Modeling Mathematical Relationship with Weight Loss and Texture on Table Grapes of ‘Red Globe’ and ‘Wink’ during Cold and Ambient Temperature Storage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Grapes

2.2. Weight Loss

2.3. Texture

2.4. Statistical Analysis

2.5. Characteristics of Weight Loss Based on the Logistic Model

2.6. Characteristics of Textural Parameters Based on Logistic Model, ExpDec1 Model, ExpDec2 Model, and Boltzmann Model

3. Results and Discussion

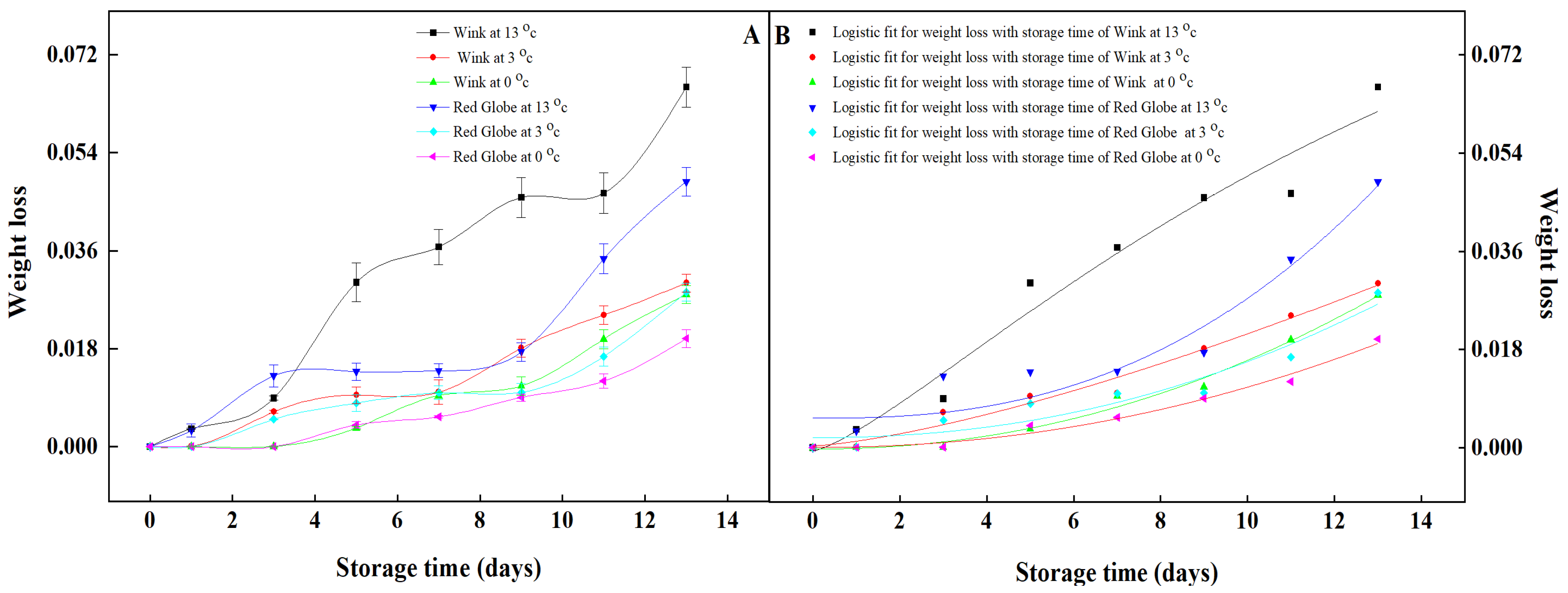

3.1. Changes in Weight Loss in Two Cultivars during Cold and Ambient Storage

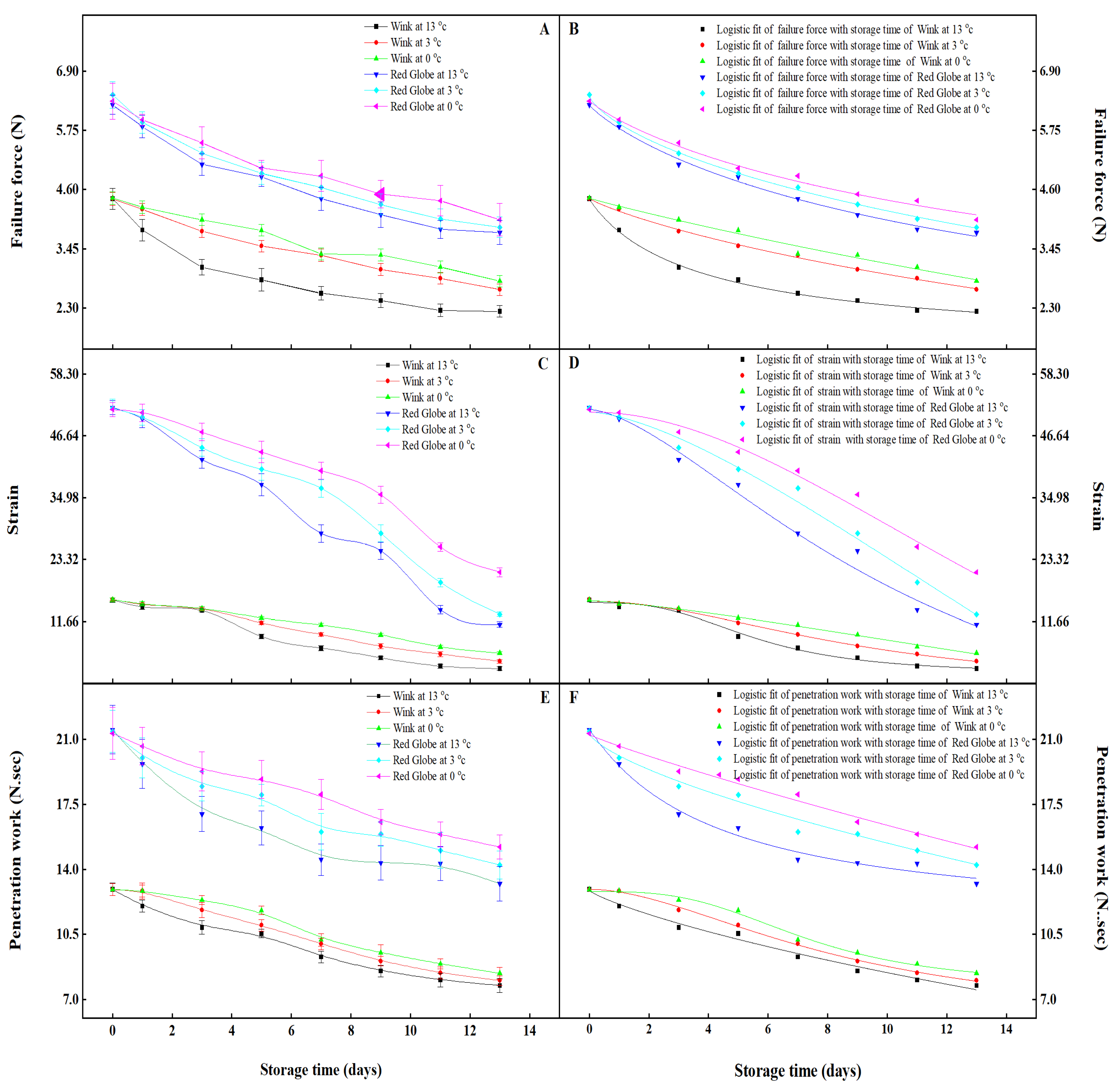

3.2. Changes of Textural Parameters in Two Cultivars during Cold and Ambient Storage

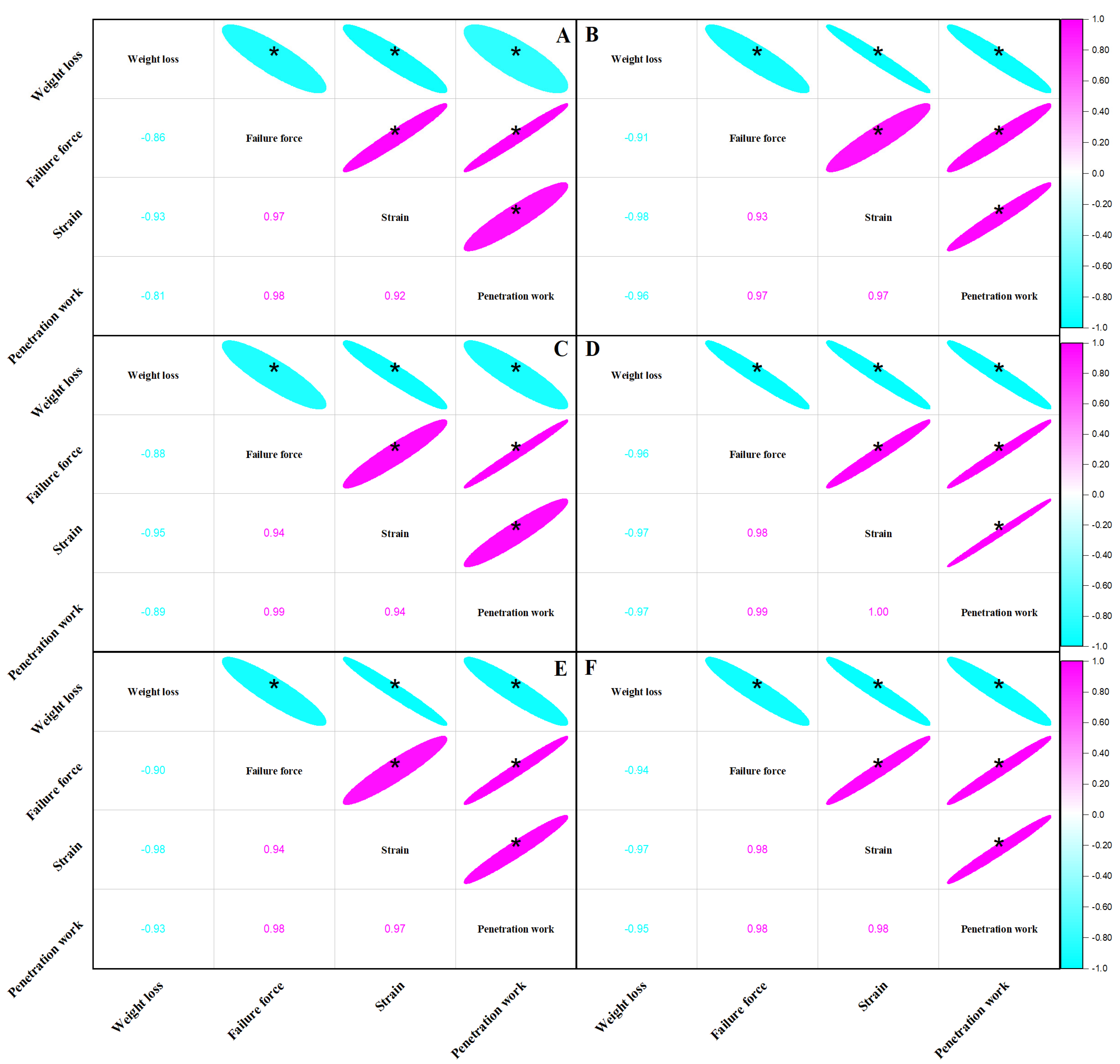

3.3. Correlation between Weight Loss and Textural Parameters of Two Cultivars during Ambient and Cold Storage

