High Hydrostatic Pressure Treatments Improved Properties of Fermentation of Apple Juice Accompanied by Higher Reserved Lactobacillus plantarum

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagent

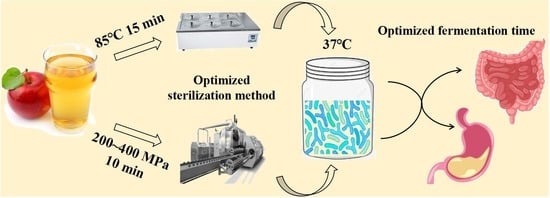

2.2. Preparation and Fermentation of Apple Juice

2.3. Total Acid and pH Values

2.4. Measurement of Color

2.5. Determination of Viable LAB Cells

2.6. Total Phenol Content and Polyphenolic Compounds

2.7. Antioxidant Activities

2.7.1. ABTS-Based Scavenging Activity

2.7.2. DPPH Scavenging Ability

2.8. Survival of L. plantarum Fermentation in Apple Juice under Simulated Gastrointestinal Conditions

2.9. Statistical Analysis

3. Results and Discussion

3.1. Comparing the Effect of Treatments on Quality Properties of Apple Juice

3.2. Effect of Fermentation on Physicochemical Properties of Apple Juice with Different Treatments

3.3. Changes in Color

3.4. Variations of Viable Cell Number during Fermentation

3.5. Comparative Analyses of Antioxidant Activity of Different Treated Apple Juices during Fermentation

3.6. Total Phenol Content and Polyphenolic Profiles

3.7. Viability of L. plantarum after Fermentation in Apple Juice under Simulated Gastrointestinal Conditions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bondonno, N.P.; Bondonno, C.P.; Ward, N.C.; Hodgson, J.M.; Croft, K.D. The cardiovascular health benefits of apples: Whole fruit vs. Isolated compounds. Trends Food Sci. Technol. 2017, 69, 243–256. [Google Scholar] [CrossRef]

- Tu, S.H.; Chen, L.C.; Ho, Y.S. An apple a day to prevent cancer formation: Reducing cancer risk with flavonoids. J. Food Drug Anal. 2017, 25, 119–124. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.; Yang, X.; Liu, R.; Liu, L.; Zhao, D.; Liu, J.; Guo, Y.R.; Long, J.G. Thinned young apple polysaccharide improves hepatic metabolic disorder in high-fat diet-induced obese mice by activating mitochondrial respiratory functions. J. Funct. Foods 2017, 33, 396–407. [Google Scholar] [CrossRef]

- Erkmen, O.; Bozoglu, T.F. Volume 2: Microorganisms in Food Preservation and Processing. In Food Microbiology: Principles into Practice; John Wiley Sons Ltd.: Chichester, UK, 2016; pp. 12–33. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, P.; Zhan, P.; Tian, H.L.; Lu, C.; Tian, P. Aroma characteristics of cloudy kiwifruit juices treated with high hydrostatic pressure and representative thermal processes. Food Res. Int. 2020, 139, 109841. [Google Scholar] [CrossRef]

- Wibowo, S.; Essel, E.; de Man, S.; Bernaert, N.; Van Droogenbroeck, B.; Grauwet, T.; Hendrickx, M. Comparing the impact of high pressure, pulsed electric field and thermal pasteurization on quality attributes of cloudy apple juice using targeted and untargeted analyses. Innov. Food Sci. Emerg. Technol. 2019, 54, 64–77. [Google Scholar] [CrossRef]

- Ma, J.; Yang, H.K.; Chen, Y.J.; Feng, X.P.; Wu, C.Y.; Long, F.Y. Purified Saponins in Momordica charantia Treated with High Hydrostatic Pressure and Ionic Liquid-Based Aqueous Biphasic Systems. Foods 2022, 11, 1930. [Google Scholar] [CrossRef]

- Velazquez-Estrada, R.M.; Hernandez-Herrero, M.M.; Rufer, C.E.; Guamis-Lopez, B.; Roig-Sagues, A.X. Influence of ultra high pressure homogenization processing on bioactive compounds and antioxidant activity of orange juice. Innov. Food Sci. Emerg. Technol. 2013, 18, 89–94. [Google Scholar] [CrossRef]

- Erkmen, O.; Doğan, C. Effects of ultra high hydrostatic pressure on Listeria monocytogenes and natural flora in broth, milk, and fruit juices. Int. J. Food Sci. Technol. 2004, 39, 91–97. [Google Scholar] [CrossRef]

