1. Introduction

Weight loss during storage is a critical factor in determining blueberry quality with 5% to 8% being the level at which blueberries can become unmarketable [

1]. This is primarily mediated by a loss of water through the cuticle, although a large proportion also occurs through the stem scar [

2]. Cultivar differences exist in the degree of water loss that occurs, and these differences have been found to be linked to both size of the stem scar and cuticle composition [

1,

3]. Water loss is related linearly to loss in firmness, except when minor water loss occurs where firmness can transiently increase [

4,

5]. Firmness at harvest and whether the fruit have been damaged, as by the utilization of mechanical harvesting, also impact the degree of softening that may occur in storage. Blueberries that are perceived as being soft when eaten are less preferred by consumers [

6], this attribute being of major importance to blueberry quality. In addition, the decline in visual quality in the form of shriveling that accompanies the loss of firmness is considered a major quality defect of blueberries [

7]. Minimizing water loss to maintain firmness is, therefore, critical to preserving blueberry quality following harvest.

The cuticular wax coating acts as a critical component to maintain blueberry quality. Chu et al. [

8] demonstrated that the removal of the epicuticular wax (bloom) of blueberries exacerbated both weight loss and decay, leading to a decline in sensory and nutritional quality. They further found that fruit so treated had reduced levels of antioxidants and evidence of oxidative damage. While the natural wax layer is thought to be vital to maintaining the quality of blueberries, experimentation has been conducted on the effectiveness of supplementing the natural wax layer after harvest with an additional coating to try to further minimize water loss and slow the rate of senescence. Prior research in blueberries has been most focused on evaluating the performance of polysaccharide-based coatings, such as sodium alginate, chitosan, hydroxypropyl methylcellulose, pectin, or pullulan [

9,

10,

11,

12,

13]. Caseinates, which are protein-based coatings, have also been studied [

9]. Often combination coatings have been utilized to try to enhance coating functionality. Examples of this are high-oleic acid sunflower oil and Aloe vera combined with chitosan to lower water vapor permeability [

14,

15].

Unfortunately, a great deal of the reported research on blueberries has indicated that the studied coatings have been either inconsistent or ineffective in reducing weight loss for reasons that are unclear. The purpose of this study was to evaluate the performance of a variety of coatings following simulated commercial storage and marketing to obtain a comparison of their effects on blueberry weight loss and quality and, more importantly, to examine potential reasons that may influence their effectiveness. The work also included evaluations on the effect of coating applications on the surface bloom, a characteristic that is indicative of fresh blueberry quality [

16] and had received inadequate attention in prior work with blueberry coatings.

2. Materials and Methods

2.1. Fruit

Varieties Snowchaser and Jewel were picked at commercial maturity from a research field at the USDA San Joaquin Valley Agricultural Sciences Center (USDA-SJVASC) on May 19 and 26, respectively, in season 1 (2020) and season 2 (2021). The field was established in 2016 with 3 m row spacing and 0.9 m between plants in a row. Both irrigation and fertilization were supplied with drip irrigation. Care was taken to pick blueberries that had no visible disorders. Fruit for scanning electron microscopy (SEM) work as well as for the examination of stem end effect were also harvested from the USDA-SJVASC research field. Fruit were obtained in the off-season from a local grocery store to perform a small subsidiary test examining the influence of handling and double coating. Variety could not be obtained in this case.

2.2. Coatings

Most coatings were selected due to their prior use in blueberry research. The coatings used were as follows: chitosan (CH, high molecular weight class, ≥75% deacylation, Sigma, St. Louis, MO, USA); Semperfresh (SF, combination of sucrose esters of fatty acids, sodium carboxymethyl cellulose, and mono- and diglycerides of fatty acids, Pace International, Wapato, WA, USA); sodium caseinate (SC, Sigma), and a carnauba wax (CAR) microemulsion (Sta-Fresh 2109, JBT, Riverside, CA, USA). Chitosan was prepared as a 1% (

w/v) solution in 1% acetic acid using a Tekmar Tissumizer (Cincinnati, OH, USA) to homogenize the mixture, increasing speed as the mixture thickened. When CH was completely incorporated, Tween 20 and glycerol were added to final concentrations of 0.1% (

w/v) and 50% (

w/w of chitosan) [

9], respectively. In addition, either 1% or 2% of oleic acid (OA) was added in season 1, using high-speed homogenization [

17]. SF was made to 1% of the active ingredients (a combination of ingredients as listed above) by dilution in water. A 2% concentration of SC was made in water followed by the addition of glycerol to make a concentration of 50% (

w/w of SC) and Tween 20 to 0.15% (

w/v) as reported earlier [

9] but substituting calcium caseinate with SC. CAR was used in undiluted form. Controls of water or acetic acid only were included to better estimate true treatment effects.

