Novel Efficient Physical Technologies for Enhancing Freeze Drying of Fruits and Vegetables: A Review

Abstract

:1. Introduction

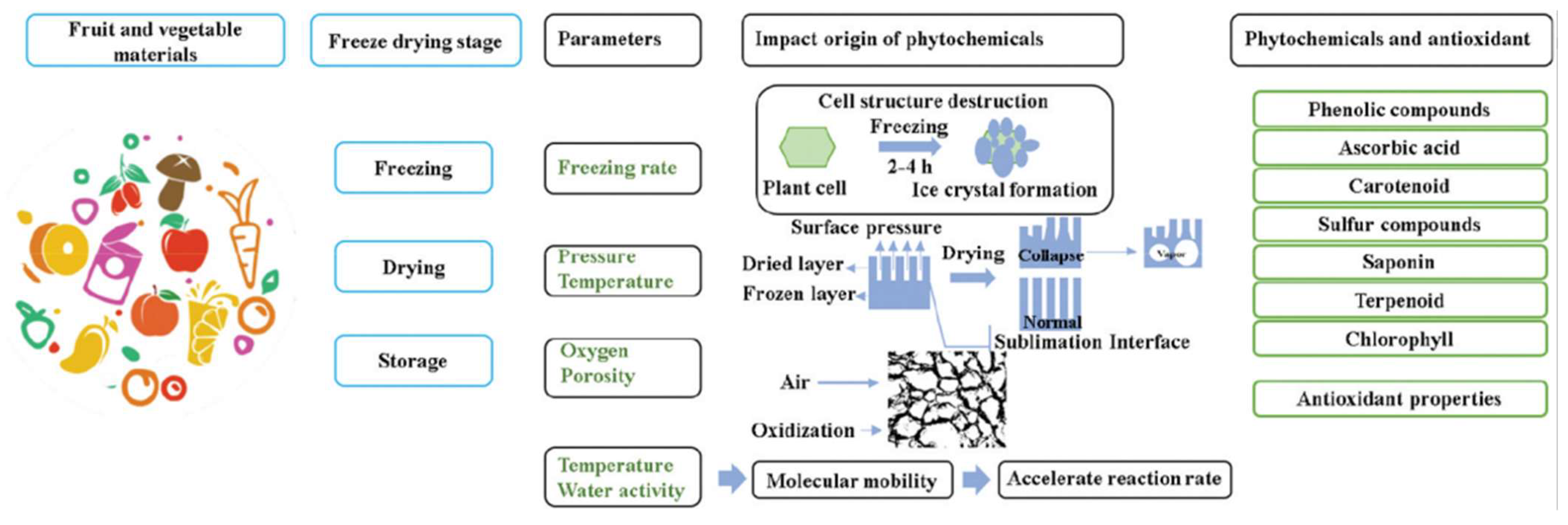

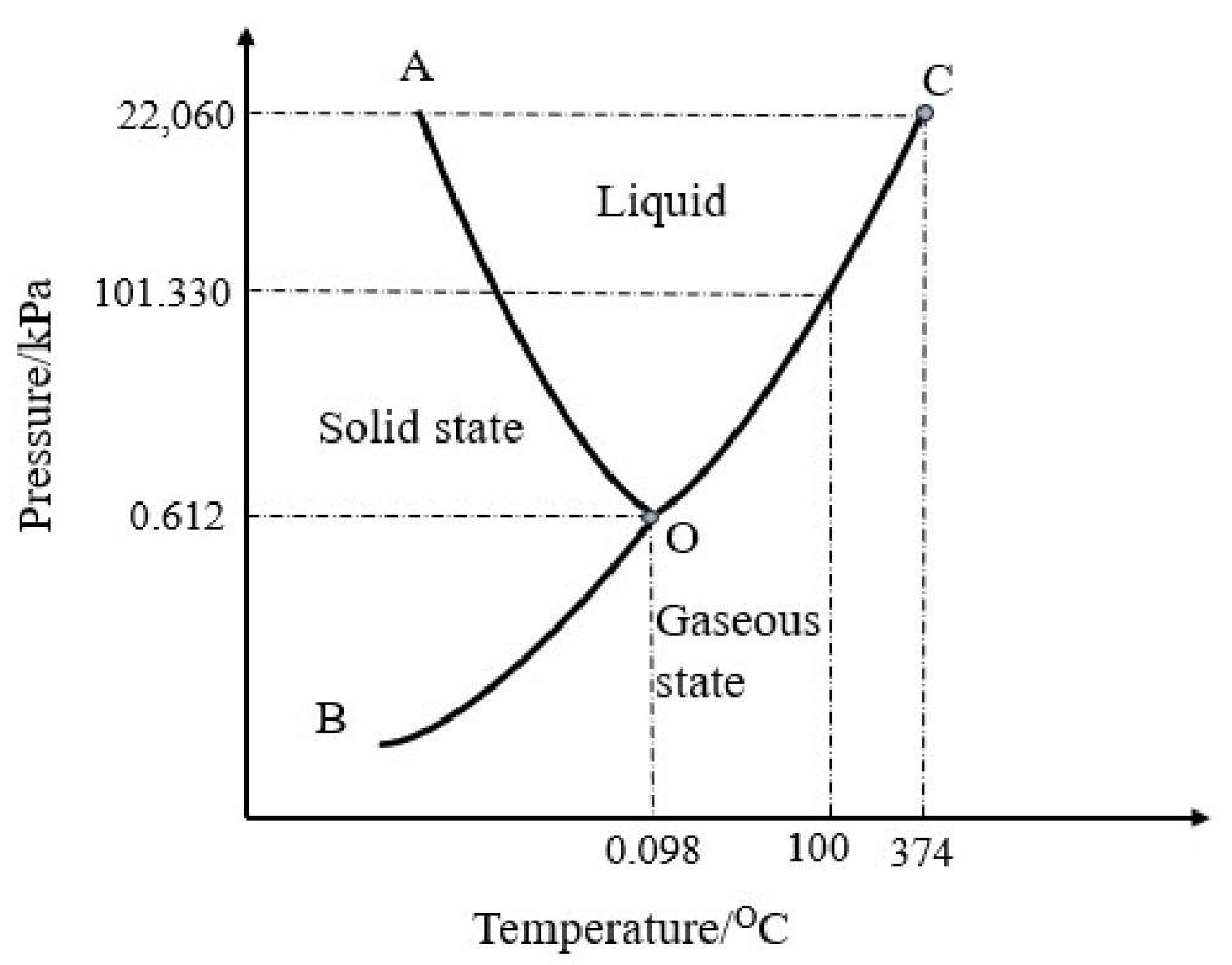

2. Freeze Drying

2.1. Principle of Freeze Drying

2.2. Mathematical Modelling of Freeze Drying

3. Physical Fields

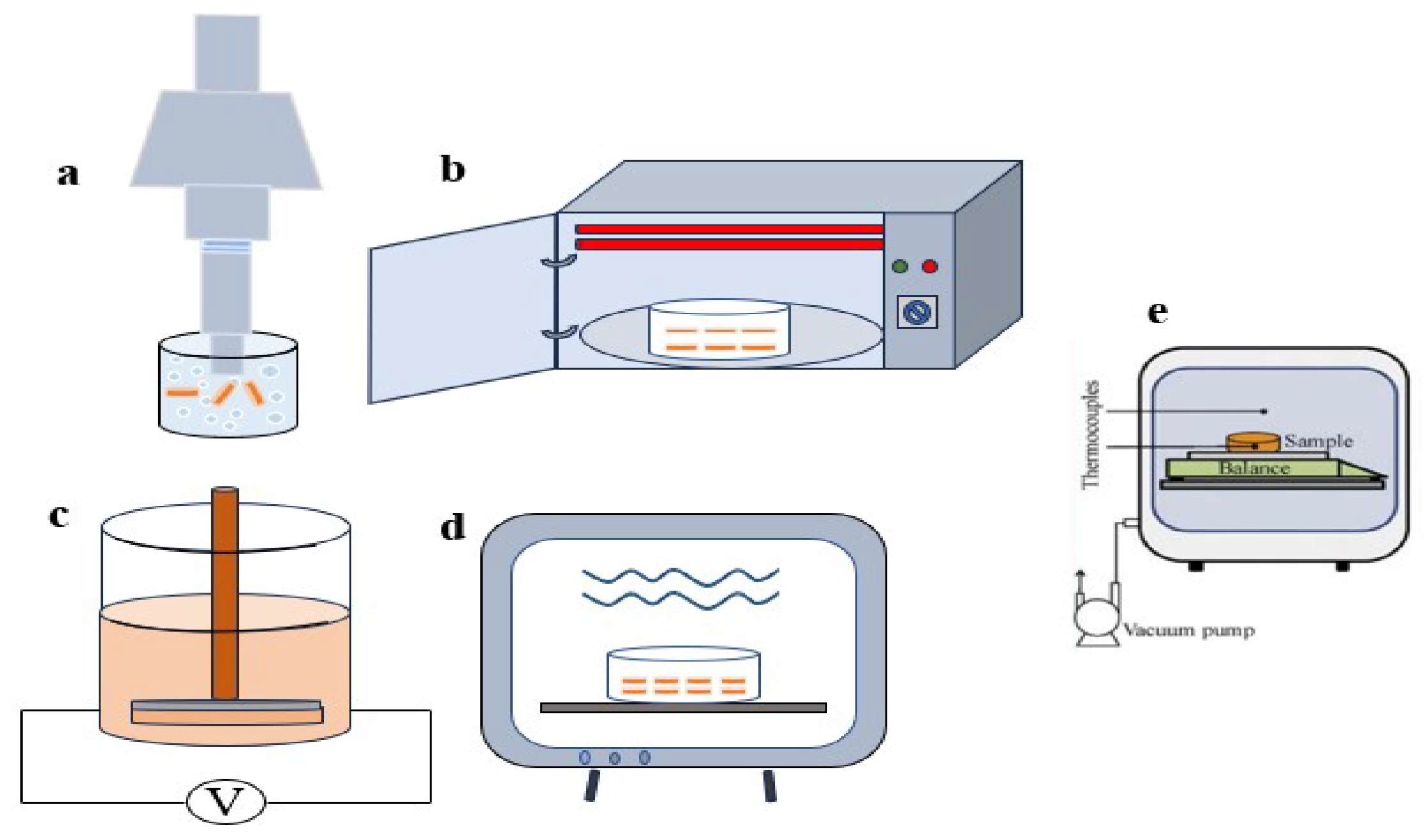

3.1. Ultrasound Technology

3.2. Infrared Radiation

3.3. Pulsed Electric Field

3.4. Microwave

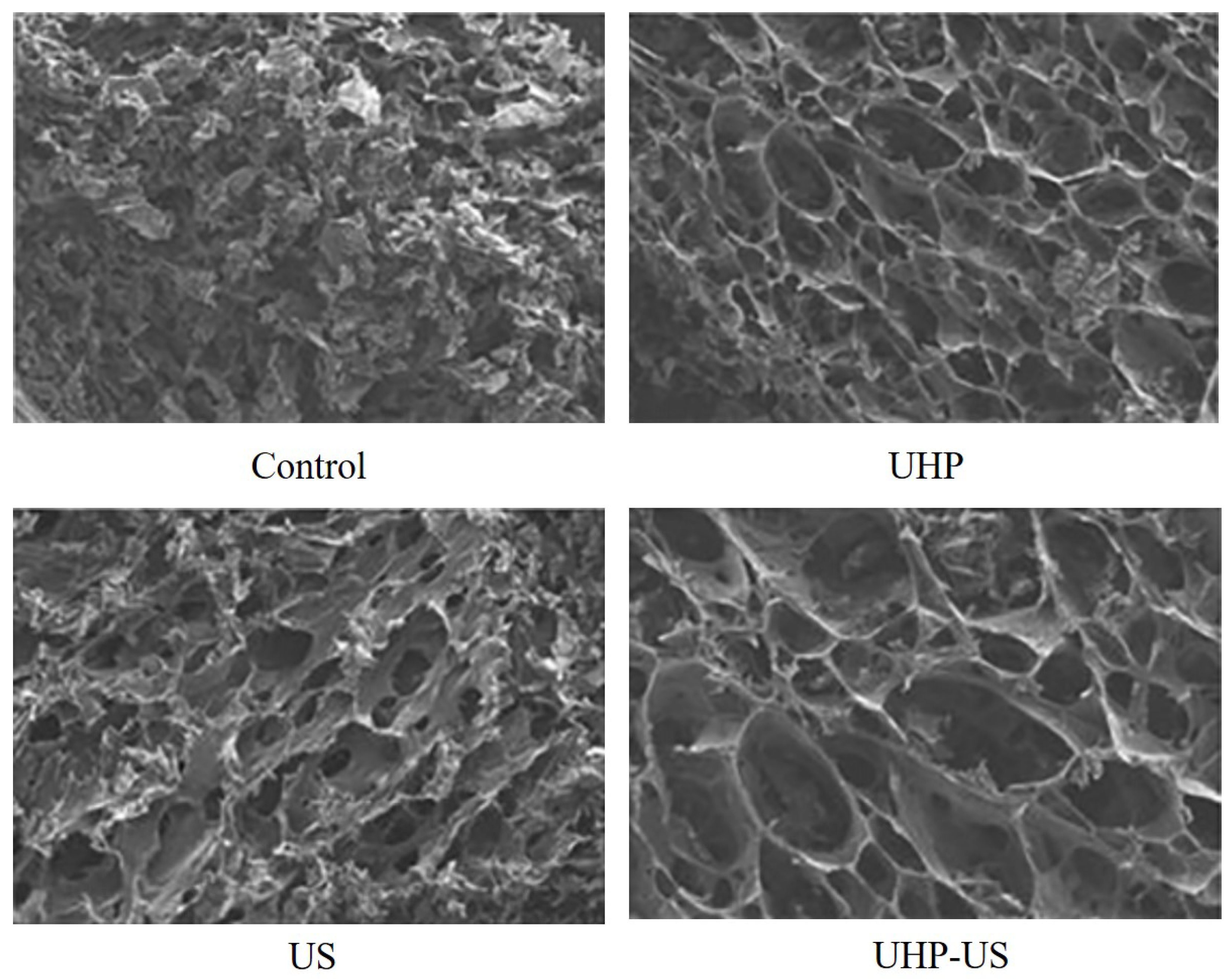

3.5. Ultra-High Pressure

4. High-Efficiency Physical Fields in Freeze Drying of Fruits and Vegetables

4.1. Ultrasound-Assisted Atmospheric Pressure Freeze Drying (AFD)

4.2. Ultrasound Pretreatment-Assisted Freeze Drying

4.3. Infrared Freeze Drying

| FVs | The Initial Moisture Content | Drying Conditions | Main Results | References |

|---|---|---|---|---|

| Apple | 5.89 ± 0.1 kg water/kg dm | Voltage: 220 V, wavelength: 3 μm, radiative heat flux: 0.11 W/m2 | The combination of IR drying and plasma treatment reduced the drying time by 18.0%, 13.0% and 10.5% for 5 mm, 7 mm and 10 mm apple slices, respectively, and reduced the total specific energy consumption. | Khudyakov et al. [92] |

| Açai puree | 94.65 ± 0.10% | Radiation power: 100 W, Infrared intensity: 2.0 W/m2, vacuum pressure: 99.8 Pa, T: 32–35 °C | Near IRFD and far IRFD saves 49.42% and 33.40% of drying time, respectively. | Oliveira et al. [52] |

| Banana | - | Radiant energy: 2.7 kW/m2, vacuum pressure: 267 Pa, distance: 150 mm; cold trap temperature: −100 °C | Continuous IRAFD can significantly reduce the drying time up to 213 min, saving more than 70% of time. Continuous IRAFD-2.7 kW/m2 fast drying can save electricity up to 8.4 × 103 kJ. | Khampakool et al. [86] |

