Innovative Plant-Based Burger Enriched with Tenebrio molitor Meal: Characterization and Shelf-Life

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Material

2.2. Experimental Design

2.3. Burger Analog Production

2.4. Physicochemical Quality of Developed Products

2.4.1. pH

2.4.2. Color

2.4.3. Moisture (H%)

2.4.4. Water Activity (aw)

2.4.5. Acidity Index

2.4.6. Peroxide Index

2.5. Microbiological Quality of Burger Analogs

2.6. Sensory Study of Burger Analogs

Quantitative Descriptive Analysis (QDA)

2.7. Shelf-Life Study for Burger Analogs Developed

2.7.1. Shelf-Life Design

2.7.2. Shelf-Life Model (Multivariate Method)

2.7.3. Spoilage Descriptive Model

2.8. Statistical Analysis

3. Results and Discussion

3.1. Iterative Development Process

3.2. Quality and Safety of Burger Analogs

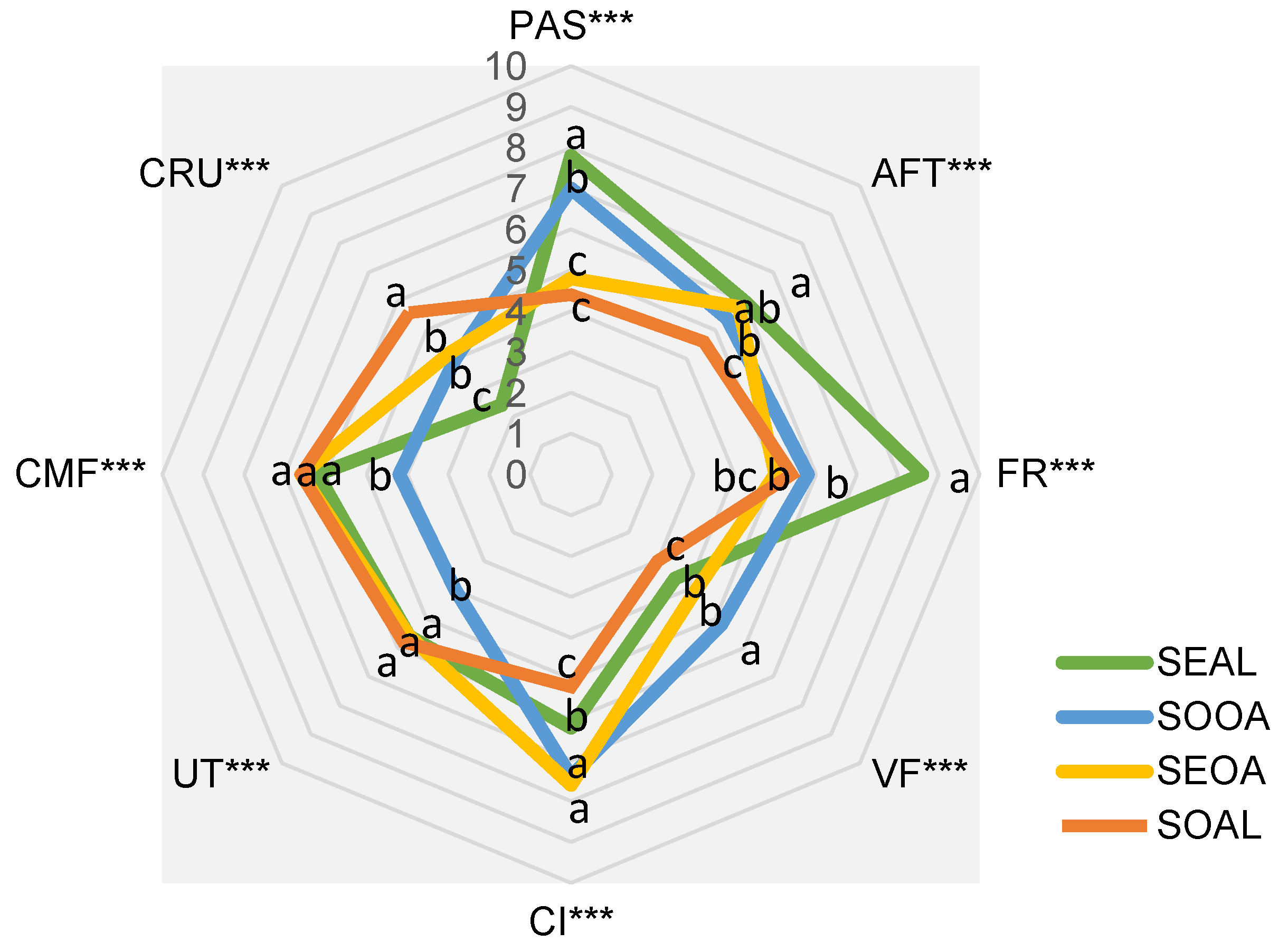

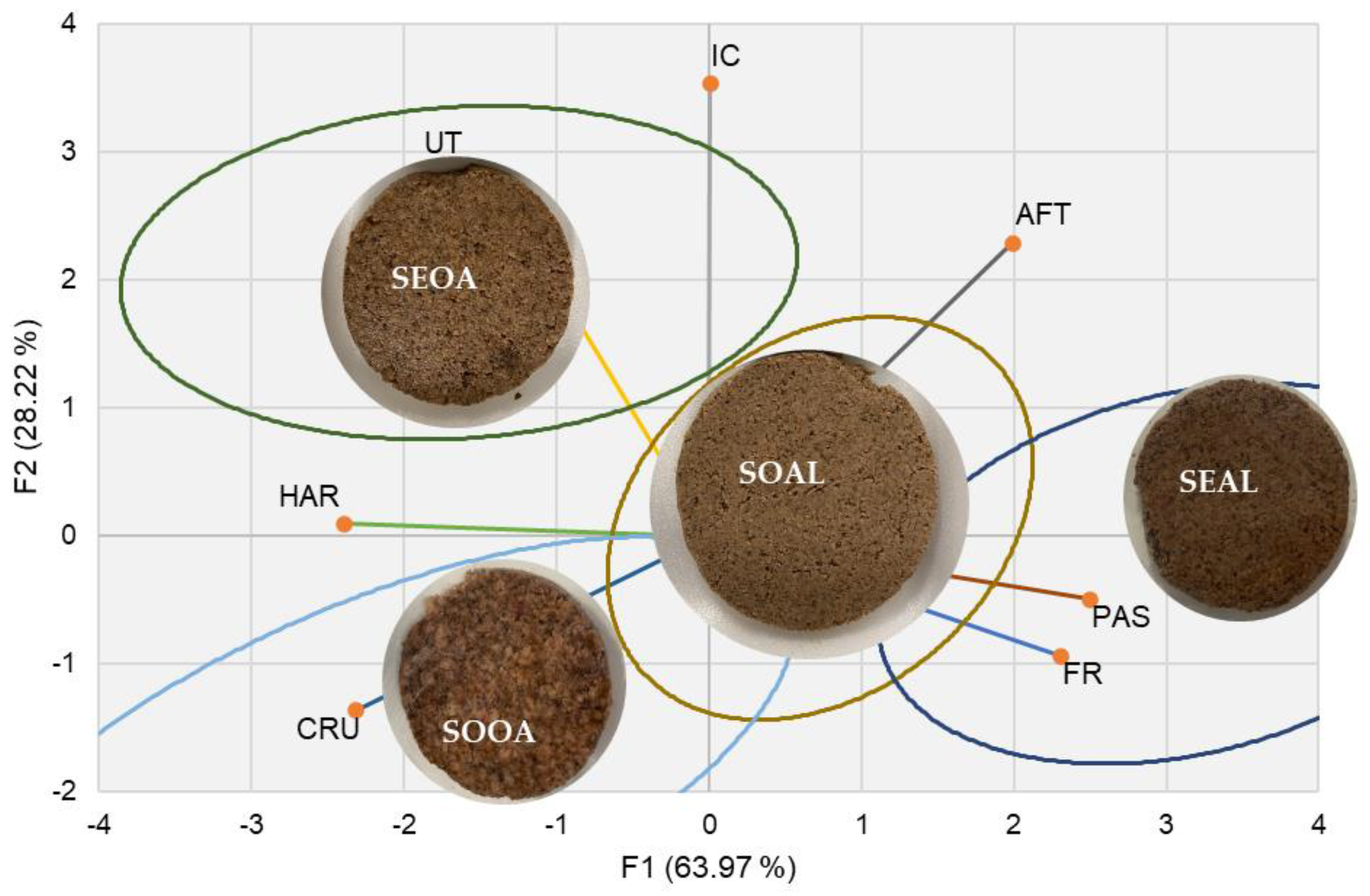

3.3. Sensory Characterization of the Burger Analogs

3.4. Shelf-Life Study

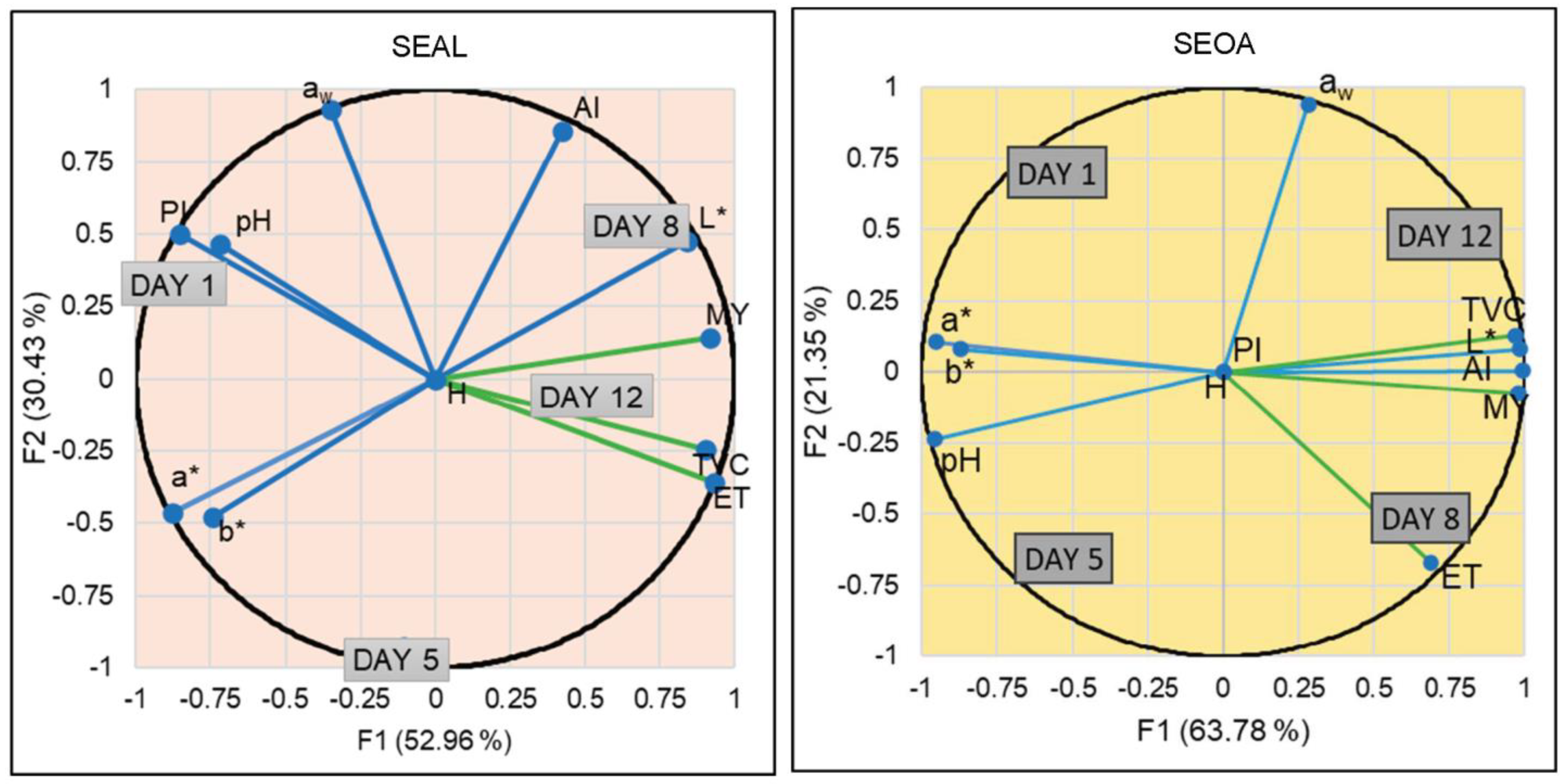

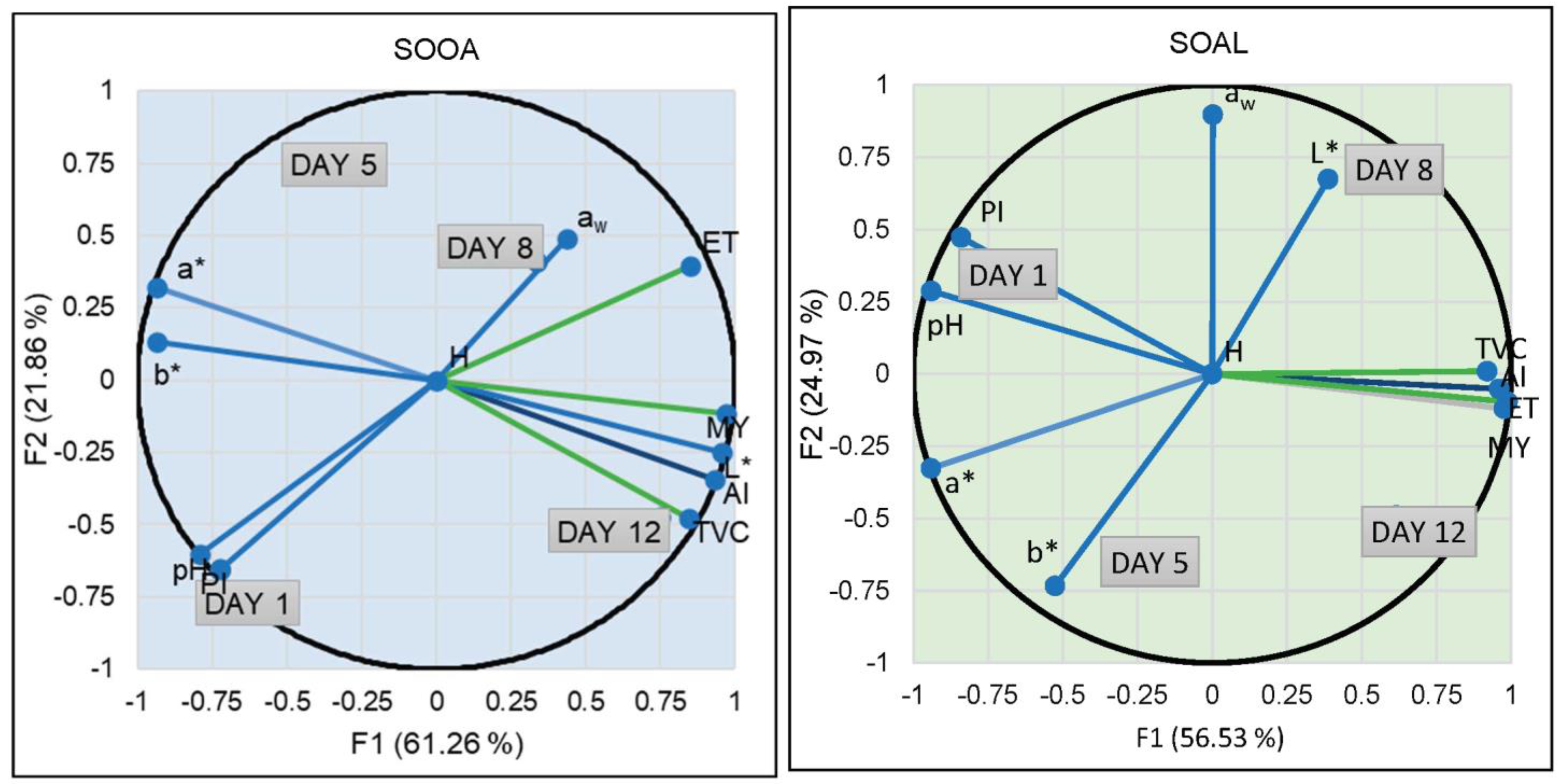

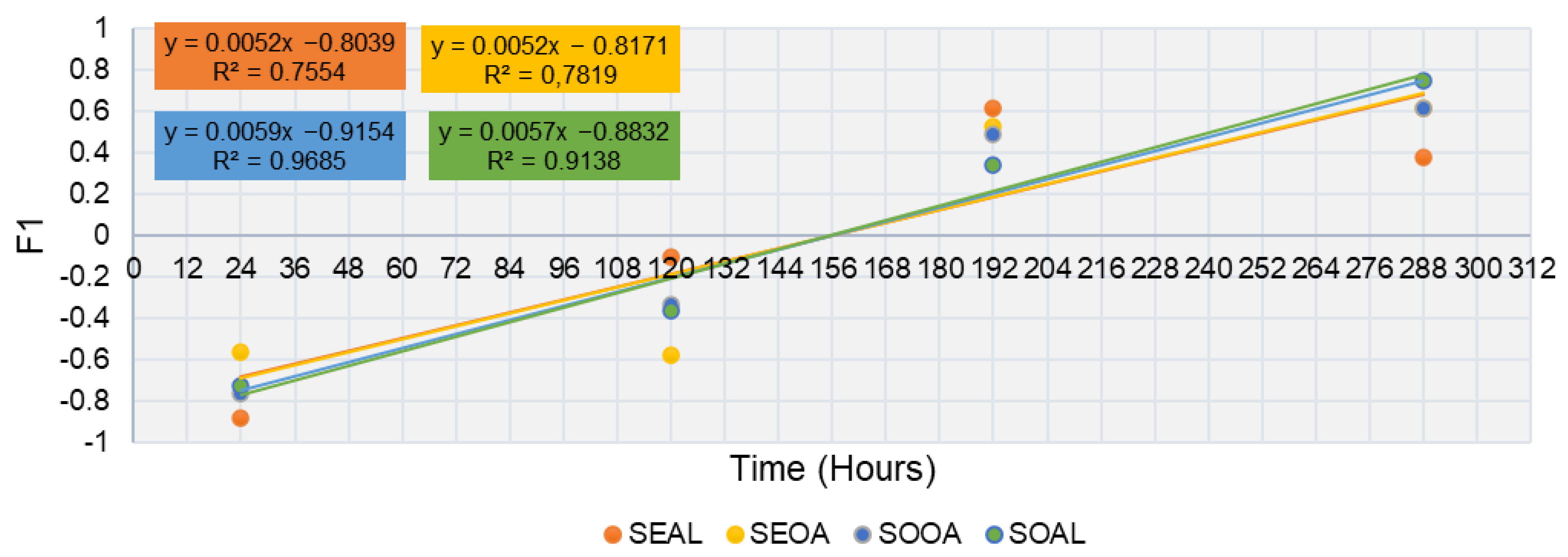

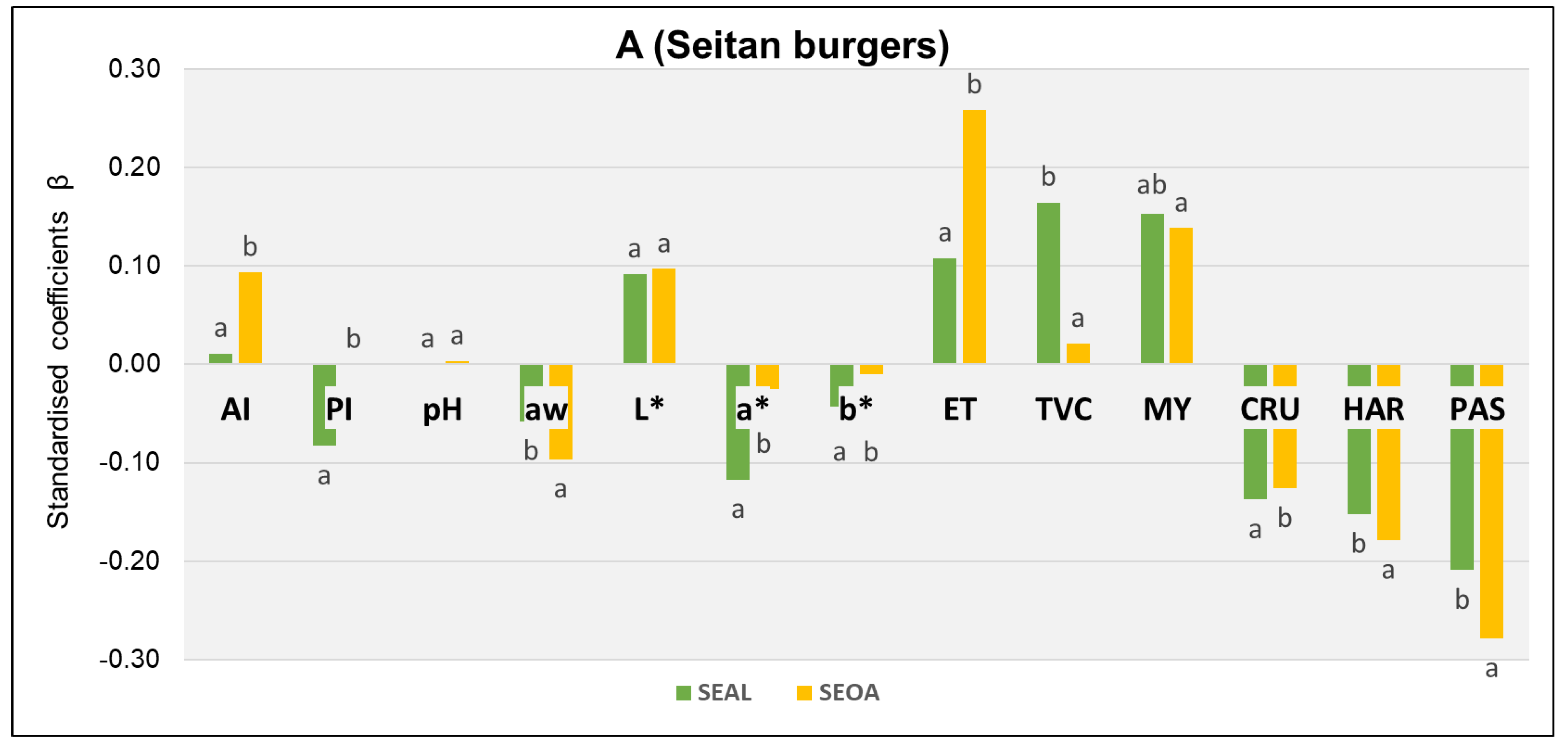

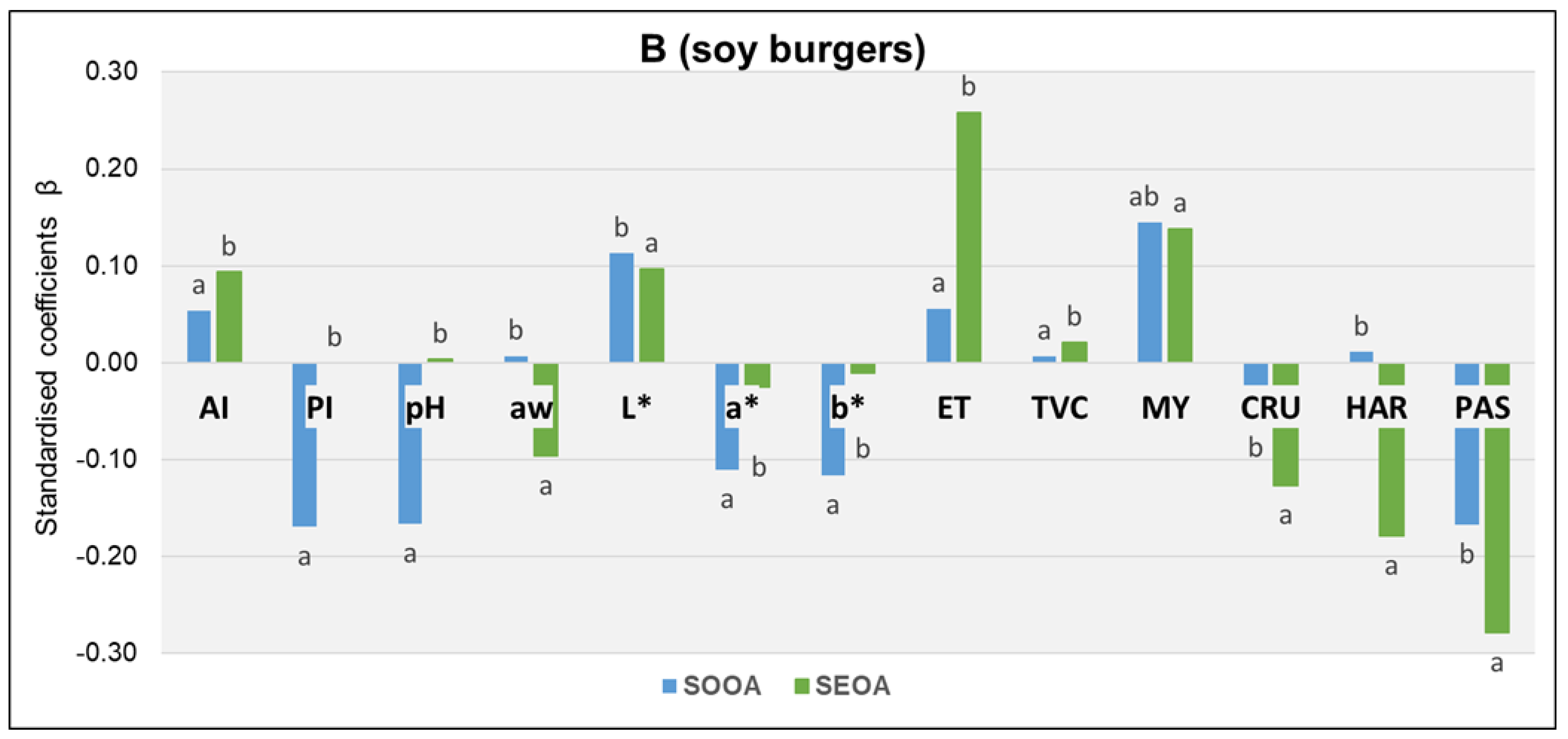

Shelf-Life Study Model (Multivariate Method)

