Toward the Development of Potentially Healthy Low-Energy-Density Snacks for Children Based on Pseudocereal and Pulse Flours

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Flour Characterization

2.2.1. Proximate Composition and Energy Intake

2.2.2. Mineral Composition

2.2.3. Particle Size Analysis

2.2.4. Functional Properties

2.3. Experimental Design and Processing of Cracker-Type Snacks

2.4. Analysis of Cracker-Type Snacks

2.4.1. Physicochemical Analysis

2.4.2. Snack Firmness

2.4.3. Optical Properties

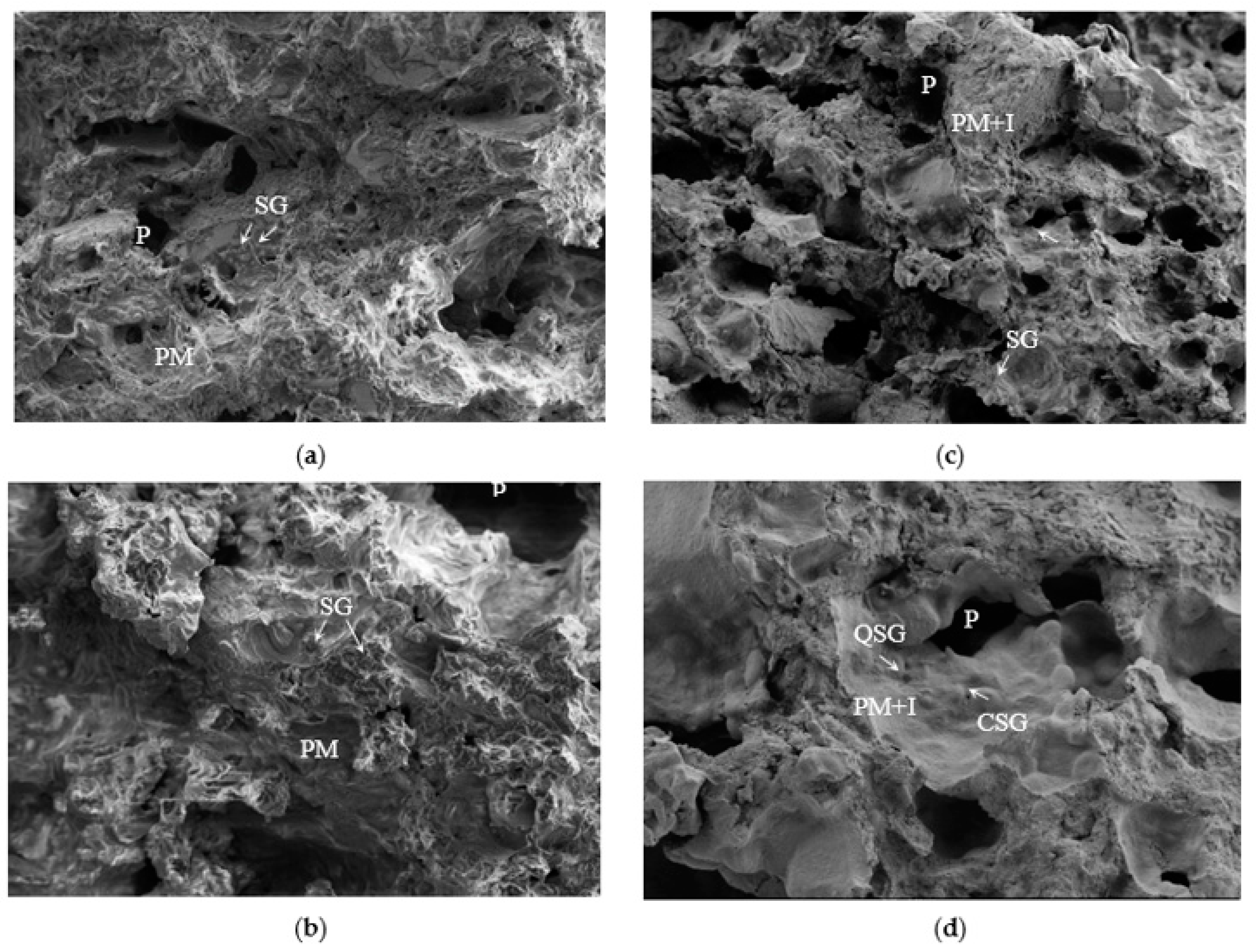

2.4.4. Microstructure

2.4.5. Sensory Evaluation

2.5. Statistical Analysis

3. Results

3.1. Flour Characterization

3.1.1. Proximate Composition and Mineral Content

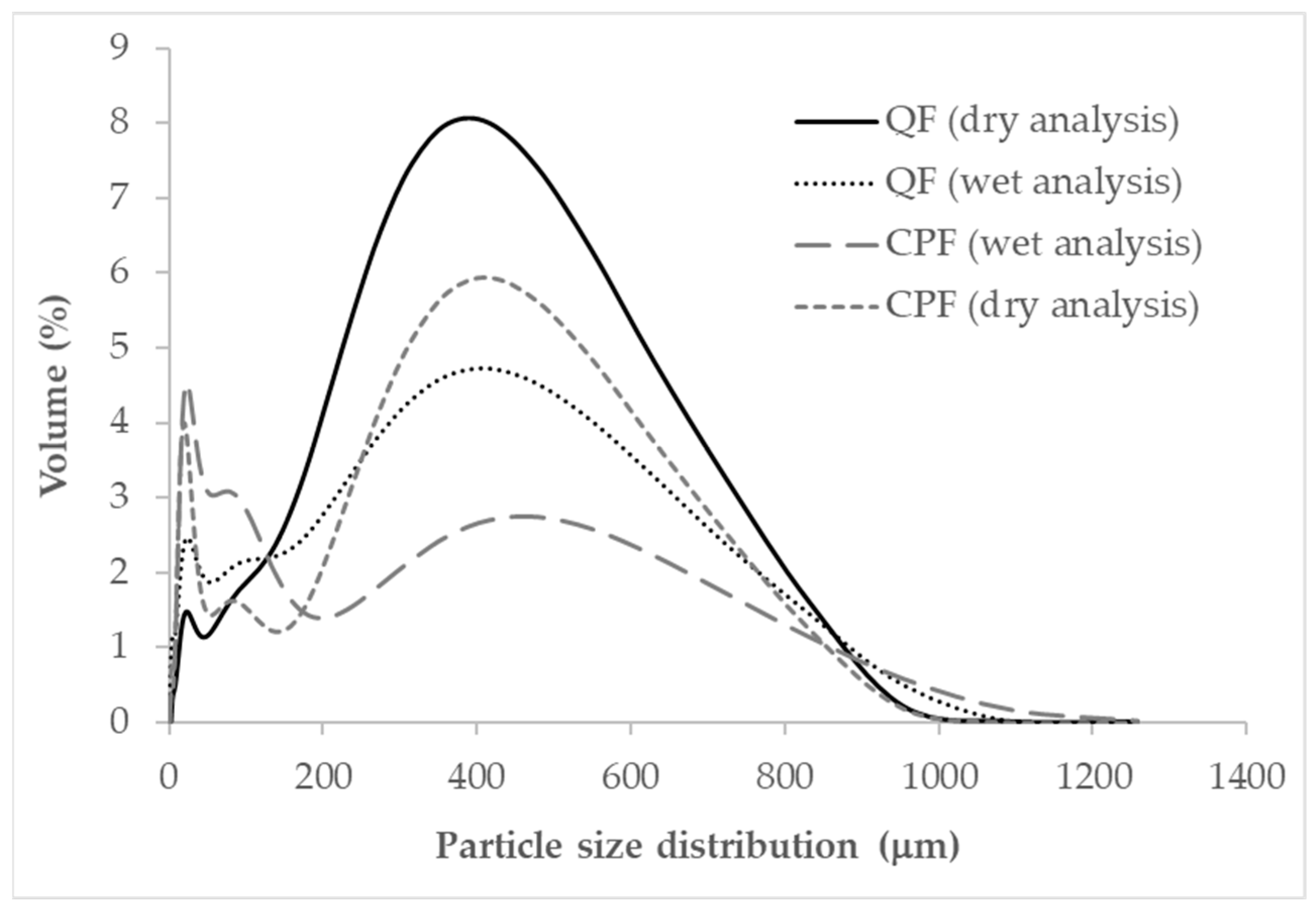

3.1.2. Particle Size Distribution

3.1.3. Functional Properties

