Recent Advances in Lycopene for Food Preservation and Shelf-Life Extension

Abstract

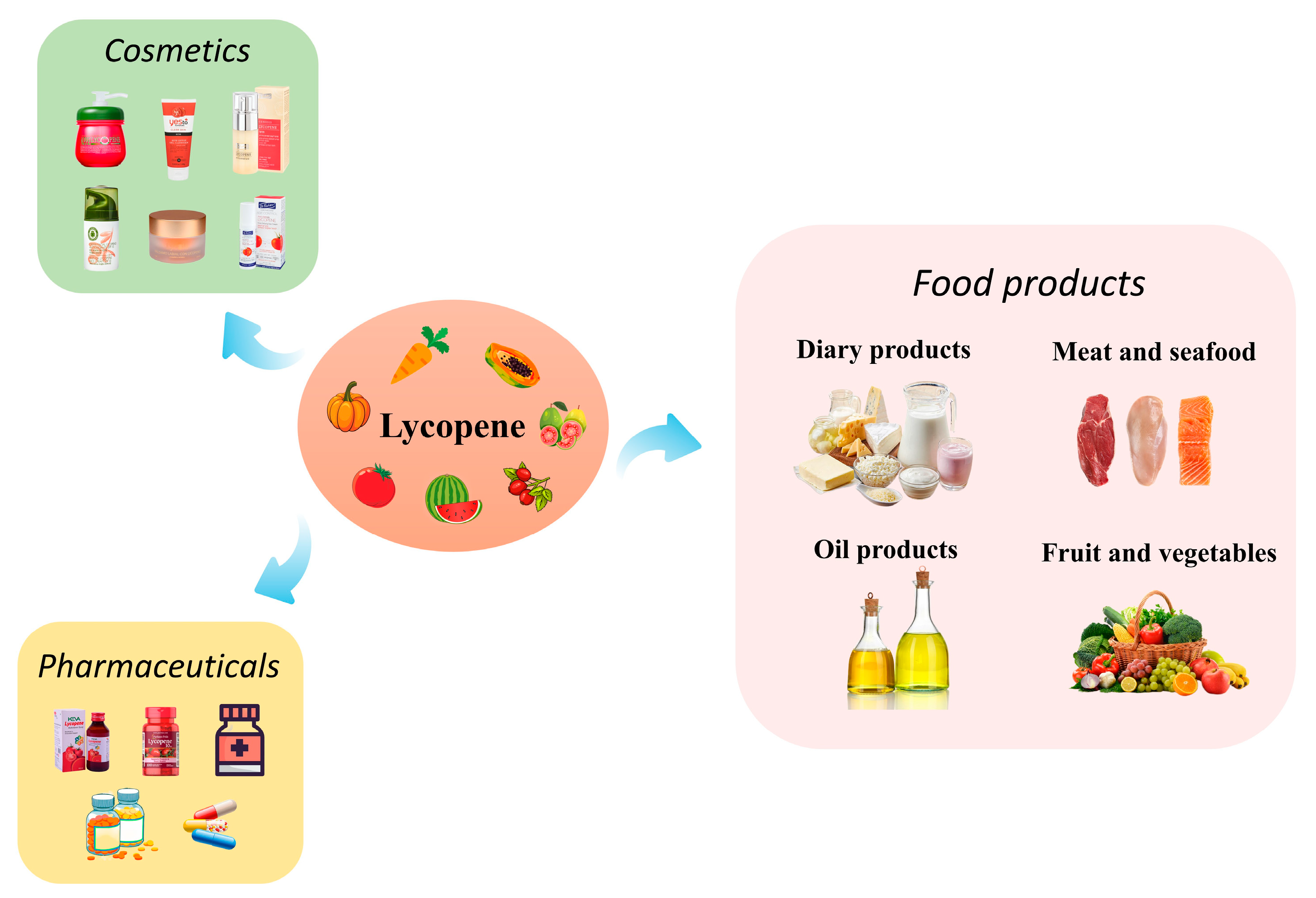

:1. Introduction

2. Properties of Lycopene

2.1. Naturally Occurring Forms in Fruits and Vegetables

2.2. Bioavailability and Stability

2.3. Benefits and Side Effects

3. Forms of Lycopene Added to Foods

3.1. Direct Addition of Extracted Lycopene

3.2. Composite Coating of Lycopene and Other Materials

3.3. Active Film Packaging with Lycopene

3.4. Emulsion Containing Lycopene

3.5. Lycopene Microcapsules

4. Effect of Lycopene as a Natural Antioxidant on the Preservation of Different Types of Foods

4.1. Meat and Seafood

4.2. Oil Products

4.3. Dairy Products

4.4. Fruits and Vegetables

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, W.T.; Wang, X.P.; Zhang, J.C.; Xia, J.; Zhang, X.S. Improvement of blueberry freshness prediction based on machine learning and multi-source sensing in the cold chain logistics. Food Control 2023, 145, 109496. [Google Scholar] [CrossRef]

- Franco, R.; Navarro, G.; Martínez-Pinilla, E. Antioxidants versus Food Antioxidant Additives and Food Preservatives. Antioxidants 2019, 8, 542. [Google Scholar] [CrossRef] [PubMed]

