Study on the Variation Law of the Main Mechanical Properties in the Processing of Longjing Tea

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Instruments and Equipment

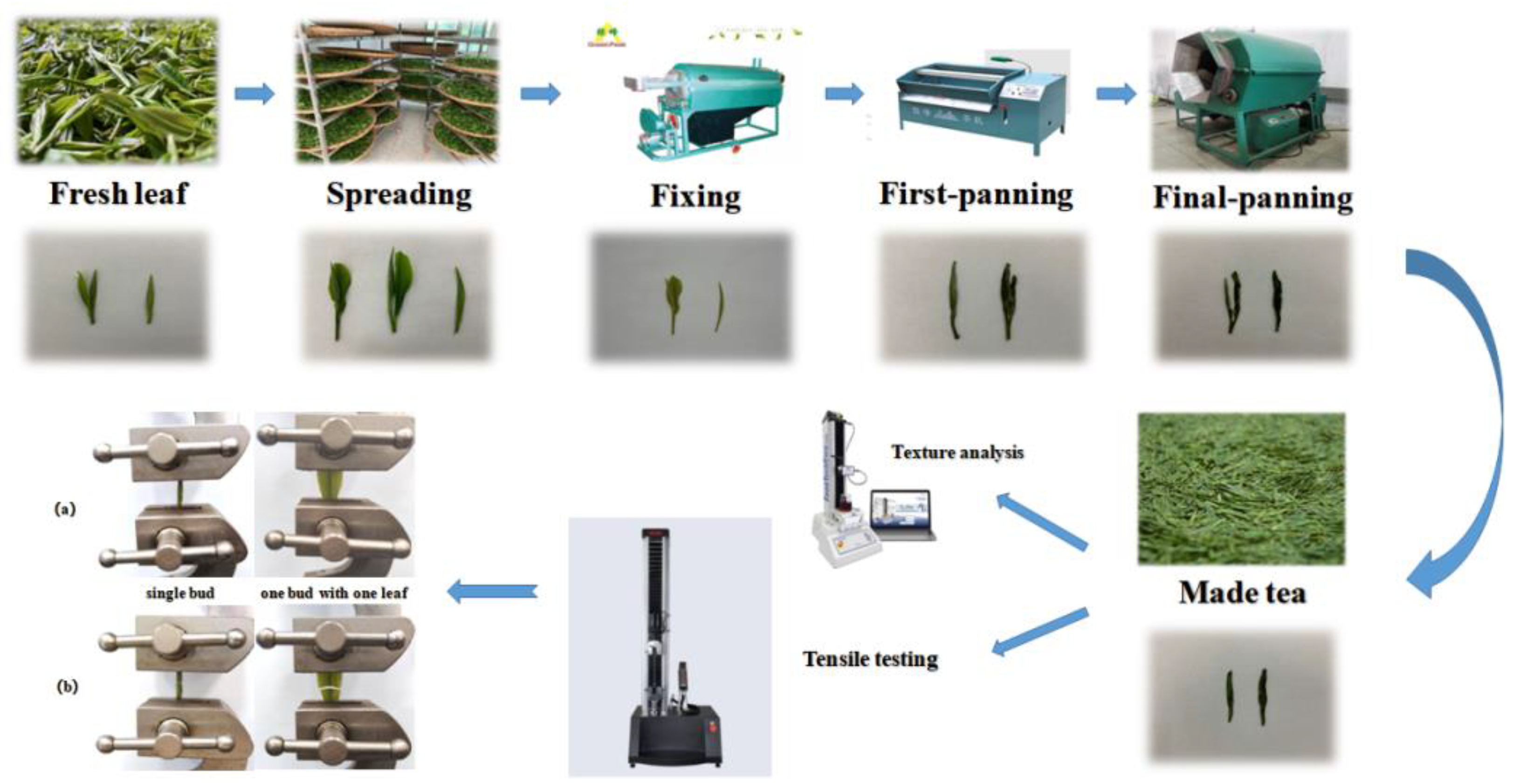

2.3. Tea Processing

2.4. Sampling

2.5. Water Content Measurement [28]

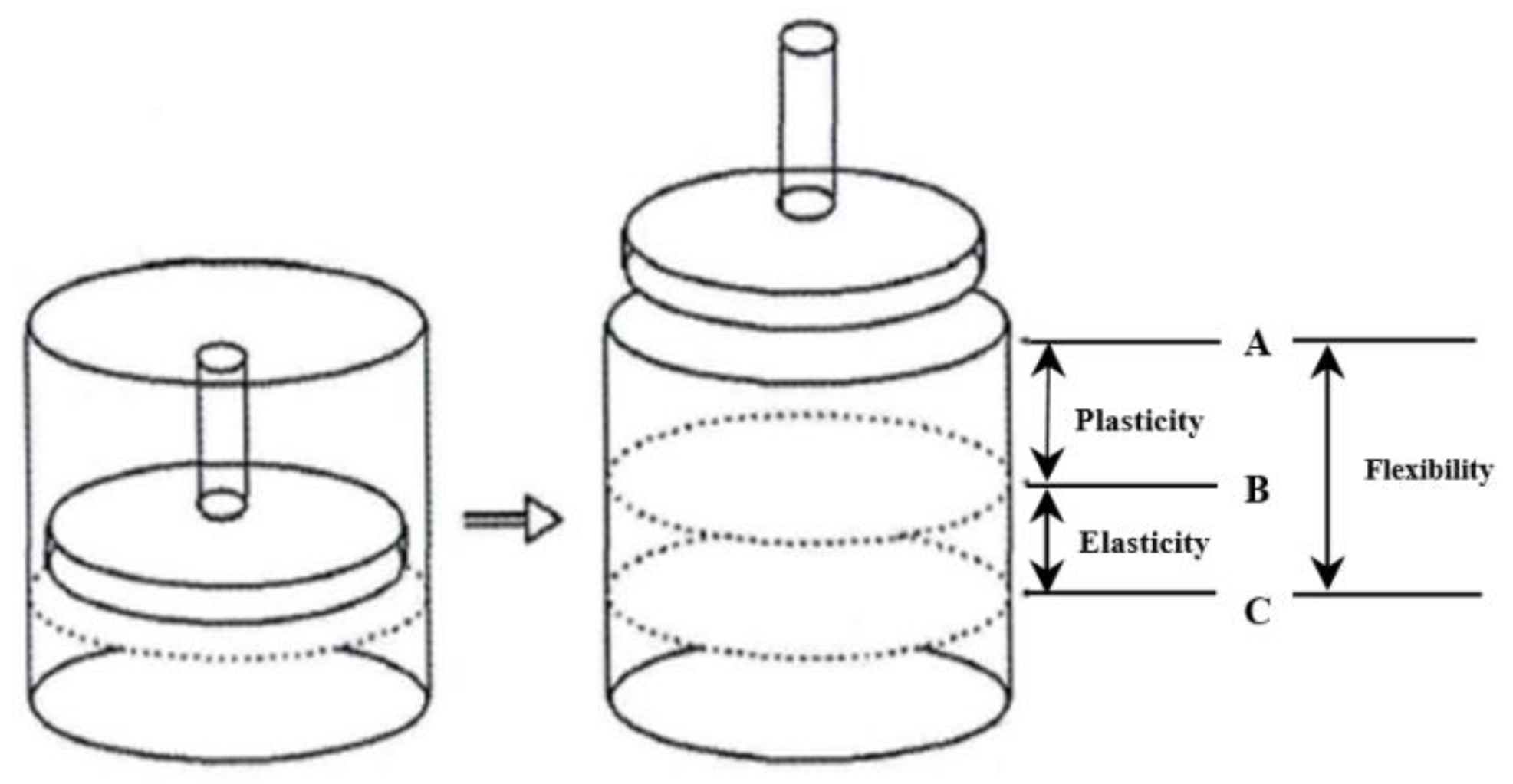

2.6. Texture Properties Measurement [29]

2.7. Tensile Properties Measurement [30]

3. Results and Discussion

3.1. Changes in Water Content of Longjing Tea during Processing

