Comparative Evaluation of Polysaccharide Binders on the Quality Characteristics of Plant-Based Patties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Plant-Based Patties

2.3. Proximate Analysis

2.4. Color and pH Measurement

2.5. Water Holding Capacity and Cooking Yield of Plant-Based Patties

2.6. Texture Profile Analysis (TPA)

2.7. Sensory Evaluation

2.8. Statistical Analysis

3. Results and Discussion

3.1. Proximate Analysis of Plant-Based Patties

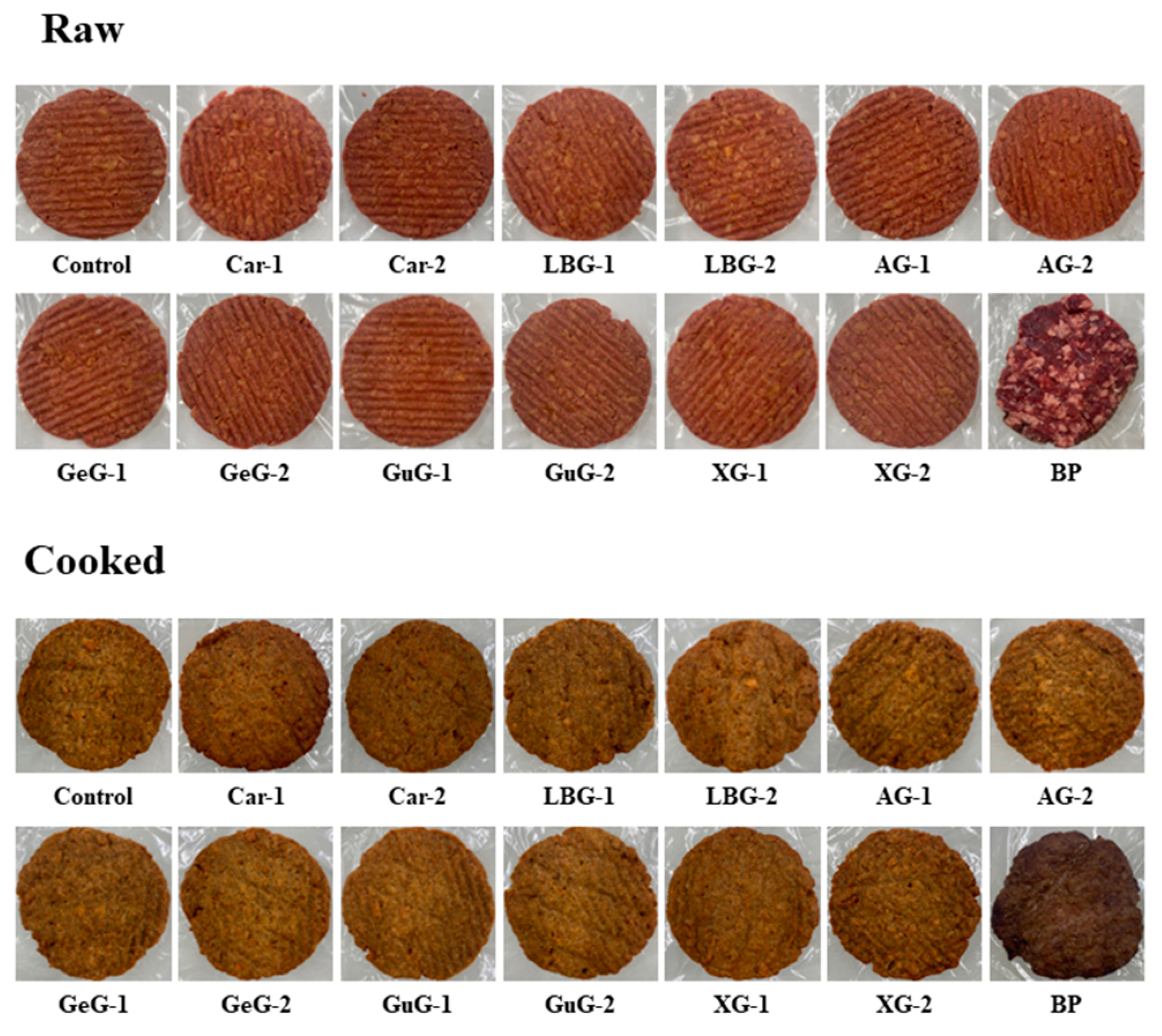

3.2. Color and pH of Plant-Based Patties

3.3. Water Holding Capacity (WHC) and Cooking Yield of Plant-Based Patties

3.4. Texture Profile Analysis of Plant-Based Patties

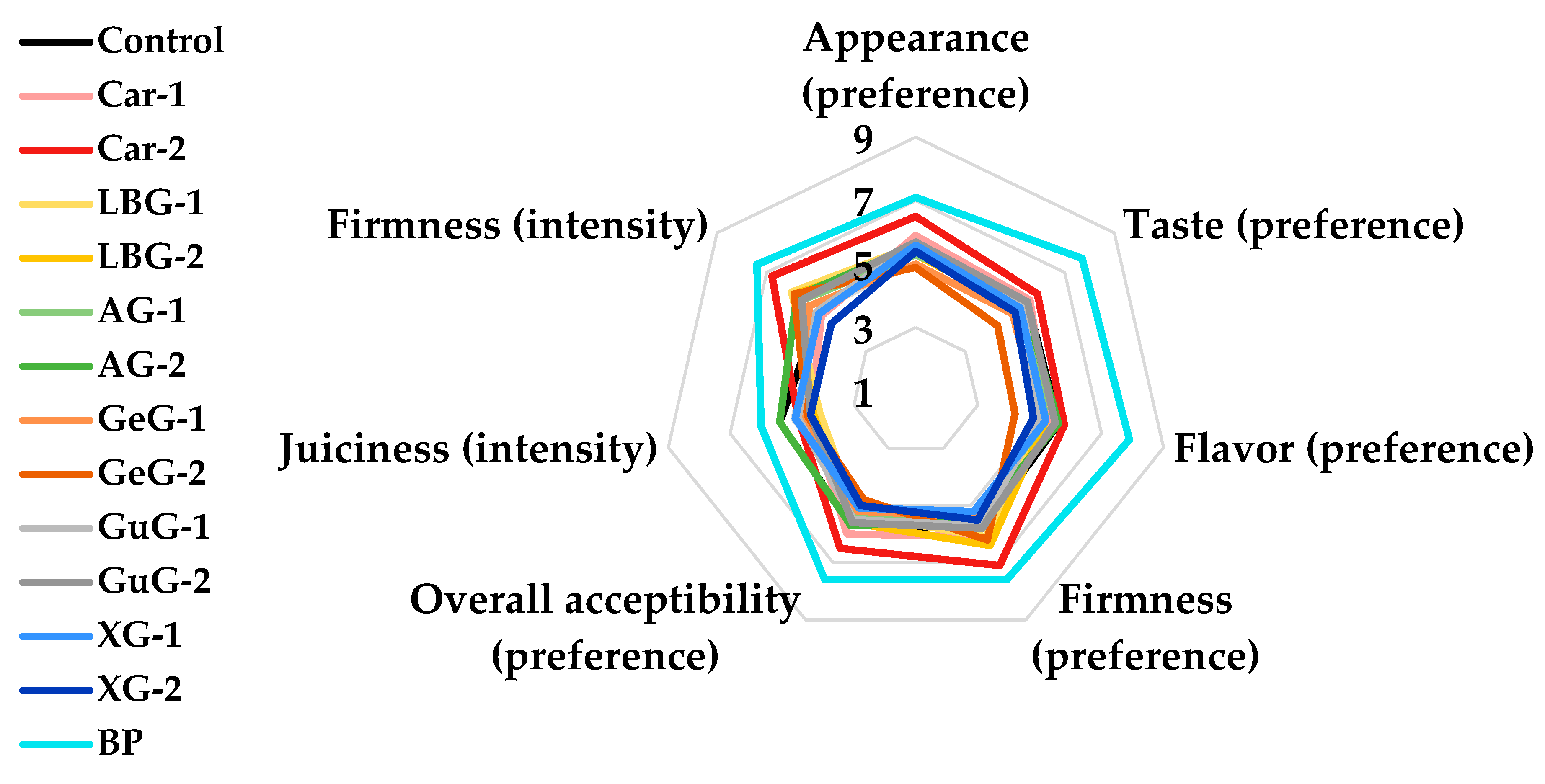

3.5. Sensory Evaluation of Plant-Based Patties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- OECD; FAO. OECD-FAO Agricultural Outlook 2021–2030; FAO: Rome, Italy, 2021; pp. 163–177. [Google Scholar]