2.3. Coating Application and Packaging

Coatings were applied either as a dip or, in the case of Semperfresh, both dip and spray at ambient temperature of (23 °C). When applied as a dip the berries were immersed for 15 s, removed from the solution, and then spread out on a screen and allowed to dry under ambient conditions. Care was taken during the coating and drying process to minimize handling and the mechanical impact of the coating process on the fruit. Spraying was accomplished by placing the berries in a single layer on a screen and using a paint sprayer (Wagner, Plymouth, MN, USA) set on a fine spray setting to simulate a potential commercial operation of coating the fruit. Drying in ambient conditions was completed on a screen. In season 1, the fruit were dip-coated a single time while in season 2, the fruit were coated twice to ensure complete coverage and potentially enhance effectiveness. In season 2 the first coating was dried on a screen for 30 min prior to recoating. The effectiveness of recoating and of utilizing additional handling during the coating process was examined in season 1 using CH + OA. In this case, there was a comparison made between minimal handling (normal procedure to apply coating) and one where the fruit were continually turned during drying. After final drying, the fruit from both years were placed into vented plastic clamshells (170 g) and the clamshells placed into boxes capable of holding 12 clamshells. Each clamshell was considered a replication and there were 4 replications per treatment for each storage time.

2.4. Storage

In season 1 blueberries were stored at either 3 weeks or 6 weeks at 1 °C and 85% relative humidity in a 7.9 m2 storage chamber equipped with a TELSEC 2000 environmental control system (Quest Controls, Palmetto, FL, USA). To better simulate commercial storage and marketing, the storage regimes in season 2 were altered to: (1) 3 weeks at 1 °C, (2) 3 weeks 1 °C + 1 week 10 °C, (3) 3 weeks 1 °C + 1 week 10 °C + 2 d 20 °C. Relative humidity was approximately 95% at 1 °C, 93% at 10 °C and 73% at 20 °C. The same storage chamber was used as in season 1.

2.5. Fruit Quality

Percent weight loss was determined by comparing the weights of the individual clamshells at the end of each of the two storage times with the initial values in the experiment. There was no removal of decayed fruit during storage. The appearance of the waxy bloom was rated from 0 to 3, where 0 = perfect, unchanged; 1 = slight loss, acceptable; 2 = moderate loss, not acceptable; 3 = severe loss, not acceptable. Berries that had visible decay, or with softening characteristics of decay, were counted as decays. Those berries that had shriveling that would be objectionable to consumers upon close examination were counted as being shriveled. The shriveling generally occurred at the stem end. Firmness was measured by the use of a FirmTech 2 (BioWorks, Wamego, KS, USA) in season 1 and a FirmTech FT7 (UP Umweltanallytische Produkte GmbH, Ibbenbürn, Germany) in season 2. Both instruments were similar in design and measured the force required in g to cause a 1 mm deflection of the berry. Twenty berries were measured for firmness from each clamshell in both years. After the removal of decayed berries, all the fruit from each clamshell were juiced to measure soluble solids concentration (SSC) and titratable acidity (TA), each clamshell being a replication. The juice was centrifuged at 8100× g for 10 min and the resulting clear supernatant was used for the measurements. SSC was determined with a digital refractometer (Atago, Tokyo, Japan) and TA with an automatic titrator (Mettler model T50, Columbus, OH, USA).

2.6. Stem end Contribution to Weight Loss

Eighty berries of similar size and no blemishes were selected from fruit (cv. San Joaquin) that were harvested at the SJVASC when the berries were commercially mature. Twenty berries were used for each of the 4 treatments which were as follows: (1) Untreated; (2) Stem ends covered, no coating; (3) Stem ends not covered, coating; (4) Stem ends covered, coating. Nail polish was used to cover and seal stem ends as in previous work [

2] and SC was the coating. Nail polish was applied to the appropriate treatments and allowed to dry, followed by the application of coating if needed. Each berry was individually coated, using forceps to dip the berries into the coating, and carefully placed to dry on Eppendorf tube racks. After drying each berry was individually weighed and reweighed daily for 4 days, after which the fruit were again weighed on day 7. From this data it was possible to estimate changes in weight loss or gain due to SC application from either the cuticle or stem end.

