Improving Drying Characteristics and Physicochemical Quality of Angelica sinensis by Novel Tray Rotation Microwave Vacuum Drying

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Reagents

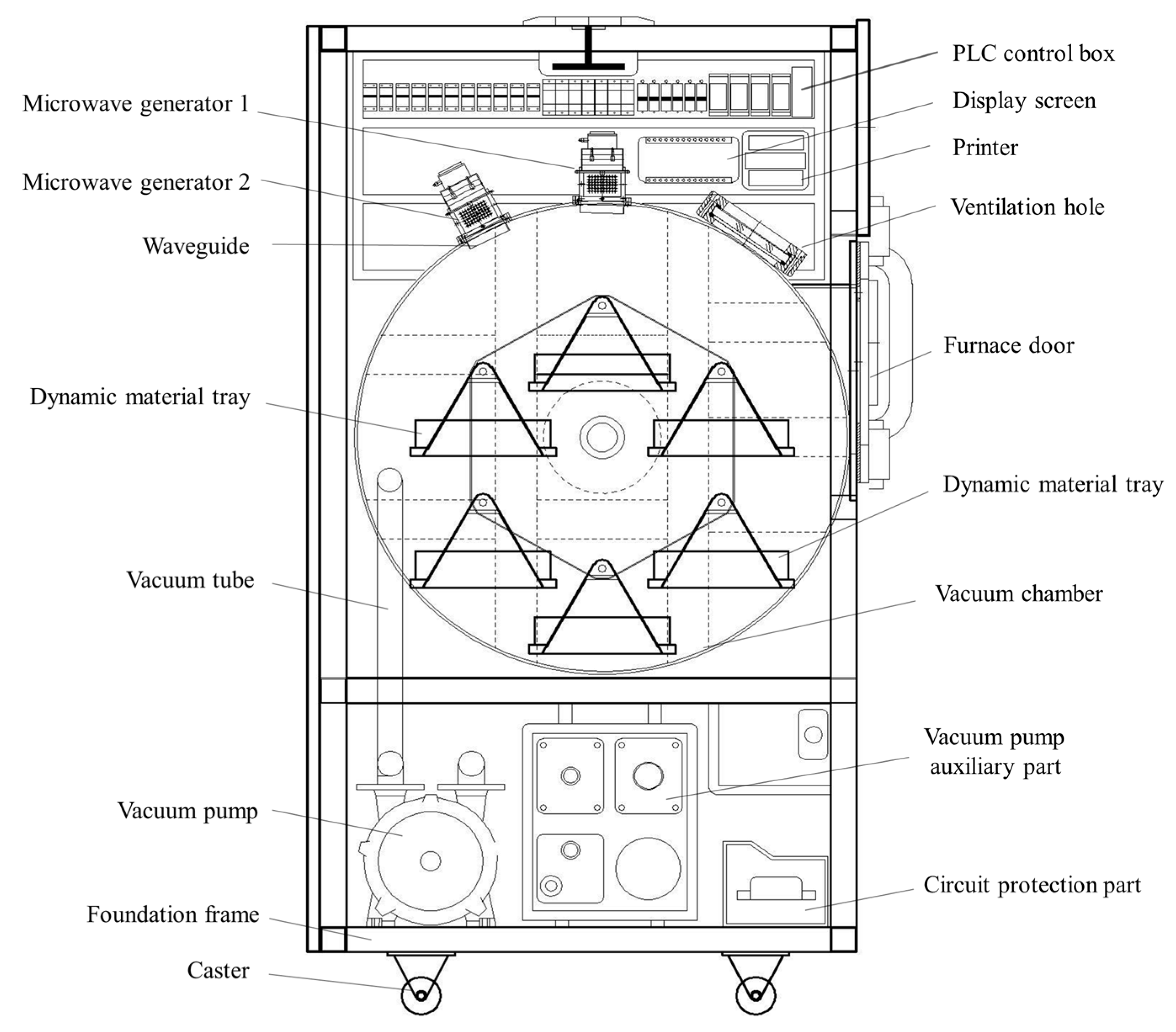

2.3. Experimental Equipments

2.4. Drying Kinetic Parameters

2.4.1. Moisture Content

2.4.2. Dry Basis Moisture Content

2.4.3. Drying Rate

2.4.4. Drying Kinetics

2.5. Color

2.6. Effect of Microwave Vacuum Drying on the Phytochemical Quality

2.6.1. Preparation of Sample Extracts

2.6.2. Determination of Natural Active Ingredients Contents

2.6.3. Determination of Total Phenols Contents (TPC)

2.6.4. Determination of Total Flavonoids Contents (TFC)

2.6.5. Determination of Polysaccharides Contents

2.6.6. Determination of Antioxidant Activity

2.7. Microstructure

2.8. Principal Components Analysis (PCA)

2.9. Entropy Weight-Coefficient of Variation Method Coupling Weight

2.10. Statistical Analysis

3. Results and Discussion

