The Drying Kinetics and CFD Multidomain Model of Cocoa Bean Variety CCN51

Abstract

:1. Introduction

- The transformation of the cocoa seeds into cocoa beans. This includes pretreatment with chemical additives, fermentation, and drying.

- The production of chocolate from the bean. In this process, roasting is highlighted.

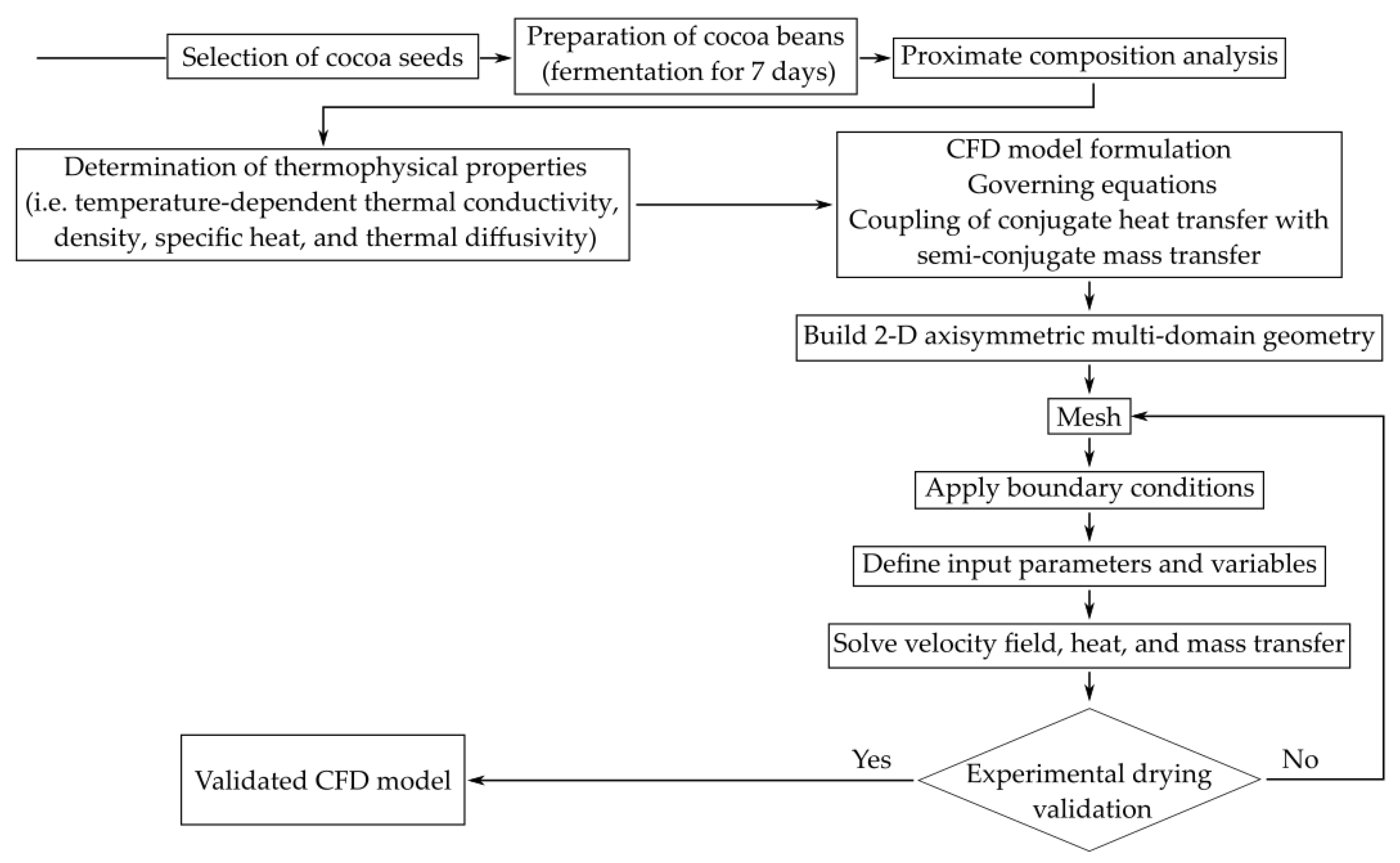

2. Materials and Methods

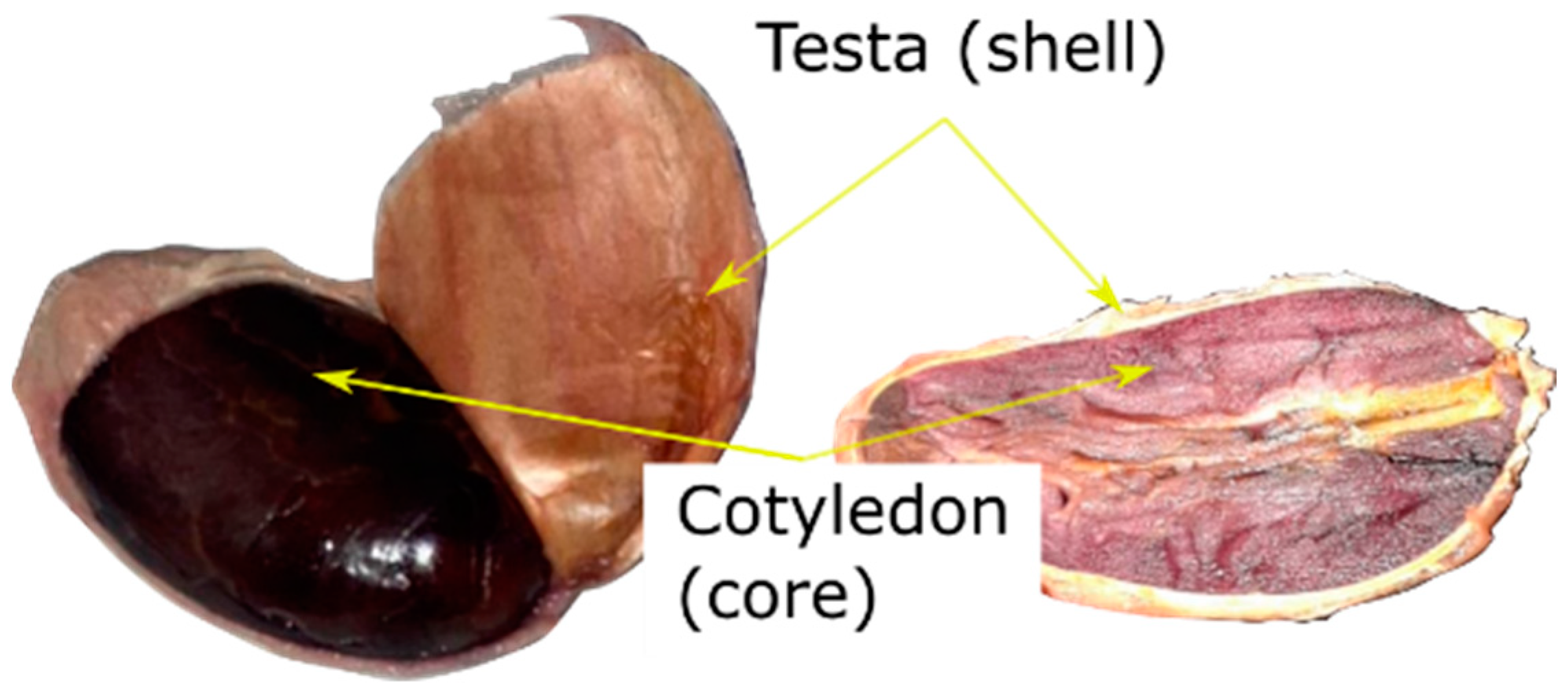

2.1. Thermophysical Properties

2.2. Experimental Drying Setup

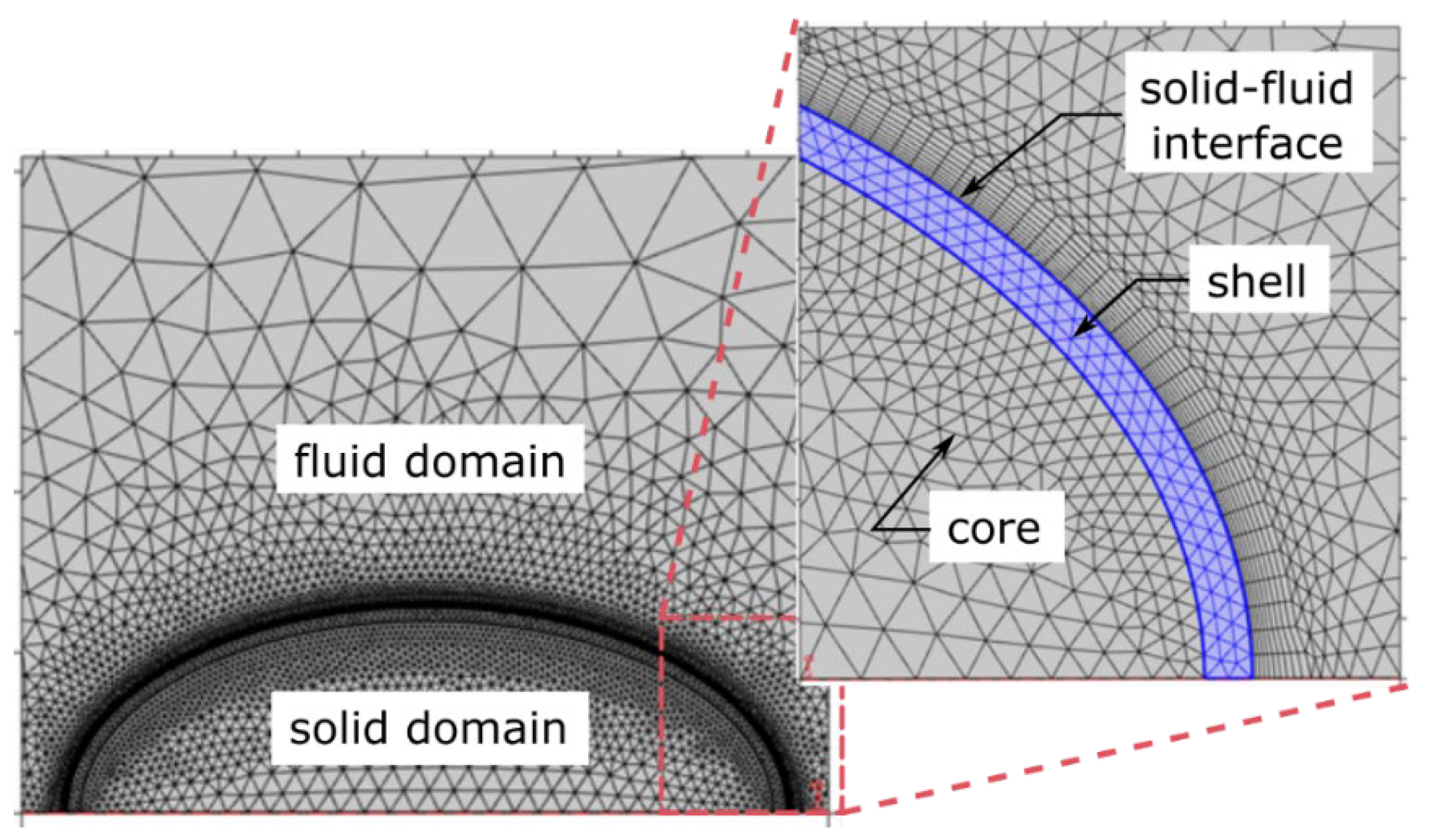

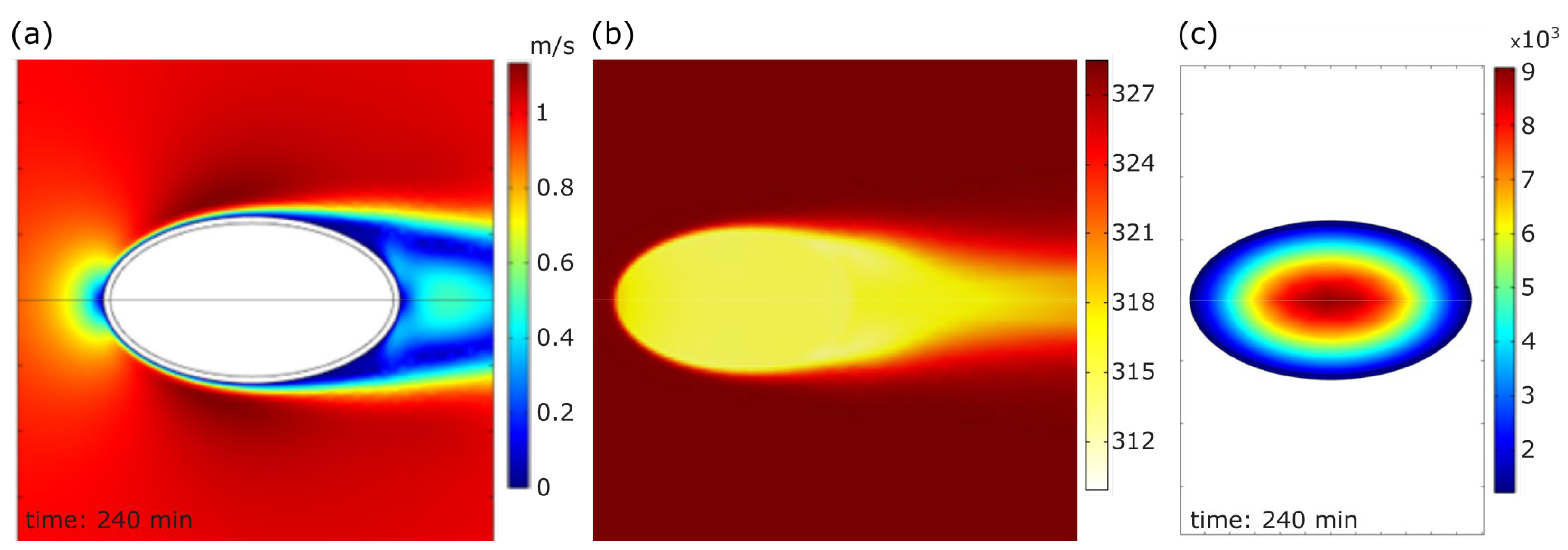

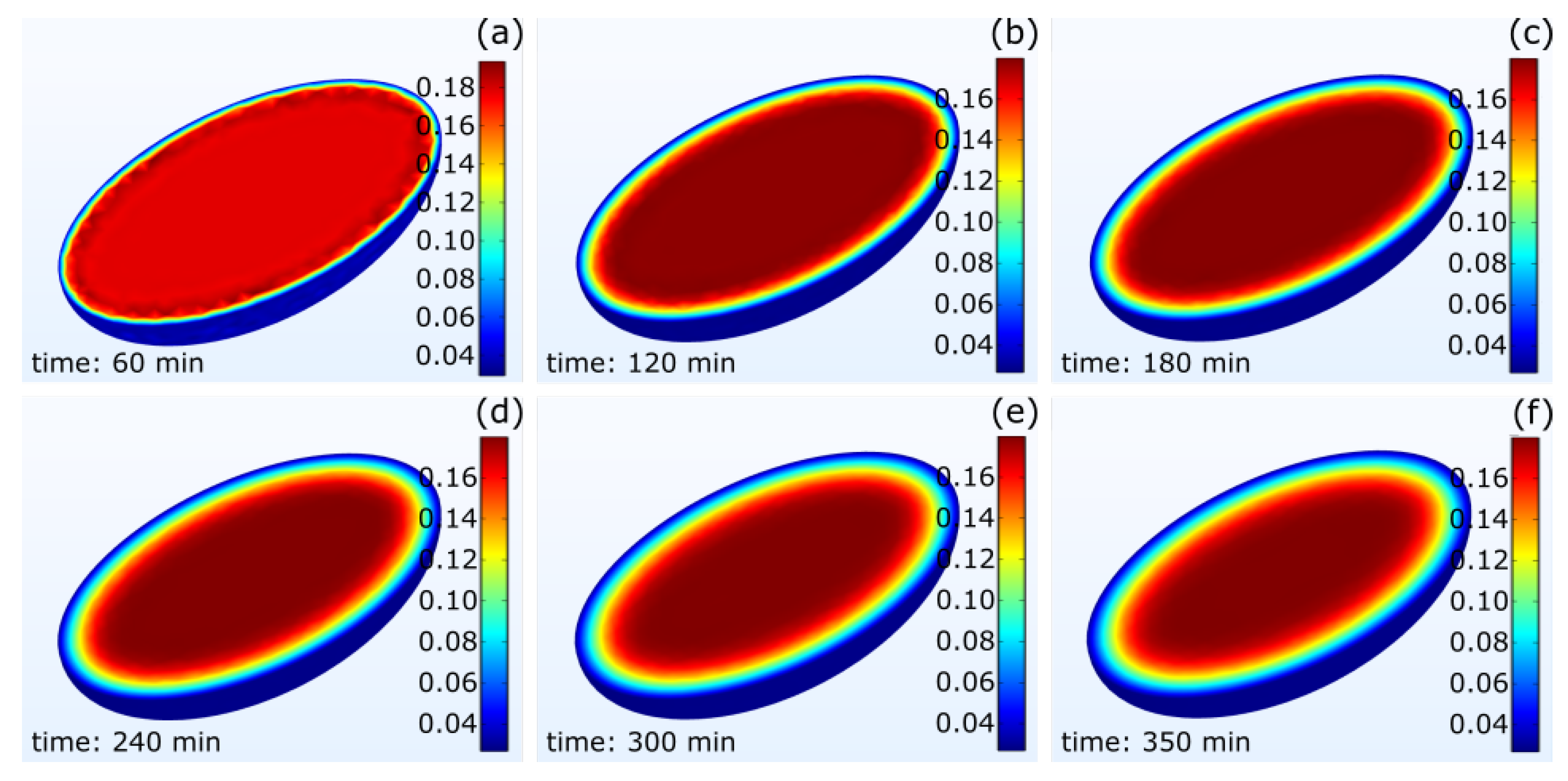

2.3. Governing Equations and the Numerical Model

