Mesoporous Activated Biochar from Crab Shell with Enhanced Adsorption Performance for Tetracycline

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemical Reagents

2.2. Preparation of Crab Shell Biochar

2.3. Preparation of Modified Crab Shell Biochar

2.4. Characterization of Crab Shell Biochar

2.5. Batch Adsorption Experiments

2.6. Adsorption Kinetics and Isothermic Studies

3. Results and Discussion

3.1. Characterization of Biochar

3.1.1. Porous Structure

3.1.2. Morphological Analysis

3.1.3. XRD Analysis

3.1.4. FTIR Analysis

3.2. Batch Adsorption Experiments

3.2.1. Effect of Initial TC Concentration

3.2.2. Effect of Adsorbent Dose

3.2.3. Effect of Initial pH

3.2.4. Effect of Adsorption Time

3.3. Adsorption Kinetics Studies

3.4. Adsorption Isotherm Studies

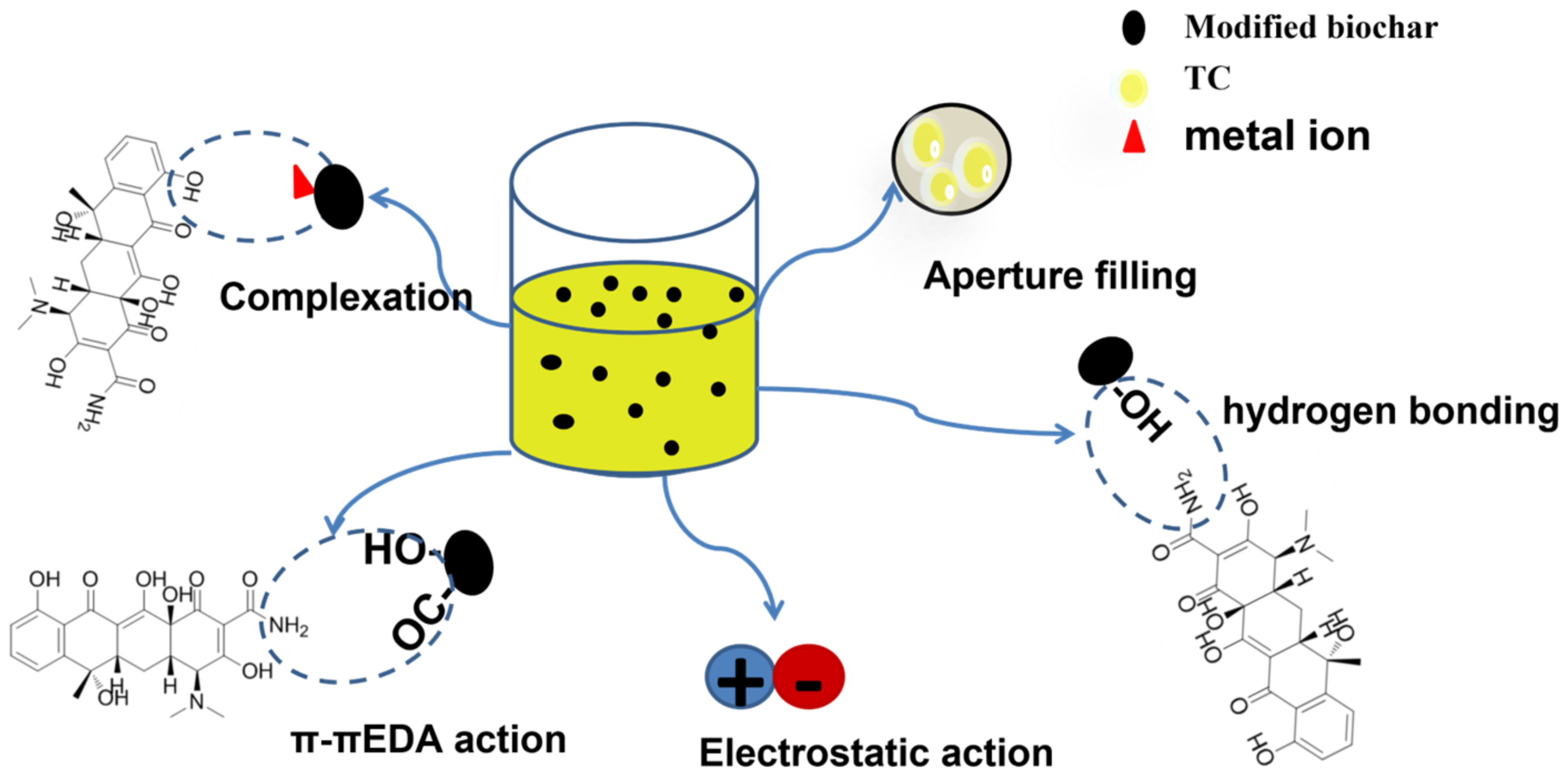

4. Adsorption Mechanism

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao, B.R.; Dou, M.M.; Wang, J.; Li, S.M.; Wang, D.Y.; Ci, L.; Fu, Y. Efficient persulfate activation by carbon defects g-C3N4 containing electron traps for the removal of antibiotics, resistant bacteria and genes. Chem. Eng. J. 2021, 426, 131677. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Y.; Zhu, D.; Li, H. Assessment of Bioavailability of Biochar-Sorbed Tetracycline to Escherichia coli for Activation of Antibiotic Resistance Genes. Environ. Sci. Technol. 2020, 54, 12920–12928. [Google Scholar] [CrossRef] [PubMed]

- Ahamad, T.; Naushad, M.; Al-Shahrani, T.; Al-Hokbany, N.; Alshehri, S.M. Preparation of chitosan based magnetic nanocomposite for tetracycline adsorption. Int. J. Biol. Macromol. 2020, 147, 258–267. [Google Scholar] [CrossRef] [PubMed]

- Morita, S.; Takano, M.; Tarumizu, A.; Goto, Y.; Tsutsumi, Y. Laboratory and clinical studies on methacycline (Rondomycin Pfizer). J. Antibiot. Ser. B 1967, 20, 335–337. [Google Scholar]