3.2. Characterization of Quinoa–Chickpea Cracker-Type Snacks

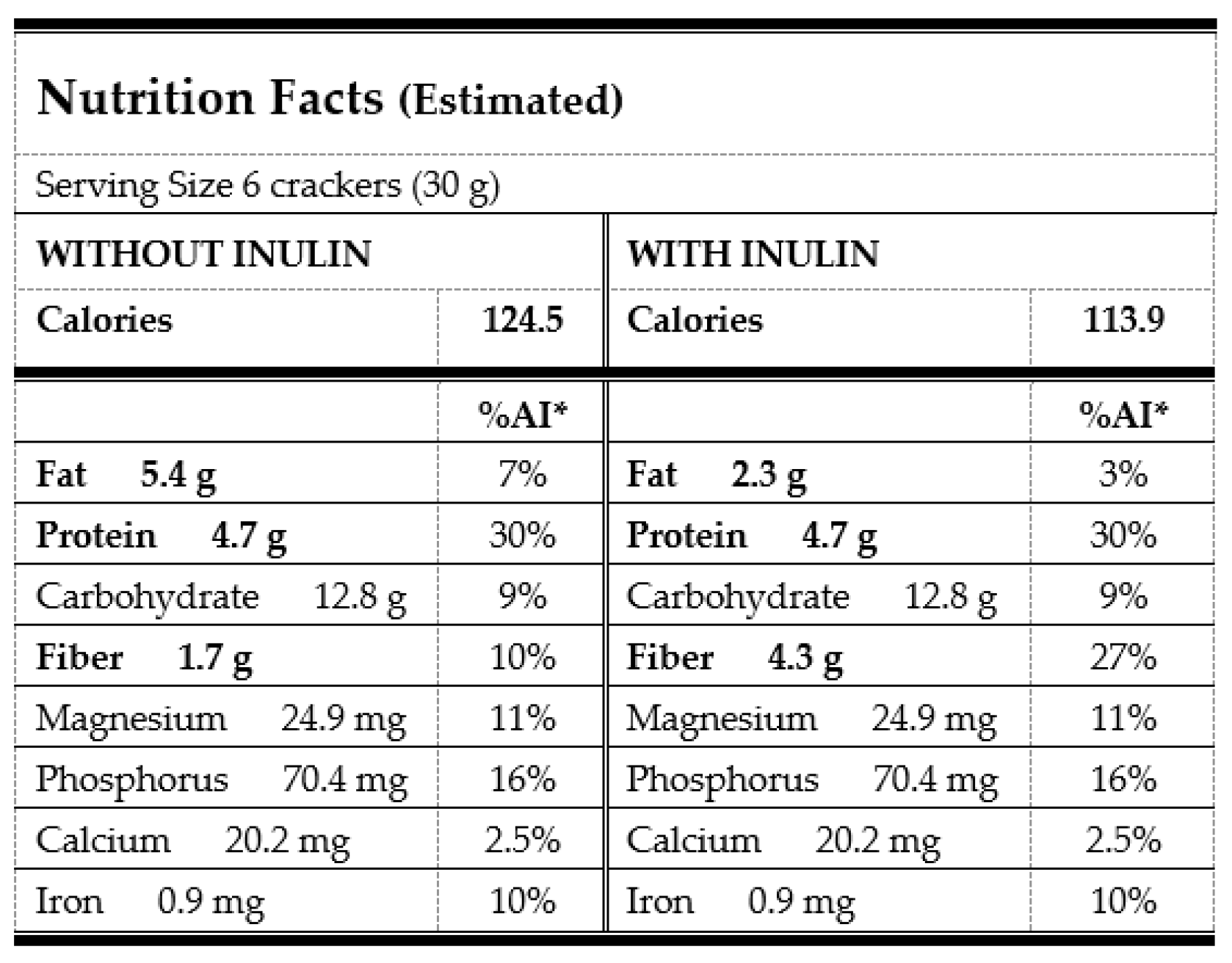

3.2.1. Physicochemical Analysis and Nutritional Aspects

3.2.2. Snack Firmness

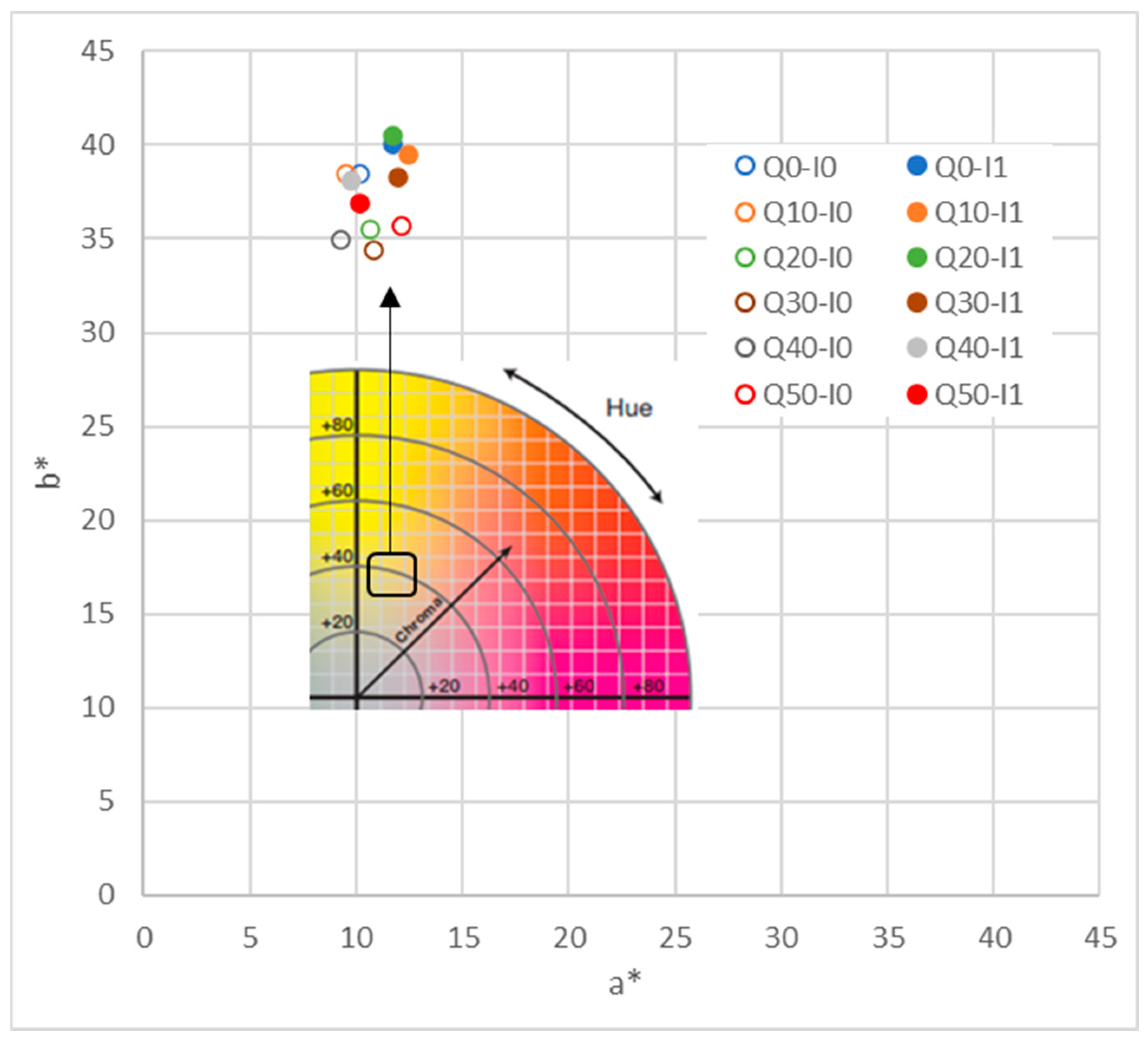

3.2.3. Optical Properties

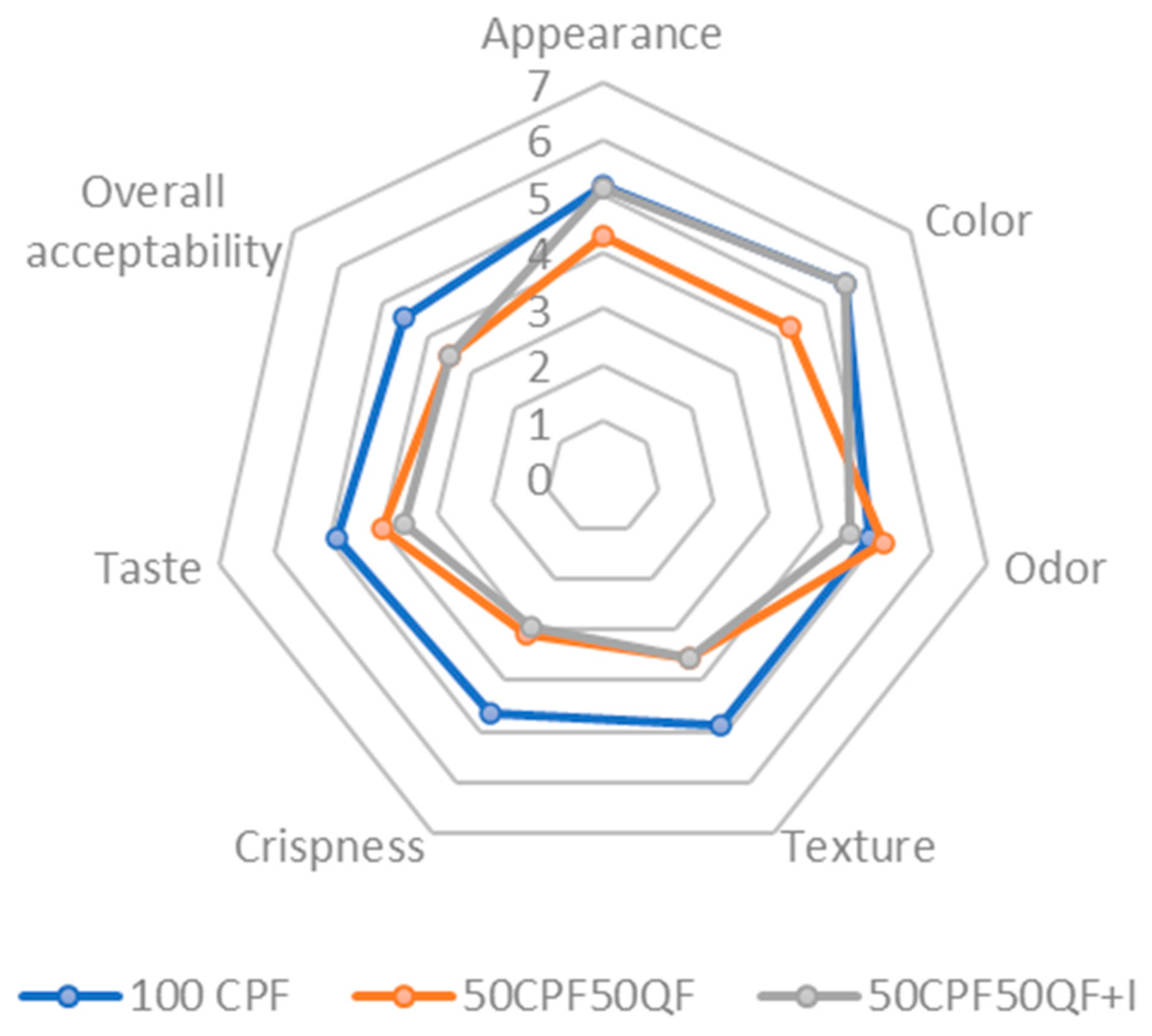

3.2.4. Sensory Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- WHO. World Health Organisation. Obesity and Overweight. 2021. Available online: https://www.who.int/news-room/fact-sheets/detail/obesity-and-overweight (accessed on 1 July 2023).

- Aranceta-Bartrina, J.; Gianzo-Citorese, M.; Pérez-Rodrigo, C. Prevalence of overweight, obesity and abdominal obesity in the Spanish population aged 3 to 24 years. The ENPE study. Rev. Esp. Cardiol. 2020, 73, 290–299. [Google Scholar] [CrossRef]