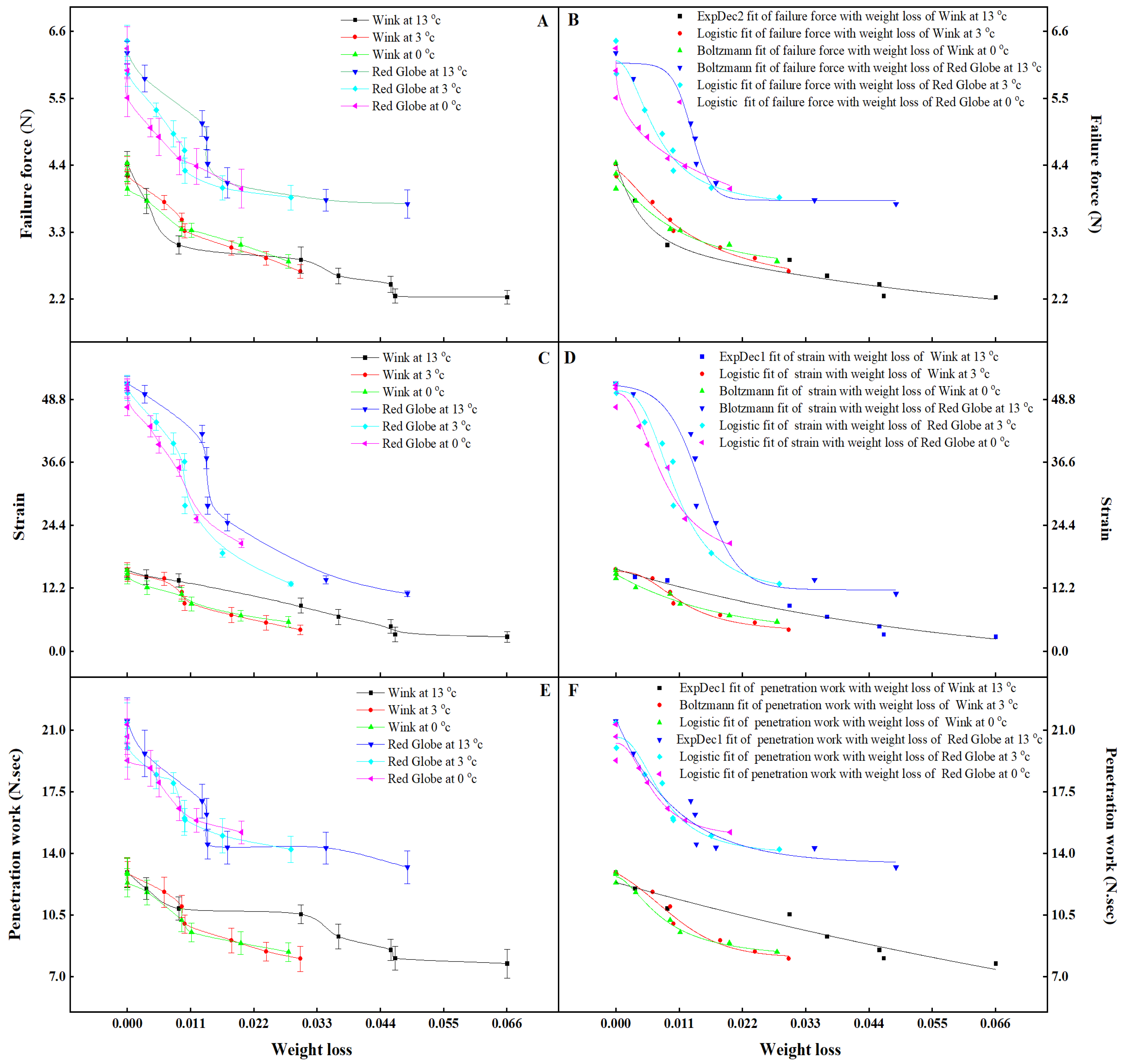

3.4. Changes and Fitting Models of Textural Parameters with Weight Loss of Two Cultivars during Ambient and Cold Storage

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Eshghi, S.; Karimi, R.; Shiri, A.; Karami, M.; Moradi, M. The novel edible coating based on chitosan and gum ghatti to improve the quality and safety of ‘Rishbaba’ table grapes during cold storage. J. Food Meas. Charact. 2021, 15, 3683–3693. [Google Scholar] [CrossRef]

- Ktenioudaki, A.; O’Donnell, C.P.; Emond, J.P.; Nunes, M.C. Blueberry supply chain: Critical steps impacting fruit quality and application of a boosted regression tree model to predict weight loss. Postharvest Biol. Technol. 2021, 179, 111590. [Google Scholar] [CrossRef]

