Total Utilization-Upcycling of Mushroom Protein By-Product: Characterization and Assessment as an Alternative Batter Ingredient for Fried Shrimp

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

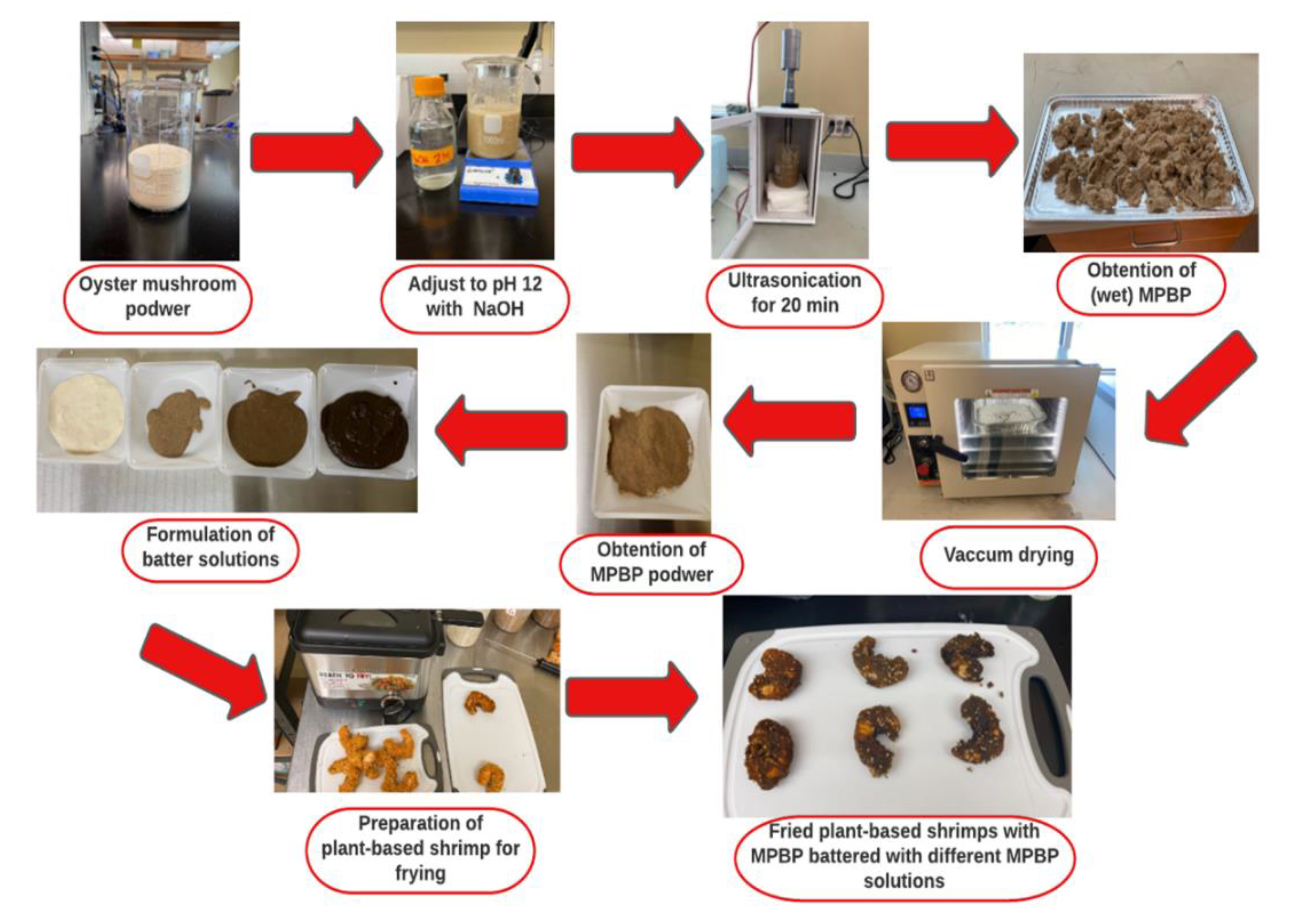

2.2. Obtaining Mushroom Protein By-Product (MPBP)

2.3. Characterization of MPBP (Mushroom Protein By-Product)

2.3.1. Chemical Composition

2.3.2. Physicochemical Properties

2.4. Battered Plant-Based Fried Shrimp Production

2.4.1. Batter Preparation

2.4.2. Preparation of Fried Batter-Coated Shrimp

2.5. Evaluation of the Fried Product

2.6. Statistical Analysis

3. Results and Discussion

3.1. Characterization of the Mushroom Protein By-Product

3.2. Assessment of Fried Batter-Coated Shrimp

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviation

| MPBP | Mushroom Protein By-Product |

| W | Wheat Flour |

| 100 W | 100% Wheat Flour |

| 75 W/25 MPBP | 75% Wheat Flour and 25% Mushroom Protein By-Product |

| 50 W/50 MPBP | 50% Wheat Flour and 50% Mushroom Protein By-Product |

| 25 W/75 MPBP | 25% Wheat Flour and 75% Mushroom Protein By-Product |

| 100 MPBP | 100% Mushroom Protein By-Product |

| MP | Mushroom Powder |

| EAI | Emulsion Activity Index |

| ESI | Emulsion Stability Index |

| WHC | Water Holding Capacity |

| OHC | Oil Holding Capacity |

| CL | Cooking Loss (%) |

| CP | Coating up (%) |

| OAC | Oil Absorption Capacity (%) |

References

- You, S.W.; Hoskin, R.T.; Komarnytsky, S.; Moncada, M. Mushrooms as functional and nutritious food ingredients for multiple applications. ACS Food Sci. Technol. 2022, 2, 1184–1195. [Google Scholar] [CrossRef]

- González, A.; Nobre, C.; Simões, L.S.; Cruz, M.; Loredo, A.; Rodríguez-Jasso, R.M.; Contreras, J.; Texeira, J.; Belmares, R. Evaluation of functional and nutritional potential of a protein concentrate from Pleurotus ostreatus mushroom. Food Chem. 2021, 346, 128884. [Google Scholar] [CrossRef] [PubMed]

- Pintado, T.; Delgado-Pando, G. Towards More Sustainable Meat Products: Extenders as a Way of Reducing Meat Content. Foods 2020, 9, 1044. [Google Scholar] [CrossRef] [PubMed]

- Correia, R.; Grace, M.H.; Esposito, D.; Lila, M.A. Wild blueberry polyphenol-protein food ingredients produced by three drying methods: Comparative physico-chemical properties, phyto-chemical content, and stability during storage. Food Chem. 2017, 235, 76–85. [Google Scholar] [CrossRef]

