Yield and Technological Quality of Pirarucu Trimming Surimi According to the Number of Washing Cycles, Rice Flour Content, and Cooking Temperature

Abstract

:1. Introduction

2. Materials and Methods

2.1. Obtaining Raw Material, Ingredients, and Reagents

2.2. Proximate Composition of Raw Materials and Surimi

2.3. Thermal and Pasting Properties of RF

2.4. Preliminary Tests

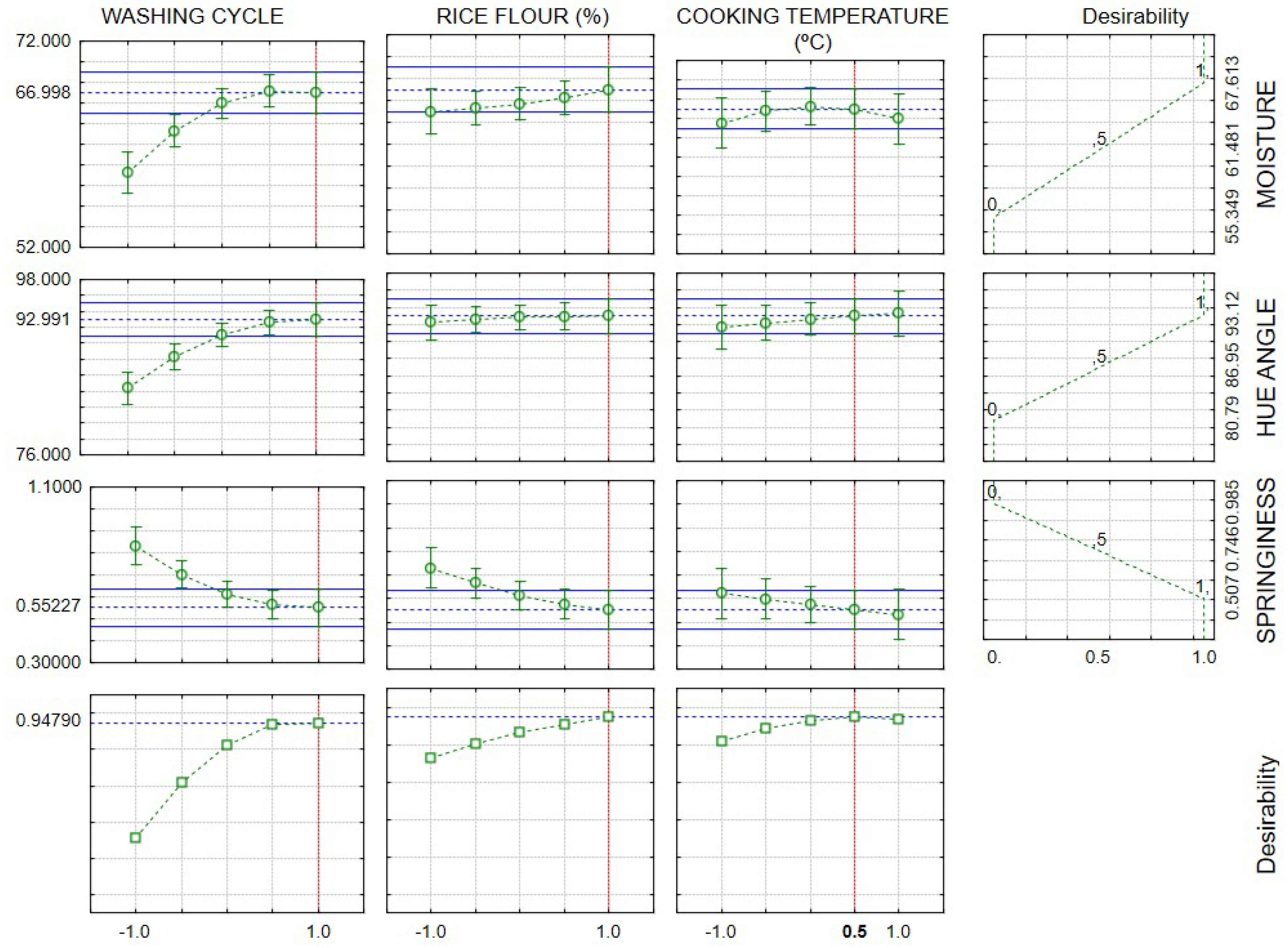

2.5. Box–Behnken Design to Optimize Surimi Quality

2.6. Instrumental Color Analysis of Surimi

2.7. Texture Profile

2.8. Freeze–Thaw Stability

2.9. Statistical Analysis

3. Results

3.1. Proximate Composition, RF Thermal, and Paste Properties

3.2. Proximate Composition of Pirarucu Trimmings

3.3. Yield and Physical, Chemical, and Technological Quality Evaluation of Pirarucu Trimming Surimi

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- IBGE—Instituto Brasileiro de Geografia e Estatistica. Pesquisa Pecuária Municipal—Produção da Aquicultura. 2021. Available online: https://sidra.ibge.gov.br/tabela/3940#resultado/ (accessed on 1 July 2023).

- Valladão, G.M.R.; Gallani, S.U.; Pilarski, F. South American fish for continental aquaculture. Rev. Aquac. 2018, 10, 351–369. [Google Scholar] [CrossRef]

- Mazorra-Manzano, M.A.; Ramírez-Suárez, J.C.; Moreno-Hernández, J.M.; Pacheco-Aguilar, R. Seafood Proteins, 2nd ed.; Elsevier: New York, NY, USA, 2017. [Google Scholar]

- Priyadarshini, B.; Xavier, M.; Nayak, B.B.; Apang, T.; Balange, A.K. Quality characteristics of tilapia surimi: Effect of single washing cycle and different washing media. J. Aquat. Food Prod. Technol. 2018, 27, 643–655. [Google Scholar] [CrossRef]

