Microbial Conjugated Linolenic Acid-Enriched Fermented Milk Using Lipase-Hydrolyzed Flaxseed Oil: Biochemical, Organoleptic and Storage Traits

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Resources

2.2. Milk Fermentation

2.3. Sugars and Organic Acids Analysis

2.4. Acids Titration

2.5. Nutritional Characterization

2.6. Volatile Compounds Analysis

2.7. Sensory Analysis

2.8. Storage Stability Assessment

2.9. Fatty Acids Analysis

2.10. Statistical Analysis

3. Results and Discussion

3.1. Sugars and Organic Acids Composition, Titratable Acidity and pH

3.1.1. Sugars

3.1.2. Organic Acids

3.1.3. Titratable Acidity and pH

3.2. Nutritional Composition

3.3. Volatile Compounds Composition

3.4. Sensory Properties

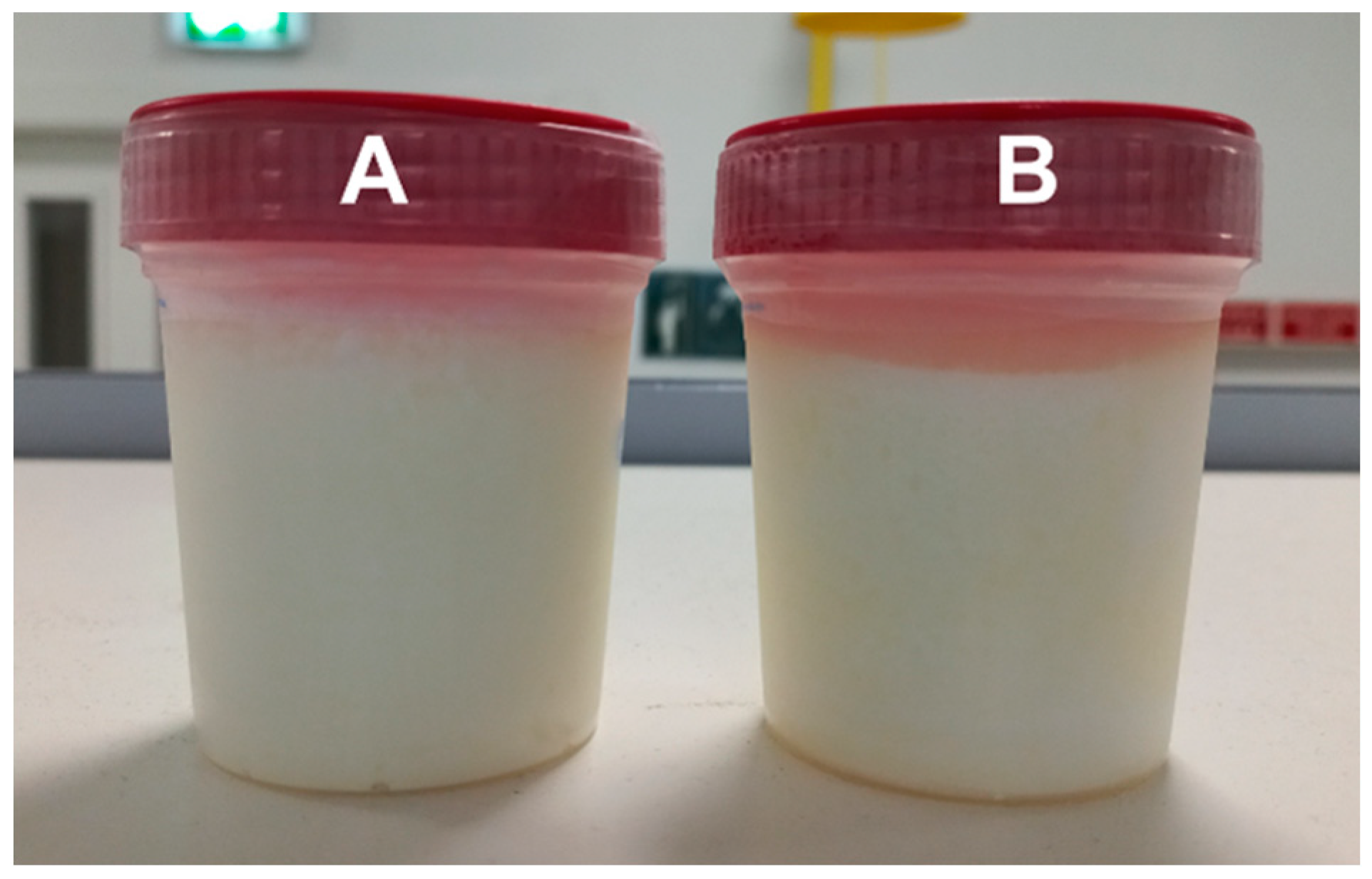

3.5. Stability during Storage

3.5.1. Microbiological Enumeration and pH

3.5.2. Fatty Acid Profile

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Health Organization. Noncommunicable Diseases. Available online: https://www.who.int/news-room/fact-sheets/detail/noncommunicable-diseases (accessed on 24 September 2023).