3. Results and Discussion

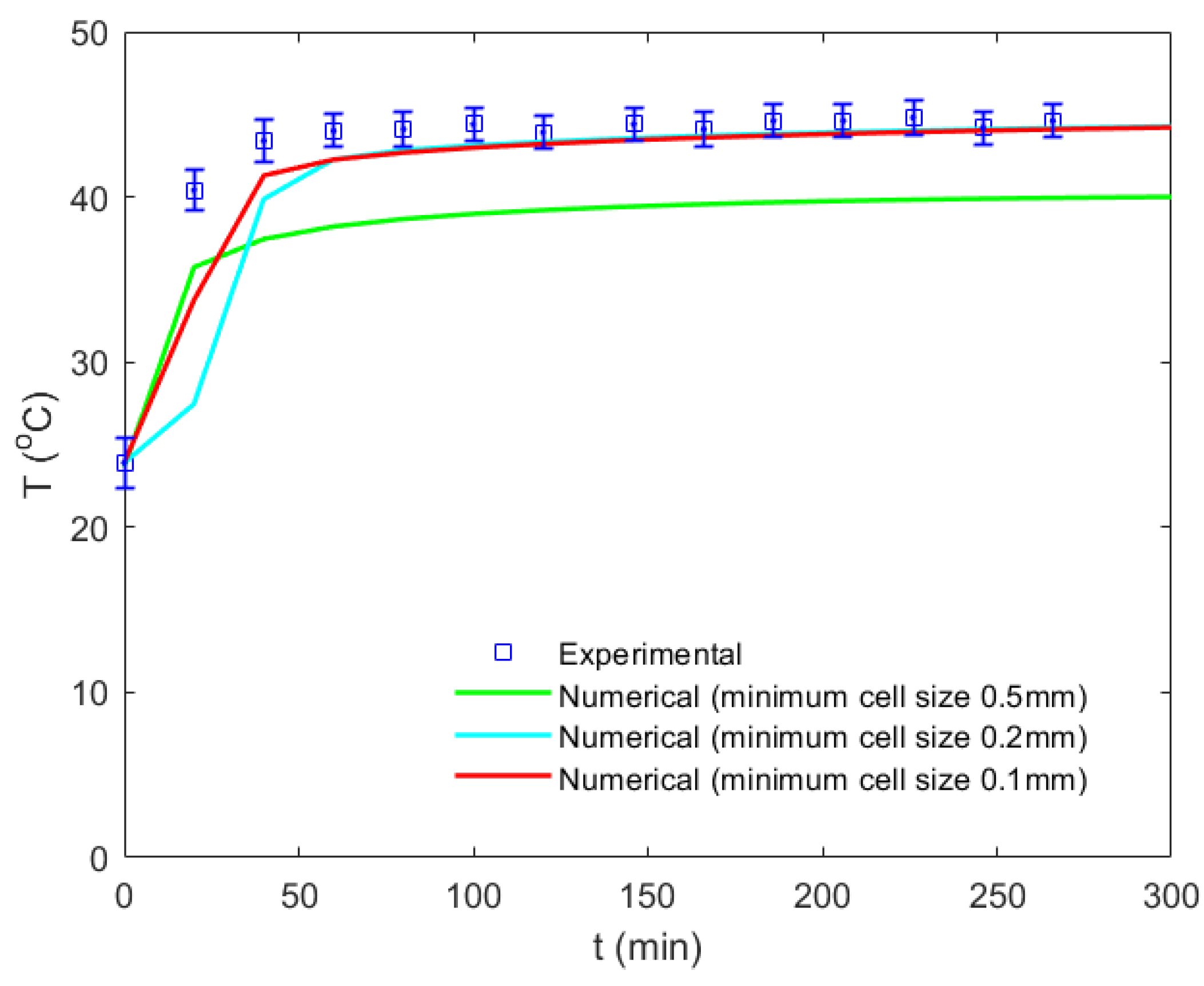

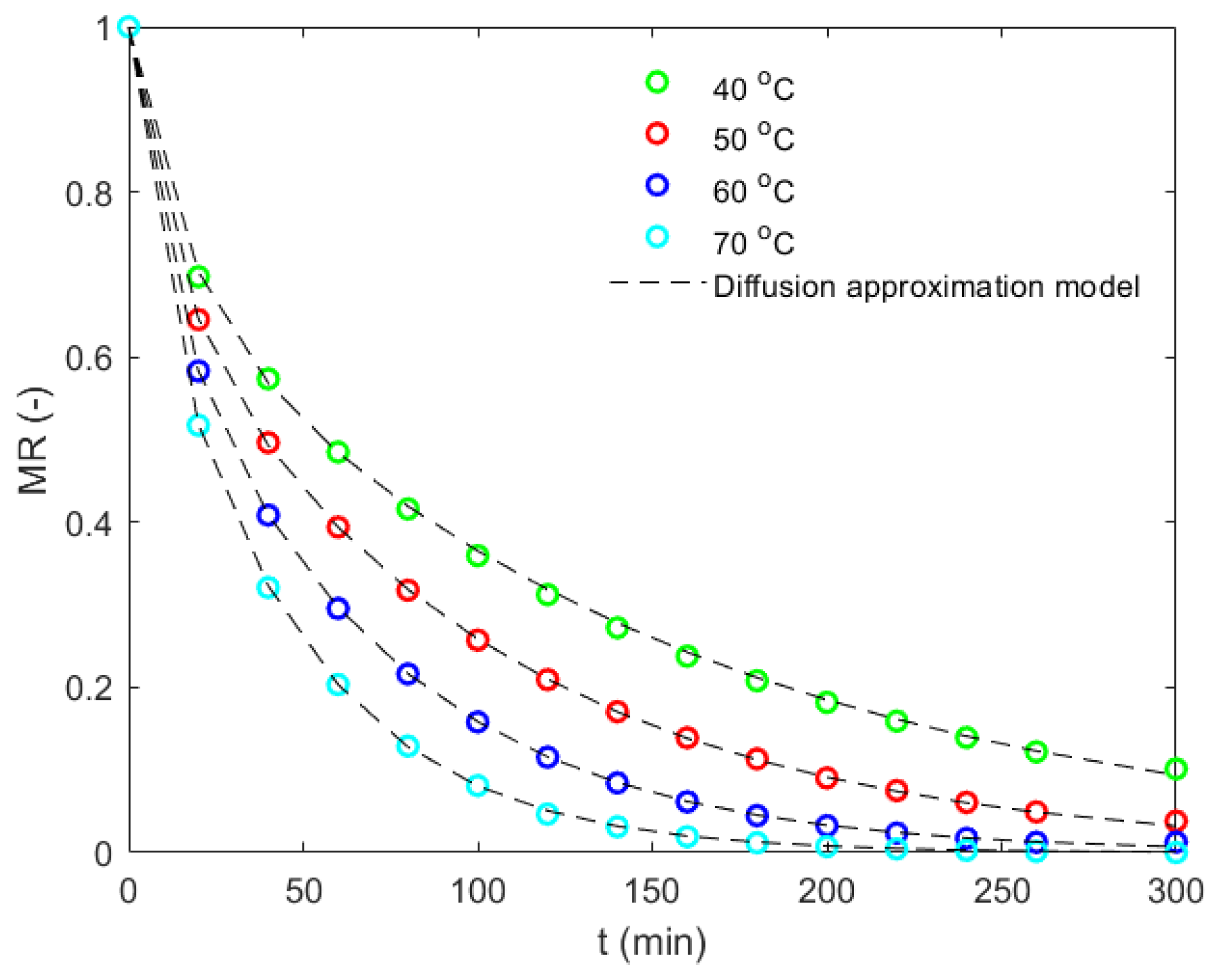

3.1. Experimental Validation of the Numerical Results

3.2. Drying Kinetics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| the largest axis of the ellipsoidal bean | initial moisture concentration in the bean | ||

| the shortest axis of the ellipsoidal bean | the local temperature inside and outside the bean | ||

| thermal diffusivity | the initial temperature of the bean | ||

| kinematic viscosity of the drying air | effective diffusivity of water in a bean | ||

| dynamic viscosity | diffusion coefficient of the water in the air | ||

