Foliar Spraying of ZnO Nanoparticles Enhanced the Yield, Quality, and Zinc Enrichment of Rice Grains

Abstract

:1. Introduction

2. Materials and Methods

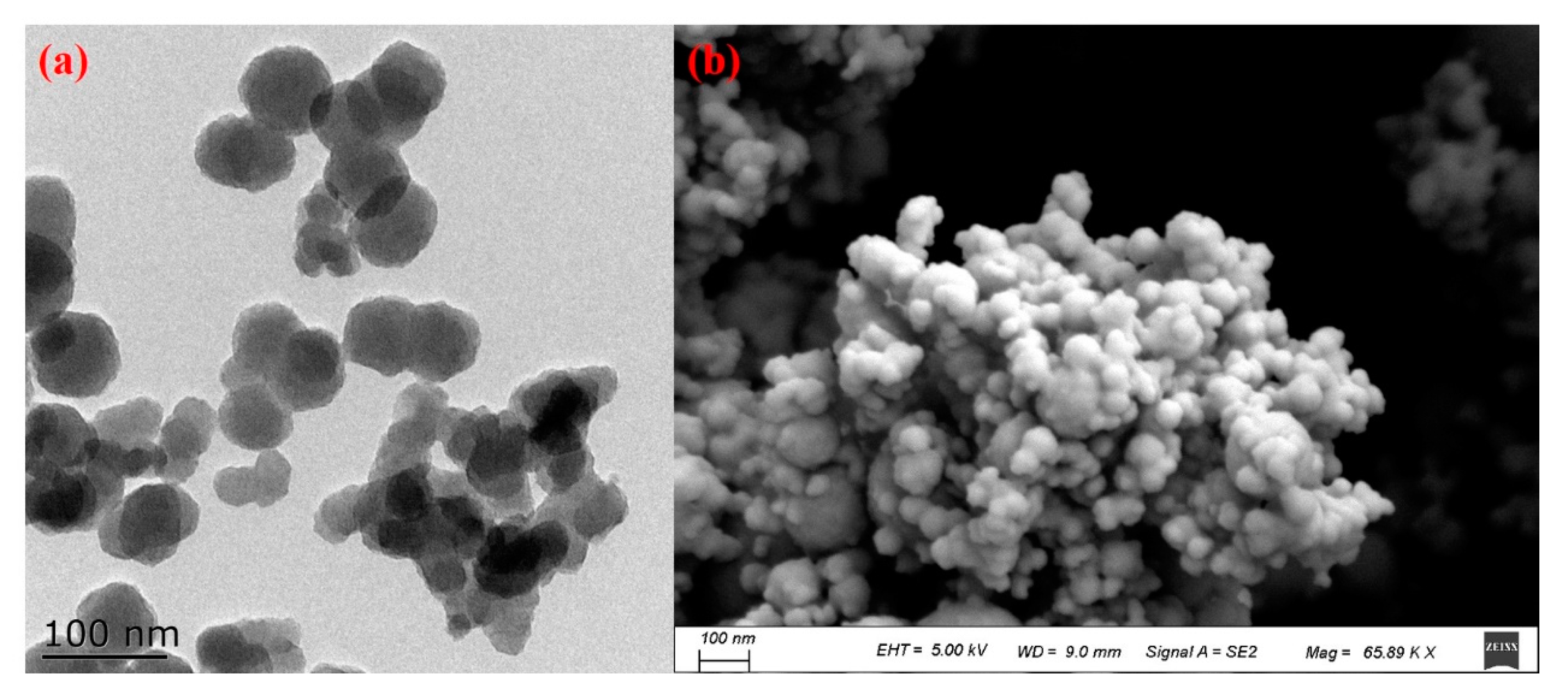

2.1. Experimental Materials

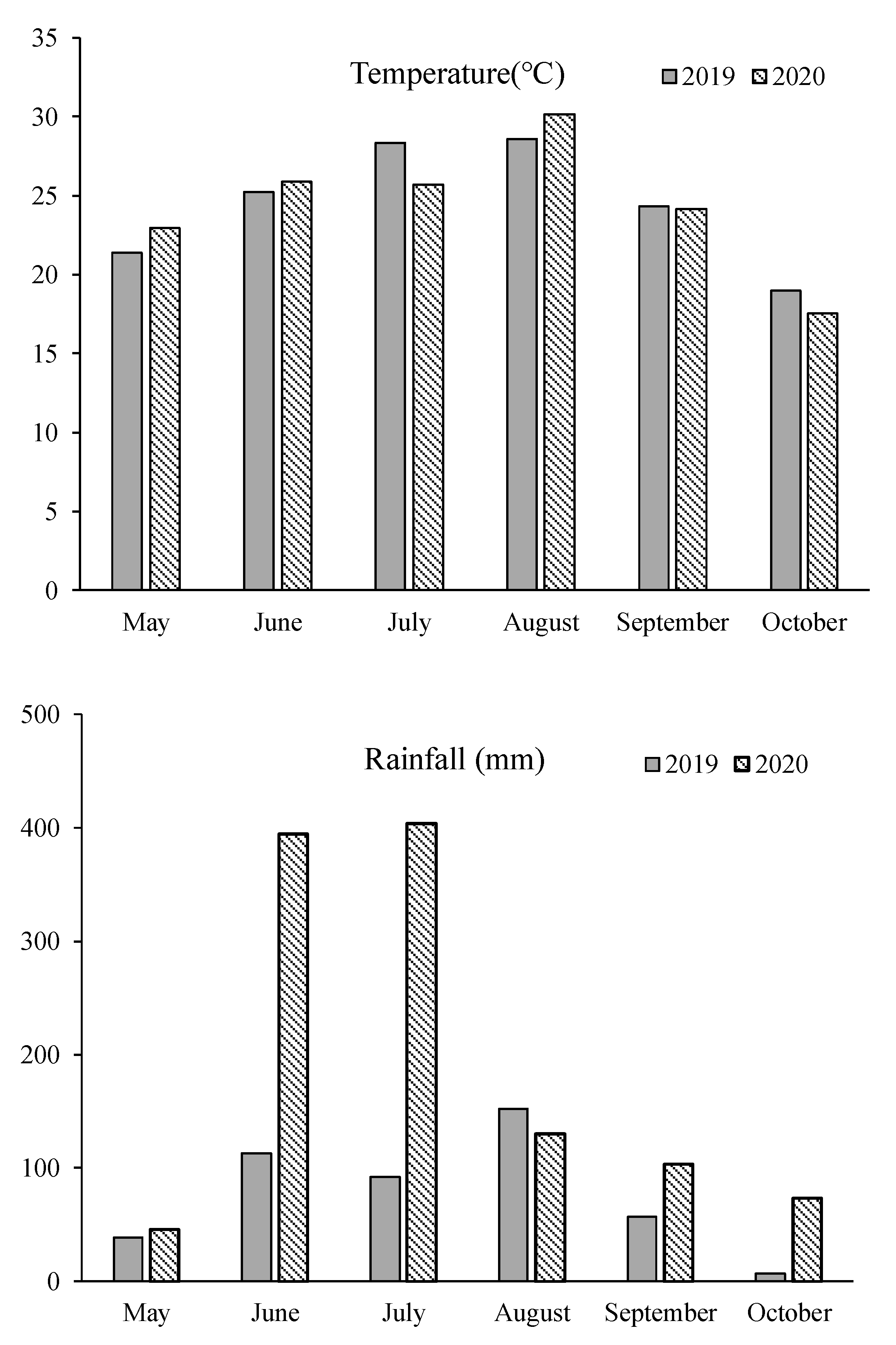

2.2. Experimental Site

2.3. Agronomic Management Systems

2.4. Sampling and Data Collection

2.4.1. Yield and Yield Components

2.4.2. Grain Quality

2.4.3. Zinc Content of Polished Rice

2.4.4. The Phytic Acid (PA) Content and Molar Ratio of PA to Zn in Polished Rice

2.4.5. Statistical Analysis

3. Results

3.1. Yield and Yield Components

3.2. Processing Quality

3.3. Appearance Quality

3.4. Nutritional Quality

3.5. Taste Quality

3.6. Steaming Quality

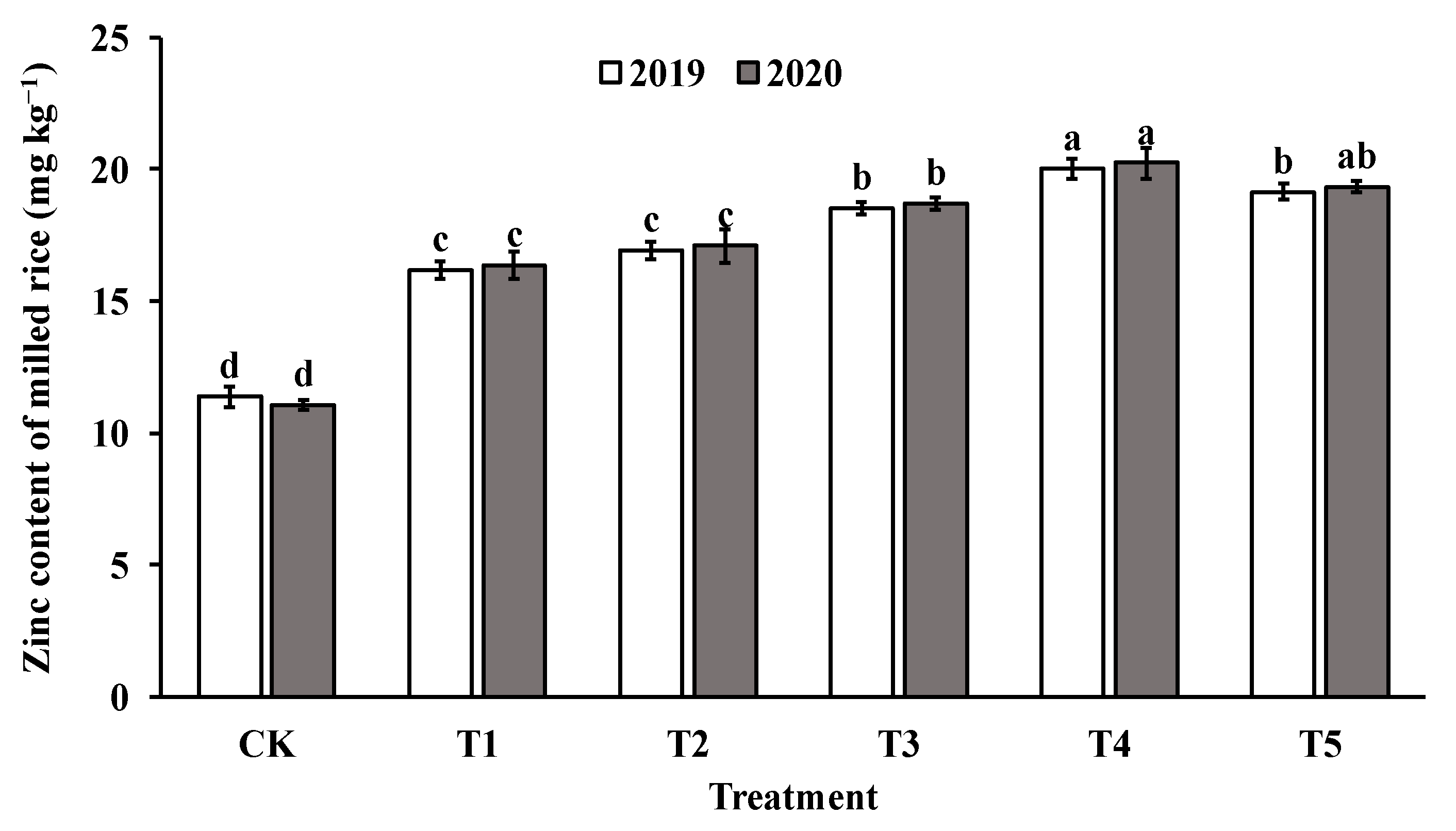

3.7. Zinc Content of Brown Rice and Polished Rice

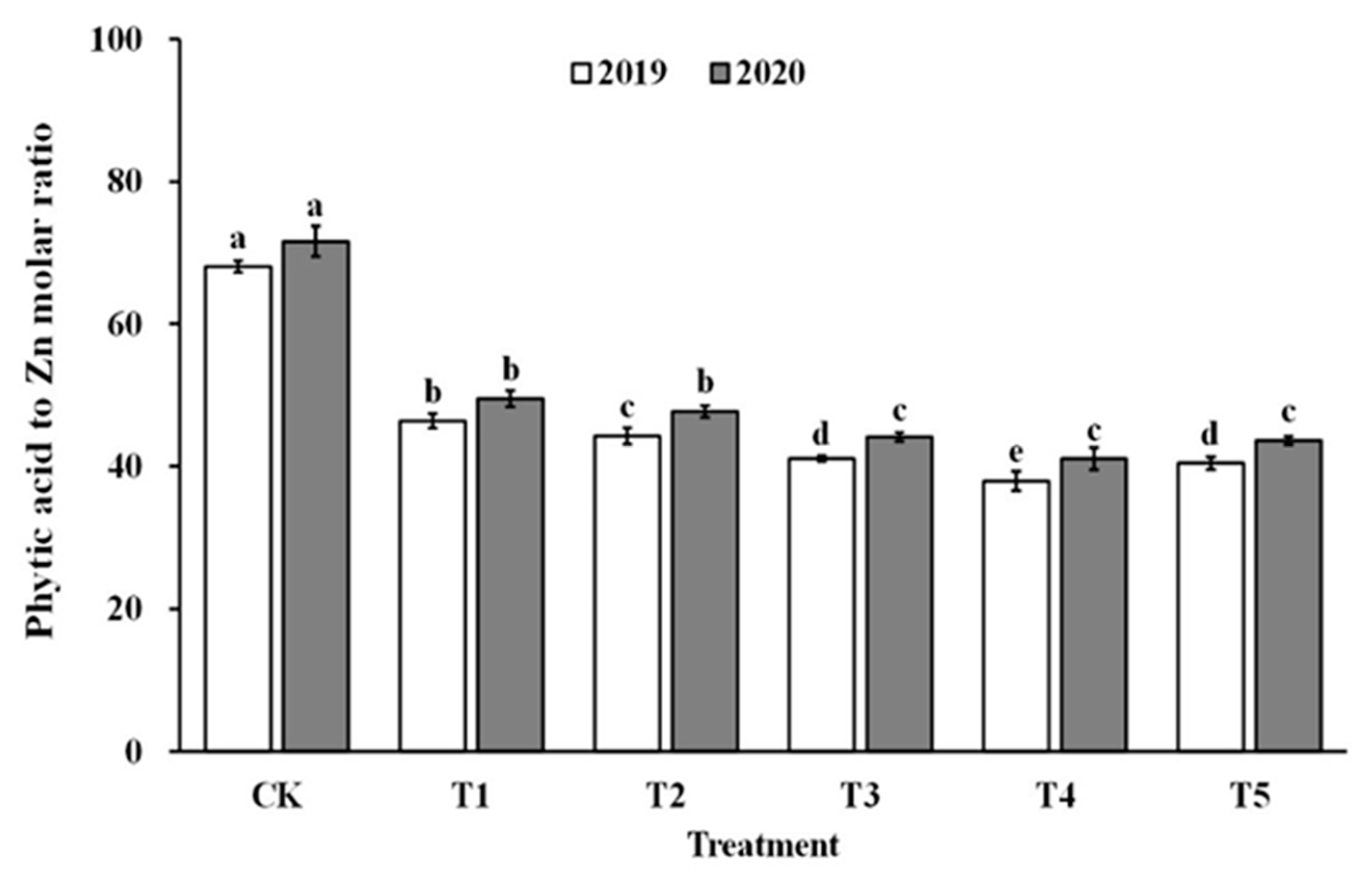

3.8. The Phytic Acid to Zinc Molar Ratio

4. Discussion

4.1. Effects of ZnO Nanoparticles Spraying on Rice Yield

4.2. Effects of ZnO Nanoparticles Spraying on Rice Quality

