The Impact of the Individual and Combined Application of Phosphorus and Sulfur Fertilizers on Potato Tuber Flavor

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Cultivation and Sample Collection

2.2. Sensory Evaluation of Materials

2.3. Volatile Flavor Compound Detection

2.4. Fatty Acid, Free Amino Acid, Total Reducing Sugar and Starch Detection

2.5. Statistical Analysis

3. Results and Discussion

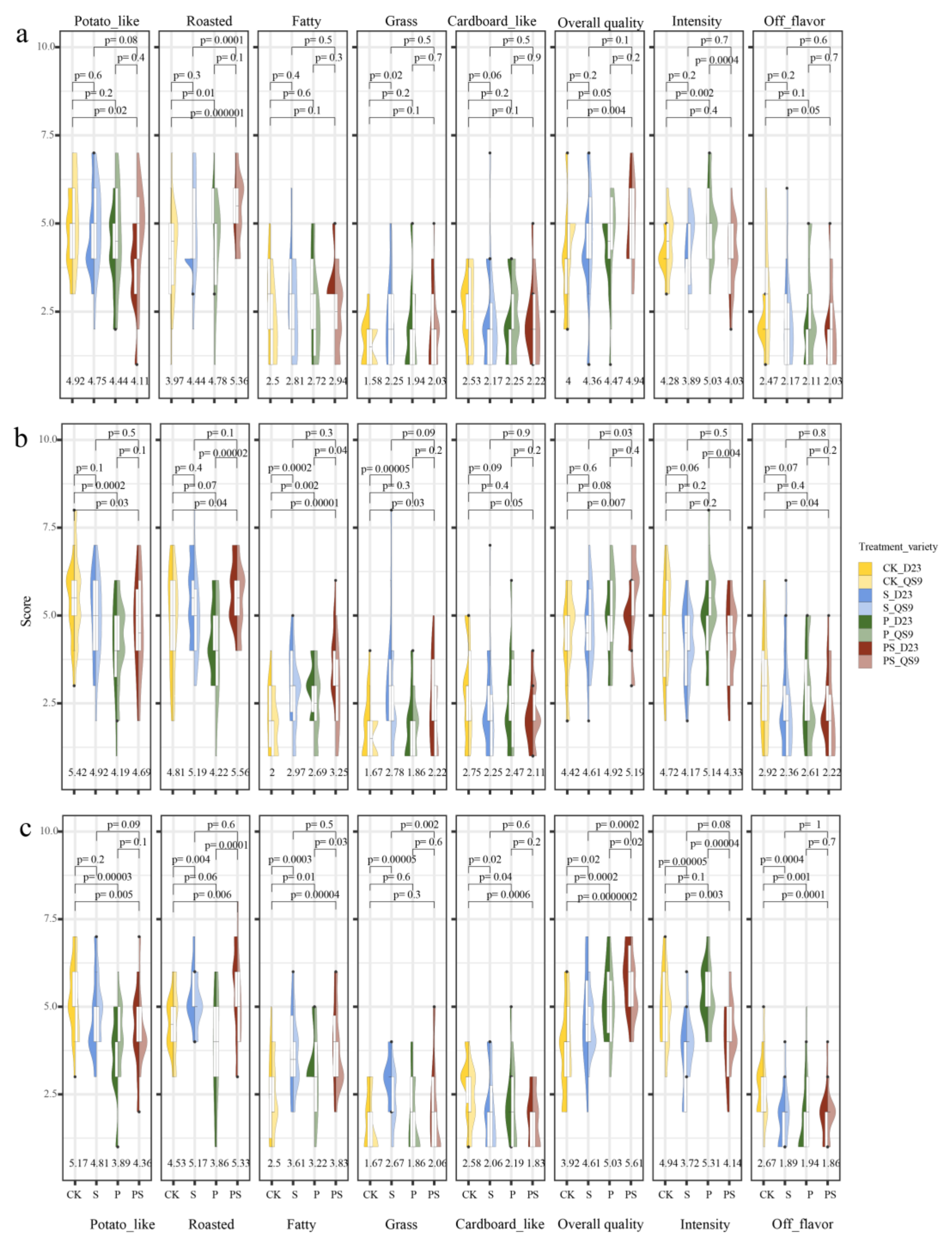

3.1. Changes in Tuber Sensory Attributes Due to Fertilizer Application