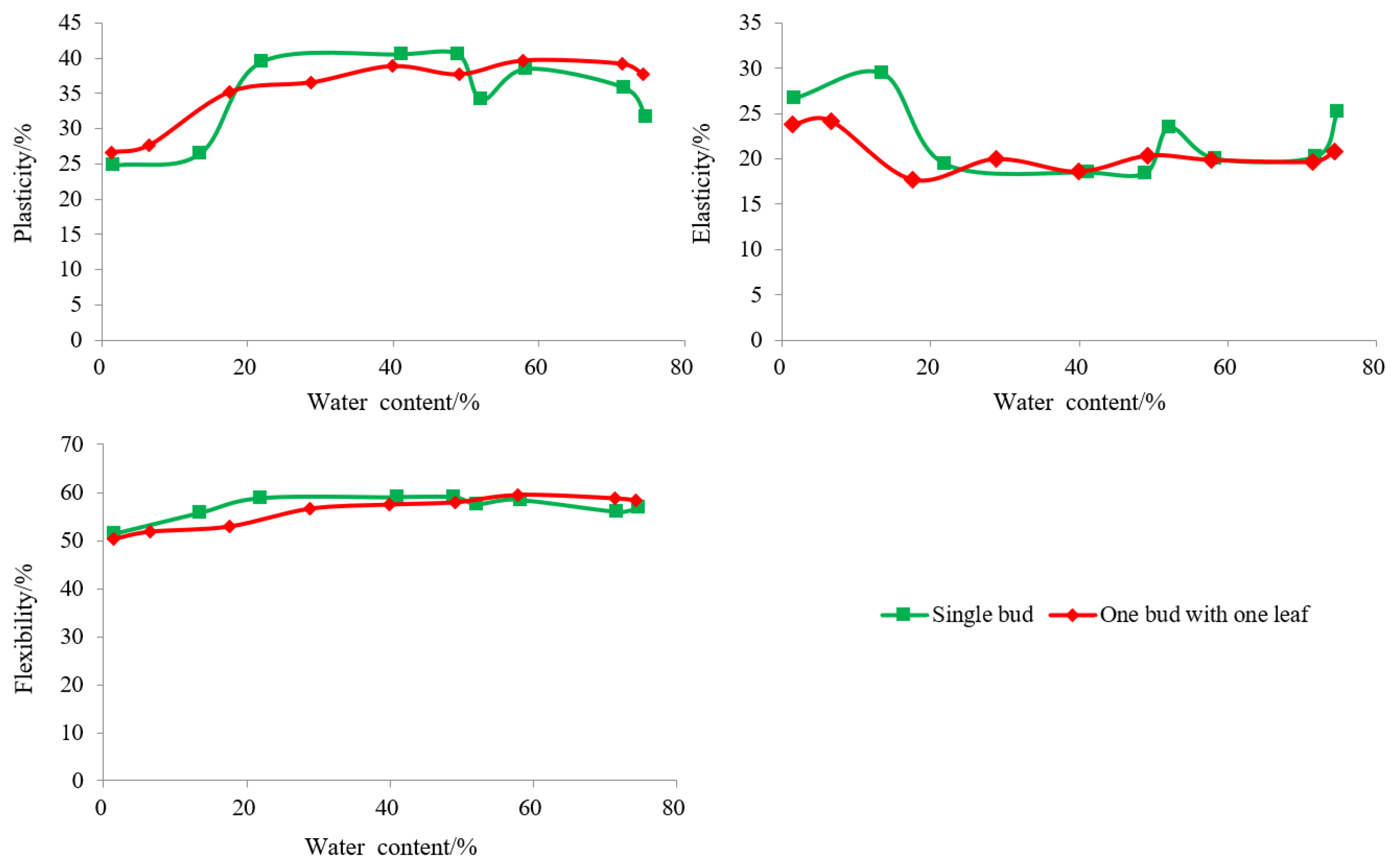

3.2. Changes in Texture Properties of Longjing Tea during Processing

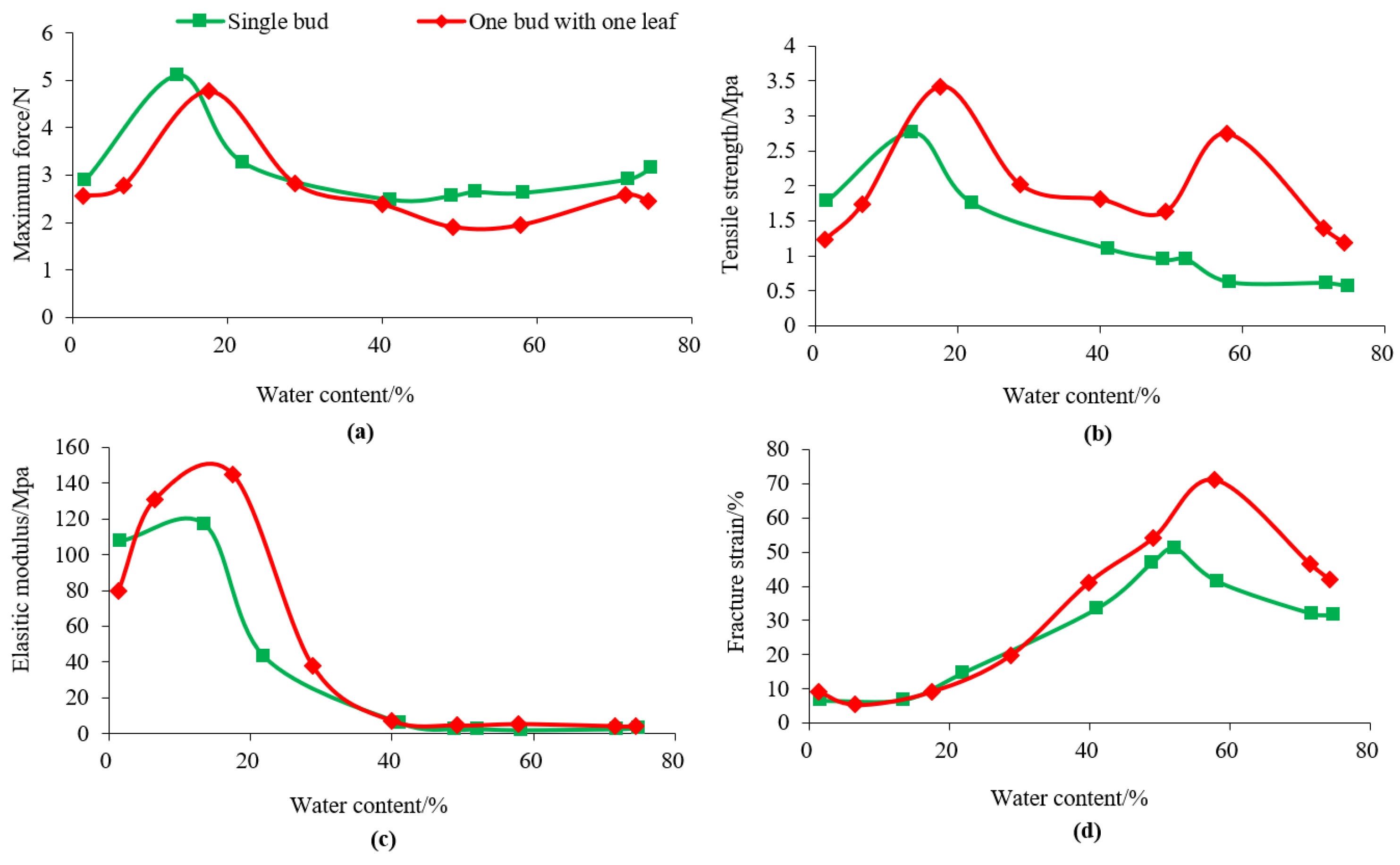

3.3. Changes in Tensile Properties of Longjing Tea during Processing

3.4. Correlation Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mao, Z.F. Top Ten Famous Teas in Zhejiang Province—West Lake Longjing; Agricultural Science and Technology Press: Beijing, China, 2011; pp. 31–55. [Google Scholar]

