Modeling Textural Properties of Cooked Germinated Brown Rice Using the near-Infrared Spectra of Whole Grain

Abstract

:1. Introduction

2. Materials and Methods

2.1. Rice Samples

2.2. GBR Uncooked Sample Scanning for NIR Spectra

2.3. The Approximate Repeatability of NIR Scanning

2.4. Method of Cooking Rice

2.5. Back Extrusion Test for Texture of Cooked GBR

2.6. The Repeatability and Reproducibility of the Measurement of Textural Properties

2.7. NIR Spectroscopy Modeling by Machine Learning

2.7.1. Calibration Set and Prediction Set Separation

2.7.2. Spectral Pretreatment

2.7.3. Modeling Algorithms

Partial Least Squares Regression

Artificial Neural Network

2.7.4. Model Performance Determination

3. Results and Discussion

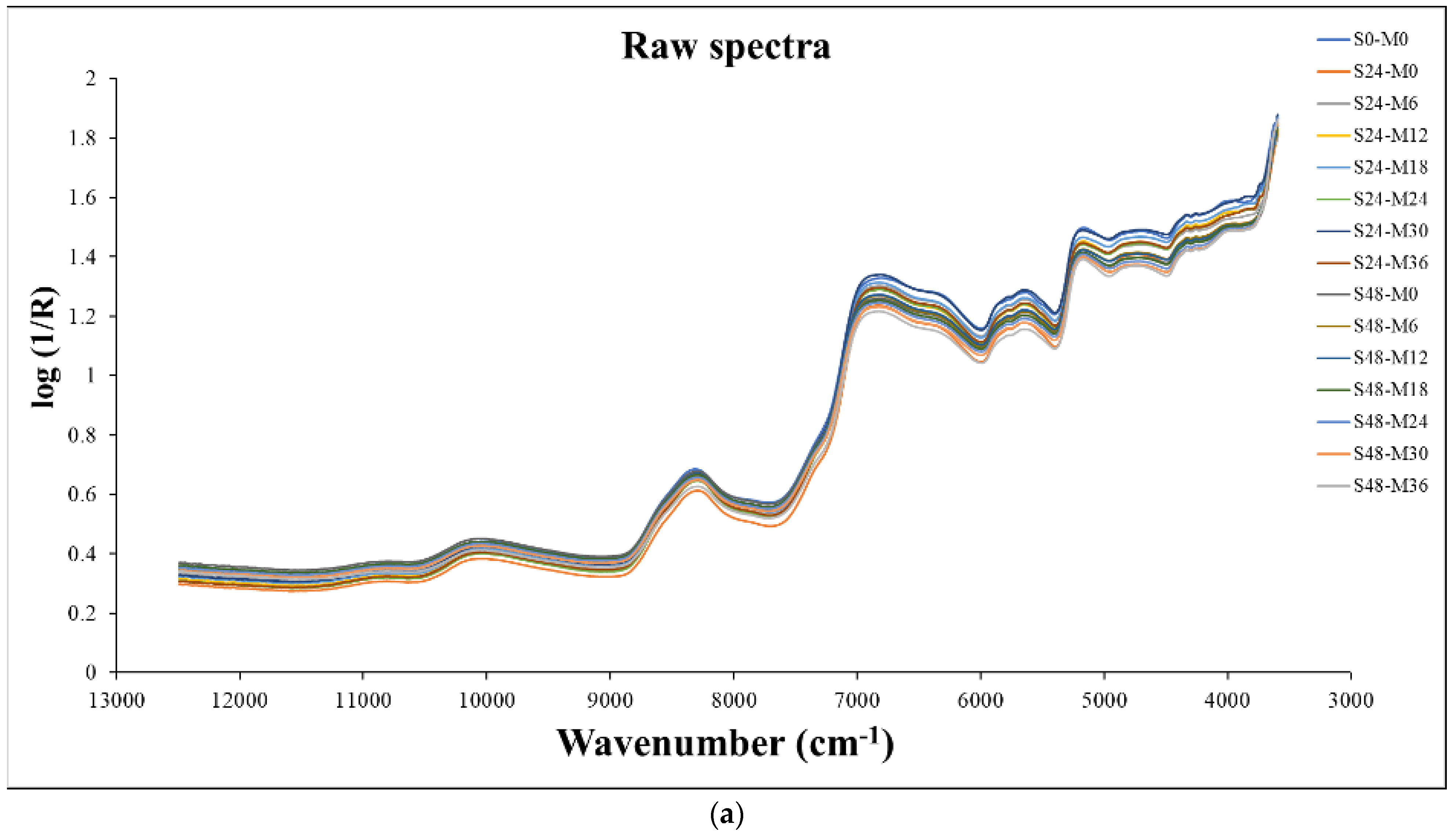

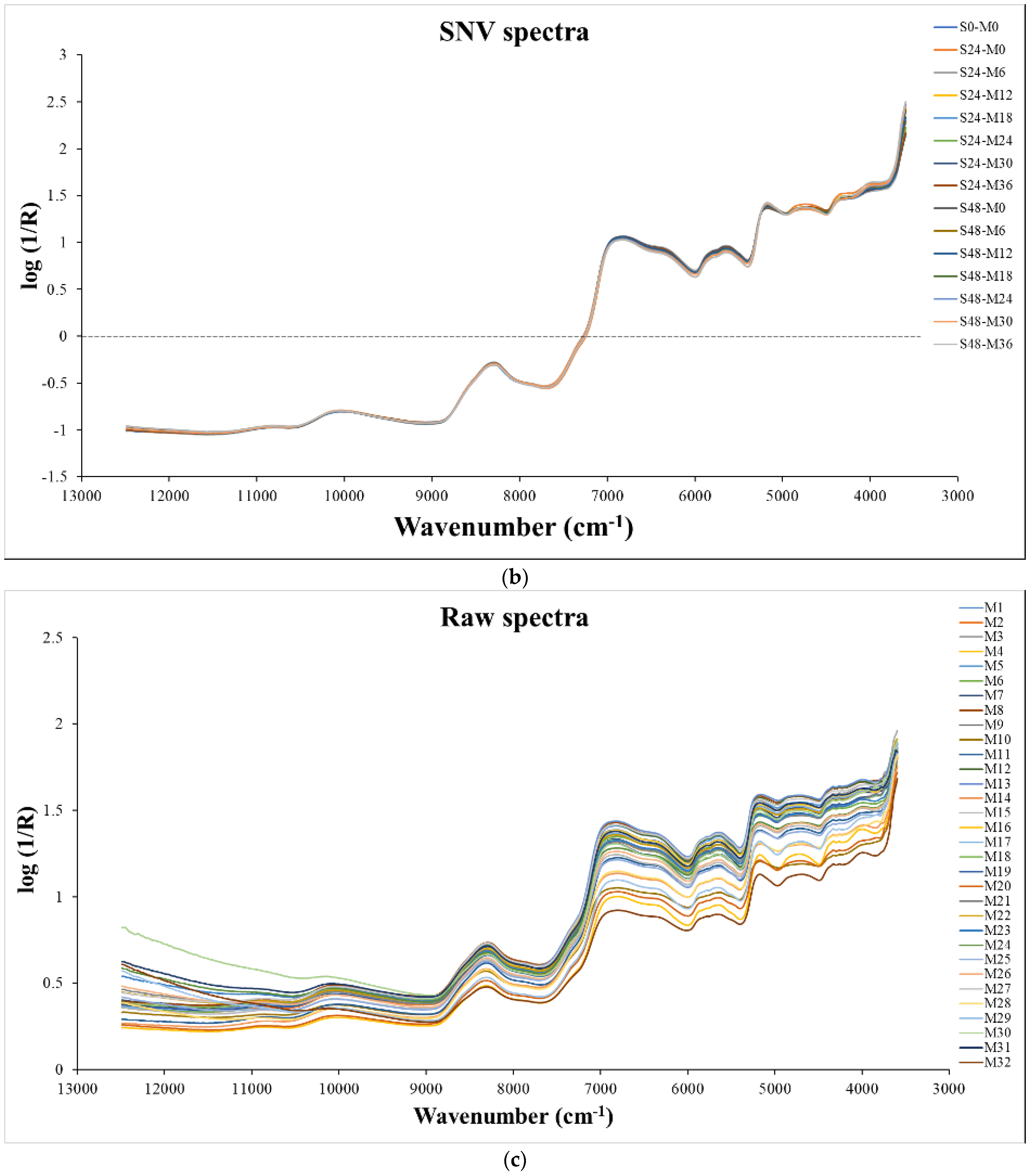

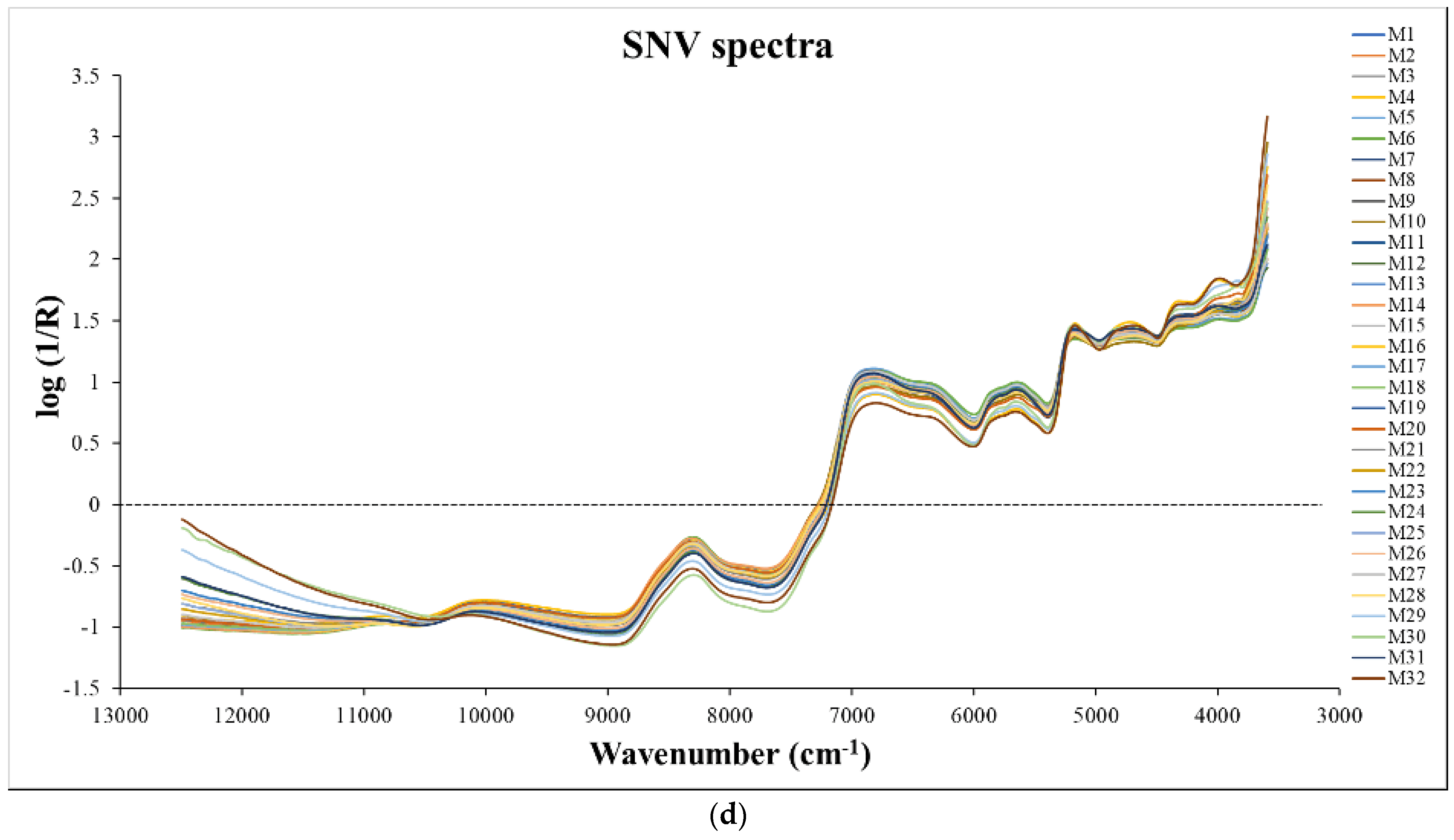

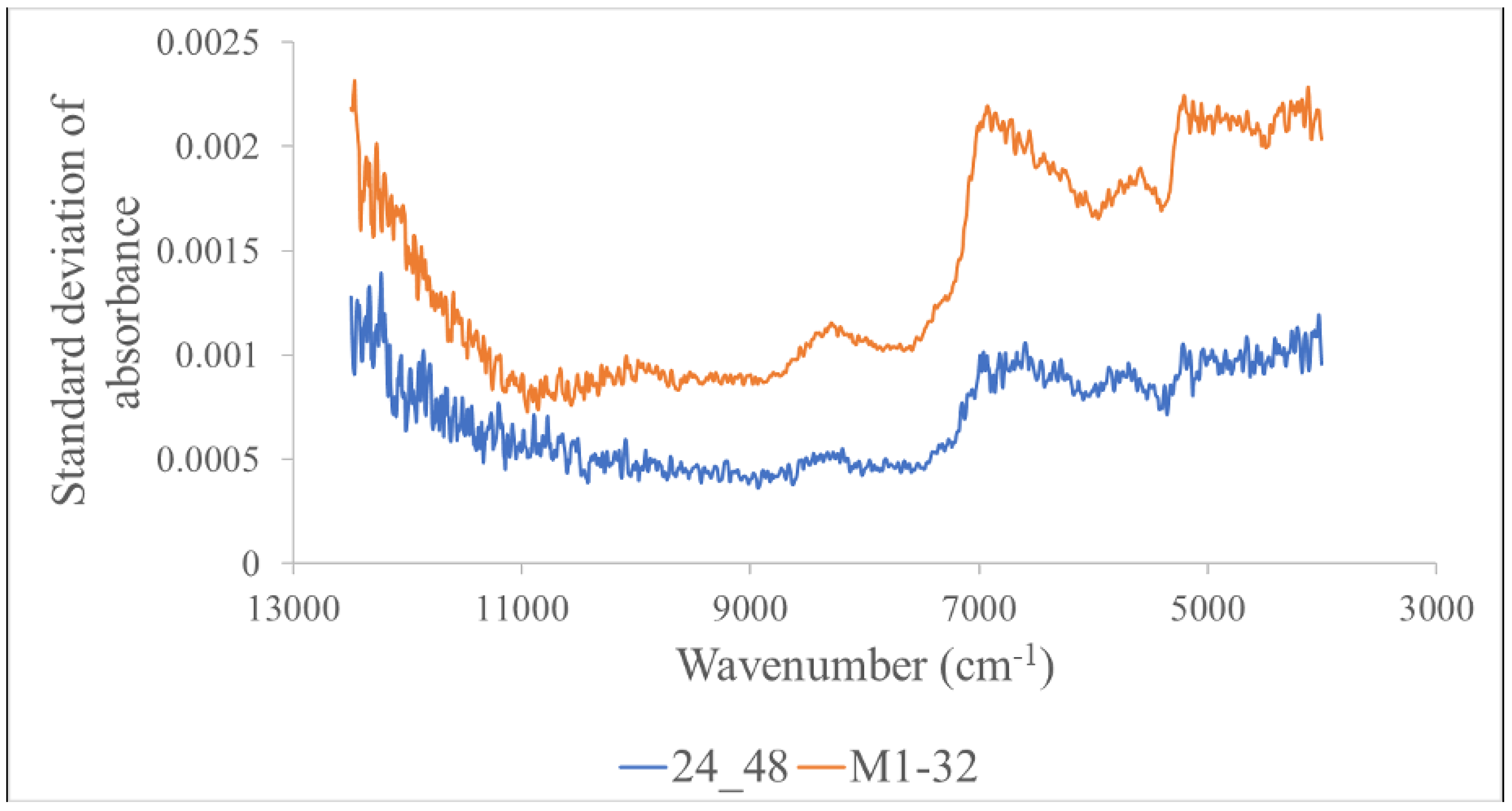

3.1. Spectral Characteristic of Whole Grain GBR

3.2. Overall Precision Test

3.3. Prediction Performance of PLS Regression Model for Texture of Cooked GBR by Uncooked GBR Grains by OPUS

3.4. Prediction Performance of PLS Regression Model for Texture of Cooked GBR by Uncooked GBR Grains by MATLAB Using Total Samples

3.5. Prediction Performance of ANN Model for Texture of Cooked GBR by Uncooked GBR Grains by MATLAB Using Total Samples