4.3. Effects of ZnO Nanoparticles Spraying on Zn Content in Edible Parts

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, L.; Xue, C.; Pan, X.; Chen, F.; Liu, Y. Application of Controlled-Release Urea Enhances Grain Yield and Nitrogen Use Efficiency in Irrigated Rice in the Yangtze River Basin, China. Front. Plant Sci. 2018, 9, 999. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.; Zhang, H.; Liu, W.; Dou, Z.; Zhou, Q.; Chen, W.; Wang, S.; Ding, Y. Nitrogen fertilizer at heading stage effectively compensates for the deterioration of rice quality by affecting the starch-related properties under elevated temperatures. Food Chem. 2019, 277, 455–462. [Google Scholar] [CrossRef] [PubMed]

- Kowsalya, P.; Sharanyakanth, P.S.; Mahendran, R. Traditional rice varieties: A comprehensive review on its nutritional, medicinal, therapeutic and health benefit potential. J. Food Compos. Anal. 2022, 114, 104742. [Google Scholar] [CrossRef]

- Wairich, A.; Ricachenevsky, F.K.; Lee, S. A tale of two metals: Biofortification of rice grains with iron and zinc. Front. Plant Sci. 2022, 13, 944624. [Google Scholar] [CrossRef]

- Hamzah Saleem, M.; Usman, K.; Rizwan, M.; Al Jabri, H.; Alsafran, M. Functions and strategies for enhancing zinc availability in plants for sustainable agriculture. Front. Plant Sci. 2010, 98, 1300–1304. [Google Scholar] [CrossRef]

- Prasad, R. Zinc biofortification of food grains in relation to food security and alleviation of zinc malnutrition. Curr. Sci. India 2022, 43, 419–425. [Google Scholar] [CrossRef]

- Zeng, H.; Wu, H.; Yan, F.; Yi, K.; Zhu, Y. Molecular regulation of zinc deficiency responses in plants. J. Plant Physiol. 2021, 261, 153419. [Google Scholar] [CrossRef]

- Stanton, C.; Sanders, D.; Kramer, U.; Podar, D. Zinc in plants: Integrating homeostasis and biofortification. Mol. Plant 2022, 15, 65–85. [Google Scholar] [CrossRef]

- Cakmak, I.; Kutman, U.B. Agronomic biofortification of cereals with zinc: A review. Eur. J. Soil Sci. 2017, 69, 172–180. [Google Scholar] [CrossRef]

- Zhang, H.P.; Wang, R.; Chen, Z.Q.; Cui, P.Y.; Lu, H.; Yang, Y.J.; Zhang, H.C. The effect of zinc oxide nanoparticles for enhancing rice (Oryza sativa L.) yield and quality. Agriculture 2021, 11, 1247. [Google Scholar] [CrossRef]