- Cui, H.C.; Zhang, J.Y.; Ao, C.; Huang, H.T.; Zheng, X.X.; Zhao, Y.; Shi, D.L.; Yu, J.Z. Difference Quality Characteristics of Xihu Longjing Tea with Different Processing Technology. Sci. Technol. Food Ind. 2021, 13, 268–273. [Google Scholar] [CrossRef]

- Pan, Y.N.; Zhang, L.Y.; Chen, P. Research Progress of Longjing Tea Processing Technology. J. Tea 2020, 46, 200–203. [Google Scholar]

- Tavakoli, H.; Mohtasebi, S.S.; Jafari, A. Effects of Moisture Content, Internode Position and Loading Rate on the Bending Characteristics of Barley Straw. Res. Agric. Eng. 2009, 46, 45–51. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.D.; Guo, W.B.; Wang, C.G.; Du, X.X.; Jin, M.; Wang, P.P.; Zhao, F.C. Research and Exploration of Mechanical Properties of Straw Materials. J. Agric. Mech. Res. 2019, 6, 265–268. [Google Scholar]

- Guo, Y.M.; Yuan, H.M.; Yin, Y.; Liang, L.; Li, H.B. Biomechanical Evaluation and Grey Relational Analysis of Lodging Resistance of Stalk Crops. Trans. Chin. Soc. Agric. Eng. 2007, 23, 14–18. [Google Scholar] [CrossRef]