- Zhang, S.Q.; Hu, C.Y.; Guo, Y.R.; Wang, X.Y.; Meng, Y.H. Polyphenols in fermented apple juice: Beneficial effects on human health. J. Funct. Foods 2020, 76, 104294. [Google Scholar] [CrossRef]

- Wang, X.W.; Han, M.Z.; Zhang, M.N.; Wang, Y.; Ren, Y.P.; Yue, T.L.; Gao, Z.P. In vitro evaluation of the hypoglycemic properties of lactic acid bacteria and its fermentation adaptability in apple juice. LWT 2020, 136, 110363. [Google Scholar] [CrossRef]

- Ayed, L.; M’hir, M.; Hamdi, M. Microbiological, Biochemical, and Functional Aspects of Fermented Vegetable and Fruit Beverages. J. Chem. 2020, 2020, 5790432. [Google Scholar] [CrossRef]

- Kwaw, E.; Ma, Y.; Tchabo, W.; Apaliya, M.T.; Wu, M.; Sackey, A.S.; Xiao, L.; Tahir, H.E. Effect of Lactobacillus strains on phenolic profile, color attributes and antioxidant activities of lactic-acid-fermented mulberry juice. Food Chem. 2018, 250, 148–154. [Google Scholar] [CrossRef]

- Han, M.; Zhang, M.; Wang, X.; Bai, X.; Yue, T.; Gao, Z. Cloudy Apple Juice Fermented by Lactobacillus Prevents Obesity via Modulating Gut Microbiota and Protecting Intestinal Tract Health. Nutrients 2021, 13, 971. [Google Scholar] [CrossRef] [PubMed]

- Erkmen, O. Microbiological Analysis of Foods and Food Processing Environments; Elsevier: London, UK, 2022; pp. 361–379. [Google Scholar]

- Yang, J.; Sun, Y.; Gao, T.; Wu, Y.; Sun, H.; Zhu, Q.; Liu, C.; Zhou, C.; Han, Y.; Tao, Y. Fermentation and Storage Characteristics of “Fuji” Apple Juice Using Lactobacillus acidophilus, Lactobacillus casei and Lactobacillus plantarum: Microbial Growth, Metabolism of Bioactives and in vitro Bioactivities. Front. Nutr. 2022, 9, 833906. [Google Scholar] [CrossRef] [PubMed]

- Zhu, D.S.; Zhang, Y.Y.; Kou, C.C.; Xi, P.S.; Liu, H. Ultrasonic and other sterilization methods on nutrition and flavor of cloudy apple juice. Ultrason. Sonochemistry 2022, 84, 105975. [Google Scholar] [CrossRef] [PubMed]

- Karioti, A.; Hadjipavlou-Litina, D.; Mensah, M.L.K.; Fleischer, T.C.; Skaltsa, H. Composition and antioxidant activity of the essential oils of Xylopia aethiopica (Dun) A. Rich. (Annonaceae) leaves, stem bark, root bark, and fresh and dried fruits, growing in Ghana. J. Agric. Food Chem. 2004, 52, 8094–8098. [Google Scholar] [CrossRef] [PubMed]

- Roberts, D.; Reyes, V.; Bonilla, F.; Dzandu, B.; Liu, C.; Chouljenko, A.; Sathivel, S. Viability of Lactobacillus plantarum NCIMB 8826 in fermented apple juice under simulated gastric and intestinal conditions. LWT 2018, 97, 144–150. [Google Scholar] [CrossRef]

- Chen, H.Y.; Li, X.Y.; Liu, B.J.; Meng, X.H. Microencapsulation of Lactobacillus bulgaricus and survival assays under simulated gastrointestinal conditions. J. Funct. Foods 2017, 29, 248–255. [Google Scholar] [CrossRef]

- Keenan, D.F.; Brunton, N.; Gormley, R.; Butler, F. Effects of Thermal and High Hydrostatic Pressure Processing and Storage on the Content of Polyphenols and Some Quality Attributes of Fruit Smoothies. J. Agric. Food Chem. 2010, 59, 601–607. [Google Scholar] [CrossRef]

- Chen, R.Z.; Meng, F.L.; Zhang, S.Q.; Liu, Z.Q. Effects of ultrahigh pressure extraction conditions on yields and antioxidant activity of ginsenoside from ginseng. Sep. Purif. Technol. 2009, 66, 340–346. [Google Scholar] [CrossRef]

- Chaikham, P.; Rattanasena, P.; Phunchaisri, C.; Sudsanor, P. Quality changes of litchi (Litchi chinensis Sonn.) in syrup due to thermal and high pressure processes. LWT 2017, 75, 751–760. [Google Scholar] [CrossRef]

