Characterization of Nano-SiO2/Zein Film Prepared Using Ultrasonic Treatment and the Ability of the Prepared Film to Resist Different Storage Environments

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Zein/SiO2 Film

2.3. Ultrasound-Assisted Preparation of Zein/SiO2 Film

2.4. Determination of Film Properties

2.4.1. Mechanical Properties

2.4.2. Moisture Content, Swelling Degree, and Solubility

2.4.3. Water Vapor Permeability (WVP) and Oxygen Permeability (OP)

2.5. Structural Characterization of Films

2.5.1. Attenuated Total Reflectance-Fourier Transform Infrared (ATR-FTIR) Spectroscopy

2.5.2. X-ray Diffraction (XRD)

2.5.3. Differential Scanning Calorimetry (DSC)

2.5.4. Scanning Electron Microscopy (SEM)

2.6. Statistical Analysis

3. Results and Discussion

3.1. Influence of Ultrasonic Treatment on Physico-Mechanical Properties of the Films

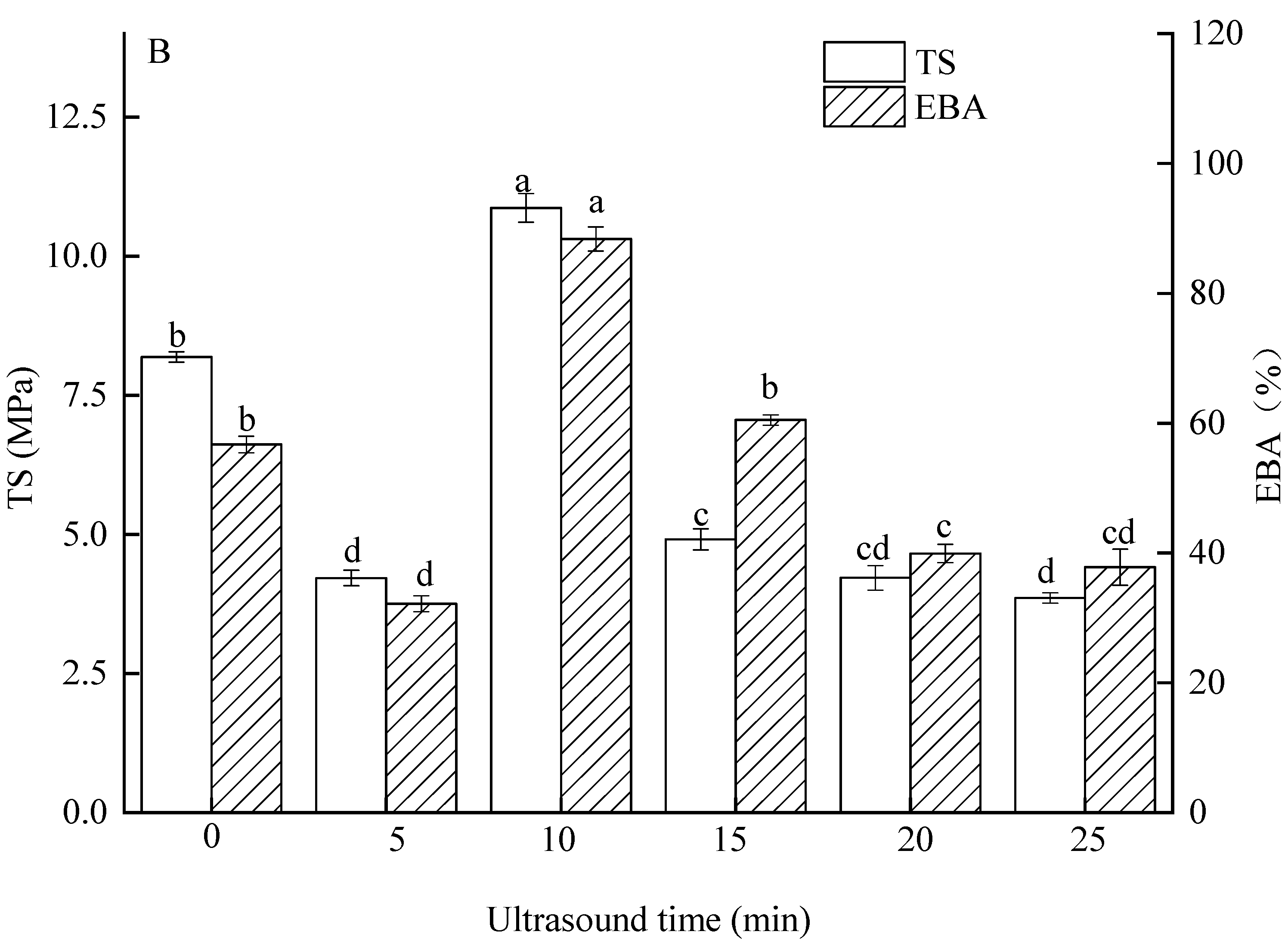

3.1.1. Single-Factor Optimization Focusing on the Mechanical Properties

