Sea Buckthorn Pretreatment, Drying, and Processing of High-Quality Products: Current Status and Trends

Abstract

1. Introduction

- (1)

- Provide an overview and analysis of different drying and pretreatment techniques for sea buckthorn. The drying dynamics, physical and chemical characteristics, microstructure, and nutrient content of sea buckthorn are assessed using single drying, combined drying, and pretreatment techniques. We will analyse the effects of different drying and pretreatment techniques on drying characteristic and quality.

- (2)

- Summarise the current problems in the field of sea buckthorn drying.

- (3)

- Analyse the current situation of superior quality processing of sea buckthorn products and the way to achieve it.

- (4)

- Summarise and forecast the main trends in sea buckthorn drying, pretreatment procedures, and high-quality processing.

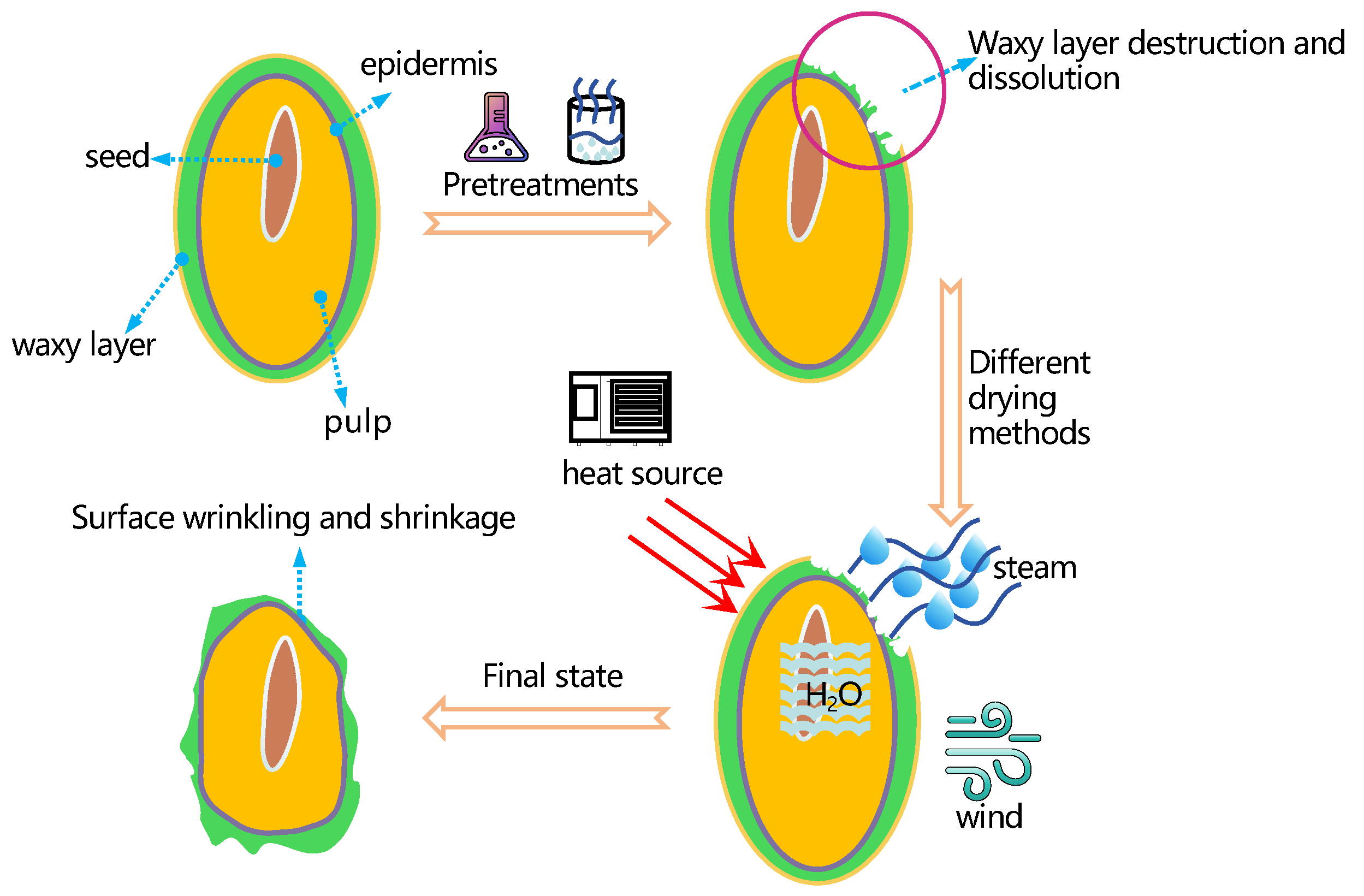

2. Research Progress of Sea Buckthorn Pretreatment Technology

2.1. Chemical Pretreatment

2.2. Physical Pretreatment

2.3. Combined Pretreatment

| Pretreatment Methods | Type | Drying Characteristics and Quality | Reference |

|---|---|---|---|

| 70 °C blanching pretreatment | Physical pretreatment | The waxy layer of sea buckthorn epidermis was partially dissolved and showed few breaks and cracks, and the drying rate increased significantly. However, the total flavonoid content was slightly lower than that of the control, and the total phenolics content decreased by about 1.4%. | [50] |

| Prick hole pretreatment | Physical pretreatment | The drying time was reduced by about 3.4%, 18%, and 24.4% when the number of prick holes was 1, 3, and 6, respectively, compared to the control group. And, it will have a higher rehydration rate and a smaller colour difference value ΔE than the colour closest to fresh sea buckthorn. | [83] |

| 2% drier | Chemical pretreatment | The waxy layer on the surface of the sea buckthorn had disappeared in dissolution, and there were slight cracks near the stomata. The water content was 22.98% higher than the control in the first 36 h of drying. In comparison to fresh samples, the total flavonoid content increased by 35.7%, the total phenolics content increased by 2%, and the brightness value L* decreased by 38.7%. The colour difference value ΔE added to 9.37% in comparison to the control. | [50] |

| 2% Na2CO3 | Chemical pretreatment | The surface waxy layer structure of sea buckthorn has been severely damaged, resulting in dissolution and a large number of cracks. The drying rate was significantly increased. Compared with the control group, the drying time was reduced by 62.17%, the browning index was decreased by 54.5%, the total flavonoid content was increased by 35.7%, and the total phenolics content was enhanced by 6% but was lower than that of the fresh samples. | [50] |

| 2% NaHCO3 | Chemical pretreatment | The dissolution of the waxy layer in the epidermis of sea buckthorn was relatively slight, and stomatal disruption was small. The drying rate significantly increased. At 36 h before drying, the moisture content was reduced by 18.53% more than the control. In comparison to the control group, the colour difference value ΔE was lowered by 13.4% and the L* value raised by 4.6%. The total flavonoid level was marginally greater than in fresh samples, and the total phenolic content was 5.4% higher than in controls. | [50] |

| 150 W Ultrasonic | Physical pretreatment | There was dissolution of the waxy layer of the sea buckthorn epidermis, but no breaks or cracks were present. The drying rate was lower than in the control group. At 36 h before drying, 1.29% less water content was removed, and the total colour difference value ΔE was reduced by 2.8% compared to the control. The browning index and ascorbic acid content were slightly lower than the control, and the differences were not significant. The total flavonoid content increased by 25%, and the total phenol content was elevated by 2.7%. | [84] |

| 150 W Ultrasonic + 3% Na2CO3 | Combined pretreatment | The waxy layer on the surface gradually dissolved, and micropores appeared at 15 min. It has accelerated the drying rate by 1–2 min compared to the control group. The total colour difference value ΔE decreased by 13–5.7% as the ultrasonic time increased from 5 to 15 min compared to the control group. The content of total phenolics was highest at 5 min. The total phenolics content gradually decreased with time and was lower than the control at 15 min. | [81] |

| 150 W Ultrasonic + 3% Na2CO3 + Prick hole | Combined pretreatment | The surface stomata of sea buckthorn were destroyed, and only the skeleton was visible. It drastically reduced drying time. When compared to the control, the greatest drying rate can be enhanced by up to 37.5% for different duration combinations. The total colour difference value ΔE can be reduced by up to 22.9%, and the total flavonoid content can be increased by about 6.1–14.8%. | [81] |