- Guo, X.; Shi, L.; Xiong, S.; Hu, Y.; You, J.; Huang, Q.; Yin, T. Gelling properties of vacuum-freeze dried surimi powder as influenced by heating method and microbial transglutaminase. LWT—Food Sci. Technol. 2019, 99, 105–111. [Google Scholar] [CrossRef]

- Li, T.; Zhao, J.; Huang, J.; Zhang, W.; Huang, J.; Fan, D.; Zhang, H. Improvement of the quality of surimi products with overdrying potato starches. J. Food Qual. 2017, 2017, 1417856. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Chen, H.; Lyu, F.; Lin, H.; Zhang, Q.; Ding, Y. Physicochemical properties and microstructure of fish myofibrillar protein-lipid composite gels: Effects of fat type and concentration. Food Hydrocoll. 2019, 90, 433–442. [Google Scholar] [CrossRef]

- Lin, W.; Han, Y.; Liu, F.; Huang, H.; Li, L.; Yang, S.; Yang, X.; Wu, Y. Effect of lipid on surimi gelation properties of the three major Chinese carp. J. Sci. Food Agr. 2020, 100, 4671–4677. [Google Scholar] [CrossRef]

- Fogaça, F.H.; Sant’ana, L.S.; Lara, J.A.F.; Mai, A.C.G.; Carneiro, D.J. Restructured products from tilapia industry byproducts: The effects of tapioca starch and washing cycles. Food Bioprod. Process. 2015, 94, 482–488. [Google Scholar] [CrossRef] [Green Version]

- Fan, M.; Hu, T.; Zhao, S.; Xiong, S.; Xie, J.; Huang, Q. Gel characteristics and microstructure of fish myofibrillar protein/cassava starch composites. Food Chem. 2017, 218, 221–230. [Google Scholar] [CrossRef]

- Jia, R.; Katano, T.; Yoshimoto, Y.; Gao, Y.; Watanabe, Y.; Nakazawa, N.; Osako, K.; Okazaki, E. Sweet potato starch with low pasting temperature to improve the gelling quality of surimi gels after freezing. Food Hydrocoll. 2018, 81, 467–473. [Google Scholar] [CrossRef]