3.1.2. Moisture Content, Swelling Degree and Solubility

3.1.3. WVP and OP

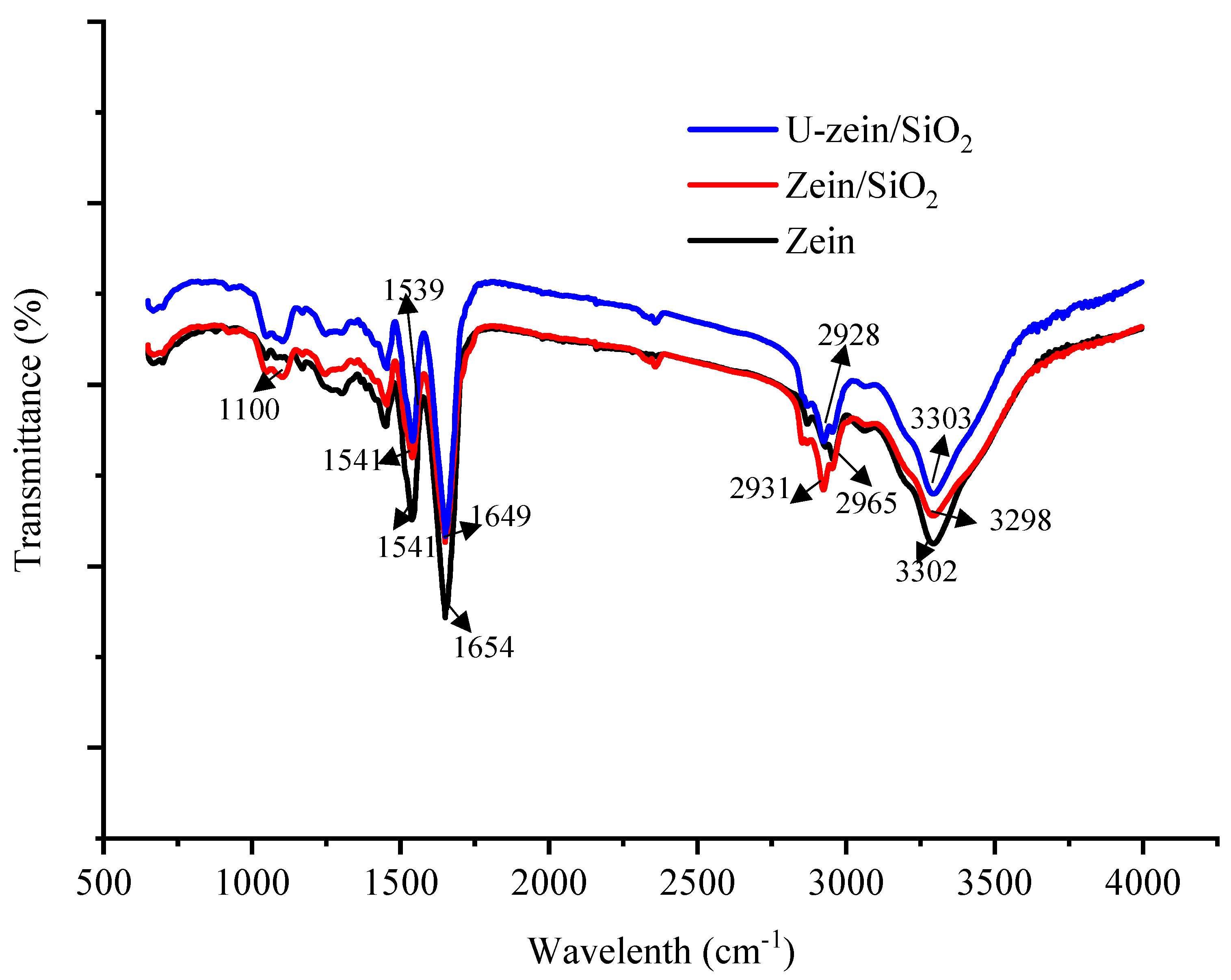

3.2. The Alterations in the Interactions and Structure of Films Caused by Exposure to Ultrasound

3.2.1. ATR-FTIR Spectra

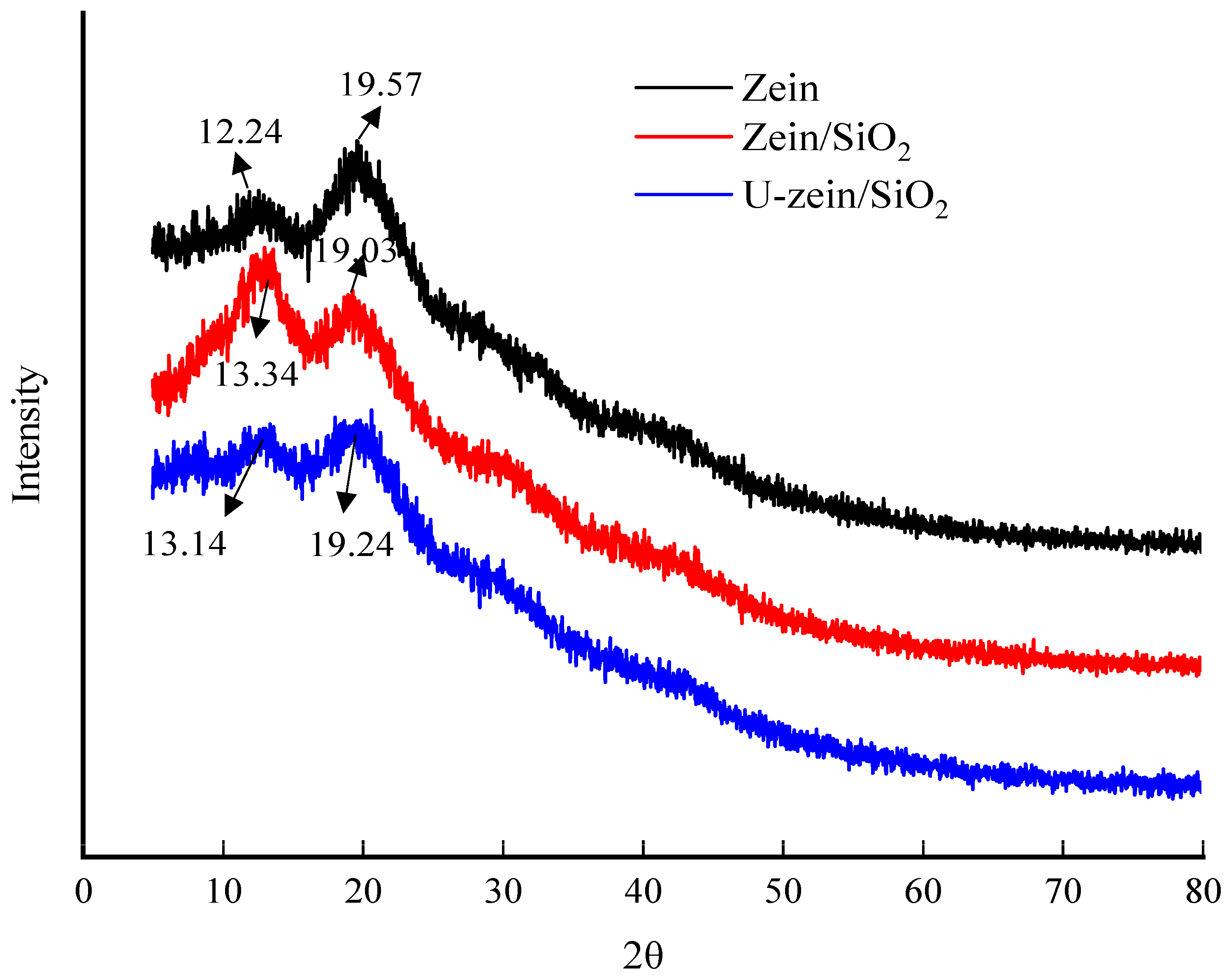

3.2.2. XRD

3.2.3. Thermal Stability

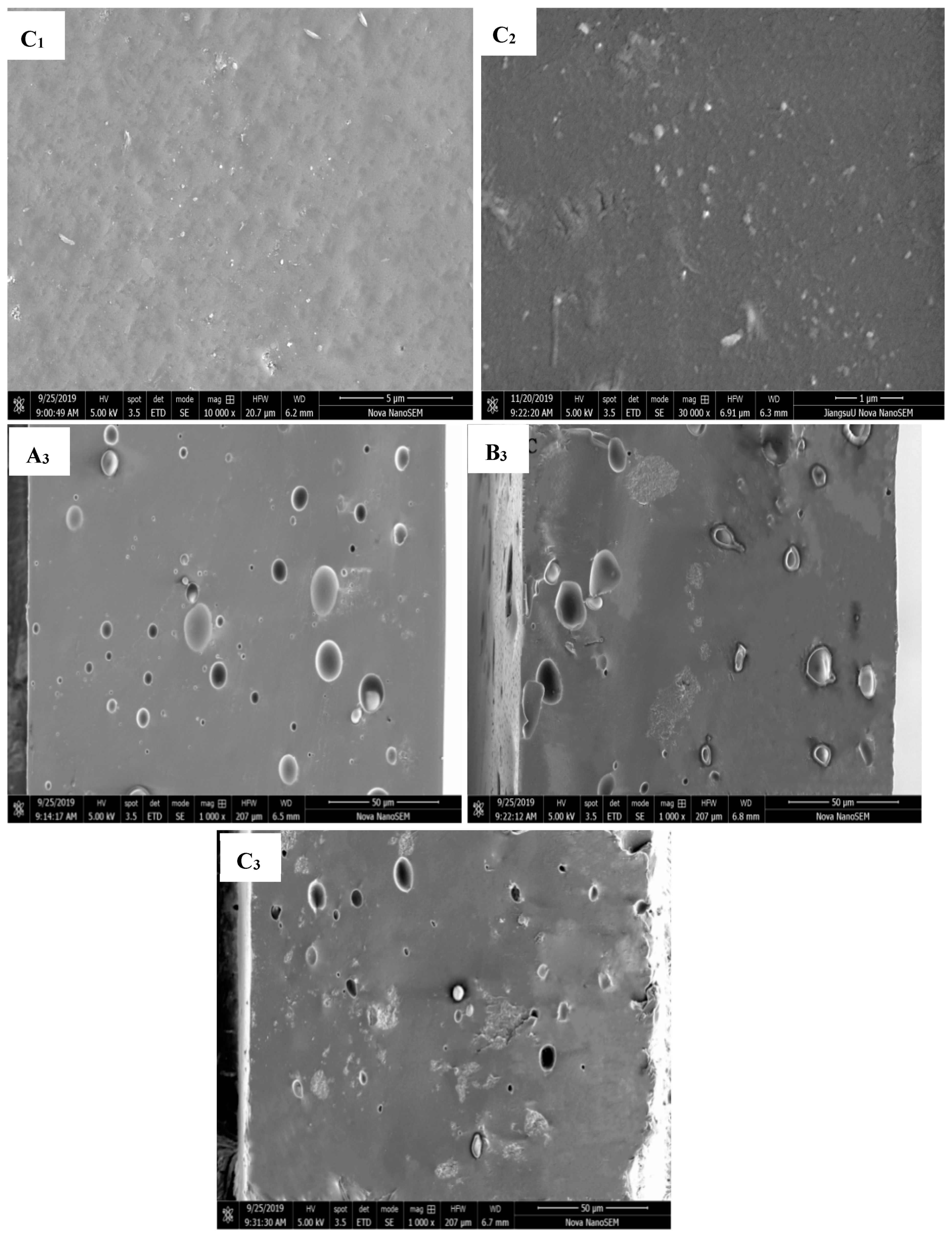

3.2.4. SEM

3.3. The Ability of U-Zein/SiO2 Film to Resist Different Storage Environments

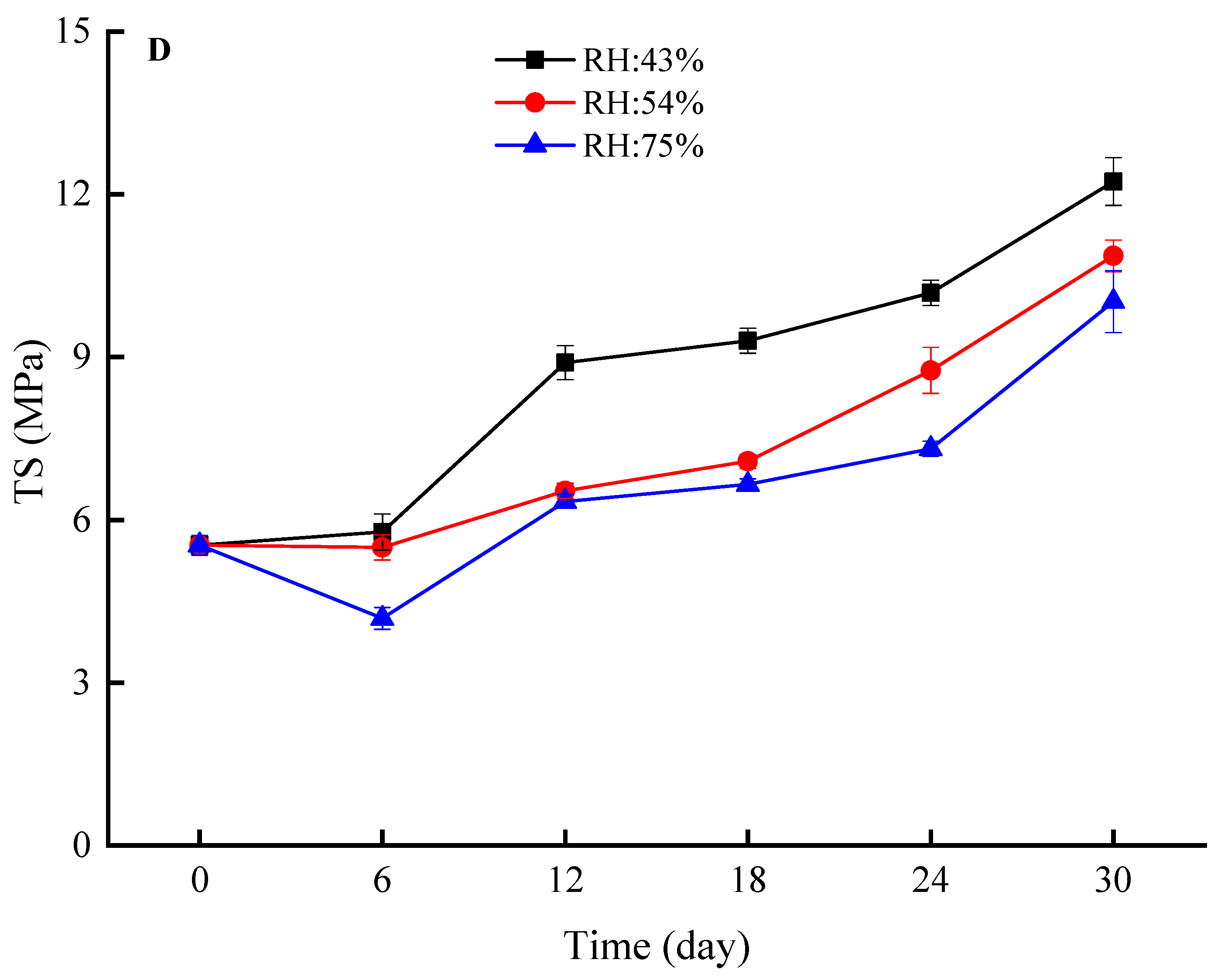

3.3.1. Ambient Humidity