- Yuan, G. Conjugated Linolenic Acids and Their Bioactivities. In Advances in Dietary Lipids and Human Health; Li, D., Ed.; Academic Press: Cambridge, UK, 2022; pp. 251–271. ISBN 978-0-12-823914-8. [Google Scholar]

- Fontes, A.L.; Pimentel, L.L.; Simões, C.D.; Gomes, A.M.; Rodríguez-Alcalá, L.M. Evidences and Perspectives in the Utilization of CLNA Isomers as Bioactive Compounds in Foods. Crit. Rev. Food Sci. Nutr. 2017, 57, 2611–2622. [Google Scholar] [CrossRef] [PubMed]

- Salsinha, A.S.; Pimentel, L.L.; Fontes, A.L.; Gomes, A.M.; Rodríguez-Alcalá, L.M. Microbial Production of Conjugated Linoleic Acid and Conjugated Linolenic Acid Relies on a Multienzymatic System. Microbiol. Mol. Biol. Rev. 2018, 82, e00019-18. [Google Scholar] [CrossRef] [PubMed]

- Shinohara, N.; Tsuduki, T.; Ito, J.; Honma, T.; Kijima, R.; Sugawara, S.; Arai, T.; Yamasaki, M.; Ikezaki, A.; Yokoyama, M.; et al. Jacaric Acid, a Linolenic Acid Isomer with a Conjugated Triene System, Has a Strong Antitumor Effect in Vitro and in Vivo. Biochim. Biophys. Acta 2012, 1821, 980–988. [Google Scholar] [CrossRef] [PubMed]

- Van Nieuwenhove, C.P.; del Huerto Moyano, A.; Van Nieuwenhove, G.A.; Molina, V.; Luna Pizarro, P. Jacaranda Oil Administration Improves Serum Biomarkers and Bioavailability of Bioactive Conjugated Fatty Acids, and Alters Fatty Acid Profile of Mice Tissues. Lipids 2022, 57, 33–44. [Google Scholar] [CrossRef] [PubMed]

- Saha, S.S.; Ghosh, M. Protective Effect of Conjugated Linolenic Acid Isomers Present in Vegetable Oils against Arsenite-Induced Renal Toxicity in Rat Model. Nutrition 2013, 29, 903–910. [Google Scholar] [CrossRef]

- de Silva, L.O.; Ranquine, L.G.; Monteiro, M.; Torres, A.G. Pomegranate (Punica granatum L.) Seed Oil Enriched with Conjugated Linolenic Acid (CLnA), Phenolic Compounds and Tocopherols: Improved Extraction of a Specialty Oil by Supercritical CO2. J. Supercrit. Fluids 2019, 147, 126–137. [Google Scholar] [CrossRef]

- Gong, M.; Hu, Y.; Wei, W.; Jin, Q.; Wang, X. Production of Conjugated Fatty Acids: A Review of Recent Advances. Biotechnol. Adv. 2019, 37, 107454. [Google Scholar] [CrossRef]

- Yang, B.; Chen, H.; Stanton, C.; Chen, Y.Q.; Zhang, H.; Chen, W. Mining Bifidobacteria from the Neonatal Gastrointestinal Tract for Conjugated Linolenic Acid Production. Bioengineered 2017, 8, 232–238. [Google Scholar] [CrossRef]

- Vahvaselkä, M.; Leskinen, H.; Mäkilä, L.; Kallio, H.; Laakso, S.; Yang, B. Microbial Enrichment of Blackcurrant Press Residue with Conjugated Linoleic and Linolenic Acids. J. Appl. Microbiol. 2021, 130, 1602–1610. [Google Scholar] [CrossRef]

- Mao, B.; Guo, W.; Huang, Z.; Tang, X.; Zhang, Q.; Yang, B.; Zhao, J.; Cui, S.; Zhang, H. Production of Conjugated Fatty Acids in Probiotic-Fermented Walnut Milk with the Addition of Lipase. LWT 2022, 172, 114204. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations Dairy Production and Products: Products. Available online: https://www.fao.org/dairy-production-products/products/en/ (accessed on 24 September 2023).