3.5. Spoilage Descriptive Model

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Profeta, A.; Baune, M.; Smetana, S.; Broucke, K.; Van Royen, G.; Weiss, J.; Hieke, S.; Heinz, V.; Terjung, N. Consumer preferences for meat blended with plant proteins—Empirical findings from Belgium. Future Foods 2021, 4, 100088. [Google Scholar] [CrossRef]

- Boukid, F. Plant-based meat analogues: From niche to mainstream. Eur. Food Res. Technol. 2021, 247, 297–308. [Google Scholar] [CrossRef]

- Ahmad, M.; Qureshi, S.; Akbar, M.H.; Siddiqui, S.A.; Gani, A.; Mushtaq, M.; Hassan, I.; Dhull, S.B. Plant-based meat alternatives: Compositional analysis, current development and challenges. Appl. Food Res. 2022, 2, 100154. [Google Scholar] [CrossRef]

- Goldstein, B.; Moses, R.; Sammons, N.; Birkved, M. Potential for curbing the environmental burdens of beef consumption in the United States using a novel plant-based meat substitute. PLoS ONE 2017, 12, e0189029. [Google Scholar] [CrossRef]

- Bakhsh, A.; Lee, S.; Lee, E.; Hwang, Y.; Joo, S. Traditional Plant-based Meat Alternatives, Current, and Future Perspective: A Review. J. Agric. Life Sci. 2021, 55, 1–10. [Google Scholar] [CrossRef]