- Dars, A.G.; Hu, K.; Liu, Q.; Abbas, A.; Xie, B.; Sun, Z. Effect of Thermo-Sonication and Ultra-High Pressure on the Quality and Phenolic Profile of Mango Juice. Foods 2019, 8, 298. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Z.; Zhang, Y.; Wang, W.; Sun, S.; Wang, J.; Li, X.; Dai, F.; Jiang, Y. Changes in Physicochemical Properties, Volatile Profiles, and Antioxidant Activities of Black Apple during High-Temperature Fermentation Processing. Front. Nutr. 2022, 8, 794231. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, F.; Ji, B.P.; Nout, R.M.J.; Fang, Q.; Yang, Z.W. Determination of organic acids evolution during apple cider fermentation using an improved HPLC analysis method. Eur. Food Res. Technol. 2008, 227, 1183–1190. [Google Scholar] [CrossRef]

- Han, M.Z.; Wang, X.W.; Zhang, M.N.; Ren, Y.P.; Yue, T.L.; Gao, Z.P. Effect of mixed Lactobacillus on the physicochemical properties of cloudy apple juice with the addition of polyphenols-concentrated solution. Food Biosci. 2021, 41, 101049. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, R.; Zhang, Y.; Yang, Y.; Sun, X.; Zhang, Q.; Yang, N. Biotransformation of phenolics and metabolites and the change in antioxidant activity in kiwifruit induced by Lactobacillus plantarum fermentation. J. Sci. Food Agric. 2020, 100, 3283–3290. [Google Scholar] [CrossRef]

- Tkacz, K.; Chmielewska, J.; Turkiewicz, I.P.; Nowicka, P.; Wojdyło, A. Dynamics of changes in organic acids, sugars and phenolic compounds and antioxidant activity of sea buckthorn and sea buckthorn-apple juices during malolactic fermentation. Food Chem. 2020, 332, 127382. [Google Scholar] [CrossRef]

- Cele, N.P.; Akinola, S.A.; Manhivi, V.E.; Shoko, T.; Remize, F.; Sivakumar, D. Influence of Lactic Acid Bacterium Strains on Changes in Quality, Functional Compounds and Volatile Compounds of Mango Juice from Different Cultivars during Fermentation. Foods 2022, 11, 682. [Google Scholar] [CrossRef]

- Ankolekar, C.; Johnson, K.; Pinto, M.; Johnson, D.; Labbe, R.G.; Greene, D.; Shetty, K. Fermentation of whole apple juice using Lactobacillus acidophilus for potential dietary management of hyperglycemia, hypertension, and modulation of beneficial bacterial responses. J. Food Biochem. 2011, 36, 718–738. [Google Scholar] [CrossRef]

- Attri, S.; Sharma, K.; Raigond, P.; Goel, G. Colonic fermentation of polyphenolics from sea buckthorn (Hippophae rhamnoides) berries: Assessment of effects on microbial diversity by principal component analysis. Food Res. Int. 2018, 105, 324–332. [Google Scholar] [CrossRef]

- Wang, H.; Sun, Z.; Rehman, R.U.; Shen, T.; Riaz, S.; Li, X.; Hua, E.B.; Zhao, J. Apple phlorizin supplementation attenuates oxidative stress in hamsters fed a high-fat diet. J. Food Biochem. 2017, 42, e12445. [Google Scholar] [CrossRef]

- Wan, C.W.; Wong, C.N.; Pin, W.K.; Wong, M.H.; Kwok, C.Y.; Chan, R.Y.; Yu, P.H.; Chan, S.W. Chlorogenic acid exhibits cholesterol lowering and fatty liver attenuating properties by up-regulating the gene expression of PPAR-alpha in hypercholesterolemic rats induced with a high-cholesterol diet. Phytotherapy Res. 2012, 27, 545–551. [Google Scholar] [CrossRef]

- Zhang, B.; Xia, T.; Duan, W.; Zhang, Z.; Wang, M. Effects of organic acids, amino acids and phenolic compounds on antioxidant characteristic of Zhenjiang aromatic vinegar. Molecules 2019, 24, 3799. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Jiang, T.; Liu, N.; Wu, C.; Xu, H.; Lei, H. Biotransformation of phenolic profiles and improvement of antioxidant capacities in jujube juice by select lactic acid bacteria. Food Chem. 2021, 339, 127859. [Google Scholar] [CrossRef]