| Chives | 90.74 ± 0.86% | T = 70 ± 5 °C | CIRD-FD significantly reduces the drying time for each intermediate moisture content by 1.1 to 3.8 h. | Gu et al. [90] |

| Cordyceps militaris | 636.92% db | Pressure: 80 Pa, the heat flux value: 0.703 W/cm2, T = 40, 50, 60, 70 °C | Under constant temperature drying conditions, RFD drying time is 7.21–17.78% shorter and energy consumption is 11.88–18.37% lower than TFD. | Wu et al. [89] |

| Pumpkin | 89.91 ± 0.29 g/ 100 g wb | Wavelength: 5–15 μm, T: 60 °C, t: 6 h | Compared to FD, FD-FIRD reduces the drying time and increases the hardness of the dried sample. | Chao et al. [91] |

| Pear | 81.03% wb | Infrared intensity: 3–5.5 kW/m2, wavelength of radiation: 2.4–3.0 µm | Mid-infrared freeze drying (MIR-FD) is fast and the drying time is 14.3~42.9% shorter than the FD method, and has a better rehydration capacity. | Antal et al. [87] |

| Quinoa | 10.3 ± 0.05% wb | Maximum heat flux density: 0.703 W/m2, W = 3 μm, pressure: 80 Pa, Infrared heating temperature: 50 °C, cold trap temperature: −40 °C | IRFD technology saves 18.2–22.7% of drying time compared to FD technology and maintains good rehydration capacity, texture and color. | Chen et al. [93] |

| Rose flowers | 82% | Pressure: 80 ± 3 Pa, the infrared glass lamps: 100 W, Infrared heating temperature: 50, 60, 70 °C, cold trap temperature: −40 °C | Compared to FD, IRPSFD offers a reduction in processing time of 8–30% and total energy savings of 15–36%. | Hnin et al. [85] |

| Strawberry | - | Radiation energy: 1.6 kW/m2, vacuum: 6.67 Pa; T = 25 °C | Compared to FD, continuous IRAFD significantly reduces drying times and consumes 42% less power. | Kang et al. [88] |

| Shiitake mushroom | 84 ± 1.7% | Wavelength zone: 2.3–3 μm, maximum power: 2.1 kW, Heating intensity: 5.8 kW/m2, T = 60 °C | MIRD in combination with FD saves 48% of drying time. | Wang et al. [94] |