| shell density | thermal conductivity | ||

| heat capacity at the constant pressure of the shell | drying air velocity | ||

| thermal conductivity of the shell | drying air temperature | ||

| core density | molar latent heat of vaporization | ||

| heat capacity at the constant pressure of the core | heat transfer coefficient between the surface of a bean and the drying air | ||

| heat capacity at the constant pressure of the drying air | mass transfer coefficient between the surface of a bean and the drying air | ||

| thermal conductivity of the core | Nusselt number | ||

| density of the drying air | Reynold number | ||

| velocity vector field of the drying air | Prandtl number | ||

| gravity vector | Sherwood number | ||

| pressure | Schmidt number | ||

| local moisture concentration | moisture content dry basis | ||

| equilibrium moisture concentration | moisture ratio |

References

- Rice, R.A.; Greenberg, R. Cacao cultivation and the conservation of biological diversity. AMBIO A J. Hum. Environ. 2000, 29, 167–173. [Google Scholar] [CrossRef]

- Beg, M.S.; Ahmad, S.; Jan, K.; Bashir, K. Status, supply chain, and processing of cocoa-A review. Trends Food Sci. Technol. 2017, 66, 108–116. [Google Scholar] [CrossRef]

- Arguello, D.; Chavez, E.; Lauryssen, F.; Vanderschueren, R.; Smolders, E.; Montalvo, D. Soil properties and agronomic factors affecting cadmium concentrations in cacao beans: A nationwide survey in Ecuador. Sci. Total Environ. 2019, 649, 120–127. [Google Scholar] [CrossRef] [PubMed]

- Counet, C.; Ouwerx, C.; Rosoux, D.; Collin, S. Relationship between procyanidin and flavor contents of cocoa liquors from different origins. J. Agric. Food Chem. 2001, 52, 6243–6249. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Alamilla, P.; Salgado-Cervantes, M.A.; Barel, M.; Berthomieu, G.; Rodriguez-Jimenez, G.C.; Garcia-Alvarado, M.A. Moisture, acidity and temperature evolution during cacao drying. J. Food Eng. 2007, 79, 1159–1165. [Google Scholar] [CrossRef]

- Vargas Jentzsch, P.; Ciobota, V.; Salinas, W.; Kampe, B.; Aponte, P.M.; Rosch, P.; Popp, J.; Ramos, L.A. Distinction of Ecuadorian varieties of fermented cocoa beans using Raman spectroscopy. Food Chem. 2016, 211, 274–280. [Google Scholar] [CrossRef]

- Rodriguez, W.M.; Torres, C.V.; Bosquez, P.D.S.; Navarrete, Y.T.; Chang, J.V.; Cedeño, E.D.A. Mejoramiento de las características físico-químicas y sensoriales del cacao CCN51 a través de la adición de una enzima y levadura durante el proceso de fermentación. Rev. Amaz. Cienc. Tecnol. 2016, 5, 169–181. [Google Scholar]