2.7. Scanning Electron Microscopy (SEM)

Coated and uncoated blueberries were carefully packed at the SJVASC in 50-mL Falcon tubes to allow little or no movement of the individual berries, placed into an insulated container with ice packs and sent to the University of Tennessee (Knoxville, TN, USA) by overnight mail. Some of the berries were half-coated to examine the coated/uncoated interface. The surfaces of coated, half-coated, and uncoated fruit were imaged using a Zeiss EVO (Zeiss, Oberkochen, Germany) SEM. Samples were mounted on aluminum holders with double-sided copper tape and analyzed directly (no gold sputter-coating needed) under variable pressure mode (40 Pa) at 200 pA. Images were processed using Microscopy Suite software (version 3.4.3, Gaitan, Pleasanton, CA, USA). All analyses were performed at the University of Tennessee Institute for Advanced Materials and Manufacturing Electron Microscopy facilities (Knoxville, TN, USA).

2.8. Blueberry Bloom Removal Experimentation

Twenty berries, that were free of injury and with substantial bloom, were selected for each of the treatments. Berries with the natural bloom present were used in half of the treatments, while berries for the other half of the treatments had the bloom removed by using Blu Tack adhesive putty (Bostik, Wauwatosa, WI, USA) as previously described [

8]. Both sets of berries had the same control and coatings applied: uncoated, CH, SF, SC, and CAR. Coatings were applied by dipping individual berries and then carefully placing them in Eppendorf tube racks to dry. The berries were then transferred to a new rack for storage at 20 °C for 4 days. Weights of the individual berries were taken after the berries had dried and then daily until the end of storage.

2.9. Statistical Analysis

Blueberry weight loss and bloom data for seasons 1 and 2 were analyzed by a completely randomized design, using a one-way ANOVA within both variety and storage time using statistical software (SPSS version 24, IBM, Chicago, IL, USA). Similarly, data examining the influence of handling on weight loss were analyzed by ANOVA within storage time and data on the impact of the epicuticular bloom by ANOVA within bloom condition and storage time, both with SPSS. Both of these analyses used a completely randomized design. Mean separations for all analyses in this manuscript were determined using Tukey’s test (p ≤ 0.05).

4. Discussion

Experimentation was undertaken in this study to thoroughly characterize the performance of several coatings that had been used in prior research with blueberries and some that had not yet been tried with this commodity. This was used to set the stage for experimentation to better understand why blueberry coatings have often been ineffective in prior research. All the coatings evaluated in this study were ineffective in reducing weight loss, a result that was consistent in both years of the research using two different varieties. In fact, in the second season, weight loss was accelerated by some of the coatings. The only positive results were with CAR when treating individual berries, an impractical procedure commercially. The lack of positive effect in our research on weight loss of chitosan-based coatings agrees with much of the prior research on this coating on blueberries [

9,

11,

14,

19,

20], although there are some reports that do indicate a benefit [

15,

21]. The relatively high water vapor permeability of chitosan film [

18] likely contributed to the poor or inconsistent results. Although components such as oleic acid are sometimes added to improve water vapor resistance [

17], this did not help lower weight loss in the first season of this study where this was tried. SF, a hydrophobic coating in contrast to the hydrophilic CAR, was reported to slow weight loss in blueberries [

9], but the results in that study were inconsistent within the duration of the test. In our experiments, SF was not effective in preventing weight loss at any time. Duan et al. [

9] also found that calcium caseinate was a poor coating to limit weight loss, the same as our findings with SC. To try to find any coating that would reduce weight loss in blueberries we also tried CAR, a coating with relatively low water vapor permeability [

18,

22]. This coating also failed, although the fact that the coating was formulated for citrus and not blueberries could have played a part. In addition, unlike in this case, citrus fruit are heat-dried after wax application which may act to soften or partially melt the wax and make its coverage more continuous. Cracking developed during storage may have also limited its effectiveness (

Figure 3A). Sodium alginate, pectin, and pullulan, other coatings that have been shown to be of no use in lessening weight loss in blueberry, were not tried [

12,

13].