4.4. Pulsed Electric Field Assisted Freeze Drying

| FVs | The Initial Moisture Content | Drying Conditions | Main Results | References |

|---|---|---|---|---|

| Apple | 85.1% | Electric field strength: 1.07 kV/cm, specific energy inputs: 0.5 kJ/kg, 1 kJ/kg | The PEF treatment reduced the apple drying time by 57% and enhanced the diffusion process, increasing the effective diffusion coefficient by 44%. | Lammerskitten et al. [97] |

| Apple | 83 ± 1% | Electric field strength: 1.07 kV/cm, specific energy inputs: 0.5 kJ/kg,1 kJ/kg, 5 kJ/kg | The treated samples retained their macroscopic shape better, inhibited and contracted macroporous processes, and had a high degree of brittleness. | Lammerskitten et al. [98] |

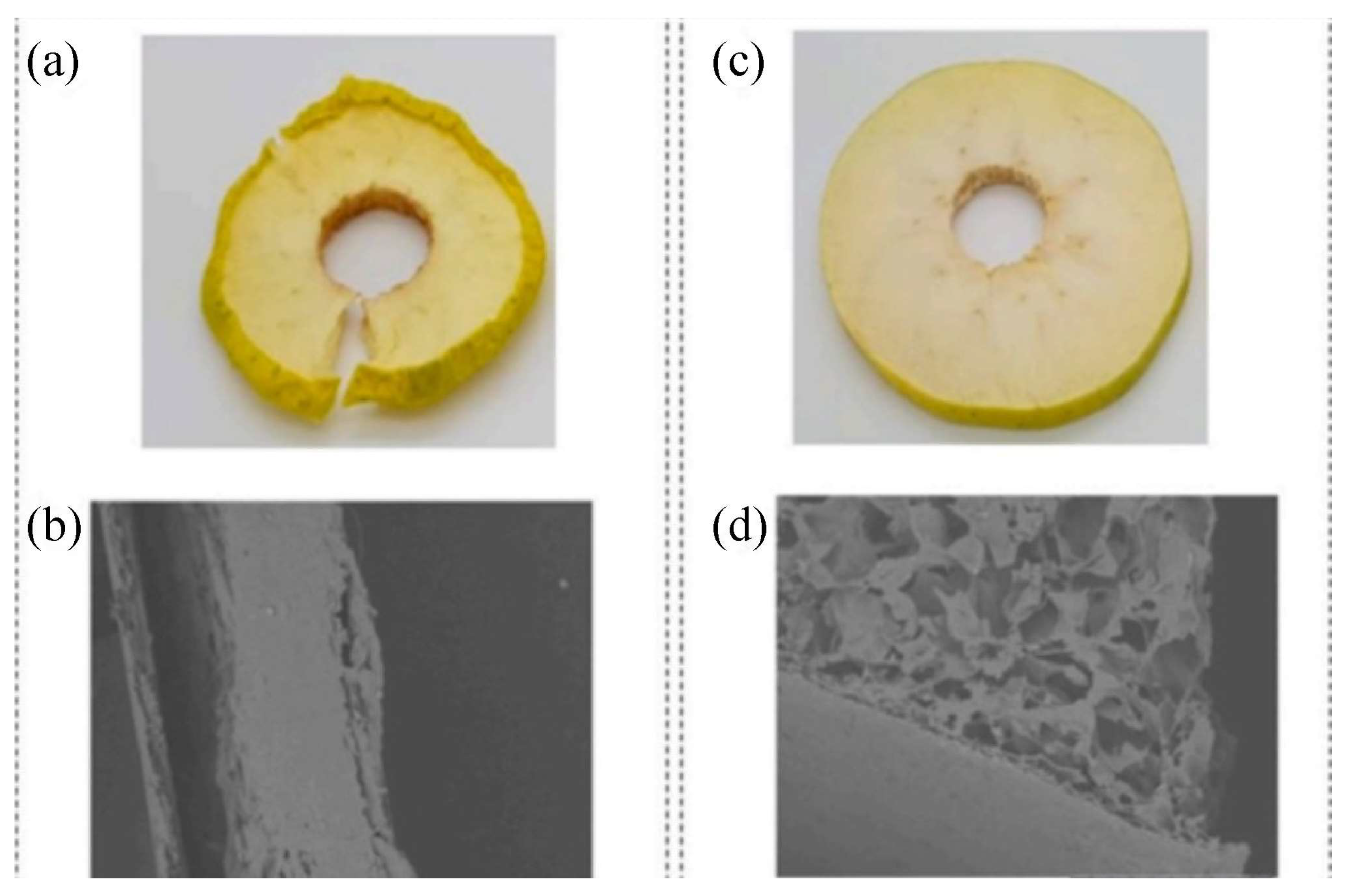

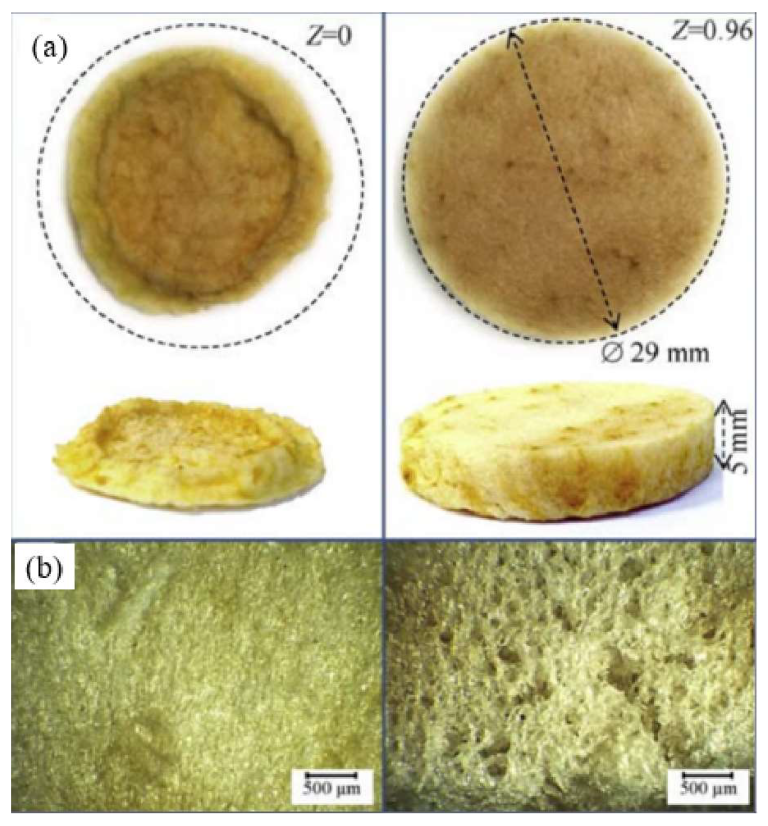

| Apple | 85% wb | Electric field strength: 800 V/cm | PEF-treated apples had excellent macroscopic shape and greater rehydration capacity, with an 86-fold increase in the pore size of the samples and a high level of rehydration capacity. | Parniakov et al. [36] |

| Apple | - | Electric field intensity: 1 kV/cm, voltage: 24 kV | PEF had a positive effect on drying rate, but PEF pretreatment damaged the cells by 25%. | Nowak et al. [100] |

| Potatoes | 89.91 ± 0.29 g/ 100 g wb | Electric field strength: E = 600 V/cm, total treatment time 26 of tPEF = 0.1 | PEF treatment had a positive effect on the freezing process of potatoes, and it accelerated the drying process. | Liu et al. [102] |

| Red beets and pineapples | 85.76 ± 1.31%, 82.36 ± 1.27% | Electric field strength: 1.07 kV/cm, specific energy inputs: 1 kJ/kg, 4 kJ/kg | After PEF treatment, the samples have less shrinkage, more uniform shape and better visual quality. | Ammelt et al. [59] |

| Strawberries and bell peppers | - | Electric field strength: 1.0 kV/cm, specific energy inputs: 0.3–6 kJ/kg | This resulted in a 50% increase in rehydration capacity, a 50% and 30% reduction in volume loss, respectively, and a 60% increase in hardness. | Fauster et al. [103] |

| Strawberries | 90 ± 0.8% | Electric field intensity: 1.07 kV/cm, specific energy input: 1 kJ/kg | Pretreated strawberries have better shape and volume retention and better visual quality, and are structurally dense. | Lammerskitten et al. [95] |