3.6. Comparison of PLS and ANN Model for Texture of Cooked GBR by Uncooked GBR Grains

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, C.Q.; Lu, C.H.; Mai, L.; Bao, L.J.; Liu, L.Y.; Zeng, E.Y. Response of rice (Oryza sativa L.) roots to nanoplastic treatment at seedling stage. J. Hazard. Mater. 2021, 401, 123412. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Li, Z.; Zhuang, B.; Zhou, F.; Li, Z.; Pan, X.; Xi, H.; Zhao, W.; Liu, H. Enrofloxacin perturbs nitrogen transformation and assimilation in rice seedlings (Oryza sativa L.). Sci. Total Environ. 2022, 802, 149900. [Google Scholar] [CrossRef] [PubMed]

- Ajith, K.; Geethalakshmi, V.; Ragunath, K.P.; Pazhanivelan, S.; Dheebakaran, G. Rice yield prediction using MODIS-NDVI (MOD13Q1) and land based observations. Int. J. Curr. Microbiol. App. Sci. 2017, 6, 2277–2293. [Google Scholar] [CrossRef]

- Pame, A.R.P.; Vithoonjit, D.; Meesang, N.; Balingbing, C.; Gummert, M.; Hung, N.V.; Singleton, G.R.; Stuart, A.M. Improving the sustainability of rice cultivation in central Thailand with biofertilizers and laser land leveling. Agronomy 2023, 13, 587. [Google Scholar] [CrossRef]

- Madhu, S.; Kamani, D.; Mesara, H. A study on production and export of rice from India. Int. Res. J. Mod. Eng. Technol. Sci. 2023, 5, 346. [Google Scholar]