- Salehi, F. Characterization of different mushrooms powder and its application in bakery products: A review. Int. J. Food Prop. 2019, 22, 1375–1385. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, M.; Devahastin, S.; Liu, Y. Progresses on processing methods of umami substances: A review. Trends Food Sci. Technol. 2019, 93, 125–135. [Google Scholar] [CrossRef]

- Martínez-Pineda, M.; Yagüe-Ruiz, C.; Vercet, A. How Batter Formulation Can Modify Fried Tempura-Battered Zucchini Chemical and Sensory Characteristics? Foods 2020, 9, 626. [Google Scholar] [CrossRef]

- Rahimi, J.; Ngadi, M.O. Effect of batter formulation and pre-drying time on oil distribution fractions in fried batter. LWT 2014, 59, 820–826. [Google Scholar] [CrossRef]

- Cruz-Solorio, A.; Villanueva-Arce, R.; Garin-Aguilar, M.E.; Leal-Lara, H.; Valencia-del Toro, G. Functinoal properties of flours and protein concentrates of 3 strains of the edible mushroom Pluerots ostreatus. J. Food Sci. Technol. 2018, 55, 3892–3901. [Google Scholar] [CrossRef]

- AOAC. AOAC Method 991.43. Total, insoluble and soluble dietary fiber in food—Enzymatic-gravimetric method, MES-TRIS buffer. In Official Methods of Analysis; AOAC International: Gaithersburg, MD, USA, 1995. [Google Scholar]

- Zhang, Q.T.; Tu, Z.C.; Xiao, H.; Wang, H.; Huang, X.Q.; Liu, G.X.; Shi, Y.; Fan, L.L.; Lin, D.R. Influence of ultrasonic treatment on the structure and emulsifying properties of peanut protein isolate. Food Bioprod. Process. 2014, 92, 30–37. [Google Scholar] [CrossRef]

- Tontul, İ.; Kasimoglu, Z.; Asik, S.; Atbakan, T.; Topuz, A. Functional properties of chickpea protein isolates dried by refractance window drying. Int. J. Biol. Macromol. 2018, 109, 1253–1259. [Google Scholar] [CrossRef]

- Sharifimehr, S.; Soltanizadeh, N.; Hossein Goli, S.A. Effects of edible coating containing nano-emulsion of Aloe vera and eugenol on the physicochemical properties of shrimp during cold storage. J. Sci. Food Agric. 2019, 99, 3604–3615. [Google Scholar] [CrossRef]

- Adrah, K.; Adegoke, S.C.; Nowlin, K.; Tahergorabi, R. Study of oleogel as a frying medium for deep-fried chicken. Food Measur. 2022, 16, 1114–1123. [Google Scholar] [CrossRef]

