Tea Harvesting and Processing Techniques and Its Effect on Phytochemical Profile and Final Quality of Black Tea: A Review

Abstract

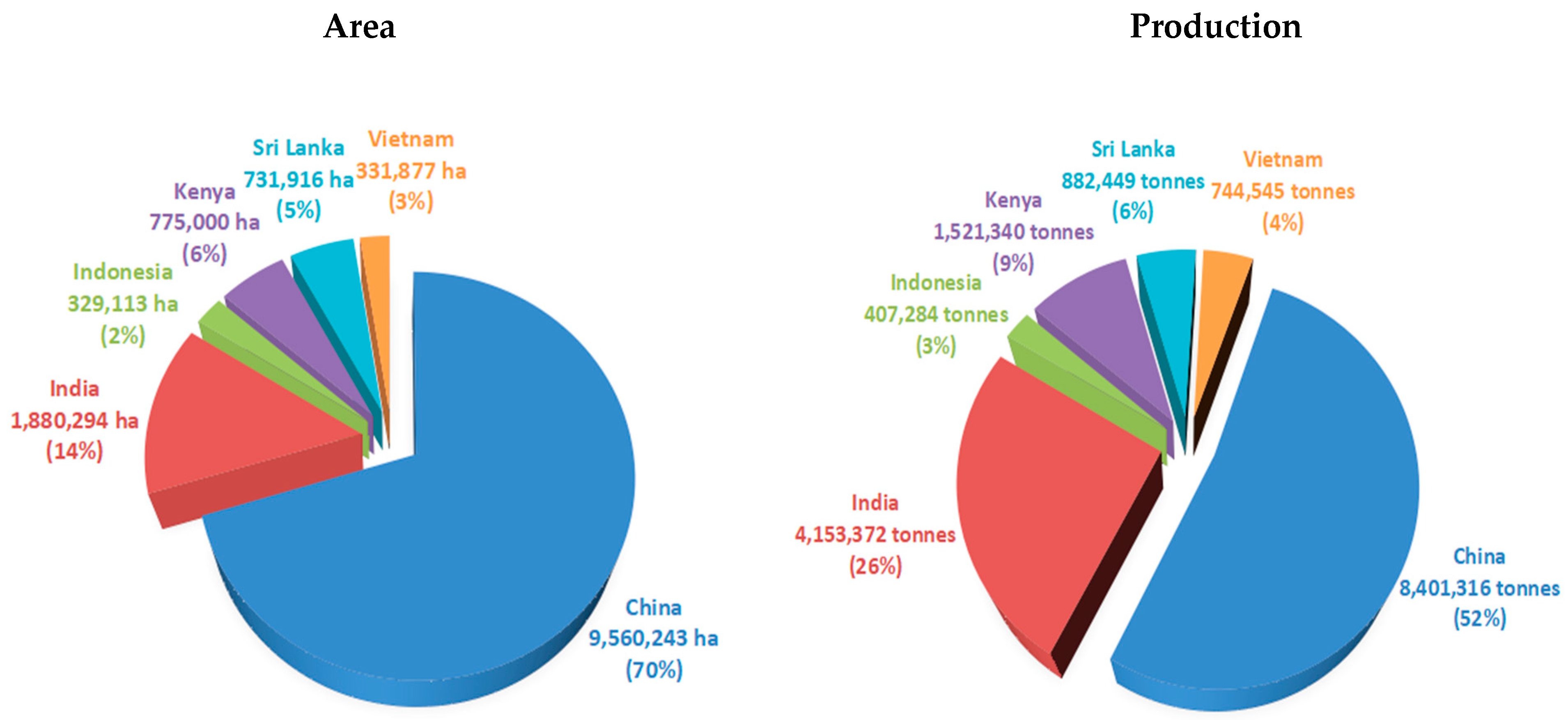

:1. Introduction

2. Black Tea’s Health Benefits and Chemical Composition

3. Black Tea’s Manufacturing Cycle and Its Influence on Quality Characteristics

3.1. Plucking/Harvesting/Picking

3.1.1. Plucking Method

3.1.2. Plucking Standard

3.1.3. Shooting Period/Plucking Interval

3.1.4. Plucking Season

4. Withering Stage

5. Rolling/Maceration Stage

6. Fermentation/Oxidation Stage

6.1. The Influence of Fermentation Process Parameters on Black Tea’s Quality Attributes

6.2. Time

6.3. Temperature

6.4. Oxygen and Relative Humidity

7. Drying/Firing Stage

Factors Influencing the Drying Process

8. Storage Method and Duration

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, Z.; Baldermann, S.; Watanabe, N. Recent Studies of the Volatile Compounds in Tea. Food Res. Int. 2013, 53, 585–599. [Google Scholar] [CrossRef]

- Liu, Z.H.; Gao, L.Z.; Chen, Z.M.; Zeng, X.; Huang, J.A.; Gong, Y.S.; Li, Q.; Liu, S.Q.; Lin, Y.; Cai, S.X.; et al. Leading progress on genomics, health benefits and utilization of tea resources in China. Nature 2019, 566. [Google Scholar]

- Vuong, Q.V. Epidemiological Evidence Linking Tea Consumption to Human Health: A Review. Crit. Rev. Food Sci. Nutr. 2014, 54, 523–536. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Ho, C.-T.; Zhou, J.; Santos, J.S.; Armstrong, L.; Granato, D. Chemistry and Biological Activities of Processed Camellia sinensis Teas: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1474–1495. [Google Scholar] [CrossRef] [PubMed]

- De Silva, M.S.D.L. The Effects of Soil Amendments on Selected Properties of Tea Soils and Tea Plants (Camellia sinensis L.) in Australia and Sri Lanka. Ph.D. Thesis, James Cook University, Queensland, Australia, 2007. [Google Scholar]

- Panda, B.K.; Datta, A.K. Quantitative Analysis of Major Phytochemicals in Orthodox Tea (Camellia sinensis), Oxidized under Compressed Air Environment. J. Food Sci. 2016, 81, C858–C866. [Google Scholar] [CrossRef] [PubMed]

- Adnan, M.; Ahmad, A.; Ahmed, D.A.; Khalid, N.; Hayat, I.; Ahmed, I. Chemical Composition and Sensory Evaluation of Tea (Camellia sinensis) Commercialized in Pakistan. Pak. J. Bot. 2013, 45, 901–907. [Google Scholar]

- Chaturvedula, V.S.P.; Prakash, I. The Aroma, Taste, Color and Bioactive Constituents of Tea. JMPR 2011, 5, 2110–2124. [Google Scholar]

- Gramza-Michałowska, A. Caffeine in Tea Camellia sinensis—Content, Absorption, Benefits and Risks of Consumption. J. Nutr. Health Aging 2014, 18, 143–149. [Google Scholar] [CrossRef]

- Li, X.; Xie, C.; He, Y.; Qiu, Z.; Zhang, Y. Characterizing the Moisture Content of Tea with Diffuse Reflectance Spectroscopy Using Wavelet Transform and Multivariate Analysis. Sensors 2012, 12, 9847–9861. [Google Scholar] [CrossRef]

- Tran, J. Green Tea: A Potential Alternative Anti-Infectious Agent Catechins and Viral Infections. Adv. Anthropol. 2013, 3, 198–202. [Google Scholar] [CrossRef]

- Pou, K.R.J. Fermentation: The Key Step in the Processing of Black Tea. J. Biosyst. Eng. 2016, 41, 85–92. [Google Scholar] [CrossRef]

- Muthumani, T.; Kumar, R.S.S. Influence of Fermentation Time on the Development of Compounds Responsible for Quality in Black Tea. Food Chem. 2007, 1, 98–102. [Google Scholar] [CrossRef]

- Zhu, K.; Ouyang, J.; Huang, J.; Liu, Z. Research Progress of Black Tea Thearubigins: A Review. Crit. Rev. Food Sci. Nutr. 2021, 61, 1556–1566. [Google Scholar] [CrossRef] [PubMed]

- Sigley, G. Tea and China’s Rise: Tea, Nationalism and Culture in the 21st Century. Int. Commun. Chin. Cult. 2015, 2, 319–341. [Google Scholar] [CrossRef]

- Majumder, A.B.; Bera, B.; Rajan, A. Tea Statistics: Global Scenario. J. Tea Sci. 2010, 8, 121–124. [Google Scholar]

- FAOSTAT. Available online: https://www.fao.org/faostat/en/#home (accessed on 12 June 2023).

