Nat. Protoc. 2007, 1, 2995–3000. [Google Scholar] [CrossRef]

- AACC 10-05.01; Guidelines for Measurement of Volume by Rapeseed Displacement. Approved Methods of the American Association of Cereal Chemists. AACC: St. Paul, MN, USA, 1999.

- Cizeikiene, D.; Jagelaviciute, J.; Stankevicius, M.; Maruska, A. Thermophilic Lactic Acid Bacteria Affect the Characteristics of Sourdough and Whole-Grain Wheat Bread. Food Biosci. 2020, 38, 100791. [Google Scholar] [CrossRef]

- AACC 74-09; Measurement of Bread Firmness by Universal Testing Machine. Approved Methods of the American Association of Cereal Chemists. AACC: St. Paul, MN, USA, 1999.

- Harris, C.R.; Millman, K.J.; van der Walt, S.J.; Gommers, R.; Virtanen, P.; Cournapeau, D.; Wieser, E.; Taylor, J.; Berg, S.; Smith, N.J.; et al. Array Programming with NumPy. Nature 2020, 585, 357–362. [Google Scholar] [CrossRef]

- Reback, J.; Jbrockmendel; McKinney, W.; Van den Bossche, J.; Roeschke, M.; Augspurger, T.; Hawkins, S.; Cloud, P.; Gfyoung; Hoefler, P.; et al. Pandas-Dev/Pandas: Pandas 1.4.4; Zenodo: Geneve, Switzerland, 2022. [Google Scholar] [CrossRef]

- Seabold, S.; Perktold, J. Statsmodels: Econometric and Statistical Modeling with Python. In Proceedings of the 9th Python in Science Conference, Austin, TX, USA, 28 June–3 July 2010. [Google Scholar] [CrossRef]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-Learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Maina, N.H.; Rieder, A.; De Bondt, Y.; Mäkelä-Salmi, N.; Sahlstrøm, S.; Mattila, O.; Lamothe, L.M.; Nyström, L.; Courtin, C.M.; Katina, K.; et al. Process-Induced Changes in the Quantity and Characteristics of Grain Dietary Fiber. Foods 2021, 10, 2566. [Google Scholar] [CrossRef] [PubMed]

- Djurle, S.; Andersson, A.A.M.; Andersson, R. Milling and Extrusion of Six Barley Varieties, Effects on Dietary Fibre and Starch Content and Composition. J. Cereal Sci. 2016, 72, 146–152. [Google Scholar] [CrossRef]

- Islam, M.Z.; An, H.G.; Kang, S.J.; Lee, Y.T. Physicochemical and Bioactive Properties of a High β-Glucan Barley Variety ‘Betaone’ Affected by Germination Processing. Int. J. Biol. Macromol. 2021, 177, 129–134. [Google Scholar] [CrossRef] [PubMed]

- Šterna, V.; Segliņa, D.; Krasnova, I.; Ķince, T.; Jansone, Z.; Bleidere, M. Sprouted Hulless Barley Grains and Their Application Possibilities for the Functional Sweet Snacks Development. Proc. Latv. Acad. Sci. Sect. B. Nat. Exact Appl. Sci. 2022, 76, 116–123. [Google Scholar] [CrossRef]

- Poutanen, K.; Flander, L.; Katina, K. Sourdough and Cereal Fermentation in a Nutritional Perspective. Food Microbiol. 2009, 26, 693–699. [Google Scholar] [CrossRef]

- Scazzina, F.; Del Rio, D.; Pellegrini, N.; Brighenti, F. Sourdough Bread: Starch Digestibility and Postprandial Glycemic Response. J. Cereal Sci. 2009, 49, 419–421. [Google Scholar] [CrossRef]

- Demirkesen-Bicak, H.; Arici, M.; Yaman, M.; Karasu, S.; Sagdic, O. Effect of Different Fermentation Condition on Estimated Glycemic Index, in Vitro Starch Digestibility, and Textural and Sensory Properties of Sourdough Bread. Foods 2021, 10, 514. [Google Scholar] [CrossRef]

- Zannini, E.; Waters, D.M.; Coffey, A.; Arendt, E.K. Production, Properties, and Industrial Food Application of Lactic Acid Bacteria-Derived Exopolysaccharides. Appl. Microbiol. Biotechnol. 2016, 100, 1121–1135. [Google Scholar] [CrossRef]

- Djurle, S.; Andersson, A.A.M.; Andersson, R. Effects of Baking on Dietary Fibre, with Emphasis on β-Glucan and Resistant Starch, in Barley Breads. J. Cereal Sci. 2018, 79, 449–455. [Google Scholar] [CrossRef]

- Pejcz, E.; Gil, Z.; Wojciechowicz-Budzisz, A.; Półtorak, M.; Romanowska, A. Effect of Technological Process on the Nutritional Quality of Naked Barley Enriched Rye Bread. J. Cereal Sci. 2015, 65, 215–219. [Google Scholar] [CrossRef]

- Nemeth, C.; Andersson, A.A.M.; Andersson, R.; Mangelsen, E.; Sun, C.; Åman, P. Relationship of Grain Fructan Content to Degree of Polymerisation in Different Barleys. Food Nutr. Sci. 2014, 05, 581–589. [Google Scholar] [CrossRef]

- Nyyssölä, A.; Ellilä, S.; Nordlund, E.; Poutanen, K. Reduction of FODMAP Content by Bioprocessing. Trends Food Sci. Technol. 2020, 99, 257–272. [Google Scholar] [CrossRef]

