Combined Effect of High Hydrostatic Pressure, Sous-Vide Cooking, and Carvacrol on the Quality of Veal, Plant-Based, and Hybrid Patties during Storage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

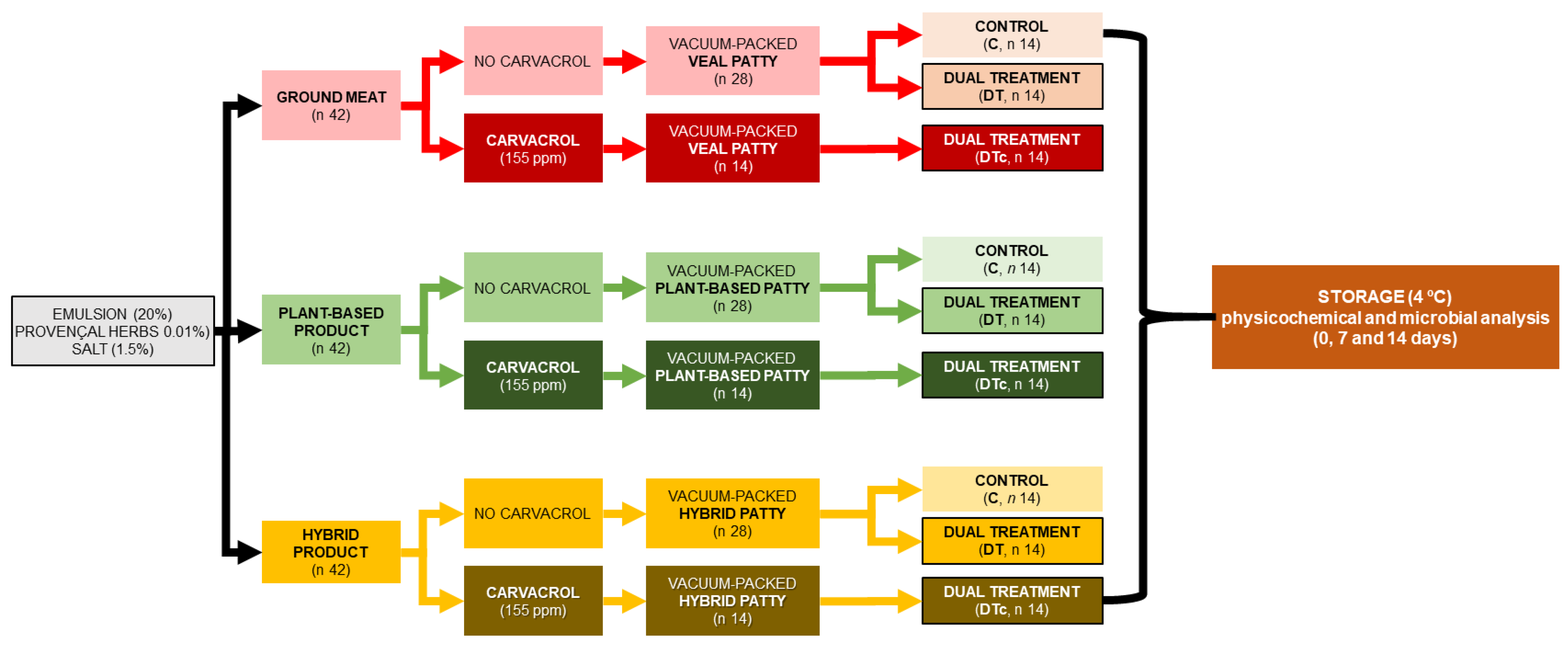

2.2. Experimental Design

2.3. Treatments

2.4. Proximate Analysis

2.5. pH

2.6. Instrumental Color

2.7. Instrumental Texture

2.8. Microbial Analysis

2.9. Statistical Analysis

3. Results and Discussion

3.1. Proximate Analysis

3.2. Effect of Treatments and Storage Time on pH

3.3. Effect of Treatments and Storage Time on Texture Parameters

3.3.1. Veal Samples

3.3.2. Plant-Based Samples

3.3.3. Hybrid Samples

3.4. Effect of Treatments and Storage Time on Color

3.4.1. Veal Samples

3.4.2. Plant-Based Samples

3.4.3. Hybrid Samples

3.5. Microbial Counts

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Grasso, S.; Goksen, G. The Best of Both Worlds? Challenges and Opportunities in the Development of Hybrid Meat Products from the Last 3 Years. LWT 2023, 173, 114235. [Google Scholar] [CrossRef]

- Baune, M.-C.; Jeske, A.-L.; Profeta, A.; Smetana, S.; Broucke, K.; Van Royen, G.; Gibis, M.; Weiss, J.; Terjung, N. Effect of Plant Protein Extrudates on Hybrid Meatballs—Changes in Nutritional Composition and Sustainability. Future Foods 2021, 4, 100081. [Google Scholar] [CrossRef]

- Sridhar, K.; Bouhallab, S.; Croguennec, T.; Renard, D.; Lechevalier, V. Recent Trends in Design of Healthier Plant-Based Alternatives: Nutritional Profile, Gastrointestinal Digestion, and Consumer Perception. Crit. Rev. Food Sci. Nutr. 2022, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Chatli, M.K.; Mehta, N.; Singh, P.; Malav, O.P.; Verma, A.K. Meat Analogues: Health Promising Sustainable Meat Substitutes. Crit. Rev. Food Sci. Nutr. 2017, 57, 923–932. [Google Scholar] [CrossRef]