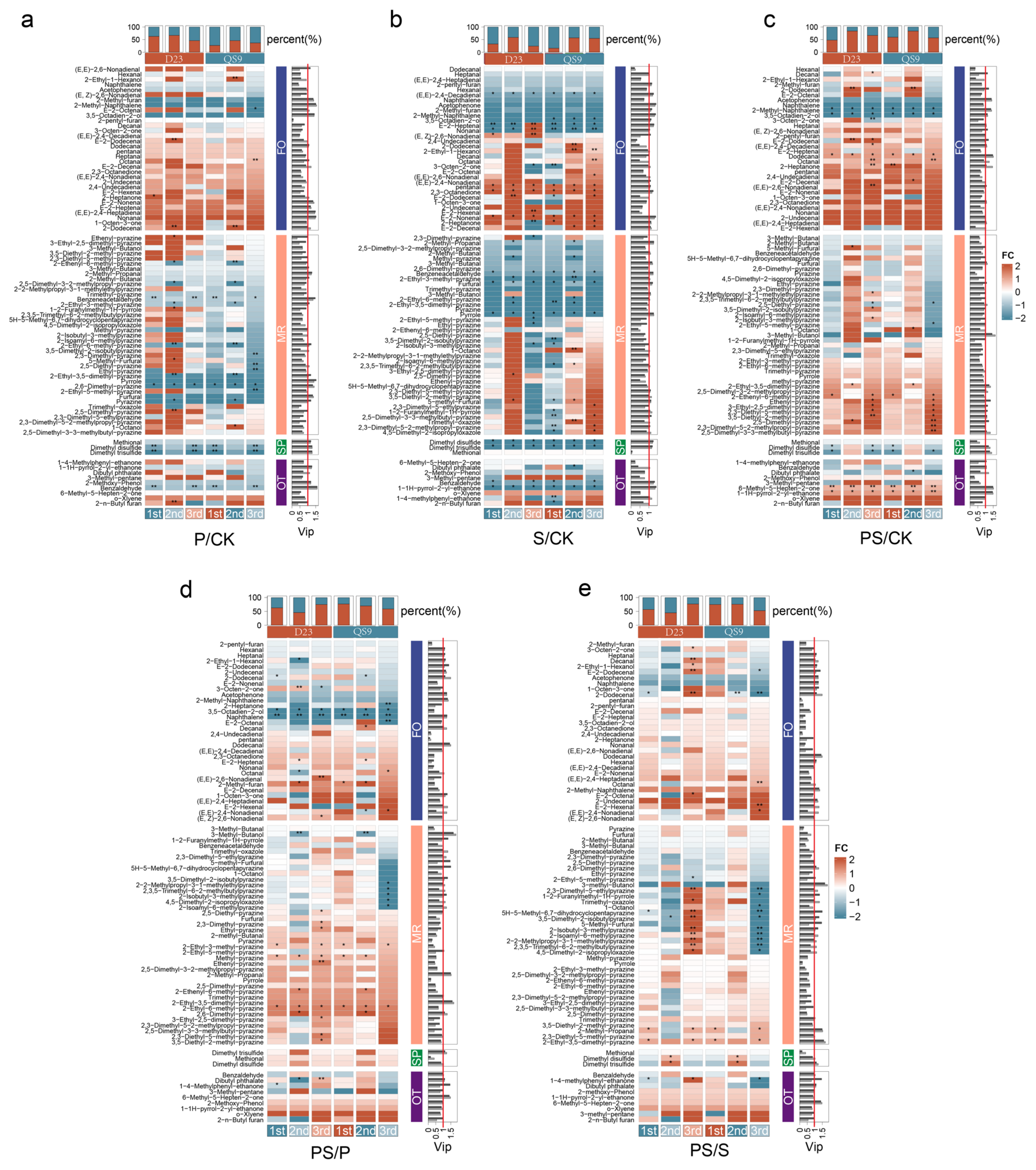

3.2. Comparison of Volatile Compounds among Different Fertilizer Treatments

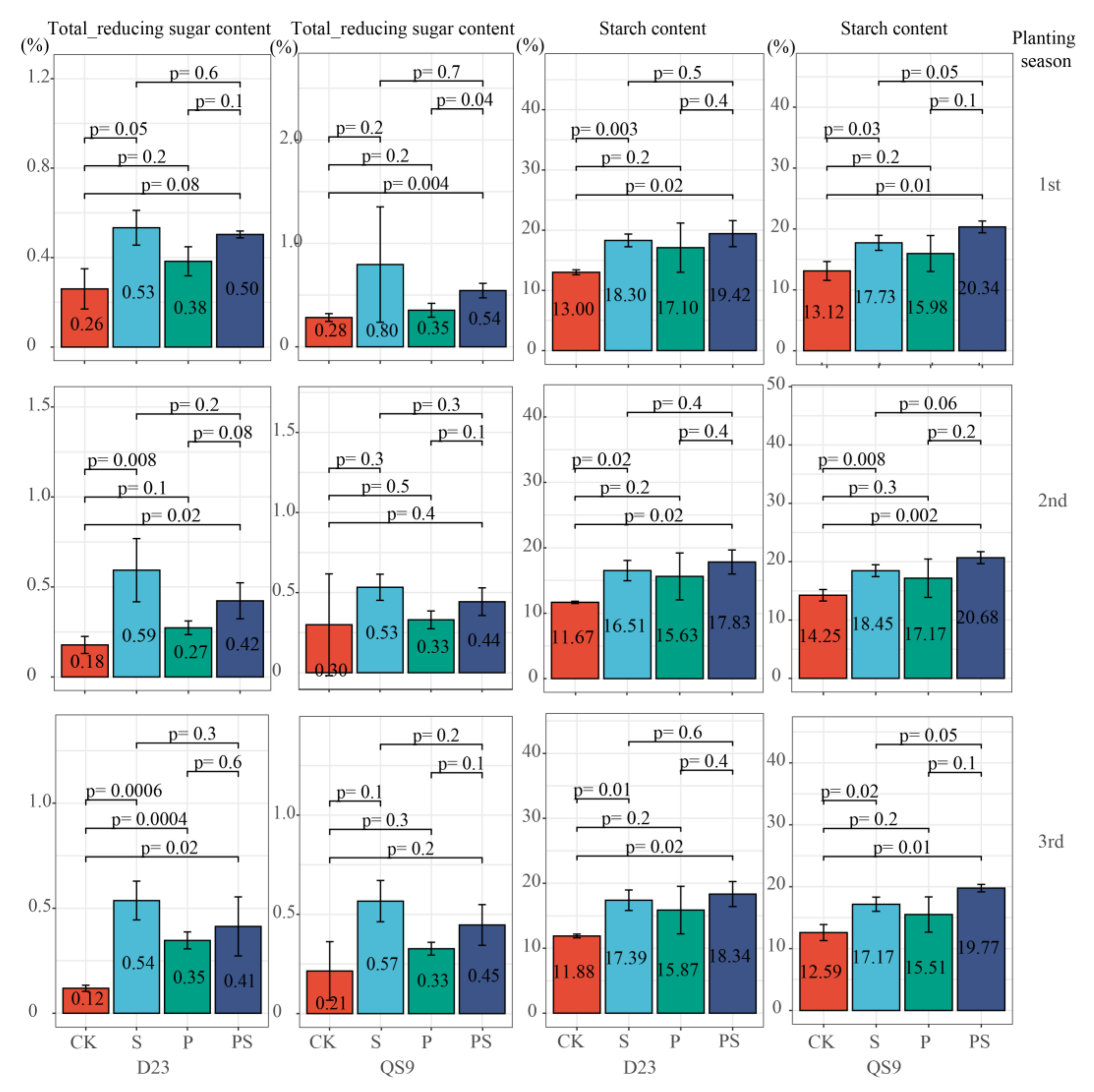

3.3. The Influence of Different Fertilization Treatments on the Content of Carbohydrates, Amino Acids, and Fatty Acids

