Effect of Spirulina in Bread Formulated with Wheat Flours of Different Alveograph Strength

Abstract

:1. Introduction

- “P”, which is also called Dough tenacity, stands for the maximum pressure needed to obtain a dough bubble; its unit is mm H2O.

- “L”, which starts measuring at the beginning of the inflation until its rupture; it is measured in mm. This can also be called extensibility.

- “P/L Ratio”, which stands for the balance between tenacity and extensibility. A high ratio indicates a resistant dough, while a low ratio indicates a weak and highly extensive dough [9].

2. Materials and Methods

2.1. Wheat Flours and Spirulina Biomass

2.2. Mixing Properties of Wheat Flours

2.3. Alveographic Test

2.4. Bread Making Procedure

2.5. Moisture and Protein Content

2.6. Bread Technological Quality

2.7. Sensory Analysis

2.8. Protein Digestibility

2.9. Total Phenolic Content and Antioxidant Capacity

2.10. Statistical Analysis

3. Results and Discussion

3.1. Alveograph Test

3.2. Flours and Spirulina Properties

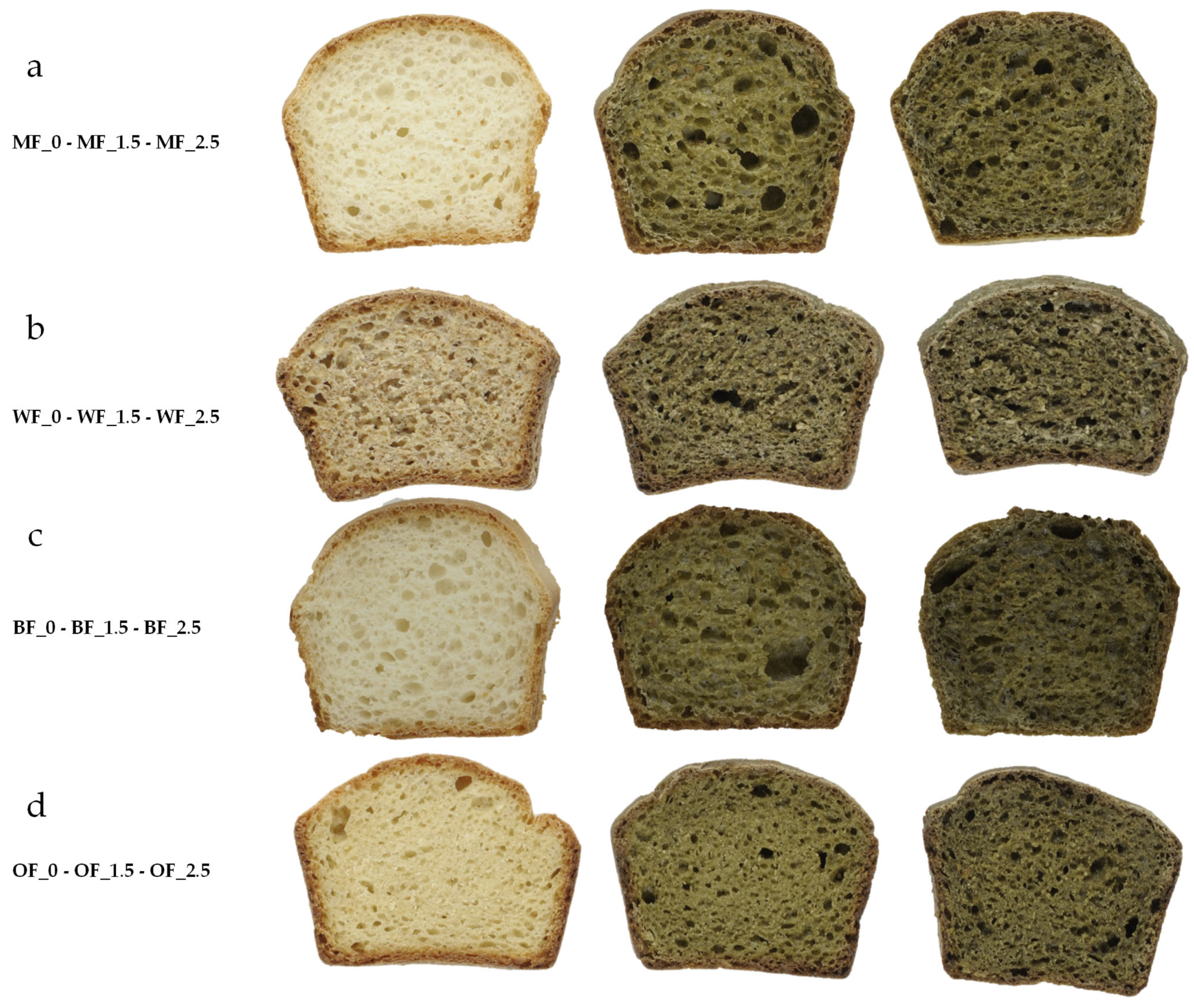

3.3. Bread Quality

3.3.1. Technological Properties

3.3.2. Sensory Properties

3.3.3. Nutritional Properties

4. Conclusions

5. Limitations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ak, B.; Avsaroglu, E.; Isik, O.; Özyurt, G.; Kafkas, E.; Etyemez, M. Nutritional and physicochemical characteristics of bread enriched with microagae Spirulina platensis. Int. J. Eng. Res. Appl. 2016, 6, 30–38. [Google Scholar]

- Shahidi, F.; Ambigaipalan, P. Phenolics and polyphenolics in foods, beverages, and spices: Antioxidant activity and health effects—A review. J. Funct. Foods 2019, 18, 820–897. [Google Scholar] [CrossRef]

- Sankaran, R.; Show, P.L.; Nagarajan, D.; Chang, J.S. Exploitation and biorefinery of microalgae. In Waste Biorefinery; Elsevier: Amsterdam, The Netherlands, 2018; pp. 571–601. [Google Scholar] [CrossRef]

- Gonçalves, A. The Unbelievable Powers of Algae That Brought Us Here. Youmatter.world. Available online: https://youmatter.world/en/microalgae-sustainability-solution-climate-change/ (accessed on 27 August 2020).