- Sanchez-Sabate, R.; Sabaté, J. Consumer Attitudes Towards Environmental Concerns of Meat Consumption: A Systematic Review. Int. J. Environ. Res. Public Health 2019, 16, 1220. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sha, L.; Xiong, Y.L. Plant Protein-Based Alternatives of Reconstructed Meat: Science, Technology, and Challenges. Trends Food Sci. Technol. 2020, 102, 51–61. [Google Scholar] [CrossRef]

- Ahmad, M.; Qureshi, S.; Akbar, M.H.; Siddiqui, S.A.; Gani, A.; Mushtaq, M.; Hassan, I.; Dhull, S.B. Plant-Based Meat Alternatives: Compositional Analysis, Current Development and Challenges. Appl. Food Res. 2022, 2, 100154. [Google Scholar] [CrossRef]

- Arshad, M.; Anwar, S.; Pasha, I.; Ahmed, F.; Aadil, R.M. Development of Imitated Meat Product by Utilizing Pea and Lentil Protein Isolates. Int. J. Food Sci. Technol. 2022, 57, 3031–3037. [Google Scholar] [CrossRef]

- Zhou, H.; Vu, G.; Gong, X.; McClements, D.J. Comparison of the Cooking Behaviors of Meat and Plant-Based Meat Analogues: Appearance, Texture, and Fluid Holding Properties. ACS Food Sci. Technol. 2022, 2, 844–851. [Google Scholar] [CrossRef]

- Meticulous Market Research Pvt. Ltd. Alternative Protein Market Worth $36.61 Billion by 2029—Exclusive Report by Meticulous Research®. Available online: https://www.globenewswire.com/en/news-release/2022/05/03/2434411/0/en/Alternative-Protein-Market-Worth-36-61-Billion-by-2029-Exclusive-Report-by-Meticulous-Research.html (accessed on 22 September 2022).

- Profeta, A.; Baune, M.-C.; Smetana, S.; Broucke, K.; Van Royen, G.; Weiss, J.; Hieke, S.; Heinz, V.; Terjung, N. Consumer Preferences for Meat Blended with Plant Proteins—Empirical Findings from Belgium. Future Foods 2021, 4, 100088. [Google Scholar] [CrossRef]

- Sødring, M.; Oostindjer, M.; Dragsted, L.O.; Haug, A.; Paulsen, J.E.; Egelandsdal, B. Chapter 19—Meat and Cancer Evidence for and Against. In New Aspects of Meat Quality; Purslow, P.P., Ed.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Duxford, UK, 2017; pp. 479–499. ISBN 978-0-08-100593-4. [Google Scholar]

- American Institute for Cancer Research. FAQ: Processed Meat and Cancer. Available online: https://www.aicr.org/news/faq-processed-meat-and-cancer/ (accessed on 22 September 2022).

- Selani, M.M.; Shirado, G.A.N.; Margiotta, G.B.; Saldaña, E.; Spada, F.P.; Piedade, S.M.S.; Contreras-Castillo, C.J.; Canniatti-Brazaca, S.G. Effects of Pineapple Byproduct and Canola Oil as Fat Replacers on Physicochemical and Sensory Qualities of Low-Fat Beef Burger. Meat Sci. 2016, 112, 69–76. [Google Scholar] [CrossRef]

- Papier, K.; Knuppel, A.; Syam, N.; Jebb, S.A.; Key, T.J. Meat Consumption and Risk of Ischemic Heart Disease: A Systematic Review and Meta-Analysis. Crit. Rev. Food Sci. Nutr. 2021, 63, 426–437. [Google Scholar] [CrossRef]

- Heck, R.T.; Vendruscolo, R.G.; de Araújo Etchepare, M.; Cichoski, A.J.; de Menezes, C.R.; Barin, J.S.; Lorenzo, J.M.; Wagner, R.; Campagnol, P.C.B. Is It Possible to Produce a Low-Fat Burger with a Healthy N − 6/N − 3 PUFA Ratio without Affecting the Technological and Sensory Properties? Meat Sci. 2017, 130, 16–25. [Google Scholar] [CrossRef]

- Muguerza, E.; Gimeno, O.; Ansorena, D.; Astiasarán, I. New Formulations for Healthier Dry Fermented Sausages: A Review. Trends Food Sci. Technol. 2004, 15, 452–457. [Google Scholar] [CrossRef]

- Janardhanan, R.; Virseda, P.; Huerta-Leidenz, N.; Beriain, M.J. Effect of High–Hydrostatic Pressure Processing and Sous-Vide Cooking on Physicochemical Traits of Biceps Femoris Veal Patties. Meat Sci. 2022, 188, 108772. [Google Scholar] [CrossRef]

- Janardhanan, R.; González-Diez, M.; Ibañez, F.C.; Beriain, M.J. Comparison of High Hydrostatic Pressure Processed Plus Sous-Vide Cooked Meat-Based, Plant-Based and Hybrid Patties According to Fat Replacement. Foods 2022, 11, 3678. [Google Scholar] [CrossRef]