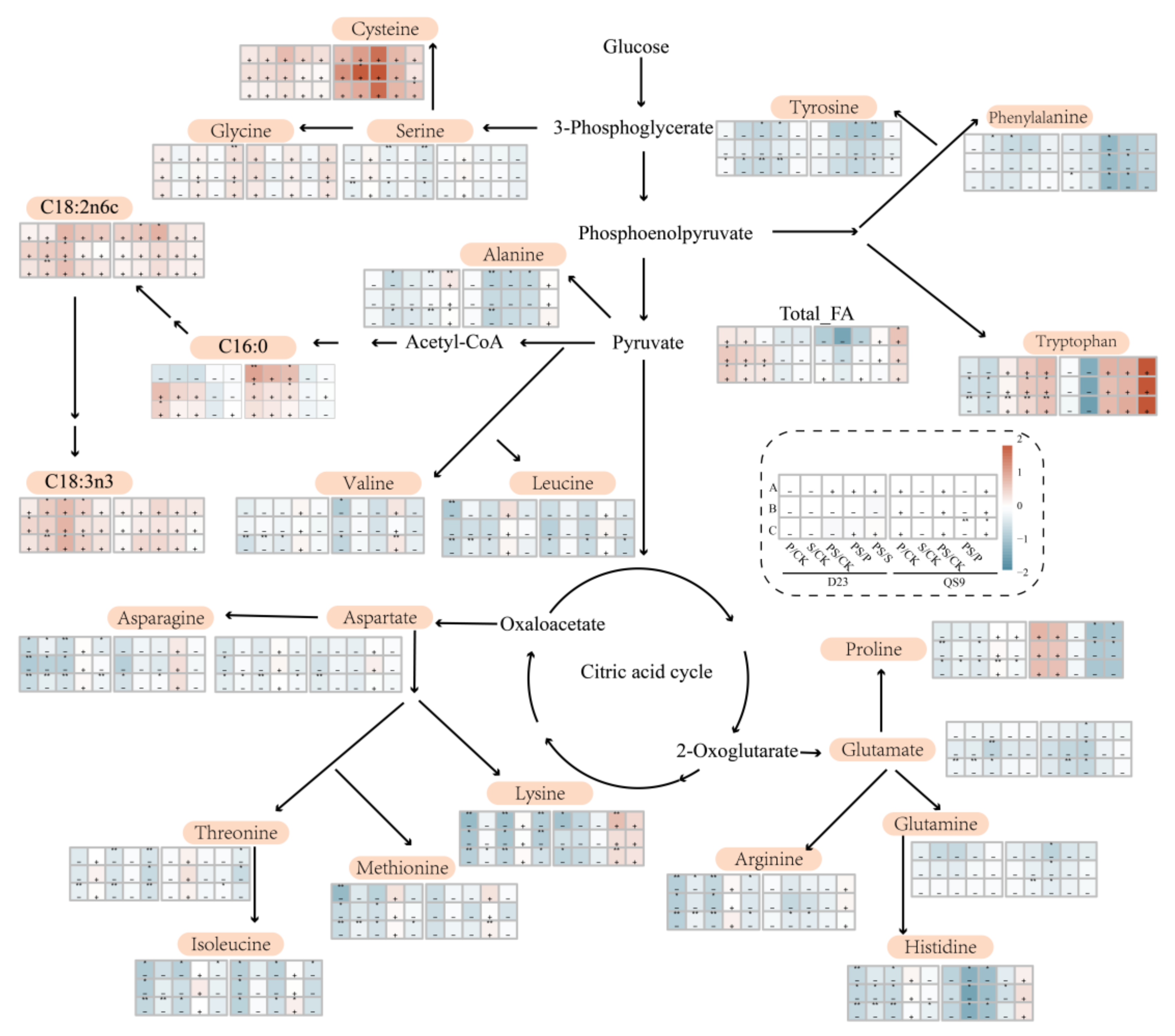

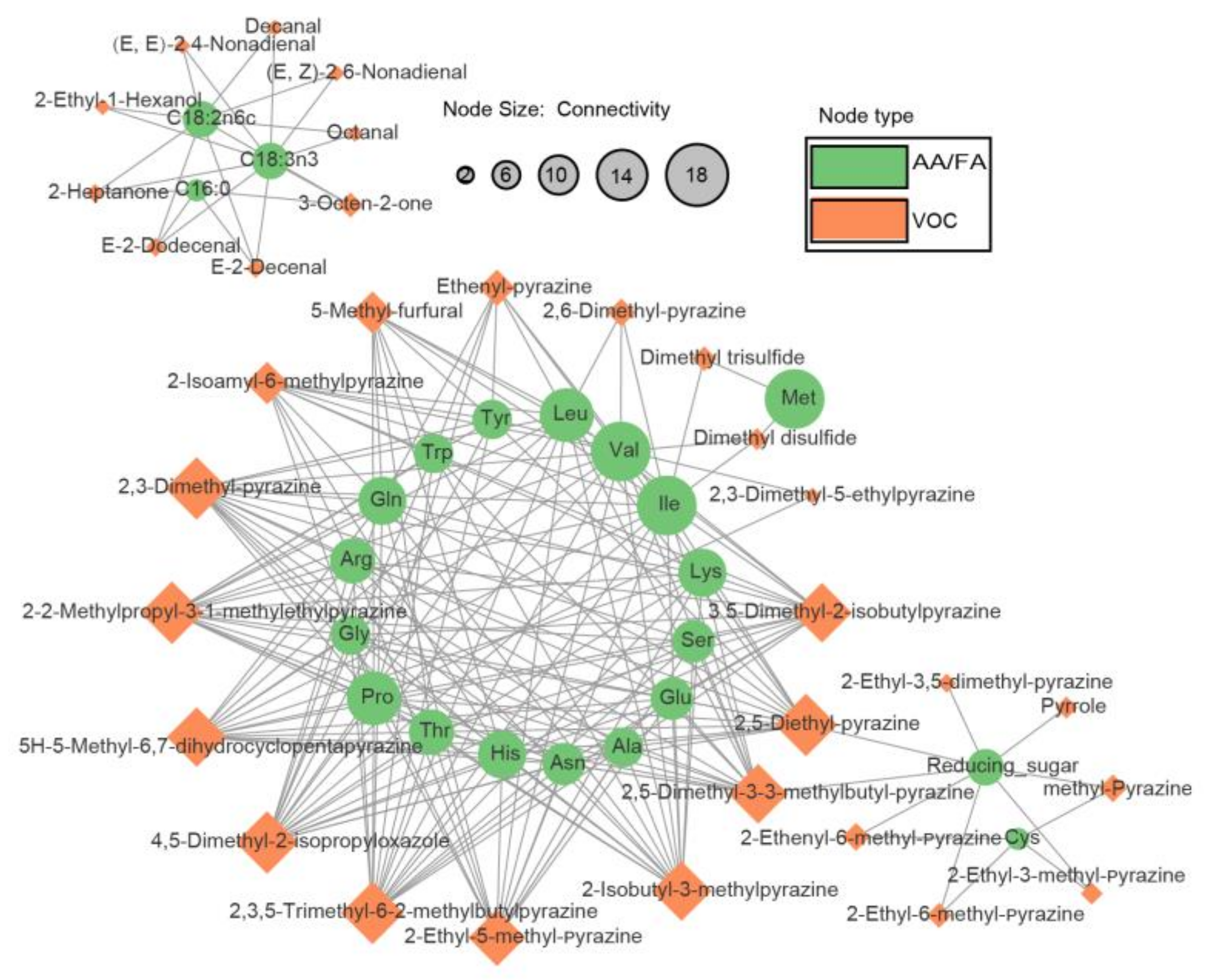

3.4. Fertilization Treatments as Key Factors Affecting the Amino Acid and Fatty Acid Contents Influencing the Composition of Volatile Compounds