- Cheng, D.; Ngo, H.H.; Guo, W.; Chang, S.W.; Nguyen, D.D.; Zhang, X.; Varjani, S.; Liu, Y. Feasibility study on a new pomelo peel derived biochar for tetracycline. Sci. Total Environ. 2020, 720, 137662. [Google Scholar] [CrossRef] [PubMed]

- Jing, X.R.; Wang, Y.Y.; Liu, W.J.; Wang, Y.K.; Jiang, H. Enhanced adsorption performance of tetracycline in aqueous solutions by methanol-modified biochar. Chem. Eng. J. 2014, 248, 168–174. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, J.L.; Cheng, L.; Zheng, Y.Y.; Xu, J. Sediment and salinity effects on the bioaccumulation of sulfamethoxazole in zebrafish (Danio rerio). Chemosphere 2017, 180, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Zhong, L.B.; Zhao, Q.; Frear, C.S.; Zheng, Y.H. Synthesis of Fe3O4/Polyacrylonitrile Composite Electrospun Nanofiber Mat for Effective Adsorption of Tetracycline. ACS Appl. Mater. Interfaces 2015, 7, 14573–14583. [Google Scholar] [CrossRef]

- Liu, C.S.; Xu, J.; Lee, D.-J.; Yu, D.Y.; Liu, L.H. Denitrifying sulfide removal process on high-tetracycline wastewater. Bioresour. Technol. 2016, 205, 254–257. [Google Scholar] [CrossRef]

- Cheng, J.X.; Jiang, L.; Sun, T.Q.; Tang, Y.; Du, Z.X.; Li, L.C.; Zhao, Q.Y. Occurrence, Seasonal Variation and Risk Assessment of Antibiotics in the Surface Water of North China. Arch. Environ. Contam. Toxicol. 2019, 77, 88–97. [Google Scholar] [CrossRef]

- Qiao, M.; Ying, G.G.; Singer, A.C.; Zhu, Y.G. Review of antibiotic resistance in China and its environment. Environ. Int. 2018, 110, 160–172. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ben, W.W.; Wang, J.; Cao, R.K.; Yang, M.; Zhang, Y.; Qiang, Z.M. Distribution of antibiotic resistance in the effluents of ten municipal wastewater treatment plants in China and the effect of treatment processes. Chemosphere 2017, 172, 392–398. [Google Scholar] [CrossRef] [PubMed]