- Block, G. Foods contributing to energy intake in the US: Data from NHANES III and NHANES 1999–2000. J. Food Compost. Anal. 2004, 17, 439–447. [Google Scholar] [CrossRef]

- AESAN. Informe del Comité Científico de la Agencia Española de Seguridad Alimentaria y Nutrición (AESAN) sobre Ingestas Nutricionales de Referencia para la población española (AESAN-2019-003). Rev. Com. Cient. 2019, 29, 43–68. [Google Scholar]

- European Food Safety Authority (EFSA). Dietary Reference Values for the European Union. Available online: https://www.efsa.europa.eu/en/topics/topic/dietary-reference-values (accessed on 17 July 2023).

- Shoaib, M.; Shehzad, A.; Omar, M.; Rakha, A.; Raza, H.; Sharif, H.R.; Shakeel, A.; Ansari, A.; Niazi, S. Inulin: Properties, health benefits and food applications. Carbohydr. Polym. 2016, 147, 444–454. [Google Scholar] [CrossRef]

- Bayarri, S.; González-Tomás, L.U.; Hernando, I.; Lluch, M.A.; Costell, E. Texture perceived on inulin-enriched low-fat semisolid dairy desserts. Rheological and structural basis. J. Texture Stud. 2011, 42, 174–184. [Google Scholar] [CrossRef]

- Nanduri, K.R.; Hirich, A.; Salehi, M.; Saadat, S.; Jacobsen, S.E. Quinoa: A new crop for harsh environments. In Sabkha Ecosystems; Khan, M.A., Boër, B., Özturk, M., Clüsener-Godt, M., Gul, B., Breckle, S.-W., Eds.; Springer Nature: Cham, Switzerland, 2019; Volume VI, pp. 301–333. [Google Scholar] [CrossRef]

- Asati, R.; Tripathi, M.K.; Tiwari, S.; Yadav, R.K.; Tripathi, N. Molecular Breeding and Drought Tolerance in Chickpea. Life 2022, 12, 1846. [Google Scholar] [CrossRef]

- López, M.J.; Mohiuddin, S.S. Biochemistry, Essential Amino Acids; StatPearls Publishing: Treasure Island, FL, USA, 2023. Available online: https://www.ncbi.nlm.nih.gov/books/NBK557845/ (accessed on 1 July 2023).