- Huang, M.; Mehany, T.; Xie, W.; Liu, X.; Guo, S.; Peng, X. Use of food carbohydrates towards the innovation of plant-based meat analogues. Trends Food Sci. Technol. 2022, 129, 155–163. [Google Scholar] [CrossRef]

- Mel, R.; Malalgoda, M. Oat protein as a novel protein ingredient: Structure, functionality, and factors impacting utilization. Cereal Chem. 2022, 99, 21–36. [Google Scholar] [CrossRef]

- Verbeke, W. Profiling consumers who are ready to adopt insects as a meat substitute in Western society. Food Qual. Prefer. 2015, 39, 147–155. [Google Scholar] [CrossRef]

- Lionetti, E.; Catassi, C. New Clues in Celiac Disease Epidemiology, Pathogenesis, Clinical Manifestations, and Treatment. Int. Rev. Immunol. 2011, 30, 219–231. [Google Scholar] [CrossRef]

- Lima, M.; Costa, R.; Rodrigues, I.; Lameiras, J.; Botelho, G. A Narrative Review of Alternative Protein Sources: Highlights on Meat, Fish, Egg and Dairy Analogues. Foods 2022, 11, 2053. [Google Scholar] [CrossRef]

- Michel, F.; Knaapila, A.; Hartmann, C.; Siegrist, M. A multi-national comparison of meat eaters’ attitudes and expectations for burgers containing beef, pea or algae protein. Food Qual. Prefer. 2021, 91, 104195. [Google Scholar] [CrossRef]