- Jia, R.; Katano, T.; Yoshimoto, Y.; Gao, Y.; Nakazawa, N.; Osako, K.; Okazaki, E. Effect of small granules in potato starch and wheat starch on quality changes of direct heated surimi gels after freezing. Food Hydrocoll. 2020, 104, 105732. [Google Scholar] [CrossRef]

- Oliveira, D.L.; Grassi, T.L.M.; Santo, E.F.E.; Cavazzana, J.F.; Marcos, M.T.S.; Ponsano, E.H.G. Washings and cryoprotectants for the production of tilapia surimi. Food Sci. Technol. 2017, 37, 432–436. [Google Scholar] [CrossRef] [Green Version]

- Bassinello, P.Z.; Ferreira, C.M. Farinha de Arroz: Alternativa Alimentar e Econômica. 2017. Available online: https://ainfo.cnptia.embrapa.br/digital/bitstream/item/169295/1/CNPAF-2017-doc315.pdf/ (accessed on 2 May 2023).

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis, 20th ed.; AOAC: Gaithersburg, MD, USA, 2016. [Google Scholar]

- International Code Council (ICC). Standard 162—Rapid Pasting Method Using the Newport Rapid Viscoanalyser, 1st ed.; ICC: Vienna, VA, USA, 1996. [Google Scholar]

- Beg, S.; Akhter, S. Box-Behnken Designs and Their Applications in Pharmaceutical Product Development. In Design of Experiments for Pharmaceutical Product Development; Beg, S., Ed.; Springer: Singapore, 2021. [Google Scholar]

- Oliveira, A.R.; Ribeiro, A.E.C.; Oliveira, E.R.; Mendes, A.C.S.; Júnior, M.S.S.; Caliari, M. Broken rice grains pregelatinized flours incorporated with lyophilized açaí pulp and the effect of extrusion on their physicochemical properties. J. Food Sci. Technol. 2019, 56, 1337–1348. [Google Scholar] [CrossRef]

- Park, J.A.E.W. Functional protein additives in surimi gels. J. Food Sci. 1994, 59, 525–527. [Google Scholar] [CrossRef]

- Priyadarshini, B.; Xavier, K.A.M.; Nayak, B.B.; Dhanapal, K.; Balange, A.K. Instrumental quality attributes of single washed surimi gels of tilapia: Effect of different washing media. LWT—Food Sci. Technol. 2017, 86, 385–392. [Google Scholar] [CrossRef]

- BRAZIL—Ministry of Agriculture, Livestock and Supply. Regulamento Técnico de Identidade e Qualidade da Farinha de Trigo. 2005. Available online: https://sistemasweb.agricultura.gov.br/sislegis/action/detalhaAto.do?method=visualizarAtoPortalMapa&chave=803790937/ (accessed on 25 April 2023).

- Fitriani, V.; Permana, L.; Setiaboma, W. Chemical and physical charaterization of cereal flakes formulated with broken rice and banana flour. IOP Conf. Ser. Earth Environ. Sci. 2019, 258, 012003. [Google Scholar] [CrossRef]

- Dautant, F.J.; Simancas, K.; Sandoval, A.J.; Muller, A.J. Effect of temperature, moisture and lipid content on the rheological properties of rice flour. J. Food Eng. 2007, 78, 1159–1166. [Google Scholar] [CrossRef]

- Pereira, J.; Zhou, G.H.; Zhang, W.G. Effects of rice flour on emulsion stability, organoleptic characteristics and thermal rheology of emulsified sausage. J. Food Nutr. Res. 2016, 4, 216–222. [Google Scholar] [CrossRef]

- Lin, Q.; Xiao, H.; Fu, X.; Tian, W.; Li, L.; Yu, F. Physico-chemical properties of flour, starch, and modified starch of two rice varieties. Agric. Sci. China. 2011, 10, 960–968. [Google Scholar] [CrossRef]

- Ahmed, I.; Qazi, I.M.; Jamal, S. Assessment of proximate compositions and functional properties of blends of broken rice and wheat flours. Sarhad J. Agric. 2016, 32, 142–150. [Google Scholar] [CrossRef]