- Ma, F.Z.; Liu, J.Z. Review on Mechanical Testing of Crop Stalks. J. Agric. Mech. Res. 2014, 36, 5–9. [Google Scholar] [CrossRef]

- GlozerKitren, F.; Ferguson, L.; Rich, R. Evaluation of Antioxidants to Reduce Physical Damage in Mechanically-Harvested ‘Manzanillo’ Olives. In Proceedings of the International Conferences on Plant Growth Substances, Puerto Vallarta, Mexico, 21–25 July 2007. [Google Scholar]

- Van Zeebroeck, M.; Tijskens, E. The discrete element method (DEM) to simulate fruit impact damage during transport and handling: Case study of vibration damage during apple bulk transport. Postharvest Biol. Technol. 2006, 41, 92–100. [Google Scholar] [CrossRef]

- Wu, T.X.; Abbott, J.A. Firmness and Force Relaxation Characteristics of Tomatoes Stored Intact or as Slices. Postharvest Biol. Technol. 2002, 24, 59–68. [Google Scholar] [CrossRef]

- Jin, X.Y. Tea Processing Engineering; China Agricultural Press: Beijing, China, 2014. [Google Scholar]

- Wang, X.H. Study on the Sieving Mechanism of Tea Plane-Surface Round Sifter. Master’s Thesis, Zhejiang University of Technology, Hangzhou, China, 2012. [Google Scholar]

- Zhang, Y.H.; Zhang, H.D.; Zhao, Y.Q.; Ning, W.Y. Study on Physical Characteristics of Yunnan Crude Tea. Hunan Agric. Sci. 2013, 4, 43–44. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.F.; Lin, H.Z.; Xu, X.Y.; Huang, Y.P.; Jin, X.Y. Research Progress on Oolong Tea Modeling Technology Based on the Mechanical Characteristics of Agricultural Materials. Subtrop. Agric. Res. 2019, 15, 138–143. [Google Scholar]

- Huang, F.; Wang, Y.; Xiong, Y.Y. Research Status and Development Trend of Mechanized Tea Picking Technology in China. Jiangsu Agric. Sci. 2019, 47, 48–51. [Google Scholar] [CrossRef]

- Yuan, H.B.; Hua, J.J.; Deng, Y.L.; Yin, J.F.; Jiang, Y.W. Mechanized Picking Technology of Famous Green Tea. China Tea 2018, 40, 4–9. [Google Scholar]

- Yu, L.Y. Current Situation and Development Suggestions of Mechanized Tea Picking and Pruning in Zhejiang Province. China Tea 2016, 38, 4–6. [Google Scholar]

- Nie, Y.C.; Chen, Y. Measurement of New Shoot Parameters and Mechanical Property Analysis of Plucking Fingers for High-quality Green Tea. Manuf. Autom. 2022, 44, 83–86. [Google Scholar]

- Luo, K.; Wu, Z.M.; Cao, C.M.; Qin, K.; Zhang, X.C.; Zhong, H. Design and Experiment of the Combined Pinch and Cut Picker for Tea Fresh Leaf Tips. Trans. Chin. Soc. Agric. Eng. 2022, 38, 1–9. [Google Scholar] [CrossRef]

- Zhang, Z.; Niu, Z.Y. The Changes of Physical Parameters in Tea Processing. J. Agric. Mech. Res. 2012, 8, 116–119+123. [Google Scholar] [CrossRef]

- Lin, Y.P. Experimental Study of Mechanical Properties and Their Influencing Factors for Oolong Tea Shape-Making Leaves. Master’s Thesis, Fujian Agriculture and Forestry University, Fuzhou, China, 2011. [Google Scholar]

- Li, C.; Ai, Z.Y.; Yu, Z.; Chen, Y.Q.; Ni, D.J. Research on Main Physical Properties of Tea Leaves in High-Quality Green Tea Processing. J. Tea Sci. 2019, 39, 705–714. [Google Scholar]

- Hirono, H.; Mizukami, Y. Dynamics of Water-Soluble Pectin in the Roasting Process During Green Tea Manufacturing. Food Sci. Technol. Res. 2018, 24, 177–181. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, X.; Zhang, F. Improving Viscosity and Gelling Properties of Leaf Pectin by Comparing Five Pectin Extraction Methods Using Green Tea Leaf as a Model Material. Food Hydrocoll. 2020, 98, 105246. [Google Scholar] [CrossRef]