3.1. Drying Characteristics

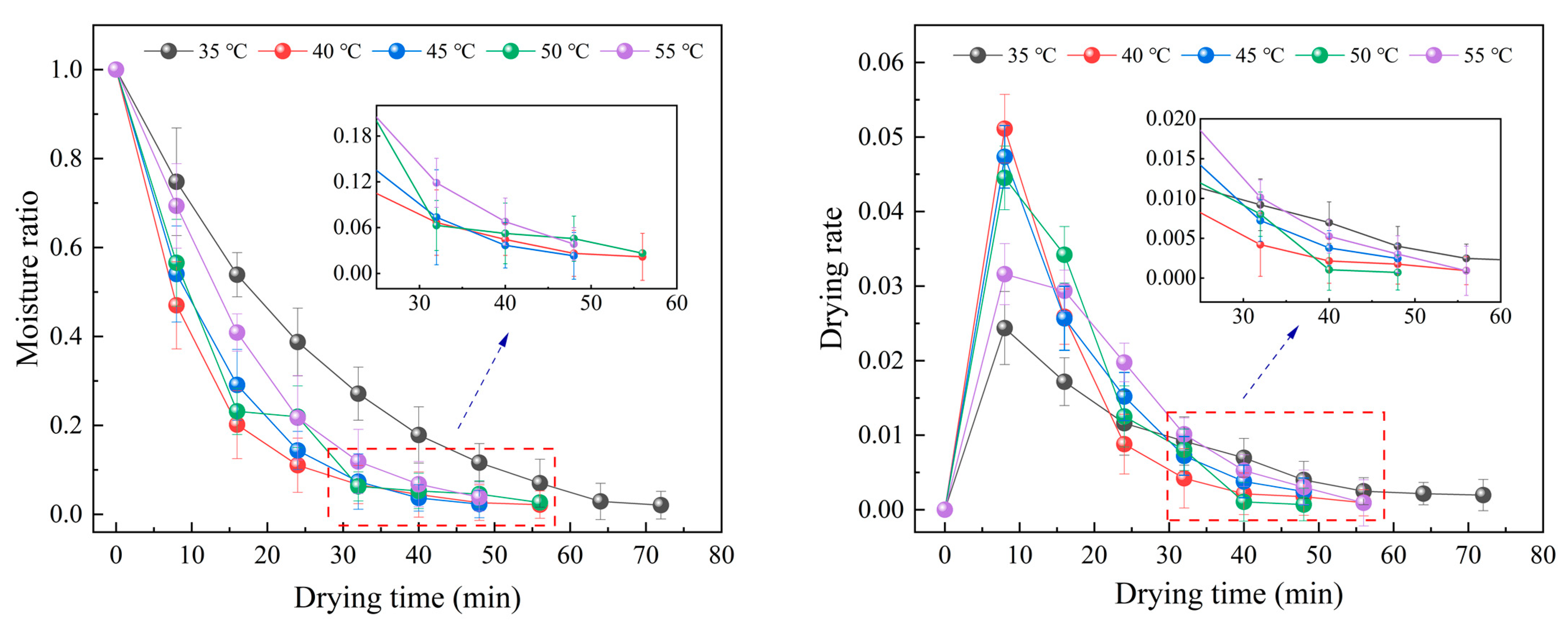

3.1.1. Effect of Radiation Temperatures on the Drying Characteristics

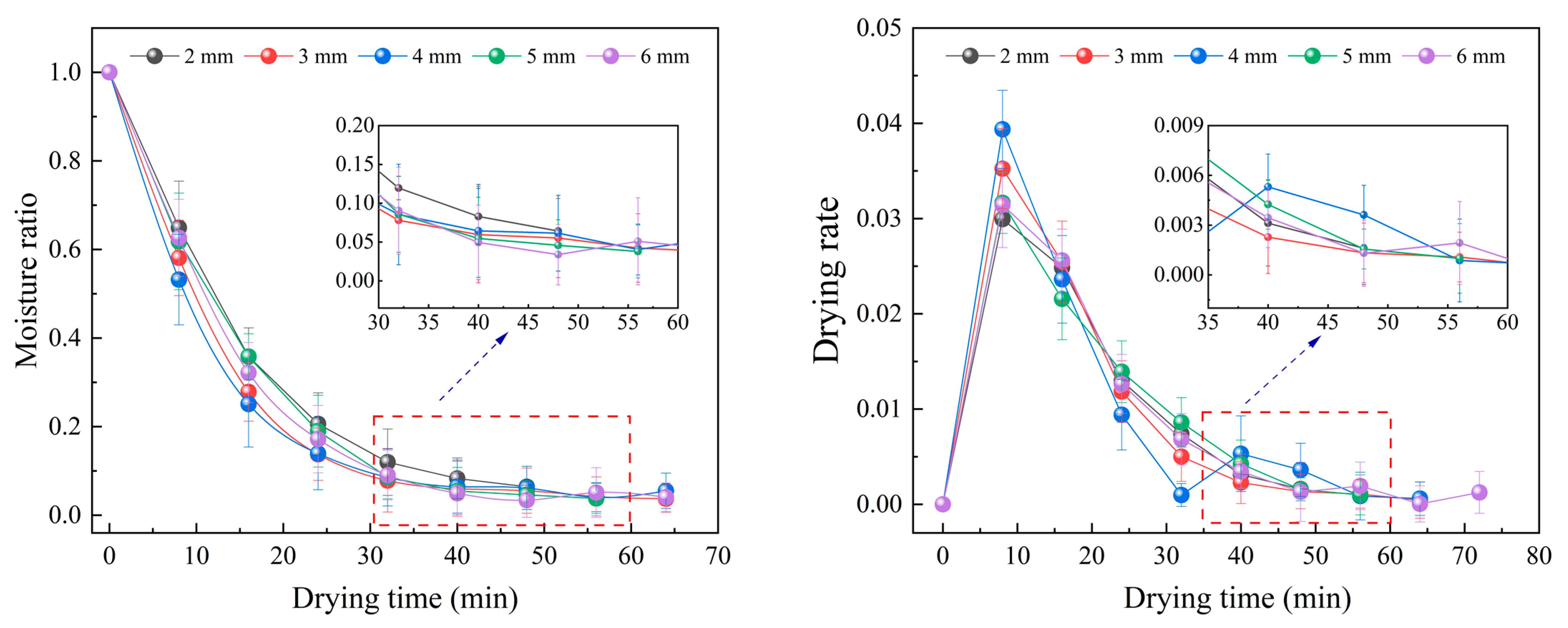

3.1.2. Effect of Slice Thickness on Drying Characteristics

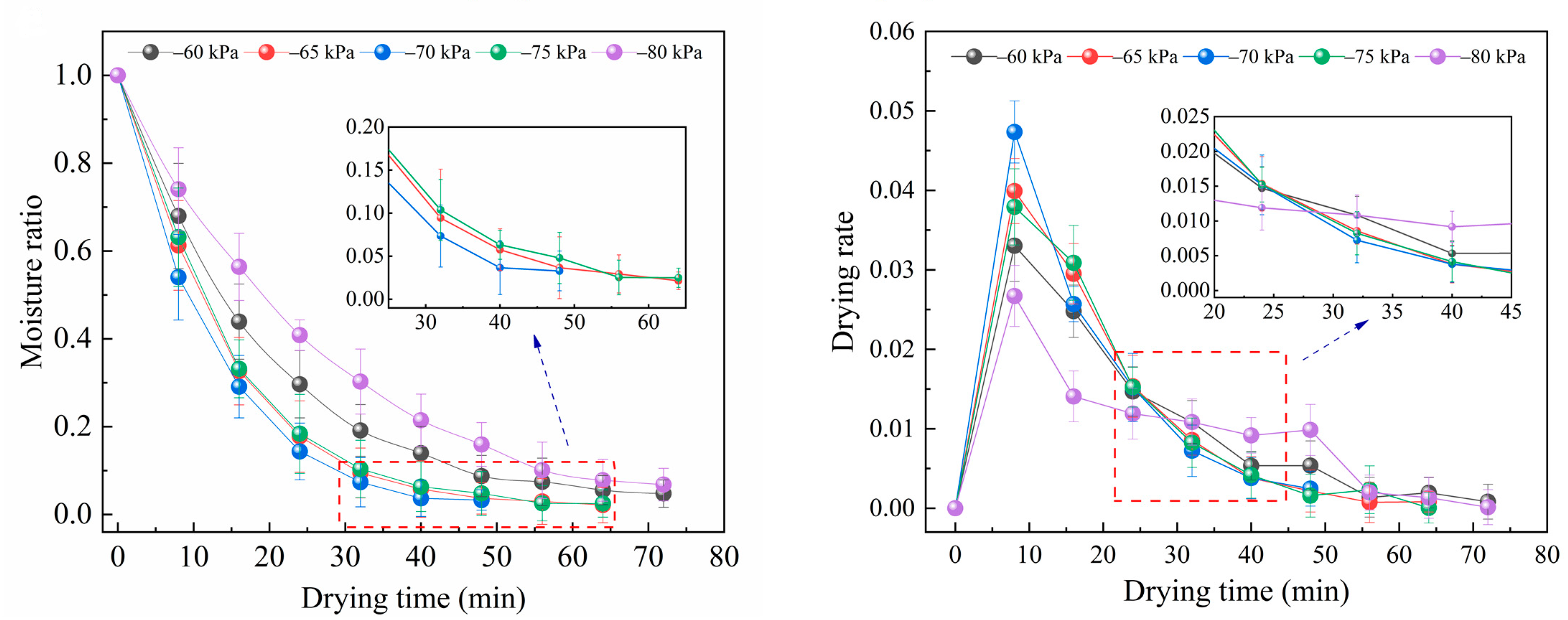

3.1.3. Effect of Vacuum Degree on the Drying Characteristics

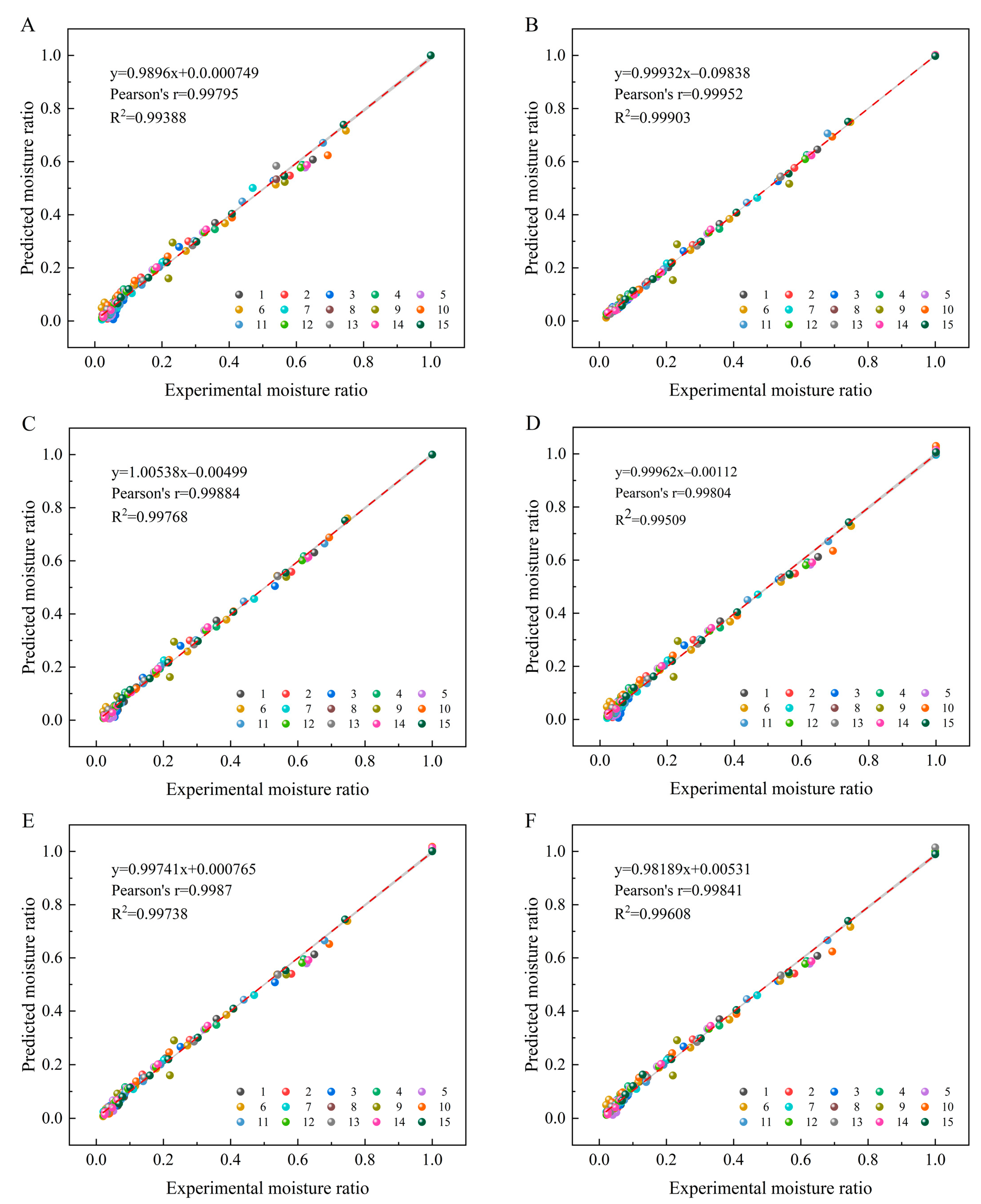

3.2. Drying Kinetics

3.3. Color

3.4. Effect on Phytochemical Quality of Angelica Sinensis

3.4.1. Natural Active Ingredient Content

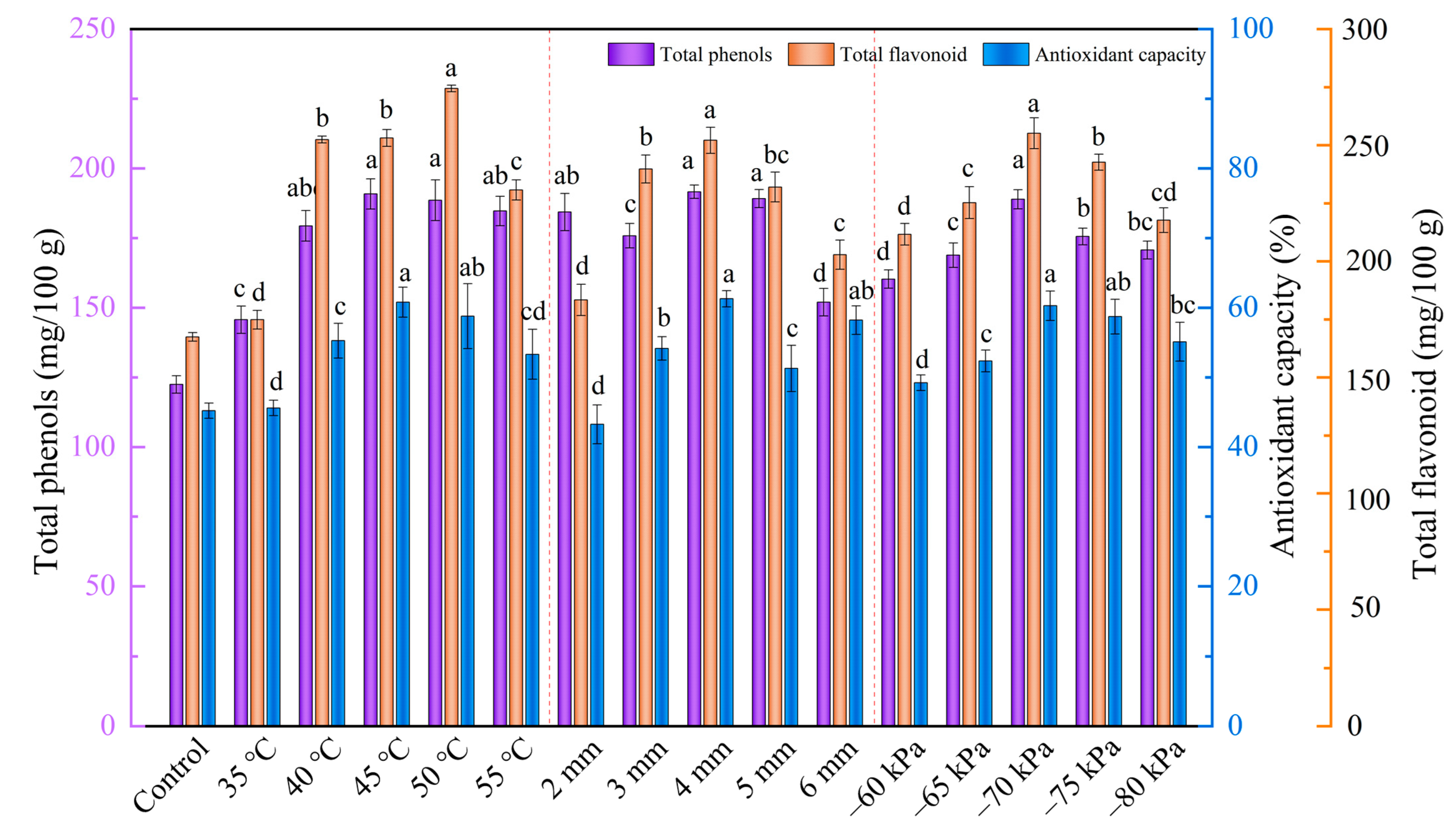

3.4.2. Total Phenol and Total Flavonoid Content

3.4.3. Antioxidant Capacity

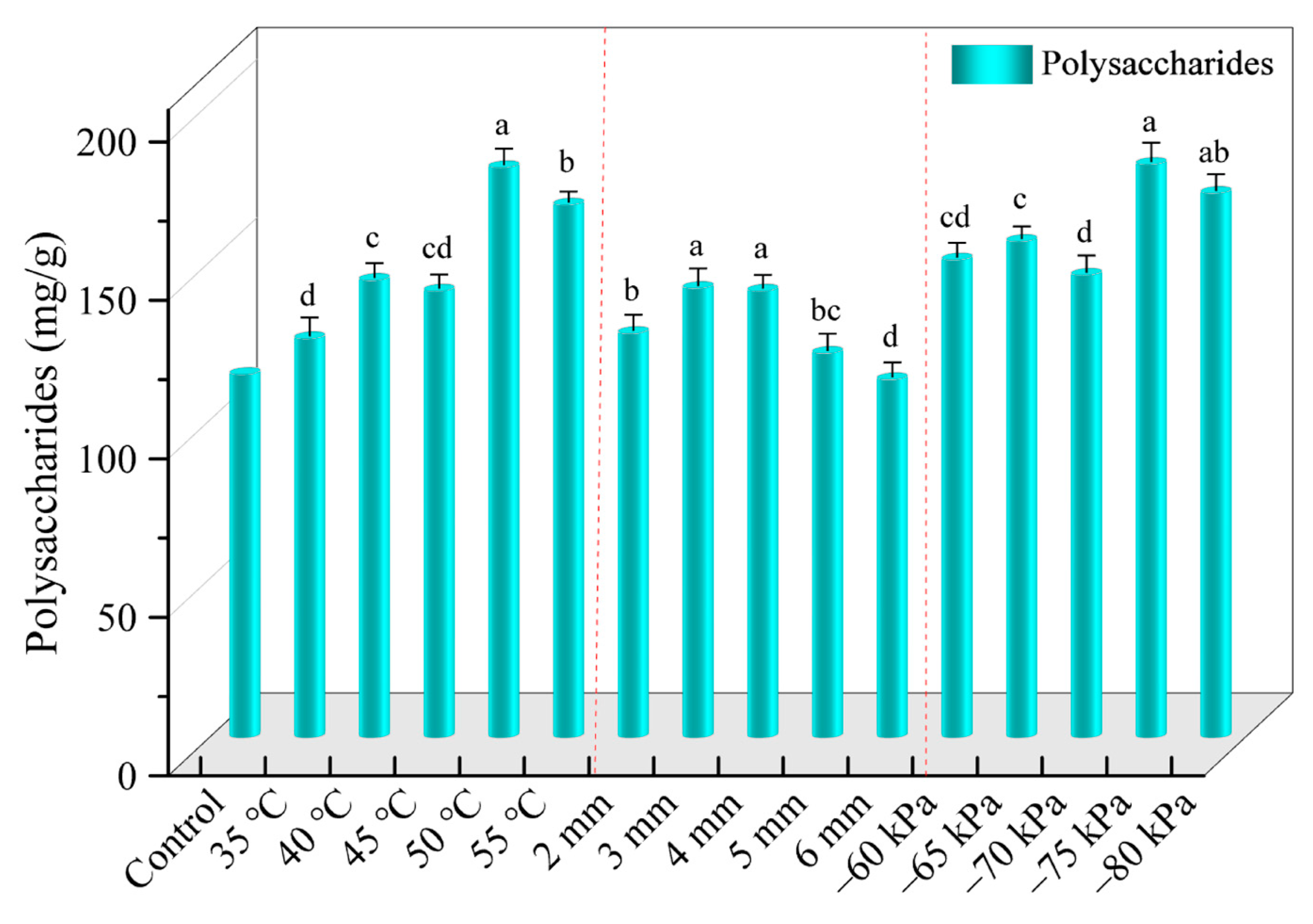

3.4.4. Polysaccharide Content

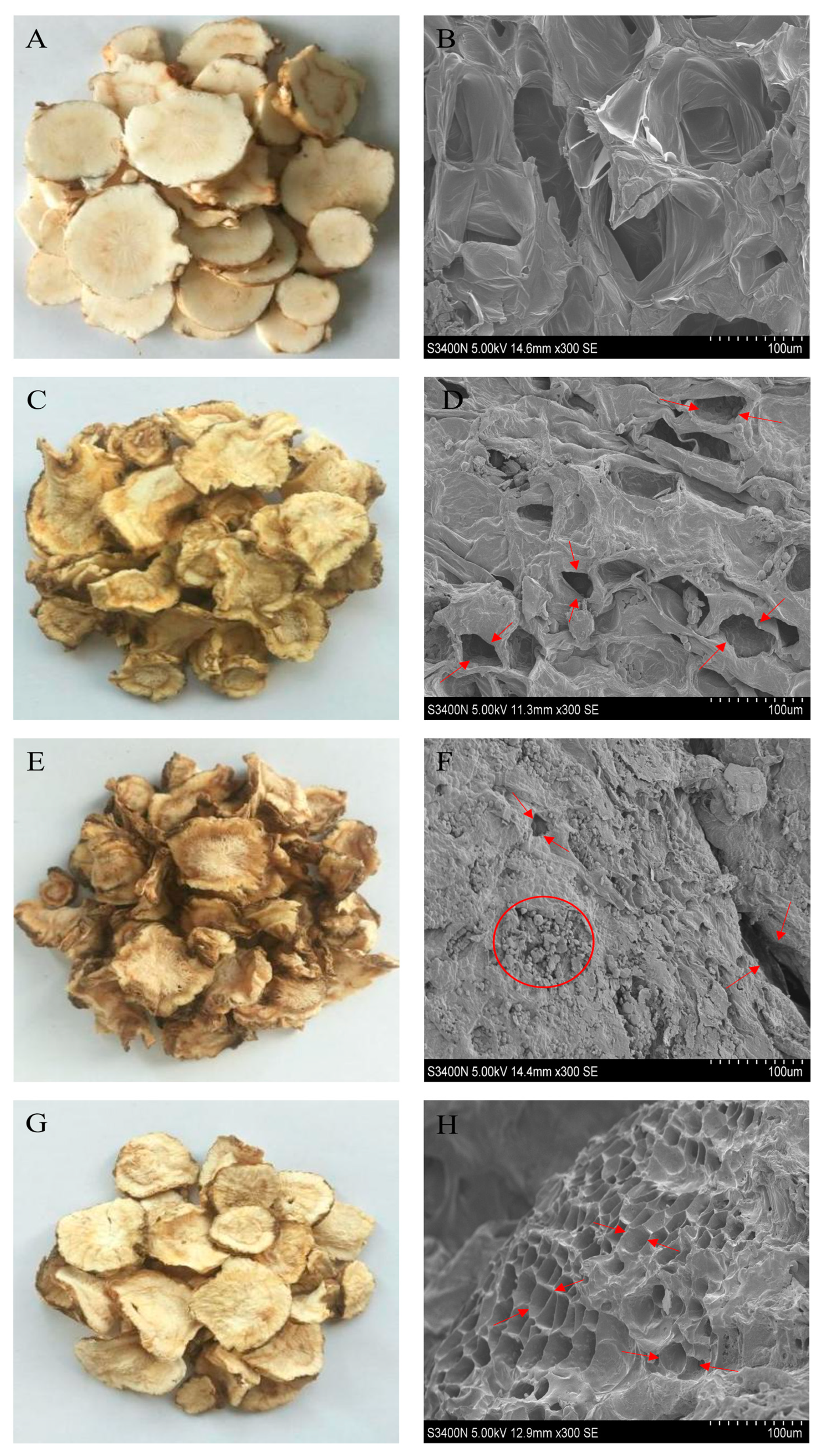

3.5. Microstructure

3.6. PCA Analysis and Pearson’s Correlation Analysis

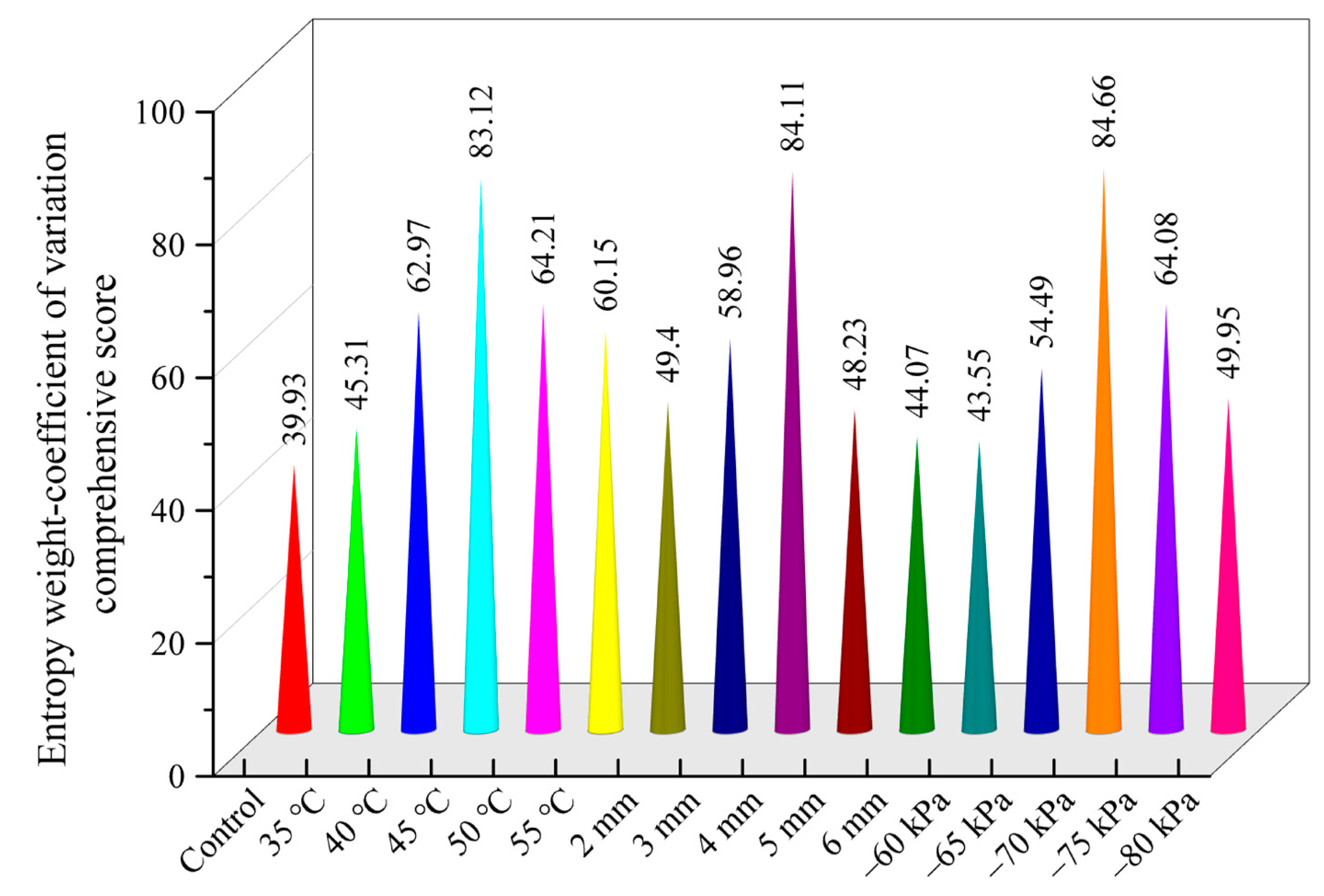

3.7. Entropy Weight-Coefficient of Variance Composite Score