- Janardhanan, R.; Huerta-Leidenz, N.; Ibañez, F.C.; Beriain, M.J. High-Pressure Processing and Sous-Vide Cooking Effects on Physicochemical Properties of Meat-Based, Plant-Based and Hybrid Patties. LWT 2023, 173, 114273. [Google Scholar] [CrossRef]

- Mukhtar, K.; Nabi, B.G.; Arshad, R.N.; Roobab, U.; Yaseen, B.; Ranjha, M.M.A.N.; Aadil, R.M.; Ibrahim, S.A. Potential Impact of Ultrasound, Pulsed Electric Field, High-Pressure Processing and Microfludization against Thermal Treatments Preservation Regarding Sugarcane Juice (Saccharum Officinarum). Ultrason. Sonochemistry 2022, 90, 106194. [Google Scholar] [CrossRef] [PubMed]

- Nabi, B.G.; Mukhtar, K.; Arshad, R.N.; Radicetti, E.; Tedeschi, P.; Shahbaz, M.U.; Walayat, N.; Nawaz, A.; Inam-Ur-Raheem, M.; Aadil, R.M. High-Pressure Processing for Sustainable Food Supply. Sustainability 2021, 13, 13908. [Google Scholar] [CrossRef]

- Roobab, U.; Shabbir, M.A.; Khan, A.W.; Arshad, R.N.; Bekhit, A.E.-D.; Zeng, X.-A.; Inam-Ur-Raheem, M.; Aadil, R.M. High-Pressure Treatments for Better Quality Clean-Label Juices and Beverages: Overview and Advances. LWT 2021, 149, 111828. [Google Scholar] [CrossRef]

- Chatur, P.; Johnson, S.; Coorey, R.; Bhattarai, R.R.; Bennett, S.J. The Effect of High Pressure Processing on Textural, Bioactive and Digestibility Properties of Cooked Kimberley Large Kabuli Chickpeas. Front. Nutr. 2022, 9, 628. [Google Scholar] [CrossRef]

- Gómez, I.; Janardhanan, R.; Ibañez, F.C.; Beriain, M.J. The Effects of Processing and Preservation Technologies on Meat Quality: Sensory and Nutritional Aspects. Foods 2020, 9, 1416. [Google Scholar] [CrossRef] [PubMed]

- Suleman, R.; Wang, Z.; Aadil, R.M.; Hui, T.; Hopkins, D.L.; Zhang, D. Effect of Cooking on the Nutritive Quality, Sensory Properties and Safety of Lamb Meat: Current Challenges and Future Prospects. Meat Sci. 2020, 167, 108172. [Google Scholar] [CrossRef] [PubMed]

- Roobab, U.; Afzal, R.; Ranjha, M.M.A.N.; Zeng, X.-A.; Ahmed, Z.; Aadil, R.M. High Pressure-Based Hurdle Interventions for Raw and Processed Meat: A Clean-Label Prospective. Int. J. Food Sci. Technol. 2022, 57, 816–826. [Google Scholar] [CrossRef]

- Chacha, J.S.; Zhang, L.; Ofoedu, C.E.; Suleiman, R.A.; Dotto, J.M.; Roobab, U.; Agunbiade, A.O.; Duguma, H.T.; Mkojera, B.T.; Hossaini, S.M.; et al. Revisiting Non-Thermal Food Processing and Preservation Methods—Action Mechanisms, Pros and Cons: A Technological Update (2016–2021). Foods 2021, 10, 1430. [Google Scholar] [CrossRef]

- García-Segovia, P.; Andrés-Bello, A.; Martínez-Monzó, J. Effect of Cooking Method on Mechanical Properties, Color and Structure of Beef Muscle (M. pectoralis). J. Food Eng. 2007, 80, 813–821. [Google Scholar] [CrossRef]

- Bellés, M.; Alonso, V.; Roncalés, P.; Beltrán, J.A. Sulfite-Free Lamb Burger Meat: Antimicrobial and Antioxidant Properties of Green Tea and Carvacrol. J. Sci. Food Agric. 2019, 99, 464–472. [Google Scholar] [CrossRef]

- Commission Regulation (EU) No 1129/2011 of 11 November 2011 Amending Annex II to Regulation (EC) No 1333/2008 of the European Parliament and of the Council by Establishing a Union List of Food Additives (Text with EEA Relevance). Available online: http://op.europa.eu/en/publication-detail/-/publication/28cb4a37-b40e-11e3-86f9-01aa75ed71a1 (accessed on 22 September 2022).

- Syed, I.; Banerjee, P.; Sarkar, P. Oil-in-Water Emulsions of Geraniol and Carvacrol Improve the Antibacterial Activity of These Compounds on Raw Goat Meat Surface during Extended Storage at 4 °C. Food Control 2020, 107, 106757. [Google Scholar] [CrossRef]

- Yanishlieva, N.V.; Marinova, E.M.; Gordon, M.H.; Raneva, V.G. Antioxidant Activity and Mechanism of Action of Thymol and Carvacrol in Two Lipid Systems. Food Chem. 1999, 64, 59–66. [Google Scholar] [CrossRef]

- Belda-Galbis, C.M.; Martínez, A.; Rodrigo, D. Antimicrobial Effect of Carvacrol on Escherichia Coli K12 Growth at Different Temperatures. In Science and Technology Against Microbial Pathogens; World Scientific: Singapore, 2011; pp. 80–84. ISBN 978-981-4354-85-1. [Google Scholar]