- Piper, J.D.; Piper, P.W. Benzoate and Sorbate Salts: A Systematic Review of the Potential Hazards of These Invaluable Preservatives and the Expanding Spectrum of Clinical Uses for Sodium Benzoate. Compr. Rev. Food Sci. Food Saf. 2017, 16, 868–880. [Google Scholar] [CrossRef] [PubMed]

- Sambu, S.; Hemaram, U.; Murugan, R.; Alsofi, A.A. Toxicological and Teratogenic Effect of Various Food Additives: An Updated Review. BioMed. Res. Int. 2022, 2022, 6829409. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhang, Y.; Zu, Y.; Yang, L.; Lu, Q.; Wang, W. Antioxidant effects of rosemary extracts on sunflower oil compared with synthetic antioxidants. Int. J. Food Sci. Technol. 2014, 49, 385–391. [Google Scholar] [CrossRef]

- Oberoi, D.P.S.; Sogi, D.S. Utilization of watermelon pulp for lycopene extraction by response surface methodology. Food Chem. 2017, 232, 316–321. [Google Scholar] [CrossRef]

- Honda, M.; Watanabe, Y.; Murakami, K.; Hoang, N.N.; Diono, W.; Kanda, H.; Goto, M. Enhanced Lycopene Extraction from Gac (Momordica cochinchinensis Spreng.) by the Z-Isomerization Induced with Microwave Irradiation Pre-Treatment. Eur. J. Lipid Sci. Technol. 2018, 120, 1700293. [Google Scholar] [CrossRef]

- Priyadarsani, S.; Patel, A.S.; Kar, A.; Dash, S. Process optimization for the supercritical carbondioxide extraction of lycopene from ripe grapefruit (Citrus paradisi) endocarp. Sci. Rep. 2021, 11, 10273. [Google Scholar] [CrossRef]

- Li, M.J.; Xia, Q.Q.; Lv, S.Z.; Tong, J.Z.; Wang, Z.B.; Nie, Q.J.; Yang, J.M. Enhanced CO2 capture for photosynthetic lycopene production in engineered Rhodopseudomonas palustris, a purple nonsulfur bacterium. Green Chem. 2022, 24, 7500–7518. [Google Scholar] [CrossRef]

- Saini, R.K.; Prasad, P.; Lokesh, V.; Shang, X.; Shin, J.; Keum, Y.S.; Lee, J.H. Carotenoids: Dietary Sources, Extraction, Encapsulation, Bioavailability, and Health Benefits—A Review of Recent Advancements. Antioxidants 2022, 11, 795. [Google Scholar] [CrossRef]

- Raiola, A.; Rigano, M.M.; Calafiore, R.; Frusciante, L.; Barone, A. Enhancing the Health-Promoting Effects of Tomato Fruit for Biofortified Food. Mediat. Inflamm. 2014, 2014, 139873. [Google Scholar] [CrossRef] [PubMed]

- Makhadmeh, I.; Albalasmeh, A.A.; Ali, M.; Thabet, S.G.; Darabseh, W.A.; Jaradat, S.; Alqudah, A.M. Molecular Characterization of Tomato (Solanum lycopersicum L.) Accessions under Drought Stress. HORT 2022, 8, 600. [Google Scholar] [CrossRef]

- Caruso, A.G.; Bertacca, S.; Parrella, G.; Rizzo, R.; Davino, S.; Panno, S. Tomato brown rugose fruit virus: A pathogen that is changing the tomato production worldwide. Ann. Appl. Biol. 2022, 181, 258–274. [Google Scholar] [CrossRef]

- Kehili, M.; Sayadi, S.; Frikha, F.; Zammel, A.; Allouche, N. Optimization of lycopene extraction from tomato peels industrial by-product using maceration in refined olive oil. Food Bioprod. Process. 2019, 117, 321–328. [Google Scholar] [CrossRef]

- Kaur, D.; Wani, A.A.; Oberoi, D.P.S.; Sogi, D.S. Effect of extraction conditions on lycopene extractions from tomato processing waste skin using response surface methodology. Food Chem. 2008, 108, 711–718. [Google Scholar] [CrossRef] [PubMed]

- Rahimi, S.; Mikani, M. Lycopene green ultrasound-assisted extraction using edible oil accompany with response surface methodology (RSM) optimization performance: Application in tomato processing wastes. Microchem. J. 2019, 146, 1033–1042. [Google Scholar] [CrossRef]

- Srivastava, S. Lycopene: Metabolism and Functional Aspects. In Bioactive Molecules in Food; Mérillon, J.-M., Ramawat, K.G., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 903–918. [Google Scholar]

- Bacanli, M.; Başaran, N.; Başaran, A.A. Lycopene: Is it Beneficial to Human Health as an Antioxidant? Turk. J. Pharm. Sci. 2017, 14, 311–318. [Google Scholar] [CrossRef]

- Przybylska, S. Lycopene—A bioactive carotenoid offering multiple health benefits: A review. Int. J. Food Sci. Technol. 2020, 55, 11–32. [Google Scholar] [CrossRef]