3. Research Progress of Sea Buckthorn Drying Technology

3.1. Natural Drying

3.2. Hot-Air Drying

3.3. Heat-Pump Drying

3.4. Infrared-Radiation Drying

3.5. Spray Drying

3.6. Pulsed Vacuum Drying

3.7. Vacuum Freeze Drying

3.8. Combined Drying

| Different Drying Methods | Drying Characteristics and Quality | Reference |

|---|---|---|

| Natural drying | The drying rate was slow. Compared to hot-air drying, drying time increased 3.4 times for natural sun-drying and 8.4 times for natural shade-drying. The total colour difference value ΔE was reduced by about 13% and the total flavonoid content by 4–29.3% compared to hot-air drying. | [94,95] |

| Hot air drying | The hot-air drying rate increased with the rise in temperature. The damage to the microstructure was severe, resulting in a serious loss of nutrients. The total phenolics content decreased by 22.7–42.3%, and the total carotenoid content decreased by 42.6–64.6% compared to the control group. | [102,103,104] |

| Infrared radiation drying | The drying time was prolonged by about 7% compared with the hot-air drying at 60 °C and 2.2 m/s, the total flavonoid content was enhanced by 17.6%, and the total phenolics content was increased by 33%. The holes left behind could be observed on the surface of sea buckthorn pulp due to the high capacity of infrared radiation, which could directly penetrate the surface of sea buckthorn pulp. | [43] |

| Heat pump drying | The drying rate of heat-pump drying was slightly slower than that of hot-air drying. Compared to hot-air drying, heat-pump drying reduced the total colour difference value ΔE by 7.6% and the browning index by 16.7%. The increase in VC content was slightly but significantly lower than vacuum freeze-drying and fresh samples. The total flavonoid content increased by about 83% and the total phenolic content decreased by about 66% compared to fresh samples. | [95] |

| Spray drying | Since the liquid is in the form of mist, the contact area with hot air is expanded, which increases the drying rate significantly. The temperature at the inlet can reach 150–220 °C, causing nutrients like VC in sea buckthorn to be lost. | [115,116] |

| Pulsed vacuum drying | Its drying rate was higher than HAD (hot air drying), IRD (infrared radiation), and IR-HAD (infrared assisted hot air drying) in the initial stage, and the drying rate decreased in the later stage. The time was extended by 15.99% and 7.83% compared to hot-air drying and IR drying, respectively. The total colour difference value ΔE was similar to that of vacuum freeze-drying and 87.7% lower compared with hot-air drying, which could better retain the nutrients and active ingredients and reduce the loss of nutrients. | [43,71] |

| Vacuum freeze drying | In comparison to the other drying techniques mentioned above, vacuum freeze-drying has the longest drying duration and consumes the most energy. However, it also has the best retention of nutrients and the lowest total colour difference ΔE and browning index. | [33,94] |

| Infrared assisted hot air drying | The drying rate was obviously increased; compared with hot-air drying and infrared drying, the drying rate increased by 11.2% and 19.6%, respectively. Compared with hot-air drying, the browning index was 40.4% higher, the total flavonoid content was 6.6% higher, and the total phenolics content was 33.3% higher. | [43] |

4. Different Methods to Achieve High-Quality Processing of Sea Buckthorn Products

4.1. Sea Buckthorn Beverages

4.2. Sea Buckthorn Freeze-Dried Powder

4.3. Sea Buckthorn Alcohol

4.4. Sea Buckthorn Oil

4.5. Sea Buckthorn Pomace

5. Conclusions and Recommendations

- (1)

- Throughout the drying process of sea buckthorn, the drying rate plays a crucial role in reducing product quality maintainance and energy consumption. The application of pretreatment technology prior to sea buckthorn drying is a significant step to enhance the drying rate and quality and decrease energy consumption. According to the research, combined pretreatment can integrate the advantages of the two pretreatments, while reducing costs and improving drying quality and efficiency. In the future, we should concentrate on the use of integrated pretreatment methods in conjunction with the actual sea buckthorn drying requirements. A balance between economy, ecology, and efficiency should be found after recognising the gap between laboratory research and practical manufacturing.

- (2)

- When processing dried sea buckthorn pulp, some small- and medium-sized enterprises (SMEs) prefer natural drying as a cost-effective processing method. Although this process is advantageous to businesses, it has significantly reduced the nutrients in sea buckthorn pulp and cannot bring forth the true worth of sea buckthorn pulp. While hot-air drying and infrared-radiation drying are faster than natural drying, they can cause greater deterioration in quality. Pulsed vacuum drying and vacuum freeze-drying are considered to have superior drying quality but suffer from slow drying rates and excessive energy consumption. In the actual production of sea buckthorn pulp drying, except for vacuum freeze-drying for the processing of sea buckthorn freeze-dried powder and natural sun-drying for the production of sea buckthorn dried fruit, the rest of the drying technology is not widely used. In this situation, it is very necessary for us to start with the research and development of drying equipment or sea buckthorn itself. Firstly, new online-measurement and control technology is introduced into the drying equipment. LF-NMR technology is used to monitor the moisture migration information, predict the drying endpoint to speed up the drying rate, and save energy consumption. The second is to study the best pretreatment technology in the early stage under different drying methods. Pretreatment technology is used to speed up the drying rate, saving energy consumption and reducing the quality deterioration at the same time. Thirdly, research on new drying technology of sea buckthorn is carried out. Through the basic theoretical research on sea buckthorn drying, the macroscopic changes in quality were investigated from the microscopic level. The effects of different drying methods and pretreatment methods on the drying characteristics and quality change mechanism of sea buckthorn were investigated. It is important to investigate the effect of different drying methods and pretreatment methods on the drying characteristics and quality change mechanism of sea buckthorn, which will be useful for the research of new pretreatment technologies such as high-pressure processing (HPP), pulsed electric field (PEF) and new drying technologies such as low-pressure superheated steam drying (SSD), far-infrared-radiation-heating-assisted pulsed vacuum drying. Radiation heating combined with pulsed vacuum drying (FIR-PVD), hot-air combined with vacuum freeze-drying (HAD-VFD), and far-infrared-radiation heating combined with pulsed vacuum drying (FIR-PVD) were applied to sea buckthorn pulp drying with significant promotion.