- Villar-Tajadura, M.A.; Rodríguez-Alcalá, L.M.; Martín, V.; de Segura, A.G.; Rodríguez, J.M.; Requena, T.; Fontecha, J. Production of Conjugated Linoleic and Conjugated Alpha-Linolenic Acid in a Reconstituted Skim Milk-Based Medium by Bifidobacterial Strains Isolated from Human Breast Milk. BioMed Res. Int. 2014, 2014, 6. [Google Scholar] [CrossRef] [PubMed]

- Fontes, A.L.; Pimentel, L.; Rodríguez-Alcalá, L.M.; Gomes, A. Effect of Pufa Substrates on Fatty Acid Profile of Bifidobacterium breve Ncimb 702258 and CLA/CLNA Production in Commercial Semi-Skimmed Milk. Sci. Rep. 2018, 8, 15591. [Google Scholar] [CrossRef] [PubMed]

- Fontes, A.L.; Pimentel, L.L.; Soares, A.M.S.; do Domingues, M.R.; Rodríguez-Alcalá, L.M.; Gomes, A.M. Study of the Viability of Using Lipase-Hydrolyzed Commercial Vegetable Oils to Produce Microbially Conjugated Linolenic Acid-Enriched Milk. Food Chem. 2023, 413, 135665. [Google Scholar] [CrossRef] [PubMed]

- Instituto Português da Qualidade. NP 1923:1987—Iogurte—Determinação Do Teor de Matéria Gorda. Técnica de Gerber. Processo Corrente. Available online: http://www1.ipq.pt/PT/site/clientes/pages/Norma.aspx?docId=IPQDOC-185-76885 (accessed on 24 September 2023).

- Instituto Português da Qualidade. NP 704:1994—Iogurte e Outros Leites Fermentados. Determinação Do Teor de Açúcares Totais. Técnica de Munson e Walker. Available online: http://www1.ipq.pt/PT/site/clientes/pages/Norma.aspx?docId=IPQDOC-185-76856 (accessed on 24 September 2023).

- AOAC. Nitrogen (Total) in Milk: Kjeldahl Method. In Official Methods of Analysis; Helrich, K., Ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1990; pp. 807–808. [Google Scholar]

- Pimentel, L.L.; Fontes, A.L.; Gomes, A.M.; Rodríguez-Alcalá, L.M. Considerations about the in Situ Derivatization and Fractionation of EFA and NEFA in Biological and Food Samples. MethodsX 2015, 2, 475–484. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.S.; Singh, T.; Pandey, A. Microbial Enzymes—An Overview. In Biomass, Biofuels and Biochemicals: Advances in Enzyme Technology; Singh, R.S., Singhania, R.R., Pandey, A., Larroche, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–40. ISBN 978-0-444-64114-4. [Google Scholar]

- Martínez-Villaluenga, C.; Gómez, R. Characterization of Bifidobacteria as Starters in Fermented Milk Containing Raffinose Family of Oligosaccharides from Lupin as Prebiotic. Int. Dairy J. 2007, 17, 116–122. [Google Scholar] [CrossRef]

- Nguyen, T.M.P.; Lee, Y.K.; Zhou, W. Effect of High Intensity Ultrasound on Carbohydrate Metabolism of Bifidobacteria in Milk Fermentation. Food Chem. 2012, 130, 866–874. [Google Scholar] [CrossRef]

- Markowiak-Kopeć, P.; Śliżewska, K. The Effect of Probiotics on the Production of Short-Chain Fatty Acids by Human Intestinal Microbiome. Nutrients 2020, 12, 1107. [Google Scholar] [CrossRef]

- LeBlanc, J.G.; Chain, F.; Martín, R.; Bermúdez-Humarán, L.G.; Courau, S.; Langella, P. Beneficial Effects on Host Energy Metabolism of Short-Chain Fatty Acids and Vitamins Produced by Commensal and Probiotic Bacteria. Microb. Cell Fact. 2017, 16, 79. [Google Scholar] [CrossRef]

- Usta-Gorgun, B.; Yilmaz-Ersan, L. Short-Chain Fatty Acids Production by Bifidobacterium Species in the Presence of Salep. Electron. J. Biotechnol. 2020, 47, 29–35. [Google Scholar] [CrossRef]

- Mani-López, E.; Palou, E.; López-Malo, A. Probiotic Viability and Storage Stability of Yogurts and Fermented Milks Prepared with Several Mixtures of Lactic Acid Bacteria. J. Dairy Sci. 2014, 97, 2578–2590. [Google Scholar] [CrossRef]