- Elsohaimy, S.A.; Refaay, T.M.; Zaytoun, M.A.M. Physicochemical and functional properties of quinoa protein isolate. Ann. Agric. Sci. 2015, 60, 297–305. [Google Scholar] [CrossRef]

- FAO/WHO. Protein Quality Evaluation: Report of a Joint FAO-WHO Expert Consulation; FAO Food Nutrition Paper; FAO: Rome, Italy, 1991; Volume 51, pp. 1–66. [Google Scholar]

- Ren, G.; Teng, C.; Fan, X.; Guo, S.; Zhao, G.; Zhang, L.; Liang, Z.; Qin, P. Nutrient composition, functional activity and industrial applications of quinoa (Chenopodium quinoa Willd.). Food Chem. 2023, 410, 135290. [Google Scholar] [CrossRef]

- Huerta, M.G.; Roemmich, J.N.; Kington, M.L.; Bovbjerg, V.E.; Weltman, A.L.; Holmes, V.F.; Patrie, J.T.; Rogol, A.D.; Nadler, J.L. Magnesium deficiency is associated with inulin resistance in obese children. Diabetes Care 2005, 28, 1175–1181. [Google Scholar] [CrossRef]

- Cuadrado-Soto, E.; López-Sobaler, A.M.; Jiménez-Ortega, A.I.; Aparicio, A.; Bermejo, L.M.; Hernández-Ruiz, A.; Lara-Villoslada, F.; Leis, R.; Martínez de Victoria, M.; Moreno, J.M.; et al. Usual Dietary Intake, Nutritional Adequacy and Food Sources of Calcium, Phosphorus, Magnesium and Vitamin D of Spanish Children Aged One to <10 Years. Findings from the EsNuPI Study. Nutrients 2020, 12, 1787. [Google Scholar] [CrossRef]

- Di Cairano, M.; Condelli, N.; Caruso, M.C.; Marti, A.; Cela, N.; Galgano, F. Functional properties and predicted glycemic index of gluten free cereal, pseudocereal and legume flours. LWT-Food Sci. Technol. 2020, 133, 109860. [Google Scholar] [CrossRef]

- Acevedo Martinez, K.A.; Yang, M.M.; de Mejia, E.G. 2021 Technological properties of chickpea (Cicer arietinum): Production of snacks and health benefits related to type-2 diabetes. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3762–3787. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International, 17th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2000. [Google Scholar]

- Fukalova Fukalova, T.; García-Martínez, M.D.; Raigón, M.D. Nutritional Composition, Bioactive Compounds, and Volatiles Profile Characterization of Two Edible Undervalued Plants: Portulaca oleracea L. and Porophyllum ruderale (Jacq.) Cass. Plants 2022, 11, 377. [Google Scholar] [CrossRef]

- ISO 13320:2009; Particle Size Analysis-Laser Diffraction Methods. AENOR: Valencia, Spain, 2009.

- Heywood, A.A.; Myers, D.J.; Bailey, T.B.; Johnson, L.A. Functional properties of low-fat soy flour produced by an extrusion expelling system. J. Am. Oil Chem. Soc. 2002, 79, 1249–1253. [Google Scholar] [CrossRef]

- Lin, C.S.; Zayas, J.F. Functionality of defatted corn germ proteins in a model system: Fat binding capacity and water retention. J. Food Sci. 1987, 52, 1308–1311. [Google Scholar] [CrossRef]

- Ahn, H.J.; Kim, J.H.; Ng, P.K.W. Functional and thermal properties of wheat, barley, and soy flours and their blends treated with a microbial transglutaminase. J. Food Sci. 2005, 70, 380–386. [Google Scholar] [CrossRef]

- Narayana, K.; Narasinga Rao, M.S. Functional properties of raw and heat processed winged bean (Psophocarpus tetragonolobus) flour. J. Food Sci. 1982, 47, 1534–1538. [Google Scholar] [CrossRef]

- Alu’datt, M.H.; Rababah, T.; Ereifej, K.; Alli, I.; Alrababah, M.A.; Almajwal, A.; Masadeh, N.; Alhamad, M.N. Effects of barley flour and barley protein isolate on chemical, functional, nutritional and biological properties of Pita bread. Food Hydrocolloid. 2012, 26, 135–143. [Google Scholar] [CrossRef]

- Colla, K.; Gamlath, S. Inulin and maltodextrin can replace fat in baked savoury legume snacks. Int. Food Sci. Technol. 2015, 50, 2297–2305. [Google Scholar] [CrossRef]

- Di Cairano, M.; Galgano, F.; Tolve, R.; Caruso, M.C.; Condelli, N. Focus on gluten free biscuits: Ingredients and issues. Trends Food Sci. Technol. 2018, 81, 203–212. [Google Scholar] [CrossRef]

- AACC International. Approved Methods of the American of Cereal Chemists, 10th ed.; AACC: St. Paul, MN, USA, 2010. [Google Scholar]

- Sarıçoban, C.; Yılmaz, M.T. Modelling the effects of processing factors on the changes in colour parameters of cooked meatballs using response surface methodology. World Appl. Sci. J. 2010, 9, 14–22. [Google Scholar]