- Iemsam-arng, M. Rice Price—Weekly. In Grain and Feed; Report Number TH2023-0047; USDA and Global Agriculture: Bangkok, Thailand, 4 August 2023. [Google Scholar]

- Srinuttrakul, W.; Mihailova, A.; Islam, M.D.; Liebisch, B.; Maxwell, F.; Kelly, S.D.; Cannavan, A. Geographical differentiation of hom mali rice cultivated in different regions of Thailand Using FTIR-ATR and NIR spectroscopy. Foods 2021, 10, 1951. [Google Scholar] [CrossRef]

- Vanavichit, W.; Kamolsukyeunyong, M.; Siangliw, J.L.; Siangliw, S.; Traprab, S.; Ruengphayak, E.; Chaichoompu, C.; Saensuk, E.; Phuvanartnarubal, T.; Toojinda, T.; et al. Thai Hom Mali rice: Origin and breeding for subsistence rainfed lowland rice system. Rice 2018, 11, 20. [Google Scholar] [CrossRef]

- Shafie, F.A.; Rennie, D. Consumer perceptions towards organic food. Procedia Soc. Behav. Sci. 2012, 49, 360–367. [Google Scholar] [CrossRef]

- Wagner, K.-H.; Brath, H. A global view on the development of non-communicable diseases. Prev. Med. 2012, 54, 38–41. [Google Scholar] [CrossRef]

- Ismail, M. Germinated Brown Rice and Bioactive Rich Fractions. Report. Available online: https://pnc.upm.edu.my/upload/dokumen/20170726114317GErminated_Broen_Rice_and_Bioactive_Rich_Fractions.pdf (accessed on 29 April 2016).