- Whitton, C.; Bogueva, D.; Marinova, D.; Phillips, C.J. Are we approaching peak meat consumption? Analysis of meat consumption from 2000 to 2019 in 35 countries and its relationship to gross domestic product. Animals 2021, 11, 3466. [Google Scholar] [CrossRef] [PubMed]

- Fiorentini, M.; Kinchla, A.J.; Nolden, A.A. Role of sensory evaluation in consumer acceptance of plant-based meat analogs and meat extenders: A scoping review. Foods 2020, 9, 1334. [Google Scholar] [CrossRef] [PubMed]

- Giromini, C.; Givens, D.I. Benefits and risks associated with meat consumption during key life processes and in relation to the risk of chronic diseases. Foods 2022, 11, 2063. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; Yong, H.I.; Kim, M.; Choi, Y.S.; Jo, C. Status of meat alternatives and their potential role in the future meat market—A review. Australas. J. Anim. Sci. 2020, 33, 1533. [Google Scholar] [CrossRef] [PubMed]

- Nelson, M.E.; Hamm, M.W.; Hu, F.B.; Abrams, S.A.; Griffin, T.S. Alignment of healthy dietary patterns and environmental sustainability: A systematic review. Adv. Nutr. 2016, 7, 1005–1025. [Google Scholar] [CrossRef]

- Santo, R.E.; Kim, B.F.; Goldman, S.E.; Dutkiewicz, J.; Biehl, E.; Bloem, M.W.; Neff, R.A.; Nachman, K.E. Considering plant-based meat substitutes and cell-based meats: A public health and food systems perspective. Front. Sustain. Food Syst. 2020, 4, 134. [Google Scholar] [CrossRef]

- Kim, T.K.; Yong, H.I.; Cha, J.Y.; Park, S.Y.; Jung, S.; Choi, Y.S. Drying-induced restructured jerky analog developed using a combination of edible insect protein and textured vegetable protein. Food Chem. 2022, 373, 131519. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Keppler, J.K.; van der Goot, A.J. Functionality of ingredients and additives in plant-based meat analogues. Foods 2021, 10, 600. [Google Scholar] [CrossRef]

- Kim, Y.J.; Shin, D.M.; Yune, J.H.; Jung, H.S.; Kwon, H.C.; Lee, K.W.; Oh, J.W.; Kim, B.G.; Han, S.G. Development of β-cyclodextrin/konjac-based emulsion gel for a pork backfat substitute in emulsion-type sausage. Gels 2022, 8, 369. [Google Scholar] [CrossRef]

- Dawkins, N.; Gager, J.; Cornillon, J.; Kim, Y.; Howard, H.; Phelps, O. Comparative studies on the physicochemical properties and hydration behavior of oat gum and oatrim in meat-based patties. J. Food Sci. 2001, 66, 1276–1282. [Google Scholar] [CrossRef]

- Pematilleke, N.; Kaur, M.; Wai, C.T.R.; Adhikari, B.; Torley, P.J. Effect of the addition of hydrocolloids on beef texture: Targeted to the needs of people with dysphagia. Food Hydrocoll. 2021, 113, 106413. [Google Scholar] [CrossRef]

- Rather, S.A.; Masoodi, F.; Akhter, R.; Gani, A.; Wani, S.; Malik, A. Xanthan gum as a fat replacer in goshtaba-a traditional meat product of India: Effects on quality and oxidative stability. J. Food Sci. Technol. 2015, 52, 8104–8112. [Google Scholar] [CrossRef] [PubMed]

- Bakhsh, A.; Lee, S.-J.; Lee, E.-Y.; Sabikun, N.; Hwang, Y.-H.; Joo, S.-T. A novel approach for tuning the physicochemical, textural, and sensory characteristics of plant-based meat analogs with different levels of methylcellulose concentration. Foods 2021, 10, 560. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.; Mehany, T.; Xie, W.; Liu, X.; Guo, S.; Peng, X. Use of food carbohydrates towards the innovation of plant-based meat analogs. Trends Food Sci. Technol. 2022, 129, 155–163. [Google Scholar] [CrossRef]