- Balbi, H.J. Chloramphenicol: A review. Pediatr. Rev. 2004, 25, 284–288. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Lang, H.; Liu, F.; Jin, S.; Yan, T. Presence of Antibiotics in Shallow Groundwater in the Northern and Southwestern Regions of China. Groundwater 2018, 56, 451–457. [Google Scholar] [CrossRef]

- Raeiatbin, P.; Sağ Açıkel, Y. Desalination and Water Treatment Removal of tetracycline by magnetic chitosan nanoparticles from medical wastewaters. Desalination Water Treat. 2017, 73, 380–388. [Google Scholar] [CrossRef]

- Leng, Y.F.; Bao, J.G.; Chang, G.F.; Zheng, H.; Li, X.X.; Du, J.K.; Snow, D.D.; Li, X. Biotransformation of tetracycline by a novel bacterial strain Stenotrophomonas maltophilia DT1. J. Hazard. Mater. 2016, 318, 125–133. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.Y.; Ma, Y.L.; Yang, J.; Wang, L.Q.; Lv, J.M.; Ren, C.J. Aqueous tetracycline degradation by H2O2 alone: Removal and transformation pathway. Chem. Eng. J. 2017, 307, 15–23. [Google Scholar] [CrossRef]

- Ahmadi, M.; Ramezani, M.H.; Jaafarzadeh, N.; Mostoufi, A.; Saeedi, R.; Barzegar, G.; Jorfi, S. Enhanced photocatalytic degradation of tetracycline and real pharmaceutical wastewater using MWCNT/TiO2 nano-composite. J. Environ. Manag. 2017, 186, 55–63. [Google Scholar] [CrossRef]

- Chen, T.W.; Luo, L.; Deng, S.H.; Shi, G.Z.; Zhang, S.R.; Zhang, Y.Z.; Deng, O.P.; Wang, L.L.; Zhang, J.; Wei, L.Y. Sorption of tetracycline on H3PO4 modified biochar derived from rice straw and swine manure. Bioresour. Technol. 2018, 267, 431–437. [Google Scholar] [CrossRef]

- Zhang, X.B.; Guo, W.S.; Ngo, H.h.; Wen, H.T.; Li, N.; Wu, W. Performance evaluation of powdered activated carbon for removing 28 types of antibiotics from water. J. Environ. Manag. 2016, 172, 193–200. [Google Scholar] [CrossRef]

- Wang, K.N.; Wu, J.J.; Zhu, M.; Zheng, Y.Z.; Tao, X. Highly effective pH-universal removal of tetracycline hydrochloride antibiotics by UiO-66-(COOH)2/GO metal–organic framework composites. J. Solid State Chem. 2020, 284, 121200. [Google Scholar] [CrossRef]

- Maged, A.; Iqbal, J.; Kharbish, S.; Ismael, I.; Bhatnagar, A. Tuning tetracycline removal from aqueous solution onto activated 2:1 layered clay mineral: Characterization, sorption and mechanistic studies. J. Hazard. Mater. 2019, 384, 121320. [Google Scholar] [CrossRef]

- Yan, L.L.; Liu, Y.; Zhang, Y.D.; Liu, S.; Wang, C.X.; Chen, W.T.; Liu, C.; Chen, Z.L.; Zhang, Y. ZnCl2 modified biochar derived from aerobic granular sludge for developed microporosity and enhanced adsorption to tetracycline. Bioresour. Technol. 2019, 297, 122381. [Google Scholar] [CrossRef] [PubMed]

- Foroughi, M.; Azqhandi, M.H.A.; Kakhki, S. Bio-inspired, high, and fast adsorption of tetracycline from aqueous media using Fe3O4-g-CN@PEI-β-CD nanocomposite: Modeling by response surface methodology (RSM), boosted regression tree (BRT), and general regression neural network (GRNN). J. Hazard. Mater. 2020, 388, 121769. [Google Scholar] [CrossRef] [PubMed]

- Nurhasanah, I.; Kadarisman; Gunawan, V.; Sutanto, H. Cerium oxide nanoparticles application for rapid adsorptive removal of tetracycline in water. J. Environ. Chem. Eng. 2020, 8, 103613. [Google Scholar] [CrossRef]