4.5. Microwave Freeze Drying (MFD)

| FVs | The Initial Moisture Content | Drying Parameters | Main Results | References |

|---|---|---|---|---|

| Apple | - | Microwave power: 3.18 W/g, Vacuum pressure: 9.15 kPa | FD-VMD combination drying reduces the total processing time of apples by up to 40%. | Li et al. [109] |

| Banana | 3.25 ± 0.03 g−1 db | Microwave power: 2, 2.5, 3, W/g; Vacuum pressure: 0.1 kPa, microwave frequency: 2450 MHz | The drying time decreases with increasing microwave power and the rehydration rate of the MFD sample is better than the MVD sample at >4.5. | Jiang et al. [110] |

| Banana | 3.25~3.67 g−1 db | Microwave power: 2 W/g, Vacuum pressure: 0.1 kPa, microwave frequency: 2450 MHz | Compared to FD, MFD can reduce drying time by 50% and has better rehydration capacity. | Jiang et al. [111] |

| Carrot | - | Microwave power: 2 W/g, Vacuum pressure: 0.1 kPa, cold trap temperature: 40 °C, microwave frequency: 2450 MHz | The rehydration rate of MWFD carrot slices was comparable to that of the freeze-dried (FD) samples and better than that of the MWVD and MWSD samples, but the drying rate was lower than that of the MWVD and MWSD. | Yan et al. [106] |

| Cordyceps militaris | - | Microwave power: 660, 760, 860 W, absolute pressure: 0.08 kPa, cold trap temperature: −40 °C | The final moisture content, water activity, rehydration time and rehydration rate of the MPFFD samples were similar to those of the FD samples, but MPFFD reduced the total drying time by 71.9%. | Wu et al. [112] |

| Hawthorns | 73.68 ± 0.15% wb | Microwave power: 1 kW, Vacuum pressure: 0.05 Pa, cold trap temperature: −40 °C | MFDs are more energy intensive and take longer to dry than HPDs. | Duan et al. [105] |

| Lettuce | - | Microwave power: 800 W, microwave frequency: 2450 MHz | MFD samples take more than 20% longer than PSMFD in total drying time and PSMFD dries more uniformly. | Wang et al. [113] |

| Mushrooms | 90% wb | Microwave power: 1 kW, Vacuum pressure: 0.05 kPa, cold trap temperature: −40 °C | The drying time for MFD is 8 h, which is much lower than AFD and FD. | Xu. et al. [104] |

| Purple-fleshed sweet potato granules | - | Microwave power: 4 W/g, Vacuum pressure: 4.5 kPa | MWFD takes longer than MWVD and MWSBD to complete drying and MWFD consumes approximately twice as much energy as MWVD. | Liu et al. [107] |

| Pineapple | - | Microwave power: 6 W/g, microwave frequency: 2450 MHz | Microwave-assisted freeze drying is 34.5% more energy efficient than pure vacuum drying and reduces drying time by 33.3%. | Chen et al. [114] |

| FVs | The Initial Moisture Content | Drying Conditions | Main Results | References |

|---|---|---|---|---|

| Banana | 3.34 ± 0.03 g/g db | Microwave power: 2 W/g, Vacuum pressure: 0.1 kPa, cold trap temperature: 40 °C, microwave frequency: 2450 MHz | Changes in starch content, reducing sugar content, structure and color of the banana slices are greatest in the primary drying stage, and the greatest change in swelling rate is in the secondary drying stage. | Jiang et al. [115] |

| Carrot | - | Microwave power: 2 W/g, Vacuum pressure: 0.1 kPa, cold trap temperature: 40 °C | MWFD carrot slices have the highest retention of carotenoids and vitamin C. | Yan et al. [106] |

| Lettuce | - | Microwave power: 800 W, microwave frequency: 2450 MHz | Compared to MFD, PSMFD samples have a uniform and dense microstructure, less color discoloration and better quality. | Wang et al. [113] |

| Purple-fleshed sweet potato granules | - | Absolute pressure: 10–30 kPa | MWFD was able to maintain a high phalloidin content of 74.98% compared to 71.41% and 53.76% for MWVD and MWSBD, respectively. The MWFD product also had good brittleness but the MWSBD product had better color and appearance. | Liu et al. [107] |

| Yam | 79.25 ± 1.84 g/100 g | Microwave power: 2 W/g; Vacuum pressure: 0.08 kPa | The MFD treated samples maintained good color and had the highest PV and FV values. | Duan et al. [108] |

5. Energy Consumption

6. Trends and Challenges for the Future

6.1. Establishing the Correlation between Drying Methods and Fruit and Vegetable Characteristics

6.2. Artificial Intelligence Technology Drives the Development of Fruit and Vegetable Drying

6.3. Synergistic Application of Multiple Drying Methods

6.4. Reducing Economic Losses

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- do Nascimento, E.M.G.C.; Mulet, A.; Ascheri, J.L.R.; de Carvalho, C.W.P.; Cárcel, J.A. Effects of high-intensity ultrasound on drying kinetics and antioxidant properties of passion fruit peel. J. Food Eng. 2016, 170, 108–118. [Google Scholar] [CrossRef]

- Menon, A.; Stojceska, V.; Tassou, S.A. A systematic review on the recent advances of the energy efficiency improvements in non-conventional food drying technologies. Trends Food Sci. Technol. 2020, 100, 67–76. [Google Scholar] [CrossRef]

- Guo, X.; Hao, Q.; Qiao, X.; Li, M.; Qiu, Z.; Zheng, Z.; Zhang, B. An evaluation of different pretreatment methods of hot-air drying of garlic: Drying characteristics, energy consumption and quality properties. LWT 2023, 180, 114685. [Google Scholar] [CrossRef]

- Dehghannya, J.; Hosseinlar, S.-H.; Heshmati, M.K. Multi-stage continuous and intermittent microwave drying of quince fruit coupled with osmotic dehydration and low temperature hot air drying. Innov. Food Sci. Emerg. Technol. 2018, 45, 132–151. [Google Scholar] [CrossRef]

- Aktaş, M.; Khanlari, A.; Amini, A.; Şevik, S. Performance analysis of heat pump and infrared–heat pump drying of grated carrot using energy-exergy methodology. Energy Convers. Manag. 2017, 132, 327–338. [Google Scholar] [CrossRef]

- Adak, N.; Heybeli, N.; Ertekin, C. Infrared drying of strawberry. Food Chem. 2017, 219, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Eun, J.B.; Maruf, A.; Das, P.R.; Nam, S.H. A review of encapsulation of carotenoids using spray drying and freeze drying. Crit. Rev. Food Sci. Nutr. 2020, 60, 3547–3572. [Google Scholar] [CrossRef] [PubMed]

- Shofian, N.M.; Hamid, A.A.; Osman, A.; Saari, N.; Anwar, F.; Dek, M.S.; Hairuddin, M.R. Effect of freeze-drying on the antioxidant compounds and antioxidant activity of selected tropical fruits. Int. J. Mol. Sci. 2011, 12, 4678–4692. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Z.; Hu, L. High efficient freeze-drying technology in food industry. Crit. Rev. Food Sci. Nutr. 2022, 62, 3370–3388. [Google Scholar] [CrossRef]

- Zotarelli, M.F.; Durigon, A.; da Silva, V.M.; Hubinger, M.D.; Laurindo, J.B. Rehydration of mango powders produced by cast-tape drying, freeze drying, and spray drying. Dry. Technol. 2020, 40, 175–187. [Google Scholar] [CrossRef]

- Silva, N.C.; Santana, R.C.; Duarte, C.R.; Barrozo, M.A.S. Impact of freeze-drying on bioactive compounds of yellow passion fruit residues. J. Food Process Eng. 2017, 40, e12514. [Google Scholar] [CrossRef]

- Du, T.; Xu, J.; Zhu, S.; Yao, X.; Guo, J.; Lv, W. Effects of spray drying, freeze drying, and vacuum drying on physicochemical and nutritional properties of protein peptide powder from salted duck egg white. Front. Nutr. 2022, 9, 1026903. [Google Scholar] [CrossRef]

- Bhatta, S.; Stevanovic Janezic, T.; Ratti, C. Freeze-drying of plant-based foods. Foods 2020, 9, 87. [Google Scholar] [CrossRef]

- Duan, X.; Yang, X.; Ren, G.; Pang, Y.; Liu, L.; Liu, Y. Technical aspects in freeze-drying of foods. Dry. Technol. 2015, 34, 1271–1285. [Google Scholar] [CrossRef]

- Assegehegn, G.; Brito-de la Fuente, E.; Franco, J.M.; Gallegos, C. The Importance of Understanding the Freezing Step and Its Impact on Freeze-Drying Process Performance. J. Pharm. Sci. 2019, 108, 1378–1395. [Google Scholar] [CrossRef]

- Ma, Y.; Yi, J.; Jin, X.; Li, X.; Feng, S.; Bi, J. Freeze-drying of fruits and vegetables in food industry: Effects on phytochemicals and bioactive properties attributes A comprehensive review. Food Rev. Int. 2023, 39, 6611–6629. [Google Scholar] [CrossRef]

- Nakagawa, K.; Tamiya, S. Influence of inner vapor transfer property of a freeze dryer on the design space of drying process. AIChE J. 2019, 65, e16571. [Google Scholar] [CrossRef]

- Duan, X.; Ding, L.; Ren, G.-y.; Liu, L.; Kong, Q. The drying strategy of atmospheric freeze drying apple cubes based on glass transition. Food Bioprod. Process. 2013, 91, 534–538. [Google Scholar] [CrossRef]

- Sandall, C.O.; King, C.J.; Wilke, C.R. The relationship between transport properties and rates of freeze-drying of poultry meat. AlChE J. 1967, 13, 428–438. [Google Scholar] [CrossRef]

- Nakagawa, K.; Ochiai, T. A mathematical model of multi-dimensional freeze-drying for food products. J. Food Eng. 2015, 161, 55–67. [Google Scholar] [CrossRef]

- Chaurasiya, V.; Singh, J. An analytical study of coupled convective heat and mass transfer with volumetric heating describing sublimation of a porous body under most sensitive temperature inputs: Application of freeze-drying. Int. J. Heat Mass Transf. 2023, 214, 124294. [Google Scholar] [CrossRef]