- Berger, S.; Bärtsch, C.; Schmidt, C.; Christandl, F.; Wyss, A.M. When Utilitarian Claims Backfire: Advertising Content and the Uptake of Insects as Food. Front. Nutr. 2018, 5, 88. [Google Scholar] [CrossRef] [PubMed]

- Mancini, S.; Fratini, F.; Turchi, B.; Mattioli, S.; Dal Bosco, A.; Tuccinardi, T.; Nozic, S.; Paci, G. Former Foodstuff Products in Tenebrio molitor Rearing: Effects on Growth, Chemical Composition, Microbiological Load, and Antioxidant Status. Animals 2019, 9, 484. [Google Scholar] [CrossRef] [PubMed]

- Navarro del Hierro, J.; Gutiérrez-Docio, A.; Otero, P.; Reglero, G.; Martin, D. Characterization, antioxidant activity, and inhibitory effect on pancreatic lipase of extracts from the edible insects Acheta domesticus and Tenebrio molitor. Food Chem. 2020, 309, 125742. [Google Scholar] [CrossRef] [PubMed]

- AESAN. Situation of Insects in Human Food. 2023. Available online: https://www.aesan.gob.es/AECOSAN/docs/documentos/seguridad_alimentaria/gestion_riesgos/INSECTOS_ALIMENTACION_pdf (accessed on 12 June 2023).

- Honrado, A.; Aínsa, A.; Marquina, P.L.; Beltrán, J.A.; Calanche, J.B. Low-fat fresh sausage from rabbit meat: An alternative to traditional rabbit consumption. Meat Sci. 2022, 194, 108973. [Google Scholar] [CrossRef]

- Hough, G.; Bratchell, N.; Wakeling, I. Consumer preference of Dulce de Leche among students in the United Kingdom. J. Sens. Stud. 1992, 7, 119–132. [Google Scholar] [CrossRef]

- COPANT NTE INEN 0038: Edible Fats and Oils; Determination of Acidity. Copan: Brescia, Italy, 1969.

- ISO 3960:2017; Animal and Vegetable fats and Oils. Determination of Peroxide Value. Iodometric (visual) Endpoint Determination. ISO: Geneva, Switzerland, 2017.

- ISO 4833-1:2013; Microbiology of the Food Chain-Horizontal Method for the Enumeration of Microorganisms-Part 1: Colony count at 30 Degrees C by the Pour Plate Technique. ISO: Geneva, Switzerland, 2013.

- ISO 21527-1:2008; Microbiology of Food and Animal Feeding Stuff—Horizontal Method for the Enumeration of Yeasts and Moulds—Part 1: Colony Count Technique in Products with Water Activity Greater than 0.95. ISO: Geneva, Switzerland, 2008.

- ISO 21528-2:2017; Microbiology of the Food Chain-Horizontal Method for the Detection and Enumeration of Enterobacteriaceae-Part 2: Colony-Count Technique. ISO: Geneva, Switzerland, 2017.

- ISO 8589:2007; Sensory Analysis-General Guidance for the Design of Test Rooms. ISO: Geneva, Switzerland, 2007.

- ISO 8586:2012; Sensory Analysis-General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. ISO: Geneva, Switzerland, 2012.

- Gacula, M. Descriptive Sensory Analysis in Practice; Food & Nutrition Press: Trumbull, CT, USA, 1997. [Google Scholar]

- ISO 13299:2016; Sensory Analysis-Methodology-General Guidance for Establishing a Sensory Profile. ISO: Geneva, Switzerland, 2016.

- Attigeri, G.V.; Pai, R.M.; Nayak, A. Stock market prediction: A big data approach. In Proceedings of the TENCON 2015-2015 IEEE Region 10 Conference, Macao, 1–4 November 2015; pp. 1–5. [Google Scholar] [CrossRef]

- ISO 16779:2015; Sensory Analysis—Assessment (Determination and Verification) of the Shelf Life of Foodstuffs. ISO: Geneva, Switzerland, 2015.

- Giménez, A.; Gagliardi, A.; Ares, G. Estimation of failure criteria in multivariate sensory shelf-life testing using survival analysis. Food Res. Int. 2017, 99, 542–549. [Google Scholar] [CrossRef]

- Dairou, V.; Sieffermann, J.-M. A Comparison of 14 Jams Characterized by Conventional Profile and a Quick Original Method, the Flash Profile. J. Food Sci. 2002, 67, 826–834. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Keppler, J.K.; van der Goot, A.J. Functionality of ingredients and additives in plant-based meat analogues. Foods 2021, 10, 600. [Google Scholar] [CrossRef]

- Buss, D. Rebuilding Plant-Based Meat. Food Technology Magazine. Chicago. 1 February 2023. Available online: https://www.ift.org/news-and-publications/food-technology-magazine/issues/2023/february/features/1-rebuilding-plant-based-meat (accessed on 13 September 2023).