- (3)

- To fully maximise the product value of sea buckthorn pulp, high-quality processing of sea buckthorn goods must begin at the front end of processing. From beverage to pomace, a complete industrial chain needs to be formed to maximise the use of resources. On this basis, new process routes should be explored or existing processes optimised in combination with the actual situation. It is also necessary to develop the deep-processing industry for sea buckthorn and improve the added value of sea buckthorn processing products. Using the above methods, the sea buckthorn processing industry will realise high-quality production.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chazdon, R.; Brancalion, P. Restoring forests as a means to many ends. Science 2019, 365, 24–25. [Google Scholar] [CrossRef]

- Hua, F.Y.; Bruijnzeel, L.A.; Meli, P. The biodiversity and ecosystem service contributions and trade-offs of forest restoration approaches. Science 2022, 376, 839–844. [Google Scholar] [CrossRef]

- Tudor, C.; Bohn, T.; Iddir, M.; Dulf, F.V.; Focsan, M.R.; Dumitrita, O.; Pintea, A. Sea Buckthorn Oil as a Valuable Source of Bioaccessible Xanthophylls. Nutrients 2020, 12, 76. [Google Scholar] [CrossRef]

- Gao, G.R.; Lv, Z.R.; Zhang, G.Y.; Li, J.Y.; Zhang, J.G.; He, C.Y. An ABA-flavonoid relationship contributes to the differences in drought resistance between different sea buckthorn subspecies. Tree Physiol. 2021, 41, 744–755. [Google Scholar] [CrossRef]

- Min, Z.R.; Zhang, J.X.; Fan, W.B.; Yang, H.H.; Xu, Z.Y. Soil Moisture Distribution and Dynamic Growth of Hippophae rhamnoides Under Different Site Conditions. J. Soil. Water Conserv. 2022, 36, 204–210. [Google Scholar] [CrossRef]

- Kanayama, Y.; Ohkawa, W.; Chiba, E.; Sato, K.; Kanahama, K.; Ofosu-Anim, J. Nutritional components and nitrogen fixation in seabuckthorn (Hippophae rhamnoides L.). Acta Hortic. 2009, 806, 309–314. [Google Scholar] [CrossRef]

- Wang, J.; Fu, B.J.; Lu, N.; Wang, S.; Zhang, L. Water use characteristics of native and exotic shrub species in the semi-arid Loess Plateau using an isotope technique. Agric. Ecosyst. Environ. 2019, 276, 55–63. [Google Scholar] [CrossRef]

- Zhang, K.; Xu, M.Z.; Wang, Z.Y.; Bi, C.F. Ecological impacts of seabuckthorn in the pisha sandstone. In Proceedings of the 16th Asia and Pacific Division Congress of the International Association of Hydraulic Engineering and Research/3rd IAHR International Symposium on Hydraulic Structures, Nanjing, China, 20–23 October 2008. [Google Scholar]

- Cui, L.Z.; Fu, Y.Y.; Liu, S.W.; Xia, K.; Tan, Z.C.; Wang, Y.X. Nutritional Value and Industry Development of Sea Buckthorn. Food Res. Dev. 2021, 42, 218–224. [Google Scholar]

- Bal, L.M.; Meda, V.; Naik, S.N.; Satya, S. Sea buckthorn berries: A potential source of valuable nutrients for nutraceuticals and cosmoceuticals. Food Res. Int. 2011, 44, 1718–1727. [Google Scholar] [CrossRef]

- Yu, L.Y.; Diao, S.F.; Zhang, G.Y.; Yu, J.G.; Zhang, T.; Luo, H.M.; Duan, A.G.; Wang, J.P.; He, C.Y.; Zhang, J.G. Genome sequence and population genomics provide insights into chromosomal evolution and phytochemical innovation of Hippophae rhamnoides. Plant Biotechnol. J. 2022, 20, 1257–1273. [Google Scholar] [CrossRef]

- Criste, A.; Urcan, A.C.; Bunea, A.; Furtuna, F.R.P.; Olah, N.K.; Madden, R.H.; Corcionivoschi, N. Phytochemical Composition and Biological Activity of Berries and Leaves from Four Romanian Sea Buckthorn (Hippophae rhamnoides L.) Varieties. Molecules 2020, 25, 1170. [Google Scholar] [CrossRef]

- Guo, R.X.; Guo, X.B.; Li, T.; Fu, X.; Liu, R.H. Comparative assessment of phytochemical profiles, antioxidant and antiproliferative activities of Sea buckthorn (Hippophae rhamnoides L.) berries. Food Chem. 2017, 221, 997–1003. [Google Scholar] [CrossRef]

- Osborn, J.L.; Claesen, J.; Brown, J.M. Microbial Flavonoid Metabolism: A Cardiometabolic Disease Perspective. Annu. Rev. Nutr. 2021, 41, 433–454. [Google Scholar] [CrossRef]

- Rybicka, I.; Kiewlicz, J.; Kowalczewski, P.; Kowalczewski, P.L.; Swigto, G. Selected dried fruits as a source of nutrients. Eur. Food Res. Technol. 2021, 247, 2409–2419. [Google Scholar] [CrossRef]

- Maftei, N.M.; Iancu, A.V.; Bogdan, R.E.G.; Gural, T.V.; Villarroel, A.R.; Pelin, A.M. A Novel Symbiotic Beverage Based on Sea Buckthorn, Soy Milk and Inulin: Production, Characterization, Probiotic Viability, and Sensory Acceptance. Microorganisms 2023, 11, 736. [Google Scholar] [CrossRef]

- Guo, C.X.; Han, L.; Li, M.P.; Yu, L.G. Seabuckthorn (Hippophae rhamnoides) Freeze-Dried Powder Protects against High-Fat Diet-Induced Obesity, Lipid Metabolism Disorders by Modulating the Gut Microbiota of Mice. Nutrients 2020, 12, 265. [Google Scholar] [CrossRef]

- Xia, Y.N.; Zha, M.S.; Liu, H.; Shuang, Q.; Chen, Y.F.; Yang, X.J. Novel Insight into the Formation of Odour-Active Compounds in Sea Buckthorn Wine and Distilled Liquor Based on GC-MS and E-Nose Analysis. Foods 2022, 11, 3273. [Google Scholar] [CrossRef]

- Sanwal, N.; Mishra, S.; Sahu, J.K.; Naik, S.N. Effect of ultrasound-assisted extraction on efficiency, antioxidant activity, and physicochemical properties of sea buckthorn (Hippophae salicipholia) seed oil. LWT-Food Sci. Technol. 2022, 153, 112386. [Google Scholar] [CrossRef]

- Cui, Q.; Liu, J.Z.; Wang, L.T.; Kang, Y.F.; Meng, Y.; Jiao, J.; Fu, Y.J. Sustainable deep eutectic solvents preparation and their efficiency in extraction and enrichment of main bioactive flavonoids from sea buckthorn leaves. J. Clean. Prod. 2018, 184, 826–835. [Google Scholar] [CrossRef]

- Ma, X.Y.; Yang, W.; Kallio, H.; Yang, B.R. Health promoting properties and sensory characteristics of phytochemicals in berries and leaves of sea buckthorn (Hippophae rhamnoides). Crit. Rev. Food Sci. Nutr. 2022, 62, 3798–3816. [Google Scholar] [CrossRef]

- Shi, J.; Wang, L.; Lu, Y.; Ji, Y.; Wang, Y.Q.; Dong, K.; Kong, X.Q.; Sun, W. Protective effects of seabuckthorn pulp and seed oils against radiation-induced acute intestinal injury. J. Radiat. Res. 2017, 58, 24–32. [Google Scholar] [CrossRef]

- Zhang, Q.G.; Zhao, J.; Shao, J.; Zhao, Y.; Yang, M.M.; Ji, A.M.; Yu, S.M. Research on the freeze-drying technology of Hippophae rhamnoides L. Trends Food Sci. Technol. 2009, 34, 39–41. [Google Scholar]

- Geng, Z.H.; Wang, J.; Zhu, L.C.; Yu, X.L.; Zhang, Q.; Li, M.Q.; Hu, B.; Yang, X.H. Metabolomics provide a novel interpretation of the changes in flavonoids during sea buckthorn (Hippophae rhamnoides L.) drying. Food Chem. 2023, 413, 135598. [Google Scholar] [CrossRef]

- Li, M.R.; Hu, J.M.; Yang, M.; Yang, J.F.; Zubarey, Y.A.A. Quality Attributes and Dielectric Properties of Sea Buckthorn Berries under Differing Freezing Regimes and Their Interrelationships. Foods 2022, 11, 3825. [Google Scholar] [CrossRef]

