Influence of Ultrasound-Assisted Vacuum Drying on Physicochemical Characteristics, Antioxidant Activity, and α-Glucosidase Inhibition Activity of Flos Sophorae Immaturus

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Ultrasound Treatments and VD Methods

2.3. Moisture Content (MC)

2.4. Stereomicroscope (SM)

2.5. Scanning Electron Microscopy (SEM)

2.6. Colour

2.7. Total Flavonoid Contents (TFC)

2.8. HPLC Analysis of Flavonoid Constituents

2.9. Antioxidant Capacity Determination

2.10. α-Glucosidase and α-Amylase Inhibition Activity

2.11. Statistical Analysis

3. Results and Discussion

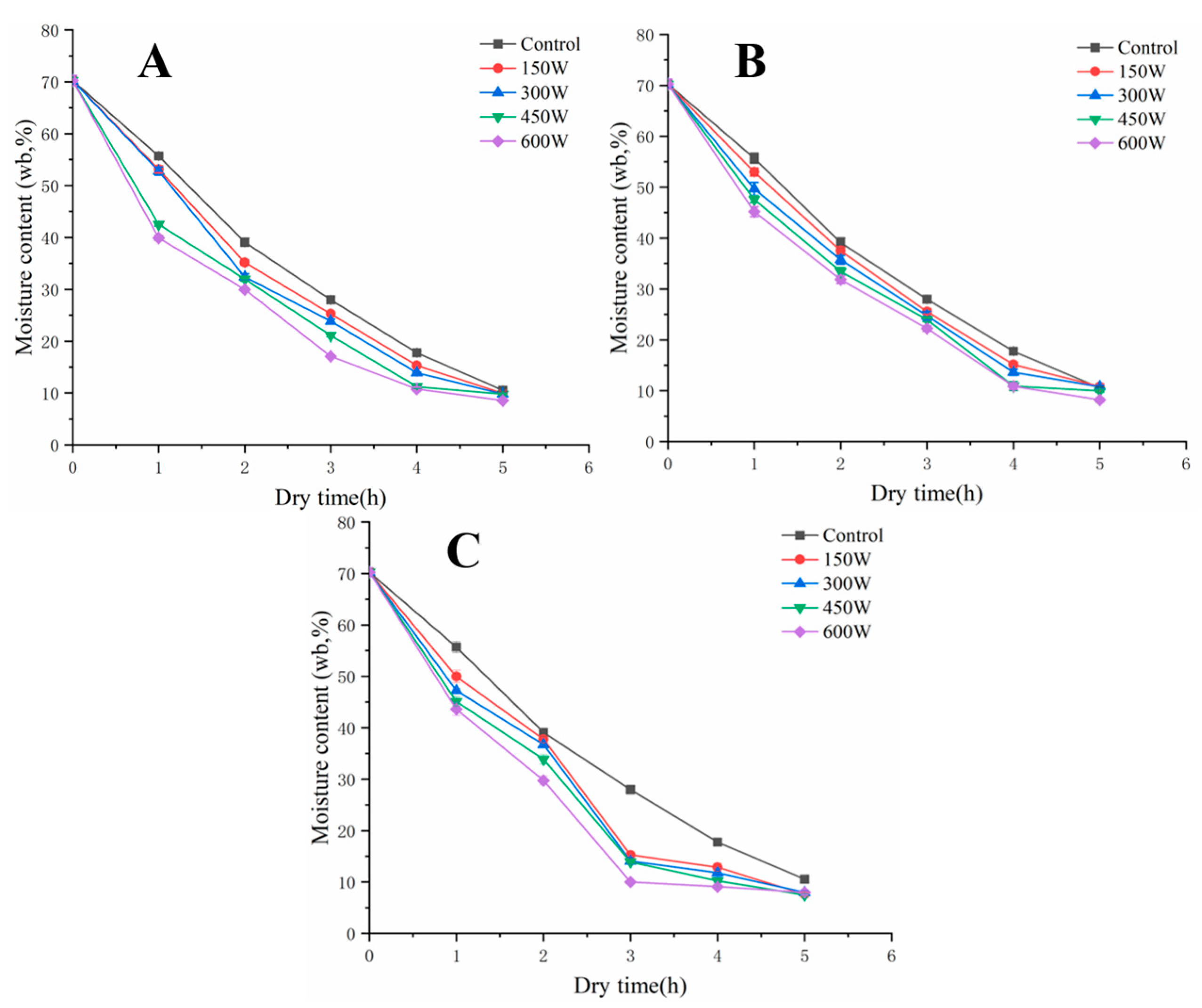

3.1. Effect of UAVD on MC of FSI

3.2. Morphology Analysis

3.3. Colour Analysis

3.4. Flavonoid Analysis

3.5. Antioxidant Capacity Analysis

3.6. Effect of UAVD on α-Glucosidase and α-Amylase Inhibition Capacity of FSI

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gong, Y.; Fan, L.; Wang, L.; Li, J. Flos Sophorae Immaturus: Phytochemistry, bioactivities, and its potential applications. Food Rev. Int. 2021, 1–19. [Google Scholar] [CrossRef]