- Veldhuizen, E.J.A.; Tjeerdsma-van Bokhoven, J.L.M.; Zweijtzer, C.; Burt, S.A.; Haagsman, H.P. Structural Requirements for the Antimicrobial Activity of Carvacrol. J. Agric. Food Chem. 2006, 54, 1874–1879. [Google Scholar] [CrossRef]

- Ait-Ouazzou, A.; Cherrat, L.; Espina, L.; Lorán, S.; Rota, C.; Pagán, R. The Antimicrobial Activity of Hydrophobic Essential Oil Constituents Acting Alone or in Combined Processes of Food Preservation. Innov. Food Sci. Emerg. Technol. 2011, 12, 320–329. [Google Scholar] [CrossRef]

- Fan, L.; Ismail, B.B.; Gao, L.; Liu, D. Comparison of High and Low Frequency Thermosonication and Carvacrol Treatments of Carrot Juice: Microbial Inactivation and Quality Retention. Appl. Food Res. 2022, 2, 100162. [Google Scholar] [CrossRef]

- Nostro, A.; Papalia, T. Antimicrobial Activity of Carvacrol: Current Progress and Future Prospectives. Recent Pat. Antiinfect Drug Discov. 2012, 7, 28–35. [Google Scholar] [CrossRef] [PubMed]

- ISO 1442:1997; Meat and Meat Products—Determination of Moisture Content (Reference Method). Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/00/60/6037.html (accessed on 10 May 2021).

- ISO 937:1978(En); Meat and Meat Products—Determination of Nitrogen Content (Reference Method). Available online: https://www.iso.org/obp/ui/#iso:std:iso:937:ed-1:v1:en (accessed on 12 May 2021).

- ISO 1443:1973(En); Meat and Meat Products—Determination of Total Fat Content. Available online: https://www.iso.org/obp/ui/#iso:std:iso:1443:ed-1:v1:en (accessed on 12 May 2021).

- ISO 936:1998(En); Meat and Meat Products—Determination of Total Ash (Reference Method). Available online: https://www.iso.org/obp/ui/#iso:std:iso:936:ed-2:v1:en (accessed on 14 July 2021).

- Rizvi, N.B.; Aleem, S.; Khan, M.R.; Ashraf, S.; Busquets, R. Quantitative Estimation of Protein in Sprouts of Vigna Radiate (Mung Beans), Lens Culinaris (Lentils), and Cicer Arietinum (Chickpeas) by Kjeldahl and Lowry Methods. Molecules 2022, 27, 814. [Google Scholar] [CrossRef]

- ISO 2917:1999(En); Meat and Meat Products—Measurement of PH—(Reference Method). Available online: https://www.iso.org/obp/ui/#iso:std:iso:2917:ed-2:v1:en (accessed on 14 July 2021).

- Mittal, G.S.; Nadulski, R.; Barbut, S.; Negi, S.C. Textural Profile Analysis Test Conditions for Meat Products. Food Res. Int. 1992, 25, 411–417. [Google Scholar] [CrossRef]

- ICMSF (International Commission on Microbiological Specifications for Foods). Microorganisms in Foods.7: Microbio-logical Testing in Food Safety Management, 2nd ed.; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-68460-4. [Google Scholar]

- USDA. What Does ‘Lean’ and ‘Extra Lean’ Beef Mean on a Nutrition Label? Available online: https://ask.usda.gov/s/article/What-does-lean-and-extra-lean-beef-mean-on-a-nutrition-label (accessed on 18 July 2021).

- Hughes, J.M.; Oiseth, S.K.; Purslow, P.P.; Warner, R.D. A Structural Approach to Understanding the Interactions between Colour, Water-Holding Capacity and Tenderness. Meat Sci. 2014, 98, 520–532. [Google Scholar] [CrossRef]

- McArdle, R.; Marcos, B.; Kerry, J.P.; Mullen, A. Monitoring the Effects of High Pressure Processing and Temperature on Selected Beef Quality Attributes. Meat Sci. 2010, 86, 629–634. [Google Scholar] [CrossRef]

- Şayin Sert, T.; Coşkun, F. The Effects of High-Pressure Processing on PH, Thiobarbituric Acid Value, Color and Texture Properties of Frozen and Unfrozen Beef Mince. Molecules 2022, 27, 3974. [Google Scholar] [CrossRef]

- de Alba, M.; Bravo, D.; Medina, M. High Pressure Treatments on the Inactivation of Salmonella Enteritidis and the Characteristics of Beef Carpaccio. Meat Sci. 2012, 92, 823–828. [Google Scholar] [CrossRef]

- Kreyenschmidt, J.; Hübner, A.; Beierle, E.; Chonsch, L.; Scherer, A.; Petersen, B. Determination of the Shelf Life of Sliced Cooked Ham Based on the Growth of Lactic Acid Bacteria in Different Steps of the Chain. J. Appl. Microbiol. 2010, 108, 510–520. [Google Scholar] [CrossRef]

- Zare, Z. High Presurre Processing of Fresh Tuna Fish and Its Effects on Shelf Life. Master Thesis, McGill University, Montreal, QC, Canada, 2004. [Google Scholar]