- Rafique, H.; Dong, R.; Wang, X.; Alim, A.; Aadil, R.M.; Li, L.; Zou, L.; Hu, X. Dietary-Nutraceutical Properties of Oat Protein and Peptides. Front. Nutr. 2022, 9, 950400. [Google Scholar] [CrossRef]

- De Marchi, M.; Costa, A.; Pozza, M.; Goi, A.; Manuelian, C.L. Detailed characterization of plant-based burgers. Sci. Rep. 2021, 11, 2049. [Google Scholar] [CrossRef]

- Botella-Martínez, C.; Viuda-Martos, M.; Fernández-López, J.A.; Pérez-Alvarez, J.A.; Fernández-López, J. Development of plant-based burgers using gelled emulsions as the fat source and beetroot juice as colourant: Effects on chemical, physicochemical, appearance and sensory characteristics. LWT 2022, 172, 114193. [Google Scholar] [CrossRef]

- Caparros Megido, R.; Gierts, C.; Blecker, C.; Brostaux, Y.; Haubruge, É.; Alabi, T.; Francis, F. Consumer acceptance of insect-based alternative meat products in Western countries. Food Qual. Prefer. 2016, 52, 237–243. [Google Scholar] [CrossRef]

- Schouteten, J.J.; De Steur, H.; De Pelsmaeker, S.; Lagast, S.; Juvinal, J.G.; De Bourdeaudhuij, I.; Verbeke, W.; Gellynck, X. Emotional and sensory profiling of insect-, plant- and meat-based burgers under blind, expected and informed conditions. Food Qual. Prefer. 2016, 52, 27–31. [Google Scholar] [CrossRef]

- Calanche, J.B.; Pedrós, S.; Roncalés, P.; Beltrán, J.A. Design of Predictive Tools to Estimate Freshness Index in Farmed Sea Bream (Sparus aurata) Stored in Ice. Foods 2020, 9, 69. [Google Scholar] [CrossRef]

| Ingredients | SEOA (%) | SOOA (%) | SEAL (%) | SOAL (%) |

|---|---|---|---|---|

| Texturized soya | 0 | 62 | 0 | 73.8 |

| Seitan | 62 | 0 | 75 | 0 |

| Insect flour | 15 | 15 | 15 | 15 |

| Water | 2.7 | 5.3 | 0.5 | 0 |

| Sodium Alginate | 0 | 0 | 1.3 | 1.25 |

| Calcium chloride | 0 | 0 | 0.5 | 0.5 |

| Oat flour | 12.6 | 10 | 0 | 0 |

| Vegetable fat | 5 | 5 | 5 | 5 |

| Salt | 1.5 | 1.5 | 1.5 | 1.5 |

| Beetroot powder | 0.5 | 0.5 | 0.5 | 0.5 |

| Flavoring | 0.2 | 0.2 | 0.2 | 0.2 |

| Sweet paprika powder | 0.1 | 0.1 | 0.1 | 0.1 |

| Smoke aroma | 0.2 | 0.2 | 0.2 | 0.2 |

| Aroma | 0.2 | 0.2 | 0.2 | 0.2 |

| Samples | AI | PI | pH | aw | H | L* | a* | b* |

|---|---|---|---|---|---|---|---|---|

| SEAL | 53.22 c | 1.736 d | 6.470 | 0.982 | 57.300 | 36.740 a | 8.730 a | 18.390 |

| SOAL | 41.182 b | 1.227 c | 6.420 | 0.978 | 52.420 | 44.295 c | 9.585 b | 19.725 |

| SOOA | 34.,861 a | 0.849 b | 6.410 | 0.979 | 58.810 | 43.245 b,c | 9.950 b | 16.440 |

| SEOA | 39.139 a,b | 0.008 a | 6.390 | 0.981 | 49.270 | 42.250 b | 8.900 a | 19.425 |

| Pr > F | 0.001 | 0.000 | >0.05 | >0.05 | >0.05 | 0.002 | 0.016 | >0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ardila, P.; Honrado, A.; Marquina, P.; Beltrán, J.A.; Calanche, J.B. Innovative Plant-Based Burger Enriched with Tenebrio molitor Meal: Characterization and Shelf-Life. Foods 2023, 12, 3460. https://doi.org/10.3390/foods12183460

Ardila P, Honrado A, Marquina P, Beltrán JA, Calanche JB. Innovative Plant-Based Burger Enriched with Tenebrio molitor Meal: Characterization and Shelf-Life. Foods. 2023; 12(18):3460. https://doi.org/10.3390/foods12183460

Chicago/Turabian StyleArdila, Paula, Adrián Honrado, Pedro Marquina, José Antonio Beltrán, and Juan B. Calanche. 2023. "Innovative Plant-Based Burger Enriched with Tenebrio molitor Meal: Characterization and Shelf-Life" Foods 12, no. 18: 3460. https://doi.org/10.3390/foods12183460

APA StyleArdila, P., Honrado, A., Marquina, P., Beltrán, J. A., & Calanche, J. B. (2023). Innovative Plant-Based Burger Enriched with Tenebrio molitor Meal: Characterization and Shelf-Life. Foods, 12(18), 3460. https://doi.org/10.3390/foods12183460