- Costa, J.A.V.; De Morais, M.G. The role of biochemical engineering in the production of biofuels from microalgae. Bioresour. Technol. 2011, 102, 2–9. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.-K.; Wang, X.; Miao, J.; Tian, Y.-T. Tofu whey wastewater is a promising basal medium for microalgae culture. Bioresour. Technol. 2018, 253, 79–84. [Google Scholar] [CrossRef]

- Caporgno, M.P.; Mathys, A. Trends in microalgae incorporation into innovative food products with potential health benefits. Front. Nutr. 2018, 5, 58. [Google Scholar] [CrossRef]

- Rubel, I.A.; Pérez, E.E.; Manrique, G.D.; Genovese, D.B. Fibre enrichment of wheat bread with Jerusalem artichoke inulin: Effect on dough rheology and bread quality. Food Struct. 2015, 3, 21–29. [Google Scholar] [CrossRef]

- Jødal, A.-S.S.; Larsen, K.L. Investigation of the relationships between the alveograph parameters. Sci. Rep. 2021, 11, 5349. [Google Scholar] [CrossRef]

- Plustea, L.; Negrea, M.; Cocan, I.; Radulov, I.; Tulcan, C.; Berbecea, A. Lupin (Lupinus spp.)-fortified bread: A sustainable, nutritionally, functionally, and technologically valuable solution for bakery. Foods 2022, 11, 2067. [Google Scholar] [CrossRef]

- Kahraman, G.; Harsa, S.; Lucisano, M.; Cappa, C. Physicochemical and rheological properties of rice-based gluten-free blends containing differently treated chickpea flours. LWT-Food Sci. Technol. 2018, 98, 276–282. [Google Scholar] [CrossRef]

- Kahraman, G.; Harsa, S.; Casiraghi, M.C.; Lucisano, M.; Cappa, C. Impact of Raw, Roasted and Dehulled Chickpea Flours on Technological and Nutritional Characteristics of Gluten-Free Bread. Foods 2022, 11, 199. [Google Scholar] [CrossRef]

- Mohammed, I.; Ahmed, A.R.; Senge, B. Effects of chickpea flour on wheat pasting properties and bread making quality. J. Food Sci. Technol. 2014, 51, 1902–1910. [Google Scholar] [CrossRef] [PubMed]

- García-Segovia, P.; Pagán-Moreno, M.J.; Lara, I.F.; Martínez-Monzó, J. Effect of microalgae incorporation on physicochemical and textural properties in wheat bread formulation. J. Food Sci. Technol. 2017, 23, 437–447. [Google Scholar] [CrossRef]

