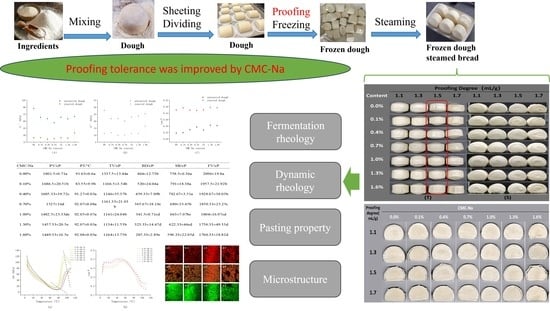

The Effect of Carboxymethyl Cellulose Sodium on the Proofing Tolerance and Quality of Frozen Dough Steamed Bread

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Frozen Dough Steamed Bread

2.3. Specific Volume

2.4. Hardness

2.5. Crust–Crumb Perimeter Ratio

2.6. Fermentation Properties

2.7. Pasting Properties

2.8. Dynamic Rheological Properties

2.8.1. Oscillation Frequency

2.8.2. Temperature Sweep

2.9. Microstructure

2.10. Statistical Analysis

3. Results and Discussion

3.1. Effects of Proofing Degree and CMC-Na on Specific Volume and Appearance of Frozen Dough Steamed Bread

3.2. Effects of Proofing Degree and CMC-Na on Secession of Crust and Crumb for Frozen Dough Steamed Bread

3.3. Effects of Proofing Degree and CMC-Na on the Texture of Frozen Dough Steamed Bread

3.4. Effect of CMC-Na on Fermentation Properties of Dough

3.5. Dynamic Rheological Properties of Frozen Dough

3.5.1. Oscillation Frequency

3.5.2. Temperature Sweep

3.6. Effect of CMC-Na on Pasting Property of Frozen Dough

3.7. Effect of CMC-Na on the Microstructure of Frozen Dough Steamed Bread

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Calderón-Domínguez, G.; Chanona-Pérez, J.; Ramos-Cruz, A.L.; López-Lara, A.I.; Tlapale-Valdivia, A.D.; Gutiérrez-López, G.F. Chapter 7—Fractal and Image Analysis of Mexican Sweet Bread Bubble Distribution: Influence of Fermentation and Mixing Time. In Bubbles in Food 2; Campbell, G.M., Scanlon, M.G., Pyle, D.L., Eds.; AACC International: St. Paul, MN, USA, 2008; pp. 73–81. ISBN 978-1-891127-59-5. [Google Scholar]

- Omedi, J.O.; Huang, W.; Zhang, B.; Li, Z.; Zheng, J. Advances in present-day frozen dough technology and its improver and novel biotech ingredients development trends—A review. Cereal Chem. 2019, 96, 34–56. [Google Scholar] [CrossRef]

- Phimolsiripol, Y.; Siripatrawan, U.; Tulyathan, V.; Cleland, D.J. Effects of freezing and temperature fluctuations during frozen storage on frozen dough and bread quality. J. Food Eng. 2008, 84, 48–56. [Google Scholar] [CrossRef]

- Lu, L.; Zhu, K. Physicochemical and fermentation properties of pre-fermented frozen dough: Comparative study of frozen storage and freeze–thaw cycles. Food Hydrocoll. 2023, 136, 108253. [Google Scholar] [CrossRef]

- Lu, L.; Zhu, K.; Yang, Z.; Guo, X.; Xing, J. Metabolomics analysis of freeze–thaw tolerance enhancement mechanism of ε-poly-l-lysine on industrial yeast. Food Chem. 2022, 382, 132315. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zheng, S.; Li, Z.; Pan, Z.; Huang, Z.; Zhao, J.; Ai, Z. Influence of three types of freezing methods on physicochemical properties and digestibility of starch in frozen unfermented dough. Food Hydrocoll. 2021, 115, 106619. [Google Scholar] [CrossRef]

- Selomulyo, V.O.; Zhou, W. Frozen bread dough: Effects of freezing storage and dough improvers. J. Cereal Sci. 2007, 45, 1–17. [Google Scholar] [CrossRef]