- Li, J.; Gong, Y.; Li, J.; Fan, L. In vitro xanthine oxidase inhibitory properties of Flos Sophorae Immaturus and potential mechanisms. Food Biosci. 2022, 47, 101711. [Google Scholar] [CrossRef]

- Gan, Z.; Chen, Q.; Fu, Y.; Chen, G. Determination of bioactive constituents in Flos Sophorae Immaturus and Cortex Fraxini by capillary electrophoresis in combination with far infrared-assisted solvent extraction. Food Chem. 2012, 130, 1122–1126. [Google Scholar] [CrossRef]

- Gong, Y.; Li, J.; Li, J.; Fan, L.; Wang, L. Effect of ultrasound-assisted freeze-dried on microstructure, bioactive substances, and antioxidant activity of Flos Sophorae Immaturus. Food Biosci. 2022, 49, 101913. [Google Scholar] [CrossRef]

- He, X.; Bai, Y.; Zhao, Z.; Wang, X.; Fang, J.; Huang, L.; Zeng, M.; Zhang, Q.; Zhang, Y.; Zheng, X. Local and traditional uses, phytochemistry, and pharmacology of Sophora japonica L.: A review. J. Ethnopharmacol. 2016, 187, 160–182. [Google Scholar] [CrossRef] [PubMed]

- Yu, Q.; Li, J.; Fan, L. Effect of drying methods on the microstructure, bioactivity substances, and antityrosinase activity of asparagus stems. J. Agric. Food Chem. 2019, 67, 1537–1545. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wang, X.; Wu, Z.; Wan, N.; Yang, M. Dehydration of hawthorn fruit juices using ultrasound-assisted vacuum drying. Ultrason. Sonochem. 2020, 68, 105219. [Google Scholar] [CrossRef] [PubMed]

- Colucci, D.; Fissore, D.; Rossello, C.; Carcel, J.A. On the effect of ultrasound-assisted atmospheric freeze-drying on the antioxidant properties of eggplant. Food Res. Int. 2018, 106, 580–588. [Google Scholar] [CrossRef]

- Baeghbali, V.; Ngadi, M.; Niakousari, M. Effects of ultrasound and infrared assisted conductive hydro-drying, freeze-drying and oven drying on physicochemical properties of okra slices. Innov. Food Sci. Emerg. Technol. 2020, 63, 102313. [Google Scholar] [CrossRef]

- Pei, Y.; Li, Z.; Xu, W.; Song, C.; Li, J.; Song, F. Effects of ultrasound pretreatment followed by far-infrared drying on physicochemical properties, antioxidant activity and aroma compounds of saffron (Crocus sativus L.). Food Biosci. 2021, 42, 101186. [Google Scholar] [CrossRef]

- Ricce, C.; Rojas, M.L.; Miano, A.C.; Siche, R.; Augusto, P.E.D. Ultrasound pre-treatment enhances the carrot drying and rehydration. Food Res. Int. 2016, 89, 701–708. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.; Cui, Q.; Yin, L.-J.; Li, Y.; Gao, M.-Z.; Meng, Y.; Li, J.; Zhang, S.-D.; Wang, W. Negative pressure cavitation based ultrasound-assisted extraction of main flavonoids from Flos Sophorae Immaturus and evaluation of its extraction kinetics. Sep. Purif. Technol. 2020, 244, 115805. [Google Scholar] [CrossRef]

- Zhang, Y.; Abatzoglou, N. Review: Fundamentals, applications and potentials of ultrasound-assisted drying. Chem. Eng. Res. Des. 2020, 154, 21–46. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, J.; Hu, B.; Yu, P.; Fan, L. Relationship between crust characteristics and oil uptake of potato strips with hot-air pre-drying during frying process. Food Chem. 2021, 360, 130045. [Google Scholar] [CrossRef]

- Liu, Y.; Tian, J.; Zhang, T.; Fan, L. Effects of frying temperature and pore profile on the oil absorption behavior of fried potato chips. Food Chem. 2021, 345, 128832. [Google Scholar] [CrossRef]