- Kobayashi, K.; Wang, X.; Wang, W. Genetically modified rice is associated with hunger, health, and climate resilience. Foods 2023, 12, 2776. [Google Scholar] [CrossRef]

- Nishinari, K.; Peyron, M.-A.; Yang, N.; Gao, Z.; Zhang, K.; Fang, Y.; Zhao, M.; Yao, X.; Hu, B.; Han, L.; et al. The role of texture in the palatability and food oral processing. Food Hydrocoll. 2023, 147, 109095. [Google Scholar] [CrossRef]

- Tikapunya, T.; Henry, J.R.; Smyth, H. Evaluating the sensory properties of unpolished Australian wild rice. Food Res. Int. 2018, 103, 406–414. [Google Scholar] [CrossRef] [PubMed]

- Chao, S.; Mitchell, J.; Prakash, S.; Bhandari, B.; Fukai, S. Effect of germination level on properties of flour paste and cooked brown rice texture of diverse varieties. J. Cereal Sci. 2021, 102, 103345. [Google Scholar] [CrossRef]

- Panchan, K.; Naivikul, O. Effect of pre-germination and parboiling on brown rice properties. Asian J. Food Agro-Ind. 2009, 2, 515–524. [Google Scholar]

- Munarko, H.; Sitanggang, A.B.; Kusnandar, F.; Budijanto, S. Effect of different soaking and germination methods on bioactive compounds of germinated brown rice. Int. J. Food Sci. 2021, 56, 4540–4548. [Google Scholar] [CrossRef]

- Srisawas, W.; Jindal, V.; Thanapase, W. Relationship between sensory textural attributes and near infrared spectra of cooked rice. J. Near Infrared Spectrosc. 2007, 15, 333–340. [Google Scholar] [CrossRef]

- Nascimento, L.Á.; Abhilasha, A.; Singh, J.; Elias, M.C.; Colussi, R. Rice germination and its impact on technological and nutritional properties: A Review. Rice Sci. 2022, 29, 201–215. [Google Scholar] [CrossRef]

- Jiamyangyuen, S.; Ooraikul, B. The physico-chemical, eating, and sensorial properties of germinated brown rice. J. Food Agric. Environ. 2008, 6, 119. [Google Scholar]

- Han, A.; Jinn, J.-R.; Mauromoustakos, A.; Wang, Y.-J. Effect of parboiling on milling, physicochemical, and textural properties of medium- and long-grain germinated brown rice. Cereal Chem. 2015, 93, 47–52. [Google Scholar] [CrossRef]

- Onmankhong, J.; Sirisomboon, P. Texture evaluation of cooked parboiled rice using nondestructive milled whole grain near infrared spectroscopy. J. Cereal Sci. 2021, 97, 103151. [Google Scholar] [CrossRef]

- Aznan, A.; Gonzalez Viejo, C.; Pang, A.; Fuentes, S. Rapid Assessment of Rice Quality Traits Using Low-Cost Digital Technologies. Foods 2022, 11, 1181. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Q.; Zhang, M.; Mujumdar, A.S.; Wang, D. Non-destructive quality determination of frozen food using NIR spectroscopy-based machine learning and predictive modelling. J. Food Eng. 2023, 343, 111374. [Google Scholar] [CrossRef]

- Kaewsorn, K.; Sirisomboon, P. Study on evaluation of gamma oryzanol of germinated brown rice by near infrared spectroscopy. J. Innov. Opt. Health Sci. 2014, 7, 1450002. [Google Scholar] [CrossRef]

- Kaewsorn, K.; Maichoon, P.; Pornchaloempong, P.; Krusong, W.; Sirisomboon, P.; Tanaka, M.; Kojima, T. Evaluation of precision and sensitivity of back extrusion test for measuring textural qualities of cooked germinated brown rice in production process. Foods 2023, 12, 3090. [Google Scholar] [CrossRef] [PubMed]

- Skoog, D.A.; Holler, F.J.; Nieman, T.A. Principles of Instrumental Analysis, 5th ed.; Harcourt Brace College Publishers: Chicago, IL, USA, 1998. [Google Scholar]

- Chen, K.J.; Huang, M. Prediction of milled rice grades using Fourier transforms near-infrared spectroscopy and artificial neural network. J. Cereal Sci. 2010, 52, 221–226. [Google Scholar] [CrossRef]

- Lapcharoensuk, R.; Sirisomboon, P. Eating quality of cooked rice determination using Fourier transform near infrared spectroscopy. J. Innov. Opt. Health Sci. 2014, 7, 1450003. [Google Scholar] [CrossRef]

- Sinelli, N.; Benedetti, S.; Bottega, G.; Riva, M.; Buratti, S. Evaluation of the optimal cooking time of rice by using FT-NIR spectroscopy and an electronic nose. J. Cereal Sci. 2006, 44, 137–143. [Google Scholar] [CrossRef]

- Williams, P.; Manley, M.; Antoniszyn, J. Near Infrared Technology: Getting the Best Out of Light, 1st ed.; African Sun Media: Stellenbosch, South Africa, 2019. [Google Scholar]

- Sirisomboon, P.; Kaewsorn, K.; Thanimkarn, S.; Phetpan, K. Non-linear viscoelastic behavior of cooked white, brown, and germinated brown Thai jasmine rice by large deformation relaxation test. Int. J. Food Prop. 2017, 20, 1547–1557. [Google Scholar] [CrossRef]

- Reyes, V.G.; Jindal, V.K. A small sample back extrusion test for measuring texture of cooked rice. J. Food Qual. 1990, 13, 109–118. [Google Scholar] [CrossRef]

- Srisawas, W.; Jindal, V. Sensory evaluation of cooked rice in relation to water-to-rice ratio and physicochemical properties. J. Texture Stud. 2007, 38, 21–41. [Google Scholar] [CrossRef]

- Parnsakhorn, S.; Noomhorm, A. Changes in physicochemical properties of parboiled brown rice during heat treatment. Agric. Eng. Int. 2008, 10, 1–20. [Google Scholar]