- Reyes, T.M.; Smith, H.R.; Wagoner, M.P.; Wilborn, B.S.; Bonner, T.; Brandebourg, T.D.; Rodning, S.P.; Sawyer, J.T. Surface Color Variations of Ground Beef Packaged Using Enhanced, Recycle Ready, or Standard Barrier Vacuum Films. Foods 2022, 11, 162. [Google Scholar] [CrossRef] [PubMed]

- Angsupanich, K.; Ledward, D.A. High Pressure Treatment Effects on Cod (Gadus morhua) Muscle. Food Chem. 1998, 63, 39–50. [Google Scholar] [CrossRef]

- Jung, S.; Ghoul, M.; de Lamballerie-Anton, M. Changes in Lysosomal Enzyme Activities and Shear Values of High Pressure Treated Meat during Ageing. Meat Sci. 2000, 56, 239–246. [Google Scholar] [CrossRef]

- Kruk, Z.A.; Yun, H.; Rutley, D.L.; Lee, E.J.; Kim, Y.J.; Jo, C. The Effect of High Pressure on Microbial Population, Meat Quality and Sensory Characteristics of Chicken Breast Fillet. Food Control 2011, 22, 6–12. [Google Scholar] [CrossRef]

- Watanabe, A.; Daly, C.C.; Devine, C.E. The Effects of the Ultimate PH of Meat on Tenderness Changes during Ageing. Meat Sci. 1996, 42, 67–78. [Google Scholar] [CrossRef]

- Zhu, S.; Riaz, M.N.; Lusas, E.W. Effect of Different Extrusion Temperatures and Moisture Content on Lipoxygenase Inactivation and Protein Solubility in Soybeans. J. Agric. Food Chem. 1996, 44, 3315–3318. [Google Scholar] [CrossRef]

- Alsalman, F.B.; Ramaswamy, H. Reduction in Soaking Time and Anti-Nutritional Factors by High Pressure Processing of Chickpeas. J. Food Sci. Technol. 2020, 57, 2572–2585. [Google Scholar] [CrossRef] [PubMed]

- de Oliveira, F.A.; Neto, O.C.; dos Santos, L.M.R.; Ferreira, E.H.R.; Rosenthal, A. Effect of High Pressure on Fish Meat Quality—A Review. Trends Food Sci. Technol. 2017, 66, 1–19. [Google Scholar] [CrossRef]

- Hall, A.E.; Moraru, C.I. Structure and Function of Pea, Lentil and Faba Bean Proteins Treated by High Pressure Processing and Heat Treatment. LWT 2021, 152, 112349. [Google Scholar] [CrossRef]

- Molina, E.; Defaye, A.B.; Ledward, D.A. Soy Protein Pressure-Induced Gels. Food Hydrocoll. 2002, 16, 625–632. [Google Scholar] [CrossRef]

- Alvarez, P.A.; Ramaswamy, H.S.; Ismail, A.A. High Pressure Gelation of Soy Proteins: Effect of Concentration, PH and Additives. J. Food Eng. 2008, 88, 331–340. [Google Scholar] [CrossRef]

- Ahmad, S.; Rizawi, J.A.; Srivastava, P.K. Effect of Soy Protein Isolate Incorporation on Quality Characteristics and Shelf-Life of Buffalo Meat Emulsion Sausage. J. Food Sci. Technol. 2010, 47, 290–294. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mastromatteo, M.; Lucera, A.; Sinigaglia, M.; Corbo, M.R. Combined Effects of Thymol, Carvacrol and Temperature on the Quality of Non Conventional Poultry Patties. Meat Sci. 2009, 83, 246–254. [Google Scholar] [CrossRef] [PubMed]

- Al-Hijazeen, M.; Mendonca, A.; Lee, E.J.; Ahn, D.U. Effect of Oregano Oil and Tannic Acid Combinations on the Quality and Sensory Characteristics of Cooked Chicken Meat. Poult. Sci. 2018, 97, 676–683. [Google Scholar] [CrossRef] [PubMed]

- Bernasconi, A.; Szerman, N.; Vaudagna, S.R.; Speroni, F. High Hydrostatic Pressure and Soybean Protein Addition to Beef Patties: Effects on the Formation of Mixed Aggregates and Technological Parameters. Innov. Food Sci. Emerg. Technol. 2020, 66, 102503. [Google Scholar] [CrossRef]

- Rogers, H.B.; Brooks, J.C.; Martin, J.N.; Tittor, A.; Miller, M.F.; Brashears, M.M. The Impact of Packaging System and Temperature Abuse on the Shelf Life Characteristics of Ground Beef. Meat Sci. 2014, 97, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Beef Research. Color Changes in Cooked Beef. Available online: https://www.beefresearch.org/resources/product-quality/fact-sheets/color-changes-in-cooked-beef (accessed on 9 December 2022).