- Srisuma, P.; Barbastathis, G.; Braatz, R.D. Analytical solutions for the modeling, optimization, and control of microwave-assisted freeze drying. Comput. Chem. Eng. 2023, 177, 108318. [Google Scholar] [CrossRef]

- Zhang, Y.; Abatzoglou, N. Review: Fundamentals, applications and potentials of ultrasound-assisted drying. Chem. Eng. Res. Des. 2020, 154, 21–46. [Google Scholar] [CrossRef]

- Fernandes, F.A.N.; Braga, T.R.; Silva, E.O.; Rodrigues, S. Use of ultrasound for dehydration of mangoes (Mangifera indica L.): Kinetic modeling of ultrasound-assisted osmotic dehydration and convective air-drying. J. Food Sci. Technol. 2019, 56, 1793–1800. [Google Scholar] [CrossRef] [PubMed]

- Naik, A.S.; Suryawanshi, D.; Kumar, M.; Waghmare, R. Ultrasonic treatment: A cohort review on bioactive compounds, allergens and physico-chemical properties of food. Curr. Res. Food Sci. 2021, 4, 470–477. [Google Scholar] [CrossRef] [PubMed]

- Fan, K.; Wu, J.X.; Chen, L.B. Ultrasound and its combined application in the improvement of microbial and physicochemical quality of fruits and vegetables: A review. Ultrason. Sonochemistry 2021, 80, 105838. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Fan, K. Influence of ultrasound treatment in combination with modified atmosphere on microorganisms and quality attributes of fresh-cut lettuce. Int. J. Food Sci. Technol. 2021, 56, 5242–5249. [Google Scholar] [CrossRef]

- Huang, D.; Men, K.; Li, D.; Wen, T.; Gong, Z.; Sunden, B.; Wu, Z. Application of ultrasound technology in the drying of food products. Ultrason. Sonochemistry 2020, 63, 104950. [Google Scholar] [CrossRef]

- Xu, B.; Sylvain Tiliwa, E.; Yan, W.; Roknul Azam, S.M.; Wei, B.; Zhou, C.; Ma, H.; Bhandari, B. Recent development in high quality drying of fruits and vegetables assisted by ultrasound: A review. Food Res. Int. 2022, 152, 110744. [Google Scholar] [CrossRef]

- Colucci, D.; Fissore, D.; Rossello, C.; Carcel, J.A. On the effect of ultrasound-assisted atmospheric freeze-drying on the antioxidant properties of eggplant. Food Res. Int. 2018, 106, 580–588. [Google Scholar] [CrossRef]

- Waghmare, R.; Kumar, M.; Yadav, R.; Mhatre, P.; Sonawane, S.; Sharma, S.; Gat, Y.; Chandran, D.; Radha; Hasan, M.; et al. Application of ultrasonication as pre-treatment for freeze drying: An innovative approach for the retention of nutraceutical quality in foods. Food Chem. 2023, 404, 134571. [Google Scholar] [CrossRef]

- van Wijngaarden, L. Mechanics of collapsing cavitation bubbles. Ultrason. Sonochemistry 2016, 29, 524–527. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.X.; Zhang, L.; Fan, K. Recent advances in ultrasound-coupled drying for improving the quality of fruits and vegetables: A review. Int. J. Food Sci. Technol. 2022, 57, 5722–5731. [Google Scholar] [CrossRef]

- Wu, J.; Jia, X.; Fan, K. Recent advances in the improvement of freezing time and physicochemical quality of frozen fruits and vegetables by ultrasound application. Int. J. Food Sci. Technol. 2022, 57, 3352–3360. [Google Scholar] [CrossRef]

- Rodríguez, Ó.; Eim, V.; Rosselló, C.; Femenia, A.; Cárcel, J.A.; Simal, S. Application of power ultrasound on the convective drying of fruits and vegetables: Effects on quality. J. Sci. Food Agric. 2017, 98, 1660–1673. [Google Scholar] [CrossRef] [PubMed]

- Parniakov, O.; Bals, O.; Lebovka, N.; Vorobiev, E. Pulsed electric field assisted vacuum freeze-drying of apple tissue. Innov. Food Sci. Emerg. Technol. 2016, 35, 52–57. [Google Scholar] [CrossRef]

- Huang, D.; Yang, P.; Tang, X.; Luo, L.; Sunden, B. Application of infrared radiation in the drying of food products. Trends Food Sci. Technol. 2021, 110, 765–777. [Google Scholar] [CrossRef]

- Zhang, W.P.; Chen, C.; Pan, Z.; Xiao, H.W.; Xie, L.; Gao, Z.J.; Zheng, Z.A. Design and performance evaluation of a pilot-scale pulsed vacuum infrared drying (PVID) system for drying of berries. Dry. Technol. 2019, 38, 1340–1355. [Google Scholar] [CrossRef]

- Delfiya, D.S.A.; Prashob, K.; Murali, S.; Alfiya, P.V.; Samuel, M.P.; Pandiselvam, R. Drying kinetics of food materials in infrared radiation drying: A review. J. Food Process Eng. 2021, 45, e13810. [Google Scholar] [CrossRef]

- Qiu, L.; Zhang, M.; Mujumdar, A.S.; Chang, L. Convenient use of near-infrared spectroscopy to indirectly predict the antioxidant activitiy of edible rose (Rose chinensis Jacq “Crimsin Glory” H.T.) petals during infrared drying. Food Chem. 2022, 369, 130951. [Google Scholar] [CrossRef]

- Alaei, B.; Amiri Chayjan, R. Drying Characteristics of Pomegranate Arils Under Near Infrared-Vacuum Conditions. J. Food Process. Preserv. 2015, 39, 469–479. [Google Scholar] [CrossRef]

- Pyrka, I.; Mantzouridou, F.T.; Nenadis, N. Optimization of olive leaves’ thin layer, intermittent near-infrared-drying. Innov. Food Sci. Emerg. Technol. 2023, 84, 103264. [Google Scholar] [CrossRef]

- Brandao, S.C.R.; da Silva, E.M.; de Arruda, G.M.P.; Netto, J.M.D.; de Medeiros, R.A.B.; Honorato, F.A.; Azoubel, P.M. Ethanol pretreatment and infrared drying of melon: Kinetics, quality parameters, and NIR spectra. J. Food Process Eng. 2023, 46, e14269. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hashim, N.; Abdan, K.; Janius, R.; Chen, G. Modelling the mid-infrared drying of sweet potato: Kinetics, mass and heat transfer parameters, and energy consumption. Heat Mass Transf. 2018, 54, 2917–2933. [Google Scholar] [CrossRef]

- Wang, N.; Yang, S.Y.; Zhang, Y.F.; Jiang, L.; Zheng, X.C.; Jiang, P.Y.; Chen, Y. Drying kinetics and quality characteristics of daylily dried by mid-infrared. Int. J. Food Eng. 2021, 17, 969–979. [Google Scholar] [CrossRef]

- Nathakaranakule, A.; Jaiboon, P.; Soponronnarit, S. Far-infrared radiation assisted drying of longan fruit. J. Food Eng. 2010, 100, 662–668. [Google Scholar] [CrossRef]

- Fernando, A.J.; Gunathunga, C.; Brumm, T.; Amaratunga, S. Drying turmeric (Curcuma longa L.) using far-Infrared radiation: Drying characteristics and process optimization. J. Food Process Eng. 2021, 44, e13780. [Google Scholar] [CrossRef]

- Liu, Y.H.; Miao, S.; Wu, J.Y.; Liu, J.X.; Yu, H.C.; Duan, X. Drying Characteristics and Modeling of Vacuum Far-Infrared Radiation Drying of Flos Lonicerae. J. Food Process. Preserv. 2015, 39, 338–348. [Google Scholar] [CrossRef]

- Liu, Y.H.; Li, X.F.; Zhu, W.X.; Luo, L.; Duan, X.; Yin, Y. Drying characteristics, kinetics model and effective moisture diffusivity of vacuum far-infrared dried Rehmanniae. Int. J. Agric. Biol. Eng. 2016, 9, 208–217. [Google Scholar]

- Jiang, C.H.; Wan, F.X.; Zang, Z.P.; Zhang, Q.; Xu, Y.R.; Huang, X.P. Influence of far-infrared vacuum drying on drying kinetics and quality characteristics of Cistanche slices. J. Food Process. Preserv. 2022, 46, e17144. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Liu, Y.H.; Sun, Z.K.; Bai, X.T.; Chen, Y.F. Drying characteristics and optimization of ultrasound-strengthened cold air drying combined with sequential far-infrared radiation drying on potato. J. Food Process. Preserv. 2020, 44, e14632. [Google Scholar] [CrossRef]

- Oliveira, N.L.; Silva, S.H.; Figueiredo, J.d.A.; Norcino, L.B.; Resende, J.V.D. Infrared-assisted freeze-drying (IRFD) of açai puree: Effects on the drying kinetics, microstructure and bioactive compounds. Innov. Food Sci. Emerg. Technol. 2021, 74, 102843. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, M.; Bhandari, B.; Li, Z. Effects of microwave-assisted pulse-spouted bed freeze-drying (MPSFD) on volatile compounds and structural aspects of Cordyceps militaris. J. Sci. Food Agric. 2018, 98, 4634–4643. [Google Scholar] [CrossRef] [PubMed]