- Mitei, Z. Growing Sustainable Tea on Kenyan Smallholder Farms. Int. J. Agric. Sustain. 2011, 9, 59–66. [Google Scholar] [CrossRef]

- Kamunya, S.M.; Wachira, F.N.; Pathak, R.S.; Muoki, R.C.; Sharma, R.K. Tea Improvement in Kenya. In Global Tea Breeding: Achievements, Challenges and Perspectives; Chen, L., Apostolides, Z., Chen, Z.-M., Eds.; Advanced Topics in Science and Technology in China; Springer: Berlin/Heidelberg, Germany, 2012; pp. 177–226. ISBN 978-3-642-31878-8. [Google Scholar]

- Astill, C.; Birch, M.R.; Dacombe, C.; Humphrey, P.G.; Martin, P.T. Factors Affecting the Caffeine and Polyphenol Contents of Black and Green Tea Infusions. J. Agric. Food Chem. 2001, 49, 5340–5347. [Google Scholar] [CrossRef]

- Sharangi, A.B. Medicinal and Therapeutic Potentialities of Tea (Camellia sinensis L.)—A Review. Food Res. Int. 2009, 42, 529–535. [Google Scholar] [CrossRef]

- Yan, S.-H. NIR Evaluation of the Quality of Tea and Its Market Price. Spectrosc. Eur. 2007, 19, 16–19. [Google Scholar]

- Laddi, A.; Prakash, N.R.; Sharma, S.; Mondal, H.S.; Kumar, A.; Kapur, P. Significant Physical Attributes Affecting Quality of Indian Black (CTC) Tea. J. Food Eng. 2012, 113, 69. [Google Scholar] [CrossRef]

- Bhattacharya, U.; Halder, B.; Mukhopadhyay, S.; Giri, A.K. Role of Oxidation-Triggered Activation of JNK and P38 MAPK in Black Tea Polyphenols Induced Apoptotic Death of A375 Cells. Cancer Sci. 2009, 100, 1971–1978. [Google Scholar] [CrossRef]

- Persson, I.A.-L.; Josefsson, M.; Persson, K.; Andersson, R.G.G. Tea Flavanols Inhibit Angiotensin-Converting Enzyme Activity and Increase Nitric Oxide Production in Human Endothelial Cells. J. Pharm. Pharmacol. 2006, 58, 1139–1144. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Tu, Y.; Xia, H.; Jie, G.; Chen, X.; He, P. Suppression of Free-Radicals and Protection against H2O2-Induced Oxidative Damage in HPF-1 Cell by Oxidized Phenolic Compounds Present in Black Tea. Food Chem. 2007, 105, 1349–1356. [Google Scholar] [CrossRef]

- Ye, F.; Qiao, X.; Gui, A.; Wang, S.; Liu, P.; Wang, X.; Teng, J.; Zheng, L.; Feng, L.; Han, H.; et al. Metabolomics Provides A Novel Interpretation of the Changes in Main Compounds during Black Tea Processing through Different Drying Methods. Molecules 2021, 26, 6739. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Yu, X.; He, C.; Qiu, A.; Li, Y.; Shu, Q.; Chen, Y.; Ni, D. Withering Degree Affects Flavor and Biological Activity of Black Tea: A Non-Targeted Metabolomics Approach. LWT 2020, 130, 109535. [Google Scholar] [CrossRef]

- Wong, M.; Sirisena, S.; Ng, K. Phytochemical Profile of Differently Processed Tea: A Review. J. Food Sci. 2022, 87, 1925–1942. [Google Scholar] [CrossRef]

- Xing, L.; Zhang, H.; Qi, R.; Tsao, R.; Mine, Y. Recent Advances in the Understanding of the Health Benefits and Molecular Mechanisms Associated with Green Tea Polyphenols. J. Agric. Food Chem. 2019, 67, 1029–1043. [Google Scholar] [CrossRef]

- Del Rio, D.; Rodriguez-Mateos, A.; Spencer, J.P.E.; Tognolini, M.; Borges, G.; Crozier, A. Dietary (Poly)Phenolics in Human Health: Structures, Bioavailability, and Evidence of Protective Effects against Chronic Diseases. Antioxid. Redox Signal. 2013, 18, 1818–1892. [Google Scholar] [CrossRef]

- Hirata, K.; Shimada, K.; Watanabe, H.; Otsuka, R.; Tokai, K.; Yoshiyama, M.; Homma, S.; Yoshikawa, J. Black Tea Increases Coronary Flow Velocity Reserve in Healthy Male Subjects. Am. J. Cardiol. 2004, 93, 1384–1388. [Google Scholar] [CrossRef]

- Duffy, S.J.; Keaney, J.F., Jr.; Holbrook, M.; Gokce, N.; Swerdloff, P.L.; Frei, B.; Vita, J.A. Short- and Long-Term Black Tea Consumption Reverses Endothelial Dysfunction in Patients with Coronary Artery Disease. Circulation 2001, 104, 151–156. [Google Scholar] [CrossRef]

- Hodgson, J.M.; Puddey, I.B.; Burke, V.; Croft, K.D. Is Reversal of Endothelial Dysfunction by Tea Related to Flavonoid Metabolism? Br. J. Nutr. 2006, 95, 14–17. [Google Scholar] [CrossRef] [PubMed]

- Davies, M.J.; Judd, J.T.; Baer, D.J.; Clevidence, B.A.; Paul, D.R.; Edwards, A.J.; Wiseman, S.A.; Muesing, R.A.; Chen, S.C. Black Tea Consumption Reduces Total and LDL Cholesterol in Mildly Hypercholesterolemic Adults. J. Nutr. 2003, 133, 3298S–3302S. [Google Scholar] [CrossRef] [PubMed]

- Ludwig, A.; Lorenz, M.; Grimbo, N.; Steinle, F.; Meiners, S.; Bartsch, C.; Stangl, K.; Baumann, G.; Stangl, V. The Tea Flavonoid Epigallocatechin-3-Gallate Reduces Cytokine-Induced VCAM-1 Expression and Monocyte Adhesion to Endothelial Cells. Biochem. Biophys. Res. Commun. 2004, 316, 659–665. [Google Scholar] [CrossRef] [PubMed]

- Bhagat, R.M.; Baruah, R.D.; Safique, S. Climate and Tea [Camellia sinensis (L.) O. Kuntze] Production with Special Reference to North Eastern India: A Review. J. Environ. Res. Dev. 2010, 4, 1017–1028. [Google Scholar]

- Khan, N.; Mukhtar, H. Tea Polyphenols in Promotion of Human Health. Nutrients 2018, 11, 39. [Google Scholar] [CrossRef] [PubMed]

- Senthil Kumar, R.S.; Murugesan, S.; Kottur, G.; Gyamfi, D. Chapter 4—Black Tea: The Plants, Processing/Manufacturing and Production. In Tea in Health and Disease Prevention; Academic Press: Cambridge, MA, USA, 2013; pp. 41–57. [Google Scholar] [CrossRef]

- Samanta, T.; Cheeni, V.; Das, S.; Roy, A.B.; Ghosh, B.C.; Mitra, A. Assessing Biochemical Changes during Standardization of Fermentation Time and Temperature for Manufacturing Quality Black Tea. J. Food Sci. Technol. 2015, 52, 2387–2393. [Google Scholar] [CrossRef] [PubMed]

- Turkmen, N.; Sarı, F.; Velioglu, Y. Factors Affecting Polyphenol Content and Composition of Fresh and Processed Tea Leaves. Akad. Gida 2009, 7, 29–40. [Google Scholar]

- Balentine, D.A.; Wiseman, S.A.; Bouwens, L.C. The Chemistry of Tea Flavonoids. Crit. Rev. Food Sci. Nutr. 1997, 37, 693–704. [Google Scholar] [CrossRef]