- Muselin, F.; Cristina, R.T.; Dumitrescu, E.; Doma, A.O.; Radulov, I.; Berbecea, A.A.; Horablaga, A.; Morariu, F.E.; Manea, D.N.; Horablaga, N.M. Quercetin Beneficial Role in the Homeostatic Variation of Certain Trace Elements in Dyslipidemic Mice. Evid Based Complement. Altern. Med. 2022, 2022, 3299505. [Google Scholar] [CrossRef]

- Li, Z.; Teng, J.; Lyu, Y.; Hu, X.; Zhao, Y.; Wang, M. Enhanced antioxidant activity for apple juice fermented with Lactobacillus plantarum ATCC14917. Molecules 2018, 24, 51. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Dai, W. Effect of phloretin treatment ameliorated the cisplatininduced nephrotoxicity and oxidative stress in experimental rats. Pharmacogn. Mag. 2022, 16, 207–213. [Google Scholar] [CrossRef]

- Li, H.; Huang, J.; Wang, Y.; Wang, X.; Ren, Y.; Yue, T.; Wang, Z.; Gao, Z. Study on the nutritional characteristics and antioxidant activity of dealcoholized sequentially fermented apple juice with Saccharomyces cerevisiae and Lactobacillus plantarum fermentation. Food Chem. 2021, 363, 130351. [Google Scholar] [CrossRef]

- Coghetto, C.C.; Brinques, G.B.; Siqueira, N.M.; Pletsch, J.; Soares, R.M.D.; Ayub, M.Z. Electrospraying microencapsulation of Lactobacillus plantarum enhances cell viability under refrigeration storage and simulated gastric and intestinal fluids. J. Funct. Foods 2016, 24, 316–326. [Google Scholar] [CrossRef]

- Xu, M.; Gagné-bourque, F.; Dumont, M.; Jabaji, S. Encapsulation of Lactobacillus casei ATCC 393 cells and evaluation of their survival after freezedrying, storage and under gastrointestinal conditions. J. Food Eng. 2016, 168, 52–59. [Google Scholar] [CrossRef]

- Devi, A.; Konerira Aiyappaa, A.A.; Waterhouse, A.L. Adsorption and biotransformation of anthocyanin glucosides and quercetin glycosides by Oenococcus oeni and Lactobacillus plantarum in model wine solution. J. Sci. Food Agric. 2019, 100, 2110–2120. [Google Scholar] [CrossRef] [PubMed]

| Treatment | Fermentation Time (h) | L* | a* | b* | ∆E |

|---|---|---|---|---|---|

| Pasteurization | 0 | 46.31 ± 0.02 fC | 20.89 ± 0.03 aC | 65.66 ± 0.06 cC | 7.33 ± 0.03 fA |

| 4 | 47.28 ± 0.04 dB | 20.37 ± 0.04 bC | 63.74 ± 0.06 dC | 7.54 ± 0.08 eA | |

| 8 | 46.81 ± 0.03 eC | 20.38 ± 0.02 bC | 66.19 ± 0.18 bC | 9.07 ± 0.09 dA | |

| 16 | 51.74 ± 0.03 cB | 18.10 ± 0.04 cC | 67.39 ± 0.15 aC | 10.98 ± 0.07 cA | |

| 24 | 53.19 ± 0.01 bA | 16.74 ± 0.03 dC | 67.50 ± 0.13 aC | 12.87 ± 0.01 bA | |

| 48 | 55.04 ± 0.03 aC | 15.19 ± 0.02 eC | 65.52 ± 0.02 cC | 15.62 ± 0.03 aA | |

| 200 MPa | 0 | 48.01 ± 0.02 fA | 25.31 ± 0.05 aA | 69.71 ± 0.18 eB | 2.88 ± 0.05 fC |

| 4 | 47.91 ± 0.02 eA | 24.54 ± 0.00 bA | 70.53 ± 0.09 dA | 3.35 ± 0.02 eC | |

| 8 | 48.94 ± 0.01 dA | 23.91 ± 0.02 cA | 71.24 ± 0.01 cA | 4.67 ± 0.06 dB | |

| 16 | 52.56 ± 0.02 cA | 20.78 ± 0.03 dB | 72.15 ± 0.08 aA | 9.53 ± 0.05 cB | |

| 24 | 52.67 ± 0.04 bB | 19.59 ± 0.00 eB | 71.46 ± 0.16 bcA | 10.27 ± 0.07 bB | |

| 48 | 56.44 ± 0.01 aB | 16.01 ± 0.03 fB | 71.64 ± 0.10 bA | 15.44 ± 0.04 aB | |

| 400 MPa | 0 | 47.86 ± 0.01 fB | 24.85 ± 0.03 aB | 70.17 ± 0.14 bA | 3.05 ± 0.05 fB |