- Sugianto, M.N. Effect of Adding Methycellulose, Kappa Carrageenan, and Xanthan Gum on the Phusical Properties of Plant-Based Nugget; Indonesia International Institute for Life Sciences: Jakarta, Indonesia, 2021. [Google Scholar]

- Majzoobi, M.; Talebanfar, S.; Eskandari, M.H.; Farahnaky, A. Improving the quality of meat-free sausages using κ-carrageenan, konjac mannan and xanthan gum. Int. J. Food Sci. Technol. 2017, 52, 1269–1275. [Google Scholar] [CrossRef]

- Samard, S.; Maung, T.T.; Gu, B.Y.; Kim, M.H.; Ryu, G.H. Influences of extrusion parameters on physicochemical properties of textured vegetable proteins and its meatless burger patty. Food Sci. Biotechnol. 2021, 30, 395–403. [Google Scholar] [CrossRef] [PubMed]

- Shin, K.O.; Hwang, H.J.; Han, K.S.; Lee, Y.J. Quality characteristics of substitute meat patties developed using Aruncus dioicus var. kamtschaticus hara. Foods 2022, 11, 1341. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Association of Official Analytical Chemists. In Official Methods of Analysis; AOAC: Rockville, MD, USA, 1990; Volume 1, pp. 69–90. [Google Scholar]

- Kim, H.; Lee, M.Y.; Lee, J.; Jo, Y.J.; Choi, M.J. Effects of glucono-δ-lactone and transglutaminase on the physicochemical and textural properties of plant-based meat patty. Foods 2022, 11, 3337. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Dekkers, B.; van der Goot, A.J. Plant-based meat analogues. In Sustainable Meat Production and Processing; Elsevier: Amsterdam, The Netherlands, 2019; pp. 103–126. [Google Scholar] [CrossRef]

- Swing, C.J.; Thompson, T.W.; Guimaraes, O.; Geornaras, I.; Engle, T.E.; Belk, K.E.; Gifford, C.L.; Nair, M.N.; Suriati, L.; Utama, I. Nutritional composition of novel plant-based meat alternatives and traditional animal-based meats. J. Food Sci. Nutr. 2021, 7, 109. [Google Scholar] [CrossRef]

- Welter, K.C.; Martins, C.M.d.M.R.; de Palma, A.S.V.; Martins, M.M.; Dos Reis, B.R.; Schmidt, B.L.U.; Saran Netto, A. Canola oil in lactating dairy cow diets reduces milk saturated fatty acids and improves its omega-3 and oleic fatty acid content. PloS ONE 2016, 11, e0151876. [Google Scholar] [CrossRef]

- Ruiz Núñez, B.; Dijck Brouwer, D.J.; Muskiet, F.A. The relation of saturated fatty acids with low-grade inflammation and cardiovascular disease. J. Nutr. Biochem. 2016, 36, 1–20. [Google Scholar] [CrossRef]

- Yusuf, K.; Saha, S.; Umar, S. Health benefits of dietary fiber for the management of inflammatory bowel disease. Biomedicines 2022, 10, 1242. [Google Scholar] [CrossRef]

- Carpenter, C.E.; Cornforth, D.P.; Whittier, D. Consumer preferences for beef color and packaging did not affect eating satisfaction. Meat Sci. 2001, 57, 359–363. [Google Scholar] [CrossRef] [PubMed]

- Hunt, M.; Sørheim, O.; Slinde, E. Color and heat denaturation of myoglobin forms in ground beef. J. Food Sci. 1999, 64, 847–851. [Google Scholar] [CrossRef]

- Chandran, J.; Nisha, P.; Singhal, R.S.; Pandit, A.B. Degradation of colour in beetroot (Beta vulgaris L.): A kinetics study. J. Food Sci. Technol. 2014, 51, 2678–2684. [Google Scholar] [CrossRef]

- Herbach, K.M.; Stintzing, F.C.; Carle, R. Stability and color changes of thermally treated betanin, phyllocactin, and hylocerenin solutions. J. Agric. Food Chem. 2006, 54, 390–398. [Google Scholar] [CrossRef] [PubMed]

- Chauhan, S.S.; LeMaster, M.N.; Clark, D.L.; Foster, M.K.; Miller, C.E.; England, E.M. Glycolysis and pH decline terminate prematurely in oxidative muscles despite the presence of excess glycogen. Meat Muscle Biol. 2019, 3. [Google Scholar] [CrossRef]