- Feng, X.R.; Hou, Y.N.; Zhang, X.X.; He, M.L.; Zhu, Y.; Sun, A.D.; Gan, Z.L. Research advances on processing and functional components of berry juice. Sci. Technol. Food Ind. 2018, 39, 334–340. [Google Scholar] [CrossRef]

- Marcal, S.; Sousa, A.S.; Taofiq, O.; Antunes, F.; Antunes, F.M.; Alcina, M.M.B.; Freitas, A.C.; Barros, L.; Ferreira, I.C.F.R.; Pintado, M. Impact of postharvest preservation methods on nutritional value and bioactive properties of mushrooms. Trends Food Sci. Technol. 2021, 110, 418–431. [Google Scholar] [CrossRef]

- Ju, H.Y.; Vidyarthi, S.K.; Karim, M.A.; Yu, X.L.; Zhang, W.P.; Xiao, H.W. Drying quality and energy consumption efficient improvements in hot air drying of papaya slices by step-down relative humidity based on heat and mass transfer characteristics and 3D simulation. Dry. Technol. 2023, 41, 460–476. [Google Scholar] [CrossRef]

- Sun, Y.N.; Zhang, M.; Mujumdar, A. Berry Drying: Mechanism, Pretreatment, Drying Technology, Nutrient Preservation, and Mathematical Models. Food Eng. Rev. 2019, 11, 61–77. [Google Scholar] [CrossRef]

- Guimarães, B.E.; Viana, M.E.; Laviola, A.C.; Aredes, M. Thermal energy storage systems applied to solar dryers: Classification, performance, and numerical modeling: An updated review. Case Stud. Therm. Eng. 2023, 45, 102986. [Google Scholar] [CrossRef]

- Selimefendigil, F.; Oztop, H.F. Three dimensional unsteady heat and mass transport from six porous moist objects in a channel under laminar forced convection. Appl. Therm. Eng. 2021, 183, 116100. [Google Scholar] [CrossRef]

- Pateiro, M.; Vargas-Ramella, M.; Franco, D.; da Cruz, A.G.; Zengin, G.; Kumar, M.; Dhama, K.; Lorenzo, J.M. The role of emerging technologies in the dehydration of berries: Quality, bioactive compounds, and shelf life. Food Chem. X 2022, 16, 100465. [Google Scholar] [CrossRef]

- Gutierrez, L.F.; Ratti, C.; Belkacemi, K. Effects of drying method on the extraction yields and quality of oils from quebec sea buckthorn (Hippophaee rhamnoides L.) seeds and pulp. Food Chem. 2008, 106, 896–904. [Google Scholar] [CrossRef]

- Canan, A.; Ibrahim, D.; Arun, M. A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Dry. Technol. 2022, 40, 1029–1050. [Google Scholar] [CrossRef]

- Adnouni, M.; Jiang, L.; Zhang, X.J.; Zhang, L.Z.; Pathare, P.B.; Roskilly, A.P. Computational modelling for decarbonised drying of agricultural products: Sustainable processes, energy efficiency, and quality improvement. J. Food Eng. 2023, 338, 111247. [Google Scholar] [CrossRef]

- Capar, T.D.; Dedebas, T.; Kavuncuoglu, H.; Karatas, S.M.; Ekici, L.; Yalcin, H. Phenolic Components, Mineral Composition, Physicochemical, and Bioactive Properties of Opuntia ficus-indica with Different Drying Methods. Erwerbs-Obstbau 2023, 65, 347–353. [Google Scholar] [CrossRef]

- Liu, Z.L.; Staniszewska, I.; Zielinska, D.; Zhou, Y.H.; Nowak, K.W.; Xiao, H.W.; Pan, Z.L.; Zielinska, M. Combined Hot Air and Microwave-Vacuum Drying of Cranberries: Effects of Pretreatments and Pulsed Vacuum Osmotic Dehydration on Drying Kinetics and Physicochemical Properties. Food Bioprocess. Technol. An. Int. J. 2020, 13, 1848–1856. [Google Scholar] [CrossRef]

- Zielinska, M.; Sadowski, P.; Błaszczak, W. Combined hot air convective drying and microwave-vacuum drying of blueberries (Vaccinium corymbosum L.): Drying kinetics and quality characteristics. Dry. Technol. 2016, 34, 665–684. [Google Scholar] [CrossRef]

- Tian, J.H. Effect of drying temperature on the content of Vc, VE and total flavonoids in seabuckthorn fruit residue. Food Eng. 2020, 4, 30–32. [Google Scholar] [CrossRef]

- Yang, W.R.; Peng, J.; Zhang, X.M.; Yu, Y.S.; Bo, Z.B.; Xu, Y.J.; Chen, S.P. Drying kinetics and quality characteristics of wampee (Clausena lansium L.): Based on different hot air-drying temperatures. Food Ferment. Ind. 2021, 47, 214–220. [Google Scholar] [CrossRef]

- Araya-Farias, M.; Makhlouf, J.; Ratti, C. Drying of Seabuckthorn (Hippophae rhamnoides L.) Berry: Impact of Dehydration Methods on Kinetics and Quality. Dry. Technol. 2011, 29, 351–359. [Google Scholar] [CrossRef]

- Jin, X.; Duan, X.; Ren, G.Y.; Chen, J.L.; Li, L.L.; Cao, W.W.; Liu, W.C. Effects of different drying methods on drying characteristics and quality of figs. Food and Fermentation Industries. Available online: https://kns.cnki.net/kcms2/article/abstract?v=vCcGnC-OR216aLLH9DwufCmNaJCNlabPi68-sWULS4WvzR0oI0kSxRiMgZWjXrn_tUXgDh8iktj0w9cooMaludCf1YpXBD9Fpnefy2Ej5hrq5lnrSKnTiCnRG2lRgIHQluUXQiHzoSQ=&uniplatform=NZKPT&language=CHS (accessed on 19 November 2023).

- Geng, Z.H.; Zhu, L.C.; Wang, J.; Yu, X.L.; Li, M.Q.; Yang, W.X.; Hu, B.; Zhang, Q.; Yang, X.H. Drying sea buckthorn berries (Hippophae rhamnoides L.): Effects of different drying methods on drying kinetics, physicochemical properties, and microstructure. Front. Nutr. 2023, 10, 1106009. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Ma, Y.H.; Dong, J.W.; Ye, G.S.; Zhang, D.; Yang, K.Y. Temporal and Spatial Expression Patterns and Protein Structure Prediction of Seabuckthorn CMO Gene under Drought Stress. Journal of Northwest Forestry University. Available online: https://kns.cnki.net/kcms2/article/abstract?v=vCcGnC-OR22og15fXEP0ktNjh7elFKCGXhU_5a3UuaPQLK7LYkHk7eVN2FRQKji7XSdfLaO7EccYVtUxQUC4lHGt6Gr5pDVB7N891b4vINzMxU4vbMLZM7tGRC-798zwJH8CXBpm6Jc=&uniplatform=NZKPT&language=CHS (accessed on 19 November 2023).