- Mohammed, M.; Sallam, A.; Alqahtani, N.; Munir, M. The combined effects of precision-controlled temperature and relative humidity on artificial ripening and quality of date fruit. Foods 2021, 10, 2636. [Google Scholar] [CrossRef] [PubMed]

- Oyom, W.; Xu, H.P.; Liu, Z.T.; Long, H.T.; Li, Y.C.; Zhang, Z.; Bi, Y.; Tahergorabi, R.; Prusky, D. Effects of modified sweet potato starch edible coating incorporated with cumin essential oil on storage quality of ‘early crisp’. LWT 2022, 153, 112475. [Google Scholar] [CrossRef]

- Khalil, U.; Rajwana, I.A.; Razzaq, K.; Farooq, U.; Saleem, B.A.; Brecht, J.K. Quality attributes and biochemical changes in white and colored table grapes as inflfluenced by harvest maturity and ambient postharvest storage. S. Afr. J. Bot. 2023, 154, 273–281. [Google Scholar] [CrossRef]

- Nia, A.E.; Taghipour, S.; Siahmansour, S. Pre-harvest application of chitosan and postharvest aloe vera gel coating enhances quality of table grape (Vitis vinifera L. cv. ‘yaghouti’) during postharvest period. Food Chem. 2021, 347, 129012. [Google Scholar]

- Artés-Hernández, F.; Aguayo, E.; Artés, F. Alternative atmosphere treatments for keeping quality of ‘Autumn Seedless’ table grapes during long-term cold storage. Postharvest Biol. Technol. 2004, 31, 59–67. [Google Scholar] [CrossRef]

- Blanckenberg, A.; Opara, U.L.; Fawole, O.A. Postharvest losses in quantity and quality of table grape (cv. Crimson Seedless) along the supply chain and associated economic, environmental and resource impacts. Sustainability 2021, 13, 4450. [Google Scholar] [CrossRef]

- Ericsem, P.; Srgb, E.; Antonio, S.W.; Vivaldo, S.J. Water loss in table grapes: Model development and validation under dynamic storage conditions. Food Sci. Technol. 2018, 38, 473–479. [Google Scholar]