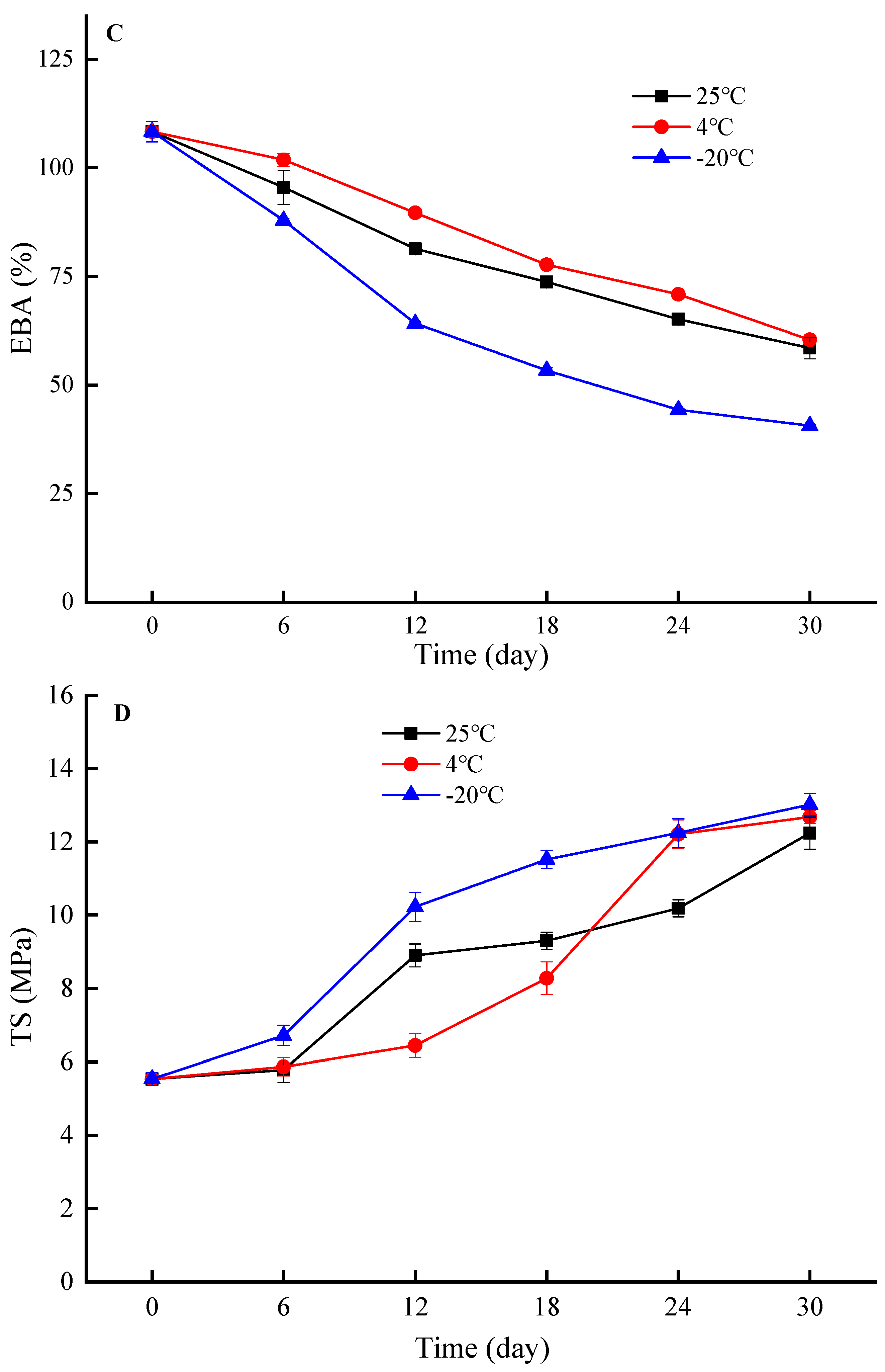

3.3.2. Ambient Temperature

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dong, M.; Tian, L.; Li, J.; Jia, J.; Dong, Y.; Tu, Y.; Liu, X.; Tan, C.; Duan, X. Improving physicochemical properties of edible wheat gluten protein films with proteins, polysaccharides and organic acid. LWT 2022, 154, 112868. [Google Scholar] [CrossRef]

- Liang, Q.; Ren, X.; Zhang, X.; Hou, T.; Chalamaiah, M.; Ma, H.; Xu, B. Effect of ultrasound on the preparation of resveratrol-loaded