- Pawar, D.A.; Giri, S.K.; Sharma, A.K. Novel alternative pretreatment approaches for production of quality raisins from grapes: Opportunities and future prospects. J. Food Process Eng. 2023, 46, e14305. [Google Scholar] [CrossRef]

- Tan, S.D.; Zhang, Q.; Xu, Y.; Liu, X.L.; Zhu, C.Y.; Yang, X.H. Research Progress of Berry Drying Pretreatment Technology. Food Sci. Technol. 2022, 47, 46–51. [Google Scholar] [CrossRef]

- Liu, Z.L.; Xie, L.; Zielinska, M.; Pan, Z.L.; Deng, L.Z.; Zhang, J.S.; Gao, L.; Wang, S.Y.; Zheng, Z.A.; Xiao, H.W. Improvement of drying efficiency and quality attributes of blueberries using innovative far-infrared radiation heating assisted pulsed vacuum drying (FIR-PVD). Innov. Food Sci. Emerg. 2022, 77, 102948. [Google Scholar] [CrossRef]

- Kostaropoulos, A.E.; Saravacos, G.D. Microwave Pretreatment for Sun-Dried Raisins. J. Food Sci. 1995, 60, 344–347. [Google Scholar] [CrossRef]

- Ni, J.B.; Ding, C.J.; Zhang, Y.M.; Song, Z.Q.; Xu, W.Q. Influence of ultrasonic pretreatment on electrohydrodynamic drying process of goji berry. J. Food Process Pres. 2020, 44, e14600. [Google Scholar] [CrossRef]

- Yao, N.N.; Che, F.B.; Zhang, T.; Li, Y.H.; Zhang, Q.; Zhang, H.; Zhou, J.J.; Wu, X. Comparative Analysis of Different Pretreatment on lmproving Hot Air Drying Effect of Seabuckthorn (Hippophae rhamnoides L.). Mod. Food Sci. Technol. 2020, 36, 211–219. [Google Scholar] [CrossRef]

- Ni, J.B.; Ding, C.J.; Zhang, Y.M.; Song, Z.Q. Impact of different pretreatment methods on drying characteristics and microstructure of goji berry under electrohydrodynamic (EHD) drying process. Innov. Food Sci. Emerg. 2020, 61, 102318. [Google Scholar] [CrossRef]

- Bao, T.; Hao, X.; Shishir, M.R.I.; Karim, N.; Chen, W. Green alternative methods for pretreatment of whole jujube before the drying process. J. Sci. Food Agric. 2022, 102, 1030–1039. [Google Scholar] [CrossRef]

- Klavins, L.; Klavins, M. Cuticular Wax Composition of Wild and Cultivated Northern Berries. Foods. 2020, 9, 587. [Google Scholar] [CrossRef]

- Wang, Z.K.; Ren, G.Y.; Duan, X.; Xu, Y.M.; Chu, Q.Q.; Zhao, M.Y. Research progress on the influence of pretreatment and drying methods on the drying characteristics and quality of Goji. Food and Fermentation Industries 2023, 49, 367–375. [Google Scholar] [CrossRef]

- Adiletta, G.; Alam, M.R.; Cinquanta, L.; Russo, P.; Albanese, D.; Di Matteo, M. Effect of Abrasive Pretreatment on Hot Dried Goji Berry. Chem. Eng. Trans. 2015, 44, 127–132. [Google Scholar] [CrossRef]

- Ciurzyńska, A.; Kowalska, H.; Czajkowska, K.; Lenart, A. Osmotic dehydration in production of sustainable and healthy food. Trends Food Sci. Technol. 2016, 50, 186–192. [Google Scholar] [CrossRef]

- Hiranvarachat, B.; Devahastin, S.; Chiewchan, N. Effects of acid pretreatments on some physicochemical properties of carrot undergoing hot air drying. Food Bioprod. Process 2010, 89, 116–127. [Google Scholar] [CrossRef]

- Antos, P.; Kurdziel, A.; Sadło, S.; Maciej, B. Preliminary Study on the Use of Ozonation for the Degradation of Dithiocarbamate Residues in the Fruit Drying Process: Mancozeb Residue in Blackcurrant is the Example Used. J. Plant Prot. Res. 2013, 53, 48–52. [Google Scholar] [CrossRef]

- Issis, F.Q.; Elsa, U.U.; Antonio, G.V.; Jacqueline, P.G.; Antu, O.C.; Alexis, P.C. Solar drying of flame seedless (Vitis vinifera L.) grape after different pretreatments: Characterization of raisin’s physicochemical and functional properties. J. Food Meas. Charact. 2023, 17, 2755–2766. [Google Scholar] [CrossRef]

- Bingol, G.; Roberts, S.J.; Balaban, O.M.; Onur, D.Y. Effect of Dipping Temperature and Dipping Time on Drying Rate and Colour Change of Grapes. Dry. Technol. 2012, 30, 597–606. [Google Scholar] [CrossRef]

- Esmaiili, M.; Sotudeh-Gharebagh, R.; Cronin, K.; Mousavi, M.E.; Rezazadeh, G. Grape Drying: A Review. Food Rev. Int. 2007, 23, 257–280. [Google Scholar] [CrossRef]

- Song, H.H.; Bi, J.F.; Chen, Q.Q.; Zhou, M.; Wu, X.; Song, J.X. Combined effects of sodium carbonate pretreatment and hybrid drying methods on the nutritional and antioxidant properties of dried Goji berries. In Proceedings of the 21st International Drying Symposium, Valencia, Spain, 11–14 September 2018. [Google Scholar] [CrossRef]

- Çağlayan, D.; Mazı, B.I. Effects of ultrasound-assisted osmotic dehydration as a pretreatment and finish drying methods on the quality of pumpkin slices. J. Food Process Pres. 2018, 42, e13679. [Google Scholar] [CrossRef]

- Pahlavanzadeh, H.; Basiri, A.; Zarrabi, M. Determination of Parameters and Pretreatment Solution for Grape Drying. Dry. Technol. 2001, 19, 217–226. [Google Scholar] [CrossRef]

- Pirone, B.; De Michelis, A.; Salvatori, D.M. Pretreatments Effect in Drying Behaviour and Colour of Mature and Immature ‘Napolitana’ Sweet Cherries. Food Bioprocess. Technol. 2014, 7, 1640–1655. [Google Scholar] [CrossRef]

- Vásquez-Parra, J.E.; Ochoa-Martinez, C.I.; Bustos-Parra, M. Effect of chemical and physical pretreatments on the convective drying of cape gooseberry fruits (Physalis peruviana). J. Food Eng. 2013, 119, 648–654. [Google Scholar] [CrossRef]

- Polatci, H.; Tasova, M.; Sin, B. Effects of pre-treatments on drying kinetics and energy consumption, heat-mass transfer coefficients, micro-structure of jujube (Zizyphus jujuba L.) fruit. Food Sci. Technol. 2022, 42, 15721. [Google Scholar] [CrossRef]

- Huang, D.; Yang, P.; Qin, Y.T.; Gong, G.L.; Tang, X.H.; Luo, W.S.; Luo, L.; Sunden, B. Infrared Drying Characteristics and Quality Variations of Lily Bulbs Under Blanching Pretreatment. J. Therm. Sci. Eng. Appl. 2022, 14, 091005. [Google Scholar] [CrossRef]

- Jiang, S.T.; Guo, N. The steam explosion pretreatment and enzymatic hydrolysis of wheat bran. Energ. Source Part A 2016, 38, 295–299. [Google Scholar] [CrossRef]

- Joseph, E.B.; Jun-Hu, C.; Da-Wen, S. Novel nonthermal and thermal pretreatments for enhancing drying performance and improving quality of fruits and vegetables. Trends Food Sci. Technol. 2021, 112, 137–148. [Google Scholar] [CrossRef]

- Araya-Farias, M.; Macaigne, O.; Ratti, C. On the Development of Osmotically Dehydrated Seabuckthorn Fruits: Pretreatments, Osmotic Dehydration, Postdrying Techniques, and Nutritional Quality. Dry. Technol. 2014, 32, 813–819. [Google Scholar] [CrossRef]

- Song, C.F.; Ma, X.T.; Wang, J.L.; Ding, T.H.; Song, W.D. Effects of ultrasound and blanching pretreatments on mass transfer and qualities of hot-air drying of perilla (Perilla frutescens L.) leaves. J. Food Process Pres. 2021, 45, e15947. [Google Scholar] [CrossRef]