- Lafarga, T.; Mayre, E.; Echeverria, G.; Viñas, I.; Villaró, S.; Acién-Fernández, F.G.; Aguiló-Aguayo, I. Potential of the microalgae Nannochloropsis and Tetraselmis for being used as innovative ingredients in baked goods. LWT-Food Sci. Technol. 2019, 115, 108439. [Google Scholar] [CrossRef]

- Ramírez-Rodrigues, M.M.; Estrada-Beristain, C.; Metri-Ojeda, J.; Pérez-Alva, A.; Baigts-Allende, D.K. Spirulina platensis protein as sustainable ingredient for nutritional food products development. Sustainability 2021, 13, 6849. [Google Scholar] [CrossRef]

- Nourmohammadi, N.; Soleimanian-Zad, S.; Shekarchizadeh, H. Effect of Spirulina (Arthrospira platensis) microencapsulated in alginate and whey protein concentrate addition on physicochemical and organoleptic properties of functional stirred yogurt. J. Sci. Food Agric. 2020, 100, 5260–5268. [Google Scholar] [CrossRef]

- Chu, W.L. Biotechnological applications of microalgae. IeJSME 2012, 6, S24–S37. [Google Scholar] [CrossRef]

- El Amasadero (ND). Catálogo Completo de Harinas. Available online: https://www.elamasadero.com/18-harinas (accessed on 1 August 2020).

- Musatti, A.; Cappa, C.; Mapelli, C.; Alamprese, C.; Rollini, M. Zymomonas mobilis in bread dough: Characterization of dough leavening performance in presence of sucrose. Foods 2020, 9, 89. [Google Scholar] [CrossRef]

- AACC. ApproVed Methods of the American Association of Cereal Chemists, 8th ed.; American Association of Cereal Chemists: St. Paul, MN, USA, 1983; p. 54-30A. [Google Scholar]

- Lafarga, T.; Gallagher, E.; Aluko, R.E.; Auty, M.A.; Hayes, M. Addition of an enzymatic hydrolysate of bovine globulins to bread and determination of hypotensive effects in spontaneously hypertensive rats. J. Agric. Food Chem. 2016, 64, 1741–1750. [Google Scholar] [CrossRef]

- Templeton, D.W.; Laurens, L.M.L. Nitrogen-to-protein conversion factors revisited for applications of microalgal biomass conversion to food, feed, and fuel. Algal Res. 2015, 11, 359–367. [Google Scholar] [CrossRef]

- Lafarga, T.; Gallagher, E.; Bademunt, A.; Bobo, G.; Echeverria, G.; Viñas, I.; Aguiló-Aguayo, I. Physiochemical and nutritional characteristics, bioaccessibility and sensory acceptance of baked crackers containing broccoli co-products. Int. J. Food Sci. Technol. 2018, 54, 634–640. [Google Scholar] [CrossRef]

- Millar, K.A.; Barry-Ryan, C.; Burke, R.; Hussey, K.; McCarthy, S.; Gallagher, E. Effect of pulse flours on the physiochemical characteristics and sensory acceptance of baked crackers. Int. J. Food Sci. 2017, 52, 1155–1163. [Google Scholar] [CrossRef]

- Lucas, B.F.; de Morais, M.G.; Santos, T.D.; Costa, J.A.V. Spirulina for snack enrichment: Nutritional, physical, and sensory evaluations. LWT-Food Sci. Technol. 2018, 90, 270–276. [Google Scholar] [CrossRef]

- Severini, C.; Azzollini, D.; Albenzio, M.; Derossi, A. On printability, quality and nutritional properties of 3D printed cereal based snacks enriched with edible insects. Food Res. Int. 2018, 106, 666–676. [Google Scholar] [CrossRef]

- Lafarga, T.; Villaró, S.; Bobo, G.; Simó, J.; Aguiló-Aguayo, I. Bioaccessibility and antioxidant activity of phenolic compounds in cooked pulses. Int. J. Food Sci. 2019, 54, 1816–1823. [Google Scholar] [CrossRef]

- Cappelli, A.; Cini, E.; Guerrini, L.; Masella, P.; Angeloni, G.; Parenti, A. Predictive models of the rheological properties and optimal water content in doughs: An application to ancient grain flours with different degrees of refining. J. Cereal Sci. 2018, 83, 229–235. [Google Scholar] [CrossRef]