- Kim, S.Y.; Hyeonbin, O.; Lee, P.; Kim, Y.S. The Quality Characteristics, Antioxidant Activity, and Sensory Evaluation of Reduced-Fat Yogurt and Nonfat Yogurt Supplemented with Basil Seed Gum as a Fat Substitute. J. Dairy Sci. 2020, 103, 1324–1336. [Google Scholar] [CrossRef] [PubMed]

- Granato, D.; Branco, G.F.; Cruz, A.G.; de Faria, J.A.F.; Shah, N.P. Probiotic Dairy Products as Functional Foods. Compr. Rev. Food Sci. Food Saf. 2010, 9, 455–470. [Google Scholar] [CrossRef] [PubMed]

- De Oliveira, R.P.S.; Perego, P.; de Oliveira, M.N.; Converti, A. Growth, Organic Acids Profile and Sugar Metabolism of Bifidobacterium lactis in Co-Culture with Streptococcus thermophilus: The Inulin Effect. Food Res. Int. 2012, 48, 21–27. [Google Scholar] [CrossRef]

- Šertović, E.; Sarić, Z.; Barać, M.; Barukčić, I.; Kostić, A.; Božanić, R. Physical, Chemical, Microbiological and Sensory Characteristics of a Probiotic Beverage Produced from Different Mixtures of Cow’s Milk and Soy Beverage by Lactobacillus acidophilus La5 and Yoghurt Culture. Food Technol. Biotechnol. 2019, 57, 461–471. [Google Scholar] [CrossRef] [PubMed]

- Instituto Nacional de Saúde Doutor Ricardo Jorge I. P.-INSA. Tabela Da Composição de Alimentos. Available online: https://portfir-insa.min-saude.pt/foodcomp/food?23052 (accessed on 24 September 2023).

- Cheng, H. Volatile Flavor Compounds in Yogurt: A Review. Crit. Rev. Food Sci. Nutr. 2010, 50, 938–950. [Google Scholar] [CrossRef] [PubMed]

- Routray, W.; Mishra, H.N. Scientific and Technical Aspects of Yogurt Aroma and Taste: A Review. Compr. Rev. Food Sci. Food Saf. 2011, 10, 208–220. [Google Scholar] [CrossRef]

- Salazar, N.; Prieto, A.; Leal, J.A.; Mayo, B.; Bada-Gancedo, J.C.; de los Reyes-Gavilán, C.G.; Ruas-Madiedo, P. Production of Exopolysaccharides by Lactobacillus and Bifidobacterium Strains of Human Origin, and Metabolic Activity of the Producing Bacteria in Milk. J. Dairy Sci. 2009, 92, 4158–4168. [Google Scholar] [CrossRef] [PubMed]

- Mituniewicz-Małek, A.; Ziarno, M.; Dmytrów, I.; Balejko, J. Short Communication: Effect of the Addition of Bifidobacterium Monocultures on the Physical, Chemical, and Sensory Characteristics of Fermented Goat Milk. J. Dairy Sci. 2017, 100, 6972–6979. [Google Scholar] [CrossRef]

- Zareba, D.; Ziarno, M.; Obiedzinski, M. Volatile Profile of Non-Fermented Milk and Milk Fermented by Bifidobacterium animalis subsp. lactis. Int. J. Food Prop. 2012, 15, 1010–1021. [Google Scholar] [CrossRef]

- Dan, T.; Wang, D.; Wu, S.; Jin, R.; Ren, W.; Sun, T. Profiles of Volatile Flavor Compounds in Milk Fermented with Different Proportional Combinations of Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophilus. Molecules 2017, 22, 1633. [Google Scholar] [CrossRef]

- Li, S.; Tang, S.; He, Q.; Gong, J.; Hu, J. Physicochemical, Textural and Volatile Characteristics of Fermented Milk Co-Cultured with Streptococcus thermophilus, Bifidobacterium animalis or Lactobacillus plantarum. Int. J. Food Sci. Technol. 2020, 55, 461–474. [Google Scholar] [CrossRef]

- Landaud, S.; Helinck, S.; Bonnarme, P. Formation of Volatile Sulfur Compounds and Metabolism of Methionine and Other Sulfur Compounds in Fermented Food. Appl. Microbiol. Biotechnol. 2008, 77, 1191–1205. [Google Scholar] [CrossRef] [PubMed]