- Page, J.; Wulf, D.; Schwotzer, T. A survey of beef muscle color and pH. J. Anim. Sci. 2001, 79, 678–687. [Google Scholar] [CrossRef]

- King, N.J.; Whyte, R. Does it look cooked? A review of factors that influence cooked meat color. J. Food Sci. 2006, 71, R31–R40. [Google Scholar] [CrossRef]

- Ebert, S.; Baune, M.-C.; Broucke, K.; Van Royen, G.; Terjung, N.; Gibis, M.; Weiss, J. Buffering capacity of wet texturized plant proteins in comparison to pork meat. Food Res. Int. 2021, 150, 110803. [Google Scholar] [CrossRef]

- He, J.; Evans, N.M.; Liu, H.; Shao, S. A review of research on plant-based meat alternatives: Driving forces, history, manufacturing, and consumer attitudes. Compr. Rev. Food Sci. Food Saf. 2020, 19, 2639–2656. [Google Scholar] [CrossRef]

- Lee, J.S.; Oh, H.; Choi, I.; Yoon, C.S.; Han, J. Physico-chemical characteristics of rice protein-based novel textured vegetable proteins as meat analogues produced by low-moisture extrusion cooking technology. LWT 2022, 157, 113056. [Google Scholar] [CrossRef]

- Sha, L.; Xiong, Y.L. Plant protein-based alternatives of reconstructed meat: Science, technology, and challenges. Trends Food Sci. Technol. 2020, 102, 51–61. [Google Scholar] [CrossRef]

- Beniwal, A.S.; Singh, J.; Kaur, L.; Hardacre, A.; Singh, H. Meat analogs: Protein restructuring during thermomechanical processing. Compr. Rev. Food Sci. Food Saf. 2021, 20, 1221–1249. [Google Scholar] [CrossRef]

- Ko, H.J.; Wen, Y.; Choi, J.H.; Park, B.R.; Kim, H.W.; Park, H.J. Meat analog production through artificial muscle fiber insertion using coaxial nozzle-assisted three-dimensional food printing. Food Hydrocoll. 2021, 120, 106898. [Google Scholar] [CrossRef]

- Takigami, S. Konjac mannan. In Handbook of Hydrocolloids; Elsevier: Amsterdam, The Netherlands, 2009; pp. 889–901. [Google Scholar]

- Ayadi, M.; Kechaou, A.; Makni, I.; Attia, H. Influence of carrageenan addition on turkey meat sausages properties. J. Food Eng. 2009, 93, 278–283. [Google Scholar] [CrossRef]

- Nanta, P.; Skolpap, W.; Kasemwong, K. Influence of hydrocolloids on the rheological and textural attributes of a gluten-free meat analog based on soy protein isolate. J. Food Process Preserv. 2021, 45, e15244. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, L.; Tu, Y.; Wu, N.; Jiang, Y.; Xu, M. Changes in texture and molecular forces of heated-induced egg white gel with adding xanthan gum. J. Food Process Eng. 2019, 42, e13071. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, S.; Wang, X.; Dong, S.; Zhao, Y.; Zeng, M. The relationship between the formation of advanced glycation end products and quality attributes of fried sturgeon fillets. LWT 2022, 159, 113161. [Google Scholar] [CrossRef]

- Sanjeewa, W.T.; Wanasundara, J.P.; Pietrasik, Z.; Shand, P.J. Characterization of chickpea (Cicer arietinum L.) flours and application in low-fat pork bologna as a model system. Food Res. Int. 2010, 43, 617–626. [Google Scholar] [CrossRef]

- Han, C.; Wang, G.; Guo, J.; Wang, J.; Yang, X. Oral oil release improves lubrication and sensory properties of meat analogs with protein-stabilized oleogel. Food Hydrocoll. 2023, 142, 108788. [Google Scholar] [CrossRef]