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hou, C.; Yin, M.; Lan, P.; Wang, H.; Nie, H.; Ji, X. Recent progress in the research of Angelica sinensis (Oliv.) Diels polysaccharides: Extraction, purification, structure and bioactivities. Chem. Biol. Technol. Agric. 2021, 8, 13. [Google Scholar] [CrossRef]

- Bi, S.-J.; Fu, R.-J.; Li, J.-J.; Chen, Y.-Y.; Tang, Y.-P. The Bioactivities and Potential Clinical Values of Angelica Sinensis Polysaccharides. Nat. Prod. Commun. 2021, 16, 1934578X21997321. [Google Scholar] [CrossRef]

- Qu, C.; Dong, W. Polysaccharides Extracted from Angelica sinensis (Oliv.) Diels Relieve the Malignant Characteristics of Glioma Cells through Regulating the MiR-373-3p-Mediated TGF-β/Smad4 Signaling Pathway. Evidence-Based Complement. Altern. Med. 2022, 2022, 7469774. [Google Scholar] [CrossRef] [PubMed]

- Khan, I.H.; Wellard, R.M.; Nagy, S.A.; Joardder, M.; Karim, M. Investigation of bound and free water in plant-based food material using NMR T 2 relaxometry. Innov. Food Sci. Emerg. Technol. 2016, 38, 252–261. [Google Scholar] [CrossRef]