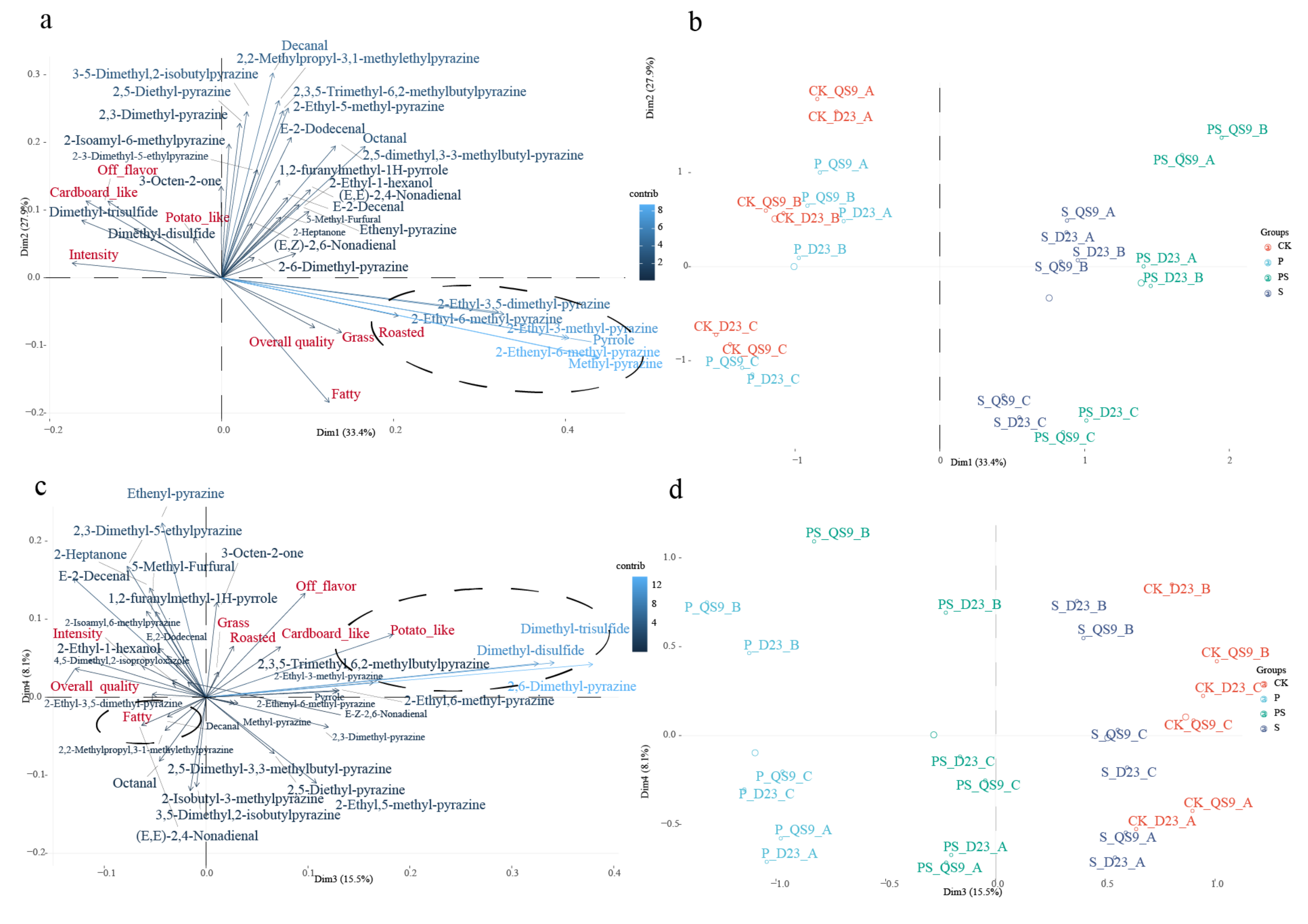

3.5. Fertilizer Application Induces Flavor Compound Alterations and Affects Tuber Flavor Evaluation

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- FAO. Tracking Progress on Food and Agriculture-Related SDG Indicators 2023. Available online: https://www.fao.org/documents/card/en/c/cc7088en (accessed on 2 October 2023).

- Zheng, C.; Jincan, Y. A Realistic Analysis of the Challenges and Opportunities of Providing the Food Security in Central Asia from the Perspective of Russia-Ukraine Conflict. Izv. Ural. Fed. U-Guman 2023, 13, 42–55. [Google Scholar] [CrossRef]

- Wang, X.; Xu, M.; Lin, B.; Bodirsky, B.L.; Xuan, J.; Dietrich, J.P.; Stevanović, M.; Bai, Z.; Ma, L.; Jin, S.; et al. Reforming China’s Fertilizer Policies: Implications for Nitrogen Pollution Reduction and Food Security. Sustain. Sci. 2022, 18, 407–420. [Google Scholar] [CrossRef]

- Peltonen-Sainio, P.; Jauhiainen, L.; Hyövelä, M.; Nissilä, E. Trade-off between Oil and Protein in Rapeseed at High Latitudes: Means to Consolidate Protein Crop Status? Field Crop. Res. 2011, 121, 248–255. [Google Scholar] [CrossRef]

- Rosen, C.J.; Bierman, P.M. Potato Yield and Tuber Set as Affected by Phosphorus Fertilization. Am. J. Potato Res. 2008, 85, 110–120. [Google Scholar] [CrossRef]

- Koch, M.; Naumann, M.; Pawelzik, E.; Gransee, A.; Thiel, H. The Importance of Nutrient Management for Potato Production Part I: Plant Nutrition and Yield. Potato Res. 2019, 63, 97–119. [Google Scholar] [CrossRef]