- Liu, B.H.; Wang, K.F.; Shu, X.G.; Liang, J.F.; Sun, X.L. Changes in fruit firmness, quality traits, and cell wall constituents of two highbush blueberries (Vaccinium corymbosum L.) during postharvest cold storage. Sci. hortic. 2019, 246, 557–562. [Google Scholar] [CrossRef]

- Amodio, M.L.; Derossi, A.; Colelli, G. Modelling sensorial and nutritional changes to better define quality and shelf life of fresh-cut melons. J. Agric. Eng. 2013, 43, 38–45. [Google Scholar] [CrossRef] [Green Version]

- Amodio, M.L.; Derossi, A.; Mastrandrea, L.; Colelli, G. A study of the estimated shelf life of fresh rocket using a non-linear model. J. Food Eng. 2015, 150, 19–28. [Google Scholar] [CrossRef]

- Yang, C.; Wang, Y.; Wu, B.; Fang, J.; Li, S. Volatile compounds evolution of three table grapes with different flavors during and after maturation. Food Chem. 2011, 128, 823–830. [Google Scholar] [CrossRef]

- Zhu, D.S.; Zhang, Q.M.; Cao, X.H.; Tao, Z.; Meng, X.J.; Li, J.R. Effect of relative humidity on the changes in water and texture of Kyoho grape during storage. Food Sci. 2014, 35, 340–345, (In Chinese with English abstract). [Google Scholar]

- Castillo, S.; Navarro, D.; Zapata, P.J.; Guillén, F.; Valero, D.; Serrano, M.; Martínez-Romero, D. Antifungal efficacy of Aloe vera in vitro and its use as a preharvest treatment to maintain postharvest table grape quality. Postharvest Biol. Technol. 2010, 57, 183–188. [Google Scholar] [CrossRef]

- Wang, X.Q.; Wang, J.F.; Liu, X.Y.; Du, F.L.; Guan, X.Q. Effect of different preservation treatments on storage in low temperature of Red Globe grape. Food Ind. 2016, 37, 98–102, (In Chinese with English abstract). [Google Scholar]

- Babalk, Z.; Onursal, C.E.; Erbas, D.; Koyuncu, M.A. Use of carvacrol helps maintain postharvest quality of red globe table grape. J. Anim. Plant Sci. 2020, 30, 655–662. [Google Scholar]

- Basak, A.; Buczek, M. Results on the use of 3,5,6-tpa against preharvest fruit drop in ‘conference’ pear. Acta Hortic. 2010, 884, 391–397. [Google Scholar] [CrossRef]

- Kong, X.B.; Xu, M.; Wan, H.L.; Han, L.X.; Liu, X.l.; Li, Q.J.; Hao, B.Q.; Zhang, S.J.; Li, X.M.; Liu, Y.H.; et al. Development of a texture evaluation system for Dongzao (Ziziphus jujuba cv. Dongzao) fruit. J. Integr. Agr. 2022, 121, 3658–3668. [Google Scholar] [CrossRef]

- Gwanpua, S.G.; Verlinden, B.E.; Hertog, M.L.A.; Bulens, O.; Van de Poel, B.; Van Ompe, J.; Nicolaï, B.M.; Geeraerd, A.H. Kinetic modeling of firmness breakdown in “braeburn” apples stored under different controlled atmosphere conditions. Postharvest Biol. Technol. 2012, 67, 68–74. [Google Scholar] [CrossRef]

- Schouten, R.E.; Natalini, A.; Tijskens, L.M.M.; Woltering, E.J.; Van Kooten, D. Modelling the firmness behavior of cut tomatoes. Postharvest Biol. Technol. 2010, 57, 44–51. [Google Scholar] [CrossRef]

- Rahman, M.S.; Al-Farsi, S.A. Instrumental texture profile analysis (TPA) of date flesh as a function of moisture content. J. Food Eng. 2005, 66, 505–511. [Google Scholar] [CrossRef]

- Li, M.; Rivera, S.; Franklin, D.; Nowak, E.; Hallett, I.; Kolenderska, S.; Urbańska, M.; Vanholsbeeck, F.; East, A. Use of optical coherence tomography and light microscopy for characterisation of mechanical properties and cellular level responses of ‘centurion’ blueberries during weight loss. J. Food Eng. 2021, 303, 110596. [Google Scholar] [CrossRef]