- Imran, M.; Ghorat, F.; Ul-Haq, I.; Ur-Rehman, H.; Aslam, F.; Heydari, M.; Shariati, M.A.; Okuskhanova, E.; Yessimbekov, Z.; Thiruvengadam, M.; et al. Lycopene as a Natural Antioxidant Used to Prevent Human Health Disorders. Antioxidants 2020, 9, 706. [Google Scholar] [CrossRef]

- Bavarsad, N.; Mapar, M.A.; Safaezadeh, M.; Latifi, S.M. A double-blind, placebo-controlled randomized trial of skin-lightening cream containing lycopene and wheat bran extract on melasma. J. Cosmet. Dermatol. 2021, 20, 1795–1800. [Google Scholar] [CrossRef]

- Rizwan, M.; Rodriguez-Blanco, I.; Harbottle, A.; Birch-Machin, M.A.; Watson, R.E.B.; Rhodes, L.E. Tomato paste rich in lycopene protects against cutaneous photodamage in humans in vivo: A randomized controlled trial. Br. J. Dermatol. 2011, 164, 154–162. [Google Scholar] [CrossRef] [PubMed]

- Leh, H.E.; Lee, L.K. Lycopene: A Potent Antioxidant for the Amelioration of Type II Diabetes Mellitus. Molecules 2022, 27, 2335. [Google Scholar] [CrossRef] [PubMed]

- Kawata, A.; Murakami, Y.; Suzuki, S.; Fujisawa, S. Anti-inflammatory Activity of beta-Carotene, Lycopene and Tri-n-butylborane, a Scavenger of Reactive Oxygen Species. In Vivo 2018, 32, 255–264. [Google Scholar] [CrossRef] [PubMed]

- Ataseven, D.; Ozturk, A.; Ozkaraca, M.; Joha, Z. Anticancer activity of lycopene in HT-29 colon cancer cell line. Med. Oncol. 2023, 40, 127. [Google Scholar] [CrossRef] [PubMed]

- Khan, U.M.; Sevindik, M.; Zarrabi, A.; Nami, M.; Ozdemir, B.; Kaplan, D.N.; Selamoglu, Z.; Hasan, M.; Kumar, M.; Alshehri, M.M.; et al. Lycopene: Food Sources, Biological Activities, and Human Health Benefits. Oxid. Med. Cell Longev. 2021, 2021, 2713511. [Google Scholar] [CrossRef] [PubMed]

- Hedayati, N.; Naeini, M.B.; Nezami, A.; Hosseinzadeh, H.; Wallace Hayes, A.; Hosseini, S.; Imenshahidi, M.; Karimi, G. Protective effect of lycopene against chemical and natural toxins: A review. Biofactors 2019, 45, 5–23. [Google Scholar] [CrossRef]

- Vallecilla-Yepez, L.; Ciftci, O.N. Increasing cis-lycopene content of the oleoresin from tomato processing byproducts using supercritical carbon dioxide. LWT 2018, 95, 354–360. [Google Scholar] [CrossRef]

- Li, Y.; Cui, Z.; Hu, L. Recent technological strategies for enhancing the stability of lycopene in processing and production. Food Chem. 2023, 405, 134799. [Google Scholar] [CrossRef]

- Cooperstone, J.L.; Ralston, R.A.; Riedl, K.M.; Haufe, T.C.; Schweiggert, R.M.; King, S.A.; Timmers, C.D.; Francis, D.M.; Lesinski, G.B.; Clinton, S.K.; et al. Enhanced bioavailability of lycopene when consumed as cis-isomers from tangerine compared to red tomato juice, a randomized, cross-over clinical trial. Mol. Nutr. Food Res. 2015, 59, 658–669. [Google Scholar] [CrossRef]

- Honda, M.; Nakayama, Y.; Nishikawa, S.; Tsuda, T. Z-Isomers of lycopene exhibit greater liver accumulation than the all-E-isomer in mice. Biosci. Biotechnol. Biochem. 2020, 84, 428–431. [Google Scholar] [CrossRef]

- Moraru, C.; Lee, T.C. Kinetic studies of lycopene isomerization in a tributyrin model system at gastric pH. J. Agric. Food Chem. 2005, 53, 8997–9004. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Yang, C.; Liu, Y.; Zhang, J.; Zhang, L. Efficient E/Z conversion of (all-E)-lycopene to Z-isomers with a high proportion of (5Z)-lycopene by metal salts. LWT 2022, 160, 113268. [Google Scholar] [CrossRef]

- Richelle, M.; Lambelet, P.; Rytz, A.; Tavazzi, I.; Mermoud, A.F.; Juhel, C.; Borel, P.; Bortlik, K. The proportion of lycopene isomers in human plasma is modulated by lycopene isomer profile in the meal but not by lycopene preparation. Br. J. Nutr. 2012, 107, 1482–1488. [Google Scholar] [CrossRef]

- Colle, I.J.P.; Lemmens, L.; Knockaert, G.; Van Loey, A.; Hendrickx, M. Carotene Degradation and Isomerization during Thermal Processing: A Review on the Kinetic Aspects. Crit. Rev. Food Sci. Nutr. 2016, 56, 1844–1855. [Google Scholar] [CrossRef] [PubMed]