- UNE-ISO 4121; Sensory Analysis. Guidelines for the Use of Quantitative Response Scale. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Contreras-Jiménez, B.; Torres-Vargas, O.L.; Rodríguez-García, M.E. Physicochemical characterization of quinoa (Chenopodium quinoa) flour and isolated starch. Food Chem. 2019, 298, 124982. [Google Scholar] [CrossRef]

- Valdez-Arana, J.C.; Steffolani, M.E.; Repo-Carrasco-Valencia, R.; Pérez, G.T.; Condezo-Hoyos, L. Physicochemical and functional properties of isolated starch and their correlation with flour from the Andean Peruvian quinoa varieties. Int. J. Biol. Macromol. 2020, 147, 997–1007. [Google Scholar] [CrossRef]

- Pellegrini, M.; Lucas-Gonzales, R.; Ricci, A.; Fontecha, J.; Fernández-López, J.; Pérez-Álvarez, J.A.; Viuda-Martos, M. Chemical, fatty acid, polyphenolic profile, techno-functional and antioxidant properties of flours obtained from quinoa (Chenopodium quinoa Willd) seeds. Ind. Crop. Prod. 2018, 111, 38–46. [Google Scholar] [CrossRef]

- Ghumman, A.; Mudgal, S.; Singh, N.; Ranjan, B.; Kaur, A.; Rana, J.C. Physicochemical, functional and structural characteristics of grains, flour and protein isolates of Indian quinoa lines. Food Res. Int. 2021, 140, 109982. [Google Scholar] [CrossRef]

- Ahmed, J.; Thomas, L.; Arfat, Y.A. Functional, rheological, microstructural and antioxidant properties of quinoa flour in dispersions as influenced by particle size. Food Res. Int. 2019, 116, 302–311. [Google Scholar] [CrossRef]

- Hussein, H.; Awada, S.; El-Sayed, I.; Ibrahima, A. Impact of chickpea as prebiotic, antioxidant and thickener agent of stirred bio-yoghurt. Ann. Agric. Sci. 2020, 65, 49–58. [Google Scholar] [CrossRef]

- Albors, A.; Raigon, M.D.; Garcia-Martinez, M.D.; Martin-Esparza, M.E. Assessment of techno-functional and sensory attributes of tiger nut fresh egg tagliatelle. LWT-Food Sci. Technol. 2016, 74, 183–190. [Google Scholar] [CrossRef]

- Martín-Esparza, M.E.; Bressi, G.B.; Raga, A.; Albors, A. Technological and nutritional aspects of gluten-free pasta based on chickpea flour and tiger nut flour. In Proceedings of the 21st International Drying Symposium, Valencia, Spain, 11–14 September 2018; Cárcel, J.A., Clemente, G., García-Pérez, J.V., Rosselló, C., Eds.; UPV: Valencia, Spain, 2018; pp. 1021–1028. [Google Scholar] [CrossRef]

- Alonso-Miravalles, L.; Zannini, E.; Bez, J.; Arent, E.K.; O’Mahony, J.A. Physical and flow properties of pseudocereal-based protein-rich ingredient powders. J. Food Eng. 2020, 281, 109973. [Google Scholar] [CrossRef]

- Shi, D.; Fidelis, M.; Ren, Y.; Stone, A.K.; Ai, Y.; Nickerson, M.T. The functional attributes of Peruvian (Kankolla and Blanca juli blend) and Northern quinoa (NQ94PT) flours and protein isolates, and their protein quality. Food Res. Int. 2019, 128, 108799. [Google Scholar] [CrossRef]

- Martínez-Preciado, A.H.; Ponce-Simental, J.A.; Schorno, A.L.; Contreras-Pacheco, M.L.; Michel, C.R.; Rivera-Ortiz, K.G.; Soltero, J.F.A. Characterization of nutritional and functional properties of “Blanco Sinaloa” chickpea (Cicer arietinum L.) variety, and study of the rheological behavior of hummus pastes. J. Food Sci. Technol. 2020, 57, 1856–1865. [Google Scholar] [CrossRef]

- Ogungbenle, H.N. Nutritional evaluation and functional properties of quinoa (Chenopodium quinoa) flour. Int. J. Food Sci. Nutr. 2003, 54, 153–158. [Google Scholar] [CrossRef] [PubMed]

- Chandra, S.; Samsher, S. Assessment of functional properties of different flours. Afr. J. Agric. Res. 2013, 8, 4849–4852. [Google Scholar]

- García, Y.; Cabrera, D.; Ballestas, J.A.; Campo, M.J. Effect of different thermal treatments on the tecfunctional properties of white bean flour (Phaseolus lunatus L.) and the determination of its potential agri-food use. INGE CUC 2019, 15, 132–142. [Google Scholar] [CrossRef]

- Fontana, A. D: Minimum Water Activity Limits for Growth of Microorganisms. In Water Activity in Foods, Fundamentals and Applications, 2nd ed.; Barbosa-Cánovas, G.V., Fontana, A.J., Jr., Schmidt, S.J., Labuza, T.P., Eds.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2020; pp. 571–572. [Google Scholar]

- European Commission. Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. Off. J. Eur. Union 2006, L404, 9–25. [Google Scholar]

- Anderson, J.W.; Baird, P.; Davis, R.H.; Ferreri, S., Jr.; Knudtson, M.; Koraym, A.; Waters, V.; Williams, C.L. Health benefits of dietary fiber. Nutr. Rev. 2009, 67, 188–205. [Google Scholar] [CrossRef]