- Ascheri, D.P.R.; Cavalcante, L.H.; Ascheri, J.L.R.; de Carvalho, C.W.P. Physical-chemical characterization of pre-cooked mixed rice flour and barley bagasse. Semin. Cienc. Agr. 2016, 37, 737–750. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Sokhansanj, S.; Bandyopadhway, S.; Bawa, A.S. Changes in moisture, protein, and fat content of fish and rice flour coextrudates during single-screw extrusion cooking. Food Bioprocess Technol. 2013, 6, 403–415. [Google Scholar] [CrossRef]

- Walter, M.; Marchezan, E.; Avila, L.A. Arroz: Composição e características nutricionais. Ciênc. Rural. 2008, 38, 1184–1192. [Google Scholar] [CrossRef] [Green Version]

- Hasjim, J.; Li, E.; Dhital, S. Milling of rice grains: Effects of starch/flour structures on gelatinization and pasting properties. Carbohydr. Polym. 2013, 92, 682–690. [Google Scholar] [CrossRef]

- Setyawati, J.D.; Ahsan, S.F.; Ong, L.K.; Soetaredjo, F.E.; Ismadji, S.; Ju, Y. Production of glutinous rice flour from broken rice via ultrasonic assisted extraction of amylose. Food Chem. 2016, 203, 158–164. [Google Scholar] [CrossRef] [PubMed]

- Li, E.; Dhital, S.; Hasjim, J. Effects of grain milling on starch structures and flour/starch properties. Starch-Stärke 2014, 66, 15–27. [Google Scholar] [CrossRef]

- Asmeda, R.; Noorlaila, A.; Norziah, M.H. Relationships of damaged starch granules and particle size distribution with pasting and thermal profiles of milled MR263 rice flour. Food Chem. 2016, 191, 45–51. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.M.; Shin, M. Effects of particle size distributions of rice flour on the quality of gluten-free rice cupcakes. LWT—Food Sci. Technol. 2014, 59, 526–532. [Google Scholar] [CrossRef]

- Kong, W.; Zhang, T.; Feng, D.; Xue, Y.; Wang, Y.; Li, Z.; Yang, W.; Xue, C. Effects of modified starches on the gel properties of Alaska Pollock surimi subjected to different temperature treatments. Food Hydrocoll. 2016, 56, 20–28. [Google Scholar] [CrossRef]

- Hunt, A.; Getty, K.J.K.; Park, J.W. Roles of Starch in Surimi Seafood: A Review. Food Rev. Int. 2009, 25, 299–312. [Google Scholar] [CrossRef]

- Coutinho, N.M.; Canto, A.C.V.C.S.; Mársico, E.T.; Silva, F.A.; Keller, L.A.M.; Conte-Junior, C.A.; Monteiro, M.L.G. Fatty acid composition and influence of temperature on the lipid stability of Arapaima gigas meat. Braz. J. Food Technol. 2019, 22, e2018132. [Google Scholar] [CrossRef]

- Martins, M.G.; Martins, D.E.G.; Pena, R.S. Chemical composition of different muscle zones in pirarucu (Arapaima gigas). Food Sci. Technol. 2017, 37, 651–656. [Google Scholar] [CrossRef] [Green Version]

- Santos, J.D.S.L.; Mársico, E.T.; Cinquini, M.A.; Silva, F.A.; Junior, C.A.C.; Monteiro, M.L.G. Physicochemical and sensory characterization of three different portions from commercial pirarucu (Arapaima gigas) fillets. Braz. J. Food Technol. 2018, 21, e2017178. [Google Scholar] [CrossRef]

- Hamzah, N.; Sarbon, N.M.; Amin, A.M. Physical properties of cobia (Rachycentron canadum) surimi: Effect of washing cycle at different salt concentrations. J. Food Sci. Technol. 2015, 52, 4773–4784. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Endoma, L.F.; Gabo, J.H.C.; Sargadillos, R.M.; Condrillon, C.G.; Francisco, W.A.; Daet, I.P.; Silaya, F.C.; Monaya, K.J.M.; Muegue, M.F.S. Physico-chemical properties and sensory quality of surimi from bigtooth pomfret (Brama orcini) at different washing cycles. Food Res. 2022, 6, 266–274. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.A.; Balange, A.K.; Senapati, S.R.; Xavier, K.A.M. Effect of different washing cycles on the quality of Pangasius hypophthalmus surimi. Fish. Technol. 2017, 54, 51–59. [Google Scholar]