- Kyriakopoulou, K.; Dekkers, B.; van der Goot, A.J. Chapter 6—Plant-Based Meat Analogues. In Sustainable Meat Production and Processing; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 103–126. ISBN 978-0-12-814874-7. [Google Scholar]

- Stanbridge, L.H.; Davies, A.R. The Microbiology of Chill-Stored Meat. In The Microbiology of Meat and Poultry; Thomson Science: London, UK, 1998; Volume 1, pp. 174–219. [Google Scholar]

- Argyri, A.A.; Papadopoulou, O.S.; Nisiotou, A.; Tassou, C.C.; Chorianopoulos, N. Effect of High Pressure Processing on the Survival of Salmonella Enteritidis and Shelf-Life of Chicken Fillets. Food Microbiol. 2018, 70, 55–64. [Google Scholar] [CrossRef]

- Mills, J.; Donnison, A.; Brightwell, G. Factors Affecting Microbial Spoilage and Shelf-Life of Chilled Vacuum-Packed Lamb Transported to Distant Markets: A Review. Meat Sci. 2014, 98, 71–80. [Google Scholar] [CrossRef]

- Egan, A.F. Lactic Acid Bacteria of Meat and Meat Products. Antonie Van Leeuwenhoek 1983, 49, 327–336. [Google Scholar] [CrossRef]

- Chenoll, E.; Macián, M.C.; Elizaquível, P.; Aznar, R. Lactic Acid Bacteria Associated with Vacuum-Packed Cooked Meat Product Spoilage: Population Analysis by RDNA-Based Methods. J. Appl. Microbiol. 2007, 102, 498–508. [Google Scholar] [CrossRef] [PubMed]

- Hamasaki, Y.; Ayaki, M.; Fuchu, H.; Sugiyama, M.; Morita, H. Behavior of Psychrotrophic Lactic Acid Bacteria Isolated from Spoiling Cooked Meat Products. Appl. Environ. Microbiol. 2003, 69, 3668–3671. [Google Scholar] [CrossRef] [PubMed]

| Sample | Moisture (%) | Protein (%) | Fat (%) | Ash (%) |

|---|---|---|---|---|

| V1 | 71.35 (0.12) a | 19.79 (0.11) ab | 6.13 (0.32) a | 2.48 (0.31) b |

| V2 | 71.24 (0.02) a | 19.57 (0.01) ab | 7.20 (0.59) a | 2.45 (0.01) b |

| PB1 | 57.41 (0.05) c | 19.80 (0.02) ab | 4.77 (0.24) a | 3.67 (0.00) a |

| PB2 | 57.19 (0.01) c | 19.55 (0.29) ab | 7.88 (3.34) a | 3.62 (0.05) a |

| H1 | 64.27 (0.54) b | 19.36 (0.13) b | 6.13 (0.15) a | 3.18 (0.00) a |

| H2 | 64.38 (0.84) b | 20.06 (0.25) a | 5.65 (0.08) a | 3.19 (0.02) a |

| Treatment | Storage Time (Days) | Veal Patty | Plant-Based Patty | Hybrid Patty |

|---|---|---|---|---|

| Control | 0 | 5.86 (0.01) c | 6.94 (0.03) a | 6.39 (0.01) c |

| 7 | 5.07 (0.01) f | 5.56 (0.02) c | 4.88 (0.02) f | |

| 14 | 5.04 (0.01) f | 6.02 (0.02) d | 4.98 (0.02) g | |

| HPP-SVCOOK | 0 | 6.50 (0.01) b | 6.95 (0.02) a | 6.79 (0.05) a |

| 7 | 5.75 (0.03) d | 6.05 (0.01) b | 5.90 (0.01) d | |

| 14 | 5.68 (0.01) e | 6.07 (0.02) b | 5.91 (0.01) d | |

| HPPSVAA | 0 | 6.80 (0.03) a | 6.93 (0.03) a | 6.73 (0.01) b |

| 7 | 5.72 (0.01) d | 6.07 (0.01) b | 5.88 (0.01) d | |

| 14 | 5.67 (0.01) e | 6.08 (0.02) b | 5.94 (0.01) e |

| Sample | Treatment | Storage Time (Days) | Hardness (N) | Springiness (N) | Cohesiveness | Chewiness |

|---|---|---|---|---|---|---|

| Veal | Control | 0 | 2.92 (0.56) g | 0.42 (0.05) e | 0.36 (0.02) e | 0.44 (0.11) d |

| 7 | 8.68 (2.23) fg | 0.61 (0.07) cd | 0.45 (0.09) bcd | 2.35 (0.70) cd | ||

| 14 | 7.93 (1.39) efg | 0.61 (0.04) cd | 0.45 (0.04) bcd | 2.15 (0.35) cd | ||

| HPP-SVCOOK | 0 | 32.32 (7.02) a | 0.77 (0.06) a | 0.49 (0.06) ab | 12.25 (3.09) a | |

| 7 | 12.02 (5.28) bc | 0.59 (0.06) abc | 0.38 (0.04) bc | 2.77 (1.66) b | ||

| 14 | 21.36 (8.01) def | 0.69 (0.09) d | 0.46 (0.08) de | 7.11 (3.43) cd | ||

| HPPSVAA | 0 | 28.00 (9.77) ab | 0.73 (0.14) ab | 0.56 (0.10) a | 11.69 (4.92) a | |

| 7 | 17.38 (8.97) cde | 0.66 (0.07) cd | 0.41 (0.08) bcd | 5.06 (3.37) bc | ||

| 14 | 15.18 (7.17) cd | 0.62 (0.06) bcd | 0.45 (0.08) cde | 4.53 (2.78) bc | ||

| Plant-based | Control | 0 | 9.16 (2.06) c | 0.61 (0.09) a | 0.26 (0.03) bc | 1.52 (0.51) bc |