- Horuz, E.; Jaafar, J.H.; Maskan, M. Ultrasonication as pretreatment for drying of tomato slices in a hot air-microwave hybrid oven. Dry. Technol. 2017, 35, 849–859. [Google Scholar] [CrossRef]

- Prothon, F.; Ahrne, L.M.; Funebo, T.; Kidman, S.; Langton, M.; Sjoholm, I. Effects of combined osmotic and microwave dehydration of apple on texture, microstructure and rehydration characteristics. LWT-Food Sci. Technol. 2001, 34, 95–101. [Google Scholar] [CrossRef]

- Yu, Y.S.; Jin, T.Z.; Xiao, G.S. Effects of pulsed electric fields pretreatment and drying method on drying characteristics and nutritive quality of blueberries. J. Food Process Pres. 2017, 41, e13303. [Google Scholar] [CrossRef]

- Ricce, C.; Rojas, L.M.; Miano, C.A.; Siche, R.; Duarte Augusto, P.E. Ultrasound pre-treatment enhances the carrot drying and rehydration. Food Res. Int. 2016, 89, 701–708. [Google Scholar] [CrossRef]

- Zhang, D.Y.; Huang, D.; Zhang, Y.X.; Liu, Y.J.; Huang, S.; Gong, G.L.; Li, L.J. Ultrasonic assisted far infrared drying characteristics and energy consumption of ginger slices. Ultrason. Sonochemistry 2023, 92, 106287. [Google Scholar] [CrossRef]

- Wang, H.; Karim, M.A.; Sriram, K.; Xie, L.; Liu, Z.L.; Gao, L.; Zhang, J.S.; Xiao, H.W. Vacuum-steam pulsed blanching (VSPB) softens texture and enhances drying rate of carrot by altering cellular structure, pectin polysaccharides and water state. Innov. Food Sci. Emerg. 2021, 74, 102801. [Google Scholar] [CrossRef]

- Wang, X.L.; Feng, Y.B.; Zhou, C.S.; Sun, Y.H.; Wu, B.G.; Yagoub, A.E.A.; Aboagarib, E.A.A. Effect of vacuum and ethanol pretreatment on infrared-hot air drying of scallion (Allium fistulosum). Food Chem. 2019, 295, 432–440. [Google Scholar] [CrossRef]

- Rojas, L.M.; Silveira, I.; Augusto, D.E.P. Ultrasound and ethanol pre-treatments to improve convective drying: Drying, rehydration and carotenoid content of pumpkin. Food Bioprod. Process 2020, 119, 20–30. [Google Scholar] [CrossRef]

- Tan, S.D.; Xu, Y.; Zhu, L.C.; Geng, Z.H.; Zhang, Q.; Yang, X.H. Hot Air Drying of Sea buckthorn (Hippophae rhamnoides L.) Berries: Effects of Different Pretreatment Methods on Drying Characteristics and Quality Attributes. Foods 2022, 11, 3675. [Google Scholar] [CrossRef]

- Santos, C.K.; Guedes, S.J.; Rojas, L.M.; Carvalho, G.R.; Agusto, D.P.E. Enhancing carrot convective drying by combining ethanol and ultrasound as pre-treatments: Effect on product structure, quality, energy consumption, drying and rehydration kinetics. Ultrason. Sonochemistry 2021, 70, 105304. [Google Scholar] [CrossRef]

- Yang, X.H.; Tan, S.D.; Xie, S.Q.; Kou, J.M.; Zhang, Q.; Liu, X.J.; Yue, Y.M.; Zhu, C.Y.; Wang, M.; Wang, J.L. A pretreatment method for hot air drying of sea buckthorn. Xinjiang Uighur Autonomous Region: CN114601131A, 6–10 June 2022. Available online: https://kns.cnki.net/kcms2/article/abstract?v=vCcGnC-OR22HsSTDNKcOXrs-xqG6HwVzIUtraJuuP4oIMe4V0i8KJpb8_hq6y7YspPx4fpDG0OiaZa3aUOS0K1dLo2SbDx_C_uThTUR-LKhqNl8RiOU5YM0Ykw7Mo3Em9BjPZN0aRLM=&uniplatform=NZKPT&language=CHS (accessed on 23 November 2023).

- Yao, N.N. Effects of Pretreatment and Drying Methods on Drying Characteristics and Quality of Hippophae rhamnoides L. Master’s Thesis, Xinjiang Agricultural University, Urumqi, China, 2020. [Google Scholar]

- Deng, L.Z.; Mujumdar, A.S.; Zhang, Q.; Yang, X.H.; Wang, J.; Zheng, Z.A.; Gao, Z.J.; Xiao, H.W. Chemical and physical pretreatments of fruits and vegetables: Effects on drying characteristics and quality attributes-a comprehensive review. Crit. Rev. Food Sci. 2019, 59, 1408–1432. [Google Scholar] [CrossRef]

- Zhu, W.X.; Zhao, Y.T.; Wu, J.Z.; Chen, P.X.; Jiang, M.M.; Chen, N.; Bao, H.; Wang, W.N. Research progress on drying technology and equipment of Rhizome Traditional Chinese Medicines. J. China Agric. Univ. 2023, 28, 153–171. [Google Scholar] [CrossRef]

- López, J.; Ah-Hen, S.K.; Vega-Gálvez, A.; Morales, A.; Garcia-Segovia, P.; Uribe, E. Effects of drying methods on quality attributes of murta (ugni molinae turcz) berries: Bioactivity, nutritional aspects, texture profile, microstructure and functional properties. J. Food Process Eng. 2017, 40, e12511. [Google Scholar] [CrossRef]

- İnci, T.T.; Dursun, P. Modelling of thin layer drying kinetics of some fruits under open-air sun dryingprocess. J. Food Eng. 2004, 65, 413–425. [Google Scholar] [CrossRef]

- Mazlum, İ.; Nizamlioglu, N.M. The effects of different drying methods on some physical and chemical properties of ‘Eksikara’ grape cultivar grown in Karaman region. J. Berry Res. 2021, 11, 395–418. [Google Scholar] [CrossRef]

- Hunashikatti, P.T.; Ramaswwamyreddy, S.; Sethia, P.M.; Goya, S.; Rohan, S.K.; Raj, S. Experimental studies on thin-layer drying of mint leaves in a solar dryer and under open sun. Curr. Sci. 2022, 122, 1066–1071. [Google Scholar] [CrossRef]

- Doymaz, I. Pretreatment effect on sun drying of mulberry fruits (Morus alba L.). J. Food Eng. 2004, 65, 205–209. [Google Scholar] [CrossRef]

- López-Vidaña, C.E.; Figueroa, P.I.; Marcos, A.G.E.; Navarro-Ocana, A.; Hernandez-Vazquez, L.; Santiago-Urbina, J.A. Solar drying kinetics and bioactive compounds of blackberry (Rubus fruticosus). J. Food Process Eng. 2019, 42, e13018. [Google Scholar] [CrossRef]

- Sri, K.R.; Kiruba, K. Sustainable food processing of selected North American native berries to support agroforestry. Crit. Rev. Food Sci. Nutr. 2021, 63, 4235–4260. [Google Scholar] [CrossRef]

- Li, Y.; Li, P.; Yang, K.L.; He, Q.; Wang, Y.; Sun, Y.H.; He, C.N.; Xiao, P.G. Impact of Drying Methods on Phenolic Components and Antioxidant Activity of Sea Buckthorn (Hippophae rhamnoides L.) Berries from Different Varieties in China. Molecules 2021, 26, 7189. [Google Scholar] [CrossRef]

- Lin, P.; Yao, N.N.; Che, F.B.; Ma, Y.; Zhang, T. Effects of Five Different Drying Methods on Drying Characteristic and Quality of Hippophae rhamnoides. Sci. Technol. Food Ind. 2022, 43, 41–48. [Google Scholar] [CrossRef]