- Lin, Q.; Zong, X.; Lin, H.; Huang, X.; Wang, J.; Nie, S. Based on quality, energy consumption selecting optimal drying methods of mango slices and kinetics modelling. Food Chem. X 2023, 17, 100600. [Google Scholar] [CrossRef] [PubMed]

- Dehghannya, J.; Ngadi, M. The application of pretreatments for producing low-fat fried foods: A review. Trends Food Sci. Technol. 2023, 140, 104150. [Google Scholar] [CrossRef]

- Zhang, C.; Lyu, X.; Zhao, W.; Yan, W.; Wang, M.; Kuan Rei, N.G.; Yang, R. Effects of combined pulsed electric field and blanching pretreatment on the physiochemical properties of French fries. Innov. Food Sci. Emerg. Technol. 2021, 67, 102561. [Google Scholar] [CrossRef]

- Ostermeier, R.; Hill, K.; Dingis, A.; Töpfl, S.; Jäger, H. Influence of pulsed electric field (PEF) and ultrasound treatment on the frying behavior and quality of potato chips. Innov. Food Sci. Emerg. Technol. 2021, 67, 102553. [Google Scholar] [CrossRef]

- Barba, F.J.; Parniakov, O.; Pereira, S.A.; Wiktor, A.; Grimi, N.; Boussetta, N.; Saraiva, J.A.; Raso, J.; Martin-Belloso, O.; Witrowa-Rajchert, D.; et al. Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Res. Int. 2015, 77, 773–798. [Google Scholar] [CrossRef]

- Ammelt, D.; Lammerskitten, A.; Wiktor, A.; Barba, F.J.; Toepfl, S.; Parniakov, O. The impact of pulsed electric fields on quality parameters of freeze-dried red beets and pineapples. Int. J. Food Sci. Technol. 2020, 56, 1777–1787. [Google Scholar] [CrossRef]

- Demir, E.; Tappi, S.; Dymek, K.; Rocculi, P.; Gómez Galindo, F. Reversible electroporation caused by pulsed electric field Opportunities and challenges for the food sector. Trends Food Sci. Technol. 2023, 139, 104120. [Google Scholar] [CrossRef]

- Ghoshal, G. Comprehensive review on pulsed electric field in food preservation: Gaps in current studies for potential future research. Heliyon 2023, 9, e17532. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Wang, C.; Guo, Y. Effects of the high-pulsed electric field pretreatment on the mechanical properties of fruits and vegetables. J. Food Eng. 2020, 274, 109837. [Google Scholar] [CrossRef]

- Onwude, D.I.; Hashim, N.; Chen, G. Recent advances of novel thermal combined hot air drying of agricultural crops. Trends Food Sci. Technol. 2016, 57, 132–145. [Google Scholar] [CrossRef]

- González-Cavieres, L.; Pérez-Won, M.; Tabilo-Munizaga, G.; Jara-Quijada, E.; Díaz-Álvarez, R.; Lemus-Mondaca, R. Advances in vacuum microwave drying (VMD) systems for food products. Trends Food Sci. Technol. 2021, 116, 626–638. [Google Scholar] [CrossRef]

- Fan, K.; Zhang, M.; Mujumdar, A.S. Recent developments in high efficient freeze-drying of fruits and vegetables assisted by microwave: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 1357–1366. [Google Scholar] [CrossRef] [PubMed]

- Duan, X.; Zhang, M.; Mujumdar, A.S.; Wang, R. Trends in microwave-assisted freeze drying of foods. Dry. Technol. 2010, 28, 444–453. [Google Scholar] [CrossRef]

- Cao, X.; Zhang, M.; Mujumdar, A.S.; Zhong, Q.; Wang, Z. Effect of microwave freeze drying on quality and energy supply in drying of barley grass. J. Sci. Food Agric. 2018, 98, 1599–1605. [Google Scholar] [CrossRef]

- Zahoor, I.; Mir, T.A.; Ayoub, W.S.; Farooq, S.; Ganaie, T.A. Recent applications of microwave technology as novel drying of food Review. Food Humanit. 2023, 1, 92–103. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, L.; Qiao, Y.; Liao, L.; Shi, D.; Wang, J.; Shi, L. Effects of ultrasound and ultra-high pressure pretreatments on volatile and taste compounds of vacuum-freeze dried strawberry slice. LWT 2022, 160, 113232. [Google Scholar] [CrossRef]

- Sun, M.; Wei, X.; Wang, H.; Xu, C.; Wei, B.; Zhang, J.; He, L.; Xu, Y.; Li, S. Structure restoration of thermally denatured collagen by ultrahigh pressure treatment. Food Bioprocess Technol. 2019, 13, 367–378. [Google Scholar] [CrossRef]

- Santacatalina, J.V.; Fissore, D.; Cárcel, J.A.; Mulet, A.; García-Pérez, J.V. Model-based investigation into atmospheric freeze drying assisted by power ultrasound. J. Food Eng. 2015, 151, 7–15. [Google Scholar] [CrossRef]

- Merone, D.; Colucci, D.; Fissore, D.; Sanjuan, N.; Carcel, J.A. Energy and environmental analysis of ultrasound-assisted atmospheric freeze-drying of food. J. Food Eng. 2020, 283, 110031. [Google Scholar] [CrossRef]

- Carrión, C.; Mulet, A.; García-Pérez, J.V.; Cárcel, J.A. Ultrasonically assisted atmospheric freeze-drying of button mushroom. Drying kinetics and product quality. Dry. Technol. 2018, 36, 1814–1823. [Google Scholar] [CrossRef]

- Moreno, C.; Brines, C.; Mulet, A.; Rosselló, C.; Cárcel, J.A. Antioxidant potential of atmospheric freeze-dried apples as affected by ultrasound application and sample surface. Dry. Technol. 2017, 35, 957–968. [Google Scholar] [CrossRef]

- Garcia-Perez, J.V.; Carcel, J.A.; Riera, E.; Rosselló, C.; Mulet, A. Intensification of Low-Temperature Drying by Using Ultrasound. Dry. Technol. 2012, 30, 1199–1208. [Google Scholar] [CrossRef]

- Brines, C.; Mulet, A.; García-Pérez, J.V.; Riera, E.; Cárcel, J.A. Influence of the ultrasonic power applied on freeze drying kinetics. Phys. Procedia 2015, 70, 850–853. [Google Scholar] [CrossRef]

- Mello, R.E.; Fontana, A.; Mulet, A.; Correa, J.L.G.; Cárcel, J.A. Ultrasound-assisted drying of orange peel in atmospheric freeze-dryer and convective dryer operated at moderate temperature. Dry. Technol. 2019, 38, 259–267. [Google Scholar] [CrossRef]

- Ren, F.; Perussello, C.A.; Zhang, Z.; Kerry, J.P.; Tiwari, B.K. Impact of ultrasound and blanching on functional properties of hot-air dried and freeze dried onions. LWT 2018, 87, 102–111. [Google Scholar] [CrossRef]

- Zhang, L.; Liao, L.; Qiao, Y.; Wang, C.; Shi, D.; An, K.; Hu, J. Effects of ultrahigh pressure and ultrasound pretreatments on properties of strawberry chips prepared by vacuum-freeze drying. Food Chem. 2020, 303, 125386. [Google Scholar] [CrossRef]

- Xu, B.; Chen, J.; Sylvain Tiliwa, E.; Yan, W.; Roknul Azam, S.M.; Yuan, J.; Wei, B.; Zhou, C.; Ma, H. Effect of multi-mode dual-frequency ultrasound pretreatment on the vacuum freeze-drying process and quality attributes of the strawberry slices. Ultrason. Sonochemistry 2021, 78, 105714. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, L.; Feng, Y.; Zhou, C.; Yagoub, A.E.A.; Wahia, H.; Ma, H.; Zhang, J.; Sun, Y. Ultrasound freeze-thawing style pretreatment to improve the efficiency of the vacuum freeze-drying of okra (Abelmoschus esculentus (L.) Moench) and the quality characteristics of the dried product. Ultrason. Sonochemistry 2021, 70, 105300. [Google Scholar] [CrossRef] [PubMed]

- Lyu, Y.; Bi, J.; Chen, Q.; Li, X.; Wu, X.; Gou, M. Effects of ultrasound, heat, ascorbic acid and CaCl(2) treatments on color enhancement and flavor changes of freeze-dried carrots during the storage period. Food Chem. 2022, 373, 131526. [Google Scholar] [CrossRef] [PubMed]

- Lyu, Y.; Bi, J.; Chen, Q.; Wu, X.; Gou, M.; Yang, X. Color enhancement mechanisms analysis of freeze-dried carrots treated by ultrasound-assisted osmosis (ascorbic acid-CaCl(2)) dehydration. Food Chem. 2022, 381, 132255. [Google Scholar] [CrossRef] [PubMed]

- Cao, X.; Zhang, M.; Mujumdar, A.S.; Zhong, Q.; Wang, Z. Effects of ultrasonic pretreatments on quality, energy consumption and sterilization of barley grass in freeze drying. Ultrason. Sonochemistry 2018, 40, 333–340. [Google Scholar] [CrossRef] [PubMed]