- Sreekumar, R.; Al-Attabi, Z.; Deeth, H.C.; Turner, M.S. Volatile Sulfur Compounds Produced by Probiotic Bacteria in the Presence of Cysteine or Methionine. Lett. Appl. Microbiol. 2009, 48, 777–782. [Google Scholar] [CrossRef] [PubMed]

- Montoya, D.; Boylston, T.D.; Mendonca, A. Preliminary Screening of Bifidobacteria spp. and Pediococcus scidilactici in a Swiss Cheese Curd Slurry Model System: Impact on Microbial Viability and Flavor Characteristics. Int. Dairy J. 2009, 19, 605–611. [Google Scholar] [CrossRef]

- van Gemert, L.J. Odour Thresholds: Compilations of Odour Threshold Values in Air, Water and Other Media, 2nd ed.; Oliemans Punter & Partners: Zeist, The Netherlands, 2003; ISBN 9081089412. 9789081089418. [Google Scholar]

- Ali, B.; Khan, K.Y.; Majeed, H.; Jin, Y.; Xu, D.; Rao, Z.; Xu, X. Impact of Soy–Cow’s Mixed Milk Enzyme Modified Cheese on Bread Aroma. LWT 2022, 154, 112793. [Google Scholar] [CrossRef]

- Prasanna, P.H.P.; Grandison, A.S.; Charalampopoulos, D. Bifidobacteria in Milk Products: An Overview of Physiological and Biochemical Properties, Exopolysaccharide Production, Selection Criteria of Milk Products and Health Benefits. Food Res. Int. 2014, 55, 247–262. [Google Scholar] [CrossRef]

- Odamaki, T.; Xiao, J.Z.; Yonezawa, S.; Yaeshima, T.; Iwatsuki, K. Improved Viability of Bifidobacteria in Fermented Milk by Cocultivation with Lactococcus lactis subspecies lactis. J. Dairy Sci. 2011, 94, 1112–1121. [Google Scholar] [CrossRef]

- Van Nieuwenhove, C.P.; Moyano, A.; Castro-Gómez, P.; Fontecha, J.; Sáez, G.; Zárate, G.; Pizarro, P.L. Comparative Study of Pomegranate and Jacaranda Seeds as Functional Components for the Conjugated Linolenic Acid Enrichment of Yogurt. LWT 2019, 111, 401–407. [Google Scholar] [CrossRef]

- Turek, K.; Wszołek, M. Comparative Study of Walnut and Camelina Sativa Oil as a Functional Components for the Unsaturated Fatty Acids and Conjugated Linoleic Acid Enrichment of Kefir. LWT 2021, 147, 111681. [Google Scholar] [CrossRef]

- Musakhanian, J.; Rodier, J.-D.; Dave, M. Oxidative Stability in Lipid Formulations: A Review of the Mechanisms, Drivers, and Inhibitors of Oxidation. AAPS PharmSciTech 2022, 23, 151. [Google Scholar] [CrossRef]

- Kishino, S.; Ogawa, J.; Yokozeki, K.; Shimizu, S. Metabolic Diversity in Biohydrogenation of Polyunsaturated Fatty Acids by Lactic Acid Bacteria Involving Conjugated Fatty Acid Production. Appl. Microbiol. Biotechnol. 2009, 84, 87–97. [Google Scholar] [CrossRef] [PubMed]

- Oh, D.-K.K.; Hong, G.-H.H.; Lee, Y.; Min, S.; Sin, H.-S.S.; Cho, S.K. Production of Conjugated Linoleic Acid by Isolated Bifidobacterium Strains. World J. Microbiol. Biotechnol. 2003, 19, 907–912. [Google Scholar] [CrossRef]

- Rodríguez-Alcalá, L.M.; Fontecha, J. Hot Topic: Fatty Acid and Conjugated Linoleic Acid (CLA) Isomer Composition of Commercial CLA-Fortified Dairy Products: Evaluation after Processing and Storage. J. Dairy Sci. 2007, 90, 2083–2090. [Google Scholar] [CrossRef] [PubMed]