- Yao, L.; Fan, L.; Duan, Z. Effect of different pretreatments followed by hot-air and far-infrared drying on the bioactive compounds, physicochemical property and microstructure of mango slices. Food Chem. 2020, 305, 125477. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.; Yang, C.; Xu, H.; Zhang, J.; Zhang, L. Study on the change of flavonoid glycosides to aglycones during the process of steamed bread containing tartary buckwheat flour and antioxidant, α-glucosidase inhibitory activities evaluation in vitro. LWT-Food Sci. Technol. 2021, 145, 111527. [Google Scholar] [CrossRef]

- Ismail, B.B.; Liu, D.; Pu, Y.; He, Q.; Guo, M. High-intensity ultrasound processing of baobab fruit pulp: Effect on quality, bioactive compounds, and inhibitory potential on the activity of alpha-amylase and alpha-glucosidase. Food Chem. 2021, 361, 130144. [Google Scholar] [CrossRef]

- Guo, Y.; Wu, B.; Guo, X.; Ding, F.; Pan, Z.; Ma, H. Effects of power ultrasound enhancement on infrared drying of carrot slices: Moisture migration and quality characterizations. LWT-Food Sci. Technol. 2020, 126, 109312. [Google Scholar] [CrossRef]

- Huang, D.; Men, K.; Li, D.; Wen, T.; Gong, Z.; Sunden, B.; Wu, Z. Application of ultrasound technology in the drying of food products. Ultrason. Sonochem. 2020, 63, 104950. [Google Scholar] [CrossRef]

- Yao, Y. Enhancement of mass transfer by ultrasound: Application to adsorbent regeneration and food drying/dehydration. Ultrason. Sonochem. 2016, 31, 512–531. [Google Scholar] [CrossRef]

- Liu, Y.-Y.; Wang, Y.; Lv, W.-Q.; Li, D.; Wang, L.-J. Freeze-thaw and ultrasound pretreatment before microwave combined drying affects drying kinetics, cell structure and quality parameters of Platycodon grandiflorum. Ind. Crops Prod. 2021, 164, 113391. [Google Scholar] [CrossRef]

- Smyth, A.P.; Seales, B.; Bradley, P.M. A pollen profile by scanning electron microscopy bracketing the mid-holocene tsuga canadensis decline at Poutwater Pond Bog, Holden, Massachusetts. Grana 2015, 54, 263–270. [Google Scholar] [CrossRef]

- Shi, X.; Yang, Y.; Li, Z.; Wang, X.; Liu, Y. Moisture transfer and microstructure change of banana slices during contact ultrasound strengthened far-infrared radiation drying. Innov. Food Sci. Emerg. Technol. 2020, 66, 102537. [Google Scholar] [CrossRef]

- Li, L.; Yu, Y.; Xu, Y.; Wu, J.; Yu, Y.; Peng, J.; An, K.; Zou, B.; Yang, W. Effect of ultrasound-assisted osmotic dehydration pretreatment on the drying characteristics and quality properties of Sanhua plum (Prunus salicina L.). LWT-Food Sci. Technol. 2021, 138, 110653. [Google Scholar] [CrossRef]

- de Araujo, F.F.; de Paulo Farias, D.; Neri-Numa, I.A.; Dias-Audibert, F.L.; Delafiori, J.; de Souza, F.G.; Catharino, R.R.; do Sacramento, C.K.; Pastore, G.M. Influence of high-intensity ultrasound on color, chemical composition and antioxidant properties of araca-boi pulp. Food Chem. 2021, 338, 127747. [Google Scholar] [CrossRef] [PubMed]

- Santos, K.C.; Guedes, J.S.; Rojas, M.L.; Carvalho, G.R.; Augusto, P.E.D. Enhancing carrot convective drying by combining ethanol and ultrasound as pre-treatments: Effect on product structure, quality, energy consumption, drying and rehydration kinetics. Ultrason. Sonochem. 2021, 70, 105304. [Google Scholar] [CrossRef] [PubMed]

- Wu, B.; Guo, X.; Guo, Y.; Ma, H.; Zhou, C. Enhancing jackfruit infrared drying by combining ultrasound treatments: Effect on drying characteristics, quality properties and microstructure. Food Chem. 2021, 358, 129845. [Google Scholar] [CrossRef]

- Qi, Y.; Sun, A.; Liu, R.; Meng, Z.; Xie, H. Isolation and purification of flavonoid and isoflavonoid compounds from the pericarp of Sophora japonica L. by adsorption chromatography on 12% cross-linked agarose gel media. J. Chromatogr. A 2007, 1140, 219–224. [Google Scholar] [CrossRef]