- Xing, Y.; Zhang, T.; Jiang, W.; Li, P.; Shi, P.; Xu, G.; Cheng, S.; Cheng, Y.; Fan, Z.; Wang, X. Effects of Irrigation and Fertilization on Different Potato Varieties Growth, Yield and Resources Use Efficiency in the Northwest China. Agric. Water Manag. 2022, 261, 107351. [Google Scholar] [CrossRef]

- Bhattarai, B.; Swarnima, K.C. Effect of Potassium on Quality and Yield of Potato Tubers—A Review. Int. J. Agric. Environ. Sci. 2016, 3, 7–12. [Google Scholar] [CrossRef]

- Gerendás, J.; Heuser, F.; Sattelmacher, B. Influence of Nitrogen and Potassium Supply on Contents of Acrylamide Precursors in Potato Tubers and on Acrylamide Accumulation in French Fries. J. Plant Nutr. 2007, 30, 1499–1516. [Google Scholar] [CrossRef]

- Sarkar, S.; Banerjee, H.; Chakraborty, I.; Sau, S.; Ray, K.; Ghosh, D.; Deb, P. Assessment of Growth, Yield, Tuber Quality and Profitability of Potato upon Boron Fertilization. J. Environ. Biol. 2018, 39, 365–372. [Google Scholar] [CrossRef]

- Bélanger, G.; Walsh, J.R.; Richards, J.E.; Milburn, P.H.; Ziadi, N. Nitrogen Fertilization and Irrigation Affects Tuber Characteristics of Two Potato Cultivars. Am. J. Potato Res. 2002, 79, 269–279. [Google Scholar] [CrossRef]

- Muttucumaru, N.; Powers, S.J.; Elmore, J.S.; Mottram, D.S.; Halford, N.G. Effects of Nitrogen and Sulfur Fertilization on Free Amino Acids, Sugars, and Acrylamide-Forming Potential in Potato. J. Agric. Food Chem. 2013, 61, 6734–6742. [Google Scholar] [CrossRef] [PubMed]

- Sharma, C.; Jayanty, S.S.; Chambers, E.; Talavera, M. Segmentation of Potato Consumers Based on Sensory and Attitudinal Aspects. Foods 2020, 9, 161. [Google Scholar] [CrossRef] [PubMed]

- Morris, W.L.; Taylor, M.A. Improving Flavor to Increase Consumption. Am. J. Potato Res. 2019, 96, 195–200. [Google Scholar] [CrossRef]

- Carneiro, R.C.V.; Duncan, S.E.; O’Keefe, S.F.; Yin, Y.; Neill, C.L.; Zhang, B. Sensory and Consumer Studies in Plant Breeding: A Guidance for Edamame Development in the U.S. Front. Sustain. Food Syst. 2020, 4, 124. [Google Scholar] [CrossRef]

- Jansky, S.H. Potato Flavor. Am. J. Potato Res. 2010, 87, 209–217. [Google Scholar] [CrossRef]

- van Loon, W.A.; Linssen, J.P.; Legger, A.; Posthumus, M.A.; Voragen, A.G. Identification and Olfactometry of French Fries Flavour Extracted at Mouth Conditions. Food Chem. 2005, 90, 417–425. [Google Scholar] [CrossRef]

- Oruna-Concha, M.J.; Bakker, J.; Ames, J.M. Comparison of the Volatile Components of Two Cultivars of Potato Cooked by Boiling, Conventional Baking and Microwave Baking. J. Sci. Food Agric. 2002, 82, 1080–1087. [Google Scholar] [CrossRef]

- Wilson, W.; MacKinnon, I.; Jarvis, M. Transfer of Heat and Moisture during Microwave Baking of Potatoes. J. Sci. Food Agric. 2002, 82, 1070–1073. [Google Scholar] [CrossRef]

- Teruel, M.D.R.; Gordon, M.; Linares, M.B.; Garrido, M.D.; Ahromrit, A.; Niranjan, K. A Comparative Study of the Characteristics of French Fries Produced by Deep Fat Frying and Air Frying. J. Food Sci. 2015, 80, E349–E358. [Google Scholar] [CrossRef]

- Di, R.; Kim, J.; Martin, M.N.; Leustek, T.; Jhoo, J.; Ho, C.-T.; Tumer, N.E. Enhancement of the Primary Flavor Compound Methional in Potato by Increasing the Level of Soluble Methionine. J. Agric. Food Chem. 2003, 51, 5695–5702. [Google Scholar] [CrossRef]

- Bough, R.A.; Holm, D.G.; Jayanty, S.S. Evaluation of Cooked Flavor for Fifteen Potato Genotypes and the Correlation of Sensory Analysis to Instrumental Methods. Am. J. Potato Res. 2019, 97, 63–77. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, M.; Liang, S. Effect of Overcooking on Flavor Compounds of Potato. Food Sci. 2017, 38, 200–204. [Google Scholar]

- Wagner, R.K.; Grosch, W. Key Odorants of French Fries. J. Am. Oil Chem. Soc. 1998, 75, 1385–1392. [Google Scholar] [CrossRef]

- Gu, X.; Yu, S.; Wu, Q.; Gong, S.; Wang, Z.; Wu, J.; Wang, S. A Case Study of a Typical Potato Flavoring Based on Aroma Characteristic of Purple Potato. Food Sci. Technol. Res. 2020, 26, 69–78. [Google Scholar] [CrossRef]