- Kandil, E.E.; El-Banna, A.A.A.; Tabl, D.M.M.; Mackled, M.I.; Ghareeb, R.Y.; Al-Huqail, A.A.; Ali, H.M.; Jebril, J.; Abdelsalam, N.R. Zinc nutrition responses to agronomic and yield traits, kernel quality, and pollen viability in rice (Oryza sativa L.). Front. Plant Sci. 2022, 13, 791066. [Google Scholar] [CrossRef] [PubMed]

- Saha, S.; Chakraborty, M.; Padhan, D.; Saha, B.; Murmu, S.; Batabyal, K.; Seth, A.; Hazra, G.C.; Mandal, B.; Bell, R.W. Agronomic biofortification of zinc in rice: Influence of cultivars and zinc application methods on grain yield and zinc bioavailability. Field Crop Res. 2017, 210, 52–60. [Google Scholar] [CrossRef]

- Xu, M.; Liu, M.; Liu, F.; Zheng, N.; Tang, S.; Zhou, J.; Ma, Q.; Wu, L. A safe, high fertilizer-efficiency and economical approach based on a low-volume spraying UAV loaded with chelated-zinc fertilizer to produce zinc-biofortified rice grains. J. Clean Prod. 2021, 323, 129188. [Google Scholar] [CrossRef]