- Zhang, L.; Qiao, Y.; Liao, L.; Shi, D.; An, K.; Jun, W.; Liu, S. Effects of ultrasound and ultra-high pressure pretreatments on volatile and taste compounds of vacuum-freeze dried strawberry slice. Lwt 2021, 160, 112012. [Google Scholar] [CrossRef]

- Stojanovic, J.; Silva, J.L. Influence of osmotic concentration, continuous high frequency ultrasound and dehydration on antioxidants, colour and chemical properties of rabbiteye blueberries. Food Chem. 2007, 101, 898–906. [Google Scholar] [CrossRef]

- Gani, A.; Baba, W.N.; Ahmad, M.; Shah, U.; Khan, A.A.; Wani, I.A.; Masoodi, F.A.; Gani, A. Effect of ultrasound treatment on physico-chemical, nutraceutical and microbial quality of strawberry. LWT-Food Sci. Technol. 2016, 66, 496–502. [Google Scholar] [CrossRef]

- Kek, S.P.; Chin, N.L.; Yusof, Y.A. Direct and indirect power ultrasound assisted pre-osmotic treatments in convective drying of guava slices. Food Bioprod. Process. 2013, 91, 495–506. [Google Scholar] [CrossRef]

- Li, Y.; Fan, L. Comparative studies on the stabilization of Flos Sophorae Immaturus beverages by various hydrocolloids. LWT-Food Sci. Technol. 2020, 123, 109117. [Google Scholar] [CrossRef]

- Liao, J.; Qu, B.; Liu, D.; Zheng, N. New method to enhance the extraction yield of rutin from Sophora japonica using a novel ultrasonic extraction system by determining optimum ultrasonic frequency. Ultrason. Sonochem. 2015, 27, 110–116. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- Qi, Y.; Yu, F.; Wang, X.; Wan, N.; Yang, M.; Wu, Z.; Li, Y. Drying of wolfberry fruit juice using low-intensity pulsed ultrasound. LWT-Food Sci. Technol. 2021, 141, 110953. [Google Scholar] [CrossRef]

- Tchabo, W.; Ma, Y.; Kwaw, E.; Zhang, H.; Li, X.; Afoakwah, N.A. Effects of ultrasound, high pressure, and manoultrasound processes on phenolic profile and antioxidant properties of a sulfur dioxide-free mulberry (Morus nigra) wine. Food Bioprocess Technol. 2017, 10, 1210–1223. [Google Scholar] [CrossRef]

- Kroehnke, J.; Szadzinska, J.; Radziejewska-Kubzdela, E.; Bieganska-Marecik, R.; Musielak, G.; Mierzwa, D. Osmotic dehydration and convective drying of kiwifruit (Actinidia deliciosa)—The influence of ultrasound on process kinetics and product quality. Ultrason. Sonochem. 2021, 71, 105377. [Google Scholar] [CrossRef] [PubMed]

- Santos, N.C.; Almeida, R.L.J.; da Silva, G.M.; Monteiro, S.S.; André, A.M.M.C.N. Effect of ultrasound pre-treatment on the kinetics and thermodynamic properties of guava slices drying process. Innov. Food Sci. Emerg. Technol. 2020, 66, 102507. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Peng, Z.; Zhao, Y.; Wu, K.; Zhou, N.; Yan, Y.; Ramaswamy, H.S.; Sun, J.; Bai, W. The impact of ultrasonic treatment on blueberry wine anthocyanin color and its in-vitro anti-oxidant capacity. Food Chem. 2020, 333, 127455. [Google Scholar] [CrossRef]

- Tao, Y.; Li, D.; Siong Chai, W.; Show, P.L.; Yang, X.; Manickam, S.; Xie, G.; Han, Y. Comparison between airborne ultrasound and contact ultrasound to intensify air drying of blackberry: Heat and mass transfer simulation, energy consumption and quality evaluation. Ultrason. Sonochem. 2021, 72, 105410. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Zhang, L.; Feng, Y.; Zhou, C.; Yagoub, A.E.A.; Wahia, H.; Ma, H.; Zhang, J.; Sun, Y. Ultrasound freeze-thawing style pretreatment to improve the efficiency of the vacuum freeze-drying of okra (Abelmoschus esculentus (L.) Moench) and the quality characteristics of the dried product. Ultrason. Sonochem. 2021, 70, 105300. [Google Scholar] [CrossRef]

- Mahindrakar, K.V.; Rathod, V.K. Ultrasound-assisted intensified aqueous extraction of phenolics from waste Syzygium cumini leaves: Kinetic studies and evaluation of antioxidant, antidiabetic and anticancer potential. Food Biosci. 2022, 46, 101547. [Google Scholar] [CrossRef]