zein particles. J. Food Eng. 2018, 221, 88–94. [Google Scholar] [CrossRef]

- Paliwal, R.; Palakurthi, S. Zein in controlled drug delivery and tissue engineering. J. Control. Release 2014, 189, 108–122. [Google Scholar] [CrossRef] [PubMed]

- Huo, W.; Wei, D.; Zhu, W.; Li, Z.; Jiang, Y. High-elongation zein films for flexible packaging by synergistic plasticization: Preparation, structure and properties. J. Cereal Sci. 2017, 79, 354–361. [Google Scholar] [CrossRef]

- Hou, X.; Xue, Z.; Xia, Y.; Qin, Y.; Zhang, G.; Liu, H.; Li, K. Effect of SiO2 nanoparticle on the physical and chemical properties of eco-friendly agar/sodium alginate nanocomposite film. Int. J. Biol. Macromol. 2019, 125, 1289–1298. [Google Scholar] [CrossRef]

- Marangoni Junior, L.; da Silva, R.G.; Anjos, C.A.R.; Vieira, R.P.; Alves, R.M.V. Effect of low concentrations of SiO2 nanoparticles on the physical and chemical properties of sodium alginate-based films. Carbohydr. Polym. 2021, 269, 118286. [Google Scholar] [CrossRef]