- Xu, L.; Wu, G.; Huang, J.; Zhang, H.; Jin, Q.; Wang, X. Sensory-Directed Flavor Analysis of Key Odorants Compounds Development of French Fries and Oils in the Break-in, Optimum and Degrading Frying Stage. Food Sci. Hum. Well 2023, 12, 140–150. [Google Scholar] [CrossRef]

- Morris, W.L.; Shepherd, T.; Verrall, S.R.; McNicol, J.W.; Taylor, M.A. Relationships between Volatile and Non-Volatile Metabolites and Attributes of Processed Potato Flavour. Phytochemistry 2010, 71, 1765–1773. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Wang, X.; Liao, W.; Xu, D.; Liu, G. Study on Nutritional Quality and Volatile Aroma Compounds of the Stir-Fried Shredded Potatoes. Am. J. Potato Res. 2022, 99, 191–205. [Google Scholar] [CrossRef]

- Coleman, E.C.; Ho, C.-T. Chemistry of Baked Potato Flavor. 1. Pyrazines and Thiazoles Indentified in the Volatile Flavor of Baked Potato. J. Agric. Food Chem. 1980, 28, 66–68. [Google Scholar] [CrossRef]

- Duckham, S.C.; Dodson, A.T.; Bakker, J.; Ames, J.M. Effect of Cultivar and Storage Time on the Volatile Flavor Components of Baked Potato. J. Agric. Food Chem. 2002, 50, 5640–5648. [Google Scholar] [CrossRef]

- Jansky, S.H. Genotypic and Environmental Contributions to Baked Potato Flavor. Am. J. Potato Res. 2008, 85, 455–465. [Google Scholar] [CrossRef]

- Thybo, A.K.; Christiansen, J.; Kaack, K.; Petersen, M.A. Effect of Cultivars, Wound Healing and Storage on Sensory Quality and Chemical Components in Pre-Peeled Potatoes. LWT-Food Sci. Technol. 2006, 39, 166–176. [Google Scholar] [CrossRef]

- Elmore, J.S.; Mottram, D.S.; Muttucumaru, N.; Dodson, A.T.; Parry, M.A.J.; Halford, N.G. Changes in Free Amino Acids and Sugars in Potatoes Due to Sulfate Fertilization and the Effect on Acrylamide Formation. J. Agric. Food Chem. 2007, 55, 5363–5366. [Google Scholar] [CrossRef] [PubMed]

- Chea, L.; Pfeiffer, B.; Schneider, D.; Daniel, R.; Pawelzik, E.; Naumann, M. Morphological and Metabolite Responses of Potatoes under Various Phosphorus Levels and Their Amelioration by Plant Growth-Promoting Rhizobacteria. Int. J. Mol. Sci. 2021, 22, 5162. [Google Scholar] [CrossRef] [PubMed]

- Pfaff, J.; Denton, A.K.; Usadel, B.; Pfaff, C. Phosphate Starvation Causes Different Stress Responses in the Lipid Metabolism of Tomato Leaves and Roots. Biochim. Biophys. Acta Mol. Cell Biol. Lipids 2020, 1865, 158763. [Google Scholar] [CrossRef]

- Bough, R. Profiling and Putative Aroma Biomarker Identification for Flavor in Potatoes Using a Trained Sensory Panel and HS-SPME GC-MS. Ph.D. Thesis, Colorado State University, Fort Collins, CO, USA, 2017. [Google Scholar]

- Leonova, S.; Shelenga, T.; Hamberg, M.; Konarev, A.V.; Loskutov, I.; Carlsson, A.S. Analysis of Oil Composition in Cultivars and Wild Species of Oat (Avena sp.). J. Agric. Food Chem. 2008, 56, 7983–7991. [Google Scholar] [CrossRef]

- Miller, G.L. Use of Dinitrosalicylic Acid Reagent for Determination of Reducing Sugar. Anal. Chem. 1959, 31, 426–428. [Google Scholar] [CrossRef]

- Xu, X. Enhanced Triacylglycerol Biosynthesis in Vegetative Tissues of Potato (Solanum tuberosum L.). Ph.D. Thesis, The University of Sydney, Sydney, NSW, Australia, 2019. [Google Scholar]

- Jouquand, C.; Niquet-Léridon, C.; Loaec, G.; Tessier, F.J. Effect of Added Nitrogen Fertilizer on Pyrazines of Roasted Chicory. J. Sci. Food Agric. 2016, 97, 1172–1177. [Google Scholar] [CrossRef]

- Li, Q.; Gao, Y.; Yang, A. Sulfur Homeostasis in Plants. Int. J. Mol. Sci. 2020, 21, 8926. [Google Scholar] [CrossRef]

- Elmore, J.S.; Parker, J.K.; Halford, N.G.; Muttucumaru, N.; Mottram, D.S. Effects of Plant Sulfur Nutrition on Acrylamide and Aroma Compounds in Cooked Wheat. J. Agric. Food Chem. 2008, 56, 6173–6179. [Google Scholar] [CrossRef]

- Ross, S.B. The Effect of Nitrogen Fertiliser on the Sensometabolomic Profile of Steamed Potatoes. Ph.D. Thesis, Massey University, Palmerston North, New Zealand, 2020. [Google Scholar]