- Kishino, S.; Takeuchi, M.; Park, S.; Hirata, A.; Kitamura, N.; Kunisawa, J.; Kiyono, H.; Iwamoto, R.; Isobe, Y.; Arita, M.; et al. Polyunsaturated Fatty Acid Saturation by Gut Lactic Acid Bacteria Affecting Host Lipid Composition. Proc. Natl. Acad. Sci. USA 2013, 110, 17808–17813. [Google Scholar] [CrossRef]

| Compound (g/100 g) | Non-Fermented Milk 1,2 | Fermented Milk | |

|---|---|---|---|

| Control 1 | CLNA-Enriched Milk 1,2 | ||

| Sugars | |||

| Lactose | 5.34 ± 0.36 a | 3.35 ± 0.16 b | 3.54 ± 0.18 b |

| Glucose | ND | 1.03 ± 0.04 | 0.89 ± 0.06 |

| Galactose | ND | 1.02 ± 0.04 | 0.88 ± 0.09 |

| Organic acids | |||

| Citric acid | 0.92 ± 0.07 | 0.86 ± 0.06 | 0.84 ± 0.04 |

| Lactic acid | ND | 0.37 ± 0.03 | 0.42 ± 0.01 |

| Formic acid | 0.29 ± 0.05 | 0.25 ± 0.05 | 0.26 ± 0.03 |

| Acetic acid | ND | 0.40 ± 0.03 | 0.44 ± 0.03 |

| Propionic acid | ND | 0.88 ± 0.03 | 0.85 ± 0.04 |

| Titratable acidity (%) | 0.13 ± 0.01 c | 0.50 ± 0.01 b | 0.69 ± 0.01 a |

| pH | 6.79 ± 0.01 b | 5.10 ± 0.01 a | 4.93 ± 0.04 a |

| Parameter (g/100 g) | Control 1 | CLNA-Enriched Milk 1,2 |

|---|---|---|

| Fat | 1.70 ± <0.01 b | 2.00 ± <0.01 a |

| Carbohydrates | 4.70 ± 0.01 | 4.60 ± 0.01 |

| of which Sugars | 3.11 ± 0.01 | 2.95 ± 0.01 |

| Protein | 3.23 ± 0.01 | 3.06 ± 0.12 |

| Dry residue | 10.30 ± 0.01 | 10.42 ± 0.05 |

| Ash | 0.70 ± 0.01 | 0.66 ± 0.01 |

| Compound (Relative Area %) 2 | Control 1,2 | CLNA-Enriched Milk 1,2 |

|---|---|---|

| Acetone | 1.22 ± 0.09 a | 0.81 ± 0.05 b |

| 2-Butanone | 1.02 ± 0.16 a | 0.58 ± 0.08 b |

| Diacetyl | 0.78 ± 0.07 | 0.68 ± 0.16 |

| 2-Heptanone | 0.74 ± 0.29 | 0.63 ± 0.12 |

| 3-Octanone | 3.97 ± 0.88 a | 2.40 ± 0.10 b |

| Acetoin | 1.11 ± 0.13 | 0.95 ± 0.16 |

| 2-Nonanone | 0.18 ± 0.02 | ND |

| Σ Ketones | 9.02 ± 1.42 a | 6.05 ± 0.67 b |

| Decane | 0.16 ± 0.04 b | 0.39 ± 0.04 a |

| Undecane | 0.15 ± 0.01 | 0.12 ± 0.03 |

| Dodecane | ND | 0.53 ± 0.19 |

| Σ Hydrocarbons | 0.31 ± 0.11 b | 1.04 ± 0.26 a |

| 2-Heptanol | 0.17 ± 0.04 | 0.14 ± 0.04 |

| 1-Hexanol | 0.29 ± 0.04 b | 0.71 ± 0.01 a |

| 2-Ethyl-1-hexanol | 0.18 ± 0.03 | ND |

| Σ Alcohols | 0.64 ± 0.11 | 0.85 ± 0.03 |

| Methyl hexanoate | ND | 0.53 ± 0.12 |

| Acetic acid | 83.02 ± 2.32 | 83.32 ± 0.77 |

| Butyric acid | 0.98 ± 0.04 | 0.85 ± 0.01 |

| Hexanoic acid | 1.79 ± 0.09 a | 1.26 ± 0.16 b |

| Octanoic acid | 0.78 ± 0.06 a | 0.35 ± 0.02 b |

| Σ Carboxylic acids and esters | 86.57 ± 2.25 | 86.31 ± 1.06 |

| Methyl thiolacetate | 0.17 ± 0.03 | ND |

| Dihydro-2-methyl-3(2H)-thiophenone | 2.13 ± 0.35 | 2.55 ± 0.20 |

| Dimethyl sulfone | 0.09 ± 0.01 | 0.06 ± 0.01 |

| Σ Sulfur compounds | 2.38 ± 0.39 | 2.61 ± 0.18 |

| Σ Unk | 1.09 ± 0.21 b | 3.14 ± 0.34 a |

| FA (mg/g) 2 | Control 1,2 | CLNA-Enriched Milk 1,2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T0d | T7d | T14d | T21d | T28d | T0d | T7d | T14d | T21d | T28d | |