| 7 | 9.37 (2.07) a | 0.49 (0.07) abc | 0.30 (0.03) ab | 1.39 (0.44) a | ||

| 14 | 13.18 (1.74) c | 0.53 (0.08) bc | 0.28 (0.02) a | 1.97 (0.52) c | ||

| HPP-SVCOOK | 0 | 11.62 (2.08) ab | 0.58 (0.08) ab | 0.28 (0.02) ab | 1.89 (0.51) ab | |

| 7 | 10.56 (1.42) bc | 0.51 (0.13) cd | 0.27 (0.03) bc | 1.43 (0.47) cd | ||

| 14 | 10.60 (1.84) bc | 0.44 (0.06) bc | 0.27 (0.02) bc | 1.25 (0.30) c | ||

| HPPSVAA | 0 | 9.11 (0.88) c | 0.35 (0.06) de | 0.25 (0.01) c | 0.79 (0.17) e | |

| 7 | 9.23 (1.74) bc | 0.29 (0.05) de | 0.24 (0.03) c | 0.67 (0.23) de | ||

| Hybrid | Control | 0 | 3.84 (0.88) e | 0.33 (0.07) d | 0.27 (0.06) e | 0.344 (0.11) d |

| 7 | 18.16 (6.65) ab | 0.67 (0.06) ab | 0.47 (0.05) a | 5.77 (2.29) a | ||

| 14 | 19.91 (4.17) ab | 0.67 (0.04) ab | 0.48 (0.04) a | 6.31 (1.31) ab | ||

| HPP-SVCOOK | 0 | 17.01 (6.15) abc | 0.70 (0.05) a | 0.44 (0.07) ab | 5.29 (2.06) ab | |

| 7 | 12.17 (3.20) bcd | 0.50 (0.07) b | 0.35 (0.06) bc | 2.16 (0.90) bc | ||

| 14 | 15.17 (3.52) cd | 0.62 (0.07) c | 0.39 (0.04) cd | 3.71 (1.16) cd | ||

| HPPSVAA | 0 | 21.31 (8.40) a | 0.70 (0.11) a | 0.45 (0.07) ab | 7.23 (3.59) a | |