- Singh, A.; Singh, N.B.; Afzal, S.; Singh, T.; Hussain, I. Zinc oxide nanoparticles: A review of their biological synthesis, antimicrobial activity, uptake, translocation and biotransformation in plants. J. Mater. Sci. 2017, 53, 185–201. [Google Scholar] [CrossRef]

- Thounaojam, T.C.; Meetei, T.T.; Devi, Y.B.; Panda, S.K.; Upadhyaya, H. Zinc oxide nanoparticles (ZnO-NPs): A promising nanoparticle in renovating plant science. Acta Physiol. Plant. 2021, 43, 136. [Google Scholar] [CrossRef]

- Afzal, S.; Singh, N.K. Effect of zinc and iron oxide nanoparticles on plant physiology, seed quality and microbial community structure in a rice-soil-microbial ecosystem. Environ. Pollut. 2022, 314, 120224. [Google Scholar] [CrossRef]

- Gao, F.; Zhang, X.; Zhang, J.; Li, J.; Niu, T.; Tang, C.; Wang, C.; Xie, J. Zinc oxide nanoparticles improve lettuce (Lactuca sativa L.) plant tolerance to cadmium by stimulating antioxidant defense, enhancing lignin content and reducing the metal accumulation and translocation. Front. Plant Sci. 2022, 13, 1015745. [Google Scholar] [CrossRef]

- Rafiq, H.; Aftab, Z.-e.-H.; Anjum, T.; Ali, B.; Akram, W.; Bashir, U.; Mirza, F.S.; Aftab, M.; Ali, M.D.; Li, G. Bio-fabrication of Zinc Oxide nanoparticles to rescue Mung Bean against Cercospora leaf spot disease. Front. Plant Sci. 2022, 13, 1052984. [Google Scholar] [CrossRef]

- Adil, M.; Bashir, S.; Bashir, S.; Aslam, Z.; Ahmad, N.; Younas, T.; Asghar, R.M.A.; Alkahtani, J.; Dwiningsih, Y.; Elshikh, M.S. Zinc oxide nanoparticles improved chlorophyll contents, physical parameters, and wheat yield under salt stress. Front. Plant Sci. 2022, 13, 932861. [Google Scholar] [CrossRef]

- GB/T 17891-2017; The Latest National Standard: High-Quality Rice. China National Standardization Administration: Beijing, China, 2018.

- Zhu, D.W.; Zhang, H.C.; Guo, B.W.; Xu, K.; Dai, Q.G.; Wei, C.X.; Zhou, G.S.; Huo, Z.Y. Physicochemical properties of indica-japonica hybrid rice starch from Chinese varieties. Food Hydrocoll. 2017, 63, 356–363. [Google Scholar] [CrossRef]

- Vaintraub, I.A.; Lapteva, N.A. Colorimetric determination of phytate in unpurified extracts of seeds and the products of their processing. Anal. Biochem. 1988, 175, 227–230. [Google Scholar] [CrossRef] [PubMed]

- Puig, M.L.; Rodriguez, A.A.; Vidal, A.A.; Bezus, R.; Maiale, S.J. Patterns of physiological parameters and nitrogen partitioning in flag leaf explain differential grain protein content in rice. Plant Physiol. Biochem. 2021, 168, 457–464. [Google Scholar] [CrossRef] [PubMed]

- Kutman, U.B.; Yildiz, B.; Ozturk, L.; Cakmak, I. Biofortification of Durum Wheat with Zinc Through Soil and Foliar Applications of Nitrogen. Cereal Chem. 2010, 87, 1–9. [Google Scholar] [CrossRef]

- Cheng, Y.F.; Dai, X.H.; Zhao, Y. Auxin biosynthesis by the yucca flavin monooxygenases controls the formation of floral organs and vascular tissues in arabidopsis. Gene Dev. 2006, 20, 1790–1799. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.Y.; Yuan, H.Y.; Ji, H.T.; Liu, H.J.; Zhang, Y.F.; Wang, G.D.; Chen, L.G.; Guo, Z. Effect of ZnO nanoparticles on the productivity, Zn biofortification, and nutritional quality of rice in a life cycle study. Plant Physiol. Biochem. 2021, 163, 87–94. [Google Scholar] [CrossRef]

- Dimkpa, C.O.; Andrews, J.; Fugice, J.; Singh, U.; Bindraban, P.S.; Elmer, W.H.; Gardea Torresdey, J.L.; White, J.C. Facile coating of urea with lowdose ZnO nanoparticles promotes wheat performance and enhances Zn uptake under drought stress. Front. Plant Sci. 2020, 11, 168. [Google Scholar] [CrossRef]

- Kheyri, N.; Norouzi, H.A.; Mobasser, H.R.; Torabi, B. Effect of silicon and zinc nanoparticles on growth, yield, and biochemical characteristics of rice. Agron. J. 2019, 111, 3084–3090. [Google Scholar] [CrossRef]

- Tyagi, R.; Sharma, A.; Srivastava, P.C.; Shankhdhar, D.; Shankhdhar, S.C. Modulation of phytic acid and phytic acid-zinc molar ratio by different modes of zinc application in rice. Indian J. Plant Physiol. 2018, 23, 529–535. [Google Scholar] [CrossRef]