- Cheevitsopon, E.; Klakankhai, T.; Kladsuk, S.; Sonsanguan, N.; Phanomsophon, T.; Sirisomboon, P.; Pornchaloempong, P. Texture properties of cooked rice evaluated by sensory test interpreted by instrument tests. In Proceedings of the XX CIGR World Congress 2022, Sustainable Agricultural Production-Water, Land, Energy and Food, Kyoto, Japan, 5–9 December 2022. [Google Scholar]

- Sirisoontaralak, P.; Noomhorm, A. Changes to physicochemical properties and aroma of irradiated rice. J. Stored Prod. Res. 2006, 42, 264–276. [Google Scholar] [CrossRef]

- Sun, Y.; Yuan, M.; Liu, X.; Su, M.; Wang, L.; Zeng, Y.; Zang, H.; Nie, L. A sample selection method specific to unknown test samples for calibration and validation sets based on spectra similarity. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2021, 258, 119870. [Google Scholar] [CrossRef] [PubMed]

- Shetty, N.; Rinnan, Å.; Gislum, R. Selection of representative calibration sample sets for near-infrared reflectance spectroscopy to predict nitrogen concentration in grasses. Chemometr. Intell. Lab. Syst. 2012, 111, 59–65. [Google Scholar] [CrossRef]

- Galvão, R.K.H.; Araujo, M.C.U.; José, G.E.; Pontes, M.J.C.; Silva, E.C.; Saldanha, T.C.B. A method for calibration and validation subset partitioning. Talanta 2005, 67, 736–740. [Google Scholar] [CrossRef]

- Li, X.; Wei, Y.; Xu, J.; Feng, X.; Wu, F.; Zhou, R.; Jin, J.; Xu, K.; Yu, X.; He, Y. SSC and pH for sweet assessment and maturity classification of harvested cherry fruit based on NIR hyperspectral imaging technology. Postharvest Biol. Technol. 2018, 143, 112–118. [Google Scholar] [CrossRef]

- Biswas, A.; Zhang, Y. Sampling Designs for Validating Digital Soil Maps: A Review. Pedosphere 2018, 28, 1–15. [Google Scholar] [CrossRef]

- Ramirez-Lopez, L.; Schmidt, K.; Behrens, T.; Wesemael, B.V.; Demattê, J.A.M.; Scholten, T. Sampling optimal calibration sets in soil infrared spectroscopy. Geoderma 2014, 226–227, 140–150. [Google Scholar] [CrossRef]

- Rafało, M. Cross validation methods: Analysis based on diagnostics of thyroid cancer metastasis. ICT Express 2022, 8, 183–188. [Google Scholar] [CrossRef]

- Bi, Y.; Yuan, K.; Xiao, W.; Wu, J.; Shi, C.; Xia, J.; Zhou, G. A local pre-processing method for near-infrared spectra, combined with spectral segmentation and standard normal variate transformation. Anal. Chim. Acta 2016, 909, 30–40. [Google Scholar] [CrossRef]

- Robert, G.; Gosselin, R. Evaluating the impact of NIR pre-processing methods via multiblock partial least-squares. Anal. Chim. Acta 2022, 1189, 339255. [Google Scholar] [CrossRef] [PubMed]

- Munnaf, M.A.; Mouazen, A.M. Removal of external influences from on-line vis-NIR spectra for predicting soil organic carbon using machine learning. CATENA 2022, 211, 106015. [Google Scholar] [CrossRef]

- Gobrecht, A.; Bendoula, R.; Roger, J.-M.; Bellon-Maurel, V. A new optical method coupling light polarization and Vis–NIR spectroscopy to improve the measurement of soil carbon content. Soil Tillage Res. 2016, 155, 461–470. [Google Scholar] [CrossRef]

- An, C.; Yan, X.; Lu, C.; Zhu, X. Effect of spectral pretreatment on qualitative identification of adulterated bovine colostrum by near-infrared spectroscopy. Infrared Phys. Technol. 2021, 118, 103869. [Google Scholar] [CrossRef]

- Yang, L.; Lua, Y.Y.; Jiang, G.; Tyler, B.J.; Linford, M.R. Multivariate analysis of TOF-SIMS spectra of monolayers on scribed silicon. Anal. Chem. 2005, 77, 4654–4661. [Google Scholar] [CrossRef] [PubMed]

- Bian, X. Spectral preprocessing methods. In Chemometric Methods in Analytical Spectroscopy Technology; Springer Nature: Singapore, 2022; pp. 111–168. [Google Scholar]

- Verboven, S.; Hubert, M.; Goos, P. Robust preprocessing and model selection for spectral data. J. Chemom. 2012, 26, 282–289. [Google Scholar] [CrossRef]

- Siesler, H.W.; Kawata, S.; Heise, H.M.; Ozaki, Y. Near-Infrared Spectroscopy: Principles, Instruments, Applications; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

- Conzen, J.P. Multivariate calibration. In A Practical Guide for Developing Methods in the Quantitative Analytical Chemistry, 2nd English ed.; Bruker Optics: Ettlingen, Germany, 2006. [Google Scholar]

- Wold, S.; Sjöström, M.; Eriksson, L. PLS-regression: A basic tool of chemometrics. Chemom. Intell. Lab. Syst. 2001, 58, 109–130. [Google Scholar] [CrossRef]

- Hanrahan, G.; Udeh, F.; Patil, D.G. CHEMOMETRICS AND STATISTICS | Multivariate Calibration Techniques. In Encyclopedia of Analytical Science, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2005; pp. 27–32. [Google Scholar]

- Lavine, B.K.; Rayens, W.S. Statistical Discriminant Analysis. In Comprehensive Chemometrics: Chemical and Biochemical Data Analysis; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- The MathWorks Inc. MATLAB Version: 9.13.0 (R2022b); The MathWorks Inc.: Natick, MA, USA, 2022; Available online: https://www.mathworks.com (accessed on 1 January 2023).

