Challenges and Prospects of Plant-Protein-Based 3D Printing

Abstract

:1. Introduction

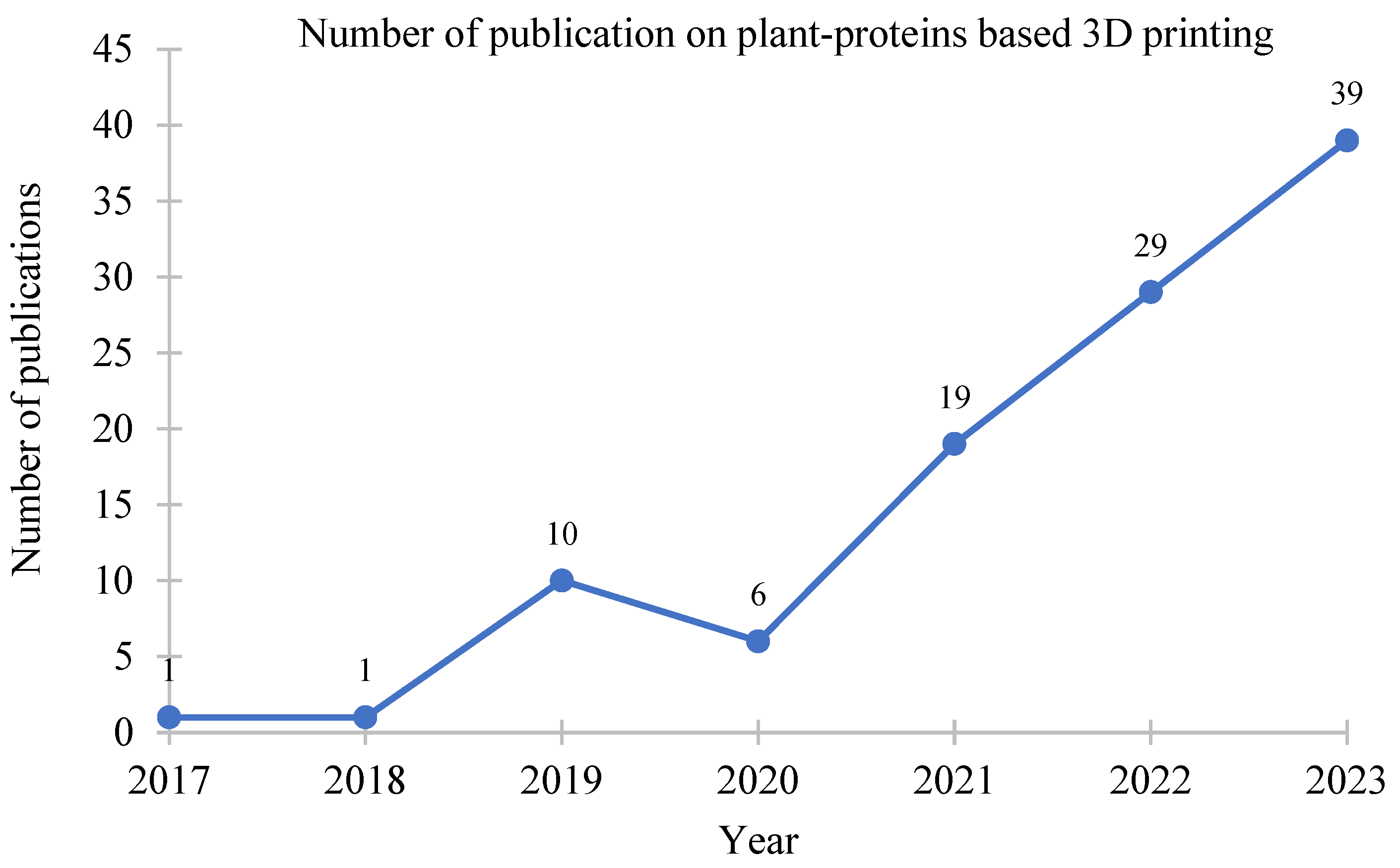

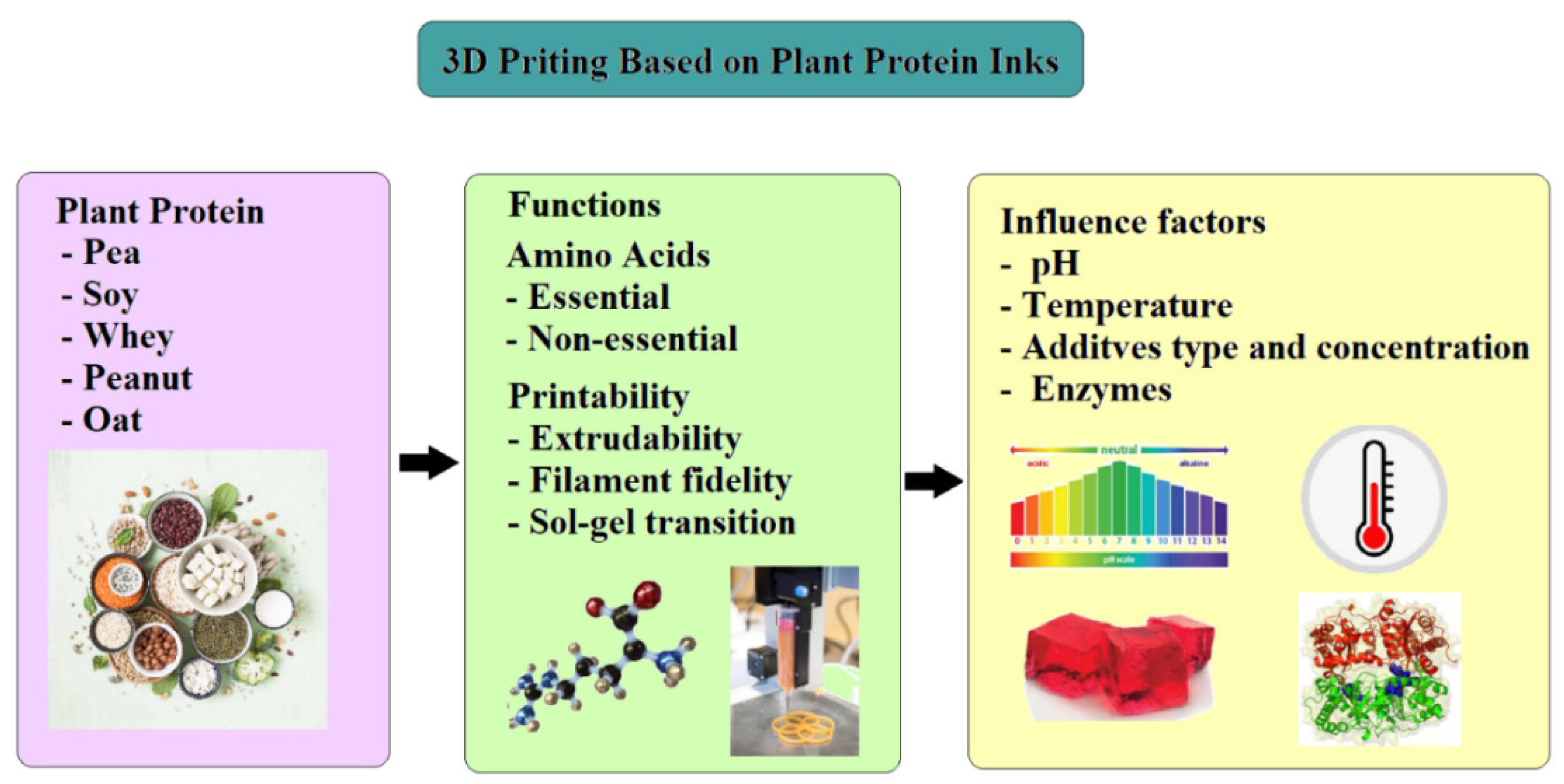

2. Trends of Plant-Protein-Based 3D Printing

3. Three-Dimensional Printer Parameters

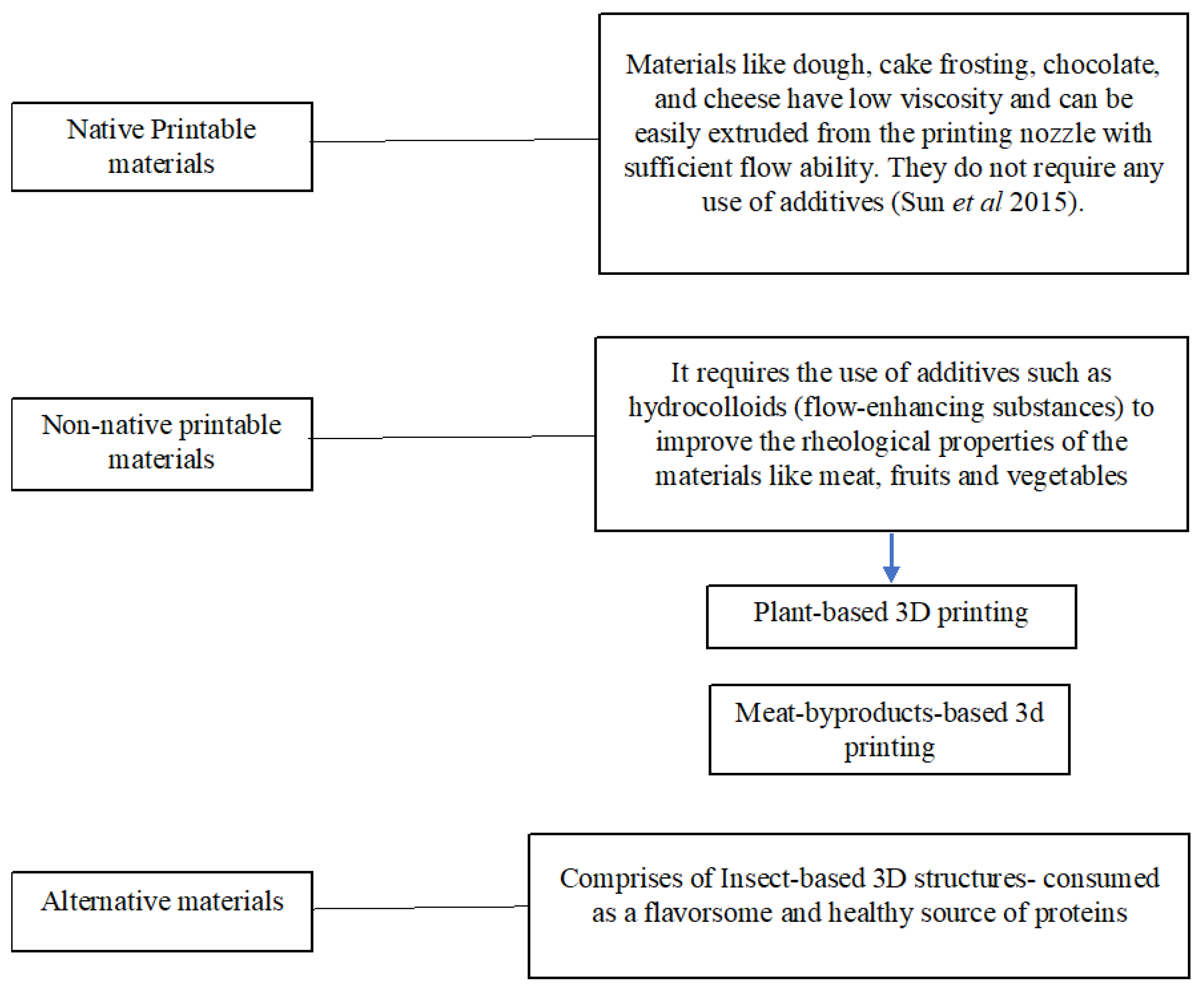

4. Technological Feasibility of Protein-Based 3D Printed Food

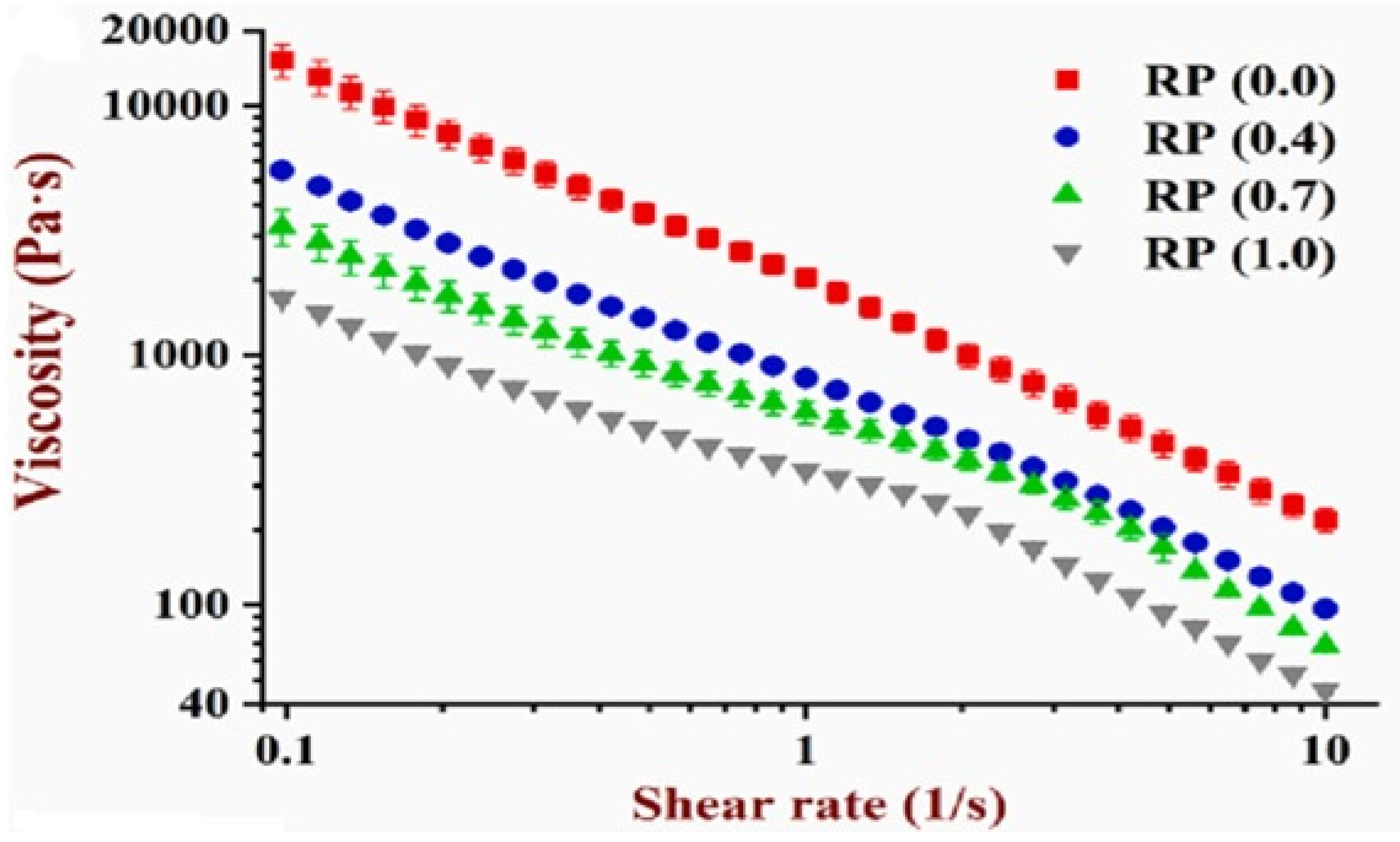