- Li, S.; Lo, C.-Y.; Pan, M.-H.; Lai, C.-S.; Ho, C.-T. Black Tea: Chemical Analysis and Stability. Food Funct. 2013, 4, 10–18. [Google Scholar] [CrossRef]

- Obanda, M.; Owuor, P.O.; Mang’oka, R.; Kavoi, M.M. Changes in Thearubigin Fractions and Theaflavin Levels Due to Variations in Processing Conditions and Their Influence on Black Tea Liquor Brightness and Total Colour. Food Chem. 2004, 2, 163–173. [Google Scholar] [CrossRef]

- Ntezimana, B.; Li, Y.; He, C.; Yu, X.; Zhou, J.; Chen, Y.; Yu, Z.; Ni, D. Different Withering Times Affect Sensory Qualities, Chemical Components, and Nutritional Characteristics of Black Tea. Foods 2021, 10, 2627. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Zhu, Y.; Liu, Y.; Liu, Y.; Dong, C.; Lin, Z.; Teng, J. Black Tea Aroma Formation during the Fermentation Period. Food Chem. 2022, 374, 131640. [Google Scholar] [CrossRef] [PubMed]

- Jolvis Pou, K.R.; Paul, S.K.; Malakar, S. 4—Industrial Processing of CTC Black Tea. In Caffeinated and Cocoa Based Beverages; Grumezescu, A.M., Holban, A.M., Eds.; Woodhead Publishing: Sawston, UK, 2019; pp. 131–162. ISBN 978-0-12-815864-7. [Google Scholar]

- Bhuyan, L.P.; Sanyt, S.; Baruahl, S.; Sabhapondit, S.; Hazarika, A.K.; Hazarikal, M. Recent Approaches to Processing Technology at Tocklai. Two Bud. 2012, 59, 34–40. [Google Scholar]

- Kimutai, G.; Ngenzi, A.; Ngoga, S.; Ramkat, R.; Förster, A. Application of Computing Techniques in Monitoring Black Tea Processing for Improved Quality: Review and Future Directions. In Soft Computing Applications; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Owuor, P.O.; Odhiambo, H.O. The Response of Quality and Yield of Black Tea of Twocamellia Sinensis Varieties to Methods and Intervals of Harvesting. J. Sci. Food Agric. 1993, 62, 337–343. [Google Scholar] [CrossRef]

- Liu, D.; Yin, L.; Yin, M. Study on processing technology and method of Kung Fu black tea. Fujian Tea 2023, 45, 27–29. [Google Scholar]

- Jing, J.; Liang, Y.; Liewan, L. Kung Fu Black Tea Is Processed Continuously and Automatically. Production Technology and Practice. Tea Process. China 2016, 51–55. [Google Scholar]

- Ravichandran, R.; Ramaswamy, P. The Impact of Mechanization of Tea Harvesting on the Quality of South Indian CTC Teas. Food Chem. 1998, 63, 61–64. [Google Scholar] [CrossRef]

- Kanwar, A. Comprehensive Review on Tea Processing. Pharma Innov. 2023, 12, 1995–2002. [Google Scholar]

- Singh, V.; Verma, D.; Singh, G. Processing Technology and Health Benefits of Green Tea. Pop. Kheti 2014, 2, 23–30. [Google Scholar]

- Karunamoorthy, B.; Somasundereswari, D. A Defect Tea Leaf Identification Using Image Processing. Prz. Elektrotech. 2013, 89, 318–320. [Google Scholar]

- Apostolides, Z.; Wright, L.P. Biochemical Analysis for Identification of Quality in Black Tea (Camellia sinensis). Ph.D. Thesis, University of Pretoria, Pretoria, South Africa, 2006. [Google Scholar]

- Obanda, M.; Owuor, P.O. Clonal Variations in the Response of Black Tea Quality Due to Plucking Standards. Food Chem. 1995, 53, 381–384. [Google Scholar] [CrossRef]

- Owuor, P.O.; Kwach, B.O. Quality and Yields of Black Tea Camellia sinensis L. O. Kuntze in Responses to Harvesting in Kenya: A Review. Asian J. Biol. Life Sci. 2012, 1, 1–7. [Google Scholar]

- Teshome, K. Effect of Tea Processing Methods on Biochemical Composition and Sensory Quality of Black Tea (Camellia sinensis (L.) O. Kuntze): A Review. JHF 2019, 11, 84–95. [Google Scholar]

- Okinda Owuor, P.; Obanda, M. The Changes in Black Tea Quality Due to Variations of Plucking Standard and Fermentation Time. Food Chem. 1998, 61, 435–441. [Google Scholar] [CrossRef]

- Sylvestre, H.; Jacqueline, N.; Alphonsine, M.; Olive, T. Impact of Plucking Interval on Tea Productivity and Green Leaf Quality. Int. J. Soil. Crop Sci. 2014, 2, 068–072. [Google Scholar]

- Waheed, A.; Hasid, F.S.; Ahmad, N.; Khan, B.M. An over View of Tea Plantation in Pakistan. Asian J. Plant Sci. 2002, 1, 495–498. [Google Scholar] [CrossRef]

- Naheed, Z.; Barech, A.R.; Sajid, M.; Khan, N.A.; Hussain, R. Effect of rolling, fermentation and drying on the quality of black tea. Sarhad J. Agric. 2007, 23, 577. [Google Scholar]

- Taylor, S.; Baker, D.; Owuor, P.; Orchard, J.; Othieno, C.; Gay, C. A Model for Predicting Black Tea Quality from the Carotenoid and Chlorophyll Composition of Fresh Green Tea Leaf. J. Sci. Food Agric. 1992, 58, 185–191. [Google Scholar] [CrossRef]

- Owuor, P.O.; Obanda, M.A.; Othieno, C.O.; Horita, H.; Tsushida, T.; Murai, T. Changes in the Chemical Composition and Quality of Black Tea Due to Plucking Standards. Agric. Biol. Chem. 1987, 51, 3383–3384. [Google Scholar] [CrossRef]

- Owuor, P.O.; Odhiambo, H.O.; Robinson, J.M.; Taylor, S.J. Variations in the Leaf Standard, Chemical Composition and Quality of Black Tea (Camellia sinensis) Due to Plucking Intervals. J. Sci. Food Agric. 1990, 52, 63–69. [Google Scholar] [CrossRef]

- Wu, S.; Yu, Q.; Shen, S.; Shan, X.; Hua, J.; Zhu, J.; Qiu, J.; Deng, Y.; Zhou, Q.; Jiang, Y.; et al. Non-Targeted Metabolomics and Electronic Tongue Analysis Reveal the Effect of Rolling Time on the Sensory Quality and Nonvolatile Metabolites of Congou Black Tea. LWT 2022, 169, 113971. [Google Scholar] [CrossRef]

- Okal, A.W.; Philip, O.; David, K.; Manguro, L.O.A. Variations of Fatty Acids Levels in Young Shoots of Clonal Tea with Location of Production and Nitrogenous Fertilizer Rates in the Kenya Highlands. J. Agric. Sci. Technol. 2012, 14, 1543–1554. [Google Scholar]

- Odhiambo, H. Nitrogen Rates and Plucking Frequency on Tea: The Effect of Plucking Frequency and Nitrogenous Fertilizer Rates on Yield and Yield Components of Tea, (Camellia sinesis (L.) O. Kuntze) in Kenya. Tea 1989, 10, 90–96. [Google Scholar]

- Baruah, S.; Hazardca, M.; Mahanta, P.K.; Horita, H.; Murai, T. Effect of Plucking Intervals on the Chemical Constituents of CTC Black Teas. Agric. Biol. Chem. 1986, 50, 1039–1041. [Google Scholar] [CrossRef]

- Hazarika, M.; Mahanta, P.K. Some Studies on Carotenoids and Their Degradation in Black Tea Manufacture. J. Sci. Food Agric. 1983, 34, 1390–1396. [Google Scholar] [CrossRef]