- Nistor, O.-V.; Seremet, L.; Andronoiu, D.G.; Rudi, L.; Botez, E. Influence of different drying methods on the physicochemical properties of red beetroot (Beta vulgaris L. var. Cylindra). Food Chem. 2017, 236, 59–67. [Google Scholar] [CrossRef] [PubMed]

- Chua, L.Y.W.; Figiel, A.; Chong, C.H.; Wojdyło, A.; Szumny, A.; Choong, T.S.Y. Antioxidant Activity, and Volatile and Phytosterol Contents of Strobilanthes crispus Dehydrated Using Conventional and Vacuum Microwave Drying Methods. Molecules 2019, 24, 1397. [Google Scholar] [CrossRef]

- Kumar, C.; Karim, M.A. Microwave-convective drying of food materials: A critical review. Crit. Rev. Food Sci. Nutr. 2017, 59, 379–394. [Google Scholar] [CrossRef] [PubMed]

- Macedo, L.L.; Corrêa, J.L.G.; Júnior, I.P.; Araújo, C.D.S.; Vimercati, W.C. Intermittent microwave drying and heated air drying of fresh and isomaltulose (Palatinose) impregnated strawberry. LWT 2021, 155, 112918. [Google Scholar] [CrossRef]

- Kahraman, O.; Malvandi, A.; Vargas, L.; Feng, H. Drying characteristics and quality attributes of apple slices dried by a non-thermal ultrasonic contact drying method. Ultrason. Sonochemistry 2021, 73, 105510. [Google Scholar] [CrossRef]

- Chen, X.; Liu, B.; Chen, Q.; Liu, Y.; Duan, X. Application of combining ozone and UV-C sterilizations in the artificial drying of persimmon fruits. LWT 2020, 134, 110205. [Google Scholar] [CrossRef]

- Babu, A.; Kumaresan, G.; Raj, V.A.A.; Velraj, R. Review of leaf drying: Mechanism and influencing parameters, drying methods, nutrient preservation, and mathematical models. Renew. Sustain. Energy Rev. 2018, 90, 536–556. [Google Scholar] [CrossRef]

- Bassey, E.J.; Cheng, J.-H.; Sun, D.-W. Improving drying kinetics, physicochemical properties and bioactive compounds of red dragon fruit (Hylocereus species) by novel infrared drying. Food Chem. 2021, 375, 131886. [Google Scholar] [CrossRef] [PubMed]