4.1. Extrudability

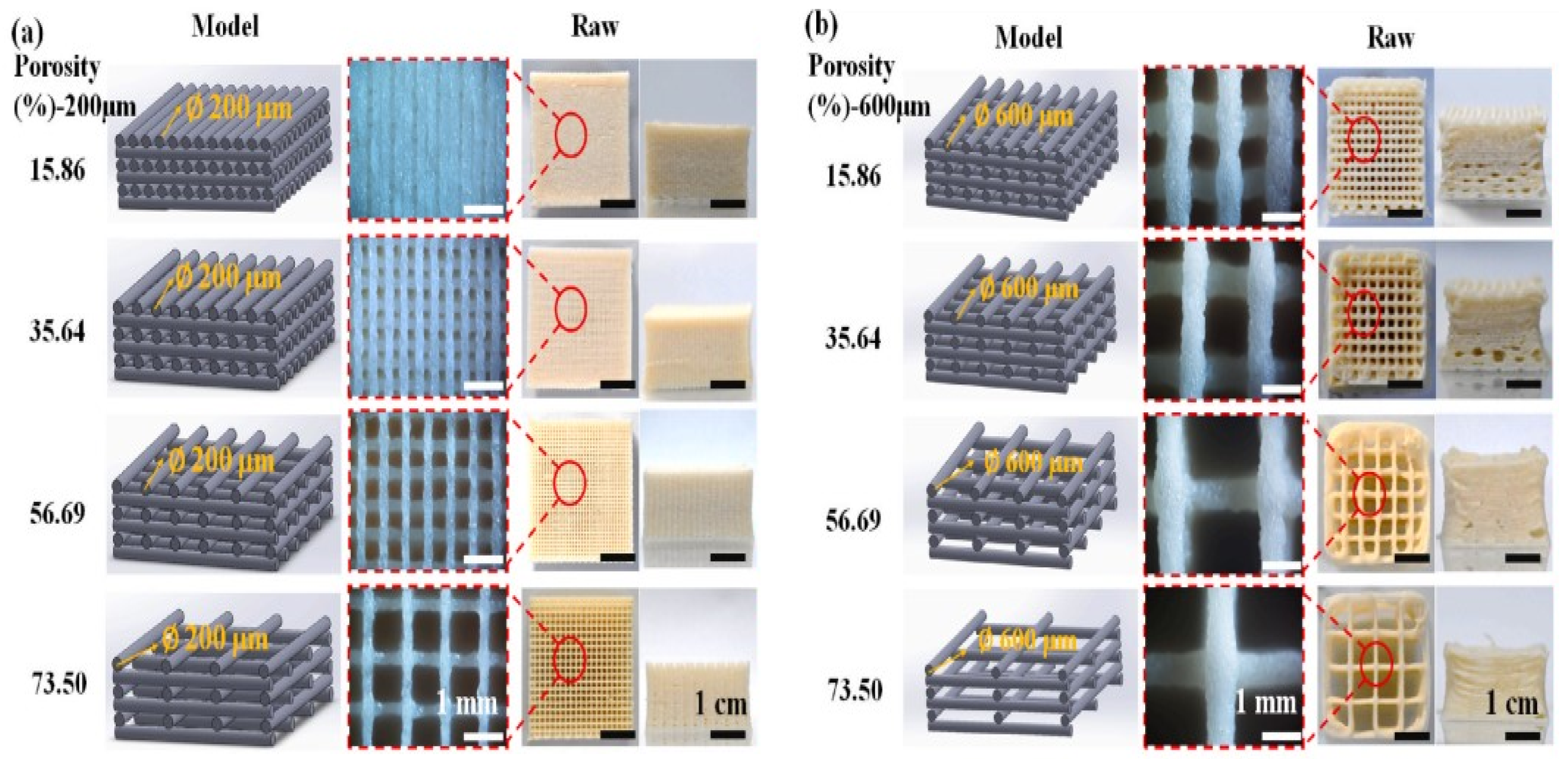

4.2. Filament Fidelity

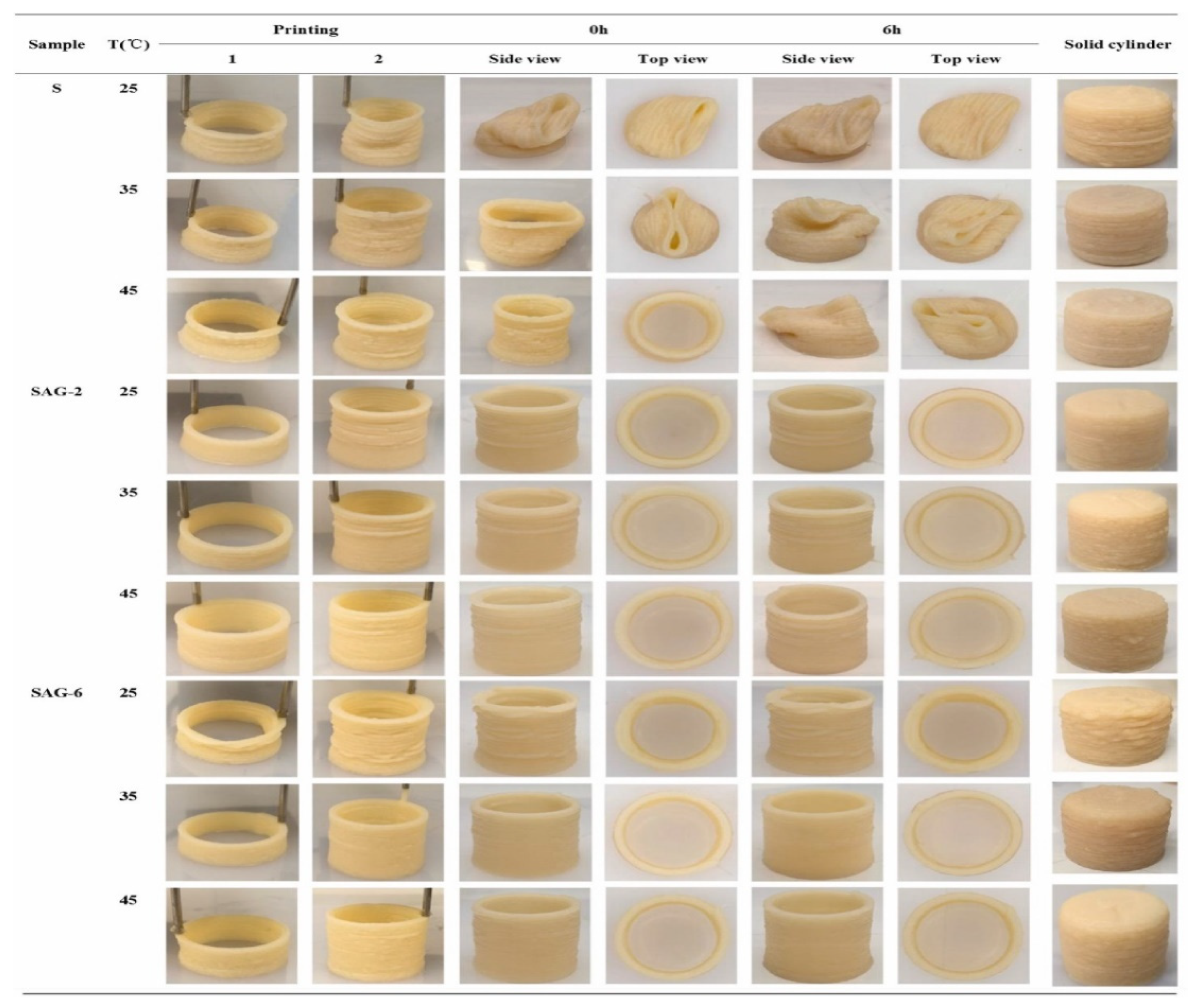

4.3. Sol–Gel Transition

5. Plant-Based Proteins for Extrusion-Based 3D Printing

5.1. Role of Plant Protein

5.1.1. Legume-Based

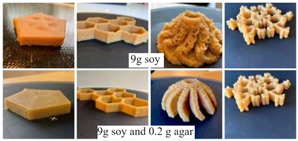

Soy Protein

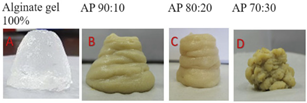

Pea Protein

Faba and Mung Bean Protein

| Category | Other Materials | Experimental Conditions | Results | References |

|---|---|---|---|---|

| Soy protein | Textured-soy protein (TSP), drawing soy protein (DSP,) xanthan gum, Konica gum, sodium alginate, guar gum, sodium carboxymethyl, cellulose | Refrigeration: 4 °C; printing nozzle temperature: 25 °C. | TSP with xanthan gum showed best printing characteristics. | [47] |