- Huang, S.; Miskelly, D. Chapter 6—Dough Preparation and Processing. In Steamed Breads; Huang, S., Miskelly, D., Eds.; Woodhead Publishing: Cambridge, UK, 2016; pp. 69–80. ISBN 978-0-08-100715-0. [Google Scholar]

- Frauenlob, J.; Moriano, M.E.; Innerkofler, U.; D’Amico, S.; Lucisano, M.; Schoenlechner, R. Effect of physicochemical and empirical rheological wheat flour properties on quality parameters of bread made from pre-fermented frozen dough. J. Cereal Sci. 2017, 77, 58–65. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, Y.; Yuan, J.; Yang, M.; Yang, R.; Gu, Z.; Xie, C.; Zhou, Q.; Jiang, D.; Zhou, J.; et al. Impact of Different Frozen Dough Technology on the Quality and Gluten Structure of Steamed Buns. Foods 2022, 11, 3833. [Google Scholar] [CrossRef]

- Jiang, Z.; Guo, X.; Xing, J.; Zhu, K. Alleviative effects of chitooligosaccharides on the quality deterioration of frozen dough subjected to freeze–thaw cycles. Food Hydrocoll. 2023, 144, 109016. [Google Scholar] [CrossRef]

- Meziani, S.; Ioannou, I.; Jasniewski, J.; Belhaj, N.; Muller, J.; Ghoul, M.; Desobry, S. Effects of freezing treatments on the fermentative activity and gluten network integrity of sweet dough. LWT—Food Sci. Technol. 2012, 46, 118–126. [Google Scholar] [CrossRef]

- Ayati, S.; Hamdami, N.; Le-Bail, A. Frozen Sangak dough and bread properties: Impact of pre-fermentation and freezing rate. Int. J. Food Prop. 2017, 20, 782–791. [Google Scholar] [CrossRef]

- Le-Bail, A.; Nicolitch, C.; Vuillod, C. Fermented Frozen Dough: Impact of Pre-fermentation Time and of Freezing Rate for a Pre-fermented Frozen Dough on Final Volume of the Bread. Food Bioprocess Technol. 2010, 3, 197–203. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, S.; Yang, X.; Wang, W.; Liu, X.; Wang, H.; Zhang, H. Enhancing the fermentation performance of frozen dough by ultrasonication: Effect of starch hierarchical structures. J. Cereal Sci. 2022, 106, 103500. [Google Scholar] [CrossRef]

- Takano, H.; Ishida, N.; Koizumi, M.; Kano, H. Imaging of the Fermentation Process of Bread Dough and the Grain Structure of Baked Breads by Magnetic Resonance Imaging. J. Food Sci. 2002, 67, 244–250. [Google Scholar] [CrossRef]

- Yue, Q.; Liu, C.; Li, L.; Zheng, X.; Bian, K. Effects of fermentation on the rheological characteristics of dough and the quality of steamed bread. J. Food Process. Preserv. 2019, 43. [Google Scholar] [CrossRef]

- Zhao, Y.; Kweon, M. Optimized Fermentation and Freezing Conditions for Ready-to-Proof and Ready-to-Bake Frozen Dough of Sweet Bread. Appl. Sci. 2021, 11, 7904. [Google Scholar] [CrossRef]

- Gabric, D.; Ben-Aissa, F.; Le-Bail, A.; Monteau, J.Y.; Curic, D. Impact of process conditions on the structure of pre-fermented frozen dough. J. Food Eng. 2011, 105, 361–366. [Google Scholar] [CrossRef]

- Rezaei, M.N.; Jayaram, V.B.; Verstrepen, K.J.; Courtin, C.M. The impact of yeast fermentation on dough matrix properties. J. Sci. Food Agric. 2016, 96, 3741–3748. [Google Scholar] [CrossRef]

- Almeida, E.L.; Chang, Y.K. Effect of proving time on the quality of frozen pre-baked French style rolls elaborated with the addition of wholegrain flour and enzymes. J. Food Sci. Technol. 2014, 51, 3390–3396. [Google Scholar] [CrossRef][Green Version]