- Marangoni Júnior, L.; da Silva, R.G.; Vieira, R.P.; Alves, R.M.V. Water vapor sorption and permeability of sustainable alginate/collagen/SiO2 composite films. LWT 2021, 152, 112261. [Google Scholar] [CrossRef]

- Kang, L.; Liang, Q.; Chen, H.; Zhou, Q.; Chi, Z.; Rashid, A.; Ma, H.; Ren, X. Insights into ultrasonic treatment on the properties of pullulan/oat protein/nisin composite film: Mechanical, structural and physicochemical properties. Food Chem. 2023, 402, 134237. [Google Scholar] [CrossRef]

- Marcuzzo, E.; Peressini, D.; Debeaufort, F.; Sensidoni, A. Effect of ultrasound treatment on properties of gluten-based film. Innov. Food Sci. Emerg. Technol. 2010, 11, 451–457. [Google Scholar] [CrossRef]

- Grari, O.; Dhouibi, L.; Lallemand, F.; Buron, C.C.; Et Taouil, A.; Hihn, J.Y. Effects of high frequency ultrasound irradiation on incorporation of SiO2 particles within polypyrrole films. Ultrason. Sonochem. 2015, 22, 220–226. [Google Scholar] [CrossRef]

- Ren, X.; Wei, X.; Ma, H.; Zhou, H.; Guo, J.; Mao, S.; Hu, A. Effects of a Dual-Frequency Frequency-Sweeping Ultrasound Treatment on the Properties and Structure of the Zein Protein. Cereal Chem. 2015, 92, 193–197. [Google Scholar] [CrossRef]

- Jin, J.; Ma, H.; Wang, K.; Yagoub Ael, G.; Owusu, J.; Qu, W.; He, R.; Zhou, C.; Ye, X. Effects of multi-frequency power ultrasound on the enzymolysis and structural characteristics of corn gluten meal. Ultrason. Sonochem. 2015, 24, 55–64. [Google Scholar] [CrossRef]

- Neka, B.; Oab, B. Effect of fibrous TiO2 filler on the structural, mechanical, barrier and optical characteristics of biodegradable maize starch/PVA composite films. Int. J. Biol. Macromol. 2019, 139, 431–439. [Google Scholar]

- Choo, K.W.; Lin, M.; Mustapha, A. Chitosan/acetylated starch composite films incorporated with essential oils: Physiochemical and antimicrobial properties. Food Biosci. 2021, 43, 101287. [Google Scholar] [CrossRef]

- Liang, Q.; Ren, X.; Qu, W.; Zhang, X.; Cheng, Y.; Ma, H. The impact of ultrasound duration on the structure of β-lactoglobulin. J. Food Eng. 2021, 292, 110365. [Google Scholar] [CrossRef]

- Haghighatpanah, N.; Omar-Aziz, M.; Gharaghani, M.; Khodaiyan, F.; Hosseini, S.S.; Kennedy, J.F. Effect of mung bean protein isolate/pullulan films containing marjoram (Origanum majorana L.) essential oil on chemical and microbial properties of minced beef meat. Int. J. Biol. Macromol. 2022, 201, 318–329. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, R.; Qin, W.; Dai, J.; Zhang, Q.; Lee, K.; Liu, Y. Physicochemical properties of gelatin films containing tea polyphenol-loaded chitosan nanoparticles generated by electrospray. Mater. Design 2020, 185, 108277. [Google Scholar] [CrossRef]

- Qu, W.; Guo, T.; Zhang, X.; Jin, Y.; Wang, B.; Wahia, H.; Ma, H. Preparation of tuna skin collagen-chitosan composite film improved by sweep frequency pulsed ultrasound technology. Ultrason. Sonochem. 2022, 82, 105880. [Google Scholar] [CrossRef]

- Tao, R.; Sedman, J.; Ismail, A. Characterization and in vitro antimicrobial study of soy protein isolate films incorporating carvacrol. Food Hydrocoll. 2022, 122, 107091. [Google Scholar] [CrossRef]

- Han, K.; Liu, Y.; Liu, Y.; Huang, X.; Sheng, L. Characterization and film-forming mechanism of egg white/pullulan blend film. Food Chem. 2020, 315, 126201. [Google Scholar] [CrossRef]

- Jin, J.; Ma, H.; Wang, B.; Yagoub Ael, G.; Wang, K.; He, R.; Zhou, C. Effects and mechanism of dual-frequency power ultrasound on the molecular weight distribution of corn gluten meal hydrolysates. Ultrason. Sonochem. 2016, 30, 44–51. [Google Scholar] [CrossRef] [PubMed]