- Zhang, Y.; Jin, X.Y.; Liu, W.; Lin, H.Z.; Huang, Y.P.; Zhou, Y.F.; Wang, J. Physicochemical and Aroma Quality Changes of Oolong Tea in Modeling Process under Different Forces Models. Sci. Technol. Food Ind. 2018, 39, 1–10+17. [Google Scholar] [CrossRef]

- Guo, L.; Yu, F.L.; Zhao, F.; Zhang, Y.; Zhu, Y.; Dai, W.D.; Dong, C.W.; Lin, Z. Correlation of Physical Properties of Granular Green Tea with Its Appearance Quality. Food Sci. 2020, 41, 25–30. [Google Scholar] [CrossRef]

- Ye, N.X. Research Methods of Tea Science; China Agricultural Press: Beijing, China, 2018. [Google Scholar]

- GB/T8304-2013; Tea-Determination of Moisture Content. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- Zhang, Z. Research on the Physical Properties and Moisture Sorption Isotherms of Tea Leaves. Master’s Thesis, Huazhong Agricultural University, Wuhan, China, 2012. [Google Scholar] [CrossRef]

- Feng, C.Y. Research and Application on Physical Properties of Tea Leaf Material. Master’s Thesis, Huazhong Agricultural University, Wuhan, China, 2013. [Google Scholar]

- Li, B. Studies on the Clean Processing Machines and the Technology of Liu’an Guapian Tea. Ph.D. Thesis, Anhui Agricultural University, Hefei, China, 2013. [Google Scholar]

- Luo, L.X. A Preliminary Study on the Relationship between Physical Properties of Fresh Leaves and Strip Formation. China Tea 1984, 4, 9–11. [Google Scholar]

- Chen, Z.G.; Wang, D.F.; Li, L.Q.; Shan, R.Q. Experiment on Tensile and Shearing Characteristics of Rind of Corn Stalk. Trans. Chin. Soc. Agric. Eng. 2012, 28, 59–65. [Google Scholar] [CrossRef]

- Khan, M.M.R.; Chen, Y.; Belsham, T.; Lague, C.; Landry, H.; Peng, Q.J.; Zhong, W. Fineness and Tensile Properties of Hemp (Cannabis sativa L.) Fibres. Biosyst. Eng. 2011, 108, 9–17. [Google Scholar] [CrossRef]

- Ni, D.J.; Zheng, Y.N.; Zhao, Y. Research and Application of Solid Theory of Famous Tea Processing. China Tea 2010, 32, 16–17. [Google Scholar] [CrossRef]

| Picking Standard | Fresh Tea Leaves | Spreading | Fixing | First Panning 1 | First Panning 2 | Final Panning 1 | Final Panning 2 | Final Panning 3 | Drying |

|---|---|---|---|---|---|---|---|---|---|

| I | 74.8 ± 0.2 | 71.8 ± 0.3 | 58.3 ± 1.8 | 52.1 ± 0.2 | 48.9 ± 0.1 | 42.1 ± 0.6 | 22.0 ± 1.6 | 13.5 ± 0.4 | 1.6 ± 0.2 |

| II | 74.3 ± 0.3 | 71.4 ± 0.8 | 57.8 ± 3.3 | 49.1 ± 0.9 | 40.0 ± 1.1 | 28.8 ± 0.5 | 17.5 ± 0.3 | 6.55 ± 0.1 | 1.3 ± 0.1 |

| Texture Properties | Picking Standard | Fresh Tea Leaves | Spreading | Fixing | First Panning 1 | First Panning 2 | Final Panning 1 | Final Panning 2 | Final Panning 3 | Drying |

|---|---|---|---|---|---|---|---|---|---|---|

| Plasticity | I | 31.6 d | 35.7 bc | 38.4 ab | 34.1 cd | 40.5 a | 40.5 a | 39.4 a | 26.4 e | 24.8 e |

| II | 37.7 ab | 39.2 a | 39.7 a | 37.7 ab | 38.8 ab | 36.5 ab | 35.1 b | 27.6 c | 26.6 c | |

| Elasticity | I | 25.1 bc | 20.3 d | 20.0 d | 23.5 c | 18.4 d | 18.5 d | 19.4 d | 29.4 a | 26.7 ab |

| II | 20.8 ab | 19.7 c | 19.9 c | 20.4 bc | 18.6 c | 20.0 c | 17.7 c | 24.2 a | 23.8 ab | |