| L-cysteine, Transglutaminase | pH: 7, heating: 90 °C; mixing: 1500 rpm (1 min) and 300 rpm (2 min). | SPI heated for 25 min with l-cysteine had best printability and stability. | [28] | |

| K-carrageenan, vanilla powder | Heating: 70 °C; microwave: 50, 80, and 110 W | SPI gel made with 3% carrageenan had the optimal viscosity for 3D printing. | [53] | |

| Guar gum, xanthan gum, soybean oil, NaCl powder | Homogenization: 800 rpm, 5 min; heating: 70 °C, 60 min. | SPI gel with xanthan showed better rheological properties but a high concentration of XG (0.5% w/w) resulted in poor flexibility. | [47] | |

| Strawberry powder | Microwave: 30, 50 and 70 W | Salt pretreatment improved the printability and shape stability of ink systems. Maximum shape accuracy—70 W. | [30] | |

| Pea protein | Alginate, calcium chloride, sodium phosphate | Temperature: 45 °C | Alginate solution (80%) and pea protein solution (20%) were most suitable for 3D printing. | [37] |

| Microwave vacuum-dried banana powder, ascorbic acid | Blending: 1 min; sifting: 300 μm; mixing: 2000 rpm, 25 °C, 6 min | Banana pastes with 15% PPI concentration retained their shape and geometry after printing. | [50] | |

| Mung bean protein | Mung bean flour, hydrochloric acid, sodium hydroxide, Coomassie Blue R250, and bromophenol blue. | Mixing with 100 mL water; blending: pH-9, 2000 rpm, 30 °C, 1 h; centrifugation: 8586× g; freeze-drying: 48 h. | Optimized extrusion parameters: feed moisture: 49.33%; screw speed: 80.66 rpm; and barrel temperature: 144.57 °C; fibrous structure, partial protein unfoldment, high retention of amino acids. | [52] |