- Cui, R.; Zhu, F. Ultrasound modified polysaccharides: A review of structure, physicochemical properties, biological activities and food applications. Trends Food Sci. Technol. 2021, 107, 491–508. [Google Scholar] [CrossRef]

- Vera, A.; Tapia, C.; Abugoch, L. Effect of high-intensity ultrasound treatment in combination with transglutaminase and nanoparticles on structural, mechanical, and physicochemical properties of quinoa proteins/chitosan edible films. Int. J. Biol. Macromol. 2020, 144, 536–543. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Ge, X.; Yang, L.; Gou, Q.; Han, L.; Yu, Q.-L. Utilization of watermelon peel as a pectin source and the effect of ultrasound treatment on pectin film properties. LWT 2021, 147, 111569. [Google Scholar] [CrossRef]

- Kang, L.X.; Liang, Q.F.; Rashid, A.; Qayum, A.; Chi, Z.Z.; Ren, X.F.; Ma, H.L. Ultrasound-assisted development and characterization of novel polyphenol-loaded pullulan/trehalose composite films for fruit preservation. Ultrason. Sonochem. 2023, 92, 106242. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, Q.; Liu, X.; Raza, H.; Ma, H.; Ren, X. Treatment with ultrasound improves the encapsulation efficiency of resveratrol in zein-gum Arabic complex coacervates. LWT 2021, 153, 112331. [Google Scholar] [CrossRef]

- Cheng, J.; Cui, L. Effects of high-intensity ultrasound on the structural, optical, mechanical and physicochemical properties of pea protein isolate-based edible film. Ultrason. Sonochem. 2021, 80, 105809. [Google Scholar] [CrossRef]

| Moisture Content (%) | Swelling Degree (%) | Solubility (%) | WVP (×10−11 g/m·s·Pa) | Peroxide Value (mmoL/kg) | |

|---|---|---|---|---|---|

| Zein | 17.49 ± 0.13 a | 97.67 ± 0.41 a | 23.35 ± 0.20 b | 13.07 ± 0.34 a | 144.97 ± 3.65 a |

| Zein/SiO2 | 16.42 ± 0.19 b | 112.93 ± 0.16 a | 24.4 ± 0.09 a | 7.21 ± 0.03 b | 99.44 ± 1.71 b |

| U-zein/SiO2 | 15.65 ± 0.18 c | 120.65 ± 0.23 b | 22.62 ± 0.26 c | 6.59 ± 0.07 b | 87.64 ± 4.13 c |

| RC (%) | T0 (°C) | TP (°C) | TC (°C) | TC − T0 (°C) | ΔH (J/g) | |

|---|---|---|---|---|---|---|

| Zein | 39.09 ± 2.34 c | 79.57 ± 1.01 a | 204.90 ± 2.31 a | 326.38 ± 1.03 a | 125.33 ± 0.88 a | 178.30 ± 2.14 b |

| Zein/SiO2 | 52.72 ± 1.92 a | 82.36 ± 1.66 a | 208.37 ± 1.16 ab | 326.35 ± 1.07 a | 126.01 ± 5.28 a | 183.89 ± 1.15 a |

| U-zein/SiO2 | 43.51 ± 1.96 b | 80.15 ± 2.37 a | 219.59 ± 2.42 b | 325.48 ± 0.92 a | 139.44 ± 3.60 a | 180.47 ± 2.35 ab |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, X.; Wang, J.; Rashid, A.; Hou, T.; Ma, H.; Liang, Q. Characterization of Nano-SiO2/Zein Film Prepared Using Ultrasonic Treatment and the Ability of the Prepared Film to Resist Different Storage Environments. Foods 2023, 12, 3056. https://doi.org/10.3390/foods12163056

Ren X, Wang J, Rashid A, Hou T, Ma H, Liang Q. Characterization of Nano-SiO2/Zein Film Prepared Using Ultrasonic Treatment and the Ability of the Prepared Film to Resist Different Storage Environments. Foods. 2023; 12(16):3056. https://doi.org/10.3390/foods12163056

Chicago/Turabian StyleRen, Xiaofeng, Junxia Wang, Arif Rashid, Ting Hou, Haile Ma, and Qiufang Liang. 2023. "Characterization of Nano-SiO2/Zein Film Prepared Using Ultrasonic Treatment and the Ability of the Prepared Film to Resist Different Storage Environments" Foods 12, no. 16: 3056. https://doi.org/10.3390/foods12163056