- Li, Y.; Shoemaker, C.F.; Ma, J.; Moon, K.J.; Zhong, F. Structure-viscosity relationships for starches from different rice varieties during heating. Food Chem. 2008, 106, 1105–1112. [Google Scholar] [CrossRef]

- Yin, X.X.; Zheng, Y.X.; Kong, X.L.; Cao, S.Y.; Chen, S.G.; Liu, D.H.; Ye, X.Q.; Tian, J.H. RG-I pectin affects the physicochemical properties and digestibility of potato starch. Food Hydrocoll. 2021, 117, 106687. [Google Scholar] [CrossRef]

- Li, C.; Luo, J.-X.; Zhang, C.-Q.; Yu, W.-W. Causal relations among starch chain length distributions, short-term retrogradation and cooked rice texture. Food Hydrocoll. 2020, 108, 106064. [Google Scholar] [CrossRef]

- Asante, M.D.; Offei, S.K.; Gracen, V.; Adu-Dapaah, H.; Danquah, E.Y.; Bryant, R.; McClung, A. Starch physicochemical properties of rice accessions and their association with molecular markers. Starch Starke 2013, 65, 1022–1028. [Google Scholar] [CrossRef]

- Torre, M.; Rodriguez, A.R.; Saura-Calixto, F. Effects of dietary fiber and phytic acid on mineral availability. Crit. Rev. Food Sci. 1991, 30, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Khampuang, K.; Lordkaew, S.; Dell, B.; Prom-u-thai, C. Foliar zinc application improved grain zinc accumulation and bioavailable zinc in unpolished and polished rice. Plant Prod. Sci. 2020, 24, 94–102. [Google Scholar] [CrossRef]

| Year | Treatment | Panicles (×106 hm−2) | Spikelets per Panicle | Grain Filling Rate (%) | 1000-Grain Weight (g) | Grain Yield (t hm−2) |

|---|---|---|---|---|---|---|

| 2019 | CK | 3.54 ± 0.20 a | 110.76 ± 8.52 b | 90.33 ± 0.60 c | 25.33 ± 0.55 b | 9.84 ± 0.20 b |

| T1 | 3.56 ± 0.26 a | 119.07 ± 3.14 ab | 91.30 ± 1.07 c | 26.30 ± 0.90 ab | 10.09 ± 0.11 ab | |

| T2 | 3.55 ± 0.20 a | 119.30 ± 4.02 ab | 92.35 ± 1.70 bc | 26.63 ± 0.19 a | 10.14 ± 0.04 a | |

| T3 | 3.54 ± 0.20 a | 119.37 ± 3.39 ab | 92.47 ± 0.57 bc | 26.73 ± 0.33 a | 10.19 ± 0.06 a | |

| T4 | 3.58 ± 0.07 a | 119.63 ± 6.18 ab | 93.49 ± 0.75 ab | 27.05 ± 0.11 a | 10.22 ± 0.19 a | |

| T5 | 3.55 ± 0.33 a | 120.92 ± 2.72 a | 94.94 ± 0.43 a | 27.08 ± 0.24 a | 10.26 ± 0.13 a | |

| 2020 | CK | 3.52 ± 0.07 a | 107.82 ± 1.50 b | 89.95 ± 0.35 b | 25.48 ± 0.20 b | 9.97 ± 0.10 b |

| T1 | 3.53 ± 0.14 a | 115.63 ± 0.88 ab | 92.09 ± 1.42 ab | 26.62 ± 0.23 ab | 10.18 ± 0.15 a | |

| T2 | 3.56 ± 0.18 a | 115.69 ± 2.03 ab | 92.25 ± 0.25 ab | 26.86 ± 0.50 ab | 10.23 ± 0.08 a | |

| T3 | 3.55 ± 0.25 a | 115.74 ± 6.10 ab | 92.47 ± 0.86 a | 27.20 ± 0.51 a | 10.29 ± 0.04 a | |

| T4 | 3.52 ± 0.29 a | 117.04 ± 4.50 a | 92.49 ± 1.39 a | 27.24 ± 0.19 a | 10.31 ± 0.13 a | |

| T5 | 3.61 ± 0.26 a | 117.70 ± 1.96 a | 93.04 ± 2.01 a | 27.32 ± 1.75 a | 10.36 ± 0.04 a |

| Year | Treatment | Brown Rice Rate (%) | Milled Rice Rate (%) | Head Rice Rate (%) |