- Saini, R.K.; Bekhit, A.E.D.A.; Roohinejad, S.; Rengasamy, K.R.R.; Keum, Y.S. Chemical Stability of Lycopene in Processed Products: A Review of the Effects of Processing Methods and Modern Preservation Strategies. J. Agric. Food Chem. 2020, 68, 712–726. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Dai, Y.; Kakuda, Y.; Mittal, G.; Xue, S.J. Effect of heating and exposure to light on the stability of lycopene in tomato puree. Food Control 2008, 19, 514–520. [Google Scholar] [CrossRef]

- Nishino, M.; Miuchi, T.; Sakata, M.; Nishida, A.; Murata, Y.; Nakamura, Y. Photostability of Lycopene Dispersed in an Aqueous Solution. Biosci. Biotechnol. Biochem. 2011, 75, 1389–1391. [Google Scholar] [CrossRef]

- Boon, C.S.; McClements, D.J.; Weiss, J.; Decker, E.A. Role of Iron and Hydroperoxides in the Degradation of Lycopene in Oil-in-Water Emulsions. J. Agric. Food Chem. 2009, 57, 2993–2998. [Google Scholar] [CrossRef]

- Abar, L.; Vieira, A.R.; Aune, D.; Stevens, C.; Vingeliene, S.; Navarro Rosenblatt, D.A.; Chan, D.; Greenwood, D.C.; Norat, T. Blood concentrations of carotenoids and retinol and lung cancer risk: An update of the WCRF–AICR systematic review of published prospective studies. Cancer Med. 2016, 5, 2069–2083. [Google Scholar] [CrossRef]

- Rowles, J.L.; Erdman, J.W. Carotenoids and their role in cancer prevention. Biochim. Biophys. Acta Mol. Cell Biol. Lipids 2020, 1865, 158613. [Google Scholar] [CrossRef]

- Tanaka, A.; Miyauchi, T.; Kitamura, S.; Iwata, H.; Hata, H.; Ujiie, H. Carotenoderma due to lycopenemia: A case report and evaluation of lycopene deposition in the skin. J. Dermatol. 2022, 49, 1320–1324. [Google Scholar] [CrossRef] [PubMed]

- Shao, A.; Hathcock, J.N. Risk assessment for the carotenoids lutein and lycopene. Regul. Toxicol. Pharmacol. 2006, 45, 289–298. [Google Scholar] [CrossRef] [PubMed]

- Tierney, A.C.; Rumble, C.E.; Billings, L.M.; George, E.S. Effect of Dietary and Supplemental Lycopene on Cardiovascular Risk Factors: A Systematic Review and Meta-Analysis. Adv. Nutr. 2020, 11, 1453–1488. [Google Scholar] [CrossRef]

- Hathcock, J.; Kriengsinyos, W. Highest Observed Intake: Definition, regulatory uses and provisional values. Regul. Toxicol. Pharmacol. 2011, 61, 115–118. [Google Scholar] [CrossRef]

- Nour, V.; Ionica, M.E.; Trandafir, I. Bread enriched in lycopene and other bioactive compounds by addition of dry tomato waste. J. Food Sci. Tech. Mys. 2015, 52, 8260–8267. [Google Scholar] [CrossRef] [PubMed]

- Kim, I.S.; Jin, S.K.; Mandal, P.K.; Kang, S.N. Quality of low-fat pork sausages with tomato powder as colour and functional additive during refrigerated storage. J. Food Sci. Technol. 2011, 48, 591–597. [Google Scholar] [CrossRef] [PubMed]

- Kehili, M.; Choura, S.; Zammel, A.; Allouche, N.; Sayadi, S. Oxidative stability of refined olive and sunflower oils supplemented with lycopene-rich oleoresin from tomato peels industrial by-product, during accelerated shelf-life storage. Food Chem. 2018, 246, 295–304. [Google Scholar] [CrossRef]

- Li, Z.X.; Shen, H.H.; Gao, M.M.; Qi, J.; Li, Q.Y. Analysis of Lycopene in Different Solvents by Spectrophotometry. Spectrosc. Spect. Anal. 2019, 39, 1114–1117. [Google Scholar] [CrossRef]

- Xie, C.N.; Ma, Z.F.; Li, F.; Zhang, H.X.; Kong, L.M.; Yang, Z.P.; Xie, W.F. Storage quality of walnut oil containing lycopene during accelerated oxidation. J. Food Sci. Tech. Mys. 2018, 55, 1387–1395. [Google Scholar] [CrossRef]

- Siwach, R.; Tokas, J.; Seth, R. Use of lycopene as a natural antioxidant in extending the shelf-life of anhydrous cow milk fat. Food Chem. 2016, 199, 541–546. [Google Scholar] [CrossRef]

- Kaur, D.; Wani, A.A.; Singh, D.P.; Sogi, D.S. Shelf Life Enhancement of Butter, Ice-Cream, and Mayonnaise by Addition of Lycopene. Int. J. Food Prop. 2011, 14, 1217–1231. [Google Scholar] [CrossRef]