5.1.2. Cereal-Based

Gluten Protein

Oat Protein

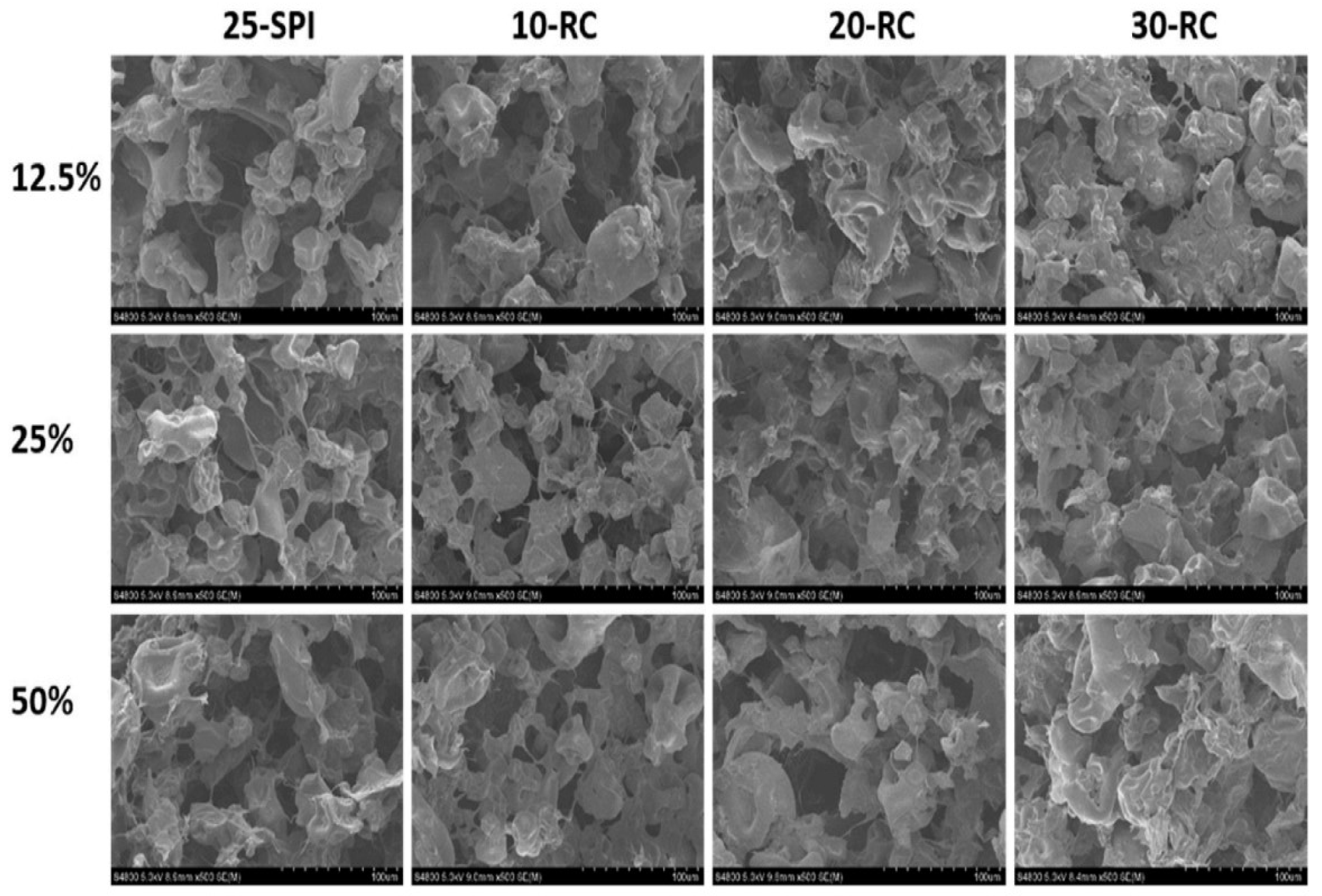

Rice Protein

5.2. Role of Additives

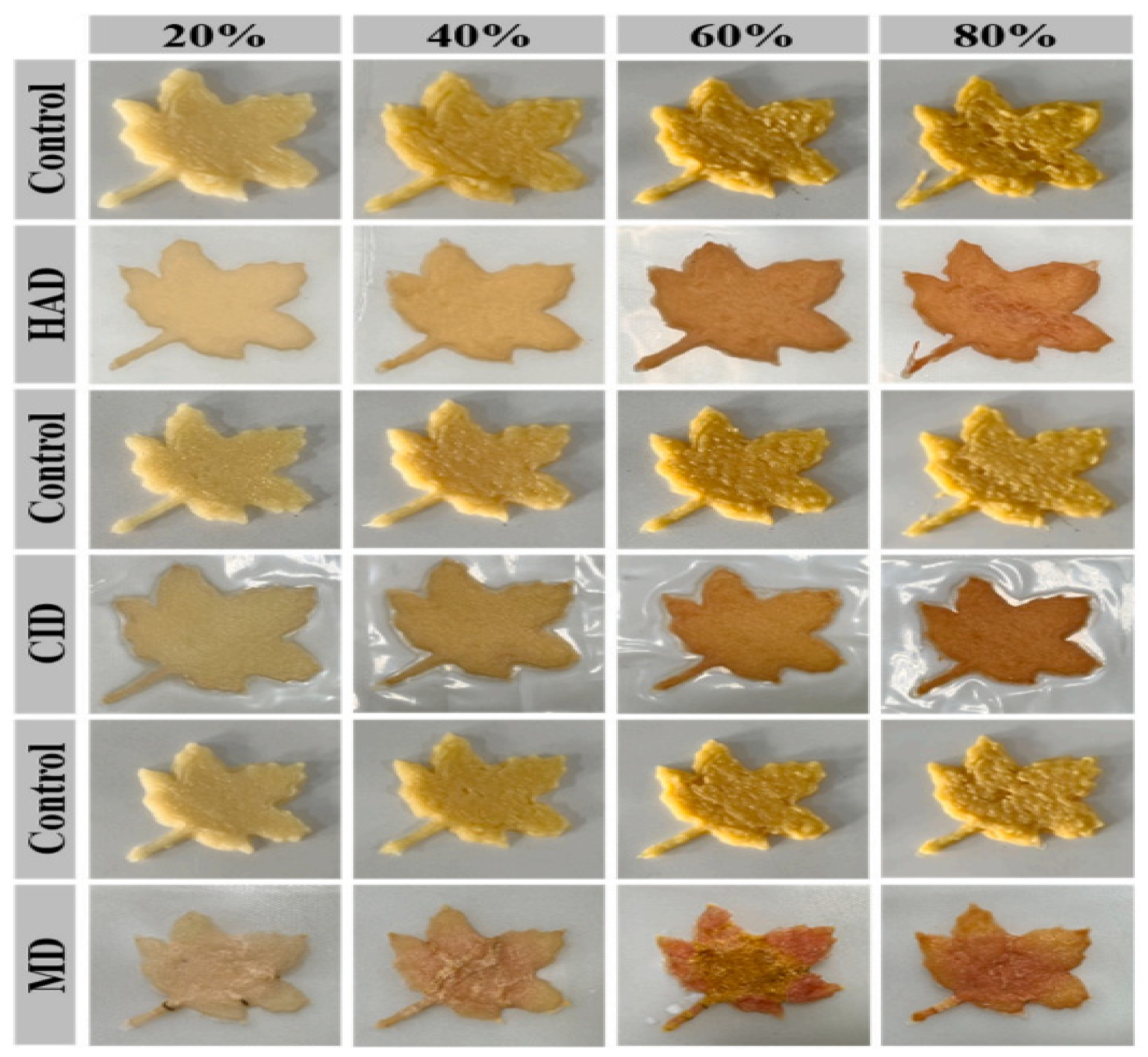

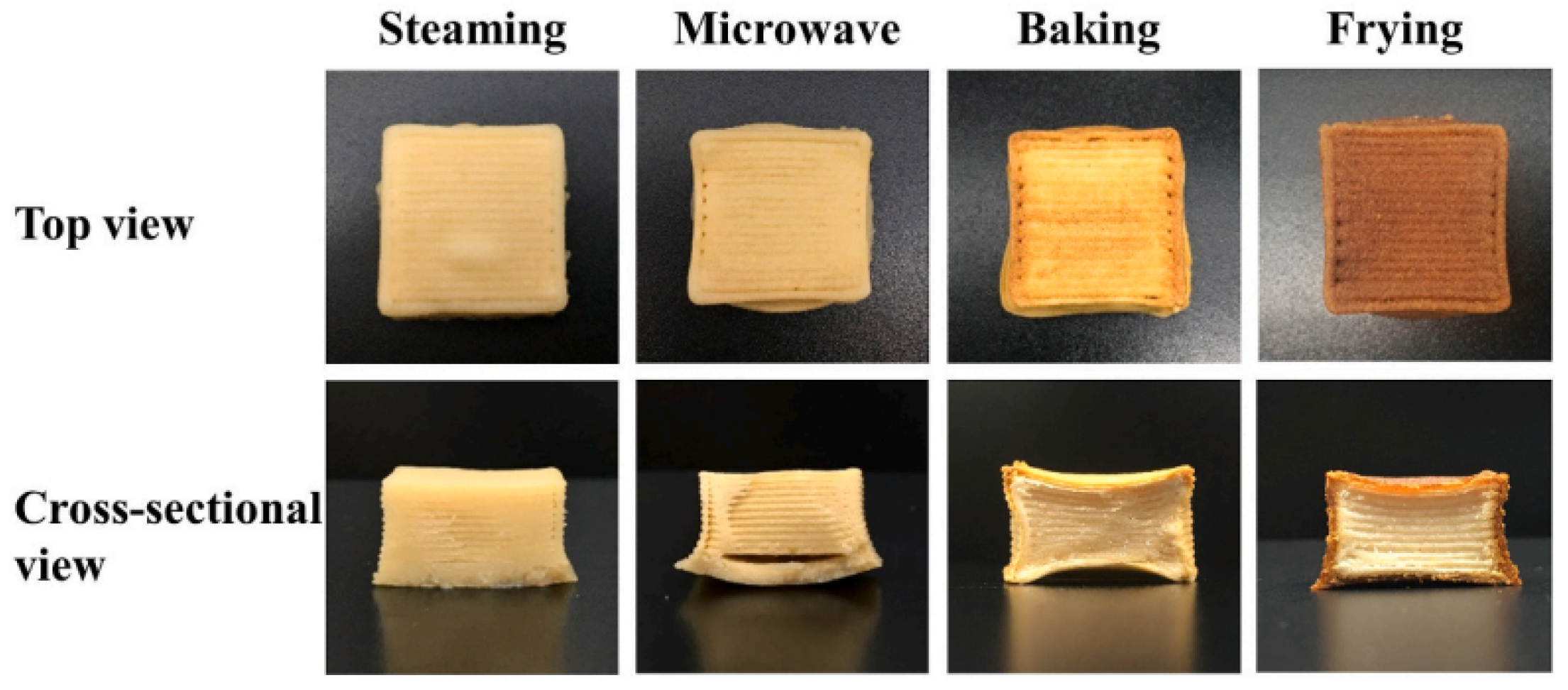

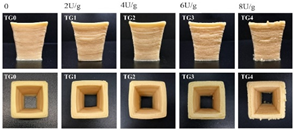

6. Post-Printing Treatments

7. Challenges and Future Perspectives

- Printing precision and shape stability are the biggest challenges to overcome. The development of future 3D-printing inks still depends on the concentration, type, and the environmental and operating conditions which need to be controlled in accordance with the rheological properties of the food. A superior finished product is made by controlling printing parameters such as pH, temperature, speed of nozzle, nozzle diameter, and the material quality and quantity. The printability and self-supporting property of the ink is improved by incorporating various additives to the ink such as hydrocolloids, carbohydrates, lipid additives, phenolic compounds, enzymes, starches, and hydrogels. Lately, there has been a demonstration of cellulose’s potential to enhance the characteristics of emulsions based on proteins. Cellulose materials are attracting attention due to their status as the main constituent in plants. Cellulose, as a sustainable and inexhaustible polymeric raw material, has the capacity to fulfill the growing need for eco-friendly products [65]. Also, it might be effective to combine 3D food printing with other cutting-edge technology. For instance, microwave and ultrasonic technologies are applied during pre- or post-processing to enhance the printing accuracy and shape stability [30].

- Preserving the textural and sensory attributes of the printed food. Sensory attributes such as mouthfeel are influenced by product texture and its ability to bind water. The sensory and textural characteristics of food are impacted by the presence of fats. However, the prolonged excessive intake of saturated fats heightens the susceptibility to numerous chronic conditions, including obesity, cardiovascular disease, and metabolic syndrome. In recent times, nutritional awareness has grown and there is an increased focus on low-fat products. Emulsions are the potential fat replacers, and incorporating cellulose into protein emulsion-based fat replacers enhances the nutritional, textural, and sensory attributes. This improvement is attributed to cellulose’s ability to effectively retain water, stabilize interfaces/networks, and thickening effects in addition to its nutritional value as dietary fiber [66].

- Meat products are characterized by a red or pink color that is obviously hard to obtain without the application of colorants. Unfortunately, the issue still exists since many consumers who choose vegetarian goods also avoid additives, which makes the matter more technologically challenging. However, the growing use of 4D printing has encouraged a more thorough investigation into product appearance, which includes color and shape.