- D’Aquino, S.; Misttiotis, A.; Briassoulis, D.; Lorenzo, M.L.D.; Malinconico, D.; Palma, A. Influence of modified atmosphere packaging on postharvest quality of cherry tomatoes held at 20 °C. Postharvest Biol. Technol. 2016, 115, 103–112. [Google Scholar] [CrossRef]

- Cheng, X.Y.; Ge, X.Z.; Xue, H.L.; Bi, Y. Relationship between mass loss percentage of fresh Goji berries and either storage time or texture parameters. Food Sci. 2020, 41, 270–275, (In Chinese with English abstract). [Google Scholar]

- Cheng, X.Y.; Zhao, Y.Y.; Xue, H.L.; Bi, Y.; Sun, C.C.; Xue, Z.X. Model fit based on the weight loss and texture parameters of MAP cherry tomatoes during storage. J. Food Process. Preserv. 2021, 46, e16204. [Google Scholar] [CrossRef]

- Valderrama, L.; Valderrama, P.; Carasek, E. A semi-quantitative model through PLS-DA in the evaluation of carbendazim in grape juices. Food Chem. 2022, 368, 130742. [Google Scholar] [CrossRef]

- Zhang, F.C.; Zhong, H.X.; Zhou, X.M.; Han, S.A.; Wang, M.; Hao, J.Z.; Wu, X.Y.; Pan, M.Q. Photosynthesis of grape leaves with ‘OSC’ trellis and cordon based on data model fitting. Photosynthetica 2021, 59, 160–170. [Google Scholar] [CrossRef]

- Dermesonlouoglou, E.; Chalkia, A.; Taoukis, P. Application of osmotic dehydration to improve the quality of dried Goji berry. J. Food Eng. 2018, 232, 36–43. [Google Scholar] [CrossRef]

- Zhang, H.M.; Tu, K.; Qiu, Z.L.; Qiao, G.; Wen, X.P. Changes in the quality of fruits of four sweet cherry cultivars grown under rain-shelter cultivation during storage at room temperature. J. Food Meas. Charact. 2022, 16, 2571–2581. [Google Scholar] [CrossRef]

- Pinto, C.; Shimakawa, K. A compressed logistic equation on bacteria growth: Inferring time-dependent growth rate. Phys. Biol. 2022, 19, 066003. [Google Scholar] [CrossRef] [PubMed]

- Amagai, K.; Yamakawa, M.; Machida, M.; Hatano, Y. The linear Boltzmann equation in column experiments of porous media. Transport Porous Med. 2020, 132, 311–331. [Google Scholar] [CrossRef] [Green Version]

- Romero, I.; Vazquez-Hernandez, M.; Tornel, M.; Escribano, M.I.; Sanchez-Ballesta, M.T. The effect of ethanol treatment on the quality of a new table grape cultivar 681-30 stored at low temperature and after a 7-day shelf-life period at 20 °C: A molecular approach. Int. J. Mol. Sci. 2021, 22, 8138. [Google Scholar] [CrossRef]

- Tongdeesoontorn, W. Effect of active packaging material fortified with clove essential oil on fungal growth and post-harvest quality changes in table grape during cold storage. Polymers 2021, 13, 3445. [Google Scholar]

- Saki, M.; ValizadehKaji, B.; Abbasifar, A.; Shahrjerdi, I. Effect of chitosan coating combined with thymol essential oil on physicochemical and qualitative properties of fresh fig (Ficus carica L.) fruit during cold storage. J. Food Meas. Charact. 2019, 13, 1147–1158. [Google Scholar] [CrossRef]

- Saleem, M.S.; Anjum, M.A.; Naz, S.; Ali, S.; Hussain, S.; Azam, M.; Sardar, H.; Khaliq, G.; Canan, H.; Ejaz, S. Incorporation of ascorbic acid in chitosan-based edible coating improves postharvest quality and storability of strawberry fruits. Int. J. Biol. Macromol. 2021, 189, 160–169. [Google Scholar] [CrossRef]

- Yang, M.; Luo, Z.; Gao, S.; Belwal, T.; Li, L. The chemical composition and potential role of epicuticular and intracuticular wax in four cultivars of table grapes. Postharvest Biol. Technol. 2021, 173, 111430. [Google Scholar] [CrossRef]

- Biswas, M.A.; Islam, M.A.; Ahmed, I.M.; Hossain, M.M.; Halim, M.A. Different sources nitrogen based fertilizers on growth, yield and nutritional quality of tomato (Lycopersicon esculentum Mill.). Acta Sci. Malays. (ASM) 2020, 4, 39–44. [Google Scholar]

- Canizo, B.V.; Escudero, L.B.; Pellerano, R.G.; Wuilloud, R.G. Data mining approach based on chemical composition of grape skin for quality evaluation and traceability prediction of grapes. Comput. Electron. Agr. 2019, 162, 514–522. [Google Scholar] [CrossRef]