- Guo, Z.M.; Ren, Z.C.; Chen, T. Effect of Drying Methods on Polyphenols Content and Antioxidant Activity of Grape Skin. Food Sci. 2013, 34, 117–121. [Google Scholar]

- Qin, D.D.; Zhang, S.W.; Guo, M.; Guo, C.X.; Li, M.P. Effect of Drying Methods on Polyphenol Composition and Antioxidant Activities of Figs (Ficus carica L.). Food Sci. 2018, 39, 102–107. [Google Scholar]

- Cui, C.J.; Zhao, D.D.; Huang, J.; Hao, J.X. Progress on research and development of goji berry drying: A review. Int. J. Food Prop. 2022, 25, 435–449. [Google Scholar] [CrossRef]

- Liu, C.S.; Wu, W.F.; Song, J.; Zhang, Y.Q.; Li, J.X.; Li, Y.Q. Characteristics and Process Optimization of Hot-Air Drying Pepper. Adv. Mater. Res. 2012, 1700, 3074–3078. [Google Scholar] [CrossRef]

- Cao, Z.Z.; Zhou, L.Y.; Bi, J.F.; Yi, J.Y.; Chen, Q.Q.; Wu, X.Y.; Zheng, J.K.; Li, S.R. Effect of different drying technologies on drying characteristics and quality of red pepper (Capsicum frutescens L.): A comparative study. J. Sci. Food Agric. 2016, 96, 3596–3603. [Google Scholar] [CrossRef]

- Jia, Y.Y.; Khalifa, I.; Hu, L.L.; Zhu, W.; Li, J.; Li, K.K.; Li, C.M. Influence of three different drying techniques on persimmon chips’characteristics: A comparison study among hot-air, combined hot-air-microwave, and vacuum-freeze drying techniques. Food Bioprod. Process 2019, 118, 67–76. [Google Scholar] [CrossRef]

- Stoica-Guzun, A.; Parvulescu, O.C.; Brosteanu, A.; Chira, N.; Stroescu, M.; Dobre, T. Influence of sea buckthorn pomace pre-treatment and drying conditions on the drying kinetics, quantity and quality of seed oil. J. Food Nutr. Res.-Slov. 2018, 57, 363–372. [Google Scholar]

- Guan, T.; Cenkowski, S.; Hydamaka, A. Effect of drying on the nutraceutical quality of sea buckthorn (Hippophae rhamnoides L. ssp. sinensis) leaves. J. Food Sci. 2005, 70, 514–518. [Google Scholar] [CrossRef]

- Kyriakopoulou, K.; Pappa, A.; Krokida, M.; Detsi, A.; Kefalas, P. Effects of Drying and Extraction Methods on the Quality and Antioxidant Activity of Sea Buckthorn (Hippophae rhamnoides) Berries and Leaves. Dry. Technol. 2013, 31, 1063–1076. [Google Scholar] [CrossRef]

- Menon, A.; Stojceska, V.; Tassou, S. A systematic review on the recent advances of the energy efficiency improvements in non-conventional food drying technologies. Trends Food Sci. Technol. 2020, 100, 67–76. [Google Scholar] [CrossRef]

- Goh, L.J.; Othman, M.Y.; Mat, S.; Ruslan, H.; Sopian, K. Review of heat pump systems for drying application. Renew. Sust. Energ Rev. 2011, 15, 4788–4796. [Google Scholar] [CrossRef]

- Salehi, F. Recent Applications and Potential of Infrared Dryer Systems for Drying Various Agricultural Products: A Review. Int. J. Fruit. Sci. 2020, 20, 586–602. [Google Scholar] [CrossRef]

- Huang, D.; Yang, P.; Tang, X.H.; Luo, L.; Sunden, B. Application of infrared radiation in the drying of food products. Trends Food Sci. Technol. 2021, 110, 765–777. [Google Scholar] [CrossRef]

- Zhu, Y.; Pan, Z.L. Processing and quality characteristics of apple slices under simultaneous infrared dry-blanching and dehydration with continuous heating. J. Food Eng. 2009, 90, 441–452. [Google Scholar] [CrossRef]

- Huang, X.P.; Li, W.Q.; Wang, Y.M.; Wan, F.X. Drying characteristics and quality of Stevia rebaudiana leaves by far-infrared radiation. LWT-Food Sci. Technol. 2021, 140, 110638. [Google Scholar] [CrossRef]

- Motevali, A.; Minaei, S.; Khoshtaghaza, M.H.; Amirnejat, H. Comparison of energy consumption and specific energy requirements of different methods for drying mushroom slices. Energy 2011, 36, 6433–6441. [Google Scholar] [CrossRef]

- Chauhan, A.K.; Patil, V. Effect of packaging material on storage ability of mango milk powder and the quality of reconstituted mango milk drink. Power Technol. 2013, 239, 86–93. [Google Scholar] [CrossRef]

- Walkling-Ribeiro, M.; Noci, F.; Cronin, D.A.; Lyng, J.G.; Morgan, D.J. Shelf life and sensory evaluation of orange juice after exposure to thermosonication and pulsed electric fields. Food Bioprod. Process 2009, 87, 102–107. [Google Scholar] [CrossRef]

- Shishir, M.R.I.; Chen, W. Trends of spray drying: A critical review on drying of fruit and vegetable juices. Trends Food Sci. Technol. 2017, 65, 49–67. [Google Scholar] [CrossRef]

- Selvamuthukumaran, M.; Khanum, F. Optimization of spray drying process for developing seabuckthorn fruit juice powder using response surface methodology. J. Food Sci. Technol. 2014, 51, 3731–3739. [Google Scholar] [CrossRef]

- Čulina, P.; Zorić, Z.; Garofulić, I.E.; Repajic, M.; Dragovic-Uzelac, V.; Pedisic, S. Optimization of the Spray-Drying Encapsulation of Sea Buckthorn Berry Oil. Foods 2023, 12, 2448. [Google Scholar] [CrossRef]

- Chen, Z.G.; Guo, X.Y.; Wu, T. A novel dehydration technique for carrot slices implementing ultrasound and vacuum drying methods. Ultrason. Sonochemistry 2016, 30, 28–34. [Google Scholar] [CrossRef]

- Zhao, L.J.; Li, Y.H.; Xie, H.; Zhang, J.L.; Wu, Z.H. Drying characteristics and product quality of whole blueberry pulp in vacuum drying process. Int. J. Food Eng. 2021, 17, 755–769. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.Y.; Hu, L.D. High efficient freeze-drying technology in food industry. Crit. Rev. Food Sci. 2022, 62, 3370–3388. [Google Scholar] [CrossRef]

- Sundaramurthi, P.; Suryanarayanan, R. Calorimetry and complementary techniques to characterize frozen and freeze-dried systems. Adv. Drug Deliv. Rev. 2012, 64, 384–395. [Google Scholar] [CrossRef]

- Tse, C.H.; Bao, L.L.; Zhang, H. Freeze-Drying of Pharmaceutical and Food Products; Woodhead Publishing: Cambridge, UK, 2010; pp. 18–67. [Google Scholar]

- Wang, R.; Zhang, M.; Mujumdar, A.S.; Sun, J.C. Microwave Freeze-Drying Characteristics and Sensory Quality of Instant Vegetable Soup. Dry. Technol. 2009, 27, 962–968. [Google Scholar] [CrossRef]

- Wang, D.Y.; Zhang, M.; Mujumdar, A.S.; Yu, D.X. Advanced Detection Techniques Using Artificial Intelligence in Processing of Berries. Food Eng. Rev. 2022, 14, 176–199. [Google Scholar] [CrossRef]

- Vishwanathan, K.H.; Hebbar, H.U.; Raghavarao, K.S.M.S. Hot Air Assisted Infrared Drying of Vegetables and Its Quality. Food Sci. Technol. Res. 2010, 16, 381–388. [Google Scholar] [CrossRef]