- Barak, S.; Mudgil, D.; Khatkar, B.S. Relationship of gliadin and glutenin proteins with dough rheology, flour pasting and bread making performance of wheat varieties. LWT-Food Sci. Technol. 2013, 51, 211–217. [Google Scholar] [CrossRef]

- Montevecchi, G.; Santunione, G.; Licciardello, F.; Köker, Ö.; Masino, F.; Antonelli, A. Enrichment of wheat flour with Spirulina. Evaluation of thermal damage to essential amino acids during bread preparation. Food Res. Int. 2022, 157, 111357. [Google Scholar] [CrossRef] [PubMed]

- Monteau, J.-Y.; Purlis, E.; Besbes, E.; Jury, V.; Le-Bail, A. Water transfer in bread during staling: Physical phenomena and modelling. J. Food Eng. 2017, 211, 95–103. [Google Scholar] [CrossRef]

- Papageorgiou, M.; Skendi, A. Flour Quality and Technological Abilities. In Engineering Aspects of Cereal and Cereal-Based Products, 1st ed.; Ferreira Guine, R.D.P., Correia, P.M.D.R., Eds.; CRC Press: Boca Raton, FL, USA, 2013; pp. 117–148. [Google Scholar] [CrossRef]

- Achour, H.Y.; Doumandji, A.; Sadi, S.; Saadi, S. Evaluation of nutritional and sensory properties of bread enriched with Spirulina. Ann. Food Sci. Technol. 2014, 15, 270–275. [Google Scholar]

- Tiwari, B.K.; Muthukumarappan, K.; O’Donnell, C.P.; Cullen, P.J. Kinetics of freshly squeezed orange juice quality changes during ozone processing. J. Agric. Food Chem. 2008, 56, 6416–6422. [Google Scholar] [CrossRef]

- Figueira, F.D.S.; Crizel, T.D.M.; Silva, C.R.; Salas-Mellado, M.D.L.M. Elaboration of gluten-free bread enriched with the microalgae Spirulina platensis. Braz. J. Food Technol. 2011, 14, 308–316. [Google Scholar] [CrossRef]

- De Marco, E.R.; Steffolani, M.E.; Martínez, C.S.; León, A.E. Effects of Spirulina biomass on the technological and nutritional quality of bread wheat pasta. LWT-Food Sci. Technol. 2014, 58, 102–108. [Google Scholar] [CrossRef]

- Batista, A.P.; Niccolai, A.; Bursic, I.; Sousa, I.; Raymundo, A.; Rodolfi, L. Microalgae as functional ingredients in savory food products: Application to wheat crackers. Foods 2019, 8, 611. [Google Scholar] [CrossRef] [PubMed]

- Stahl, W.; Van Den Berg, H.; Arthur, J.; Bast, A.; Dainty, J.; Faulks, R.M.; Astley, S.B. Bioavailability, and metabolism. Mol. Aspects Med. 2002, 23, 39–100. [Google Scholar] [CrossRef]

- Koli, D.K.; Rudra, S.G.; Bhowmik, A.; Pabbi, S. Nutritional, functional, textural, and sensory evaluation of Spirulina enriched green pasta: A potential dietary and health supplement. Foods. 2022, 11, 979. [Google Scholar] [CrossRef]

- Nunes, M.C.; Graça, C.; Vlaisavljević, S.; Tenreiro, A.; Sousa, I.; Raymundo, A. Microalgal cell disruption: Effect on the bioactivity and rheology of wheat bread. Algal Res. 2020, 45, 101749. [Google Scholar] [CrossRef]

- Różyło, R.; Hameed Hassoon, W.; Gawlik-Dziki, U.; Siastała, M.; Dziki, D. Study on the physical and antioxidant properties of gluten-free bread with brown algae. J. Food 2017, 15, 196–203. [Google Scholar] [CrossRef]

- Goiris, K.; Muylaert, K.; Fraeye, I.; Foubert, I.; De Brabanter, J.; De Cooman, L. Antioxidant potential of microalgae in relation to their phenolic and carotenoid content. J. Appl. Phycol. 2012, 24, 1477–1486. [Google Scholar] [CrossRef]