- Rangel-Vargas, E.; Rodriguez, J.A.; Domínguez, R.; Lorenzo, J.M.; Sosa, M.E.; Andrés, S.C.; Rosmini, M.; Pérez-Alvarez, J.A.; Teixeira, A.; Santos, E.M. Edible Mushrooms as a Natural Source of Food Ingredient/Additive Replacer. Foods 2021, 10, 2687. [Google Scholar] [CrossRef]

- U.S. Food and Drugs Administration. CFR—Code of Federal Regulations Title 21, 21CFR137.200; U.S. Food and Drugs Administration: Silver Spring, MD, USA, 2019. [Google Scholar]

- Kim, J.; Lim, J.; Bae, I.Y.; Park, H.G.; Gyu, L.; Lee, S. Particle size effect of Lentinus edodes mushroom (Chamsong-i) powder on the physicochemical, rheological, and oil-resisting properties of frying batters. J. Texture Stud. 2010, 41, 381–395. [Google Scholar] [CrossRef]

- Gurtler, J.B.; Doyle, M.P.; Kornacki, J.L. The microbiological safety of spices and low-water activity foods: Correcting historic misassumptions. In The Microbiological Safety of Low Water Activity Foods and Spices; Springer: New York, NY, USA, 2014; pp. 3–13. [Google Scholar]

- Padial-Domínguez, M.; Espejo-Carpio, F.J.; Pérez-Gálvez, R.; Guadix, A.; Guadix, E.M. Optimization of the emulsifying properties of food protein hydrolysates for the production of fish oil-in-water emulsions. Foods 2020, 9, 636. [Google Scholar] [CrossRef]

- Huang, S.; Martinez, M.M.; Bohrer, B.M. The Compositional and Functional Attributes of Commercial Flours from Tropical Fruits (Breadfruit and Banana). Foods 2019, 8, 586. [Google Scholar] [CrossRef]

- Sudha, M. Apple pomace (by-product of fruit juice industry) as a flour fortification strategy. In Flour and Breads and Their Fortification in Health and Disease Prevention; Elsevier: Amsterdam, The Netherlands, 2011; pp. 395–405. [Google Scholar]

- Eshak, N.S. Sensory evaluation and nutritional value of balady flat bread supplemented with banana peels as a natural source of dietary fiber. Ann. Agric. Sci. 2016, 61, 229–235. [Google Scholar] [CrossRef]

- Wang, N.; Maximiuk, L.; Fenn, D.; Nickerson, M.T.; Hou, A. Development of a method for determining oil absorption capacity in pulse flours and protein materials. Cereal Chem. 2020, 97, 1111–1117. [Google Scholar] [CrossRef]

- Asokapandian, S.; Swamy, G.J.; Hajjul, H. Deep fat frying of foods: A critical review on process and product parameters. Crit. Rev. Food Sci. Nutr. 2020, 60, 3400–3413. [Google Scholar] [CrossRef]

- Albert, A.; Perez-Munuera, I.; Quiles, A.; Salvador, A.; Fiszman, S.M.; Hernando, I. Adhesion in fried battered nuggets: Performance of different hydrocolloids as predusts using three cooking procedures. Food Hydrocoll. 2009, 23, 1443–1448. [Google Scholar] [CrossRef]

- Primo-Martín, C.; Sanz, T.; Steringa, D.W.; Salvador, A.; Fiszman, S.M.; Van Vliet, T. Performance of cellulose derivatives in deep-fried battered snacks: Oil barrier and crispy properties. Food Hydrocoll. 2010, 24, 702–708. [Google Scholar] [CrossRef]

- Brannan, R.G.; Mah, E.; Schott, M.; Yuan, S.; Casher, K.L.; Myers, A.; Herrick, C. Influence of ingredients that reduce oil absorption during immersion frying of battered and breaded foods. Eur. J. Lipid Sci. Technol. 2014, 116, 240–254. [Google Scholar] [CrossRef]

- Yahya, F.; Yusof, M.; Chen, K. Effect of varying ratios of oyster mushroom powder to tapioca flour on the physicochemical properties and sensory acceptability of fried mushroom crackers. Appl. Biol. 2017, 46, 57–62. [Google Scholar]

- Dogan, S.F.; Sahin, S.; Sumnu, G. Effects of soy and rice flour addition on batter rheology and quality of deep-fat chicken nuggets. J. Food Eng. 2005, 71, 127–132. [Google Scholar] [CrossRef]

- Fiszman, S.; Salvador, A. Recent developments in coating batters. Trends Food Sci. Technol. 2003, 14, 399–407. [Google Scholar] [CrossRef]