- Owuor, P.O.; Langat, J.K.A. Changes in Chemical Composition of Black Tea Due Tu Pruning. Trop. Sci. 1988, 28, 127–132. [Google Scholar]

- Owuor, P.O.; Kamau, D.M.; Kamunya, S.M.; Msomba, S.W.; Uwimana, M.A.; Okal, A.W.; Kwach, B.O. Effects of Genotype, Environment and Management on Yields and Quality of Black Tea. In Genetics, Biofuels and Local Farming Systems; Lichtfouse, E., Ed.; Sustainable Agriculture Reviews; Springer: Dordrecht, The Netherlands, 2011; Volume 7, pp. 277–307. ISBN 978-94-007-1520-2. [Google Scholar]

- Uddin, M.J.; Hoque, M.R.; Ahmed, M.; Saha, J.K. Studies on the Effect of Saturation Deficit on the Yield of Tea. Pak. J. Meteorol. 2005, 2, 3–8. [Google Scholar]

- Owuor, P.O. Clonal Variations in the Response of Black Tea Quality Parameters to Time of the Year in Western Kenya Highlands. Trop. Sci. 1994, 34, 225–230. [Google Scholar]

- Wachira, F.; Ng’etich, W.; Omolo, J.; Mamati, G. Genotype\times Environment Interactions for Tea Yields. Euphytica 2002, 127, 289–297. [Google Scholar] [CrossRef]

- Ng’etich, W.; Stephens, W. Responses of Tea to Environment in Kenya. 1. Genotype × Environment Interactions for Total Dry Matter Production and Yield. Exp. Agric. 2001, 37, 333–342. [Google Scholar] [CrossRef]

- Owuor, P.O.; Othieno, C.O.; Kamau, D.M.; Wanyoko, J.K.; Ng’etich, W.K. Long Term Fertilizer Use on High Yielding Clone S15/10: Tea Yields. Int. J. Tea Sci. 2008, 7. [Google Scholar]

- Laddi, A.; Prakash, N.R.; Kumar, A. Quality Evaluation of Black CTC Teas Based upon Seasonal Variations. Int. J. Food Sci. Technol. 2014, 49, 493–500. [Google Scholar] [CrossRef]

- Pouri, Z.; Givianrad, M.H.; Seyedeyn Ardebili, S.M.; Larijani, K. Seasonal Variations in Phenolic Compounds of Black Tea (Camellia sinensis L.). Iran. J. Med. Aromat. Plants Res. 2011, 27, 57–71. [Google Scholar] [CrossRef]

- Yamanishi, T. Special Issue Tea. Food Rev. Int. 1995, 11, 477–505. [Google Scholar]

- Obanda, M. Comparison of the Tannin and Catechin Contents of Japanese and Kenyan Tea Cultivars. TRFK Annu. Rep. 1997, 125–128. [Google Scholar]

- Harbowy, M.E.; Balentine, D.A.; Davies, A.P.; Cai, Y. Tea Chemistry. Crit. Rev. Plant Sci. 1997, 16, 415–480. [Google Scholar] [CrossRef]

- Ye, F.; Guo, X.; Li, B.; Chen, H.; Qiao, X. Characterization of Effects of Different Tea Harvesting Seasons on Quality Components, Color and Sensory Quality of “Yinghong 9” and “Huangyu” Large-Leaf-Variety Black Tea. Molecules 2022, 27, 8720. [Google Scholar] [CrossRef]

- Salman, S.; Yılmaz, C.; Gökmen, V.; Ozdemir, F. Effects of Fermentation Time and Shooting Period on Amino Acid Derivatives and Free Amino Acid Profiles of Tea. LWT 2020, 137, 110481. [Google Scholar] [CrossRef]

- Zheng, X.Q.; Jin, J.; Chen, H.; Du, Y.Y.; Ye, J.H.; Lu, J.L.; Lin, C.; Dong, J.J.; Sun, Q.L.; Wu, L.Y. Effect of Ultraviolet B Irradiation on Accumulation of Catechins in Tea (Camellia sinensis (L) O. Kuntze. Afr. J. Biotechnol. 2008, 7. [Google Scholar]

- Sud, R.G.; Baru, A. Seasonal Variations in Theaflavins, Thearubigins, Total Colour and Brightness of Kangra Orthodox Tea (Camellia sinensis (L) O Kuntze) in Himachal Pradesh. J. Sci. Food Agric. 2000, 80, 1291–1299. [Google Scholar] [CrossRef]

- Xu, W.; Song, Q.; Li, D.; Wan, X. Discrimination of the Production Season of Chinese Green Tea by Chemical Analysis in Combination with Supervised Pattern Recognition. J. Agric. Food Chem. 2012, 60, 7064–7070. [Google Scholar] [CrossRef] [PubMed]

- Owuor, P.O.; Obanda, M.; Nyirenda, H.E.; Mandala, W.L. Influence of Region of Production on Clonal Black Tea Chemical Characteristics. Food Chem. 2008, 108, 263. [Google Scholar] [CrossRef]

- Carr, M.K.V.; Stephens, W. Climate, Weather and the Yield of Tea. In Tea: Cultivation to Consumption; Willson, K.C., Clifford, M.N., Eds.; Springer: Dordrecht, The Netherlands, 1992; pp. 87–135. ISBN 978-94-011-2326-6. [Google Scholar]

- Yao, L.; Caffin, N.; D’arcy, B.; Jiang, Y.; Shi, J.; Singanusong, R.; Liu, X.; Datta, N.; Kakuda, Y.; Xu, Y. Seasonal Variations of Phenolic Compounds in Australia-Grown Tea (Camellia sinensis). J. Agric. Food Chem. 2005, 53, 6477–6483. [Google Scholar] [CrossRef] [PubMed]

- Nixon, D.J.; Burgess, P.J.; Sanga, B.N.K.; Carr, M.K.V. A Comparison of the Responses of Mature and Young Clonal Tea to Drought. Exp. Agric. 2001, 37, 391–402. [Google Scholar] [CrossRef]

- Odhiambo, H.O.; Owuor, P.O.; Othieno, C.O. Factors Affecting Tea Quality: I. Agron. Pract. A Rev. Tea 1988, 9, 36–40. [Google Scholar]

- Rawat, R.; Gulati, A. Seasonal and Clonal Variations in Some Major Glycosidic Bound Volatiles in Kangra Tea (Camellia sinensis (L.) O. Kuntze). Eur. Food Res. Technol. 2008, 226, 1241–1249. [Google Scholar] [CrossRef]

- Owuor, P.; Obanda, M. Comparative Responses in Plain Black Tea Quality Parameters of Different Tea Clones to Fermentation Temperature and Duration. Food Chem. 2001, 72, 319–327. [Google Scholar] [CrossRef]

- Graham, H.N. Green Tea Composition, Consumption, and Polyphenol Chemistry. Prev. Med. 1992, 21, 334–350. [Google Scholar] [CrossRef]

- Soheili-Fard, F.; Ghassemzadeh, H.R.; Salvatian, S.B. Impact of Withering Time Duration on Some Biochemical Properties and Sensory Quality Attributes of Black Tea. Biol. Forum 2015, 7, 1045–1049. [Google Scholar]

- Sharma, A.; Dutta, P.P. Scientific and Technological Aspects of Tea Drying and Withering: A Review. Agric. Eng. Int. CIGR J. 2018, 20, 210–220. [Google Scholar]

- Deb, S.; Jolvis Pou, K.R. A Review of Withering in the Processing of Black Tea. J. Biosyst. Eng. 2016, 41, 365–372. [Google Scholar] [CrossRef]

- Jabeen, S.; Alam, S.; Saleem, M.; Ahmad, W.; Bibi, R.; Hamid, F.S.; Shah, H.U. Withering Timings Affect the Total Free Amino Acids and Mineral Contents of Tea Leaves during Black Tea Manufacturing. Arab. J. Chem. 2019, 12, 2411–2417. [Google Scholar] [CrossRef]

- Omiadze, N.T.; Mchedlishvili, N.I.; Rodrigez-Lopez, J.N.; Abutidze, M.O.; Sadunishvili, T.A.; Pruidze, N.G. Biochemical Processes at the Stage of Withering during Black Tea Production. Appl. Biochem. Microbiol. 2014, 50, 394–397. [Google Scholar] [CrossRef]