|---|---|---|---|---|

| 2019 | CK | 84.94 ± 0.18 e | 75.45 ± 0.18 b | 59.26 ± 0.48 b |

| T1 | 85.45 ± 0.12 d | 76.12 ± 0.26 a | 60.85 ± 0.94 a | |

| T2 | 85.68 ± 0.18 cd | 76.29 ± 0.09 a | 61.44 ± 0.89 a | |

| T3 | 85.87 ± 0.14 bc | 75.87 ± 0.29 ab | 61.69 ± 0.77 a | |

| T4 | 86.49 ± 0.17 a | 75.49 ± 0.13 b | 61.76 ± 0.88 a | |

| T5 | 86.06 ± 0.10 b | 76.27 ± 0.44 a | 61.72 ± 1.15 a | |

| 2020 | CK | 85.23 ± 0.35 b | 75.55 ± 0.24 b | 59.27 ± 0.88 b |

| T1 | 85.48 ± 0.13 ab | 75.76 ± 0.33 ab | 60.57 ± 0.73 ab | |

| T2 | 85.56 ± 0.07 ab | 75.92 ± 0.36 ab | 60.83 ± 0.88 ab | |

| T3 | 85.64 ± 0.18 ab | 76.12 ± 0.26 ab | 61.15 ± 0.75 ab | |

| T4 | 86.19 ± 0.58 a | 76.32 ± 0.14 a | 61.28 ± 0.70 a | |

| T5 | 86.18 ± 0.39 a | 76.40 ± 0.40 a | 61.38 ± 0.77 a |

| Year | Treatment | Length/Width | Chalkiness Grain Rate (%) | Chalkiness Degree (%) |

|---|---|---|---|---|

| 2019 | CK | 1.669 ± 0.020 b | 57.56 ± 1.04 a | 18.14 ± 1.880 a |

| T1 | 1.694 ± 0.015 ab | 52.28 ± 2.76 b | 17.74 ± 1.12 ab | |

| T2 | 1.709 ± 0.007 a | 51.07 ± 3.24 b | 17.07 ± 2.10 ab | |

| T3 | 1.713 ± 0.012 a | 51.83 ± 0.51 b | 16.82 ± 0.47 ab | |

| T4 | 1.703 ± 0.004 a | 43.95 ± 1.54 c | 14.73 ± 0.68 b | |

| T5 | 1.702 ± 0.005 a | 45.98 ± 1.59 c | 14.82 ± 0.91 b | |

| 2020 | CK | 1.679 ± 0.004 b | 56.81 ± 3.40 a | 20.42 ± 1.84 a |

| T1 | 1.695 ± 0.013 ab | 53.27 ± 2.73 ab | 18.73 ± 1.14 ab | |

| T2 | 1.705 ± 0.004 a | 49.47 ± 4.52 abc | 16.01 ± 1.68 cd | |

| T3 | 1.709 ± 0.007 a | 47.88 ± 4.01 bc | 17.97 ± 0.67 abc | |

| T4 | 1.710 ± 0.008 a | 43.88 ± 1.10 c | 14.73 ± 0.88 d | |

| T5 | 1.707 ± 0.010 a | 49.53 ± 2.66 abc | 16.97 ± 1.95 bcd |

| Year | Treatment | Protein Content (%) | Amylose Content (%) |

|---|---|---|---|

| 2019 | CK | 7.27 ± 0.50 a | 11.36 ± 0.68 a |

| T1 | 7.30 ± 0.30 a | 11.50 ± 0.72 a | |

| T2 | 7.40 ± 0.14 a | 11.63 ± 0.59 a | |

| T3 | 7.23 ± 0.05 a | 11.22 ± 0.24 a | |

| T4 | 7.20 ± 0.01 a | 11.14 ± 0.44 a | |

| T5 | 7.20 ± 0.15 a | 11.04 ± 0.28 a | |

| 2020 | CK | 7.27 ± 0.12 a | 12.43 ± 0.30 a |

| T1 | 7.30 ± 0.14 a | 11.98 ± 0.60 ab | |

| T2 | 7.17 ± 0.09 a | 12.19 ± 0.74 ab | |

| T3 | 7.10 ± 0.16 a | 12.38 ± 0.45 a | |

| T4 | 7.07 ± 0.12 a | 11.66 ± 0.29 ab | |

| T5 | 7.07 ± 0.21 a | 11.21 ± 0.30 b |

| Year | Treatment | Taste Value | Appearance Value | Hardness Value | Viscosity Value | Balance Value |

|---|---|---|---|---|---|---|

| 2019 | CK | 71.27 ± 1.68 b | 6.67 ± 0.26 b | 6.70 ± 0.14 ab | 7.20 ± 0.22 b | 6.70 ± 0.28 b |

| T1 | 78.17 ± 0.63 ab | 7.77 ± 0.12 a | 6.20 ± 0.08 b | 8.43 ± 0.17 a | 7.87 ± 0.12 a | |

| T2 | 79.17 ± 1.53 a | 7.97 ± 0.24 a | 6.37 ± 0.05 ab | 8.43 ± 0.21 a | 8.03 ± 0.26 a | |

| T3 | 78.97 ± 1.91 a | 7.87 ± 0.29 a | 6.07 ± 0.24 b | 8.57 ± 0.21 a | 7.97 ± 0.29 a | |

| T4 | 82.37 ± 2.22 a | 8.07 ± 1.01 a | 6.03 ± 0.79 b | 8.60 ± 0.86 a | 8.13 ± 0.97 a | |

| T5 | 79.03 ± 2.95 a | 7.97 ± 0.41 a | 7.00 ± 0.17 a | 8.37 ± 0.33 a | 8.03 ± 0.42 a | |

| 2020 | CK | 73.97 ± 1.41 b | 7.40 ± 0.16 b | 6.27 ± 0.51 ab | 7.50 ± 0.24 c | 7.33 ± 0.12 b |