| 4 | 47.95 ± 0.01 eA | 24.03 ± 0.02 bB | 69.50 ± 0.15 cB | 3.70 ± 0.03 eB | |

| 8 | 48.39 ± 0.00 dB | 23.44 ± 0.01 cB | 70.46 ± 0.11 abB | 4.46 ± 0.03 dC | |

| 16 | 50.38 ± 0.02 cC | 22.14 ± 0.02 dA | 69.62 ± 0.17 cB | 6.73 ± 0.04 cC | |

| 24 | 50.61 ± 0.01 bC | 21.52 ± 0.02 eA | 70.19 ± 0.17 bB | 7.34 ± 0.02 bC | |

| 48 | 56.71 ± 0.02 aA | 17.09 ± 0.03 fA | 70.66 ± 0.13 aB | 14.82 ± 0.02 aC |

| Category/ Fermentation Time | Content (mg/L) | |||||

|---|---|---|---|---|---|---|

| 0 h | 4 h | 8 h | 16 h | 24 h | 48 h | |

| Gallic acid | 4.30 ± 0.00 c | 4.12 ± 0.08 d | 4.52 ± 0.05 b | 3.94 ± 0.00 e | 3.64 ± 0.05 f | 4.89 ± 0.00 a |

| Catechins | 4.26 ± 0.00 a | 3.68 ± 0.02 ab | 3.25 ± 0.04 b | 3.49 ± 0.02 b | 3.90 ± 0.16 ab | 3.78 ± 0.45 ab |

| Caffeic acid | 1.44 ± 0.00 d | 1.49 ± 0.01 cd | 1.47 ± 0.00 cd | 1.52 ± 0.01 c | 1.62 ± 0.01 b | 1.70 ± 0.04 a |

| Epicatechin | 2.83 ± 0.00 a | 2.34 ± 0.02 c | 2.32 ± 0.06 d | 2.45 ± 0.01 b | 2.36 ± 0.06 bc | 2.44 ± 0.02 bc |

| Chlorogenic acid | 0.24 ± 0.00 d | 0.27 ± 0.03 d | 0.30 ± 0.02 d | 0.55 ± 0.03 c | 0.75 ± 0.10 b | 1.42 ± 0.28 a |

| Ferulic acid | 4.47 ± 0.00 a | 4.01 ± 0.11 c | 3.98 ± 0.05 c | 4.35 ± 0.01 ab | 4.17 ± 0.01 bc | 3.91 ± 0.14 c |

| Rutin | 3.77 ± 0.00 b | 3.76 ± 0.12 b | 3.68 ± 0.00 b | 3.76 ± 0.03 b | 3.71 ± 0.01 b | 4.08 ± 0.06 a |

| Phlorizin | 1.12 ± 0.00 ab | 1.11 ± 0.01 b | 1.13 ± 0.00 ab | 1.15 ± 0.00 a | 1.14 ± 0.01 ab | 1.14 ± 0.02 ab |

| Quercetin | - | 1.58 ± 0.00 ab | 1.58 ± 0.00 b | 1.59 ± 0.00 a | 1.57 ± 0.00 b | 1.57 ± 0.01 b |

| Phloretin | 1.04 ± 0.00 c | 1.05 ± 0.00 ab | 1.05 ± 0.00 ab | 1.06 ± 0.00 a | 1.05 ± 0.00 ab | 1.05 ± 0.00 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Wang, Y.; Zhao, M.; Tong, P.; Lv, L.; Gao, Z.; Liu, J.; Long, F. High Hydrostatic Pressure Treatments Improved Properties of Fermentation of Apple Juice Accompanied by Higher Reserved Lactobacillus plantarum. Foods 2023, 12, 441. https://doi.org/10.3390/foods12030441

Ma J, Wang Y, Zhao M, Tong P, Lv L, Gao Z, Liu J, Long F. High Hydrostatic Pressure Treatments Improved Properties of Fermentation of Apple Juice Accompanied by Higher Reserved Lactobacillus plantarum. Foods. 2023; 12(3):441. https://doi.org/10.3390/foods12030441

Chicago/Turabian StyleMa, Jing, Yu Wang, Mengya Zhao, Pengyan Tong, Liuqing Lv, Zhenpeng Gao, Jing Liu, and Fangyu Long. 2023. "High Hydrostatic Pressure Treatments Improved Properties of Fermentation of Apple Juice Accompanied by Higher Reserved Lactobacillus plantarum" Foods 12, no. 3: 441. https://doi.org/10.3390/foods12030441