- Santander Muñoz, M.; Rodriguez Cortina, J.; Vaillant, F.E.; Escobar Parra, S. An overview of the physical and biochemical transformation of cocoa seeds to beans and to chocolate: Flavor formation. Crit. Rev. Food Sci. Nutr. 2020, 60, 1593–1613. [Google Scholar] [CrossRef]

- Afoakwa, E.O.; Paterson, A.; Fowler, M.; Ryan, A. Flavor formation and character in cocoa and chocolate: A critical review. Crit. Rev. Food Sci. Nutr. 2008, 48, 840–857. [Google Scholar] [CrossRef]

- Aprotosoaie, A.C.; Luca, S.V.; Miron, A. Flavor chemistry of cocoa and cocoa products—An overview. Compr. Rev. Food Sci. Food Saf. 2016, 15, 73–91. [Google Scholar] [CrossRef]

- Kaya, A.; Aydin, O.; Dinger, I. Numerical modeling of forced-convection drying of cylindrical moist objects. Numer. Heat Transf. Part A Appl. 2007, 51, 843–854. [Google Scholar] [CrossRef]

- Mujumdar, A.S. Research and development in drying: Recent trends and future prospects. Dry. Technol. 2004, 22, 1–26. [Google Scholar] [CrossRef]

- Shimpy, M.; Kumar, M.; Kumar, A. Designs, Performance and Economic Feasibility of Domestic Solar Dryers. Food Eng. Rev. 2023, 15, 156–186. [Google Scholar] [CrossRef]

- Jha, A.; Tripathy, P.P. Recent advancements in Design, Application, and Simulation Studies of Hybrid Solar Drying Technology. Food Eng. Rev. 2021, 13, 375–410. [Google Scholar] [CrossRef]

- Dzelagha, B.F.; Ngwa, N.M.; Nde Bup, D. A Review of Cocoa Drying Technologies and the Effect on Bean Quality Parameters. Int. J. Food Sci. 2020, 2020, 8830127. [Google Scholar] [CrossRef] [PubMed]

- Lukinov, A.V. Heat and Mass Transfer in Capillary-Porous Bodies; Pergamon Press: Oxford, UK, 1966. [Google Scholar]

- Hnin, K.K.; Zhang, M.; Zhu, Y. Emerging food drying technologies with energy-saving characteristics: A review. Dry. Technol. 2019, 37, 1465–1480. [Google Scholar] [CrossRef]

- Chua, L.S.; Abd Wahab, N.S. Drying Kinetics of jaboticaba Berries and Natural Fermentation for Anthocyanin-Rich Fruit Vinegar. Foods 2023, 12, 65. [Google Scholar] [CrossRef] [PubMed]

- Wanderley, R.d.O.S.; de Figueiredo, R.M.F.; Queiroz, A.J.d.M.; dos Santos, F.S.; Paiva, Y.F.; Ferreira, J.P.d.L.; de Lima, A.G.B.; Gomes, J.P.; Costa, C.C.; da Silva, W.P.; et al. The Temperature Influence on Drying Kinetics and Physico-Chemical Properties of Pomegranate Peels and Seeds. Foods 2023, 12, 286. [Google Scholar] [CrossRef] [PubMed]

- Jha, A.; Moses, J.A.; Anandharamakrishnan, C. 13-Smartphone-based detection devices for the agri-food industry. In Smartphone-Based Detection Devices; Elsevier: Amsterdam, The Netherlands, 2021; pp. 269–310. [Google Scholar]

- Jha, A.; Trpathy, P.P. Optimization of process parameters and numerical modeling of heat and mass transfer during simulated solar drying of paddy. Comput. Electron. Agric. 2021, 187, 106215. [Google Scholar] [CrossRef]

- Irudayaraj, J.; Haghighi, K.; Stroshine, R.L. Finite element analysis of drying with application to cereal grains. J. Agric. Eng. Res. 1992, 53, 209–229. [Google Scholar] [CrossRef]

- Erbay, Z.; Icier, F. A review of thin layer drying of foods: Theory, modeling, and experimental results. Crit. Rev. Food Sci. Nutr. 2010, 50, 441–464. [Google Scholar] [CrossRef]

- Azmir, J.; Hou, Q.; Yu, A. CFD-DEM simulation of drying of food grains with particle shrinkage. Powder Technol. 2019, 343, 792–802. [Google Scholar] [CrossRef]

- Khan, M.I.H.; Welsh, Z.; Gu, Y.; Karim, M.A.; Bhandari, B. Modelling of simultaneous heat and mass transfer considering the spatial distribution of air velocity during intermittent microwave convective drying. Int. J. Heat Mass Transf. 2020, 153, 119668. [Google Scholar] [CrossRef]

- Bravo, A.; McGaw, D.R. Fundamental artificial drying characteristics of cocoa beans. Trop. Agric. 1974, 51, 395–406. [Google Scholar]