- Surasani, V.K.R. Acid and alkaline solubilization (pH shift) process: A better approach for the utilization of fish processing waste and by-products. Environ. Sci. Poll. Res. 2018, 25, 18345–18363. [Google Scholar] [CrossRef]

- Fogaça, F.H.S.; Trinca, L.A.; Bombo, A.J.; Sant’ana, L.S. Optimization of the surimi production from mechanically recovered fish meat (MRFM) using response surface methodology. J. Food Qual. 2013, 36, 209–216. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.; Chen, Q.; Kong, B.; Han, J.; He, X. The influence of superchilling and cryoprotectants on protein oxidation and structural changes in the myofibrillar proteins of common carp (Cyprinus carpio) surimi. LWT—Food Sci. Technol. 2014, 57, 603–611. [Google Scholar] [CrossRef]

- Priyadarshana, M.K.C.; Walpita, C.N. Study of the best washing cycle for processing of surimi from the amblygaster sirm fish. In Proceedings of the ICSUSL (International Conference of Sabaragamuwa University of Sri Lanka), Belihuloya, Sri Lanka, 6–8 December 2019. [Google Scholar]

- Liu, H.; Nie, Y.; Chen, H. Effect of different starches on colors and textural properties of surimi-starch gels. Int. J. Food Prop. 2014, 17, 1439–1448. [Google Scholar] [CrossRef]

- Petcharat, T.; Benjakul, S. Effect of gellan incorporation on gel properties of bigeye snapper surimi. Food Hydrocoll. 2018, 77, 746–753. [Google Scholar] [CrossRef]

| Experiments | Coded Variables | Actual Variables | ||||

|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X1 | X2 | X3 | |

| 1 | −1 | −1 | 0 | 1 | 2 | 70 |

| 2 | −1 | 1 | 0 | 1 | 8 | 70 |

| 3 | 1 | −1 | 0 | 5 | 2 | 70 |

| 4 | 1 | 1 | 0 | 5 | 8 | 70 |

| 5 | 0 | 0 | 0 | 3 | 5 | 70 |

| 6 | −1 | 0 | −1 | 1 | 5 | 55 |

| 7 | −1 | 0 | 1 | 1 | 5 | 95 |

| 8 | 1 | 0 | −1 | 5 | 5 | 55 |

| 9 | 1 | 0 | 1 | 5 | 5 | 95 |

| 10 | 0 | 0 | 0 | 3 | 5 | 70 |

| 11 | 0 | −1 | −1 | 3 | 2 | 55 |

| 12 | 0 | −1 | 1 | 3 | 2 | 95 |

| 13 | 0 | 1 | −1 | 3 | 8 | 55 |

| 14 | 0 | 1 | 1 | 3 | 8 | 95 |

| 15 | 0 | 0 | 0 | 3 | 5 | 70 |

| Properties | Values |

|---|---|

| Gelatinization initial temperature 1 | 60.12 ± 0.53 |

| Gelatinization peak temperature 1 | 63.88 ± 0.00 |

| Gelatinization final temperature 1 | 69.71 ± 0.04 |

| Gelatinization enthalpy (ΔH) 2 | 5.72 ± 0.06 |

| Pasting temperature 2 | 65.20 ± 0.07 |

| Peak viscosity 3 | 212.50 ± 0.82 |

| Breakdown viscosity 3 | 169.67 ± 0.59 |

| Tendency to retrogradation 3 | 148.13 ± 3.95 |

| Final viscosity 3 | 317.79 ± 3.36 |

| Treatments | Actual Variables | Response Variables | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| x1 | x2 | x3 | Yield (%) | Moisture (%) | Protein (%) | Lipids (%) | Hue (°) | Chroma (Dimensionless) | Whiteness (%) | |