- Ehsani, A.; Jasour, M.S.; Agh, N.; Hashemi, M.; Khodadadi, M. Rancidity development of refrigerated rainbow trout (Oncorhynchus mykiss) fillets: Comparative effects of in vivo and in vitro lycopene. J. Sci. Food Agric. 2018, 98, 559–565. [Google Scholar] [CrossRef] [PubMed]

- Thakur, R.; Pristijono, P.; Scarlett, C.J.; Bowyer, M.; Singh, S.P.; Vuong, Q.V. Starch-based films: Major factors affecting their properties. Int. J. Biol. Macromol. 2019, 132, 1079–1089. [Google Scholar] [CrossRef]

- Yousuf, B.; Qadri, O.S.; Srivastava, A.K. Recent developments in shelf-life extension of fresh-cut fruits and vegetables by application of different edible coatings: A review. LWT 2018, 89, 198–209. [Google Scholar] [CrossRef]

- Suhag, R.; Kumar, N.; Petkoska, A.T.; Upadhyay, A. Film formation and deposition methods of edible coating on food products: A review. Food Res. Int. 2020, 136, 109582. [Google Scholar] [CrossRef]

- Ganiari, S.; Choulitoudi, E.; Oreopoulou, V. Edible and active films and coatings as carriers of natural antioxidants for lipid food. Trends Food Sci. Technol. 2017, 68, 70–82. [Google Scholar] [CrossRef]

- Ehsani, A.; Paktarmani, M.; Yousefi, M. Efficiency of dietary sodium alginate coating incorporated with lycopene in preserving rainbow trout. Food Sci. Biotechnol. 2017, 26, 557–562. [Google Scholar] [CrossRef]

- Ehsani, A.; Hashemi, M.; Raeisi, M.; Naghibi, S.S.; Afshari, A. Rainbow trout fillet biopreservation by edible chitosan-based coating containing egg yolk antibody (IgY) and lycopene. J. Food Sci. Tech. Mys. 2020, 57, 282–292. [Google Scholar] [CrossRef]

- Khalida, P.; Afifa, E.N.; Novita, T.H.; Purnawan, C. Edible Coating Chitosan and Lycopene Isolated from Watermelon as a Solution to Extend Fruit and Vegetables Storage Time from After Harvest Damage. In Proceedings of the 11th Regional Conference on Chemical Engineering (RCChE), Yogyakarta, Indonesia, 7–8 November 2018. [Google Scholar]

- Rezaei, M.; Pirsa, S.; Chavoshizadeh, S. Photocatalytic/Antimicrobial Active Film Based on Wheat Gluten/ZnO Nanoparticles. J. Inorg. Organomet. Polym. Mater. 2020, 30, 2654–2665. [Google Scholar] [CrossRef]

- Pirsa, S.; Farshchi, E.; Roufegarinejad, L. Antioxidant/Antimicrobial Film Based on Carboxymethyl Cellulose/Gelatin/TiO2-Ag Nano-Composite. J. Polym. Environ. 2020, 28, 3154–3163. [Google Scholar] [CrossRef]

- Pirouzifard, M.; Yorghanlu, R.A.; Pirsa, S. Production of active film based on potato starch containing Zedo gum and essential oil of Salvia officinalisand study of physical, mechanical, and antioxidant properties. J. Thermoplast. Compos. Mater. 2020, 33, 915–937. [Google Scholar] [CrossRef]

- Huang, W.T.; Wang, X.P.; Xia, J.; Li, Y.L.; Zhang, L.W.; Feng, H.H.; Zhang, X.S. Flexible sensing enabled agri-food cold chain quality control: A review of mechanism analysis, emerging applications, and system integration. Trends Food Sci. Technol. 2023, 133, 189–204. [Google Scholar] [CrossRef]

- Stoll, L.; Rech, R.; Flores, S.H.; Nachtigall, S.M.B.; Rios, A.D. Poly(acid lactic) films with carotenoids extracts: Release study and effect on sunflower oil preservation. Food Chem. 2019, 281, 213–221. [Google Scholar] [CrossRef]

- Pirsa, S.; Asadi, S. Innovative smart and biodegradable packaging for margarine based on a nano composite polylactic acid/lycopene film. Food Addit. 2021, 38, 856–869. [Google Scholar] [CrossRef] [PubMed]

- Noronha, C.M.; de Carvalho, S.M.; Lino, R.C.; Barreto, P.L.M. Characterization of antioxidant methylcellulose film incorporated with α-tocopherol nanocapsules. Food Chem. 2014, 159, 529–535. [Google Scholar] [CrossRef] [PubMed]

- Assis, R.Q.; Lopes, S.M.; Costa, T.M.H.; Flores, S.H.; Rios, A.D. Active biodegradable cassava starch films incorporated lycopene nanocapsules. Ind. Crops Prod. 2017, 109, 818–827. [Google Scholar] [CrossRef]

- Tupuna-Yerovi, D.S.; Schmidt, H.; Rios, A.d.O. Biodegradable sodium alginate films incorporated with lycopene and beta-carotene for food packaging purposes. Food Sci. Technol. Int. 2023, 10820132231172362. [Google Scholar] [CrossRef]