- Production efficiency. The size and speed of 3D food printing prevent its usage in industrial-scale food production. Although the printing speed or nozzle diameter can be increased, doing so frequently leads to a loss of printing resolution. Researchers have suggested speeding up printing by using adaptive algorithms, which might change the printing settings to balance the printing quality and time [48]. Using multi-nozzle printers to print multiple 3D objects at once is another possible strategy. Future studies should look into the incorporation of phenolic compounds such as flavonoids, as they are closely related to the sensory and nutritional quality of the food. Future research must examine these issues and opportunities for plant-protein-based inks.

- Consumer acceptance: Acceptability and pleasantness of 3D-printed food is one of the major challenges. A study conducted by Lupton et al. [67] reported the concerns of many participants that the food created using a printer might be inedible, unsafe, or nutritionally deficient. Additionally, the term ‘printer,’ typically linked with non-food industries, appeared to negatively influence participants’ willingness to accept such technology. Ross et al. [68] conducted a study on Irish people and reported that the attitudes of consumers towards the use of 3D food printing technologies might differ depending on the consumer’s country of residence. A study revealed that consumer acceptance to 3D-printed food depends on (1) the initial information provided, i.e., the first impression consumers receive, and that (2) well-designed communication has the potential to positively shape consumers’ attitudes toward 3D-printed food [69].

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsä-Kortelainen, S.; Sozer, N. Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 2018, 220, 20–27. [Google Scholar] [CrossRef]

- Derossi, A.; Caporizzi, R.; Azzollini, D.; Severini, C. Application of 3D printing for customized food. A case on the development of a fruit-based snack for children. J. Food Eng. 2018, 220, 65–75. [Google Scholar] [CrossRef]

- Wang, T.; Kaur, L.; Furuhata, Y.; Aoyama, H.; Singh, J. 3D Printing of Textured Soft Hybrid Meat Analogues. Foods 2022, 11, 478. [Google Scholar] [CrossRef]

- Mu, X.; Agostinacchio, F.; Xiang, N.; Pei, Y.; Khan, Y.; Guo, C.; Cebe, P.; Motta, A.; Kaplan, D.L. Recent advances in 3D printing with protein-based inks. Prog. Polym. Sci. 2021, 115, 101375. [Google Scholar] [CrossRef]

- Wen, Y.; Chao, C.; Che, Q.T.; Kim, H.W.; Park, H.J. Development of plant-based meat analogs using 3D printing: Status and opportunities. Trends Food Sci. Technol. 2023, 132, 76–92. [Google Scholar] [CrossRef]

- Singh, M.; Trivedi, N.; Enamala, M.K.; Kuppam, C.; Parikh, P.; Nikolova, M.P.; Chavali, M. Plant-based meat analogue (PBMA) as a sustainable food: A concise review. Eur. Food Res. Technol. 2021, 247, 2499–2526. [Google Scholar] [CrossRef]

- Liu, Z.; Bhandari, B.; Prakash, S.; Mantihal, S.; Zhang, M. Linking rheology and printability of a multicomponent gel system of carrageenan-xanthan-starch in extrusion based additive manufacturing. Food Hydrocoll. 2019, 87, 413–424. [Google Scholar] [CrossRef]

- Mantihal, S.; Kobun, R.; Lee, B.B. 3D food printing of as the new way of preparing food: A review. Int. J. Gastron. Food Sci. 2020, 22, 100260. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, W.; Huang, D.; Fuh, J.Y.H.; Hong, G.S. An Overview of 3D Printing Technologies for Food Fabrication. Food Bioprocess Technol. 2015, 8, 1605–1615. [Google Scholar] [CrossRef]

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3d printing technologies applied for food design: Status and prospects. J. Food Eng. 2016, 179, 44–54. [Google Scholar] [CrossRef]

- Pérez, B.; Nykvist, H.; Brøgger, A.F.; Larsen, M.B.; Falkeborg, M.F. Impact of macronutrients printability and 3D-printer parameters on 3D-food printing: A review. Food Chem. 2019, 287, 249–257. [Google Scholar] [CrossRef]

- Chen, J.; Sun, H.; Mu, T.; Blecker, C.; Richel, A.; Richard, G.; Jacquet, N.; Haubruge, E.; Goffin, D. Effect of temperature on rheological, structural, and textural properties of soy protein isolate pastes for 3D food printing. J. Food Eng. 2022, 323, 110917. [Google Scholar] [CrossRef]

- Liu, L.; Ciftci, O.N. Effects of high oil compositions and printing parameters on food paste properties and printability in a 3D printing food processing model. J. Food Eng. 2020, 288, 110135. [Google Scholar] [CrossRef]

- Natural Machines, Advanced User Settings Explained, Knowl. Base. 2021. Available online: https://support.naturalmachines.com/portal/en/kb/articles/advanced-settings-explained (accessed on 7 September 2023).

- Huang, M.S.; Zhang, M.; Bhandari, B. Assessing the 3D Printing Precision and Texture Properties of Brown Rice Induced by Infill Levels and Printing Variables. Food Bioprocess Technol. 2019, 12, 1185–1196. [Google Scholar] [CrossRef]

- Shi, H.; Li, J.; Xu, E.; Yang, H.; Liu, D.; Yin, J. Microscale 3D printing of fish analogues using soy protein food ink. J. Food Eng. 2023, 347, 111436. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, M.; Bhandari, B.; Yang, C. Investigation on FishSurimi Gel as Promising Food Material for 3D Printing. J. Food Eng. 2018, 220, 101–108. [Google Scholar] [CrossRef]

- Severini, C.; Derossi, A.; Azzollini, D. Variables affecting the printability of foods: Preliminary tests on cereal-based products. Innov. Food Sci. Emerg. Technol. 2016, 38, 281–291. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, M.; Prakash, S.; Liu, Y. Physical properties of 3D printed baking dough as affected by different compositions. Innov. Food Sci. Emerg. Technol. 2018, 49, 202–210. [Google Scholar] [CrossRef]

- Liu, Z.; Bhandari, B.; Zhang, M. Incorporation of probiotics (Bifidobacterium animalis subsp. Lactis) into 3D printed mashed potatoes: Effects of variables on the viability. Food Res. Int. 2019, 128, 108795. [Google Scholar] [CrossRef]

- Carranza, T.; Guerrero, P.; de la Caba, K.; Etxabide, A. Texture-modified soy protein foods: 3D printing design and red cabbage effect. Food Hydrocoll. 2023, 145, 109141. [Google Scholar] [CrossRef]

- Ramachandraiah, K. Potential development of sustainable 3d-printed meat analogues: A review. Sustainability 2021, 13, 938. [Google Scholar] [CrossRef]

- Dick, A.; Bhandari, B.; Prakash, S. 3D printing of meat. Meat Sci. 2019, 153, 35–44. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.W.; Lee, J.H.; Park, S.M.; Lee, M.H.; Lee, I.W.; Doh, H.S.; Park, H.J. Effect of Hydrocolloids on Rheological Properties and Printability of Vegetable Inks for 3D Food Printing. J. Food Sci. 2018, 83, 2923–2932. [Google Scholar] [CrossRef] [PubMed]

- Malda, J.; Visser, J.; Melchels, F.P.; Jüngst, T.; Hennink, W.E.; Dhert, W.J.A.; Groll, J.; Hutmacher, D.W. 25th anniversary article: Engineering hydrogels for biofabrication. Adv. Mater. 2013, 25, 5011–5028. [Google Scholar] [CrossRef]

- Gao, T.; Gillispie, G.J.; Copus, J.S.; Pr, A.K.; Seol, Y.-J.; Atala, A.; Yoo, J.-J.; Lee, S.-J. Optimization of gelatin–alginate composite bioink printability using rheological parameters: A systematic approach. Biofabrication 2018, 10, 034106. [Google Scholar] [CrossRef] [PubMed]