- Nikolaou, A.; Varzakas, T.; Kourkoutas, Y. Effect of Organic Fertilization Treatment, Frying Oil and Cultivar Variety on the Volatile Profile of Potato Tubers. Curr. Res. Nutr. Food Sci. 2016, 4, 1–8. [Google Scholar] [CrossRef]

- Martin, F.L.; Ames, J.M. Comparison of Flavor Compounds of Potato Chips Fried in Palmolein and Silicone Fluid. J. Am. Oil Chem. Soc. 2001, 78, 863–866. [Google Scholar] [CrossRef]

- Blanda, G.; Cerretani, L.; Comandini, P.; Toschi, T.G.; Lercker, G. Investigation of Off-Odour and off-Flavour Development in Boiled Potatoes. Food Chem. 2010, 118, 283–290. [Google Scholar] [CrossRef]

- Dobson, G.; Griffiths, D.W.; Davies, H.V.; McNicol, J.W. Comparison of Fatty Acid and Polar Lipid Contents of Tubers from Two Potato Species, Solanum tuberosum and Solanum phureja. J. Agric. Food Chem. 2004, 52, 6306–6314. [Google Scholar] [CrossRef] [PubMed]

- Martin, F.L.; Ames, J.M. Formation of Strecker Aldehydes and Pyrazines in a Fried Potato Model System. J. Agric. Food Chem. 2001, 49, 3885–3892. [Google Scholar] [CrossRef]

- Mandin, O.; Duckham, S.C.; Ames, J. Volatile Compounds from Potato-like Model Systems. J. Agric. Food Chem. 1999, 47, 2355–2359. [Google Scholar] [CrossRef] [PubMed]

- Limacher, A.; Kerler, J.; Davidek, T.; Schmalzried, F.; Blank, I. Formation of Furan and Methylfuran by Maillard-Type Reactions in Model Systems and Food. J. Agric. Food Chem. 2008, 56, 3639–3647. [Google Scholar] [CrossRef]

- Kocadağlı, T.; Methven, L.; Kant, A.; Parker, J.K. Targeted Precursor Addition to Increase Baked Flavour in a Low-Acrylamide Potato-Based Matrix. Food Chem. 2021, 339, 128024. [Google Scholar] [CrossRef]

- Bradbury, L.M.T.; Henry, R.J.; Waters, D.L.E. Flavor Development in Rice. In Biotechnology in Flavor Production; Wiley: Hoboken, NJ, USA, 2008; pp. 130–146. [Google Scholar] [CrossRef]

- Jalmi, S.K.; Bhagat, P.K.; Verma, D.; Noryang, S.; Tayyeba, S.; Singh, K.; Sharma, D.; Sinha, A.K. Traversing the Links between Heavy Metal Stress and Plant Signaling. Front. Plant Sci. 2018, 9, 12. [Google Scholar] [CrossRef]

- Müller, R.; Morant, M.; Jarmer, H.; Nilsson, L.; Nielsen, T.H. Genome-Wide Analysis of the Arabidopsis Leaf Transcriptome Reveals Interaction of Phosphate and Sugar Metabolism. Plant Physiol. 2006, 143, 156–171. [Google Scholar] [CrossRef]

- El-Labban, A.A. Physicochemical Characteristics of Some New Peanut Varieties Cultivated in Egypt. Egypt. J. Appl. Sci. 2022, 37, 71–81. [Google Scholar] [CrossRef]

| Fertilization Treatment | Abbreviation | P Fertilization Level (kg·ha−1) | S Fertilization Level (kg·ha−1) |

|---|---|---|---|

| No phosphorus and sulfur application | CK | 0 | 0 |

| Individual phosphorus application | P | 180 | 0 |

| Individual sulfur application | S | 0 | 90 |

| Combined phosphorus and sulfur application | PS | 180 | 90 |

| Planting Season | Total P (%) | Available N (mg·Kg−1) | Total K (g·Kg−1) | Available K (mg·Kg−1) | Available S (mg·Kg−1) | pH | Organic Matter (%) |

|---|---|---|---|---|---|---|---|

| 1st | 2.04 | 75.98 | 2.22 | 17.45 | 29.1 | 3.23 | 3.11 |

| 2nd | 2.15 | 75.41 | 2.15 | 19.8 | 32.4 | 3.15 | 3.03 |

| 3rd | 1.93 | 74.37 | 2.47 | 17.8 | 31.7 | 3.46 | 3.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, K.; Li, M.; Zhou, J.; Guo, H. The Impact of the Individual and Combined Application of Phosphorus and Sulfur Fertilizers on Potato Tuber Flavor. Foods 2023, 12, 3764. https://doi.org/10.3390/foods12203764

Li K, Li M, Zhou J, Guo H. The Impact of the Individual and Combined Application of Phosphorus and Sulfur Fertilizers on Potato Tuber Flavor. Foods. 2023; 12(20):3764. https://doi.org/10.3390/foods12203764

Chicago/Turabian StyleLi, Kaifeng, Maoxing Li, Jinhua Zhou, and Huachun Guo. 2023. "The Impact of the Individual and Combined Application of Phosphorus and Sulfur Fertilizers on Potato Tuber Flavor" Foods 12, no. 20: 3764. https://doi.org/10.3390/foods12203764