| C4 | 0.018 ± 0.002 | 0.015 ± <0.001 | 0.017 ± 0.001 | 0.013 ± 0.001 | 0.015 ± 0.002 | 0.013 ± 0.001 | 0.015 ± 0.001 | 0.016 ± 0.001 | 0.014 ± 0.002 | 0.012 ± 0.002 |

| C6 | 0.016 ± 0.002 | 0.012 ± 0.001 | 0.015 ± <0.001 | 0.010 ± 0.001 | 0.013 ± 0.002 | 0.010 ± 0.001 | 0.013 ± <0.001 | 0.013 ± 0.001 | 0.011 ± 0.001 | 0.010 ± 0.001 |

| C8 | 0.015 ± 0.002 | 0.010 ± 0.001 | 0.014 ± <0.001 | 0.008 ± 0.001 | 0.011 ± 0.003 | 0.009 ± 0.001 | 0.011 ± <0.001 | 0.012 ± 0.002 | 0.009 ± 0.001 | 0.008 ± 0.001 |

| C10 | 0.039 ± 0.004 | 0.029 ± <0.001 | 0.038 ± 0.001 | 0.024 ± 0.001 | 0.031 ± 0.008 | 0.023 ± 0.002 | 0.031 ± 0.001 | 0.031 ± 0.003 | 0.024 ± 0.001 | 0.023 ± 0.003 |

| C12 | 0.048 ± 0.006 | 0.037 ± <0.001 | 0.047 ± 0.001 | 0.031 ± 0.002 | 0.038 ± 0.009 | 0.030 ± 0.001 | 0.040 ± 0.001 | 0.041 ± 0.003 | 0.032 ± 0.001 | 0.030 ± 0.004 |

| C14 | 0.131 ± 0.015 a | 0.102 ± 0.002 b | 0.128 ± 0.004 a | 0.091 ± 0.005 b | 0.106 ± 0.025 ab | 0.080 ± 0.001 b | 0.109 ± 0.002 a | 0.108 ± 0.008 a | 0.090 ± 0.006 ab | 0.082 ± 0.010 ab |

| C14:1 c9 | 0.017 ± 0.001 | 0.015 ± <0.001 | 0.016 ± 0.001 | 0.012 ± 0.001 | 0.012 ± 0.002 | 0.012 ± <0.001 | 0.015 ± 0.001 | 0.014 ± 0.001 | 0.012 ± <0.001 | 0.010 ± 0.001 |

| C15 | 0.013 ± 0.002 | 0.010 ± <0.001 | 0.013 ± 0.001 | 0.009 ± 0.001 | 0.010 ± 0.002 | 0.008 ± <0.001 | 0.011 ± <0.001 | 0.011 ± 0.001 | 0.010 ± 0.001 | 0.009 ± 0.001 |

| C16 | 0.340 ± 0.049 a | 0.263 ± 0.001 b | 0.325 ± 0.010 a | 0.250 ± 0.014 b | 0.275 ± 0.064 ab | 0.373 ± 0.008 c | 0.496 ± 0.020 a | 0.482 ± 0.028 a | 0.441 ± 0.032 ab | 0.401 ± 0.023 bc |

| C16:1 c9 | 0.020 ± 0.003 | 0.015 ± <0.001 | 0.018 ± <0.001 | 0.015 ± 0.001 | 0.017 ± 0.003 | 0.013 ± <0.001 | 0.019 ± 0.001 | 0.018 ± 0.001 | 0.016 ± 0.001 | 0.015 ± 0.001 |

| C17 | 0.005 ± 0.001 | 0.004 ± <0.001 | 0.005 ± <0.001 | 0.004 ± <0.001 | 0.004 ± 0.001 | 0.005 ± <0.001 | 0.006 ± <0.001 | 0.006 ± <0.001 | 0.006 ± 0.001 | 0.005 ± <0.001 |

| C18 | 0.104 ± 0.018 | 0.082 ± 0.001 | 0.095 ± 0.004 | 0.075 ± 0.006 | 0.073 ± 0.018 | 0.334 ± 0.008 b | 0.410 ± 0.034 a | 0.327 ± 0.011 b | 0.275 ± 0.012 c | 0.213 ± 0.001 d |

| C18:1 c9 | 0.160 ± 0.025 a | 0.115 ± 0.003 b | 0.149 ± <0.001 a | 0.125 ± 0.006 ab | 0.142 ± 0.033 ab | 0.658 ± 0.029 b | 0.821 ± 0.062 a | 0.810 ± 0.043 a | 0.776 ± 0.009 a | 0.765 ± 0.007 a |