- Hernández-López, I.; Valdés, J.R.B.; Castellari, M.; Aguiló-Aguayo, I.; Morillas-España, A.; Sánchez-Zurano, A.; Lafarga, T. Utilisation of the marine microalgae Nannochloropsis sp. and Tetraselmis sp. as innovative ingredients in the formulation of wheat tortillas. Algal. Res. 2021, 58, 102361. [Google Scholar] [CrossRef]

| Sample | Flour (g) | Water (g) | Spirulina (g) | Salt (g) | Yeast (g) | Mixing Time (min) |

|---|---|---|---|---|---|---|

| MF-0 | 400 | 246.8 | 0 | 8.0 | 6.0 | 11.2 |

| MF-1.5 | 400 | 252.8 | 6.0 | 8.0 | 6.0 | 8.9 |

| MF-2.5 | 400 | 257.2 | 10.0 | 8.0 | 6.0 | 8.5 |

| WF-0 | 400 | 286.0 | 0 | 8.0 | 6.0 | 7.3 |

| WF-1.5 | 400 | 292.4 | 6.0 | 8.0 | 6.0 | 7.0 |

| WF-2.5 | 400 | 296.0 | 10.0 | 8.0 | 6.0 | 6.9 |

| BF-0 | 400 | 230.4 | 0 | 8.0 | 6.0 | 3.0 |

| BF-1.5 | 400 | 238.0 | 6.0 | 8.0 | 6.0 | 2.9 |

| BF-2.5 | 400 | 240.8 | 10.0 | 8.0 | 6.0 | 2.9 |

| OF-0 | 400 | 306.8 | 0 | 8.0 | 6.0 | 7.6 |

| OF-1.5 | 400 | 313.2 | 6.0 | 8.0 | 6.0 | 6.9 |

| OF-2.5 | 400 | 318.0 | 10.0 | 8.0 | 6.0 | 7.0 |

| Sample | P (mmH20) | L (mm) | P/L Ratio | W (10−4 J) |

|---|---|---|---|---|

| MF-0 | 89 | 68 | 1.31 | 251 |

| WF-0 | 152 | 17 | 8.94 | 126 |

| BF-0 | 57 | 51 | 1.12 | 105 |

| OF-0 | 149 | 9 | 16.56 | 66 |

| Sample | Moisture (%) | Protein (%) | Water Absorption (%) | Development Time (min) | Stability (min) |

|---|---|---|---|---|---|

| MF-0 | 11.4 | 11.7 ± 0.2 Ab | 61.7 ± 1.8 Ca | 10.2 ± 0.9 Aa | 21.7 ± 1.8 Aa |

| MF-1.5 | 11.3 | 12.5 ± 0.1 Aab | 63.2 ± 2.1 Ca | 7.9 ± 0.1 Ab | 11.7 ± 0.8 Ab |

| MF-2.5 | 11.2 | 13.2 ± 0.5 Aa | 64.3 ± 1.6 Ca | 7.5 ± 0.3 Ab | 9.8 ± 0.1 Ab |

| WF-0 | 9.5 | 10.3 ± 0.1 Ba | 71.5 ± 0.4 Bb | 6.4 ± 0.1 Ba | 7.0 ± 0.1 Ba |

| WF-1.5 | 9.4 | 10.5 ± 0.2 Ba | 73.1 ± 0.1 Ba | 6.0 ± 0.1 Bb | 3.5 ± 0.1 Bb |

| WF-2.5 | 9.4 | 11.1 ± 0.3 Aba | 74.0 ± 0.2 Ba | 5.9 ± 0.1 Bb | 3.2 ± 0.2 Cb |

| BF-0 | 11.6 | 7.9 ± 0.3 Ca | 57.8 ± 0.1 Dc | 1.9 ± 0.1 Ca | 2.6 ± 0.6 Cb |

| BF-1.5 | 11.5 | 8.5 ± 0.4 Ca | 59.5 ± 0.1 Db | 1.9 ± 0.1 Ca | 4.3 ± 0.1 Ba |

| BF-2.5 | 11.4 | 9.1 ± 0.3 Ba | 60.2 ± 0.3 Da | 1.9 ± 0.1 Ca | 4.5 ± 0.1 Ba |

| OF-0 | 6.9 | 9.8 ± 0.1 Ba | 76.7 ± 0.3 Ac | 6.6 ± 0.1 Ba | 7.0 ± 0.3 Ba |

| OF-1.5 | 6.9 | 9.8 ± 0.2 Ba | 78.3 ± 0.1 Ab | 5.9 ± 0.2 Bb | 5.1 ± 0.3 Bb |

| OF-2.5 | 6.9 | 11.0 ± 0.8 Ba | 79.5 ± 0.2 Aa | 6.0 ± 0.1 Bb | 5.0 ± 0.1 Bb |

| Scheme | Moisture (%) | Loaf Weight (g) | Loaf Height (mm) | Specific Volume (mL/g) |