- Sadiq, R.; Rodriguez, M.J.; Mian, H.R. Empirical Models to Predict Disinfection By-Products (DBPs) in Drinking Water: An Updated Review. In Encyclopedia of Environmental Health, 2nd ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2019; pp. 324–338. [Google Scholar]

- Mohseni-Dargah, M.; Falahati, Z.; Dabirmanesh, B.; Nasrollahi, P.; Khajeh, K. Machine learning in surface plasmon resonance for environmental monitoring. In Artificial Intelligence and Data Science in Environmental Sensing; Elsevier Inc.: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Malekian, A.; Chitsaz, N. Concepts, procedures, and applications of artificial neural network models in streamflow forecasting. In Advances in Streamflow Forecasting; Elsevier Inc.: Amsterdam, The Netherlands, 2021; pp. 115–147. [Google Scholar]

- Park, Y.-S.; Lek, S. Artificial Neural Networks: Multilayer Perceptron for Ecological Modeling. In Developments in Environmental Modelling; Elsevier B.V.: Amsterdam, The Netherlands, 2016; Volume 28, pp. 123–140. [Google Scholar]

- Osborne, B.G.; Fearn, T.; Hindle, P.H. Practical NIR Spectroscopy with Applications in Food and Beverage Analysis, 2nd ed.; Longman Scientific and Technical: London, UK, 1993. [Google Scholar]

- Sirisomboon, P.; Nawayon, J. Evaluation of total solids of curry soup containing coconut milk by near infrared spectroscopy. J. Near Infrared Spectrosc. 2016, 24, 191–198. [Google Scholar] [CrossRef]

- Pornchaloempong, P.; Sharma, S.; Phanomsophon, T.; Srisawat, K.; Inta, W.; Sirisomboon, P.; Prinyawiwatkul, W.; Nakawajana, N.; Lapcharoensuk, R.; Teerachaichayut, S. Non-destructive quality evaluation of tropical fruit (Mango and Mangosteen) Purée using near-infrared spectroscopy combined with partial least squares regression. Agriculture 2022, 12, 2060. [Google Scholar] [CrossRef]

- Lim, C.H.; Sirisomboon, P. Near infrared spectroscopy as an alternative method for rapid evaluation of toluene swell of natural rubber latex and its products. J. Near Infrared Spectrosc. 2018, 26, 159–168. [Google Scholar] [CrossRef]

- Musa, A.S.; Umar, M.; Ismail, M. Physicochemical properties of germinated brown rice (Oryza sativa L.) starch. Afr. J. Biotechnol. 2011, 10, 6281–6291. [Google Scholar]

- Sampaio, P.S.; Soares, A.; Castanho, A.; Almeida, A.S.; Oliveira, J.; Brites, C. Optimization of rice amylose determination by NIR-spectroscopy using PLS chemometrics algorithms. Food Chem. 2018, 242, 196–204. [Google Scholar] [CrossRef]

- Lu, Z.H.; Sasaki, T.; Li, Y.Y.; Yoshihashi, T.; Li, L.T.; Kohyama, K. Effect of amylose content and rice type on dynamic viscoelasticity of a composite rice starch gel. Food Hydrocoll. 2009, 23, 1712–1719. [Google Scholar] [CrossRef]

- Sampaio, P.S.; Brites, C.M. Near-Infrared Spectroscopy and Machine Learning: Analysis and Classification Methods of Rice. In Integrative Advances in Rice Research; Huang, M., Ed.; IntechOpen: London, UK, 2022. [Google Scholar]

- Bett-Garber, K.; Champagne, E.; Ingram, D.; McClung, A. Influence of water-to-rice ratio on cooked rice flavor and texture. Cereal Chem. 2007, 84, 614–619. [Google Scholar] [CrossRef]

- Roy, P.; Ijiri, T.; Okadome, H.; Nei, D.; Orikasa, T.; Nakamura, N.; Shiina, T. Effect of processing conditions on overall energy consumption and quality of rice (Oryza sativa L.). J. Food Eng. 2008, 89, 343–348. [Google Scholar] [CrossRef]

- Dibba, D.; Weaver, L.T.; Hudson, G.J. Water content of cooked rice is related to variety and cooking method. Nutr. Res. 1991, 11, 1397–1402. [Google Scholar] [CrossRef]

- Cawley, G.C.; Talbot, N.L.C. On over-fitting in model selection and subsequent selection bias in performance evaluation. J. Mach. Learn. Res. 2010, 11, 2079–2107. [Google Scholar]

- Ludwig, B.; Murugan, R.; Parama, V.R.; Vohland, M. Accuracy of estimating soil properties with mid-infrared spectroscopy: Implications of different chemometric approaches and software packages related to calibration sample size. Soil Sci. Soc. Am. J. 2019, 83, 1542–1552. [Google Scholar] [CrossRef]

- Vrahatis, M.N.; Magoulas, G.D.; Parsopoulos, K.E.; Plagianakos, V.P. Introduction to Artificial Neural Networks Training and Applications. In Proceedings of the 15th Annual Conference of Hellenic Society for Neuroscience, Patras, Greece, 27–29 October 2000. [Google Scholar]

- Sampaio, P.S.; Carbas, B.; Brites, C. Development of prediction models for the pasting parameters of rice based on near-infrared and machine learning tools. Appl. Sci. 2023, 13, 9081. [Google Scholar] [CrossRef]

- Sitakalin, C.; Meullenet, J.F.C. Prediction of cooked rice texture using an extrusion test in combination with partial least squares regression and artificial neural networks. Cereal Chem. 2001, 78, 391–394. [Google Scholar] [CrossRef]

- Lin, L.H.; Lu, F.M.; Chang, Y.C. Prediction of protein content in rice using a near-infrared imaging system as diagnostic technique. Int. J. Agric. Biol. Eng. 2019, 12, 195–200. [Google Scholar] [CrossRef]

| Parameter | Treatment | Total | Cal | Pre | Calibration Set | Prediction Set | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Range | Mean | SD | Range | Mean | SD | |||||

| Adhesiveness, Nmm | Condition-adjusted GBR (24 and 48 h soaking) | 60 | 42 | 18 | (−81.15)–(−56.70) | −67.41 | 6.28 | (−77.93)–(−56.99) | −69.09 | 6.78 |

| Toughness, Nmm | 60 | 42 | 18 | 162.32–245.79 | 201.78 | 20.50 | 172.99–245.40 | 203.87 | 21.97 | |

| Hardness, N | 60 | 42 | 18 | 16.55–24.87 | 20.29 | 1.85 | 17.88–23.71 | 20.86 | 2.00 | |

| Stickiness, N | 60 | 42 | 18 | (−7.67)–(−4.48) | −5.78 | 0.88 | (−7.37)–(−4.65) | −6.15 | 0.88 | |

| Adhesiveness, Nmm | KDML (1–16) | 64 | 46 | 18 | (−78.86)–(−39.13) | −64.22 | 7.71 | (−76.41)–(−40.69) | −62.77 | 10.58 |

| Toughness, Nmm | 64 | 46 | 18 | 109.69–240.80 | 196.85 | 25.63 | 112.22–233.45 | 193.51 | 35.98 | |