- Pagno, C.H.; de Farias, Y.B.; Costa, T.M.H.; Rios, A.d.O.; Flôres, S.H. Synthesis of biodegradable films with antioxidant properties based on cassava starch containing bixin nanocapsules. J. Food Sci. Technol. 2016, 53, 3197–3205. [Google Scholar] [CrossRef]

- Zeng, Y.B.; Wang, Y.; Tang, J.H.; Zhang, H.T.; Dai, J.W.; Li, S.Q.; Yan, J.; Qin, W.; Liu, Y.W. Preparation of sodium alginate/konjac glucomannan active films containing lycopene microcapsules and the effects of these films on sweet cherry preservation. Int. J. Biol. Macromol. 2022, 215, 67–78. [Google Scholar] [CrossRef] [PubMed]

- Araiza-Calahorra, A.; Akhtar, M.; Sarkar, A. Recent advances in emulsion-based delivery approaches for curcumin: From encapsulation to bioaccessibility. Trends Food Sci. Technol. 2018, 71, 155–169. [Google Scholar] [CrossRef]

- Meroni, E.; Raikos, V. Formulating orange oil-in-water beverage emulsions for effective delivery of bioactives: Improvements in chemical stability, antioxidant activity and gastrointestinal fate of lycopene using carrier oils. Food Res. Int. 2018, 106, 439–445. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Yuan, C.H.Y.; Li, W.C.; Zhao, L.; Huang, Y.B.; Li, H.H.; Liu, G.; Ni, H.; Raikos, V. Physicochemical and nutritional properties of yogurt emulsion with lycopene during chilled storage. J. Food Sci. Technol. 2022, 59, 4037–4044. [Google Scholar] [CrossRef] [PubMed]

- Raikos, V.; Hayward, N.; Hayes, H.; Meroni, E.; Ranawana, V. Optimising the ratio of long- to short-chain triglycerides of the lipid phase to enhance physical stability and bioaccessibility of lycopene-loaded beverage emulsions. Int. J. Food Sci. Technol. 2019, 54, 1355–1362. [Google Scholar] [CrossRef]

- Baghabrishami, R.G.; Goli, S.A.H. Tomato seed oil-enriched tomato juice: Effect of oil addition type and heat treatment on lycopene bioaccessibility and oxidative stability. Food Chem. 2023, 402, 134217. [Google Scholar] [CrossRef] [PubMed]

- Himanath, G.; Shruthy, R.; Preetha, R.; Sreejit, V. Nanoemulsion with Coconut Oil and Soy Lecithin as a Stable Delivery System for Lycopene and Its Incorporation into Yogurt to Enhance Antioxidant Properties and Maintain Quality. ACS Food Sci. Technol. 2021, 1, 1538–1549. [Google Scholar] [CrossRef]

- Liu, Q.; Huang, H.; Chen, H.; Lin, J.; Wang, Q. Food-Grade Nanoemulsions: Preparation, Stability and Application in Encapsulation of Bioactive Compounds. Molecules 2019, 24, 4242. [Google Scholar] [CrossRef]

- Chang, R.; Liu, B.; Wang, Q.; Zhang, J.; Yuan, F.; Zhang, H.; Chen, S.; Liang, S.; Li, Y. The encapsulation of lycopene with α-lactalbumin nanotubes to enhance their anti-oxidant activity, viscosity and colloidal stability in dairy drink. Food Hydrocoll. 2022, 131, 107792. [Google Scholar] [CrossRef]

- Wu, H.; Wu, Y.; Cui, Z.; Hu, L. Nutraceutical delivery systems to improve the bioaccessibility and bioavailability of lycopene: A review. Crit. Rev. Food Sci. Nutr. 2023, 1–19. [Google Scholar] [CrossRef]

- Martins, V.F.R.; Pintado, M.E.; Morais, R.M.S.C.; Morais, A.M.M.B. Valorisation of Micro/Nanoencapsulated Bioactive Compounds from Plant Sources for Food Applications Towards Sustainability. Foods 2023, 12, 32. [Google Scholar] [CrossRef]

- Martínez-Hernández, G.B.; Castillejo, N.; Artés-Hernández, F. Effect of fresh–cut apples fortification with lycopene microspheres, revalorized from tomato by-products, during shelf life. Postharvest Biol. Technol. 2019, 156, 110925. [Google Scholar] [CrossRef]

- Rocha-Selmi, G.A.; Favaro-Trindade, C.S.; Grosso, C.R.F. Morphology, Stability, and Application of Lycopene Microcapsules Produced by Complex Coacervation. J. Chem. 2013, 2013, 982603. [Google Scholar] [CrossRef]

- Chen, Y.; Lu, P.; Yuan, F. Preparation and Stability Evaluation of Novel Lycopene Microcapsules. Food Sci. 2021, 42, 134–140. [Google Scholar]

- Gheonea, I.; Aprodu, I.; Cîrciumaru, A.; Râpeanu, G.; Bahrim, G.E.; Stănciuc, N. Microencapsulation of lycopene from tomatoes peels by complex coacervation and freeze-drying: Evidences on phytochemical profile, stability and food applications. J. Food Eng. 2021, 288, 110166. [Google Scholar] [CrossRef]