- Xu, K.; Wu, C.; Fan, G.; Kou, X.; Li, X.; Li, T.; Dou, J.; Zhou, Y. Rheological properties, gel properties and 3D printing performance of soy protein isolate gel inks added with different types of apricot polysaccharides. Int. J. Biol. Macromol. 2023, 242, 124624. [Google Scholar] [CrossRef]

- Yu, X.; Zhao, Z.; Zhang, N.; Yan, B.; Gao, W.; Huang, J.; Zhao, J.; Zhang, H.; Chen, W.; Fan, D. Effects of preheating-induced denaturation treatments on the printability and instant curing property of soy protein during microwave 3D printing. Food Chem. 2022, 397, 133682. [Google Scholar] [CrossRef]

- Qiu, Y.; McClements, D.J.; Chen, J.; Li, C.; Liu, C.; Dai, T. Construction of 3D printed meat analogs from plant-based proteins: Improving the printing performance of soy protein- and gluten-based pastes facilitated by rice protein. Food Res. Int. 2023, 167, 112635. [Google Scholar] [CrossRef]

- Fan, H.; Zhang, M.; Liu, Z.; Ye, Y. Effect of microwave-salt synergetic pre-treatment on the 3D printing performance of SPI-strawberry ink system. LWT 2020, 122, 109004. [Google Scholar] [CrossRef]

- Guo, Z.; Arslan, M.; Li, Z.; Cen, S.; Shi, J.; Huang, X.; Xiao, J.; Zou, X. Application of Protein in Extrusion-Based 3D Food Printing: Current Status and Prospectus. Foods 2022, 11, 1902. [Google Scholar] [CrossRef]

- Lin, Q.; Hu, Y.; Qiu, C.; Li, X.; Sang, S.; McClements, D.J.; Chen, L.; Long, J.; Xu, X.; Wang, J.; et al. Peanut protein-polysaccharide hydrogels based on semi-interpenetrating networks used for 3D/4D printing. Food Hydrocoll. 2023, 137, 108332. [Google Scholar] [CrossRef]

- Mirazimi, F.; Saldo, J.; Sepulcre, F.; Gràcia, A.; Pujola, M. Enriched puree potato with soy protein for dysphagia patients by using 3D printing. Food Front. 2022, 3, 706–715. [Google Scholar] [CrossRef]

- Clark, C.C.; Aleman, J.; Mutkus, L.; Skardal, A. A mechanically robust thixotropic collagen and hyaluronic acid bioink supplemented with gelatin nanoparticles. Bioprinting 2019, 16, e00058. [Google Scholar] [CrossRef]

- Li, H.; Tan, Y.J.; Leong, K.F.; Li, L. 3D Bioprinting of Highly Thixotropic Alginate/Methylcellulose Hydrogel with Strong Interface Bonding. ACS Appl. Mater. Interfaces 2017, 9, 20086–20097. [Google Scholar] [CrossRef] [PubMed]

- Kolpakova, V.V.; Gaivoronskaya, I.S.; Kovalenok, V.A.; Slozhenkina, M.I.; Mosolov, A.A. Protein plant-based composites synthesized with transglutaminase. IOP Conf. Ser. Earth Environ. Sci 2021, 677, 032046. [Google Scholar] [CrossRef]

- Oyinloye, T.M.; Yoon, W.B. Stability of 3D printing using a mixture of pea protein and alginate: Precision and application of additive layer manufacturing simulation approach for stress distribution. J. Food Eng. 2020, 288, 110127. [Google Scholar] [CrossRef]

- Cortez-Trejo, M.C.; Gaytán-Martínez, M.; Reyes-Vega, M.; Mendoza, S. Protein-gum-based gels: Effect of gum addition on microstructure, rheological properties, and water retention capacity. Trends Food Sci. Technol. 2021, 116, 303–317. [Google Scholar] [CrossRef]

- Lanaro, M.; Forrestal, D.P.; Scheurer, S.; Slinger, D.J.; Liao, S.; Powell, S.K.; Woodruff, M.A. 3D printing complex chocolate objects: Platform design, optimization and evaluation. J. Food Eng. 2017, 215, 13–22. [Google Scholar] [CrossRef]

- Chao, D.; Aluko, R.E. Modification of the structural, emulsifying, and foaming properties of an isolated pea protein by thermal pretreatment. CYTA-J. Food 2018, 16, 357–366. [Google Scholar] [CrossRef]

- Zhang, T.; Dou, W.; Zhang, X.; Zhao, Y.; Zhang, Y.; Jiang, L.; Sui, X. The development history and recent updates on soy protein-based meat alternatives. Trends Food Sci. Technol. 2021, 109, 702–710. [Google Scholar] [CrossRef]

- Lam, A.C.Y.; Can Karaca, A.; Tyler, R.T.; Nickerson, M.T. Pea protein isolates: Structure, extraction, and functionality. Food Rev. Int. 2018, 34, 126–147. [Google Scholar] [CrossRef]

- Nowacka, M.; Trusinska, M.; Chraniuk, P.; Drudi, F.; Lukasiewicz, J.; Nguyen, N.P.; Przybyszewska, A.; Pobiega, K.; Tappi, S.; Tylewicz, U.; et al. Developments in Plant Proteins Production for Meat and Fish Analogues. Molecules 2023, 28, 2966. [Google Scholar] [CrossRef] [PubMed]

- Doss, A.; Esther, A.; Rajalakshmi, R. Influence of UV-B treatment on the accumulation of free phenols and tannins in the legumes of Abrus precatorius L. and Vigna mungo (L.) Hepper. Phytomedicine Plus 2022, 2, 100189. [Google Scholar] [CrossRef]

- Shan, H.; Lu, S.W.; Jiang, L.Z.; Wang, L.K.; Liao, H.; Zhang, R.Y.; Dai, C.J.; Yao, X.M.; Zhang, Y.L.; Su, P.; et al. Gelation property of alcohol-extracted soy protein isolate and effects of various reagents on the firmness of heat-induced gels. Int. J. Food Prop. 2015, 18, 627–637. [Google Scholar] [CrossRef]

- Chiang, J.H.; Loveday, S.M.; Hardacre, A.K.; Parker, M.E. Effects of soy protein to wheat gluten ratio on the physicochemical properties of extruded meat analogues. Food Struct. 2018, 19, 100102. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, M.; Bhandari, B. 3D Printing of Steak-like Foods Based on Textured Soybean Protein. Foods 2021, 10, 2011. [Google Scholar] [CrossRef] [PubMed]

- Voon, S.L.; An, J.; Wong, G.; Zhang, Y.; Chua, C.K. 3D food printing: A categorised review of inks and their development. Virtual Phys. Prototyp. 2019, 14, 203–218. [Google Scholar] [CrossRef]

- Ding, J.; Ju, H.; Zhong, L.; Qi, L.; Sun, N.; Lin, S. Reducing the allergenicity of pea protein based on the enzyme action of alcalase. Food Funct. 2021, 12, 5940–5948. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, H.W.; Park, H.J. Effect of pea protein isolate incorporation on 3D printing performance and tailing effect of banana paste. LWT-Food Sci. Technol. 2021, 150, 111916. [Google Scholar] [CrossRef]

- Fiorentini, M.; Kinchla, A.J.; Nolden, A.A. Role of sensory evaluation in consumer acceptance of plant-based meat analogs and meat extenders: A scoping review. Foods 2020, 9, 1334. [Google Scholar] [CrossRef]

- Brishti, F.H.; Chay, S.Y.; Muhammad, K.; Ismail-Fitry, M.R.; Zarei, M.; Saari, N. Texturized mung bean protein as a sustainable food source: Effects of extrusion on its physical, textural and protein quality. Innov. Food Sci. Emerg. Technol. 2021, 67, 102591. [Google Scholar] [CrossRef]

- Phuhongsung, P.; Zhang, M.; Bhandari, B. 4D printing of products based on soy protein isolate via microwave heating for flavor development. Food Res. Int. 2020, 137, 109605. [Google Scholar] [CrossRef] [PubMed]