| 1 | 1 | 2 | 70 | 90.26 | 56.00 ± 0.23 | 11.84 ± 0.59 | 27.31 ± 0.98 | 80.79 ± 0.54 | 12.86 ± 0.62 | 49.26 ± 2.23 |

| 2 | 1 | 8 | 70 | 89.88 | 59.73 ± 0.44 | 10.75 ± 0.42 | 29.38 ± 0.55 | 83.13 ± 0.85 | 13.18 ± 0.67 | 46.73 ± 2.25 |

| 3 | 5 | 2 | 70 | 87.57 | 64.87 ± 0.50 | 9.50 ± 0.20 | 34.65 ± 0.70 | 93.12 ± 0.67 | 9.80 ± 0.46 | 60.02 ± 1.72 |

| 4 | 5 | 8 | 70 | 80.29 | 67.61 ± 0.27 | 9.74 ± 0.24 | 31.24 ± 0.75 | 92.99 ± 0.84 | 9.00 ± 0.30 | 62.65 ±1.21 |

| 5 | 3 | 5 | 70 | 88.60 | 64.71 ± 0.18 | 10.17 ± 0.21 | 30.20 ± 0.78 | 88.98 ± 0.49 | 9.92 ± 0.54 | 58.95 ± 2.41 |

| 6 | 1 | 5 | 55 | 92.39 | 55.35 ± 0.54 | 11.55 ± 0.33 | 32.36 ± 0.55 | 81.95 ± 2.00 | 11.07 ± 0.41 | 55.86 ± 2.01 |

| 7 | 1 | 5 | 95 | 89.52 | 56.31 ± 0.10 | 11.88 ± 0.41 | 34.33 ± 1.69 | 83.83 ± 0.54 | 11.27 ± 0.41 | 55.68 ± 1.30 |

| 8 | 5 | 5 | 55 | 77.55 | 65.00 ± 0.59 | 10.42 ± 0.25 | 33.90 ± 0.87 | 91.99 ± 0.85 | 8.86 ± 0.40 | 64.45 ± 1.53 |

| 9 | 5 | 5 | 95 | 77.09 | 64.36 ± 0.94 | 9.09 ± 0.27 | 35.03 ± 0.04 | 92.46 ± 0.95 | 9.10 ± 0.29 | 63.00 ± 1.15 |

| 10 | 3 | 5 | 70 | 93.07 | 65.16 ± 0.48 | 7.15 ± 0.15 | 29.35 ± 6.87 | 90.37 ± 0.47 | 10.24 ± 0.44 | 58.50 ± 1.66 |

| 11 | 3 | 2 | 55 | 84.04 | 62.10 ± 0.35 | 8.90 ± 0.36 | 25.43 ± 0.67 | 89.39 ± 1.34 | 9.30 ± 0.44 | 63.24 ± 1.94 |

| 12 | 3 | 2 | 95 | 90.80 | 63.23 ± 0.85 | 9.94 ± 0.47 | 23.19 ± 1.19 | 88.68 ± 1.66 | 9.20 ± 0.48 | 62.52 ± 1.90 |

| 13 | 3 | 8 | 55 | 89.20 | 63.06 ± 0.35 | 8.82 ± 0.40 | 22.70 ± 0.39 | 89.39 ± 1.15 | 9.34 ± 0.40 | 61.90 ± 0.40 |

| 14 | 3 | 8 | 95 | 91.45 | 65.01 ± 0.52 | 8.80 ± 0.34 | 18.02 ± 0.88 | 91.48 ± 0.79 | 9.50 ± 0.35 | 59.14 ± 3.05 |

| 15 | 3 | 5 | 70 | 89.95 | 63.92 ± 0.84 | 9.16 ± 0.27 | 20.74 ± 0.14 | 90.89 ± 0.43 | 9.68 ± 0.41 | 60.59 ± 1.62 |

| Treatments | Actual Variables | Response Variables | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| x1 | x2 | x3 | Hardness (N) | Elasticity (Ratio) | Cohesiveness (Ratio) | Gumminess (N) | Chewiness (N × mm) | Adhesiveness (Ratio) | 1 Week (%) | 4 Week (%) | |