- Sato, I.; Yamane, H.; Hirakawa, N.; Otobe, K.; Yamada, M. Varietal differences in the texture of grape berries measured by penetration tests. Vitis—J. Grapevine Res. 1997, 36, 7–10. [Google Scholar]

- Cai, C.; Xu, C.J.; Li, X.; Ferguson, I.; Chen, K.S. Accumulation of lignin in relation to change in activities of lignification enzymes in loquat fruit flesh after harvest. Postharvest Biol. Technol. 2006, 40, 163–169. [Google Scholar] [CrossRef]

- Kamdee, C.; Imsabai, W.; Kirk, R.; Allan, A.C.; Ferguson, I.B.; Ketsa, S. Regulation of lignin biosynthesis in fruit pericarp hardening of mangosteen (Garcinia mangostana L.) after impact. Postharvest Biol. Technol. 2014, 97, 68–76. [Google Scholar] [CrossRef]

- Kajuna, S.; BilanskI, W.K.; Mittal, G.S. Textural changes of banana and plantain pulp during ripening. J. Sci. Food Agric. 1997, 75, 244–250. [Google Scholar] [CrossRef]

- Adegoroye, A.S.; Jolliffe, P.A.; Tung, M.A. Textural characteristics of tomato fruits (Lycopersicon esculentum) affected by sunscald. J. Sci. Food Agric. 2010, 49, 95–102. [Google Scholar] [CrossRef]

- Park, J.M.; Moon, J.; Bae, J.W.; Jang, M. Strain rate effects of dynamic compressive deformation on mechanical properties and microstructure of CoCrFeMnNi high-entropy alloy. Mat. Sci. Eng. A-Struct. 2018, 719, 155–163. [Google Scholar] [CrossRef]

- Tóth, A.M.; Veres, S.; Zsófi, Z. Texture analysis as a method for grape berry characterization. Acta Agrar. Debr. 2022, 2, 57–64. [Google Scholar] [CrossRef]

- Basile, T.; Marsico, A.D.; Perniola, R. Use of artificial neural networks and NIR spectroscopy for non-destructive grape texture prediction. Foods 2022, 11, 281. [Google Scholar] [CrossRef]

- Nunes, M.C.N.; Brecht, J.K.; Morais, A.M.B.; Sargent, S.A. Possible influences of water loss and polyphenol oxidase activity on anthocyanin content and discoloration in fresh ripe strawberry (cv.OsoGrande) during storage at 1 °C. J. Food Sci. 2005, 70, 79–84. [Google Scholar] [CrossRef]

- Nunes, M.C.N.; Emond, J.P.; Rauth, M.; Dea, S.; Chau, K.V. Environmental conditions encountered during typical consumer retail display affect fruit and vegetable quality and waste. Postharvest Biol. Technol. 2009, 51, 232–241. [Google Scholar] [CrossRef]

- Wang, L.N.; Brouard, E.; Prodhomme, D.; Hilbert, G.; Renaud, C.; Petit, J.; Edwards, E.; Betts, A.; Delrot, S.; Ollat, N.; et al. Regulation of anthocyanin and sugar accumulation in grape berry through carbon limitation and exogenous ABA application. Food Res. Int. 2022, 160, 111478. [Google Scholar] [CrossRef]

- Cheng, G.P.; Yang, E.; Lu, W.J.; Jia, Y.X.; Jiang, Y.M.; Duan, X.W. Effect of nitric oxide on ethylene synthesis and softening of banana fruit slice during ripening. J. Agric. Food Chem. 2009, 57, 5799–5804. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Li, Z.C.; Han, Z.H.; Xue, S.L.; Bi, Y.; Prusky, D. Effects of nitric oxide treatment on lignin biosynthesis and texture properties at wound sites of muskmelons. Food Chem. 2021, 362, 130193. [Google Scholar] [CrossRef] [PubMed]