- Hnin, K.K.; Zhang, M.; Ju, R.; Wang, B. A novel infrared pulse-spouted freeze drying on the drying kinetics, energy consumption and quality of edible rose flowers. LWT 2021, 136, 110318. [Google Scholar] [CrossRef]

- Khampakool, A.; Soisungwan, S.; Park, S.H. Potential application of infrared assisted freeze drying (IRAFD) for banana snacks: Drying kinetics, energy consumption, and texture. LWT 2019, 99, 355–363. [Google Scholar] [CrossRef]

- Antal, T.; Tarek-Tilistyák, J.; Cziáky, Z.; Sinka, L. Comparison of drying and quality characteristics of pear (Pyrus Communis L.) using mid-infrared-freeze drying and single stage of freeze drying. Int. J. Food Eng. 2017, 13, 20160294. [Google Scholar] [CrossRef]

- Kang, S.W.; Hwang, J.H.; Chung, K.H.; Park, S.H. Evaluation of infrared assisted freeze drying for strawberry snacks: Drying kinetics, energy efficiency and quality attributes. Food Sci. Biotechnol. 2021, 30, 1087–1096. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, M.; Bhandari, B. A novel infrared freeze drying (IRFD) technology to lower the energy consumption and keep the quality of Cordyceps militaris. Innov. Food Sci. Emerg. Technol. 2019, 54, 34–42. [Google Scholar] [CrossRef]

- Gu, C.; Ma, H.; Tuly, J.A.; Guo, L.; Zhang, X.; Liu, D.; Ouyang, N.; Luo, X.; Shan, Y. Effects of catalytic infrared drying in combination with hot air drying and freeze drying on the drying characteristics and product quality of chives. LWT 2022, 161, 113363. [Google Scholar] [CrossRef]

- Chao, E.; Li, J.; Fan, L. Influence of combined freeze-drying and far-infrared drying technologies on physicochemical properties of seed-used pumpkin. Food Chem. 2023, 398, 133849. [Google Scholar] [CrossRef] [PubMed]

- Khudyakov, D.; Sosnin, M.; Shorstkii, I.; Okpala, C.O.R. Cold filamentary microplasma pretreatment combined with infrared dryer: Effects on drying efficiency and quality attributes of apple slices. J. Food Eng. 2022, 329, 111049. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, M.; Bhandari, B.; Chen, J. Instant quinoa prepared by different cooking methods and infrared-assisted freeze drying: Effects of variables on the physicochemical properties. Food Chem. 2022, 370, 131091. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhang, M.; Adhikari, B. Drying of shiitake mushroom by combining freeze-drying and mid-infrared radiation. Food Bioprod. Process. 2015, 94, 507–517. [Google Scholar] [CrossRef]

- Lammerskitten, A.; Wiktor, A.; Mykhailyk, V.; Samborska, K.; Gondek, E.; Witrowa-Rajchert, D.; Toepfl, S.; Parniakov, O. Pulsed electric field pre-treatment improves microstructure and crunchiness of freeze-dried plant materials: Case of strawberry. LWT 2020, 134, 110266. [Google Scholar] [CrossRef]

- Liu, C.; Grimi, N.; Bals, O.; Lebovka, N.; Vorobiev, E. Effects of pulsed electric fields and preliminary vacuum drying on freezing assisted processes in potato tissue. Food Bioprod. Process. 2021, 125, 126–133. [Google Scholar] [CrossRef]

- Lammerskitten, A.; Mykhailyk, V.; Wiktor, A.; Toepfl, S.; Nowacka, M.; Bialik, M.; Czyżewski, J.; Witrowa-Rajchert, D.; Parniakov, O. Impact of pulsed electric fields on physical properties of freeze-dried apple tissue. Innov. Food Sci. Emerg. Technol. 2019, 57, 102211. [Google Scholar] [CrossRef]

- Lammerskitten, A.; Wiktor, A.; Siemer, C.; Toepfl, S.; Mykhailyk, V.; Gondek, E.; Rybak, K.; Witrowa-Rajchert, D.; Parniakov, O. The effects of pulsed electric fields on the quality parameters of freeze-dried apples. J. Food Eng. 2019, 252, 36–43. [Google Scholar] [CrossRef]

- Tylewicz, U.; Aganovic, K.; Vannini, M.; Toepfl, S.; Bortolotti, V.; Dalla Rosa, M.; Oey, I.; Heinz, V. Effect of pulsed electric field treatment on water distribution of freeze-dried apple tissue evaluated with DSC and TD-NMR techniques. Innov. Food Sci. Emerg. Technol. 2016, 37, 352–358. [Google Scholar] [CrossRef]

- Nowak, D.; Jakubczyk, E. Effect of pulsed electric field pre-treatment and the freezing methods on the kinetics of the freeze-drying process of apple and its selected physical properties. Foods 2022, 11, 2407. [Google Scholar] [CrossRef]

- Arshad, R.N.; Abdul-Malek, Z.; Roobab, U.; Munir, M.A.; Naderipour, A.; Qureshi, M.I.; El-Din Bekhit, A.; Liu, Z.-W.; Aadil, R.M. Pulsed electric field: A potential alternative towards a sustainable food processing. Trends Food Sci. Technol. 2021, 111, 43–54. [Google Scholar] [CrossRef]

- Liu, C.; Grimi, N.; Lebovka, N.; Vorobiev, E. Effects of pulsed electric fields treatment on vacuum drying of potato tissue. LWT 2018, 95, 289–294. [Google Scholar] [CrossRef]

- Fauster, T.; Giancaterino, M.; Pittia, P.; Jaeger, H. Effect of pulsed electric field pretreatment on shrinkage, rehydration capacity and texture of freeze-dried plant materials. LWT 2020, 121, 108937. [Google Scholar] [CrossRef]

- Xu, D.; Wei, L.; Guangyue, R.; Wenchao, L.; Yunhong, L. Comparative study on the effects and efficiencies of three sublimation drying methods for mushrooms. Int. J. Agric. Biol. Eng. 2015, 8, 91–97. [Google Scholar]

- Duan, X.; Liu, W.C.; Ren, G.Y.; Yang, X. Effects of different drying methods on the physical characteristics and flavor of dried hawthorns (Crataegus spp.). Dry. Technol. 2017, 35, 1412–1421. [Google Scholar] [CrossRef]

- Yan, W.Q.; Zhang, M.; Huang, L.L.; Tang, J.; Mujumdar, A.S.; Sun, J.-C. Studies on different combined microwave drying of carrot pieces. Int. J. Food Sci. Technol. 2010, 45, 2141–2148. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, M.; Mujumdar, A.S. Comparison of three microwave-assisted drying methods on the physiochemical, nutritional and sensory qualities of re-structured purple-fleshed sweet potato granules. Int. J. Food Sci. Technol. 2012, 47, 141–147. [Google Scholar] [CrossRef]

- Duan, L.; Duan, X.; Ren, G. Structural characteristics and texture during the microwave freeze drying process of Chinese yam chips. Dry. Technol. 2019, 38, 928–939. [Google Scholar] [CrossRef]

- Li, R.; Huang, L.; Zhang, M.; Mujumdar, A.S.; Wang, Y.C. Freeze drying of apple slices with and without application of microwaves. Dry. Technol. 2014, 32, 1769–1776. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, M.; Mujumdar, A.S.; Lim, R.X. Comparison of the effect of microwave freeze drying and microwave vacuum drying upon the process and quality characteristics of potato/banana re-structured chips. Int. J. Food Sci. Technol. 2011, 46, 570–576. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, M.; Mujumdar, A.S.; Lim, R.X. Comparison of drying characteristic and uniformity of banana cubes dried by pulse-spouted microwave vacuum drying, freeze drying and microwave freeze drying. J. Sci. Food Agric. 2014, 94, 1827–1834. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Zhang, M.; Bhandari, B.; Li, Z. Effects of microwave assisted pulse fluidized bed freeze-drying (MPFFD) on quality attributes of Cordyceps militaris. Food Biosci. 2019, 28, 7–14. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, M.; Mujumdar, A.S.; Mothibe, K.J. Microwave-assisted pulse-spouted bed freeze-drying of stem lettuce slices—Effect on product quality. Food Bioprocess Technol. 2012, 6, 3530–3543. [Google Scholar] [CrossRef]

- Chen, B.L.; Lin, G.S.; Amani, M.; Yan, W.M. Microwave-assisted freeze drying of pineapple: Kinetic, product quality, and energy consumption. Case Stud. Therm. Eng. 2023, 41, 102682. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, M.; Mujumdar, A.S. Physico-chemical changes during different stages of MFD/FD banana chips. J. Food Eng. 2010, 101, 140–145. [Google Scholar] [CrossRef]

- Chizoba Ekezie, F.G.; Sun, D.W.; Han, Z.; Cheng, J.H. Microwave-assisted food processing technologies for enhancing product quality and process efficiency: A review of recent developments. Trends Food Sci. Technol. 2017, 67, 58–69. [Google Scholar] [CrossRef]

- Carvalho, M.J.; Perez-Palacios, T.; Ruiz-Carrascal, J. Physico-chemical and sensory characteristics of freeze-dried and air-dehydrated yogurt foam. LWT 2017, 80, 328–334. [Google Scholar] [CrossRef]