- Demir, M.K.; Kilinç, M. Utilization of quinoa flour in cookie production. Int. Food Res. J. 2017, 24, 2394–2401. [Google Scholar]

- Moawad, E.M.M.; Rizk, I.R.S.; Kishk, Y.F.M.; Youssif, M.R.G. Effect of substitution of wheat flour with quinoa flour on quality of pan bread and biscuit. AUJASCI Arab Univ. J. Agric. Sci. 2019, 26, 2387–2400. [Google Scholar] [CrossRef]

- Di Cairano, M.; Condelli, N.; Caruso, M.C.; Cela, N.; Tolve, R.; Galgano, F. Use of underexploited flours for the reduction of glycaemic index of gluten-free biscuits: Physicochemical and sensory characterization. Food Bioprocess Technol. 2021, 14, 1490–1501. [Google Scholar] [CrossRef]

- Ma, Z.; Boye, J.I.; Simpson, B.K.; Prasher, S.O.; Monpetit, D.; Malcolmson, L. Thermal processing effects on the functional properties and microstructure of lentil, chickpea, and pea flours. Food Res. Int. 2011, 44, 2534–2544. [Google Scholar] [CrossRef]

- Zucco, F.; Borsuk, Y.; Amtfield, S.D. Physical and nutritional evaluation of wheat cookies supplemented with pulse flours of different particle sizes. LWT-Food Sci. Technol. 2011, 44, 2070–2076. [Google Scholar] [CrossRef]

- Purlis, E. Browning development in bakery products—A review. J. Food Eng. 2010, 99, 239–249. [Google Scholar] [CrossRef]

- Brito, I.L.; Souza, E.L.; Felex, S.S.S.; Madruga, M.S.; Yamashita, F.; Magnani, M. Nutritional and sensory characteristics of gluten-free quinoa (Chenopodium quinoa Willd)-based cookies development using an experimental mixture design. J. Food Sci. Technol. 2015, 9, 5866–5873. [Google Scholar] [CrossRef]

- El-Sohaimy, S.A.; Shehata, M.G.; Mehany, T.; Zeitoun, M.A. Nutritional, Physicochemical, and Sensorial Evaluation of Flat Bread Supplemented with Quinoa Flour. Int. J. Food Sci. 2019, 2019, 4686727. [Google Scholar] [CrossRef] [PubMed]

- Tiefenbacher, K.F. The Technology of Wafers and Waffles I Operational Aspects; Academic Press: London, UK, 2017; pp. 123–225. [Google Scholar]

- Stikic, R.; Glamoclija, D.; Demin, M.; Vucelic-Radovic, B.; Jovanovic, Z.; Milojkovic-Opsenica, D.; Jacobsen, S.E.; Milovanovic, M. Agronomical and nutritional evaluation of quinoa seeds (Chenopodium quinoa Willd.) as an ingredient in bread formulations. J. Cereal Sci. 2012, 55, 132–138. [Google Scholar] [CrossRef]

| g/100 g Flour | ||

|---|---|---|

| Sample | CPF | QF |

| 100CPF | 100 | 0 |

| 90CPF10QF | 90 | 10 |

| 80CPF20QF | 80 | 20 |

| 70CPF30QF | 70 | 30 |

| 60CPF40QF | 60 | 40 |

| 50CPF50QF | 50 | 50 |

| QF | CPF | I ** | ||

|---|---|---|---|---|

| Water (g/100 g) | 11.323 (0.109) | 10.05 (0.12) | 0 | |

| Protein (g/100 g) | 22.2 (0.7) | 22.32 (1.02) | 5.7 | |

| Fat (g/100 g) | 5 (2) | 4.9 (0.5) | - | |

| Ash (g/100 g) | 2.56 (0.07) | 2.61 (0.08) | - | |

| Individual Mineral Content (mg/100 g) | Fe | 3.64 (0.09) | 5.1 (0.8) | - |

| Cu | 0.53 (0.08) | 0.73 (0.14) | - | |

| Zn | 3.3 (1.3) | 2.9 (0.2) | - | |

| Ca | 58.88 (1.07) | 130 (14) | - | |

| Mg | 122 (2) | 112.0 (0.3) | - | |

| P | 325 (5) | 337 (4) | - | |

| K | 252 (4) | 266 (5) | - | |

| Na | 17 (7) | 3.52 (0.12) | - | |

| B | 0.75 (0.02) | 0.80 (0.03) | - | |

| Mn | 1.49 (0.04) | 1.81 (0.02) | - | |

| Mo | 0.547 (0.102) | 0.37 (0.12) | - | |

| Se | ND | ND | - | |

| Crude fiber (g/100 g) | 2.2 (0.2) | 13.6 (0.7) | 77.5 | |

| DC * (g/100 g) | 58.901 | 61.5 | - | |

| Energy (kcal/100 g) | 369.40 | 379.38 | 179 | |

| D [4.3] (µm) | d (0.1) (µm) | d (0.5) (µm) | d (0.9) (µm) | Span | |

|---|---|---|---|---|---|

| QFDA | 273 (4) aA | 22.1 (0.5) aA | 259 (4) aA | 547 (4) aA | 2.03 (0.02) bB |

| CPFDA | 192 (16) bA | 11.0 (0.4) bA | 93 (26) bA | 519 (19) bA | 5.6 (1.3) aB |

| QFWA | 189 (6) aB | 5.3 (0.2) bB | 99 (6) aB | 504 (13) aB | 5.0 (0.2) bA |

| CPFWA | 138 (8) bB | 10.1 (0.2) aB | 45.4 (1.7) bB | 446 (28) bB | 9.6 (0.4) aA |