|---|---|---|---|---|

| MF-0 | 31.1 ± 1.3 Ba | 44.8 ± 0.5 Bb | 47 ± 1 Aa | 4.01 ± 0.4 Aa |

| MF-1.5 | 29.4 ± 0.0 ABa | 46.6 ± 0.3 Ba | 37 ± 1 Bb | 3.14 ± 0.3 Ab |

| MF-2.5 | 31.0 ± 0.9 Aa | 44.1 ± 0.5 Cc | 48 ± 1 Aa | 3.71 ± 0.3 Aab |

| WF-0 | 37.2 ± 0.9 Aab | 44.7 ± 0.5 Bb | 42 ± 1 Ba | 2.71 ± 0.2 Cb |

| WF-1.5 | 31.3 ± 1.3 Aa | 44.5 ± 0.4 Cb | 39 ± 1 Ab | 2.99 ± 0.2 Aab |

| WF-2.5 | 34.4 ± 0.2 Ab | 41.5 ± 0.6 Ba | 41 ± 1 Ba | 3.16 ± 0.2 Ba |

| BF-0 | 34.6 ± 0.2 Aa | 45.8 ± 0.5 Ab | 31 ± 1 Da | 3.22 ± 0.2 Bb |

| BF-1.5 | 27.4 ± 0.2 Bc | 47.3 ± 0.6 Aa | 30 ± 1 Ca | 3.32 ± 0.2 Aab |

| BF-2.5 | 32.0 ± 0.4 Ab | 45.9 ± 0.3 Bb | 31 ± 1 Da | 3.60 ± 0.2 Aa |

| OF-0 | 28.6 ± 0.5 Ba | 38.7 ± 1.1 Ab | 38 ± 1 Ca | 2.38 ± 0.2 Ca |

| OF-1.5 | 28.7 ± 3.0 Ba | 38.3 ± 1.2 Bb | 38 ± 1 ABa | 2.39 ± 0.2 Ba |

| OF-2.5 | 32.6 ± 2.4 Aa | 37.6 ± 1.0 Aa | 37 ± 1 Ca | 2.28 ± 0.2 Ca |

| Sample | L* | a* | b* | TDC | ||||

|---|---|---|---|---|---|---|---|---|

| Crust | Crumb | Crust | Crumb | Crust | Crumb | Crust | Crumb | |

| MF-0 | 52.6 ± 3.9 ABa | 63.8 ± 2.2 Aa | 15.9 ± 1.1 Ba | 2.9 ± 0.1 Ca | 28.1 ± 0.7 Aa | 11.7 ± 0.7 Dc | - | - |

| MF-1.5 | 43.2 ± 3.3 Ab | 42.3 ± 2.9 Ab | 9.6 ± 1.5 Ab | 1.4 ± 0.5 Bb | 26.7 ± 1.5 Ab | 20.6 ± 0.6 ABa | 11.5 | 23.3 |

| MF-2.5 | 40.1 ± 2.0 Ab | 29.8 ± 1.4 Bc | 6.2 ± 0.9 ABc | 1.6 ± 0.3 Bb | 17.1 ± 1.0 Ac | 16.4 ± 0.9 Bb | 19.3 | 34.4 |

| WF-0 | 51.5 ± 3.5 ABa | 64.1 ± 4.1 Aa | 16.0 ± 1.1 Ba | 2.9 ± 0.1 Ca | 26.6 ± 1.7 Aa | 13.2 ± 0.8 Cc | - | - |

| WF-1.5 | 41.4 ± 1.1 Ab | 40.9 ± 2.8 Ab | 8.1 ± 0.9 Ab | 1.3 ± 0.1 Bb | 19.5 ± 0.7 ABb | 20.1 ± 0.7 ABa | 14.7 | 24.3 |

| WF-2.5 | 38.7 ± 2.2 ABb | 36.4± 1.6 Ac | 15 ± 1.0 Ac | 1.5 ± 0.2 Bb | 17.6 ± 1.4 Ac | 19.1 ± 0.6 Ab | 18.1 | 28.3 |