- Das, S.K.; Tewari, V.K. Mechanization of Tea Leaf Handling in Trough Withering System. Agric. Eng. Int. CIGR J. 2006. [Google Scholar]

- Mahanta, P.K.; Baruah, S. Relationship between Process of Withering and Aroma Characteristics of Black Tea. J. Sci. Food Agric. 1989, 46, 461–468. [Google Scholar] [CrossRef]

- Baruah, D.; Bhuyan, L.P.; Hazarika, M. Impact of Moisture Loss and Temperature on Biochemical Changes during Withering Stage of Black Tea Processing on Four Tocklai Released Clones. Two Bud. 2012, 59, 134–142. [Google Scholar]

- Wright, L.P.; Mphangwe, N.I.K.; Nyirenda, H.E.; Apostolides, Z. Analysis of the Theaflavin Composition in Black Tea (Camellia sinensis) for Predicting the Quality of Tea Produced in Central and Southern Africa. J. Sci. Food Agric. 2002, 82, 517–525. [Google Scholar] [CrossRef]

- Sanyal, S. Tea Manufacturing Manual; Tea Research Association, Tocklai Experimental Station: Jorhat, India, 2011. [Google Scholar]

- Zheng, X.-Q.; Li, Q.-S.; Xiang, L.-P.; Liang, Y.-R. Recent Advances in Volatiles of Teas. Molecules 2016, 21, 338. [Google Scholar] [CrossRef]

- Owuor, P.O.; Tsushida, T.; Horita, H.; Murai, T. Effects of Artificial Withering on the Chemical Composition and Quality of Black Tea. Trop. Sci. 1987. [Google Scholar]

- Ullah, M.R.; Gogoi, N.; Baruah, D. The Effect of Withering on Fermentation of Tea Leaf and Development of Liquor Characters of Black Teas. J. Sci. Food Agric. 1984, 35, 1142–1147. [Google Scholar] [CrossRef]

- Wu, H.; Huang, W.; Chen, Z.; Chen, Z.; Shi, J.; Kong, Q.; Sun, S.; Jiang, X.; Chen, D.; Yan, S. GC–MS-Based Metabolomic Study Reveals Dynamic Changes of Chemical Compositions during Black Tea Processing. Food Res. Int. 2019, 120, 330–338. [Google Scholar] [CrossRef] [PubMed]

- Lee, L.-S.; Kim, Y.-C.; Park, J.-D.; Kim, Y.-B.; Kim, S.-H. Changes in Major Polyphenolic Compounds of Tea (Camellia sinensis) Leaves during the Production of Black Tea. Food Sci. Biotechnol. 2016, 25, 1523–1527. [Google Scholar] [CrossRef] [PubMed]

- Owuor, P.O.; Orchard, J.E. Withering, Annual Report. Tea Res. Found. Kenya 1989, 89–102. [Google Scholar]

- Borah, A.; Gogoi, T.P.D.; Gogoi, M.; Kalita, M.M.; Dutta, P.; Das, P.J.; Tamuly, P. A Biochemical Approach to the Study of Chemical Basis of Stress during Tea Processing. Two Bud. 2012, 59, 74–77. [Google Scholar]

- Wang, K.; Chen, Q.; Lin, Y.; Li, S.; Lin, H.; Huang, J.; Zhonghua, L. Comparison of Phenolic Compounds and Taste of Chinese Black Tea. Food Sci. Technol. Res. 2014, 20, 639–646. [Google Scholar] [CrossRef]

- Mike, J. The Evaluation of Volatile Quality Factors in Black Tea. A report for the Rural Industries Research and Development Corporation Project No: UQ-61A, Publication. 1998. Available online: https://agrifutures.com.au/product/evaluation-of-volatile-quality-factors-in-black-tea/ (accessed on 4 October 2023).

- Singh, D.; Samantal, T.; Das, S.; Ghoshl, A.K.; Mitra, A.; Ghosh, B.C. Development Ofacustomized Trough Tostudy Withering Oftea Leaves. Two Bud. 2012, 59, 143–147. [Google Scholar]

- Tomlins, K.I.; Mashingaidze, A. Influence of Withering, Including Leaf Handling, on the Manufacturing and Quality of Black Teas—A Review. Food Chem. 1997, 60, 573–580. [Google Scholar] [CrossRef]

- Javed, A. Role of Processing Conditions in Determining Tea Quality; College of Technology, GB Pant University of Agriculture and Technology: Pantnagar, India, 2015; Available online: https://www.researchgate.net/publication/282978886 (accessed on 12 June 2023).

- Caffin, N.; D’Arcy, B.; Yao, L.; Rintoul, G. Developing an Index of Quality for Australian Tea. RIRDC Publ. 2004, 4, 33. [Google Scholar]

- Das, S.; Samanta, T.; Datta, A.K. Analysis and Modeling of Major Polyphenols during Oxidation in Production of Black Tea. J. Food Process. Preserv. 2019, 43, e14283. [Google Scholar] [CrossRef]

- Hajiboland, R. Environmental and Nutritional Requirements for Tea Cultivation. Folia Hortic. 2017, 29, 199–220. [Google Scholar] [CrossRef]

- Owuor, P.O.; Tsushida, T.; Horita, H.; Murai, T. Comparison of the Chemical Composition of Black Teas from Main Tea Producing Parts of the World; Maseno University: Kisumu, Kenya, 1986. [Google Scholar]

- Takeo, T.; Mahanta, P.K. Comparison of Black Tea Aromas of Orthodox and CTC Tea and of Black Teas Made from Different Varieties. J. Sci. Food Agric. 1983, 34, 307–310. [Google Scholar] [CrossRef]

- Takeo, T.; Mahanta, P.K. Why CTC Tea Is Less Fragrant. Two Bud. 1983, 30, 76–77. [Google Scholar]

- Shimin, W.U.; Qinyan, Y.U.; Jiayi, Z.H.U.; Jinjie, H.U.A.; Shuai, S.; Yongwen, J.; Haibo, Y.; Jia, L.I. Analysis of the Effect of Rolling Speed on the Congou Black Tea Quality Using Electronic Tongue and Metabolomics. Food Sci. 2023, 44, 301. [Google Scholar] [CrossRef]

- Sari, F.; Velioglu, Y.S. Changes in Theanine and Caffeine Contents of Black Tea with Different Rolling Methods and Processing Stages. Eur. Food Res. Technol. 2013, 237, 229–236. [Google Scholar] [CrossRef]

- Jiang, J.-X.; He, H.-F.; Chu, F.-Y.; Ye, Y.; Tong, H.-R. Effect of rolling temperature on the quality of congou black tea. Sci. Technol. Food Ind. 2017, 7, 90–95. [Google Scholar] [CrossRef]

- Zhu, H.-K.; He, H.-F.; Ye, Y.; Dong, C.-W.; Gui, A.-H.; Gao, M.-Z.; Chen, L. Influence of Rolling Temperature on Physicochemical Quality of Congou Black Tea. Mod. Food Sci. Technol. 2017, 33, 168–175. [Google Scholar] [CrossRef]

- Lee, J.-H. Study on the Effects of Rolling and Fermentation Processes on the Components, Physical and Chemical Properties and Antioxidant Activity of Black Tea Polysaccharides. Master’s Thesis, Zhejiang University, Hangzhou, China, 2022. [Google Scholar]

- Tüfekci, M.; Güner, S. The Determination of Optimum Fermentation Time in Turkish Black Tea Manufacture. Food Chem. 1997, 60, 53–56. [Google Scholar] [CrossRef]

- Kimutai, G.; Ngenzi, A.; Said, R.N.; Kiprop, A.; Förster, A. An Optimum Tea Fermentation Detection Model Based on Deep Convolutional Neural Networks. Data 2020, 5, 44. [Google Scholar] [CrossRef]

- Koch, W.; Kukula-Koch, W.; Komsta, Ł. Black Tea Samples Origin Discrimination Using Analytical Investigations of Secondary Metabolites, Antiradical Scavenging Activity and Chemometric Approach. Molecules 2018, 23, 513. [Google Scholar] [CrossRef]