- Jiang, N.; Liu, C.; Li, D.; Zhang, Z.; Liu, C.; Wang, D.; Niu, L.; Zhang, M. Evaluation of freeze drying combined with microwave vacuum drying for functional okra snacks: Antioxidant properties, sensory quality, and energy consumption. LWT 2017, 82, 216–226. [Google Scholar] [CrossRef]

- Krishnan, K.R.; Rayaguru, K.; Nayak, P.K. Ultra-sonicated vacuum drying’s effect on antioxidant activity, TPC, TFC and color of elephant apple slices. Food Biosci. 2020, 36, 100629. [Google Scholar] [CrossRef]

- Bhat, T.A.; Hussain, S.Z.; Wani, S.M.; Rather, M.A.; Reshi, M.; Naseer, B.; Qadri, T.; Khalil, A. The impact of different drying methods on antioxidant activity, polyphenols, vitamin C and rehydration characteristics of Kiwifruit. Food Biosci. 2022, 48, 101821. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, C.; Lei, Y.; Yu, H.; Xi, H.; Duan, X. Contact ultrasound strengthened far-infrared radiation drying on pear slices: Effects on drying characteristics, microstructure, and quality attributes. Dry. Technol. 2019, 37, 745–758. [Google Scholar] [CrossRef]

- Behera, B.; Balasubramanian, P. Experimental and modelling studies of convective and microwave drying kinetics for microalgae. Bioresour. Technol. 2021, 340, 125721. [Google Scholar] [CrossRef] [PubMed]

- Jha, P.; Meghwal, M.; Prabhakar, P.K. Microwave drying of banana blossoms (Musa acuminata): Mathematical modeling and drying energetics. J. Food Process. Preserv. 2021, 45, e15717. [Google Scholar] [CrossRef]

- Zhang, M.; Tang, J.; Mujumdar, A.S.; Wang, S. Trends in microwave-related drying of fruits and vegetables. Trends Food Sci. Technol. 2006, 17, 524–534. [Google Scholar] [CrossRef]

- Çelen, S. Effect of Microwave Drying on the Drying Characteristics, Color, Microstructure, and Thermal Properties of Trabzon Persimmon. Foods 2019, 8, 84. [Google Scholar] [CrossRef] [PubMed]

- Béttega, R.; Rosa, J.G.; Corrêa, R.G.; Freire, J.T. Comparison of carrot (Daucus carota) drying in microwave and in vacuum microwave. Braz. J. Chem. Eng. 2014, 31, 403–412. [Google Scholar] [CrossRef]

- Huang, X.; Li, W.; Wang, Y.; Wan, F. Drying characteristics and quality of Stevia rebaudiana leaves by far-infrared radiation. LWT 2021, 140, 110638. [Google Scholar] [CrossRef]

- Sun, X.; Ohanenye, I.C.; Ahmed, T.; Udenigwe, C.C. Microwave treatment increased protein digestibility of pigeon pea (Cajanus cajan) flour: Elucidation of underlying mechanisms. Food Chem. 2020, 329, 127196. [Google Scholar] [CrossRef]

- Zia, M.P.; Alibas, I. Influence of the drying methods on color, vitamin C, anthocyanin, phenolic compounds, antioxidant activity, and in vitro bioaccessibility of blueberry fruits. Food Biosci. 2021, 42, 101179. [Google Scholar] [CrossRef]

- Kostas, E.T.; Beneroso, D.; Robinson, J.P. The application of microwave heating in bioenergy: A review on the microwave pre-treatment and upgrading technologies for biomass. Renew. Sustain. Energy Rev. 2017, 77, 12–27. [Google Scholar] [CrossRef]

- Li, L.; Ren, X.; Chen, J.; Cao, W.; Ren, G.; Bhandari, B.; Ren, A.; Duan, X. Changes and relationships of viscoelastic and physical properties of Chinese yam during a novel multiphase microwave drying process. LWT 2022, 168, 113969. [Google Scholar] [CrossRef]

- Calín-Sánchez, Á.; Figiel, A.; Lech, K.; Szumny, A.; Carbonell-Barrachina, Á.A. Effects of Drying Methods on the Composition of Thyme (Thymus vulgaris L.) Essential Oil. Dry. Technol. 2013, 31, 224–235. [Google Scholar] [CrossRef]

- González-Cavieres, L.; Pérez-Won, M.; Tabilo-Munizaga, G.; Jara-Quijada, E.; Díaz-Álvarez, R.; Lemus-Mondaca, R. Advances in vacuum microwave drying (VMD) systems for food products. Trends Food Sci. Technol. 2021, 116, 626–638. [Google Scholar] [CrossRef]

- Huang, D.; Men, K.; Tang, X.; Li, W.; Sherif, S. Microwave intermittent drying characteristics of camellia oleifera seeds. J. Food Process Eng. 2020, 44, e13608. [Google Scholar] [CrossRef]

- Ren, X.; Li, L.; Chen, J.; Zhao, L.; Liu, P.; Cao, W.; Ren, A.; Ren, G.; Bhandari, B.; Duan, X. Drying characteristics and quality of Chinese yam by multiphase microwave drying based on fractal theory. Dry. Technol. 2022, 40, 3310–3323. [Google Scholar] [CrossRef]

- Mounir, S.; Amami, E.; Allaf, T.; Mujumdar, A.; Allaf, K. Instant controlled pressure drop (DIC) coupled to intermittent microwave/airflow drying to produce shrimp snacks: Process performance and quality attributes. Dry. Technol. 2019, 38, 695–711. [Google Scholar] [CrossRef]

- Shi, X.; Yang, Y.; Li, Z.; Wang, X.; Liu, Y. Moisture transfer and microstructure change of banana slices during contact ultrasound strengthened far-infrared radiation drying. Innov. Food Sci. Emerg. Technol. 2020, 66, 102537. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, L.; Feng, Y.; Yagoub, A.E.; Sun, Y.; Ma, H.; Zhou, C. Vacuum pulsation drying of okra (Abelmoschus esculentus L. Moench): Better retention of the quality characteristics by flat sweep frequency and pulsed ultrasound pretreatment. Food Chem. 2020, 326, 127026. [Google Scholar] [CrossRef] [PubMed]

- Macedo, L.L.; Corrêa, J.L.G.; Araújo, C.D.S.; Vimercati, W.C.; Pio, L.A.S. Process optimization and ethanol use for obtaining white and red dragon fruit powder by foam mat drying. J. Food Sci. 2021, 86, 426–433. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Han, L.; Yu, Q.-L.; Lin, L. Effect of a sea buckthorn pomace extract-esterified potato starch film on the quality and spoilage bacteria of beef jerky sold in supermarket. Food Chem. 2020, 326, 127001. [Google Scholar] [CrossRef]

- Chao, E.; Tian, J.; Fan, L.; Zhang, T. Drying methods influence the physicochemical and functional properties of seed-used pumpkin. Food Chem. 2021, 369, 130937. [Google Scholar] [CrossRef]

- Jiang, C.; Wan, F.; Zang, Z.; Zhang, Q.; Ma, G.; Huang, X. Effect of an Ultrasound Pre-Treatment on the Characteristics and Quality of Far-Infrared Vacuum Drying with Cistanche Slices. Foods 2022, 11, 866. [Google Scholar] [CrossRef]

- Feng, Y.; Tan, C.P.; Zhou, C.; Yagoub, A.E.A.; Xu, B.; Sun, Y.; Ma, H.; Xu, X.; Yu, X. Effect of freeze-thaw cycles pretreatment on the vacuum freeze-drying process and physicochemical properties of the dried garlic slices. Food Chem. 2020, 324, 126883. [Google Scholar] [CrossRef]