| BF-0 | 48.5 ± 1.9 Ba | 56.1 ± 2.5 Ba | 15.0 ± 1.0 Ba | 8.2 ± 0.3 Aa | 23.7 ± 1.8 Ba | 17.9 ± 0.6 Bb | - | - |

| BF-1.5 | 38.4 ± 1.4 Bb | 37.8 ± 1.9 Bb | 7.8 ± 0.7 Ab | 2.4 ± 0.2 Ab | 16.4 ± 0.9 Bb | 20.1 ± 0.7 Ba | 14.4 | 19.1 |

| BF-2.5 | 35.4 ± 0.8 Cc | 34.8 ± 2.0 Ac | 5.4 ± 0.5 BCc | 1.5 ± 0.2 Ac | 17.8 ± 0.7 Bc | 19.9 ± 0.8 Aa | 17.1 | 22.1 |

| OF-0 | 53.6 ± 2.5 Aa | 64.6 ± 0.7 Aa | 17.0 ± 2.6 Aa | 5.4 ± 0.1 Ba | 28.2 ± 2.6 Aa | 22.6 ± 0.2 ACa | - | - |

| OF-1.5 | 40.9 ± 0.9 ABb | 42.7 ± 0.9 Ab | 6.2 ± 1.8 Ab | 1.1 ± 0.1 Ba | 18.3 ± 1.0 Cb | 20.7 ± 0.1 Ab | 19.4 | 22.3 |

| OF-2.5 | 37.0 ± 0.4 BCc | 36.3 ± 0.4 Ac | 4.8 ± 1.1 Cb | 0.9 ± 0.1 Bc | 14.4 ± 0.3 Bc | 18.9 ± 0.1 Ac | 24.8 | 28.9 |

| Sample | AI (%) | PI |

|---|---|---|

| MF-0 | 81.61 ± 14 Aa | 3.9 ± 1.2 Aa |

| MF-1.5 | 77.78 ± 15 Aa | 3.8 ± 0.7 Aa |

| MF-2.5 | 82.59 ± 12 Aa | 4.1 ± 0.8 Aa |

| WF-0 | 76.44 ± 15 Aa | 3.7 ± 1.2 Aa |

| WF-1.5 | 77.78 ± 15 Aa | 3.5 ± 1.1 Aa |

| WF-2.5 | 77.33 ± 15 Aa | 3.6 ± 1.2 Aa |

| BF-0 | 83.57 ± 12 Aa | 4.2 ± 0.8 Aa |

| BF-1.5 | 81.64 ± 14 Aa | 3.9 ± 1.0 Aa |

| BF-2.5 | 78.74 ± 15 Aa | 3.8 ± 0.8 Aa |

| OF-0 | 75.25 ± 14 Aa | 3.4 ± 1.1 Aa |

| OF-1.5 | 72.73 ± 15 Aa | 3.4 ± 1.2 Aa |

| OF-2.5 | 81.82 ± 15 Aa | 3.8 ± 1.0 Aa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-López, I.; Alamprese, C.; Cappa, C.; Prieto-Santiago, V.; Abadias, M.; Aguiló-Aguayo, I. Effect of Spirulina in Bread Formulated with Wheat Flours of Different Alveograph Strength. Foods 2023, 12, 3724. https://doi.org/10.3390/foods12203724

Hernández-López I, Alamprese C, Cappa C, Prieto-Santiago V, Abadias M, Aguiló-Aguayo I. Effect of Spirulina in Bread Formulated with Wheat Flours of Different Alveograph Strength. Foods. 2023; 12(20):3724. https://doi.org/10.3390/foods12203724

Chicago/Turabian StyleHernández-López, Israel, Cristina Alamprese, Carola Cappa, Virginia Prieto-Santiago, Maribel Abadias, and Ingrid Aguiló-Aguayo. 2023. "Effect of Spirulina in Bread Formulated with Wheat Flours of Different Alveograph Strength" Foods 12, no. 20: 3724. https://doi.org/10.3390/foods12203724

APA StyleHernández-López, I., Alamprese, C., Cappa, C., Prieto-Santiago, V., Abadias, M., & Aguiló-Aguayo, I. (2023). Effect of Spirulina in Bread Formulated with Wheat Flours of Different Alveograph Strength. Foods, 12(20), 3724. https://doi.org/10.3390/foods12203724