- Xiang, W.; Zhang, X.; Chen, J.; Zou, W.; He, F.; Hu, X.; Tsang, D.; Ok, Y.; Gao, B. Biochar technology in wastewater treatment: A critical review. Chemosphere 2020, 252, 126539. [Google Scholar] [CrossRef]

- Wang, H.; Fang, C.R.; Wang, Q.; Chu, Y.X.; Song, Y.L.; Chen, Y.M.; Xue, X.D. Sorption of tetracycline on biochar derived from rice straw and swine manure. RSC Adv. 2018, 8, 16260–16268. [Google Scholar] [CrossRef] [Green Version]

- Hoslett, J.; Ghazal, H.; Katsou, E.; Jouhara, H. The removal of tetracycline from water using biochar produced from agricultural discarded material. Sci. Total Environ. 2020, 751, 141755. [Google Scholar] [CrossRef]

- Qin, L.; Zhou, Z.P.; Dai, J.D.; Ma, P.; Zhao, H.B.; He, J.S.; Xie, A.; Li, C.X.; Yan, Y.S. Novel N-doped hierarchically porous carbons derived from sustainable shrimp shell for high-performance removal of sulfamethazine and chloramphenicol. J. Taiwan Inst. Chem. Eng. 2016, 62, 228–238. [Google Scholar] [CrossRef]

- Gu, S.W.; Zhang, D.F.; Gao, Y.Q.; Qi, R.Z.; Chen, W.F.; Xu, Z.H. Fabrication of porous carbon derived from cotton/polyester waste mixed with oyster shells: Pore-forming process and application for tetracycline removal. Chemosphere 2021, 270, 129483. [Google Scholar] [CrossRef]

- Mahari, W.A.W.; Waiho, K.; Azwar, E.; Fazhan, H.; Peng, W.; Ishak, S.D.; Tabatabaei, M.; Yek, P.N.Y.; Almomani, F.; Aghbashlo, M.; et al. A state-of-the-art review on producing engineered biochar from shellfish waste and its application in aquaculture wastewater treatment. Chemosphere 2021, 288, 132559. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.H.; Wang, M.; Shi, C.X.; Huang, J.; Zhang, B. Adsorption of tetracycline and ciprofloxacin on activated carbon prepared from lignin with H3PO4 activation. Desalination Water Treat. 2014, 52, 2678–2687. [Google Scholar] [CrossRef]

- Hoda, N.; Bayram, E.; Ayranci, E. Kinetic and equilibrium studies on the removal of acid dyes from aqueous solutions by adsorption onto activated carbon cloth. J. Hazard. Mater. 2006, 137, 344–351. [Google Scholar] [CrossRef]

- Gücek, A.; Sener, S.; Bilgen, S.; Mazmanci, M. Adsorption and kinetic studies of cationic and anionic dyes on pyrophyllite from aqueous solutions. J. Colloid Interface Sci. 2005, 286, 53–60. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.Y.; Xin, Z.W.; Fei, X.Y.; Luo, H.Y.; Li, H.Y.; Lu, B.X.; Li, Z.M.; Wei, G.T. Study on adsorption of tetracycline by red mud-based ceramsite. J. Water Supply Res. Technol. Aqua 2018, 68, 39–50. [Google Scholar] [CrossRef]

- Zhou, J.Y.; Song, Z.F.; Yang, Y.S. Preparation of low-cost sludge-based mesoporous carbon and its adsorption of tetracycline antibiotics. Water Sci. Technol. 2019, 79, 676–687. [Google Scholar] [CrossRef]

- Chao, Y.H.; Zhu, W.S.; Yan, B.; Lin, Y.B.; Xun, S.H.; Ji, H.Y.; Wu, X.Y.; Li, H.M.; Han, C.R. Macroporous polystyrene resins as adsorbents for the removal of tetracycline antibiotics from an aquatic environment. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Provisional). Pure Appl. Chem. 1982, 54, 2201–2218. [Google Scholar] [CrossRef]

- Azargohar, R.; Dalai, A.K. Steam and KOH activation of biochar: Experimental and modeling studies. Microporous Mesoporous Mater. 2008, 110, 413–421. [Google Scholar] [CrossRef]