It is recognized that coatings have other functions than just lessening weight loss. Since firmness can be reduced by weight loss [

5], coatings could potentially make blueberries more firm. Although firmness has been positively impacted in blueberries by coatings in some studies [

9,

21], often there have been no or inconsistent effects such as those obtained in this study (

Supplementary Tables S1 and S2). Our results were not surprising given the poor ability of our coatings to limit weight loss. This was the same situation with shrivel, another quality attribute directly related to weight loss. Decay can cause a severe loss in the marketability of the fruit and, accordingly, this has been an important target of most of the prior studies with blueberry coatings. In the second season, the inhibitory effect of CH on decay was clear in both varieties as has been often noted in various commodities by others [

23]. Antioxidant capacity may potentially also be altered by coatings but was not evaluated in this study that focuses on weight loss and external factors due to their greater importance.

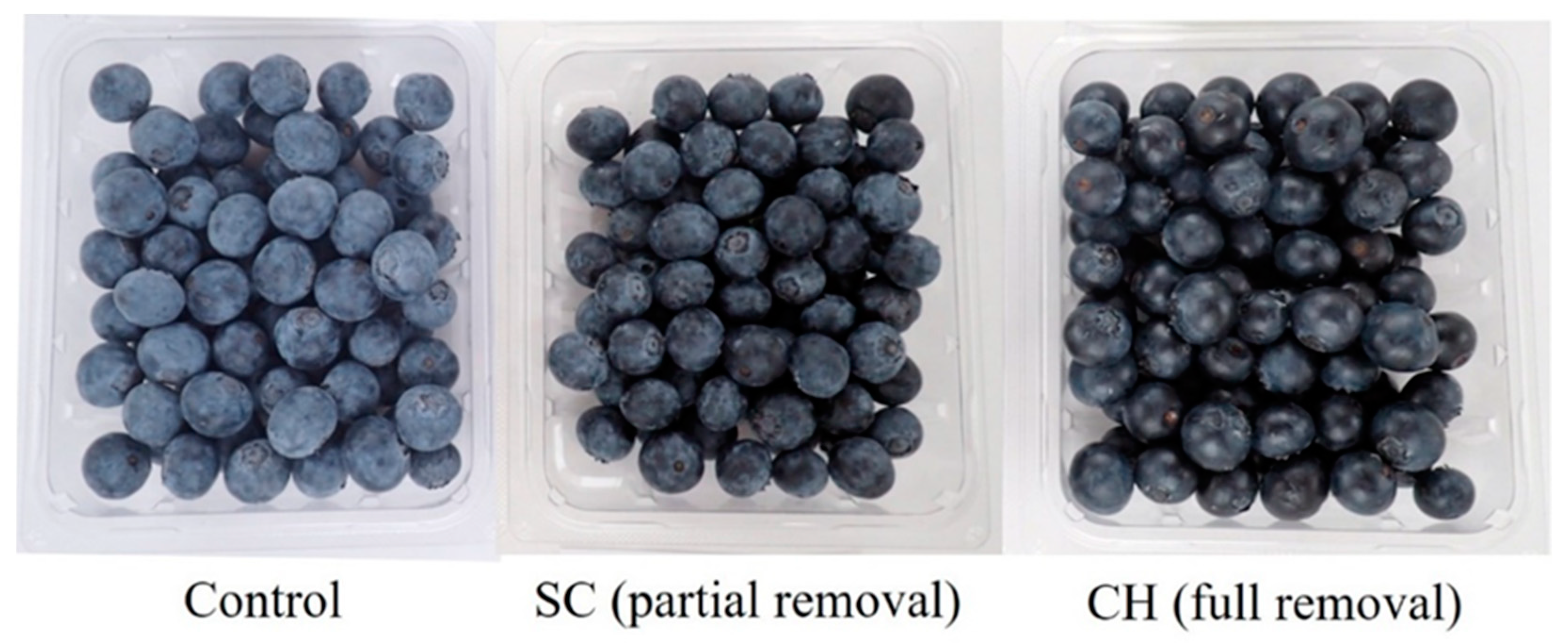

The appearance of coated blueberries has not been commented on in almost all prior studies yet is very likely important. Mannozzi et al. [