| 1 | 1 | 2 | 70 | 4.89 ± 0.13 | 0.98 ± 0.01 | 0.56 ± 0.09 | 2.74 ± 0.39 | 2.68 ± 0.38 | 0.92 ± 0.13 | 96.67 ± 0.07 | 96.53 ± 0.15 |

| 2 | 1 | 8 | 70 | 4.52 ± 0.20 | 0.98 ± 0.01 | 0.49 ± 0.03 | 2.20 ± 0.15 | 2.15 ± 0.15 | 0.78 ± 0.06 | 90.46 ± 0.05 | 87.65 ± 2.03 |

| 3 | 5 | 2 | 70 | 5.00 ± 0.26 | 0.97 ± 0.03 | 0.55 ± 0.04 | 2.73 ± 0.15 | 2.64 ± 0.11 | 0.72 ± 0.06 | 89.24 ± 0.81 | 88.81 ± 2.00 |

| 4 | 5 | 8 | 70 | 4.27 ± 0.11 | 0.96 ± 0.02 | 0.61 ± 0.04 | 2.60 ± 0.12 | 2.50 ± 0.14 | 0.59 ± 0.07 | 88.63 ± 0.90 | 85.16 ± 0.48 |

| 5 | 3 | 5 | 70 | 5.16 ± 0.27 | 0.98 ± 0.02 | 0.45 ± 0.02 | 2.32 ± 0.23 | 2.27 ± 0,17 | 0.67 ± 0.07 | 81.79 ± 0.45 | 88.97 ± 2.54 |

| 6 | 1 | 5 | 55 | 6.15 ± 0.23 | 0.99 ± 0.00 | 0.40 ± 0.05 | 2.45 ± 0.25 | 2.44 ± 0.25 | 0.64 ± 0.07 | 96.11 ± 0.14 | 96.31 ± 0.39 |

| 7 | 1 | 5 | 95 | 4.21 ± 0.08 | 0.97 ± 0.02 | 0.59 ± 0.15 | 2.48 ± 0.60 | 2.40 ± 0.55 | 0.99 ± 0.14 | 96.08 ± 0.14 | 95.71 ± 0.32 |

| 8 | 5 | 5 | 55 | 4.46 ± 0.15 | 0.97 ± 0.02 | 0.56 ± 0.04 | 2.51 ± 0.27 | 2.45 ± 0.27 | 0.68 ± 0.03 | 82.91 ± 1.48 | 85.33 ± 1.25 |

| 9 | 5 | 5 | 95 | 5.43 ± 0.20 | 0.97 ± 0.02 | 0.50 ± 0.03 | 2.72 ± 0.22 | 2.62 ± 0.21 | 0.60 ± 0.05 | 91.22 ± 2.01 | 88.54 ± 1.26 |

| 10 | 3 | 5 | 70 | 5.19 ± 0.28 | 0.98 ± 0.03 | 0.49 ± 0.06 | 2.52 ± 0.28 | 2.47 ± 0.25 | 0.64 ± 0.06 | 90.34 ± 1.10 | 91.19 ± 0.69 |

| 11 | 3 | 2 | 55 | 3.93 ± 0.11 | 0.95 ± 0.00 | 0.43 ± 0.02 | 1.68 ± 0.07 | 1.60 ± 0.06 | 0.74 ± 0.06 | 86.36 ± 1.03 | 88.68 ± 0.38 |

| 12 | 3 | 2 | 95 | 6.31 ± 0.19 | 0.97 ± 0.02 | 0.48 ± 0.01 | 3.03 ± 0.14 | 2.93 ± 0.16 | 0.85 ± 0.14 | 90.49 ± 2.57 | 94.96 ± 0.03 |

| 13 | 3 | 8 | 55 | 3.96 ± 0.15 | 0.98 ± 0.02 | 0.48 ± 0.09 | 1.92 ± 0.40 | 1.88 ± 0.38 | 0.51 ± 0.07 | 87.83 ± 0.96 | 90.95 ± 1.13 |