- Du, M.; Lu, W.; Zhang, Y.; Mata, A.; Fang, Y. Natural polymer-sourced interpenetrating network hydrogels: Fabrication, properties, mechanism and food applications. Trends Food Sci. Technol. 2021, 116, 342–356. [Google Scholar] [CrossRef]

| Ingredients (%)/Patty Groups | Control | Car-1 | Car-2 | LBG-1 | LBG-2 | AG-1 | AG-2 | GeG-1 | GeG-2 | GuG-1 | GuG-2 | XG-1 | XG-2 | BP |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Textured pea protein | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 0 |

| Water | 56.0725 | 55.0725 | 54.0725 | 55.0725 | 54.0725 | 55.0725 | 54.0725 | 55.0725 | 54.0725 | 55.0725 | 54.0725 | 55.0725 | 54.0725 | 0 |

| Methylcellulose | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 0 |

| Konjac glucomannan | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0 |

| κ-Carrageenan | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Locust bean gum | 0 | 0 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Arabic gum | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Gellan gum | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 0 |

| Guar gum | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 0 | 0 | 0 |

| Xanthan gum | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 0 |

| Salt | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 0 |

| Beet powder | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0 |

| Ginger powder | 0.3275 | 0.3275 | 0.3275 | 0.3275 | 0.3275 | 0.3275 | 0.3275 | 0.3275 | 0.3275 | 0.3275 | 0.3275 | 0.3275 | 0.3275 | 0 |

| Isolated pea protein | 4.75 | 4.75 | 4.75 | 4.75 | 4.75 | 4.75 | 4.75 | 4.75 | 4.75 | 4.75 | 4.75 | 4.75 | 4.75 | 0 |

| Garlic powder | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 |

| Yeast extract | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 |

| Black pepper | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0 |

| Canola oil | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 0 |

| Coconut oil | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 0 |

| Lean beef | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 80 |

| Beef back fat | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 20 |

| Total | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Parameters | Plant-Based Patty Groups | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | Car-1 | Car-2 | LBG-1 | LBG-2 | AG-1 | AG-2 | GeG-1 | GeG-2 | GuG-1 | GuG-2 | XG-1 | XG-2 | |

| Moisture (%) | 56.37 ± 0.31 a | 55.68 ± 0.15 cd | 54.41 ± 0.05 f | 55.85 ± 0.12 bc | 54.72 ± 0.21 e | 56.10 ± 0.17 ab | 54.72 ± 0.17 e | 55.69 ± 0.28 cd | 54.84 ± 0.21 e | 55.78 ± 0.09 bc | 54.98 ± 0.19 e | 55.39 ± 0.05 d | 54.39 ± 0.11 f |

| Protein (%) | 18.08 ± 0.18 d | 18.53 ± 0.05 bc | 18.29 ± 0.19 cd | 18.67 ± 0.02 b | 18.16 ± 0.06 d | 18.69 ± 0.17 b | 18.36 ± 0.18 cd | 18.17 ± 0.09 d | 19.62 ± 0.05 a | 18.59 ± 0.19 bc | 18.59 ± 0.25 bc | 18.33 ± 0.11 cd | 18.36 ± 0.27 cd |

| Fat (%) | 10.20 ± 0.23 a | 9.38 ± 0.06 c | 9.72 ± 0.08 b | 9.79 ± 0.14 b | 9.59 ± 0.06 bc | 9.35 ± 0.12 c | 8.95 ± 0.08 d | 9.67 ± 0.14 b | 9.76 ± 0.10 b | 10.24 ± 0.29 a | 9.58 ± 0.13 bc | 9.76 ± 0.18 b | 9.72 ± 0.11 b |

| Ash (%) | 2.19 ± 0.06 ef | 2.31 ± 0.07 bc | 2.45 ± 0.04 a | 2.21 ± 0.03 def | 2.27 ± 0.01 cde | 2.25 ± 0.03 cdef | 2.25 ± 0.02 cdef | 2.37 ± 0.06 b | 2.47 ± 0.06 a | 2.19 ± 0.01 ef | 2.18 ± 0.03 f | 2.29 ± 0.06 cd | 2.30 ± 0.05 bc |

| Total Carbohydrates (%) | 13.16 ± 0.34 g | 14.10 ± 0.24 ef | 15.13 ± 0.21 bc | 13.48 ± 0.10 g | 15.27 ± 0.14 ab | 13.61 ± 0.16 fg | 15.71 ± 0.30 a | 14.10 ± 0.20 ef | 13.31 ± 0.29 g | 13.19 ± 0.39 g | 14.68 ± 0.52 cd | 14.23 ± 0.21 de | 15.24 ± 0.28 ab |