13] mentioned that blueberries treated with sodium alginate or pectin were bluer than the controls. The loss of waxy bloom is responsible for this as was acknowledged in Duan et al. [

9]. In this study, we performed visual evaluations for the condition of the bloom to gauge the impact of the different coatings more completely on this quality parameter. Most treatments, including the controls, had some negative impact, although sometimes not to the degree that would likely impact consumer preference. Some coatings, such as CH (with or without OA) and CAR, always were very damaging and caused a complete or near complete removal of the bloom (

Table 1 and

Table 2;

Figure 1). Other coatings, such as SF and SC were more intermediate in effect, causing only a partial bloom removal. A recent study by our laboratory found that partial bloom removal was acceptable to sensory panelists, but full removal was not [

24]. This means that a bloom-damaging coating such as CH, despite its benefits in reducing decay, is likely not acceptable for fresh blueberries unless some more gentle means of application can be devised.

After confirmation of the ineffectiveness of the coatings tested in this study, the research moved to experimentation designed to have a better understanding of potential factors for why the coatings were not more efficacious. One of the first areas of the investigation was to examine the impact of handling during the application process as handling was required to both coat and dry the fruit. Using CH + OA as the test coating, it was found that if the amount of handling during the drying process was increased beyond what was normally practiced (minimal handling) the weight loss was significantly greater (

Table 3). The results were also similar to CAR (results not shown). This indicates that the methodology of application can influence the success of the coating. The reason for this observation is not known but it is supposed that the coverage of the coating may be compromised by excessive handling. Indeed, SEM observations of blueberries coated with CH, SF, or SC indicated that these coatings formed films with a tendency to flake off (

Supplementary Figure S1). Attempts to alter the application method to improve coating performance by spraying instead of dipping were not successful (

Table 1). Further experimentation using an air-brush to delicately apply the coating and then drying without handling were also not successful. Surprisingly, it was found that with the CH + OA coating, even the application of an additional coat (using minimal handling during drying) did not lessen weight loss and, in fact, weight loss was even greater than the single coat with minimal handling (

Table 3). In one of the few mentions of the mode of coating application for blueberries, Duan et al. [

9] noted in their conclusion that dipping may have reduced the effectiveness of their coatings but offered no explanation of why that may have been so.

The stem end, although small in area relative to the cuticle, was found to be responsible for an average of 40% of the total weight loss in a study that examined a range of highbush blueberry genotypes [

2]. To gain insight whether the stem end may be more difficult to coat, and negatively affect coating effectiveness, SC was applied to both blueberries that had the stem end completely blocked using nail polish [

2] and control blueberries where the stem end had not been blocked. Eliminating water loss through the stem end eliminated approximately 50% of the total weight loss (

Figure 2A), like the findings of Moggia et al. [

2]. Same as the research presented earlier in this study, SC did not reduce weight loss in either sets of blueberries. In this case, the handling of the coated blueberries cannot be blamed for the ineffectiveness as each fruit was carefully coated and dried individually. Calculated estimates of the relative effect of SC on both regions indicated the cuticle weight loss was slightly increased over time while that from the stem end does not change much or even slightly declined due to SC application. It appears that, at least with SC, that poor coverage of the stem end was not the reason of the ineffectiveness of the coating in limiting weight loss.

In this study application of coating often led to a visible darkening of the blueberries (

Figure 1) due to the loss of epicuticular bloom (

Figure 3C). Prior research had shown that removal of the bloom increased weight loss in blueberries [

8] and indicated the possibility that damage to the bloom due to coating application may be at least partially responsible for the poor coating performance that we observed. To examine this possibility coatings were applied to natural blueberries (bloom present) and to others that had the bloom artificially removed (

Table 4). It should also be noted here that the berries were all individually coated and dried, eliminating the effect of handling. Analysis across treatments indicated that removal of the bloom did result in greater weight loss (

p ≤ 0.5) as had been previously seen [

8], the difference being up to 1.36% by day 3. If damage to the bloom would have played a significant role in the failure of the coatings to prevent weight loss, however, there should have been significant differences between the uncoated and coated blueberries in the group that had the bloom removed as the bloom, in that case, was not a factor. This was not observed, however, indicating that loss of bloom did not influence coating performance.