- Wan Daud, W.R.; Mcor Talib, M.Z.; Hakimi lbrahim, M. Characteristic drying curves of cocoa beans. Dry. Technol. 1996, 14, 2387–2396. [Google Scholar] [CrossRef]

- Nganhou, J. Heat and mass transfer through a thick bed of cocoa beans during drying. Heat Mass Transf. 2004, 40, 727–735. [Google Scholar] [CrossRef]

- Hii, C.L.; Law, C.L.; Suzannah, S. Drying kinetics of the individual layer of cocoa beans during heat pump drying. J. Food Eng. 2012, 108, 276–282. [Google Scholar] [CrossRef]

- Hii, C.L.; Law, C.L.; Law, M.C. Simulation of heat and mass transfer of cocoa beans under stepwise drying conditions in a heat pump dryer. Appl. Therm. Eng. 2013, 54, 264–271. [Google Scholar] [CrossRef]

- Choi, Y. Food Thermal Property Prediction as Effected by Temperature and Composition; Purdue University: West Lafayette, IN, USA, 1985. [Google Scholar]

- INEN Instituto Ecuatoriano de Normalización. NTE INEN 1676: 2013 Cacao Products. Loss on Drying (Moisture) in Cacao Products. Gravimetric Method, 1st ed.; INEN: Quito, Ecuador, 2013; Available online: https://www.normalizacion.gob.ec/buzon/normas/1676-1R.pdf (accessed on 5 February 2023).

- Association of Official Analytical Chemists. Official Methods of Analysis of the Association of Official Analytical Chemists; Association of Official Analytical Chemists: Washington, DC, USA, 1970. [Google Scholar]

- Phinney, D.M.; Frelka, J.C.; Heldman, D.R. Composition-based prediction of temperature-dependent thermophysical food properties: Reevaluating component groups and prediction models. J. Food Sci. 2017, 82, 6–15. [Google Scholar] [CrossRef]

- Jinap, S. Organic acids in cocoa beans—A review. ASEAN Food J. 1994, 9, 3–12. [Google Scholar]

- Herman, C.; Spreutels, L.; Turomzsa, N.; Konagano, E.M.; Haut, B. Convective drying of fermented Amazonian cocoa beans (Theobroma cacao var. Forasteiro). Experiments and mathematical modeling. Food Bioprod. Process. 2018, 108, 81–94. [Google Scholar] [CrossRef]

- Akpinar, E.K.A.; Krzykowski, D.; Dziki, S.; Rudy, U.; Gawlik-Dziki, R.; Polak, B. Mathematical modelling and experimental investigation on sun and solar drying of white mulberry. J. Mech. Sci. Technol. 2008, 22, 1544–1553. [Google Scholar] [CrossRef]

| Sample | Protein (%) | Fat (%) | Carbohydrate (%) | Fiber (%) | Ash (%) | Water (%) |

|---|---|---|---|---|---|---|

| Testa (shell) | 8.89 | 26.0 | 27.98 | 0.0 | 2.23 | 34.9 |

| Cotyledon (core) | 4.8 | 0.32 | 28.0 | 0.0 | 2.28 | 64.6 |

| Sample | (kg/m3) | (kJ/kg°C) | (W/m°C) | (m2/s) × 10−7 |

|---|---|---|---|---|

| Testa (shell) | 1117.6 | 2.660 | 0.427 | 1.436 |

| Cotyledon (core) | 1135.7 | 3.294 | 0.544 | 1.454 |

| Drying Constants | 40 °C | 50 °C | 60 °C | 70 °C |

|---|---|---|---|---|

| (min−1) | 0.066 | 0.082 | 0.105 | 0.181 |

| 0.280 | 0.268 | 0.243 | 0.184 | |

| 0.103 | 0.127 | 0.149 | 0.128 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castillo-Orozco, E.; Garavitto, O.; Saavedra, O.; Mantilla, D. The Drying Kinetics and CFD Multidomain Model of Cocoa Bean Variety CCN51. Foods 2023, 12, 1082. https://doi.org/10.3390/foods12051082

Castillo-Orozco E, Garavitto O, Saavedra O, Mantilla D. The Drying Kinetics and CFD Multidomain Model of Cocoa Bean Variety CCN51. Foods. 2023; 12(5):1082. https://doi.org/10.3390/foods12051082

Chicago/Turabian StyleCastillo-Orozco, Eduardo, Oguier Garavitto, Omar Saavedra, and David Mantilla. 2023. "The Drying Kinetics and CFD Multidomain Model of Cocoa Bean Variety CCN51" Foods 12, no. 5: 1082. https://doi.org/10.3390/foods12051082

APA StyleCastillo-Orozco, E., Garavitto, O., Saavedra, O., & Mantilla, D. (2023). The Drying Kinetics and CFD Multidomain Model of Cocoa Bean Variety CCN51. Foods, 12(5), 1082. https://doi.org/10.3390/foods12051082