- Dobraszczyk, B.J.; Smewing, J.; Albertini, M.; Maesmans, G.; Schofield, J.D. Extensional Rheology and Stability of Gas Cell Walls in Bread Doughs at Elevated Temperatures in Relation to Breadmaking Performance. Cereal Chem. 2003, 80, 218–224. [Google Scholar] [CrossRef]

- Zhu, X.; Yuan, P.; Zhang, T.; Wang, Z.; Cai, D.; Chen, X.; Shen, Y.; Xu, J.; Song, C.; Goff, D. Effect of carboxymethyl chitosan on the storage stability of frozen dough: State of water, protein structures and quality attributes. Food Res. Int. 2022, 151, 110863. [Google Scholar] [CrossRef]

- Rosell, C.M.; Collar, C.; Haros, M. Assessment of hydrocolloid effects on the thermo-mechanical properties of wheat using the Mixolab. Food Hydrocoll. 2007, 21, 452–462. [Google Scholar] [CrossRef]

- Fekete, T.; Borsa, J.; Takács, E.; Wojnárovits, L. Synthesis of cellulose derivative based superabsorbent hydrogels by radiation induced crosslinking. Cellulose 2014, 21, 4157–4165. [Google Scholar] [CrossRef]

- Smewing, J. AACCI Approved Methods Technical Committee Report on the Collaborative Study for a New AACCI Method (10-16.01): Volumetric and Dimensional Profile Determination of Baked Products Using Laser Topography—VolScan Profiler Method. Cereal Food World 2016, 61, 18–23. [Google Scholar] [CrossRef][Green Version]

- Zhang, H.; Sun, H.; Ma, M.; Mu, T. Dough rheological properties, texture, and structure of high-moisture starch hydrogels with different potassium-, and calcium-based compounds. Food Hydrocoll. 2023, 137, 108337. [Google Scholar] [CrossRef]

- Ishwarya, S.P.; Desai, K.M.; Naladala, S.; Anandharamakrishnan, C. Bran-induced effects on the evolution of bubbles and rheological properties in bread dough. J. Texture Stud. 2017, 48, 415–426. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Tacer-Caba, Z.; Immonen, M.; Kemell, M.; Varis, J.J.; Jian, C.; Maina, N.H. Understanding the influence of in situ produced dextran on wheat dough baking performance: Maturograph, biaxial extension, and dynamic mechanical thermal analysis. Food Hydrocoll. 2022, 131, 107844. [Google Scholar] [CrossRef]

- Falade, A.T.; Emmambux, M.N.; Buys, E.M.; Taylor, J.R.N. Improvement of maize bread quality through modification of dough rheological properties by lactic acid bacteria fermentation. J. Cereal Sci. 2014, 60, 471–476. [Google Scholar] [CrossRef]

- Arp, C.G.; Correa, M.J.; Ferrero, C. Improving quality: Modified celluloses applied to bread dough with high level of resistant starch. Food Hydrocoll. 2021, 112, 106302. [Google Scholar] [CrossRef]

- Jiang, Z.; Le Bail, A.; Wu, A. Effect of the thermostable xylanase B (XynB) from Thermotoga maritima on the quality of frozen partially baked bread. J. Cereal Sci. 2008, 47, 172–179. [Google Scholar] [CrossRef]

- Rubenthaler, G.L.; Pomeranz, Y.; Huang, M.L. Steamed bread. 4. negative steamer-spring of strong flours. Cereal Chem. 1992, 69, 334–337. [Google Scholar]

- Pérez-Nieto, A.; Chanona-Pérez, J.J.; Farrera-Rebollo, R.R.; Gutiérrez-López, G.F.; Alamilla-Beltrán, L.; Calderón-Domínguez, G. Image analysis of structural changes in dough during baking. LWT—Food Sci. Technol. 2010, 43, 535–543. [Google Scholar] [CrossRef]

- Rezaei, M.N.; Dornez, E.; Jacobs, P.; Parsi, A.; Verstrepen, K.J.; Courtin, C.M. Harvesting yeast (Saccharomyces cerevisiae) at different physiological phases significantly affects its functionality in bread dough fermentation. Food Microbiol. 2014, 39, 108–115. [Google Scholar] [CrossRef]