- Lemmens, E.; Moroni, A.V.; Pagand, J.; Heirbaut, P.; Ritala, A.; Karlen, Y.; Lê, K.; Van den Broeck, H.C.; Brouns, F.J.P.H.; De Brier, N. Impact of Cereal Seed Sprouting on Its Nutritional and Technological Properties: A Critical Review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 305–328. [Google Scholar] [CrossRef] [PubMed]

- Hübner, F.; O’Neil, T.; Cashman, K.D.; Arendt, E.K. The Influence of Germination Conditions on Beta-Glucan, Dietary Fibre and Phytate during the Germination of Oats and Barley. Eur. Food Res. Technol. 2010, 231, 27–35. [Google Scholar] [CrossRef]

- Struyf, N.; Laurent, J.; Verspreet, J.; Verstrepen, K.J.; Courtin, C.M. Saccharomyces Cerevisiae and Kluyveromyces Marxianus Cocultures Allow Reduction of Fermentable Oligo-, Di-, and Monosaccharides and Polyols Levels in Whole Wheat Bread. J. Agric. Food Chem. 2017, 65, 8704–8713. [Google Scholar] [CrossRef]

- Marti, A.; Cardone, G.; Pagani, M.A.; Casiraghi, M.C. Flour from Sprouted Wheat as a New Ingredient in Bread-Making. LWT-Food Sci. Technol. 2018, 89, 237–243. [Google Scholar] [CrossRef]

- Montemurro, M.; Pontonio, E.; Gobbetti, M.; Rizzello, C.G. Investigation of the Nutritional, Functional and Technological Effects of the Sourdough Fermentation of Sprouted Flours. Int. J. Food Microbiol. 2019, 302, 47–58. [Google Scholar] [CrossRef]

- Robles-Ramírez, M.d.C.; Ortega-Robles, E.; Monterrubio-López, R.; Mora-Escobedo, R.; Beltrán-Orozco, M.d.C. Barley Bread with Improved Sensory and Antioxidant Properties. Int. J. Gastron. Food Sci. 2020, 22, 100279. [Google Scholar] [CrossRef]

- Cakir, E.; Arici, M.; Durak, M.Z. Effect of Starter Culture Sourdough Prepared with Lactobacilli and Saccharomyces Cerevisiae on the Quality of Hull-Less Barley-Wheat Bread. Lwt 2021, 152, 112230. [Google Scholar] [CrossRef]

| Stage | Sourdough Composition | Calculated Flour Amount (g/100g) in Inoculum | Calculated Flour Amount (%) in Sourdough | Parameters | |||

|---|---|---|---|---|---|---|---|

| Inoculum (g) | Flour (g) | Water (g) | Temperature (°C) | Time (h) | |||

| 1st | 100 | 113 | 43.5 | 30 | 24 | ||

| 2nd | 100 | 100 | 137 | 43.5 | 42.5 | 31 | 14 |

| 3rd | 100 | 100 | 130 | 42.5 | 43.2 | 28.5 | 12 |

| Materials | HBB | WWB | ||||

|---|---|---|---|---|---|---|

| Spontaneous Sourdough Fermentation | Spontaneous Sourdough Fermentation | Yeast Fermentation | Spontaneous Sourdough Fermentation | Spontaneous Sourdough Fermentation | Yeast Fermentation | |

| HBB-S % fw | HBB-G % fw | HBB-Y % fw | WWB-S % fw | WWB-G % fw | WWB-Y % fw | |

| HBF | 84.0 | 84.0 | 100.0 | |||

| WWF | 84.0 | 84.0 | 100.0 | |||

| HBS-S | 37.0 | 37.0 | ||||

| HBS-G | 37.0 | 37.0 | ||||

| Barley malt | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 |

| Salt | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Sugar | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Fresh yeast | 3.0 | 3.0 | ||||

| Water | 67 | 67 | 67 | 67 | 67 | 67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reidzane, S.; Gramatina, I.; Galoburda, R.; Komasilovs, V.; Zacepins, A.; Bljahhina, A.; Kince, T.; Traksmaa, A.; Klava, D. Composition of Polysaccharides in Hull-Less Barley Sourdough Bread and Their Impact on Physical Properties of Bread. Foods 2023, 12, 155. https://doi.org/10.3390/foods12010155

Reidzane S, Gramatina I, Galoburda R, Komasilovs V, Zacepins A, Bljahhina A, Kince T, Traksmaa A, Klava D. Composition of Polysaccharides in Hull-Less Barley Sourdough Bread and Their Impact on Physical Properties of Bread. Foods. 2023; 12(1):155. https://doi.org/10.3390/foods12010155

Chicago/Turabian StyleReidzane, Sanita, Ilze Gramatina, Ruta Galoburda, Vitalijs Komasilovs, Aleksejs Zacepins, Anastassia Bljahhina, Tatjana Kince, Anna Traksmaa, and Dace Klava. 2023. "Composition of Polysaccharides in Hull-Less Barley Sourdough Bread and Their Impact on Physical Properties of Bread" Foods 12, no. 1: 155. https://doi.org/10.3390/foods12010155

APA StyleReidzane, S., Gramatina, I., Galoburda, R., Komasilovs, V., Zacepins, A., Bljahhina, A., Kince, T., Traksmaa, A., & Klava, D. (2023). Composition of Polysaccharides in Hull-Less Barley Sourdough Bread and Their Impact on Physical Properties of Bread. Foods, 12(1), 155. https://doi.org/10.3390/foods12010155