- Xu, Y.; Zang, Z.; Zhang, Q.; Wang, T.; Shang, J.; Huang, X.; Wan, F. Characteristics and Quality Analysis of Radio Frequency-Hot Air Combined Segmented Drying of Wolfberry (Lycium barbarum). Foods 2022, 11, 1645. [Google Scholar] [CrossRef]

- Sharma, H.; Mandil, G.; Monnier, É.; Cor, E.; Zwolinski, P. Sizing a hybrid hydrogen production plant including life cycle assessment indicators by combining NSGA-III and principal component analysis (PCA). Energy Convers. Manag. X 2023, 18, 100361. [Google Scholar] [CrossRef]

- Utrilla-Vázquez, M.; Rodríguez-Campos, J.; Avendaño-Arazate, C.H.; Gschaedler, A.; Lugo-Cervantes, E. Analysis of volatile compounds of five varieties of Maya cocoa during fermentation and drying processes by Venn diagram and PCA. Food Res. Int. 2019, 129, 108834. [Google Scholar] [CrossRef]

- Izli, N.; Polat, A. Effect of convective and microwave methods on drying characteristics, color, rehydration and microstructure properties of ginger. Food Sci. Technol. 2019, 39, 652–659. [Google Scholar] [CrossRef]

- Nguyen, V.T.; Van Vuong, Q.; Bowyer, M.C.; Van Altena, I.A.; Scarlett, C.J. Effects of Different Drying Methods on Bioactive Compound Yield and Antioxidant Capacity of Phyllanthus amarus. Dry. Technol. 2014, 33, 1006–1017. [Google Scholar] [CrossRef]

- Ishibashi, R.; Numata, T.; Tanigawa, H.; Tsuruta, T. In-situ measurements of drying and shrinkage characteristics during microwave vacuum drying of radish and potato. J. Food Eng. 2022, 323, 110988. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Li, X.; Zhu, J.; Wang, X.; Ma, L. Drying characteristics, quality changes, parameters optimization and flavor analysis for microwave vacuum drying of garlic (Allium sativum L.) slices. LWT 2023, 173, 114372. [Google Scholar] [CrossRef]

- Garcia-Noguera, J.; Oliveira, F.I.P.; Weller, C.L.; Rodrigues, S.; Fernandes, F.A.N. Effect of ultrasonic and osmotic dehydration pre-treatments on the colour of freeze dried strawberries. J. Food Sci. Technol. 2012, 51, 2222–2227. [Google Scholar] [CrossRef]

- M’Hiri, N.; Ghali, R.; Ben Nasr, I.; Boudhrioua, N. Effect of different drying processes on functional properties of industrial lemon byproduct. Process Saf. Environ. Prot. 2018, 116, 450–460. [Google Scholar] [CrossRef]

- Song, C.; Wu, T.; Li, Z.; Li, J.; Chen, H. Analysis of the heat transfer characteristics of blackberries during microwave vacuum heating. J. Food Eng. 2018, 223, 70–78. [Google Scholar] [CrossRef]

- Yao, L.; Fan, L.; Duan, Z. Effect of different pretreatments followed by hot-air and far-infrared drying on the bioactive compounds, physicochemical property and microstructure of mango slices. Food Chem. 2020, 305, 125477. [Google Scholar] [CrossRef] [PubMed]

- Zannou, O.; Pashazadeh, H.; Ghellam, M.; Hassan, A.M.A.; Koca, I. Optimization of drying temperature for the assessment of functional and physical characteristics of autumn olive berries. J. Food Process. Preserv. 2021, 45, e15658. [Google Scholar] [CrossRef]

- Zhang, Q.; Wan, F.; Zang, Z.; Jiang, C.; Xu, Y.; Huang, X. Effect of ultrasonic far-infrared synergistic drying on the characteristics and qualities of wolfberry (Lycium barbarum L.). Ultrason. Sonochemistry 2022, 89, 106134. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.; Wang, Y.; Yue, J.; Liu, Z.; Zheng, Y.; Qian, B.; Zhong, Y.; Zhao, Y. Thermal behavior, microstructure and protein quality of squid fillets dried by far-infrared assisted heat pump drying. Food Control 2013, 36, 102–110. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, H.; Xu, J.; Zhuang, W.; Zheng, B.; Lo, Y.M.; Tian, Y. Microwave vacuum drying of lotus (Nelumbo nucifera Gaertn.) seeds: Effects of ultrasonic pretreatment on color, antioxidant activity, and rehydration capacity. LWT 2021, 149, 111603. [Google Scholar] [CrossRef]

- He, X.; Lin, R.; Cheng, S.; Wang, S.; Yuan, L.; Wang, H.; Wang, H.; Tan, M. Effects of microwave vacuum drying on the moisture migration, microstructure, and rehydration of sea cucumber. J. Food Sci. 2021, 86, 2499–2512. [Google Scholar] [CrossRef] [PubMed]

- Boateng, I.D.; Soetanto, D.A.; Yang, X.; Zhou, C.; Saalia, F.K.; Li, F. Effect of pulsed-vacuum, hot-air, infrared, and freeze-drying on drying kinetics, energy efficiency, and physicochemical properties of Ginkgo biloba L. seed. J. Food Process Eng. 2021, 44, e13655. [Google Scholar] [CrossRef]

- Lim, Y.P.; Pang, S.F.; Yusoff, M.M.; Abdul Mudalip, S.K.; Gimbun, J. Correlation between the extraction yield of mangiferin to the antioxidant activity, total phenolic and total flavonoid content of Phaleria macrocarpa fruits. J. Appl. Res. Med. Aromat. Plants 2019, 14, 100224. [Google Scholar] [CrossRef]

- Mouhoubi, K.; Boulekbache-Makhlouf, L.; Mehaba, W.; Himed-Idir, H.; Madani, K. Convective and microwave drying of coriander leaves: Kinetics characteristics and modeling, phenolic contents, antioxidant activity, and principal component analysis. J. Food Process Eng. 2021, 45, e13932. [Google Scholar] [CrossRef]

| Model Name | Mathematical Equation |

|---|---|

| Newton | MR = exp(−kt) |

| Midilli | MR = aexp(−ktn) + b |

| Weibull | MR = exp[−(k/α)β] |

| Handerson and Pabis | MR = aexp(−kt) |

| Logarithmic | MR = aexp(−kt) + b |

| Two-term exponential | MR = aexp(−kt) + (1 − a)exp(−kat) |

| Experiments Number | Drying Conditions | Color | |||

|---|---|---|---|---|---|

| L* | a* | b* | ΔE | ||

| 1 | 35 °C/4 mm/−70 kPa | 69.69 ± 2.59 bcd | 1.77 ± 0.89 e | 19.01 ± 2.12 cd | 12.38 ± 3.46 bc |

| 2 | 40 °C/4 mm/−70 kPa | 74.21 ± 1.08 b | 1.91 ± 0.32 de | 15.38 ± 1.06 e | 6.99 ± 1.64 de |

| 3 | 45 °C/4 mm/−70 kPa | 77.67 ± 0.89 a | 2.84 ± 1.01 bc | 20.10 ± 2.01 c | 6.70 ± 1.98 de |

| 4 | 50 °C/4 mm/−70 kPa | 66.54 ± 2.01 d | 1.97 ± 1.12 de | 19.82 ± 3.12 cd | 15.54 ± 3.41 b |

| 5 | 55 °C/4 mm/−70 kPa | 63.58 ± 1.32 e | 2.28 ± 0.67 d | 21.63 ± 2.32 bc | 18.90 ± 2.43 a |

| 6 | 45 °C/2 mm/−70 kPa | 64.92 ± 2.61 de | 1.81 ± 0.61 e | 22.01 ± 1.11 b | 17.85 ± 1.98 ab |