- Kusano, R.; Matsuo, Y.; Saito, Y.; Tanaka, T. Oxidation Mechanism of Black Tea Pigment Theaflavin by Peroxidase. Tetrahedron Lett. 2015, 56, 5099–5102. [Google Scholar] [CrossRef]

- Hilal, Y.; Engelhardt, U. Characterisation of White Tea–Comparison to Green and Black Tea. J. Verbraucherschutz Leb. 2007, 2, 414–421. [Google Scholar] [CrossRef]

- Luczaj, W.; Skrzydlewska, E. Antioxidative Properties of Black Tea. Prev. Med. 2005, 40, 910–918. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.-S.; Liu, B.-L.; Chang, Y.-N. Bioactivities and Sensory Evaluation of Pu-Erh Teas Made from Three Tea Leaves in an Improved Pile Fermentation Process. J. Biosci. Bioeng. 2010, 109, 557–563. [Google Scholar] [CrossRef] [PubMed]

- Kuhnert, N.; Clifford, M.N.; Müller, A. Oxidative Cascade Reactions Yielding Polyhydroxy-Theaflavins and Theacitrins in the Formation of Black Tea Thearubigins: Evidence by Tandem LC-MS. Food Funct. 2010, 1, 180–199. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharyya, N.; Seth, S.; Tudu, B.; Tamuly, P.; Jana, A.; Ghosh, D.; Bandyopadhyay, R.; Bhuyan, M.; Sabhapandit, S. Detection of Optimum Fermentation Time for Black Tea Manufacturing Using Electronic Nose. Sens. Actuators B Chem. 2007, 122, 627–634. [Google Scholar] [CrossRef]

- Obanda, M.; Owuor, P.O.; Mang’oka, R. Changes in the Chemical and Sensory Quality Parameters of Black Tea Due to Variations of Fermentation Time and Temperature. Food Chem. 2001, 75, 395–404. [Google Scholar] [CrossRef]

- Saikia, D.; Boruah, P.K.; Sarma, U. Development and Implementation of a Sensor Network to Monitor Fermentation Process Parameter in Tea Processing. Int. J. Smart Sens. Intell. Syst. 2014, 7, 1254–1270. [Google Scholar] [CrossRef]

- Asil, M.H.; Rabiei, B.; Ansari, R.H. Optimal Fermentation Time and Temperature to Improve Biochemical Composition and Sensory Characteristics of Black Tea. Aust. J. Crop Sci. 2012, 6, 550–558. [Google Scholar]

- Stodt, U.W.; Blauth, N.; Niemann, S.; Stark, J.; Pawar, V.; Jayaraman, S.; Koek, J.; Engelhardt, U.H. Investigation of Processes in Black Tea Manufacture through Model Fermentation (Oxidation) Experiments. J. Agric. Food Chem. 2014, 62, 7854–7861. [Google Scholar] [CrossRef]

- Yao, L.H.; Jiang, Y.M.; Caffin, N.; D’arcy, B.; Datta, N.; Liu, X.; Singanusong, R.; Xu, Y. Phenolic Compounds in Tea from Australian Supermarkets. Food Chem. 2006, 96, 614–620. [Google Scholar] [CrossRef]

- Sharma, V.; Rao, L.J.M. A Thought on the Biological Activities of Black Tea. Crit. Rev. Food Sci. Nutr. 2009, 49, 379–404. [Google Scholar] [CrossRef] [PubMed]

- Ansari, H.R.; Asil, H.M.; Rabiei, B.; Dadashpour, A. Impacts of Flushing and Fermentation Times on the Quality of Black Tea. Genetika 2011, 43, 537–548. [Google Scholar] [CrossRef]

- Borah, S.; Bhuyan, M. Non-Destructive Testing of Tea Fermentation Using Image Processing. Insight-Non-Destr. Test. Cond. Monit. 2003, 45, 55–58. [Google Scholar] [CrossRef]

- Gill, G.S.; Kumar, A.; Agarwal, R. Monitoring and Grading of Tea by Computer Vision—A Review. J. Food Eng. 2011, 106, 13–19. [Google Scholar] [CrossRef]

- Tang, P.; Shen, D.-Y.; Xu, Y.-Q.; Zhang, X.-C.; Shi, J.; Yin, J.-F. Effect of Fermentation Conditions and Plucking Standards of Tea Leaves on the Chemical Components and Sensory Quality of Fermented Juice. J. Chem. 2018, 2018, 4312875. [Google Scholar] [CrossRef]

- Wang, H.; Shen, S.; Wang, J.; Jiang, Y.; Li, J.; Yang, Y.; Hua, J.; Yuan, H. Novel Insight into the Effect of Fermentation Time on Quality of Yunnan Congou Black Tea. LWT 2022, 155, 112939. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, J.; Yuan, H.; Ouyang, W.; Li, J.; Hua, J.; Jiang, Y. Effects of Fermentation Temperature and Time on the Color Attributes and Tea Pigments of Yunnan Congou Black Tea. Foods 2022, 11, 1845. [Google Scholar] [CrossRef] [PubMed]

- Hua, J.; Wang, H.; Yuan, H.; Yin, P.; Wang, J.; Guo, G.; Jiang, Y. New Insights into the Effect of Fermentation Temperature and Duration on Catechins Conversion and Formation of Tea Pigments and Theasinensins in Black Tea. J. Sci. Food Agric. 2022, 102, 2750–2760. [Google Scholar] [CrossRef]

- Ravichandran, R.; Parthiban, R. The Impact of Processing Techniques on Tea Volatiles. Food Chem. 1998, 62, 347–353. [Google Scholar] [CrossRef]

- Cloughley, J.B. The Effect of Temperature on Enzyme Activity during the Fermentation Phase of Black Tea Manufacture. J. Sci. Food Agric. 1980, 31, 920–923. [Google Scholar] [CrossRef]

- Qu, F.; Zeng, W.; Tong, X.; Feng, W.; Chen, Y.; Ni, D. The New Insight into the Influence of Fermentation Temperature on Quality and Bioactivities of Black Tea. LWT 2020, 117, 108646. [Google Scholar] [CrossRef]

- Subramanian, N.; Venkatesh, P.; Ganguli, S.; Sinkar, V.P. Role of Polyphenol Oxidase and Peroxidase in the Generation of Black Tea Theaflavins. J. Agric. Food Chem. 1999, 47, 2571–2578. [Google Scholar] [CrossRef] [PubMed]

- Robertson, A. The Chemistry and Biochemistry of Black Tea Production—The Non-Volatiles. In Tea: Cultivation to Consumption; Springer: Berlin/Heidelberg, Germany, 1992; pp. 555–601. [Google Scholar]

- Obanda, M.; Owuor, P.O. The Effect of Chemical Wither Duration and Dryer Type on Quality of Black Tea Manufactured in a Commercial Factory. Tea 1992, 13, 50–61. [Google Scholar]

- Vargas, R.; Vecchietti, A. Influence of Raw Material Moisture on the Synthesis of Black Tea Production Process. J. Food Eng. 2016, 173, 76–84. [Google Scholar] [CrossRef]

- Temple, S.J.; Temple, C.M.; van Boxtel, A.J.B.; Clifford, M.N. The Effect of Drying on Black Tea Quality. J. Sci. Food Agric. 2001, 81, 764–772. [Google Scholar] [CrossRef]

- Konar, H.; Datta, A. Optimization of Process Parameters for Vacuum Drying ofCTC Tea. Two Bud 2012, 59, 84–88. [Google Scholar]

- Teshome, K.; Debela, A.; Garedew, W. Effect of Drying Temperature and Duration on Biochemical Composition and Quality of Black Tea (Camellia sinensis L.) O. Kuntze at Wush Wush, South Western Ethiopia. Asian J. Plant Sci. 2013, 12, 235. [Google Scholar] [CrossRef]