- Jia, C.; Cao, D.; Ji, S.; Lin, W.; Zhang, X.; Muhoza, B. Whey protein isolate conjugated with xylo-oligosaccharides via maillard reaction: Characterization, antioxidant capacity, and application for lycopene microencapsulation. LWT 2020, 118, 108837. [Google Scholar] [CrossRef]

- Pu, C.; Tang, W. Encapsulation of lycopene in Chlorella pyrenoidosa: Loading properties and stability improvement. Food Chem. 2017, 235, 283–289. [Google Scholar] [CrossRef]

- Souza, A.L.R.; Hidalgo-Chavez, D.W.; Pontes, S.M.; Gomes, F.S.; Cabral, L.M.C.; Tonon, R.V. Microencapsulation by spray drying of a lycopene-rich tomato concentrate: Characterization and stability. LWT—Food Sci. Technol. 2018, 91, 286–292. [Google Scholar] [CrossRef]

- Amaro-Blanco, G.; Machado, T.; Pinto-Andrade, L.; Proaño, F.; Manzano, R.; Delgado-Adámez, J.; Ramírez, R. Effect of tomato paste addition and high pressure processing to preserve pork burgers. Eur. Food Res. Technol. 2018, 244, 827–839. [Google Scholar] [CrossRef]

- Egan, H.; Cox, H.E.; Pearson, D. Pearson’s Chemical Analysis of Foods; Livingstone: Edinburgh, UK, 1981. [Google Scholar]

- Goulas, A.E.; Kontominas, M.G. Effect of salting and smoking-method on the keeping quality of chub mackerel (Scomber japonicus): Biochemical and sensory attributes. Food Chem. 2005, 93, 511–520. [Google Scholar] [CrossRef]

- Kirk, R.S.; Sawyer, R.; Harold, E. Pearson’s Composition and Analysis of Foods; Addison-Wesley Longman Ltd.: Saddle River, NJ, USA, 1991. [Google Scholar]

- Taghvaei, M.; Jafari, S.M. Application and stability of natural antioxidants in edible oils in order to substitute synthetic additives. J. Food Sci. Technol. 2015, 52, 1272–1282. [Google Scholar] [CrossRef]

- Varas Condori, M.A.; Pascual Chagman, G.J.; Barriga-Sanchez, M.; Villegas Vilchez, L.F.; Ursetta, S.; Guevara Pérez, A.; Hidalgo, A. Effect of tomato (Solanum lycopersicum L.) lycopene-rich extract on the kinetics of rancidity and shelf-life of linseed (Linum usitatissimum L.) oil. Food Chem. 2020, 302, 125327. [Google Scholar] [CrossRef]

- Le Grandois, J.; Guffond, D.; Hamon, E.; Marchioni, E.; Werner, D. Combined microplate-ABTS and HPLC-ABTS analysis of tomato and pepper extracts reveals synergetic and antagonist effects of their lipophilic antioxidative components. Food Chem. 2017, 223, 62–71. [Google Scholar] [CrossRef] [PubMed]

- Bayarmaa, B.; Na Yeon, K.; Hye Lyun, J.; Mee Ree, K. Evaluation of the Antioxidant Capacity and Phenolic Content of Agriophyllum pungens Seed Extracts from Mongolia. Prev. Nutr. Food Sci. 2013, 18, 188–195. [Google Scholar]

- Sy, C.; Caris-Veyrat, C.; Dufour, C.; Boutaleb, M.; Borel, P.; Dangles, O. Inhibition of iron-induced lipid peroxidation by newly identified bacterial carotenoids in model gastric conditions: Comparison with common carotenoids. Food Funct. 2013, 4, 698–712. [Google Scholar] [CrossRef] [PubMed]

- Steenson, D.F.; Min, D.B. Effects of β-carotene and lycopene thermal degradation products on the oxidative stability of soybean oil. J. Am. Oil Chem. Soc. 2000, 77, 1153–1160. [Google Scholar] [CrossRef]

- Ehsani, A.; Hashemi, M.; Jazani, N.H.; Aliakbarlu, J.; Shokri, S.; Naghibi, S.S. Effect of Echinophora platyloba DC. essential oil and lycopene on the stability of pasteurized cream obtained from cow milk. Vet. Res. Forum 2016, 7, 139–148. [Google Scholar]

- Cesa, S. Malondialdehyde contents in infant milk formulas. J. Agric. Food Chem. 2004, 52, 2119–2122. [Google Scholar] [CrossRef]

- Finnegan, E.; O’Beirne, D. Characterising deterioration patterns in fresh-cut fruit using principal component analysis. II: Effects of ripeness stage, seasonality, processing and packaging. Postharvest Biol. Technol. 2015, 100, 91–98. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, H.B.; Chung, H.S.; Moon, K.D. Browning control of fresh-cut lettuce by phytoncide treatment. Food Chem. 2014, 159, 188–192. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, M.; Bhandari, B.; Gao, Z. Recent developments in novel shelf life extension technologies of fresh-cut fruits and vegetables. Trends Food Sci. Technol. 2017, 64, 23–38. [Google Scholar] [CrossRef]