- Kaveh, M.; Abbaspour-Gilandeh, Y.; Fatemi, H.; Chen, G. Impact of different drying methods on the drying time, energy, and quality of green peas. J. Food Process. Preserv. 2021, 45, e15503. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, M.; Liu, Y.; Mujumdar, A.S.; Liu, H. The energy consumption and color analysis of freeze/microwave freeze banana chips. Food Bioprod. Process. 2013, 91, 464–472. [Google Scholar] [CrossRef]

- Prosapio, V.; Lopez-Quiroga, E. Freeze-drying technology in foods. Foods 2020, 9, 3526. [Google Scholar] [CrossRef]

- Kutyauripo, I.; Rushambwa, M.; Chiwazi, L. Artificial intelligence applications in the agrifood sectors. J. Agric. Food Res. 2023, 11, 100502. [Google Scholar] [CrossRef]

- Karaağaç, M.O.; Ergün, A.; Ağbulut, Ü.; Gürel, A.E.; Ceylan, İ. Experimental analysis of CPV/T solar dryer with nano-enhanced PCM and prediction of drying parameters using ANN and SVM algorithms. Sol. Energy 2021, 218, 57–67. [Google Scholar] [CrossRef]

- Chakravartula, S.S.N.; Bandiera, A.; Nardella, M.; Bedini, G.; Ibba, P.; Massantini, R.; Moscetti, R. Computer vision-based smart monitoring and control system for food drying: A study on carrot slices. Comput. Electron. Agric. 2023, 206, 107654. [Google Scholar] [CrossRef]

- Makarichian, A.; Chayjan, A.R.; Ahmadi, E.; Mohtasebi, S.S. Assessment the influence of different drying methods and pre-storage periods on garlic (Allium Sativum L.) aroma using electronic nose. Food Bioprod. Process. 2021, 127, 198–211. [Google Scholar] [CrossRef]

- Zhang, K.; Cheng, J.; Hong, Q.; Dong, W.; Chen, X.; Wu, G.; Zhang, Z. Identification of changes in the volatile compounds of robusta coffee beans during drying based on HS-SPME/GC-MS and E-nose analyses with the aid of chemometrics. LWT 2022, 161, 113317. [Google Scholar] [CrossRef]

- Harguindeguy, M.; Fissore, D. On the effects of freeze-drying processes on the nutritional properties of foodstuff: A review. Dry. Technol. 2020, 38, 846–868. [Google Scholar] [CrossRef]

- Różyło, R. Recent trends in methods used to obtain natural food colorants by freeze-drying. Trends Food Sci. Technol. 2020, 102, 39–50. [Google Scholar] [CrossRef]

- Stratta, L.; Capozzi, L.C.; Franzino, S.; Pisano, R. Economic Analysis of a Freeze-Drying Cycle. Processes 2020, 8, 1399. [Google Scholar] [CrossRef]

| FVs | The Initial Moisture Content | Drying Conditions | Main Results | References |

|---|---|---|---|---|

| Apple | 6.2 ± 0.4 kg water/kg dm | T: −10 °C; Frequency: 21.7 kHz; Ultrasonic power: 0, 10.3, 20.5 and 30.8 kW/m3 | The application of ultrasound resulted in a reduction in drying time (88% for cylindrical samples and 92% for sheet samples) and a reduction in total drying energy consumption of 68.8% (cylindrical samples) and 78.8% (sheet samples). | Moreno et al. [74] |

| Apple, carrot and eggplant | T: −10, 0, 10, 20 °C, Air velocity: 1, 2, 4 m/s; Ultrasonic power 0, 10.3, 20.5 kW/m3 | When ultrasound is applied, the total energy consumption of the process is reduced by 70%. | Merone et al. [72] | |

| Apple | 6.2 ± 0.4 water/kg dm | T: −10 °C, 15% RH; Frequency: 21 kHz; Air velocity: 2 m/s; Ultrasonic power: 0, 10.3, 20.5, 30.8 kW/m3, | The effective diffusion coefficient of ultrasound is 4.8 times higher at the lowest power (10.3 kW/m3), and the higher the power used, the better the drying effect. | Brines et al. [76] |

| Carrot, eggplant, and apple | 7.58 ± 0.90, 6.10 ± 0.37, and 14.57 ± 0.27 water/kg dm | T: −14.1 °C, 7 ± 3% RH; Frequency: 21.9 kHz; Air velocity: 2 ± 1 m/s; Ultrasonic power: 19.5 kW/m3 | In the presence of ultrasound, the drying time was shortened (about 65–70%), and the mass transfer coefficient and effective moisture diffusion rate were increased by 96–170% and 407–428%, respectively. | Garcia-Perez et al. [75] |

| Eggplant | Frequency: 21.9 kHz; T: (−5, −7.5, −10 °C); Air velocities (2, 5 m/s); Ultrasonic power: 0, 25, 50 W | No significant difference compared to samples dried without ultrasound, the potential effect of ultrasound to enhance the antioxidant response was not significant. | Colucci et al. [30] | |

| Orange peel | 2.47 ± 0.08 kg water/kg dm (dry basis moisture content) | AFD (T: −10 °C, MTD (T: 50); Air velocity: 1 m/s; Ultrasonic power: 20.5 kW/m3 | In the presence of ultrasound, the freeze drying process is accelerated and the drying time is reduced by about 57% compared to medium temperature convection drying (MTD). | Mello et al. [77] |

| FVs | The Initial Moisture Content | Drying Conditions | Main Results | References |

|---|---|---|---|---|

| Carrots | - | T: 25 °C; t: 10 min; Frequency: 40 kHz; Ultrasonic power: 100 W. | Ultrasound combined with ascorbic acid and after ultrasonic treatment with ascorbic acid and CaCl2 (UAA-CaCl2), the a* value, color and TCC of carrots were increased by 29.66%, 16.59% and 13.40%, respectively, and the thermal stability was increased by 3.40%. | Lyu et al. [82] |

| Carrots | 88 g/g wb | T: 25 °C; t: 10 min; Frequency: 40 kHz | The UAA treatment resulted in structural integrity of the cells, reduced porosity, induction of carotenoid distribution and increased retention of carotenoid material (51.73%). | Lyu et al. [83] |

| Grass | - | T: 10 °C; t: 10 min; Frequency: 20 kHz; Ultrasonic power: 10, 30, 45, 60 W/L | Compared to untreated, ultrasonic power (10 W/L) had the highest L* (51.5%) and lowest a* (9.3%). UT (30W/L) treated dry samples had 9.2 g/kg of flavonoids and 10.5 g/kg of chlorophyll. UT (45 W/L) reduced drying time by 14% and energy consumption The UT (45 W/L) reduced drying time by 14% and energy consumption by 19%. UT (60 W/L) reduced the total number of microorganisms by 33%. | Cao et al. [84] |

| Onions | - | T: 70 °C; t: (1, 3, 5 min); Frequency: 20 kHz; Ultrasonic power: 24.4–61 μm | The retention of bioactive substances in the samples was increased after freeze drying compared to hot-air drying, thus improving the antioxidant capacity of the onion slices. | Ren et al. [78] |

| Okra | 87.17 ± 0.68% dm | T: 25 °C; t: 30 min; Frequency: 40 kHz; Ultrasonic power: 25 W/L | The application of ultrasound and different freeze–thaw treatments reduced the drying time by 25.0% to 62.50% and the total energy consumption by 24.28% to 62.35%. | Xu et al. [81] |

| Strawberry | 85.62 ± 2.76% dm | T: −20 °C; t: 25 min; Frequency: 40 kHz; Ultrasonic power: 200 W | The combination of ultrasound and high-pressure treatment promotes the diffusion of water, reduces energy consumption and also improves the color and antioxidant activity of the product. | Zhang et al. [79] |

| Strawberry | 92.65 ± 0.83% wb (wet basis moisture content) | T: 25 ± 1 °C, t: 30 min, Frequency: 20, 40 kHz; Ultrasonic power: 30 W/L | The drying time of the ultrasound-treated strawberry slices was reduced by 15.25% to 50.00% compared to the control, with dual-frequency ultrasound reducing drying time even more and providing higher quality. | Xu et al. [80] |

| Strawberry | - | T: 25 °C; t: 25 min; Frequency: 40 kHz | The aroma and taste of the vacuum freeze-dried strawberry slices pretreated with ultrasound were superior to those of the UHP-treated samples, with the glucose and fructose contents (sweetness) of the samples increasing by 19.42% and 23.51%, respectively, and the malic acid content (acidity) decreasing by 5.03%. | Wang et al. [69] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yao, J.; Chen, W.; Fan, K. Novel Efficient Physical Technologies for Enhancing Freeze Drying of Fruits and Vegetables: A Review. Foods 2023, 12, 4321. https://doi.org/10.3390/foods12234321

Yao J, Chen W, Fan K. Novel Efficient Physical Technologies for Enhancing Freeze Drying of Fruits and Vegetables: A Review. Foods. 2023; 12(23):4321. https://doi.org/10.3390/foods12234321

Chicago/Turabian StyleYao, Jianhua, Wenjuan Chen, and Kai Fan. 2023. "Novel Efficient Physical Technologies for Enhancing Freeze Drying of Fruits and Vegetables: A Review" Foods 12, no. 23: 4321. https://doi.org/10.3390/foods12234321