- Almansa, C.; Molina-Sabio, M.; Rodriguez-Reinoso, F. Adsorption of methane into ZnCl2-activated carbon derived discs. Microporous Mesoporous Mater. 2004, 76, 185–191. [Google Scholar] [CrossRef]

- Song, X.L.; Zhang, Y.; Chang, C.M. Novel Method for Preparing Activated Carbons with High Specific Surface Area from Rice Husk. Ind. Eng. Chem. Res. 2012, 51, 15075–15081. [Google Scholar] [CrossRef]

- Lu, H.L.; Zhang, W.H.; Wang, S.Z.; Zhuang, L.W.; Yang, Y.X.; Qiu, R.L. Characterization of sewage sludge-derived biochars from different feedstocks and pyrolysis temperatures. J. Anal. Appl. Pyrolysis 2013, 102, 137–143. [Google Scholar] [CrossRef]

- Gao, R.L.; Xiang, L.; Hu, H.Q.; Fu, Q.L.; Zhu, J.; Liu, Y.H.; Huang, G.Y. High-efficiency removal capacities and quantitative sorption mechanisms of Pb by oxidized rape straw biochars. Sci. Total Environ. 2020, 699, 134262. [Google Scholar] [CrossRef]

- Peng, C.; Zhai, Y.B.; Zhu, Y.; Xu, B.B.; Wang, T.F.; Li, C.T.; Zeng, G.M. Production of char from sewage sludge employing hydrothermal carbonization: Char properties, combustion behavior and thermal characteristics. Fuel 2016, 176, 110–118. [Google Scholar] [CrossRef]

- Chia, C.H.; Gong, B.; Joseph, S.; Marjo, C.E.; Munroe, P.; Rich, A.M. Imaging of mineral-enriched biochar by FTIR, Raman and SEM-EDX. Vib. Spectrosc. 2012, 62, 248–257. [Google Scholar] [CrossRef]

- Hedayati, K.; Azarakhsh, S.; Ghanbari, D. Synthesis and magnetic investigation of cobalt ferrite nanoparticles prepared via a simple chemical precipitation method. J. Nanostructures 2016, 6, 127–131. [Google Scholar] [CrossRef]

- Puziy, A.M.; Poddubnaya, O.I.; Martínez-Alonso, A.; Suárez-García, F.; Tascón, J.M.D. Synthetic carbons activated with phosphoric acid: I. Surface chemistry and ion binding properties. Carbon 2002, 40, 1493–1505. [Google Scholar] [CrossRef]

- Peiris, C.; Gunatilake, S.R.; Mlsna, T.E.; Mohan, D.; Vithanage, M. Biochar based removal of antibiotic sulfonamides and tetracyclines in aquatic environments: A critical review. Bioresour. Technol. 2017, 246, 150–159. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, Z.; Fang, X.; Chen, Y.; Fan, S.; Xu, H. Preparation of magnetic porous biochar through hydrothermal pretreatment combined with K2FeO4 activation to improve tetracycline removal. Microporous Mesoporous Mater. 2022, 343, 112188. [Google Scholar] [CrossRef]

- Zhu, X.D.; Liu, Y.C.; Qian, F.; Zhou, C.; Zhang, S.C.; Chen, J.M. Preparation of magnetic porous carbon from waste hydrochar by simultaneous activation and magnetization for tetracycline removal. Bioresour. Technol. 2014, 154, 209–214. [Google Scholar] [CrossRef]

- Krause, R.T. Multiresidue Method for Determining N-Methylcarbamate Insecticides in Crops, Using High Performance Liquid Chromatography. J. AOAC Int. 1980, 63, 1114–1124. [Google Scholar] [CrossRef]

- Yang, X.; Xu, G.R.; Yu, H.R.; Zhang, Z. Preparation of ferric-activated sludge-based adsorbent from biological sludge for tetracycline removal. Bioresour. Technol. 2016, 211, 566–573. [Google Scholar] [CrossRef] [PubMed]