| Parameters | Plant-Based Patty Groups | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | Car-1 | Car-2 | LBG-1 | LBG-2 | AG-1 | AG-2 | GeG-1 | GeG-2 | GuG-1 | GuG-2 | XG-1 | XG-2 | BP | ||

| Raw | L* | 51.22 ± 0.17 ab | 50.92 ± 0.66 ab | 50.96 ± 0.67 ab | 51.02 ± 0.53 ab | 51.00 ± 0.65 ab | 50.64 ± 0.35 b | 50.66 ± 0.36 b | 50.95 ± 0.64 ab | 51.13 ± 0.49 ab | 50.64 ± 0.23 b | 50.68 ± 0.65 b | 51.57 ± 0.40 a | 51.52 ± 0.57 a | 51.01 ± 0.58 ab |

| a* | 16.30 ± 0.19 gh | 17.50 ± 0.41 d | 17.59 ± 0.17 cd | 16.80 ± 0.38 ef | 16.94 ± 0.42 e | 17.92 ± 0.27 bc | 18.08 ± 0.37 b | 16.22 ± 0.27 h | 16.46 ± 0.28 fgh | 16.20 ± 0.17 h | 16.26 ± 0.24 gh | 16.66 ± 0.38 efg | 17.02 ± 0.34 e | 19.04 ± 0.70 a | |

| b* | 13.02 ± 0.14 de | 13.90 ± 0.23 ab | 13.95 ± 0.12 ab | 13.24 ± 0.15 cd | 13.38 ± 0.21 c | 13.73 ± 0.21 b | 14.11 ± 0.16 a | 13.21 ± 0.09 cd | 13.28 ± 0.48 cd | 13.25 ± 0.12 cd | 13.16 ± 0.31 cd | 12.74 ± 0.25 e | 12.72 ± 0.22 e | 13.85 ± 0.57 ab | |

| pH | 6.49 ± 0.03 cd | 6.51 ± 0.01 bc | 6.52 ± 0.04 bc | 6.50 ± 0.02 bcd | 6.54 ± 0.01 ab | 6.49 ± 0.02 cd | 6.42 ± 0.01 f | 6.50 ± 0.02 bcd | 6.46 ± 0.00 de | 6.51 ± 0.01 bc | 6.56 ± 0.01 a | 6.43 ± 0.01 ef | 6.38 ± 0.05 g | 5.52 ± 0.05 h | |

| Cooked | L* | 47.60 ± 1.31 a | 44.73 ± 0.58 cd | 44.05 ± 0.94 d | 45.68 ± 0.95 bc | 45.41 ± 0.94 c | 45.33 ± 0.58 c | 45.22 ± 0.48 c | 46.68 ± 0.91 ab | 46.59 ± 0.94 ab | 45.78 ± 1.06 bc | 45.50 ± 0.72 c | 46.96 ± 0.45 ab | 46.97 ± 1.37 ab | 41.11 ± 1.26 e |

| a* | 7.23 ± 0.29 a | 7.22 ± 0.49 a | 7.30 ± 0.52 a | 7.27 ± 0.37 a | 7.29 ± 0.29 a | 7.23 ± 0.19 a | 7.28 ± 0.29 a | 7.11 ± 0.35 a | 7.35 ± 0.17 a | 7.20 ± 0.27 a | 7.19 ± 0.13 a | 7.23 ± 0.35 a | 7.35 ± 0.41 a | 5.50 ± 0.30 b | |

| b* | 17.48 ± 0.54 a | 17.37 ± 0.35 a | 17.61 ± 0.61 a | 17.36 ± 0.93 a | 17.39 ± 0.34 a | 17.47 ± 0.23 a | 17.34 ± 0.75 a | 17.16 ± 0.72 a | 17.61 ± 0.28 a | 17.47 ± 0.66 a | 17.58 ± 0.30 a | 17.58 ± 0.73 a | 17.57 ± 1.21 a | 5.80 ± 0.61 b | |

| pH | 6.36 ± 0.01 ab | 6.35 ± 0.01 ab | 6.30 ± 0.00 d | 6.37 ± 0.01 a | 6.37 ± 0.01 a | 6.35 ± 0.02 ab | 6.29 ± 0.02 d | 6.36 ± 0.01 ab | 6.37 ± 0.04 a | 6.33 ± 0.01 bc | 6.37 ± 0.01 a | 6.31 ± 0.00 cd | 6.25 ± 0.01 e | 5.71 ± 0.01 f | |