- Vági, E.; Simándi, B.; Vásárhelyiné, K.P.; Daood, H.; Kéry, Á.; Doleschall, F.; Nagy, B. Supercritical carbon dioxide extraction of carotenoids, tocopherols and sitosterols from industrial tomato by-products. J. Supercrit. 2007, 40, 218–226. [Google Scholar] [CrossRef]

| Food Sources | Contents (mg/100 g) |

|---|---|

| Tomato | 0.72–4.2 |

| Pumpkin | 0.38–0.46 |

| Sweet potato | 0.02–0.11 |

| Pink grapefruit | 0.35–3.36 |

| Carrot | 0.65–0.78 |

| Pink guava | 5.23–5.5 |

| Watermelon | 2.30–7.20 |

| Apricot | 0.01–0.05 |

| Papaya | 0.11–5.3 |

| Rosehip | 0.68–0.71 |

| Food Products | Lycopene Addition Form | Concentration of Lycopene | Results | Refs. |

|---|---|---|---|---|

| Low-fat pork sausage | Tomato powder | No mention | Tomato powder up to 1.5% was found to be well acceptable for up to 30 days at refrigerated storage. | [47] |

| Pork burgers | Tomato paste | 145.5 ± 8.8 mg/100 g | Tomato paste containing lycopene increased the lipid oxidation stability of burgers during storage. | [89] |

| Rainbow trout | Alginate coating with lycopene | 0.5, 1, 1.5, and 3% w/v | Alginate coating with 3% lycopene had the best performance. | [58] |

| Rainbow trout | Chitosan-based coating containing extracted egg yolk antibody along with lycopene | 1.5 and 3% | Egg yolk antibodies and lycopene to the coating solution significantly reduced lipid oxidation and improved sensory attributes. | [59] |

| Walnut oil | Lycopene with a purity of 95% | 0.001 to 0.015% | 0.005% lycopene exhibited the greatest antioxidant effect. | [50] |

| Linseed oil | Lycopene extract from tomato | 40, 80 and 120 mg lycopene/kg oil | The oxidative stability index of 80 mg lycopene/kg in linseed oil at 110 °C is the same as that of 200 mg/kg BHT. | [94] |

| Refined olive and sunflower oils | Lycopene-rich oleoresin extracts | 5, 10, 20, and 40 µg/g | It is recommended that refined olive oil and sunflower oil be preserved with 5 µg/g and 40 µg/g lycopene, respectively. | [48] |

| Margarine | Polylactic acid /titanium dioxide/lycopene nanocomposite film | 3% w/v | The film controlled the oxidation factor and significantly extended the shelf-life of margarine. | [66] |

| Sunflower oil | Polylactic acid films containing lycopene | No mention | The oxygen barrier and lycopene release properties of films improve the oxidative stability of sunflower oil. | [65] |

| Butter and ice cream | Lycopene crystals | Butter (20 ppm) and ice cream (70 ppm) | Lycopene improved the oxidative stability of butter and ice cream during 4-month storage. | [52] |

| Anhydrous cow milk fat | Lycopene extract | 30, 60, 90, 120, and 150 ppm | Lycopene at all levels significantly prevented the development of oxidative rancidity in milk fat | [51] |

| Pasteurized cream | Lycopene extract | 20 and 50 ppm | Lycopene prolonged the shelf-life of the cream, and the results of the sensory evaluation were acceptable during storage. | [99] |

| Yogurt | Emulsion | 1.5 mg/g oil phase | Improved physicochemical stability and rheological properties after the addition of lycopene to yogurt using emulsion. | [74] |

| Yogurt | Nanoemulsion | 0.2, 0.4, 0.6, 0.8, and 1% | Yogurt containing lycopene nanoemulsions showed better antioxidant and physicochemical properties, as well as improved survival of Lactobacillus bulgaricus for up to 28 days. | [77] |

| Sweet cherry | Composite film containing lycopene microcapsules | 10 mL lycopene extract oil to prepare microcapsules | Lycopene effectively reduced cherry oxidation and extended shelf-life during storage. | [71] |

| Grape | Edible coating containing lycopene | 0.375, 0.75, 1.125, and 1.5% | The combination of 1.5% (75 lycopene: 25 chitosan) had the greatest preservation capacity. | [60] |

| Fresh-cut apple | Lycopene microspheres | 5 mL cis–lycopene-rich oil was added to 50 mL of gelatine solution to form a microsphere | The dipping treatment of fresh–cut apples, including 2 g/L lycopene microspheres, reduced browning while quality was maintained, and some bioactive compounds even enhanced after 9 d at 5 °C. | [82] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Yu, F. Recent Advances in Lycopene for Food Preservation and Shelf-Life Extension. Foods 2023, 12, 3121. https://doi.org/10.3390/foods12163121

Li Z, Yu F. Recent Advances in Lycopene for Food Preservation and Shelf-Life Extension. Foods. 2023; 12(16):3121. https://doi.org/10.3390/foods12163121

Chicago/Turabian StyleLi, Zhixi, and Fanqianhui Yu. 2023. "Recent Advances in Lycopene for Food Preservation and Shelf-Life Extension" Foods 12, no. 16: 3121. https://doi.org/10.3390/foods12163121