- Tan, X.; Liu, S.B.; Liu, Y.G.; Gu, Y.L.; Zeng, G.M.; Cai, X.X.; Yan, Z.L.; Yang, C.P.; Hu, X.J.; Chen, B. One-pot synthesis of carbon supported calcined-Mg/Al layered double hydroxides for antibiotic removal by slow pyrolysis of biomass waste. Sci. Rep. 2016, 6, 39691. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Li, Y.J.; Zhang, L.; Huang, H.; Hu, J.; Shah, S.M.; Su, X.G. Adsorption and removal of tetracycline antibiotics from aqueous solution by graphene oxide. J. Colloid Interface Sci. 2012, 368, 540–546. [Google Scholar] [CrossRef]

| Sample | SBET (m2/g) | Vtot (cm3/g) | Average Pore Diameter (nm) |

|---|---|---|---|

| CS | 9.57 | 0.03 | 10.84 |

| 500−CSB | 41.16 | 0.02 | 2.26 |

| 600−CSB | 78.11 | 0.04 | 2.05 |

| 700−CSB | 127.38 | 0.05 | 1.68 |

| 800−CSB | 181.79 | 0.11 | 2.37 |

| 900−CSB | 177.91 | 0.11 | 2.41 |

| Sample | SBET (m2/g) | Vtot (cm3/g) | Average Pore Diameter (nm) |

|---|---|---|---|

| 800−CSB | 181.79 | 0.11 | 2.37 |

| M−CSB | 271.25 | 0.18 | 2.66 |

| K−CSB | 1095.14 | 0.63 | 2.18 |

| P−CSB | 381.16 | 0.21 | 2.24 |

| Sample | PFO | PSO | |||||

|---|---|---|---|---|---|---|---|

| qe 1 (mg/g) | K1 g/(mg·min) | R2 | qe 2 (mg/g) | K2 g/(mg·min) | R2 | ||

| K−CSB | 100 mg/L | 47.8322 | 0.0025 | 0.7955 | 98.0392 | 0.0003 | 0.9994 |

| 200 mg/L | 125.8134 | 0.0024 | 0.9874 | 196.0784 | 0.0001 | 0.9968 | |

| 400 mg/L | 172.0526 | 0.0020 | 0.7737 | 384.6154 | 0.0001 | 0.9994 | |

| P−CSB | 100 mg/L | 36.4339 | 0.0025 | 0.7783 | 98.0392 | 0.0005 | 0.9998 |

| 200 mg/L | 81.5731 | 0.0028 | 0.8008 | 181.8182 | 0.0002 | 0.9995 | |

| 400 mg/L | 130.5949 | 0.0018 | 0.6621 | 333.3333 | 0.0001 | 0.9992 | |

| M−CSB | 100 mg/L | 57.9511 | 0.0027 | 0.9046 | 86.9565 | 0.0001 | 0.9770 |

| 200 mg/L | 98.4944 | 0.0002 | 0.9287 | 172.4138 | 0.0001 | 0.9958 | |

| 400 mg/L | 174.2690 | 0.0014 | 0.7280 | 277.7778 | 0.0001 | 0.9954 | |

| Sample | Langmuir | Freundlich | ||||

|---|---|---|---|---|---|---|

| qm (mg/g) | KL (L/mg) | R2 | n | KF [(mg/g)(L/mg)1/n] | R2 | |

| K−CSB | 400.00 | 0.1142 | 0.9852 | 2.1044 | 59.7041 | 0.6901 |

| P−CSB | 357.14 | 5.5044 | 0.9933 | 2.5714 | 57.0484 | 0.8259 |

| M−CSB | 277.78 | 1.8072 | 0.9939 | 2.7034 | 49.8291 | 0.7208 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Ji, L.; Han, X.; Wu, Z.; Cai, L.; Guo, J.; Wang, Y. Mesoporous Activated Biochar from Crab Shell with Enhanced Adsorption Performance for Tetracycline. Foods 2023, 12, 1042. https://doi.org/10.3390/foods12051042

Sun J, Ji L, Han X, Wu Z, Cai L, Guo J, Wang Y. Mesoporous Activated Biochar from Crab Shell with Enhanced Adsorption Performance for Tetracycline. Foods. 2023; 12(5):1042. https://doi.org/10.3390/foods12051042

Chicago/Turabian StyleSun, Jiaxing, Lili Ji, Xiao Han, Zhaodi Wu, Lu Cai, Jian Guo, and Yaning Wang. 2023. "Mesoporous Activated Biochar from Crab Shell with Enhanced Adsorption Performance for Tetracycline" Foods 12, no. 5: 1042. https://doi.org/10.3390/foods12051042