- Román, L.; Pico, J.; Antolín, B.; Martínez, M.M.; Gómez, M. Extruded flour improves batter pick-up, coating crispness and aroma profile. Food Chem. 2018, 260, 106–114. [Google Scholar] [CrossRef]

- Rosell, C.M.; Santos, E.; Collar, C. Physico-chemical properties of commercial fibres from different sources: A comparative approach. Food Res. Int. 2009, 42, 176–184. [Google Scholar] [CrossRef]

- Pęksa, A.; Miedzianka, J.; Kita, A.; Tajner-Czopek, A.; Rytel, E. The quality of fried snacks fortified with fiber and protein supplements. Potravinárstvo 2010, 4, 59–64. [Google Scholar] [CrossRef]

- Aleman, R.S.; Paz, G.; Morris, A.; Prinyawiwatkul, W.; Moncada, M.; King, J.M. High protein brown rice flour, tapioca starch & potato starch in the development of gluten-free cupcakes. LWT—Food Sci. Technol. 2021, 152, 112326. [Google Scholar]

- Aleman, R.S.; Morris, A.; Prinyawiwatkul, W.; Moncada, M.; King, J.M. Physicochemical properties of Frontière rice flour and its application in a gluten-free cupcake. Cereal Chem. 2022, 99, 303–315. [Google Scholar] [CrossRef]

| Formulation | Wheat Flour | MPBP Powder |

|---|---|---|

| 1 | 100% | 0% |

| 2 | 75% | 25% |

| 3 | 50% | 50% |

| 4 | 25% | 75% |

| 5 | 0% | 100% |

| Chemical Composition | |

|---|---|

| Moisture (%) | 1.05 ± 0.83 |

| Protein (%) | 10.70 ± 0.70 |

| Fat (%) | 0.54 ± 0.03 |

| Carbohydrates (%) | 78.78 ± 0.89 |

| Ash (%) | 8.91 ± 0.12 |

| Total Dietary Fiber (%) | 56.6 ± 3.09 |

| Insoluble Dietary Fiber (%) | 49.3 ± 1.55 |

| Soluble Dietary Fiber (%) | 7.3 ± 0.34 |

| Physicochemical Attributes | |

|---|---|

| pH | 11.69 ± 0.05 |

| Aw | 0.044 ± 0.00 |

| L* | 58.56 ± 2.45 |

| a* | 5.61 ± 0.49 |

| b* | 18.03 ± 1.23 |

| 35 mesh (500 µm) (%) | 0.47 ± 0.08 |

| 60 mesh (250 µm) (%) | 21.65 ± 2.76 |

| 120 mesh (125 µm) (%) | 41.18 ± 3.89 |

| 230 mesh (63 µm) (%) | 37.53 ± 2.67 |

| <230 mesh (<63 µm) (%) | 0.82 ± 0.07 |

| Functional Attributes | |

|---|---|

| Emulsifying Activity Index (m2/gr) | 7.62 ± 0.07 |

| Emulsion Stability Index (min) | 52.42 ± 4.58 |

| Water Holding Capacity (%) | 4.88 ± 0.16 |

| Solubility | 4.87 ± 0.47 |

| Oil Holding Capacity (%) | 4.82 ± 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcia, D.; You, S.W.; Aleman, R.S.; King, J.M.; Komarnytsky, S.; Hoskin, R.T.; Moncada, M. Total Utilization-Upcycling of Mushroom Protein By-Product: Characterization and Assessment as an Alternative Batter Ingredient for Fried Shrimp. Foods 2023, 12, 763. https://doi.org/10.3390/foods12040763

Garcia D, You SW, Aleman RS, King JM, Komarnytsky S, Hoskin RT, Moncada M. Total Utilization-Upcycling of Mushroom Protein By-Product: Characterization and Assessment as an Alternative Batter Ingredient for Fried Shrimp. Foods. 2023; 12(4):763. https://doi.org/10.3390/foods12040763

Chicago/Turabian StyleGarcia, Diego, Seung Woon You, Ricardo S. Aleman, Joan M. King, Slavko Komarnytsky, Roberta Targino Hoskin, and Marvin Moncada. 2023. "Total Utilization-Upcycling of Mushroom Protein By-Product: Characterization and Assessment as an Alternative Batter Ingredient for Fried Shrimp" Foods 12, no. 4: 763. https://doi.org/10.3390/foods12040763

APA StyleGarcia, D., You, S. W., Aleman, R. S., King, J. M., Komarnytsky, S., Hoskin, R. T., & Moncada, M. (2023). Total Utilization-Upcycling of Mushroom Protein By-Product: Characterization and Assessment as an Alternative Batter Ingredient for Fried Shrimp. Foods, 12(4), 763. https://doi.org/10.3390/foods12040763