| 7 | 11.01 (3.30) ab | 0.52 (0.09) ab | 0.31 (0.03) ab | 1.86 (1.09) ab | ||

| 14 | 20.30 (7.78) d | 0.64 (0.10) c | 0.44 (0.11) de | 5.92 (3.14) cd |

| Sample | Treatment | Storage Time (Days) | L* | a* | b* |

|---|---|---|---|---|---|

| Veal | Control | 0 | 44.38 (2.86) c | 9.83 (1.04) bc | 25.15 (1.32) a |

| 7 | 41.78 (2.75) c | 10.42 (1.47) bc | 23.75 (2.16) ab | ||

| 14 | 36.42 (1.52) d | 12.88 (1.48) a | 22.66 (2.59) abc | ||

| HPP-SVCOOK | 0 | 53.95 (1.85) a | 5.54 (0.58) e | 20.40 (0.10) cd | |

| 7 | 48.71 (1.66) b | 9.39 (1.13) bcd | 22.61 (1.61) bc | ||

| 14 | 49.31 (1.65) b | 8.26 (0.91) d | 20.85 (0.99) cd | ||

| HPPSVAA | 0 | 53.23 (2.18) a | 4.83 (0.79) e | 18.66 (2.68) d | |

| 7 | 49.60 (1.52) b | 8.51 (0.66) cd | 21.64 (1.66) bc | ||

| 14 | 49.03 (1.05) b | 8.61 (0.75) cd | 21.39 (1.19) bc | ||

| Plant-based | Control | 0 | 59.77 (1.27) a | 8.52 (0.72) bc | 26.68 (1.04) e |

| 7 | 57.54 (1.39) ab | 10.04 (0.64) ab | 32.08 (1.29) bc | ||

| 14 | 59.25 (1.97) bc | 9.28 (0.93) a | 29.91 (1.36) a | ||

| HPP-SVCOOK | 0 | 59.08 (0.95) ab | 8.57 (0.65) bc | 26.64 (1.39) e | |

| 7 | 58.15 (1.47) ab | 8.35 (0.60) bc | 28.04 (0.93) cd | ||

| 14 | 58.68 (1.88) abc | 8.62 (0.75) c | 29.11 (1.49) cde | ||

| HPPSVAA | 0 | 59.33 (1.33) ab | 8.70 (0.46) bc | 27.82 (1.96) de | |

| 7 | 56.38 (1.48) abc | 10.02 (0.62) a | 31.83 (1.22) a | ||

| 14 | 57.97 (0.80) c | 10.18 (0.35) a | 32.13 (1.64) ab | ||

| Hybrid | Control | 0 | 50.60 (2.76) bc | 11.59 (1.66) a | 32.15 (1.76) a |

| 7 | 53.13 (1.74) bc | 7.84 (0.51) bc | 25.09 (1.28) b | ||

| 14 | 50.84 (3.74) abc | 7.39 (0.75) b | 26.36 (1.19) b | ||

| HPP-SVCOOK | 0 | 53.87 (1.75) ab | 5.87 (0.98) de | 24.92 (3.55) b | |

| 7 | 51.18 (3.57) abc | 4.64 (0.96) f | 25.48 (3.18) b | ||

| 14 | 52.54 (1.35) bc | 3.46 (1.28) ef | 24.32 (2.50) b | ||

| HPPSVAA | 0 | 55.08 (1.78) a | 5.87 (0.89) de | 27.61 (2.01) b | |

| 7 | 50.38 (1.47) abc | 6.91 (0.84) cd | 26.95 (2.37) b | ||

| 14 | 51.98 (1.54) c | 6.39 (0.90) bcd | 26.06 (2.67) b |

| Time (Days) | ||||

|---|---|---|---|---|

| Sample | Treament | 0 | 7 | 14 |

| Veal | Control | 5.29 (0.72) a | 6.07 (1.03) a | 6.43 (1.21) a |

| HPP-SVCOOK | 2.06 (0.32) b | 1.92 (0.32) b | 4.55 (0.27) b | |

| HPPSVAA | 2.43 (0.28) b | 4.71 (1.19) a | 5.80 (0.36) ab | |

| Plant-based | Control | 5.06 (0.47) a | 6.86 (0.98) a | 8.33 (0.94) a |

| HPP-SVCOOK | 2.46 (0.14) b | 5.47 (0.96) a | 8.55 (1.03) a | |

| HPPSVAA | 2.53 (0.33) b | 4.93 (1.25) a | 7.96 (0.78) a | |

| Hybrid | Control | 5.56 (0.65) a | 6.60 (0.85) a | 6.87 (1.01) a |

| HPP-SVCOOK | 2.85 (0.21) b | 5.10 (1.02) a | 7.39 (0.67) a | |

| HPPSVAA | 2.46 (0.27) b | 5.07 (1.10) a | 7.63 (0.94) a | |

| Time (Days) | ||||

|---|---|---|---|---|

| Sample | Treatment | 0 | 7 | 14 |

| Veal | Control | 3.08 (0.46) b | 3.62 (0.74) b | 4.53 (0.72) b |

| HPP-SVCOOK | <1 c | 1.21 (0.12) c | <1 d | |

| HPPSVAA | <1 c | 1.47 (0.21) c | <1 d | |

| Plant-based | Control | 5.69 (0.25) a | 6.23 (0.54) a | 7.01 (0.38) a |

| HPP-SVCOOK | <1 c | 1.47 (0.18) c | 1.57 (0.61) d | |

| HPPSVAA | <1 c | 1.24 (0.17) c | <1 d | |

| Hybrid | Control | 5.53 (0.63) a | 5.80 (0.38) a | 6.10 (0.41) a |

| HPP-SVCOOK | <1 c | <1 c | 3.51 (0.51) b | |

| HPPSVAA | <1 c | 1.09 (0.08) c | 2.66 (0.65) c | |

| Time (Days) | ||||

|---|---|---|---|---|

| Sample | Treatment | 0 | 7 | 14 |

| Veal | Control | 1.87 (0.45) | 3.72 (0.32) b | 4.16 (0.59) c |

| HPP-SVCOOK | 1.30 (0.21) | 2.10 (0.27) c | <1 e | |

| HPPSVAA | 1.30 (0.23) | 1.90 (0.21) c | <1 e | |

| Plant-based | Control | 2.39 (0.88) | 5.50 (0.71) a | 8.87 (0.85) a |

| HPP-SVCOOK | 2.17 (0.62) | 3.11 (0.31) b | 2.87 (0.43) d | |

| HPPSVAA | 2.17 (0.47) | 3.00 (0.41) b | <1 e | |

| Hybrid | Control | 1.54 (0.14) | 4.20 (0.61) b | 6.08 (0.71) b |

| HPP-SVCOOK | 1.92 (0.37) | <1 d | <1 e | |

| HPPSVAA | 1.69 (0.31) | 2.22 (0.18) c | <1 e | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janardhanan, R.; Olarte, C.; Sanz, S.; Rota, C.; Beriain, M.J. Combined Effect of High Hydrostatic Pressure, Sous-Vide Cooking, and Carvacrol on the Quality of Veal, Plant-Based, and Hybrid Patties during Storage. Foods 2023, 12, 289. https://doi.org/10.3390/foods12020289

Janardhanan R, Olarte C, Sanz S, Rota C, Beriain MJ. Combined Effect of High Hydrostatic Pressure, Sous-Vide Cooking, and Carvacrol on the Quality of Veal, Plant-Based, and Hybrid Patties during Storage. Foods. 2023; 12(2):289. https://doi.org/10.3390/foods12020289

Chicago/Turabian StyleJanardhanan, Rasmi, Carmen Olarte, Susana Sanz, Carmina Rota, and María José Beriain. 2023. "Combined Effect of High Hydrostatic Pressure, Sous-Vide Cooking, and Carvacrol on the Quality of Veal, Plant-Based, and Hybrid Patties during Storage" Foods 12, no. 2: 289. https://doi.org/10.3390/foods12020289

APA StyleJanardhanan, R., Olarte, C., Sanz, S., Rota, C., & Beriain, M. J. (2023). Combined Effect of High Hydrostatic Pressure, Sous-Vide Cooking, and Carvacrol on the Quality of Veal, Plant-Based, and Hybrid Patties during Storage. Foods, 12(2), 289. https://doi.org/10.3390/foods12020289