| T1 | 79.00 ± 2.16 ab | 7.93 ± 0.31 ab | 6.03 ± 0.19 b | 8.40 ± 0.22 b | 8.03 ± 0.31 a | |

| T2 | 79.33 ± 2.62 a | 8.00 ± 0.36 ab | 6.07 ± 0.12 b | 8.47 ± 0.31 ab | 8.10 ± 0.36 a | |

| T3 | 80.67 ± 2.05 a | 8.17 ± 0.34 a | 6.00 ± 0.14 b | 8.63 ± 0.12 ab | 8.30 ± 0.29 a | |

| T4 | 81.67 ± 1.70 a | 8.33 ± 0.21 a | 5.90 ± 0.08 b | 8.70 ± 0.14 ab | 8.43 ± 0.16 a | |

| T5 | 81.33 ± 2.62 a | 8.23 ± 0.26 a | 6.80 ± 0.51 a | 9.17 ± 0.58 a | 8.30 ± 0.29 a |

| Year | Treatment | Peak Viscosity (cP) | Trough Viscosity (cP) | Final Viscosity (cP) | Breakdown (cP) | Setback (cP) |

|---|---|---|---|---|---|---|

| 2019 | CK | 2655.00 ± 32.14 b | 2004.67 ± 97.68 a | 2478.00 ± 91.91 a | 650.33 ± 61.34 b | −177.00 ± 20.06 a |

| T1 | 2725.67 ± 14.57 a | 1846.00 ± 55.47 ab | 2388.67 ± 38.68 a | 879.67 ± 43.53 a | −337.00 ± 25.82 ab | |

| T2 | 2742.00 ± 27.50 a | 1758.67 ± 74.81 ab | 2313.33 ± 60.48 a | 983.33 ± 74.77 a | −428.67 ± 63.57 b | |

| T3 | 2747.00 ± 18.52 a | 1753.33 ± 11.59 b | 2386.33 ± 14.74 a | 993.67 ± 27.65 a | −360.67 ± 11.24 ab | |

| T4 | 2696.00 ± 41.94 ab | 1712.67 ± 22.55 b | 2351.33 ± 41.04 a | 983.33 ± 20.43 a | −344.67 ± 30.01 ab | |

| T5 | 2727.33 ± 17.79 a | 1830.33 ± 69.74 ab | 2358.33 ± 80.16 a | 897.00 ± 47.22 a | −369.00 ± 62.45 b | |

| 2020 | CK | 2708.00 ± 42.58 ab | 1937.33 ± 64.85 a | 2430.67 ± 154.05 a | 770.67 ± 36.26 b | −277.33 ± 28.00 a |

| T1 | 2683.33 ± 15.95 ab | 1706.33 ± 28.57 b | 2239.33 ± 35.57 b | 977.00 ± 37.27 a | −444.00 ± 44.03 b | |

| T2 | 2602.67 ± 10.02 c | 1604.33 ± 51.16 bc | 2168.00 ± 50.69 bc | 998.33 ± 60.93 a | −434.67 ± 60.01 b | |

| T3 | 2661.33 ± 14.47 b | 1652.00 ± 42.00 bc | 2235.67 ± 32.25 bc | 1009.33 ± 40.02 a | −425.67 ± 20.40 b | |

| T4 | 2732.67 ± 36.35 a | 1714.33 ± 43.36 b | 2259.33 ± 11.37 b | 1018.33 ± 52.37 a | −473.33 ± 32.03 b | |

| T5 | 2559.67 ± 12.52 c | 1544.00 ± 29.51 c | 2118.67 ± 34.79 c | 1015.67 ± 31.47 a | −441.00 ± 37.04 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Fang, R.; Yuan, X.; Chen, J.; Mi, K.; Wang, R.; Zhang, H.; Zhang, H. Foliar Spraying of ZnO Nanoparticles Enhanced the Yield, Quality, and Zinc Enrichment of Rice Grains. Foods 2023, 12, 3677. https://doi.org/10.3390/foods12193677

Wang S, Fang R, Yuan X, Chen J, Mi K, Wang R, Zhang H, Zhang H. Foliar Spraying of ZnO Nanoparticles Enhanced the Yield, Quality, and Zinc Enrichment of Rice Grains. Foods. 2023; 12(19):3677. https://doi.org/10.3390/foods12193677

Chicago/Turabian StyleWang, Sijia, Ruotong Fang, Xijun Yuan, Jie Chen, Kailiang Mi, Rui Wang, Haipeng Zhang, and Hongcheng Zhang. 2023. "Foliar Spraying of ZnO Nanoparticles Enhanced the Yield, Quality, and Zinc Enrichment of Rice Grains" Foods 12, no. 19: 3677. https://doi.org/10.3390/foods12193677

APA StyleWang, S., Fang, R., Yuan, X., Chen, J., Mi, K., Wang, R., Zhang, H., & Zhang, H. (2023). Foliar Spraying of ZnO Nanoparticles Enhanced the Yield, Quality, and Zinc Enrichment of Rice Grains. Foods, 12(19), 3677. https://doi.org/10.3390/foods12193677