- Geng, Z.H.; Li, M.Q.; Zhu, L.C.; Zhang, X.Q.; Zhu, H.B.; Yang, X.H.; Yu, X.L.; Zhang, Q.; Hu, B. Design and Experiment of Combined Infrared and Hot-Air Dryer Based on Temperature and Humidity Control with Sea Buckthorn (Hippophae rhamnoides L.). Foods 2023, 12, 2299. [Google Scholar] [CrossRef]

- Zhao, G.H.; Zhang, R.F.; Liu, L.; Deng, Y.Y.; Wei, Z.C.; Zhang, Y.; Ma, Y.X.; Zhang, M.W. Different thermal drying methods affect the phenolic profiles, their bioaccessibility and antioxidant activity in Rhodomyrtus tomentosa (Ait.) Hassk berries. LWT-Food Sci. Technol. 2017, 79, 260–266. [Google Scholar] [CrossRef]

- Wray, D.; Ramaswamy, H.S. Quality Attributes of Microwave Vacuum Finish-Dried Fresh and Microwave-Osmotic Pretreated Cranberries. J. Food Process Pres. 2015, 39, 3067–3079. [Google Scholar] [CrossRef]

- Zhong, X.; You, F.; Zhou, Z.Y.; Hu, J.Z.; Zhang, B.; Yu, J. Analysis and Suggestions on the Seabuckthorn Industry Development in China. World For. Res. 2021, 34, 102–106. [Google Scholar] [CrossRef]

- Das, A.; Raychaudhuri, U.; Chakraborty, R. Cereal based functional food of Indian subcontinent: A review. J. Food Sci. Technol. 2012, 49, 665–672. [Google Scholar] [CrossRef]

- Gomez-Lopez, V.M.; Pataro, G.; Tiwari, B.; Gozzi, M.; Meireles, M.A.A.; Wang, S.J.; Guamis, B.; Pan, Z.L.; Ramaswamy, H.; Sastry, S.; et al. Guidelines on reporting treatment conditions for emerging technologies in food processing. Crit. Rev. Food Sci. 2022, 62, 5925–5949. [Google Scholar] [CrossRef]

- Liu, X.N.; Han, J.C.; Li, L.Y. Effect of sea-buckthorn original juice clarification on the aroma components of wine. Sci. Technol. Food Ind. 2012, 33, 292–295. [Google Scholar] [CrossRef]

- Chen, X.J.; Ma, Y.; Diao, T.W.; Leng, Y.J.; Lai, X.Q.; Wei, X. Pulsed electric field technology for the manufacturing processes of wine: A review. J. Food Process Pres. 2022, 46, e16750. [Google Scholar] [CrossRef]

- Ma, N.A. Comparative Analysis of Nutritional Components and Flavoring Components of Seabuckthorn Wine & Grape Wine. Liquor. Mak. Sci. Technol. 2014, 2, 92–97. [Google Scholar] [CrossRef]

- Silva-Barbieri, D.; Salazar, F.N.; Lopez, F.; Brossard, N.; Escalona, N.; Perez-Correa, J.R. Advances in White Wine Protein Stabilization Technologies. Molecules 2022, 27, 1251. [Google Scholar] [CrossRef]

- Belcar, J.; Gorzelany, J. Feasibility of Defatted Juice from Sea-Buckthorn Berries (Hippophae rhamnoides L.) as a Wheat Beer Enhancer. Molecules 2022, 27, 3916. [Google Scholar] [CrossRef]

- Gao, J.J.; Li, D.; Su, D.; Wu, T.Q.; Zhao, J.M.; Zhang, W.X.; Song, Y.; Gao, S. Research Progress on the Extraction Technology of Seabuckthorn Fruit Oil and the Application of Nutritional Factors. Sci. Technol. Food Ind. 2022, 43, 400–407. [Google Scholar] [CrossRef]

- Vilas-Franquesa, A.; Juan, B.; Saldo, J. Targeted analysis of sea buckthorn oil extracted by accelerated solvent extraction technique using green and conventional solvents. LWT-Food Sci. Technol. 2022, 164, 113643. [Google Scholar] [CrossRef]

- Dong, K.; Fernando, W.M.B.; Durham, R.; Stockmann, R.; Jayasena, V. Nutritional Value, Health-promoting Benefits and Food Application of Sea Buckthorn. Food Rev. Int. 2023, 39, 2122–2137. [Google Scholar] [CrossRef]

- Vilas-Franquesa, A.; Saldo, J.; Juan, B. Sea buckthorn (Hippophae rhamnoides) oil extracted with hexane, ethanol, diethyl ether and 2-MTHF at different temperatures-An individual assessment. J. Food Compos. Anal. 2022, 114, 104752. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, F.H.; Ma, F.L.; Zang, Q.Q.; Chen, P.; Wei, X.S.; Deng, Q.C. Progress of extraction methods of oil from sea buckthorn (Hippophae rhamnoides L.). China Oils Fats 2016, 41, 16–20. [Google Scholar]

- Modupalli, N.; Krisshnan, A.; Sunil, C.K.; Chidanand, D.V.; Natarajan, V.; Koidis, A.; Rawson, A. Effect of novel combination processing technologies on extraction and quality of rice bran oil. Crit. Rev. Food Sci. 2022, 2022, 1–23. [Google Scholar] [CrossRef]

- Nour, V.; Panaite, T.D.; Corbu, A.R.; Ropota, M.; Turcu, R.P. Nutritional and Bioactive Compounds in Dried Sea-Buckthorn Pomace. Erwerbs-Obstbau 2021, 63, 91–98. [Google Scholar] [CrossRef]

- Stanciu, I.; Ungureanu, E.L.; Popa, E.E.; Geicu-Cristea, M.; Draghici, M.; Mitelut, A.C.; Mustatea, G.; Popa, M.E. The Experimental Development of Bread with Enriched Nutritional Properties Using Organic Sea Buckthorn Pomace. Appl. Sci. 2023, 13, 6513. [Google Scholar] [CrossRef]

- Tian, J.H.; Zhang, C.Y.; Wei, L. Study on the extraction technology and antioxidant activity of total flavonoids from the pomace of sea buckthorn. Nat. Product. Res. Dev. 2021, 33, 65–72. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Li, M.; Zhu, L.; Geng, Z.; Liu, X.; Cheng, Z.; Zhao, M.; Zhang, Q.; Yang, X. Sea Buckthorn Pretreatment, Drying, and Processing of High-Quality Products: Current Status and Trends. Foods 2023, 12, 4255. https://doi.org/10.3390/foods12234255

Zhang X, Li M, Zhu L, Geng Z, Liu X, Cheng Z, Zhao M, Zhang Q, Yang X. Sea Buckthorn Pretreatment, Drying, and Processing of High-Quality Products: Current Status and Trends. Foods. 2023; 12(23):4255. https://doi.org/10.3390/foods12234255

Chicago/Turabian StyleZhang, Xuetao, Mengqing Li, Lichun Zhu, Zhihua Geng, Xinyu Liu, Zheyu Cheng, Mengxu Zhao, Qian Zhang, and Xuhai Yang. 2023. "Sea Buckthorn Pretreatment, Drying, and Processing of High-Quality Products: Current Status and Trends" Foods 12, no. 23: 4255. https://doi.org/10.3390/foods12234255

APA StyleZhang, X., Li, M., Zhu, L., Geng, Z., Liu, X., Cheng, Z., Zhao, M., Zhang, Q., & Yang, X. (2023). Sea Buckthorn Pretreatment, Drying, and Processing of High-Quality Products: Current Status and Trends. Foods, 12(23), 4255. https://doi.org/10.3390/foods12234255