- Feng, C.; Zhang, M.; Bhandari, B. Materials Properties of Printable Edible Inks and Printing Parameters Optimization during 3D Printing: A review. Crit. Rev. Food Sci. Nutr. 2019, 59, 3074–3081. [Google Scholar] [CrossRef]

- Correa, M.J.; Pérez, G.T.; Ferrero, C. Pectins as Breadmaking Additives: Effect on Dough Rheology and Bread Quality. Food Bioprocess Technol. 2011, 5, 2889–2898. [Google Scholar] [CrossRef]

- Brückner-Gühmann, M.; Kratzsch, A.; Sozer, N.; Drusch, S. Oat protein as plant-derived gelling agent: Properties and potential of modification. Futur. Foods 2021, 4, 100053. [Google Scholar] [CrossRef]

- de Angelis, D.; Kaleda, A.; Pasqualone, A.; Vaikma, H.; Tamm, M.; Tammik, M.-L.; Squeo, G.; Summo, C. Physicochemical and sensorial evaluation of meat analogues produced from dry-fractionated pea and oat proteins. Foods 2020, 9, 1754. [Google Scholar] [CrossRef] [PubMed]

- Lorenz, T.; Iskandar, M.M.; Baeghbali, V.; Ngadi, M.O.; Kubow, S. 3D Food Printing Applications Related to Dysphagia: A Narrative Review. Foods 2022, 11, 1789. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; Dai, Q.; Xu, D.; Hu, L.; Li, H.; Hati, S.; Chitrakar, B.; Yao, L.; Mo, H. Pea protein-xanthan gum interaction driving the development of 3D printed dysphagia diet. Food Hydrocoll. 2023, 139, 108497. [Google Scholar] [CrossRef]

- Wen, Y.; Kim, H.W.; Park, H.J. Effects of transglutaminase and cooking method on the physicochemical characteristics of 3D-printable meat analogs. Innov. Food Sci. Emerg. Technol. 2022, 81, 103114. [Google Scholar] [CrossRef]

- Kewuyemi, Y.O.; Kesa, H.; Adebo, O.A. Trends in functional food development with three-dimensional (3D) food printing technology: Prospects for value-added traditionally processed food products. Crit. Rev. Food Sci. Nutr. 2022, 62, 7866–7904. [Google Scholar] [CrossRef]

- Demei, K.; Zhang, M.; Phuhongsung, P.; Mujumdar, A.S. 3D food printing: Controlling characteristics and improving technological effect during food processing. Food Res. Int. 2022, 156, 111120. [Google Scholar] [CrossRef] [PubMed]

- Shen, C.; Chen, W.; Li, C.; Chen, X.; Cui, H.; Lin, L. 4D printing system stimulated by curcumin/whey protein isolate nanoparticles: A comparative study of sensitive color change and post-processing. J. Food Eng. 2023, 342, 111357. [Google Scholar] [CrossRef]

- He, C.; Zhang, M.; Fang, Z. 3D printing of food: Pretreatment and post-treatment of materials. Crit. Rev. Food Sci. Nutr. 2020, 60, 2379–2392. [Google Scholar] [CrossRef] [PubMed]

- Dai, L.; Cheng, T.; Duan, C.; Zhao, W.; Zhang, W.; Zou, X.; Aspler, J.; Ni, Y. 3D printing using plant-derived cellulose and its derivatives: A review. Carbohydr. Polym. 2018, 203, 71–86. [Google Scholar] [CrossRef]

- Dai, H.; Luo, Y.; Huang, Y.; Ma, L.; Chen, H.; Fu, Y.; Yu, Y.; Zhu, H.; Wang, H.; Zhang, Y. Recent advances in protein-based emulsions: The key role of cellulose. Food Hydrocoll. 2023, 136, 108260. [Google Scholar] [CrossRef]

- Lupton, D.; Turner, B. ‘Both Fascinating and Disturbing’: Consumer Responses to 3D FoodPrinting and Implications for Food Activism. In Digital Food Activism; Schneider, T., Eli, K., Dolan, C., Ulijaszek, S., Eds.; Routledge: London, UK, 2016; Available online: https://ssrn.com/abstract=2799191 (accessed on 26 November 2023).

- Ross, M.M.; Collins, A.M.; McCarthy, M.B.; Kelly, A.L. Overcoming barriers to consumer acceptance of 3D-printed foods in the food service sector. Food Qual. Prefer. 2022, 100, 1004615. [Google Scholar] [CrossRef]

- Brunner, T.A.; Delley, M.; Denkel, C. Consumer’s attitudes and chane in attitude toward 3D-printed food. Food Qual. Prefer. 2018, 68, 389–396. [Google Scholar] [CrossRef]

| Ingredient Ratio (w:w:w:w) | Oil Content (%, w/w) | Manufacturer-Defined Printing Speed (Actual Printing Speed, mm/s) | Manufacturer-Defined Extruding Rate (Actual Extruding Rate, mm3/s | Printed Shape | Printing Quality Score | ||||

|---|---|---|---|---|---|---|---|---|---|

| No. | CS | W | CO | WPI | |||||

| A | 20 | 25 | 25 | 25 | 26.3 | 100 (21.1) | 100 (20.0) |  | 1 |

| B | 22 | 25 | 25 | 25 | 25.8 | 100 (21.1) | 100 (20.0) |  | 3 |

| C | 25 | 25 | 25 | 25 | 25.0 | 100 (21.1) | 120 (26.8) |  | 3 |

| D | 25 | 25 | 25 | 22 | 25.8 | 100 (21.1) | 110 (23.3) |  | 2 |

| E | 25 | 25 | 25 | 20 | 26.3 | 100 (21.1) | 100 (20.0) |  | 4 |

| F | 25 | 28 | 25 | 25 | 24.3 | 100 (21.1) | 100 (20.0) |  | 2 |

| Protein | Control | Guar Gum | Sodium Alginate | Hydroxyethyl Cellulose | Xanthan Gum | Sodium Carboxymethyl Cellulose | Konjac Gum |

|---|---|---|---|---|---|---|---|

| Textured Soybean Protein |  |  |  |  |  |  |  |

| Drawing Soy Protein |  |  |  |  |  |  |  |

| Types | Additives | Materials | Finding | References | |

|---|---|---|---|---|---|

| Hydrocolloids | Alginate | Pea protein powder (PP), calcium chloride | Increased gel strength. |  | [37] |

| Agar | Soy protein acid hydrolysate (SPAH) | Improved mechanical strength and increased self-supporting capacity of 3D printed structures. |  | [33] | |

| Kappa-carrageenan | Soy protein isolate (SPI), vanilla powder (for flavor) | 3D printed structures with smooth surfaces and denser gel network structures. |  | [53] | |

| Xanthan gum (XG) | Pea protein isolate (PPI) | A small amount of XG improved mechanical strength and chewing and swallowing easiness. |  | [59] | |

| Others | Transglutaminase (TGase) powder | Mung bean protein isolate (MBPI), methylcellulose (MC) | Smooth printed surface, improved mechanical strength, increased hardness. Optimal TG: 4 U/g of MBPI. |  | [60] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mittal, S.; Bhuiyan, M.H.R.; Ngadi, M.O. Challenges and Prospects of Plant-Protein-Based 3D Printing. Foods 2023, 12, 4490. https://doi.org/10.3390/foods12244490

Mittal S, Bhuiyan MHR, Ngadi MO. Challenges and Prospects of Plant-Protein-Based 3D Printing. Foods. 2023; 12(24):4490. https://doi.org/10.3390/foods12244490

Chicago/Turabian StyleMittal, Shivani, Md. Hafizur Rahman Bhuiyan, and Michael O. Ngadi. 2023. "Challenges and Prospects of Plant-Protein-Based 3D Printing" Foods 12, no. 24: 4490. https://doi.org/10.3390/foods12244490

APA StyleMittal, S., Bhuiyan, M. H. R., & Ngadi, M. O. (2023). Challenges and Prospects of Plant-Protein-Based 3D Printing. Foods, 12(24), 4490. https://doi.org/10.3390/foods12244490