- Janssen, F.; Wouters, A.G.B.; Delcour, J.A. Gas cell stabilization by aqueous-phase constituents during bread production from wheat and rye dough and oat batter: Dough or batter liquor as model system. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3881–3917. [Google Scholar] [CrossRef]

- Xie, D.; Lei, Y.; Li, X. Effect of sucrose levels on dynamic rheology properties of dough during fermentation process. International J. Food Sci. Technol. 2023, 58, 1326–1335. [Google Scholar] [CrossRef]

- Arp, C.G.; Correa, M.J.; Ferrero, C. Modified celluloses improve the proofing performance and quality of bread made with a high content of resistant starch. J. Sci. Food Agric. 2023, 103, 3041–3049. [Google Scholar] [CrossRef]

- Meerts, M.; Vaes, E.; Botteldoorn, S.; Courtin, C.M.; Cardinaels, R.; Moldenaers, P. The time-dependent rheology of fermenting wheat flour dough: Effects of salt and sugar. Rheol. Acta 2018, 57, 813–827. [Google Scholar] [CrossRef]

- Singh, A.P.; Bhattacharya, M. Development of dynamic modulus and cell opening of dough during baking. J. Texture Stud. 2005, 36, 44–67. [Google Scholar] [CrossRef]

- Meerts, M.; Ramirez Cervera, A.; Struyf, N.; Cardinaels, R.; Courtin, C.M.; Moldenaers, P. The effects of yeast metabolites on the rheological behaviour of the dough matrix in fermented wheat flour dough. J. Cereal Sci. 2018, 82, 183–189. [Google Scholar] [CrossRef]

- Salvador, A.; Sanz, T.; Fiszman, S.M. Dynamic rheological characteristics of wheat flour–water doughs. Effect of adding NaCl, sucrose and yeast. Food Hydrocoll. 2006, 20, 780–786. [Google Scholar] [CrossRef]

- Singh, S.; Singh, N. Relationship of polymeric proteins and empirical dough rheology with dynamic rheology of dough and gluten from different wheat varieties. Food Hydrocoll. 2013, 33, 342–348. [Google Scholar] [CrossRef]

- Correa, M.J.; Añón, M.C.; Pérez, G.T.; Ferrero, C. Effect of modified celluloses on dough rheology and microstructure. Food Res. Int. 2010, 43, 780–787. [Google Scholar] [CrossRef]

- Sobanwa, M.; Foster, T.J.; Yakubov, G.; Watson, N.J. How hydrocolloids can control the viscoelastic properties of acid-swollen collagen pastes. Food Hydrocoll. 2022, 126, 107486. [Google Scholar] [CrossRef]

- Troncoso Recio, R.; Pérez Guerra, N.; Torrado Agrasar, A.; Tovar Rodríguez, C.A. Influence of Casein Hydrolysates and Yeast on the Rheological Properties of Wheat Dough. Gels 2022, 8, 689. [Google Scholar] [CrossRef]

- Jiang, Q.; Wei, X.; Liu, Q.; Zhang, T.; Chen, Q.; Yu, X.; Jiang, H. Rheo-fermentation properties of bread dough with different gluten contents processed by 3D printing. Food Chem. 2024, 433, 137318. [Google Scholar] [CrossRef]

- Lee, S.; Campanella, O. Impulse viscoelastic characterization of wheat flour dough during fermentation. J. Food Eng. 2013, 118, 266–270. [Google Scholar] [CrossRef]

- Upadhyay, R.; Ghosal, D.; Mehra, A. Characterization of bread dough: Rheological properties and microstructure. J. Food Eng. 2012, 109, 104–113. [Google Scholar] [CrossRef]

- Alpers, T.; Tauscher, V.; Steglich, T.; Becker, T.; Jekle, M. The Self-Enforcing Starch–Gluten System—Strain–Dependent Effects of Yeast Metabolites on the Polymeric Matrix. Polymers 2021, 13, 30. [Google Scholar] [CrossRef]

- Verheyen, C.; Jekle, M.; Becker, T. Effects of Saccharomyces cerevisiae on the structural kinetics of wheat dough during fermentation. Food Sci. Technol. 2014, 58, 194–202. [Google Scholar] [CrossRef]