| Hardness, N | 64 | 46 | 18 | 11.90–24.52 | 20.24 | 2.73 | 12.11–24.27 | 19.59 | 3.62 | |

| Stickiness, N | 64 | 46 | 18 | (−7.12)–(−2.84) | −5.15 | 1.04 | (−6.85)–(−3.12) | −4.82 | 1.13 | |

| Adhesiveness, Nmm | Various varieties (17–32) | 64 | 46 | 18 | (−84.93)–(−52.45) | −69.04 | 8.59 | (−83.79)–(−55.22) | −69.44 | 9.24 |

| Toughness, Nmm | 64 | 46 | 18 | 131.94–300.55 | 197.98 | 39.34 | 152.77–276.90 | 212.36 | 40.37 | |

| Hardness, N | 64 | 46 | 18 | 14.23–29.86 | 20.27 | 3.33 | 15.87–27.93 | 21.93 | 4.05 | |

| Stickiness, N | 64 | 46 | 18 | (−7.20)–(−3.12) | −5.31 | 0.88 | (−6.18)–(−3.18) | −5.08 | 0.95 | |

| Adhesiveness, Nmm | Market (1–32) | 128 | 90 | 38 | (−84.93)–(−39.13)) | −66.71 | 8.54 | (−83.79)–(−40.69) | −65.94 | 10.12 |

| Toughness, Nmm | 128 | 90 | 38 | 109.69–300.55 | 197.80 | 33.01 | 112.22–276.90 | 201.73 | 38.76 | |

| Hardness, N | 128 | 90 | 38 | 11.90–29.86 | 20.27 | 3.12 | 12.11–27.93 | 20.69 | 3.76 | |

| Stickiness, N | 128 | 90 | 38 | (−7.20)–(−2.84) | −5.14 | 0.95 | (−7.12)–(−3.12) | −5.17 | 1.08 | |

| Adhesiveness, Nmm | All samples | 188 | 129 | 59 | (−84.93)–(−39.13) | −67.17 | 7.80 | (−83.79)–(−40.69) | −66.43 | 9.28 |

| Toughness, Nmm | 188 | 132 | 56 | 109.69–300.55 | 198.20 | 24.74 | 112.22–276.90 | 199.41 | 36.72 | |

| Hardness, N | 188 | 133 | 55 | 11.90–29.86 | 20.16 | 2.37 | 12.11–27.93 | 20.45 | 3.40 | |

| Stickiness, N | 188 | 131 | 57 | (−7.67)–(−2.84) | −5.38 | 0.93 | (−7.67)–(−3.12) | −5.49 | 1.12 | |

| Hardness | Toughness | Stickiness | Adhesiveness | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Calibration | Prediction | Calibration | Prediction | Calibration | Prediction | Calibration | Prediction | ||

| IS | number | 150 | 38 | 150 | 38 | 150 | 38 | 150 | 38 |

| min | 11.90 | 12.11 | 109.69 | 112.22 | −7.67 | −7.37 | −84.93 | −83.79 | |

| max | 29.86 | 29.86 | 300.55 | 300.55 | −2.84 | −2.84 | −39.13 | −39.13 | |

| mean | 20.39 | 20.52 | 199.75 | 201.32 | −5.39 | −5.35 | −67.00 | −66.69 | |

| SD | 3.32 | 4.51 | 34.40 | 46.02 | 1.10 | 1.35 | 9.83 | 13.68 | |

| KS | number | 150 | 38 | 150 | 38 | 150 | 38 | 150 | 38 |

| min | 11.90 | 15.87 | 109.69 | 152.77 | −7.67 | −7.67 | −84.93 | −83.79 | |

| max | 29.86 | 29.86 | 300.55 | 300.55 | −2.84 | −3.12 | −39.13 | −52.45 | |

| mean | 20.32 | 20.79 | 199.31 | 203.05 | −5.36 | −5.48 | −66.33 | −69.35 | |

| SD | 3.27 | 4.67 | 34.00 | 47.23 | 1.13 | 1.25 | 9.97 | 13.25 | |

| sort | number | 150 | 150 | 150 | 38 | 150 | 38 | 150 | 38 |

| min | 11.90 | 11.90 | 109.69 | 112.22 | −7.67 | −7.37 | −84.93 | −83.79 | |

| max | 29.86 | 29.86 | 300.55 | 275.84 | −2.84 | −3.12 | −39.13 | −52.45 | |

| mean | 20.46 | 20.46 | 200.39 | 198.77 | −5.38 | −5.40 | −66.83 | −67.38 | |

| SD | 3.33 | 3.33 | 34.39 | 45.84 | 1.10 | 1.34 | 9.98 | 13.29 | |

| cv | number | 151 | 37 | 151 | 37 | 151 | 37 | 151 | 37 |

| min | 11.90 | 12.11 | 109.69 | 112.22 | −7.67 | −7.37 | −84.93 | −83.79 | |

| max | 29.86 | 26.32 | 300.55 | 300.55 | −2.84 | −2.84 | −39.13 | −39.13 | |

| mean | 20.31 | 20.84 | 197.92 | 208.80 | −5.41 | −5.28 | −66.78 | −67.59 | |

| SD | 3.39 | 4.33 | 33.50 | 48.59 | 1.09 | 1.37 | 9.92 | 13.57 | |

| Treatment | Parameter | Pretreatment | Rank | Wavenumber | Calibration | Prediction | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| R2 | RMSEC | RPD | r2 | RMSEP | RPD | Bias | |||||

| Condition-adjusted GBR (24 and 48 h soaking) | adhesiveness | Constant offset elimination | 2 | 9403.8–6094.3, 5054–4242.9 | 0.63 | 3.94 | 1.64 | 0.75 | 3.33 | 2.13 | 1.20 |

| toughness | Constant offset elimination | 5 | 5778–5446.3, 4605.4–4242.9 | 0.79 | 10.10 | 2.17 | 0.86 | 8.10 | 2.73 | −2.10 | |

| hardness | no spec | 2 | 6102–5757.3 | 0.59 | 1.22 | 1.55 | 0.92 | 0.55 | 3.95 | 0.26 | |

| stickiness | no spec | 1 | 8454.9–7498.3, 4605.4–4242.9 | 0.12 | 0.84 | 1.07 | 0.03 | 0.84 | 1.01 | −0.19 | |

| KDML (1–16) | adhesiveness | first + MSC | 9 | 7506–5446.3 | 0.84 | 3.44 | 2.51 | 0.74 | 5.29 | 2.05 | 1.64 |