| Cultivar | Temperature | Equation | R-Square | Adj. R-Square |

|---|---|---|---|---|

| 13 °C | 0.93158 | 0.88026 | ||

| Red Globe | 3 °C | 0.93102 | 0.87928 | |

| 0 °C | 0.98425 | 0.97243 | ||

| Wink | 13 °C | 0.96782 | 0.94367 | |

| 3 °C | 0.98071 | 0.96625 | ||

| 0 °C | 0.98973 | 0.98202 |

| Cultivars | Coefficient | Temperature | ||

|---|---|---|---|---|

| 13 °C | 3 °C | 0 °C | ||

| Red Globe | ||||

| Wink | ||||

| Cultivar | Parameter | Temperature | Equation | R-Square | Adj. R-Square |

|---|---|---|---|---|---|

| Red Globe | Failure Force | 13 °C | 0.99482 | 0.99094 | |

| 3 °C | 0.99892 | 0.99812 | |||

| 0 °C | 0.99417 | 0.98979 | |||

| Strain | 13 °C | 0.99218 | 0.98632 | ||

| 3 °C | 0.99591 | 0.99284 | |||

| 0 °C | 0.99234 | 0.98659 | |||

| Penetration work | 13 °C | 0.98164 | 0.96787 | ||

| 3 °C | 0.98102 | 0.96679 | |||

| 0 °C | 0.98823 | 0.9794 | |||

| Wink | Failure Force | 13 °C | 0.99700 | 0.99476 | |

| 3 °C | 0.99779 | 0.99613 | |||

| 0 °C | 0.98567 | 0.97493 | |||

| Strain | 13 °C | 0.99243 | 0.98675 | ||

| 3 °C | 0.99710 | 0.99492 | |||

| 0 °C | 0.99608 | 0.99413 | |||

| Penetration work | 13 °C | 0.98275 | 0.96981 | ||

| 3 °C | 0.99866 | 0.99765 | |||

| 0 °C | 0.99281 | 0.98742 |

| Cultivar | Parameter | Coefficient | Temperature | ||

|---|---|---|---|---|---|

| 13 °C | 3 °C | 0 °C | |||

| Red Globe | Failure force | ||||

| Strain | |||||

| Penetration work | |||||

| Wink | Failure force | ||||

| Strain | |||||

| Penetration work | |||||

| Cultivar | Parameter | Temperature | Equation | R-Square | Adj. R-Square |

|---|---|---|---|---|---|

| Red Globe | Failure force | 13 °C | 0.97083 | 0.94895 | |

| 3 °C | 0.96500 | 0.93875 | |||

| 0 °C | 0.97180 | 0.95065 | |||

| Strain | 13 °C | 0.97837 | 0.96215 | ||

| 3 °C | 0.98895 | 0.98067 | |||

| 0 °C | 0.98358 | 0.97126 | |||

| Penetration work | 13 °C | 0.89864 | 0.8581 | ||

| 3 °C | 0.93022 | 0.87788 | |||

| 0 °C | 0.96170 | 0.93298 | |||

| Wink | Failure force | 13 °C | 0.94455 | 0.93703 | |

| 3 °C | 0.98469 | 0.9732 | |||

| 0 °C | 0.95667 | 0.92417 | |||

| Strain | 13 °C | 0.97816 | 0.96943 | ||

| 3 °C | 0.97830 | 0.96021 | |||

| 0 °C | 0.97821 | 0.96186 | |||

| Penetration work | 13 °C | 0.90820 | 0.87148 | ||

| 3 °C | 0.97018 | 0.96723 | |||

| 0 °C | 0.98940 | 0.98144 |

| Cultivar | Parameter | Coefficient | Temperature | ||||

|---|---|---|---|---|---|---|---|

| 13 °C | 3 °C | 0 °C | |||||

| Red Globe | Failure force | ||||||

| Strain | |||||||

| Penetration work | |||||||

| Wink | Failure force | ||||||

| Strain | |||||||

| Penetration work | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, X.; Li, R.; Zhao, Y.; Bai, Y.; Wu, Y.; Bao, P.; Huang, Z.; Bi, Y. Modeling Mathematical Relationship with Weight Loss and Texture on Table Grapes of ‘Red Globe’ and ‘Wink’ during Cold and Ambient Temperature Storage. Foods 2023, 12, 2443. https://doi.org/10.3390/foods12132443

Cheng X, Li R, Zhao Y, Bai Y, Wu Y, Bao P, Huang Z, Bi Y. Modeling Mathematical Relationship with Weight Loss and Texture on Table Grapes of ‘Red Globe’ and ‘Wink’ during Cold and Ambient Temperature Storage. Foods. 2023; 12(13):2443. https://doi.org/10.3390/foods12132443

Chicago/Turabian StyleCheng, Xiaoyan, Rongxia Li, Youyi Zhao, Yuhe Bai, Yuanling Wu, Peipei Bao, Zijie Huang, and Yang Bi. 2023. "Modeling Mathematical Relationship with Weight Loss and Texture on Table Grapes of ‘Red Globe’ and ‘Wink’ during Cold and Ambient Temperature Storage" Foods 12, no. 13: 2443. https://doi.org/10.3390/foods12132443