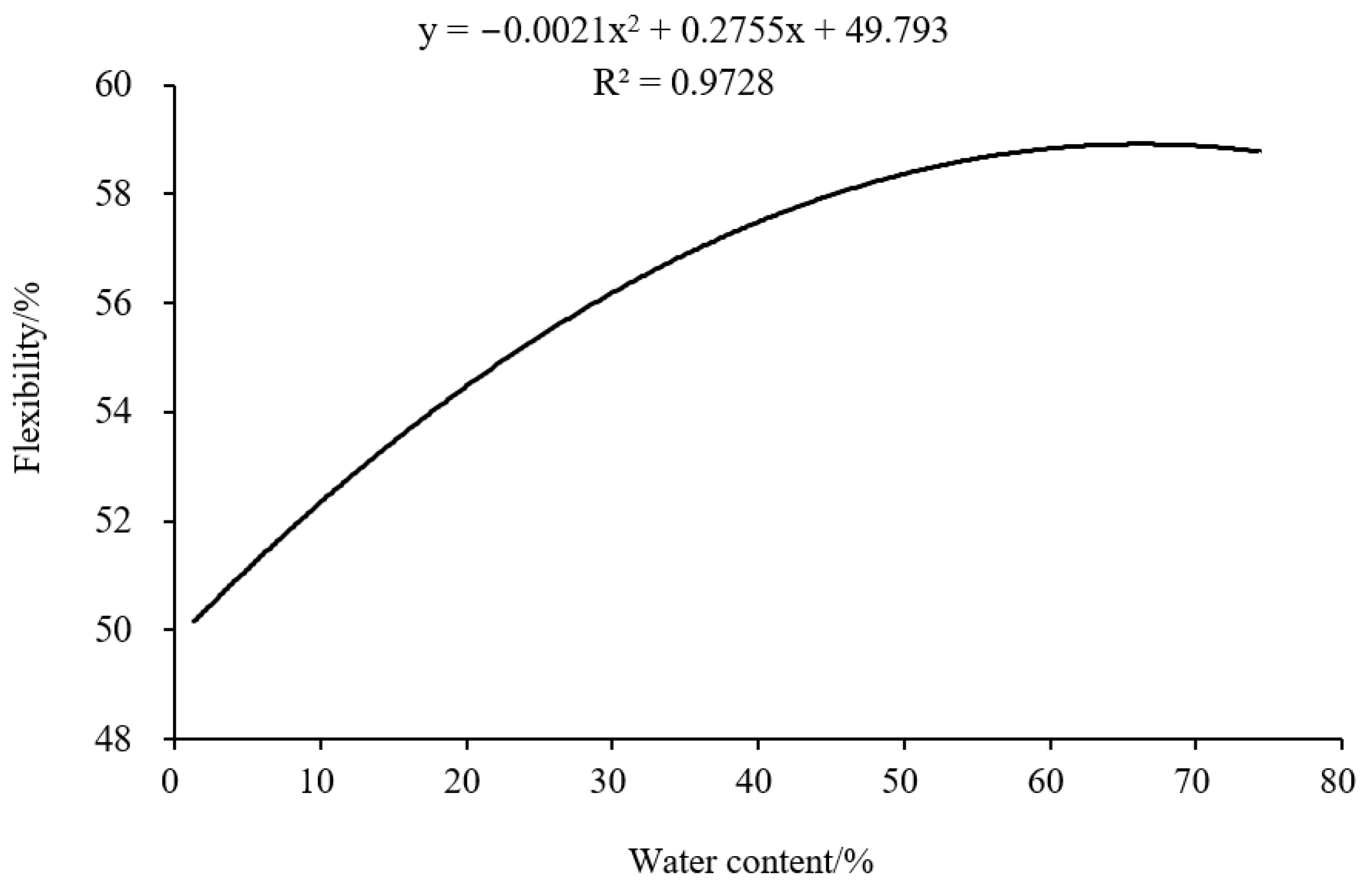

| Flexibility | I | 56.8 bc | 56.0 c | 58.5 ab | 57.6 ab | 58.9 a | 59.0 a | 58.9 a | 55.8 c | 51.5 d |

| II | 57.7 a | 58.8 a | 59.5 a | 58.0 a | 57.4 a | 56.5 a | 52.8 b | 51.8 b | 50.4 b |

| Texture Properties | Picking Standard | Fresh Tea Leaves | Spreading | Fixing | First Panning 1 | First Panning 2 | Final Panning 1 | Final Panning 2 | Final Panning 3 | Drying |