| toughness | first + MSC | 5 | 9403.8–7498.3, 4605.4–4242.9 | 0.68 | 15.50 | 1.76 | 0.84 | 14.00 | 2.51 | 1.27 | |

| hardness | SNV | 9 | 7506–5446.3, 4605.4–4242.9 | 0.87 | 1.12 | 2.74 | 0.85 | 1.39 | 2.90 | −0.67 | |

| stickiness | first + straight | 7 | 7506–4597.7 | 0.76 | 0.55 | 2.06 | 0.68 | 0.63 | 1.94 | 0.26 | |

| Various varieties (17–32) | adhesiveness | Con off eli | 8 | 7506–6094.3, 5454–4597.7 | 0.70 | 5.23 | 1.81 | 0.87 | 3.19 | 2.91 | 0.82 |

| toughness | SNV | 9 | 9403.8–6094.3 | 0.84 | 17.40 | 2.53 | 0.82 | 16.90 | 2.35 | 2.45 | |

| hardness | MSC | 10 | 9403.8–7498.3, 6102–4597.7 | 0.97 | 0.63 | 5.95 | 0.32 | 3.25 | 1.29 | 1.13 | |

| stickiness | no spec | 7 | 7506–6094.3, 5029.7–4597.7 | 0.71 | 0.52 | 1.84 | 0.73 | 0.48 | 2.00 | −0.14 | |

| Market (1–32) | adhesiveness | SNV | 5 | 9403.8–7498.3, 4605.4–4420.3 | 0.34 | 7.13 | 1.23 | 0.48 | 7.20 | 1.49 | 2.70 |

| toughness | no spec | 10 | 9403.8–6094.3, 5454–4597.7 | 0.64 | 20.90 | 1.68 | 0.71 | 20.50 | 1.87 | 1.61 | |

| hardness | MSC | 7 | 9403.8–6094.3, 5454–4597.7 | 0.50 | 2.31 | 1.41 | 0.61 | 2.31 | 1.62 | 0.33 | |

| stickiness | first + MSC | 5 | 6102–4597.7 | 0.42 | 0.77 | 1.32 | 0.44 | 0.80 | 1.34 | −0.07 | |

| total sample | adhesive-ness | Min-Max | 7 | 9403.8–7498.3, 4605.4–4242.9 | 0.52 | 5.54 | 1.45 | 0.21 | 8.16 | 1.14 | 1.33 |

| toughness | no spec | 10 | 9403.8–7498.3, 6102–5770.3 | 0.53 | 20.10 | 1.46 | 0.63 | 22.20 | 1.69 | −5.11 | |

| hardness | SNV | 9 | 9403.8–7498.3, 6102–4597.7 | 0.55 | 1.89 | 1.50 | 0.56 | 2.23 | 1.51 | −0.16 | |

| stickiness | SNV | 10 | 9403.8–6094.3, 5454–4597.7 | 0.53 | 0.70 | 1.45 | 0.21 | 0.98 | 1.14 | −0.14 | |

| Parameter | Sampling | Pretreatment | Hidden Layer | Calibration | Prediction | ||||

|---|---|---|---|---|---|---|---|---|---|

| R2 | RMSEC | r2 | RMSEP | RPD | Bias | ||||

| Adhesiveness (Nmm) | IS | SNV | 10 | 0.92 | 2.26 | 0.62 | 5.62 | 1.6 | 0.42 |

| KS | raw | 5 | 0.75 | 4.20 | 0.61 | 4.49 | 1.6 | −0.51 | |

| sort | raw | 5 | 0.65 | 4.98 | 0.39 | 6.08 | 1.3 | 0.27 | |

| CV | SNV | 20 | 0.97 | 1.35 | 0.91 | 2.63 | 3.4 | −0.08 | |

| Toughness (Nmm) | IS | raw | 10 | 0.99 | 2.77 | 0.52 | 21.60 | 1.4 | −1.49 |

| KS | raw | 20 | 1.00 | 1.40 | 0.92 | 9.98 | 3.5 | 1.55 | |

| sort | raw | 5 | 0.80 | 13.46 | 0.55 | 22.16 | 1.5 | −4.12 | |

| CV | SNV | 25 | 0.98 | 3.94 | 0.87 | 10.50 | 2.8 | 1.09 | |

| Hardness (N) | IS | SNV | 25 | 0.73 | 1.50 | 0.54 | 2.01 | 1.5 | −0.28 |

| KS | SNV | 25 | 1.00 | 0.10 | 0.94 | 0.77 | 4.3 | 0.02 | |

| sort | raw | 5 | 0.68 | 1.63 | 0.53 | 2.10 | 1.5 | 0.25 | |

| CV | raw | 30 | 1.00 | 0.16 | 0.87 | 1.27 | 2.8 | 0.17 | |

| Stickiness (N) | IS | SNV | 15 | 1.00 | 0.05 | 0.28 | 0.86 | 1.2 | −0.05 |

| KS | SNV | 5 | 0.73 | 0.54 | 0.61 | 0.55 | 1.6 | −0.02 | |

| sort | raw | 30 | 0.99 | 0.12 | 0.09 | 0.97 | 1.1 | 0.15 | |

| CV | raw | 15 | 0.80 | 0.44 | 0.64 | 0.65 | 1.7 | −0.02 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaewsorn, K.; Phanomsophon, T.; Maichoon, P.; Pokhrel, D.R.; Pornchaloempong, P.; Krusong, W.; Sirisomboon, P.; Tanaka, M.; Kojima, T. Modeling Textural Properties of Cooked Germinated Brown Rice Using the near-Infrared Spectra of Whole Grain. Foods 2023, 12, 4516. https://doi.org/10.3390/foods12244516

Kaewsorn K, Phanomsophon T, Maichoon P, Pokhrel DR, Pornchaloempong P, Krusong W, Sirisomboon P, Tanaka M, Kojima T. Modeling Textural Properties of Cooked Germinated Brown Rice Using the near-Infrared Spectra of Whole Grain. Foods. 2023; 12(24):4516. https://doi.org/10.3390/foods12244516

Chicago/Turabian StyleKaewsorn, Kannapot, Thitima Phanomsophon, Pisut Maichoon, Dharma Raj Pokhrel, Pimpen Pornchaloempong, Warawut Krusong, Panmanas Sirisomboon, Munehiro Tanaka, and Takayuki Kojima. 2023. "Modeling Textural Properties of Cooked Germinated Brown Rice Using the near-Infrared Spectra of Whole Grain" Foods 12, no. 24: 4516. https://doi.org/10.3390/foods12244516