| Parameters | Plant-Based Patty Groups | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | Car-1 | Car-2 | LBG-1 | LBG-2 | AG-1 | AG-2 | GeG-1 | GeG-2 | GuG-1 | GuG-2 | XG-1 | XG-2 | BP | |

| Hardness (N) | 8.88 ± 0.78 e | 11.37 ± 0.97 bc | 14.90 ± 1.12 a | 9.29 ± 0.97 de | 12.33 ± 1.34 b | 6.67 ± 0.85 fg | 6.06 ± 0.55 g | 8.82 ± 0.75 e | 10.56 ± 1.18 cd | 9.03 ± 0.94 e | 9.36 ± 1.28 de | 7.44 ± 1.53 f | 7.12 ± 0.89 fg | 15.28 ± 1.94 a |

| Springiness | 0.48 ± 0.02 f | 0.57 ± 0.01 c | 0.67 ± 0.01 b | 0.50 ± 0.01 e | 0.55 ± 0.03 d | 0.46 ± 0.03 g | 0.45 ± 0.03 g | 0.49 ± 0.01 ef | 0.54 ± 0.01 d | 0.39 ± 0.01 h | 0.39 ± 0.01 h | 0.44 ± 0.01 g | 0.39 ± 0.01 h | 0.82 ± 0.03 a |

| Cohesiveness | 0.38 ± 0.01 de | 0.39 ± 0.01 c | 0.44 ± 0.01 b | 0.40 ± 0.02 c | 0.43 ± 0.01 b | 0.37 ± 0.02 e | 0.36 ± 0.02 e | 0.38 ± 0.02 de | 0.39 ± 0.02 cd | 0.32 ± 0.01 f | 0.32 ± 0.01 f | 0.37 ± 0.01 e | 0.36 ± 0.02 e | 0.69 ± 0.02 a |

| Chewiness (N) | 1.46 ± 0.23 ef | 2.37 ± 0.16 d | 3.92 ± 0.32 b | 1.69 ± 0.08 e | 2.78 ± 0.23 c | 1.08 ± 0.18 g | 0.97 ± 0.27 g | 1.48 ± 0.14 ef | 2.19 ± 0.16 d | 1.23 ± 0.16 fg | 1.27 ± 0.19 fg | 1.33 ± 0.25 efg | 1.02 ± 0.11 g | 7.10 ± 0.91 a |

| Gumminess (N) | 3.43 ± 0.30 efg | 4.40 ± 0.22 d | 6.27 ± 0.59 b | 3.72 ± 0.38 ef | 5.74 ± 0.60 c | 2.38 ± 0.28 h | 2.20 ± 0.42 h | 3.35 ± 0.41 fg | 3.87 ± 0.39 e | 3.08 ± 0.35 g | 3.10 ± 0.26 g | 2.42 ± 0.43 h | 2.34 ± 0.31 h | 9.81 ± 0.79 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, J.-H.; Keum, D.-H.; Hong, S.-J.; Kim, Y.-J.; Han, S.-G. Comparative Evaluation of Polysaccharide Binders on the Quality Characteristics of Plant-Based Patties. Foods 2023, 12, 3731. https://doi.org/10.3390/foods12203731

Han J-H, Keum D-H, Hong S-J, Kim Y-J, Han S-G. Comparative Evaluation of Polysaccharide Binders on the Quality Characteristics of Plant-Based Patties. Foods. 2023; 12(20):3731. https://doi.org/10.3390/foods12203731

Chicago/Turabian StyleHan, Jong-Hyeon, Dong-Hyun Keum, Seong-Joon Hong, Yea-Ji Kim, and Sung-Gu Han. 2023. "Comparative Evaluation of Polysaccharide Binders on the Quality Characteristics of Plant-Based Patties" Foods 12, no. 20: 3731. https://doi.org/10.3390/foods12203731

APA StyleHan, J.-H., Keum, D.-H., Hong, S.-J., Kim, Y.-J., & Han, S.-G. (2023). Comparative Evaluation of Polysaccharide Binders on the Quality Characteristics of Plant-Based Patties. Foods, 12(20), 3731. https://doi.org/10.3390/foods12203731