- Jekle, M.; Becker, T. Effects of Acidification, Sodium Chloride, and Moisture Levels on Wheat Dough: II. Modeling of Bread Texture and Staling Kinetics. Food Biophys. 2012, 7, 200–208. [Google Scholar] [CrossRef]

- Jekle, M.; Mühlberger, K.; Becker, T. Starch–gluten interactions during gelatinization and its functionality in dough like model systems. Food Hydrocoll. 2016, 54, 196–201. [Google Scholar] [CrossRef]

- Rouillé, J.; Chiron, H.; Colonna, P.; Della Valle, G.; Lourdin, D. Dough/crumb transition during French bread baking. J. Cereal Sci. 2010, 52, 161–169. [Google Scholar] [CrossRef]

- Turbin-Orger, A.; Shehzad, A.; Chaunier, L.; Chiron, H.; Della Valle, G. Elongational properties and proofing behaviour of wheat flour dough. J. Food Eng. 2016, 168, 129–136. [Google Scholar] [CrossRef]

- Varela, P.; Fiszman, S.M. Hydrocolloids in fried foods. A review. Food Hydrocoll. 2011, 25, 1801–1812. [Google Scholar] [CrossRef]

- Balet, S.; Guelpa, A.; Fox, G.; Manley, M. Rapid Visco Analyser (RVA) as a Tool for Measuring Starch-Related Physiochemical Properties in Cereals: A Review. Food Anal. Methods 2019, 12, 2344–2360. [Google Scholar] [CrossRef]

- Cozzolino, D. The use of the rapid visco analyser (RVA) in breeding and selection of cereals. J. Cereal Sci. 2016, 70, 282–290. [Google Scholar] [CrossRef]

- Gałkowska, D.; Juszczak, L. Effects of amino acids on gelatinization, pasting and rheological properties of modified potato starches. Food Hydrocoll. 2019, 92, 143–154. [Google Scholar] [CrossRef]

- Yang, K.; Luo, X.; Zhai, Y.; Liu, J.; Chen, K.; Shao, X.; Wu, X.; Li, Y.; Chen, Z. Influence of sodium alginate on the gelatinization, rheological, and retrogradation properties of rice starch. Int. J. Biol. Macromol. 2021, 185, 708–715. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Bai, Y.; Zhang, Q.; Hu, X.; Shen, Q. Effects of potassium alum addition on physicochemical, pasting, thermal and gel texture properties of potato starch. Int. J. Food Sci. Technol. 2011, 46, 1621–1627. [Google Scholar] [CrossRef]

- Zhao, T.; Li, X.; Ma, Z.; Hu, X.; Wang, X.; Zhang, D. Multiscale structural changes and retrogradation effects of addition of sodium alginate to fermented and native wheat starch. Int. J. Biol. Macromol. 2020, 163, 2286–2294. [Google Scholar] [CrossRef] [PubMed]

- Sandhu, K.S.; Singh, N.; Malhi, N.S. Some properties of corn grains and their flours I: Physicochemical, functional and chapati-making properties of flours. Food Chem. 2007, 101, 938–946. [Google Scholar] [CrossRef]

- Jekle, M.; Becker, T. Wheat dough microstructure: The relation between visual structure and mechanical behavior. Crit. Rev. Food Sci. Nutr. 2015, 55, 369–382. [Google Scholar] [CrossRef] [PubMed]

- Alpers, T.; Becker, T.; Jekle, M. Strain-dependent assessment of dough’s polymer structure and functionality during the baking process. PLoS ONE 2023, 18, e282670. [Google Scholar] [CrossRef] [PubMed]

| Content of CMC-Na (%) | Hm (mm) | T1 (h) | Vt (mL) | R (%) | Tx (h) |

|---|---|---|---|---|---|

| 0.00 | 28.80 ± 3.82 b | 1.49 ± 0.13 c | 1897.50 ± 106.77 a | 72.15 ± 1.34 a | 0.84 ± 0.02 a |

| 0.10 | 40.35 ± 0.07 a | 1.14 ± 0.01 d | 2002.50 ± 31.82 a | 66.00 ± 0.71 d | 0.73 ± 0.01 a |