| 7 | 45 °C/3 mm/−70 kPa | 76.96 ± 1.91 ab | 3.59 ± 1.21 a | 25.21 ± 0.89 a | 11.87 ± 1.79 bc |

| 8 | 45 °C/4 mm/−70 kPa | 77.77 ± 1.77 a | 2.81 ± 1.23 bc | 20.22 ± 1.71 c | 6.79 ± 2.58 de |

| 9 | 45 °C/5 mm/−70 kPa | 71.48 ± 2.09 c | 3.42 ± 0.29 ab | 21.76 ± 0.98 bc | 12.36 ± 1.95 bc |

| 10 | 45 °C/6 mm/−70 kPa | 71.93 ± 2.22 c | 3.10 ± 2.01 b | 19.61 ± 1.21 cd | 10.75 ± 3.01 c |

| 11 | 45 °C/4 mm/−60 kPa | 73.81 ± 1.77 bc | 1.36 ± 0.99 f | 18.96 ± 0.66 d | 8.98 ± 1.44 d |

| 12 | 45 °C/4 mm/−65 kPa | 77.18 ± 3.01 a | 1.65 ± 0.37 ef | 18.62 ± 1.19 d | 6.07 ± 2.05 e |

| 13 | 45 °C/4 mm/−70 kPa | 77.97 ± 1.89 a | 2.86 ± 1.01 bc | 20.04 ± 2.59 c | 6.77 ± 2.01 de |

| 14 | 45 °C/4 mm/−75 kPa | 74.93 ± 2.31 b | 2.96 ± 0.79 bc | 19.62 ± 2.36 cd | 8.50 ± 2.65 d |

| 15 | 45 °C/4 mm/−80 kPa | 74.93 ± 1.95 b | 2.62 ± 0.22 c | 20.75 ± 3.45 c | 8.53 ± 3.21 d |

| Drying Conditions | Organic Acids/(μg/g) | Phthalides/(μg/g) | ||||

|---|---|---|---|---|---|---|

| Chlorogenic Acid | Ferulic Acid | Senkyunolide I | Senkyunolide H | 3-Butenylphthalide | Ligustilide | |

| Control | 216.48 ± 6.77 cde | 849.62 ± 4.47 f | 24.46 ± 4.91 def | 189 ± 3.35 bc | 211.67 ± 4.72 g | 1620.52 ± 8.49 e |

| 35 °C/4 mm/−70 kPa | 132.60 ± 7.29 e | 857.08 ± 5.74 f | 19.41 ± 0.37 f | 153.25 ± 6.49 c | 403.29 ± 4.27 cd | 1847.70 ± 12.01 d |

| 40 °C/4 mm/−70 kPa | 246.84 ± 4.46 d | 888.22 ± 7.47 ef | 49.46 ± 4.57 de | 235.68 ± 2.17 b | 712.55 ± 7.32 a | 2341.44 ± 9.01 b |

| 45 °C/4 mm/−70 kPa | 579.10 ± 6.29 b | 1681.90 ± 5.71 a | 167.07 ± 4.24 a | 281.92 ± 3.59 a | 450.81 ± 7.62 c | 2528.22 ± 8.09 a |

| 50 °C/4 mm/−70 kPa | 860.10 ± 9.24 a | 1633.94 ± 4.38 ab | 69.04 ± 3.11 d | 74.95 ± 2.01 e | 242.39 ± 1.29 ef | 1611.70 ± 13.21 e |

| 55 °C/4 mm/−70 kPa | 457.92 ± 3.99 c | 986.25 ± 5.49 cde | 89.64 ± 2.08 c | 88.44 ± 0.37 de | 346.24 ± 6.21 d | 1806.88 ± 12.01 de |

| 45 °C/2 mm/−70 kPa | 199.49 ± 5.08 de | 949.52 ± 6.99 e | 62.76 ± 1.49 d | 108.25 ± 0.99 d | 228.62 ± 2.04 f | 2016.40 ± 14.22 c |

| 45 °C/3 mm/−70 kPa | 230.79 ± 6.55 d | 1022.86 ± 9.23 de | 118.55 ± 4.66 b | 132.21 ± 4.22 cd | 271.35 ± 7.44 e | 1954.44 ± 6.28 bcd |

| 45 °C/4 mm/−70 kPa | 582.37 ± 8.29 b | 1676.22 ± 9.98 a | 168.73 ± 1.29 a | 278.92 ± 3.59 a | 446.88 ± 5.62 c | 2520.45 ± 10.22 a |

| 45 °C/5 mm/−70 kPa | 330.26 ± 5.11 cd | 1520.40 ± 8.97 b | 16.13 ± 1.29 f | 116.49 ± 2.01 d | 211.95 ± 2.49 g | 1983.60 ± 13.22 cd |

| 45 °C/6 mm/−70 kPa | 347.09 ± 7.63 c | 1255.23 ± 4.59 cd | 14.81 ± 0.42 f | 86.43 ± 3.66 de | 229.56 ± 7.42 f | 1997.91 ± 11.88 cd |

| 45 °C/4 mm/−60 kPa | 359.73 ± 3.66 c | 896.28 ± 3.11 ef | 14.69 ± 3.12 f | 66.38 ± 2.33 e | 324.78 ± 6.72 de | 2166.12 ± 7.01 bc |

| 45 °C/4 mm/−65 kPa | 401.22 ± 4.37 bc | 1158.18 ± 3.99 d | 51.64 ± 0.91 de | 146.28 ± 3.01 cd | 384.86 ± 2.97 cd | 1845.26 ± 15.01 d |

| 45 °C/4 mm/−70 kPa | 588.37 ± 10.01 b | 1671.31 ± 7.68 a | 166.13 ± 1.22 a | 284.32 ± 5.79 a | 449.78 ± 3.42 c | 2516.30 ± 11.47 a |

| 45 °C/4 mm/−75 kPa | 461.13 ± 5.16 c | 1306.10 ± 7.71 c | 32.61 ± 3.10 e | 199.24 ± 6.48 bc | 624.19 ± 4.99 b | 2200.65 ± 13.22 bc |

| 45 °C/4 mm/−80 kPa | 359.35 ± 6.57 c | 1142.94 ± 10.21c | 34.56 ± 1.49 e | 96.93 ± 3.66 cde | 326.28 ± 3.84 de | 2197.82 ± 8.10 bc |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zang, Z.; Huang, X.; He, C.; Zhang, Q.; Jiang, C.; Wan, F. Improving Drying Characteristics and Physicochemical Quality of Angelica sinensis by Novel Tray Rotation Microwave Vacuum Drying. Foods 2023, 12, 1202. https://doi.org/10.3390/foods12061202

Zang Z, Huang X, He C, Zhang Q, Jiang C, Wan F. Improving Drying Characteristics and Physicochemical Quality of Angelica sinensis by Novel Tray Rotation Microwave Vacuum Drying. Foods. 2023; 12(6):1202. https://doi.org/10.3390/foods12061202

Chicago/Turabian StyleZang, Zepeng, Xiaopeng Huang, Cuncai He, Qian Zhang, Chunhui Jiang, and Fangxin Wan. 2023. "Improving Drying Characteristics and Physicochemical Quality of Angelica sinensis by Novel Tray Rotation Microwave Vacuum Drying" Foods 12, no. 6: 1202. https://doi.org/10.3390/foods12061202

APA StyleZang, Z., Huang, X., He, C., Zhang, Q., Jiang, C., & Wan, F. (2023). Improving Drying Characteristics and Physicochemical Quality of Angelica sinensis by Novel Tray Rotation Microwave Vacuum Drying. Foods, 12(6), 1202. https://doi.org/10.3390/foods12061202