| WHC (g/g) | FAC (g/g) | FC (%) | FS (%) | SC (mL/g) | |

|---|---|---|---|---|---|

| QF | 1.70 (0.15) a | 1.4 (0.3) a | 16.6 (1.2) b | 77 (8) a | 2.82 (0.15) a |

| CPF | 1.98 (0.2) b | 1.25 (0.04) b | 28.3 (1.2) a | 19.8 (0.5) b | 1.12 (0.02) b |

| Without Inulin (I = 0) | With Inulin (I = 1) | |||||||

|---|---|---|---|---|---|---|---|---|

| Sample | Water Content (g/g) | Weight (g) | Thickness (mm) | aw | Water Content (g/g) | Weight (g) | Thickness (mm) | aw |

| 100CPF | 0.120 (0.015) aA | 5.0 (0.3) aA | 2.000 (<0.001) aA | 0.490 (0.016) aA | 0.1200 (0.0013) aA | 5.00 (0.15) aA | 2.0 (0.3) aA | 0.50 (0.02) aA |

| 90CPF10QF | 0.120 (0.012) aA | 5.0 (0.3) aA | 2.0 (0.4) aA | 0.500 (0.012) aA | 0.130 (<0.001) aA | 5.000 (<0.001) aA | 3.000 (<0.001) aA | 0.540 (<0.001) aA |

| 80CPF20QF | 0.140 (<0.001) aA | 6.000 (<0.001) aA | 2.000 (<0.001) aA | 0.550 (<0.001) aA | 0.13 (0.05) aA | 5.0 (0.5) aA | 3.0 (0.2) aA | 0.550 (0.012) aA |

| 70CPF30QF | 0.140 (0.003) aA | 5.00 (0.07) aA | 3.0 (0.8) aA | 0.5400 (0.0008) aA | 0.140 (0.005) aA | 5.0 (0.6) aA | 3.0 (0.6) aA | 0.540 (0.004) aA |

| 60CPF40QF | 0.140 (0.007) aA | 5.000 (0.112) aA | 2.000 (<0.001) aA | 0.550 (0.005) aA | 0.130 (0.011) aA | 5.0 (0.4) aA | 2.0 (0.3) aA | 0.530 (0.012) aA |

| 50CPF50QF | 0.14 (0.04) aA | 5.0 (0.7) aA | 3.0 (0.7) aA | 0.530 (0.006) aA | 0.10 (0.04) aA | 6.00 (0.6) aA | 3.0 (0.8) aA | 0.490 (0.007) aA |

| Without Inulin (I = 0) | With Inulin (I = 1) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sample | L*ab | C*ab | h*ab | BI | F (N) | L*ab | C*ab | h*ab | BI | F (N) |

| 100CPF | 65.0 (0.7) aA | 40.0 (0.4) aB | 76.0 (1.7) aA | 103 (4) abB | 29.03 (1.12) bcB | 64 (2) aA | 42.0 (0.9) aA | 74 (3) bA | 112 (9) bA | 85 (5) aA |

| 90CPF10QF | 63 (3) aA | 40 (3) aB | 75 (2) aB | 104 (3) abB | 24 (2) cB | 59 (3) cdB | 41.0 (0.8) aA | 72 (3) bA | 124 (8) aA | 60 (17) bA |

| 80CPF20QF | 58.16 (1.06) cA | 37 (2) bB | 73.4 (1.9) bA | 109 (10) abB | 32 (8) bB | 59.7 (1.2) cdA | 42.2 (0.9) aA | 73.84 (1.14) abA | 126 (7) aA | 56 (15) bA |

| 70CPF30QF | 55.9 (0.4) dB | 36 (3) bB | 72.6 (1.2) bcA | 111 (11) aB | 31 (6) bB | 57.6 (0.) dA | 40.0 (0.8) bA | 72.7 (1.3) bA | 123 (5) aA | 46 (12) bA |

| 60CPF40QF | 59.1 (0.8) bB | 36.2 (1.2) bB | 75.2 (0.5) aA | 103 (4) bB | 28 (4) bcB | 61.8 (0.9) bA | 39.3 (1.4) bA | 75.678 (1.012) aA | 108 (7) bA | 48 (4) bA |

| 50CPF50QF | 58.4 (0.8) bcB | 37.7 (0.8) bA | 71.2 (1.8) cB | 110 (6) aA | 44 (9) aB | 60.3 (0.8) bcA | 38.3 (0.5) cA | 74.6 (1.6) abA | 108 (3) bA | 40 (6) bA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martín-Esparza, M.E.; Raigón, M.D.; García-Martínez, M.D.; Albors, A. Toward the Development of Potentially Healthy Low-Energy-Density Snacks for Children Based on Pseudocereal and Pulse Flours. Foods 2023, 12, 2873. https://doi.org/10.3390/foods12152873

Martín-Esparza ME, Raigón MD, García-Martínez MD, Albors A. Toward the Development of Potentially Healthy Low-Energy-Density Snacks for Children Based on Pseudocereal and Pulse Flours. Foods. 2023; 12(15):2873. https://doi.org/10.3390/foods12152873

Chicago/Turabian StyleMartín-Esparza, Maria Eugenia, María Dolores Raigón, María Dolores García-Martínez, and Ana Albors. 2023. "Toward the Development of Potentially Healthy Low-Energy-Density Snacks for Children Based on Pseudocereal and Pulse Flours" Foods 12, no. 15: 2873. https://doi.org/10.3390/foods12152873

APA StyleMartín-Esparza, M. E., Raigón, M. D., García-Martínez, M. D., & Albors, A. (2023). Toward the Development of Potentially Healthy Low-Energy-Density Snacks for Children Based on Pseudocereal and Pulse Flours. Foods, 12(15), 2873. https://doi.org/10.3390/foods12152873