- Lee, J.; Hwang, Y.-S.; Kang, I.-K.; Choung, M.-G. Lipophilic Pigments Differentially Respond to Drying Methods in Tea (Camellia sinensis L.) Leaves. LWT—Food Sci. Technol. 2015, 61, 201–208. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Y.; Huo, J.; Zhao, T.; Ren, J.; Wei, X. Effect of Different Drying Methods on Chemical Composition and Bioactivity of Tea Polysaccharides. Int. J. Biol. Macromol. 2013, 62, 714–719. [Google Scholar] [CrossRef]

- Owuor, P.O.; Orchard, J.E. Variations in Black Tea Quality Due to Changing Withering Techniques in Smallholder Factories. Tea 1991, 12, 32–40. [Google Scholar]

- Owuor, P.O.; Orchard, J.E. Effects of Storage Time in a Two-Stage Withering Process on the Quality of Seedling Black Tea. Food Chem. 1992, 45, 45–49. [Google Scholar] [CrossRef]

- Kavish, K.; Botheju, W.S.; De Silva, C.S. Impact of Inlet Drying Temperature in Endless Chain Pressure Dryers on the Quality Characteristics of Leafy Type of Tea Produced Using Different Leaf Standards. OUSL J. 2016, 10, 73–92. [Google Scholar] [CrossRef]

- Rabeta, M.S.; Vithyia, M. Effect of Different Drying Methods on the Antioxidant Properties of Vitex Negundo Linn. Tea. Int. Food Res. J. 2013, 20, 3171. [Google Scholar]

- Kongsoontornkijkul, P.; Ekwongsupasarn, P.; Chiewchan, N.; Devahastin, S. Effects of Drying Methods and Tea Preparation Temperature on the Amount of Vitamin C in Indian Gooseberry Tea. Dry. Technol. 2006, 24, 1509–1513. [Google Scholar] [CrossRef]

- Hirun, S.; Utama-ang, N.; Vuong, Q.V.; Scarlett, C.J. Investigating the Commercial Microwave Vacuum Drying Conditions on Physicochemical Properties and Radical Scavenging Ability of Thai Green Tea. Dry Technol. 2014, 32, 47–54. [Google Scholar] [CrossRef]

- Qu, F.; Zhu, X.; Ai, Z.; Ai, Y.; Qiu, F.; Ni, D. Effect of Different Drying Methods on the Sensory Quality and Chemical Components of Black Tea. LWT 2019, 99, 112–118. [Google Scholar] [CrossRef]

- Rumaisa, N.; Hanim, M.R.N.; Hii, C.L. Superheated Steam Drying of Black Tea and Quality Improvement. Int. J. Food Eng. 2018, 14. [Google Scholar] [CrossRef]

- Yan, Z.; Zhou, Z.; Jiao, Y.; Huang, J.; Yu, Z.; Zhang, D.; Chen, Y.; Ni, D. Hot-Air Drying Significantly Improves the Quality and Functional Activity of Orange Black Tea Compared with Traditional Sunlight Drying. Foods 2023, 12, 1913. [Google Scholar] [CrossRef]

- Nagalakshmi, D.; Sastry, V.R.B.; Pawde, A. Rumen Fermentation Patterns and Nutrient Digestion in Lambs Fed Cottonseed Meal Supplemental Diets. Anim. Feed. Sci. Technol. 2003, 103, 1–14. [Google Scholar] [CrossRef]

- Cloughley, J.B. Storage Deterioration in Central African Tea: Methods of Reducing the Rate of Theaflavin Degradation. J. Sci. Food Agric. 1981, 32, 1224–1228. [Google Scholar] [CrossRef]

- Huang, A.; Jiang, Z.; Tao, M.; Wen, M.; Xiao, Z.; Zhang, L.; Zha, M.; Chen, J.; Liu, Z.; Zhang, L. Targeted and Nontargeted Metabolomics Analysis for Determining the Effect of Storage Time on the Metabolites and Taste Quality of Keemun Black Tea. Food Chem. 2021, 359, 129950. [Google Scholar] [CrossRef] [PubMed]

- Mahanta, P.K. Colour and Flavour Characteristics of Made Tea. In Analysis of Nonalcoholic Beverages; Springer: Berlin/Heidelberg, Germany, 1988; pp. 221–295. [Google Scholar]

- Springett, M.B.; Williams, B.M.; Barnes, R.J. The Effect of Packaging Conditions and Storage Time on the Volatile Composition of Assam Black Tea Leaf. Food Chem. 1994, 49, 393–398. [Google Scholar] [CrossRef]

- Debnath, S.; Tanti, A.; Sabhapandit, S.; Phukan, I.; Dutta, P.; Barthakur, A. Storage Deterioration of Quality of CTC Black Tea. Two Bud. 2012, 59, 31–33. [Google Scholar]

- Wickramasinghe, R.L.; Perera, K. Chemical Changes during Storage of Black Tea. Tea Q. 1972, 43, 147–152. [Google Scholar]

- Stagg, G.V. Chemical Changes Occurring during the Storage of Black Tea. J. Sci. Food Agric. 1974, 25, 1015–1034. [Google Scholar] [CrossRef]

- Dougan, J.; Glossop, E.J.; Howard, G.E.; Jones, B.D. A Study of the Changes Occurring in Black Tea during Storage; Tropical Products Institute: Salem, MA, USA, 1978. [Google Scholar]

- Chang, M.-Y.; Lin, Y.-Y.; Chang, Y.-C.; Huang, W.-Y.; Lin, W.-S.; Chen, C.-Y.; Huang, S.-L.; Lin, Y.-S. Effects of Infusion and Storage on Antioxidant Activity and Total Phenolic Content of Black Tea. Appl. Sci. 2020, 10, 2685. [Google Scholar] [CrossRef]

- Jiménez-Zamora, A.; Delgado-Andrade, C.; Rufián-Henares, J.A. Antioxidant Capacity, Total Phenols and Color Profile during the Storage of Selected Plants Used for Infusion. Food Chem. 2016, 199, 339–346. [Google Scholar] [CrossRef]

- La Torre, C.; Fazio, A.; Caputo, P.; Plastina, P.; Caroleo, M.C.; Cannataro, R.; Cione, E. Effects of Long-Term Storage on Radical Scavenging Properties and Phenolic Content of Kombucha from Black Tea. Molecules 2021, 26, 5474. [Google Scholar] [CrossRef]

| Parameters (Chemical Quality) | Hand Plucked | Shear-Plucked A | Shear-Plucked B | Hand Plucked | Shear-Plucked | ||

|---|---|---|---|---|---|---|---|

| Theaflavin (%) | 0.78 | 0.71 | 0.76 | [53] | 13.16 μmols g−l | 12.81 μmols g−l | [50] |

| Thearubigins (%) | 7.60 | 8.10 | 7.90 | 13.64 | 14.12 | ||

| High polymerized substances (%) | 7.10 | 7.70 | 7.30 | ||||

| Total liquor color | 2.60 | 2.50 | 2.60 | 3.16 | 3.23 | ||

| Water extract (%) | 41.90 | 40.70 | 41.60 | ||||

| Crude fiber (%) | 15.40 | 14.90 | 15.20 | ||||

| Caffeine (%) | 3.30 | 3.00 | 3.10 | 2.72 | 2.57 | ||

| Lipid (%) | 3.00 | 3.30 | 3.10 | ||||

| Protein (%) | 16.0 | 16.6 | 16.2 | ||||

| Taster’s score | |||||||

| A | 33.00 | 30.00 | 32.00 | ||||

| B | 36.00 | 32.00 | 33.00 | ||||

| Biochemical constituents | |||||||

| Total catechin (%) | 18.4 | 17.8 | 18.2 | ||||

| Total polyphenols (%) | 27.7 | 26.6 | 27.5 | ||||

| PPO activity (U/mg protein) | 24.4 | 23.1 | 23.0 | ||||

| Total lipid (%) | 6.3 | 7.7 | 7.3 | ||||

| Total protein (%) | 14.1 | 15.3 | 15.1 | ||||

| Fatty acids | |||||||

| Palmitic (16:0) | 15.3 | 14.6 | 14.9 | ||||

| Stearic (18:0) | 8.0 | 7.7 | 8.0 | ||||

| Oleic (18:1) | 7.4 | 8.8 | 8.1 | ||||

| Linoleic (18:2) | 20.7 | 22.5 | 21.3 | ||||

| Linolenic (183) | 37.2 | 37.0 | 36.8 |

| Parameters | Plucking Standard | Plucking Interval | Rolling Time | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bud | 1 Leaf +Bud | 2 Leaves +Bud | 3 Leave +Bud | 4 Leaves +Bud | 5 Leaves +Bud | 5 Days | 7 Days | 9 Days | 11 Days | 50/Min Rolling | 75/Min Rolling | 100/Min Rolling | 125/Min Rolling | ||||