| 14 | 3 | 8 | 95 | 4.55 ± 0.22 | 0.96 ± 0.01 | 0.55 ± 0.07 | 2.48 ± 0.29 | 2.38 ± 0.28 | 0.62 ± 0.04 | 90.16 ± 0.16 | 88.52 ± 0.98 |

| 15 | 3 | 5 | 70 | 6.05 ± 0.32 | 0.95 ± 0.01 | 0.51 ± 0.08 | 3.10 ± 0.45 | 2.95 ± 0.43 | 0.63 ± 0.10 | 88.19 ± 1.36 | 89.12 ± 1.96 |

| Responses | Adjusted Model | p | R2 | LA |

|---|---|---|---|---|

| Moisture | y = 64.77 + 4.31x1 − 2.84 x12 + 1.15x2 − 1.54x32 | 0.0039 | 0.97 | 0.41 |

| Lipids | y = 26.40 + 7.77 x12 − 3.80x22 | 0.038 | 0.71 | 0.96 |

| Proteins | y = 11.213 − 0.456x1 | 0.000 | 0.86 | 0.99 |

| Whiteness | y = 58.51 + 5.32x1 − 3.21x12 + 3.82x32 | 0.022 | 0.89 | 0.24 |

| Chroma | y = 10.11 − 1.45x1 + 0.98 x12 − 0.89x32 | 0.0016 | 0.93 | 0.32 |

| Hue angle | y = 80.97 + 2.56x1 | 0.000000 | 0.95 | 0.57 |

| Cohesiveness | y = 0.483 + 0.022x1 + 0.049x12 + 0.030x3 + 0.034x1x2 − 0.063x1x3 | 0.024 | 0.82 | 0.60 |

| Springiness | y = 0.665 − 0.091x1 + 0.075x12 − 0.092x2 + 0.062x3 − 0.106x1x3 | 0.00038 | 0.96 | 0.33 |

| Freeze stability | y = 90.43 − 3.54x1 − 2.09x2 | 0.025 | 0.68 | 0.22 |

| yield | y = 94.86 − 2.4717x1 | 0.003 | 0.51 | 0.36 |

| Parameters | Actual Value (Experimental) | Model Value (Predicted) | % Error |

|---|---|---|---|

| Yield (%) | 74.73 | 89.59 | 20% |

| Moisture (%) | 66.27 | 62.17 | 6% |

| Lipids (%) | 15.93 | 20.93 | 31% |

| Proteins (%) | 8.38 | 8.99 | 7% |

| Whiteness (%) | 56.15 | 61.54 | 10% |

| Chroma (dimensionless) | 10.45 | 9.41 | 10% |

| Hue angle (°) | 93.08 | 89.88 | 3% |

| Cohesiveness (ratio) | 0.46 | 0.46 | 1% |

| Springiness (ratio) | 0.47 | 0.72 | 54% |

| Freeze–thaw stability after 4 weeks (%) | 91.60 | 92.94 | 1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Magalhães, G.L.; Soares Júnior, M.S.; Caliari, M.; Monteiro, M.L.G.; Mársico, E.T. Yield and Technological Quality of Pirarucu Trimming Surimi According to the Number of Washing Cycles, Rice Flour Content, and Cooking Temperature. Foods 2023, 12, 2748. https://doi.org/10.3390/foods12142748

Magalhães GL, Soares Júnior MS, Caliari M, Monteiro MLG, Mársico ET. Yield and Technological Quality of Pirarucu Trimming Surimi According to the Number of Washing Cycles, Rice Flour Content, and Cooking Temperature. Foods. 2023; 12(14):2748. https://doi.org/10.3390/foods12142748

Chicago/Turabian StyleMagalhães, Gabriella Leite, Manoel Soares Soares Júnior, Márcio Caliari, Maria Lúcia Guerra Monteiro, and Eliane Teixeira Mársico. 2023. "Yield and Technological Quality of Pirarucu Trimming Surimi According to the Number of Washing Cycles, Rice Flour Content, and Cooking Temperature" Foods 12, no. 14: 2748. https://doi.org/10.3390/foods12142748