- Mello, R.E.; Fontana, A.; Mulet, A.; Corrêa, J.L.G.; Cárcel, J.A. PEF as pretreatment to ultrasound-assisted convective drying: Influence on quality parameters of orange peel. Innov. Food Sci. Emerg. Technol. 2021, 72, 102753. [Google Scholar] [CrossRef]

- Dzah, C.S.; Duan, Y.; Zhang, H.; Boateng, N.A.S.; Ma, H. Ultrasound-induced lipid peroxidation: Effects on phenol content and extraction kinetics and antioxidant activity of Tartary buckwheat (Fagopyrum tataricum) water extract. Food Biosci. 2020, 37, 100719. [Google Scholar] [CrossRef]

- Zhang, C.; Liu, D.; Gao, H. Kinetics, physicochemical properties, and antioxidant activities of Angelica keiskei processed under four drying conditions. LWT-Food Sci. Technol. 2018, 98, 349–357. [Google Scholar] [CrossRef]

- Oboh, G.; Ademosun, A.O.; Ayeni, P.O.; Omojokun, O.S.; Bello, F. Comparative effect of quercetin and rutin on α-amylase, α-glucosidase, and some pro-oxidant-induced lipid peroxidation in rat pancreas. Comp. Clin. Pathol. 2014, 24, 1103–1110. [Google Scholar] [CrossRef]

- Ji, Y.; Liu, D.; Jin, Y.; Zhao, J.; Zhao, J.; Li, H.; Li, L.; Zhang, H.; Wang, H. In vitro and in vivo inhibitory effect of anthocyanin-rich bilberry extract on α-glucosidase and α-amylase. LWT-Food Sci. Technol. 2021, 145, 111484. [Google Scholar] [CrossRef]

- Li, M.; Bao, X.; Zhang, X.; Ren, H.; Cai, S.; Hu, X.; Yi, J. Exploring the phytochemicals and inhibitory effects against α-glucosidase and dipeptidyl peptidase-IV in chinese pickled chili pepper: Insights into mechanisms by molecular docking analysis. LWT-Food Sci. Technol. 2022, 162, 113467. [Google Scholar] [CrossRef]

- Liu, S.; Yu, J.; Guo, S.; Fang, H.; Chang, X. Inhibition of pancreatic α-amylase by Lonicera caerulea berry polyphenols in vitro and their potential as hyperglycemic agents. LWT-Food Sci. Technol. 2020, 126, 109288. [Google Scholar] [CrossRef]

- Zhu, X.; Zhang, Z.; Hinds, L.M.; Sun, D.W.; Tiwari, B.K. Applications of ultrasound to enhance fluidized bed drying of Ascophyllum Nodosum: Drying kinetics and product quality assessment. Ultrason. Sonochem. 2021, 70, 105298. [Google Scholar] [CrossRef] [PubMed]

- Xie, Z.; Sun, Y.; Lam, S.; Zhao, M.; Liang, Z.; Yu, X.; Yang, D.; Xu, X. Extraction and isolation of flavonoid glycosides from Flos Sophorae Immaturus using ultrasonic-assisted extraction followed by high-speed countercurrent chromatography. J. Sep. Sci. 2014, 37, 957–965. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, Y.; Li, J.; Li, J.; Fan, L.; Wang, L. Influence of Ultrasound-Assisted Vacuum Drying on Physicochemical Characteristics, Antioxidant Activity, and α-Glucosidase Inhibition Activity of Flos Sophorae Immaturus. Foods 2023, 12, 671. https://doi.org/10.3390/foods12030671

Gong Y, Li J, Li J, Fan L, Wang L. Influence of Ultrasound-Assisted Vacuum Drying on Physicochemical Characteristics, Antioxidant Activity, and α-Glucosidase Inhibition Activity of Flos Sophorae Immaturus. Foods. 2023; 12(3):671. https://doi.org/10.3390/foods12030671

Chicago/Turabian StyleGong, Yuhong, Jun Li, Jinwei Li, Liuping Fan, and Li Wang. 2023. "Influence of Ultrasound-Assisted Vacuum Drying on Physicochemical Characteristics, Antioxidant Activity, and α-Glucosidase Inhibition Activity of Flos Sophorae Immaturus" Foods 12, no. 3: 671. https://doi.org/10.3390/foods12030671

APA StyleGong, Y., Li, J., Li, J., Fan, L., & Wang, L. (2023). Influence of Ultrasound-Assisted Vacuum Drying on Physicochemical Characteristics, Antioxidant Activity, and α-Glucosidase Inhibition Activity of Flos Sophorae Immaturus. Foods, 12(3), 671. https://doi.org/10.3390/foods12030671