| Caffeine % | 3.89 | 3.42 | 2.11 | 1.56 | 1.29 | 1.22 | [66] | 4.4 | 4.79 | 4.3 | 3.81 | [67] | [68] | ||||

| Theaflavins µM/g or % | 23.21 | 33.43 | 34.71 | 29.99 | 27.33 | 22.42 | 1.12% | 1.22% | 1.2% | 1.4% | 0.3007 ± 0.0046% | 0.3698 ± 0.0047% | 0.3968 ± 0.0013% | 0.3825 ± 0.0098% | |||

| Thearubigins % | 8.26 | 12.93 | 17.81 | 18.19 | 18.99 | 16.68 | 13.5 | 13.9 | 14.9 | 15.74 | 3.0475 ± 0.0529 | 3.5088 ± 0.1417 | 4.3983 ± 0.0949 | 5.1962 ± 0.0681 | |||

| Total water-soluble solids % | 48.2 | 50.6 | 47.9 | 45.00 | 41.9 | 42.6 | 44.3 | 44.4 | 42.5 | 41.44 | |||||||

| Ash % | 7.21 | 6.78 | 6.1 | 6.38 | 6.37 | 6.65 | 5.95 | 6.15 | 6.16 | 6.15 | |||||||

| Crude fiber % | 6.76 | 8.12 | 10.22 | 13.68 | 14.86 | 16.65 | 6.7 | 7.00 | 9.4 | 10.15 | |||||||

| Sum of Group I | 3.61 | 4.47 | 4.63 | 4.86 | 5.23 | 5.74 | |||||||||||

| Sum of Group II | 8.18 | 8.30 | 6.94 | 5.50 | 5.06 | 4.54 | |||||||||||

| FI. (II/I) | 2.26 | 1.86 | 1.50 | 1.13 | 0.97 | 0.79 | |||||||||||

| TF/TR % | 0.08 | 0.09 | 0.09 | 0.09 | |||||||||||||

| Taster’s Evaluation | Very Good | Good | Good | Fair | |||||||||||||

| Theabrownin% | 5.5444 ± 0.0535 | 6.2834 ± 0.0373 | 6.4246 ± 0.0509 | 6.707 ± 0.0509 | |||||||||||||

| Time (min) | TFs 1 (%) | TR 2 (%) | Caffeine (%) | C 3 (%) | EC 4 (%) | EGCG 5 (%) | ECG 6 (%) | Time (min) | Color | Taste | Aroma | Strength | Infusion | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 15 | 1.61 | 10.5 | 2.71 | 0.632 | 0.310 | 8.15 | 0.574 | [13] | 135 | Dull | Fair | Fair | Weak | Dark/Dull | [64] |

| 30 | 2.29 | 12.5 | 2.93 | 0.207 | 0.923 | 4.11 | 0.377 | 140 | Dull and light red | Fair | Good | Weak | Mixed | ||

| 45 | 2.59 | 12.7 | 2.90 | 0.240 | 0.914 | 3.23 | 0.289 | 145 | Dull and light red | Fair | Good | Strong | Even and Bright | ||

| 60 | 2.43 | 13.1 | 2.74 | 0.271 | 0.844 | 2.83 | 0.231 | 165 | Dull | Fair | Very Good | Strong | Coppery | ||

| 75 | 2.38 | 13.3 | 2.88 | 0.250 | 0.787 | 1.77 | 0.165 | 175 | Light Red | Good | Excellent | Very Strong | Dark or Dull | ||

| 90 | 2.29 | 14.2 | 2.86 | 0.321 | 0.417 | 2.03 | 0.144 | 305 | Bright Red | Very Excellent | Excellent | Very Strong | Dark and Dull | ||

| 105 | 2.28 | 13.1 | 2.68 | 0.304 | 0.750 | 1.21 | 0.098 | ||||||||

| 120 | 2.20 | 12.9 | 2.81 | 0.295 | 0.614 | 1.46 | 0.084 | ||||||||

| 135 | 2.03 | 13.2 | 2.86 | 0.341 | 0.870 | 1.63 | 0.084 | ||||||||

| 150 | 1.98 | 12.8 | 2.51 | 0.249 | 0.636 | 1.42 | 0.055 | ||||||||

| 165 | 2.01 | 12.8 | 2.76 | 0.252 | 0.434 | 1.13 | 0.054 | ||||||||

| 180 | 1.96 | 13.3 | 2.72 | 0.23 | 0.867 | 1.25 | 0.052 |

| Different Drying Methods | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Parameters | HDT 1 | FDT 2 | MDT 3 | LDT 4 | MLDT 5 | HA 6 | HR 7 | ||

| Dry tea color (10%) | 84.0 ± 0.5 | 89.0 ± 1.7 | 88.3 ± 1.2 | 88.8 ± 1.6 | 88.8 ± 2.4 | [171] | 90 ± 0.5 | 88 ± 0.7 | [27] |

| Dry tea streak (10%) | 83.3 ± 0.6 | 83.5 ± 0.5 | 82.3 ± 2.1 | 82.7 ± 1.5 | 83.0 ± 2.0 | 86 ± 1.0 | 90 ± 0.8 | ||

| Liquor color (10%) | 89.5 ± 1.3 | 89.3 ± 3.1 | 87.7 ± 1.5 | 88.2 ± 1.3 | 90.0 ± 1.5 | 91 ± 0.5 | 89 ± 0.6 | ||

| Aroma (30%) | 81.5 ± 0.5 | 84.0 ± 1.8 | 90.0 ± 2.2 | 86.2 ± 2.0 | 91.3 ± 1.8 | 89 ± 0.6 | 87 ± 0.4 | ||

| Taste (30%) | 81.8 ± 1.0 | 84.2 ± 2.1 | 90.0 ± 1.8 | 87.0 ± 2.0 | 91.5 ± 1.5 | 89 ± 0.5 | 85 ± 0.7 | ||

| Infused leaf (10%) | 84.0 ± 0.5 | 84.2 ± 1.0 | 83.0 ± 1.0 | 83.7 ± 1.0 | 83.8 ± 2.0 | 89 ± 0.8 | 88 ± 0.5 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aaqil, M.; Peng, C.; Kamal, A.; Nawaz, T.; Zhang, F.; Gong, J. Tea Harvesting and Processing Techniques and Its Effect on Phytochemical Profile and Final Quality of Black Tea: A Review. Foods 2023, 12, 4467. https://doi.org/10.3390/foods12244467

Aaqil M, Peng C, Kamal A, Nawaz T, Zhang F, Gong J. Tea Harvesting and Processing Techniques and Its Effect on Phytochemical Profile and Final Quality of Black Tea: A Review. Foods. 2023; 12(24):4467. https://doi.org/10.3390/foods12244467

Chicago/Turabian StyleAaqil, Muhammad, Chunxiu Peng, Ayesha Kamal, Taufiq Nawaz, Fei Zhang, and Jiashun Gong. 2023. "Tea Harvesting and Processing Techniques and Its Effect on Phytochemical Profile and Final Quality of Black Tea: A Review" Foods 12, no. 24: 4467. https://doi.org/10.3390/foods12244467

APA StyleAaqil, M., Peng, C., Kamal, A., Nawaz, T., Zhang, F., & Gong, J. (2023). Tea Harvesting and Processing Techniques and Its Effect on Phytochemical Profile and Final Quality of Black Tea: A Review. Foods, 12(24), 4467. https://doi.org/10.3390/foods12244467