|---|---|---|---|---|---|---|---|---|---|---|

| Maximum Force | I | 3.15 bc | 2.91 bcd | 2.62 cd | 2.64 cd | 2.56 cd | 2.48 d | 3.26 b | 5.11 a | 2.89 bcd |

| II | 2.44 b | 2.57 b | 1.95 b | 1.91 b | 2.39 b | 2.82 b | 4.77 a | 2.78 b | 2.56 b | |

| Tensile Strength | I | 0.57 d | 0.61 d | 0.62 d | 0.95 c | 0.95 c | 1.10 c | 1.75 b | 2.76 a | 1.78 b |

| II | 1.18 d | 1.40 cd | 2.76 b | 1.63 cd | 1.81 cd | 2.02 c | 3.42 a | 1.74 cd | 1.24 d | |

| Elastic Modulus | I | 3.11 d | 2.72 d | 2.17 d | 2.55 d | 2.42 d | 5.77 d | 43.3 c | 117 a | 107 b |

| II | 4.12 d | 4.12 d | 5.19 d | 4.59 d | 7.23 d | 37.8 c | 145 a | 131 a | 79.8 b | |

| Fracture Strain | I | 31.6 c | 31.8 c | 41.2 b | 51.0 a | 47.0 a | 33.6 c | 14.5 d | 6.79 e | 6.57 e |

| II | 42.0 c | 46.7 bc | 71.3 a | 54.0 b | 41.2 c | 19.8 d | 9.01 e | 5.34 e | 9.22 e |

| Correlation Coefficient | Water Content | Plasticity | Elasticity | Flexibility | Maximum Force | Tensile Strength | Elastic Modulus | |

|---|---|---|---|---|---|---|---|---|

| Water Content | 1 | |||||||

| Plasticity | 0.465 | 1 | ||||||

| Elasticity | −0.418 | −0.958 ** | 1 | |||||

| Flexibility | 0.453 | 0.881 ** | −0.707 * | 1 | ||||

| Maximum Force | −0.431 | −0.583 * | 0.717 * | −0.252 | 1 | |||

| Tensile Strength | −0.876 ** | −0.541 | 0.596 | −0.349 | 0.797 | 1 | ||

| Elastic Modulus | −0.873 ** | −0.780 | 0.749 * | −0.685 | 0.717 | 0.909 ** | 1 | |

| Fracture Strain | 0.749 * | 0.632 | −0.575 * | 0.606 | −0.661 | −0.790 * | −0.884 * | 1 |

| Correlation Coefficient | Water Content | Plasticity | Elasticity | Flexibility | Maximum Force | Tensile Strength | Elastic Modulus | |

|---|---|---|---|---|---|---|---|---|

| Water Content | 1 | |||||||

| Plasticity | 0.837 ** | 1 | ||||||

| Elasticity | −0.450 | −0.817 ** | 1 | |||||

| Flexibility | 0.927 ** | 0.930 ** | −0.548 | 1 | ||||

| Maximum Force | −0.434 | −0.208 | −0.331 | −0.513 | 1 | |||

| Tensile Strength | −0.201 | 0.207 | −0.565 | −0.061 | 0.619 | 1 | ||

| Elastic Modulus | −0.816 ** | −0.725 * | 0.279 | −0.875 ** | 0.765 * | 0.423 | 1 | |

| Fracture Strain | 0.829 ** | 0.793 * | −0.393 | 0.901 ** | −0.651 | −0.034 | −0.850 ** | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Wang, X.; Zhang, D.; Chen, Y.; Jiang, X.; Ni, D. Study on the Variation Law of the Main Mechanical Properties in the Processing of Longjing Tea. Foods 2023, 12, 2587. https://doi.org/10.3390/foods12132587

Li C, Wang X, Zhang D, Chen Y, Jiang X, Ni D. Study on the Variation Law of the Main Mechanical Properties in the Processing of Longjing Tea. Foods. 2023; 12(13):2587. https://doi.org/10.3390/foods12132587

Chicago/Turabian StyleLi, Chen, Xiaoyong Wang, De Zhang, Yuqiong Chen, Xinfeng Jiang, and Dejiang Ni. 2023. "Study on the Variation Law of the Main Mechanical Properties in the Processing of Longjing Tea" Foods 12, no. 13: 2587. https://doi.org/10.3390/foods12132587