| 0.40 | 44.43 ± 5.17 a | 1.83 ± 0.17 b | 2015.33 ± 7.64 a | 67.27 ± 1.35 cd | 0.76 ± 0.10 a |

| 0.70 | 45.50 ± 2.11 a | 2.88 ± 0.10 a | 1975.67 ± 46.26 a | 70.53 ± 0.93 ab | 0.81 ± 0.08 a |

| 1.00 | 44.93 ± 1.84 a | 3.00 ± 0.00 a | 1991.67 ± 16.86 a | 67.63 ± 0.92 bcd | 0.67 ± 0.05 a |

| 1.30 | 46.05 ± 2.76 a | 3.00 ± 0.00 a | 1983.50 ± 79.9 a | 69.80 ± 0.71 abc | 0.68 ± 0.00 a |

| 1.60 | 44.10 ± 2.79 a | 2.99 ± 0.02 a | 1962.67 ± 73.76 a | 69.47 ± 2.39 abc | 0.7 ± 0.11 a |

| Content of CMC-Na (%) | PV (mPa∙s) | PT (°C) | TV (mPa∙s) | BD (mPa∙s) | SB (mPa∙s) | FV (mPa∙s) |

|---|---|---|---|---|---|---|

| 0.00 | 1801.50 ± 0.71 a | 91.63 ± 0.6 a | 1337.50 ± 13.44 a | 464.00 ± 12.73 b | 758.50 ± 6.36 a | 2096.00 ± 19.8 a |

| 0.10 | 1686.50 ± 20.51 b | 83.55 ± 9.9 b | 1166.50 ± 3.54 b | 520.00 ± 24.04 a | 791.00 ± 18.38 a | 1957.50 ± 21.92 b |

| 0.40 | 1605.33 ± 39.72 c | 91.27 ± 0.03 a | 1146.00 ± 35.37 b | 459.33 ± 7.09 b | 782.67 ± 3.51 a | 1928.67 ± 38.03 b |

| 0.70 | 1527.00 ± 16 d | 92.07 ± 0.08 a | 1161.33 ± 21.03 b | 365.67 ± 18.18 c | 689.00 ± 33.45 b | 1850.33 ± 23.25 c |

| 1.00 | 1482.50 ± 23.33 de | 92.05 ± 0.07 a | 1141.00 ± 24.04 b | 341.50 ± 0.71 cd | 663.00 ± 7.07 bc | 1804.00 ± 16.97 cd |

| 1.30 | 1457.33 ± 20.5 e | 92.07 ± 0.03 a | 1134.00 ± 11.53 b | 323.33 ± 14.47 d | 622.33 ± 46 cd | 1756.33 ± 49.33 d |

| 1.60 | 1449.33 ± 16.5 e | 92.08 ± 0.03 a | 1164.00 ± 13.75 b | 285.33 ± 2.89 e | 596.33 ± 22.05 d | 1760.33 ± 18.82 d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.-F.; Zhu, K.-X.; Guo, X.-N. The Effect of Carboxymethyl Cellulose Sodium on the Proofing Tolerance and Quality of Frozen Dough Steamed Bread. Foods 2024, 13, 870. https://doi.org/10.3390/foods13060870

Liu S-F, Zhu K-X, Guo X-N. The Effect of Carboxymethyl Cellulose Sodium on the Proofing Tolerance and Quality of Frozen Dough Steamed Bread. Foods. 2024; 13(6):870. https://doi.org/10.3390/foods13060870

Chicago/Turabian StyleLiu, Si-Fan, Ke-Xue Zhu, and Xiao-Na Guo. 2024. "The Effect of Carboxymethyl Cellulose Sodium on the Proofing Tolerance and Quality of Frozen Dough Steamed Bread" Foods 13, no. 6: 870. https://doi.org/10.3390/foods13060870

APA StyleLiu, S.-F., Zhu, K.-X., & Guo, X.-N. (2024). The Effect of Carboxymethyl Cellulose Sodium on the Proofing Tolerance and Quality of Frozen Dough Steamed Bread. Foods, 13(6), 870. https://doi.org/10.3390/foods13060870