| C18:2 c9c12 (LA) | 0.025 ± 0.002 | 0.017 ± 0.001 | 0.022 ± <0.001 | 0.020 ± 0.001 | 0.025 ± 0.005 | 0.333 ± 0.002 b | 0.402 ± 0.034 a | 0.371 ± 0.031 ab | 0.396 ± 0.008 a | 0.389 ± 0.023 a |

| C18:3 c9c12c15 (α-LNA) | 0.003 ± <0.001 | 0.002 ± <0.001 | 0.002 ± <0.001 | 0.002 ± <0.001 | 0.003 ± <0.001 | 0.308 ± 0.030 | 0.379 ± 0.044 | 0.307 ± 0.065 | 0.366 ± 0.024 | 0.345 ± 0.015 |

| C18:2 c9t11 (CLA) | 0.002 ± <0.001 | 0.002 ± <0.001 | 0.002 ± <0.001 | 0.002 ± <0.001 | 0.002 ± <0.001 | 0.089 ± 0.021 | 0.103 ± 0.003 | 0.112 ± 0.009 | 0.108 ± 0.001 | 0.139 ± 0.024 |

| C18:2 CLA t,t | ND | ND | ND | ND | ND | 0.018 ± 0.004 | 0.022 ± 0.002 | 0.023 ± 0.002 | 0.023 ± 0.001 | 0.027 ± 0.003 |

| C18:3 c9t11c15 (CLNA) | ND | ND | ND | ND | ND | 0.652 ± 0.081 c | 0.736 ± 0.018 c | 0.756 ± 0.044 bc | 0.775 ± 0.002 b | 0.929 ± 0.013 a |

| C18:3 t9t11c15 (CLNA) | ND | ND | ND | ND | ND | 0.116 ± 0.016 c | 0.137 ± 0.013 bc | 0.137 ± 0.010 bc | 0.155 ± 0.004 ab | 0.171 ± 0.008 a |

| SFA | 0.728 ± 0.101 a | 0.565 ± 0.002 b | 0.697 ± 0.020 a | 0.517 ± 0.031 b | 0.576 ± 0.132 ab | 0.884 ± 0.023 b | 1.143 ± 0.057 a | 1.047 ± 0.058 a | 0.913 ± 0.059 b | 0.792 ± 0.045 c |

| MUFA | 0.197 ± 0.029 a | 0.145 ± 0.003 b | 0.183 ± 0.001 a | 0.152 ± 0.007 ab | 0.171 ± 0.039 ab | 0.683 ± 0.029 b | 0.854 ± 0.064 a | 0.843 ± 0.045 a | 0.804 ± 0.010 a | 0.791 ± 0.005 a |

| PUFA | 0.030 ± 0.003 | 0.021 ± 0.001 | 0.026 ± <0.001 | 0.023 ± 0.001 | 0.030 ± 0.006 | 1.516 ± 0.090 c | 1.778 ± 0.113 b | 1.707 ± 0.119 bc | 1.823 ± 0.037 b | 1.999 ± 0.023 a |

| Σ FA | 0.955 ± 0.133 a | 0.731 ± 0.002 b | 0.906 ± 0.020 a | 0.692 ± 0.039 b | 0.777 ± 0.177 ab | 3.083 ± 0.142 b | 3.776 ± 0.234 a | 3.597 ± 0.219 a | 3.540 ± 0.032 a | 3.589 ± 0.017 a |

| FA (mg/g) 2 | Control 1,2 | CLNA-Enriched Milk 1,2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| T0d | T7d | T14d | T21d | T28d | T0d | T7d | T14d | T21d | T28d | |

| C4 | 0.213 ± <0.001 | 0.202 ± 0.010 | 0.197 ± 0.017 | 0.204 ± 0.033 | 0.210 ± 0.002 | 0.192 ± 0.007 ab | 0.217 ± 0.009 a | 0.175 ± 0.003 b | 0.215 ± 0.025 a | 0.200 ± 0.006 a |

| C6 | 0.180 ± 0.006 | 0.159 ± 0.014 | 0.163 ± 0.002 | 0.168 ± 0.019 | 0.165 ± 0.006 | 0.161 ± 0.011 abc | 0.182 ± 0.013 a | 0.144 ± 0.001 c | 0.177 ± 0.022 ab | 0.158 ± <0.001 bc |

| C8 | 0.113 ± 0.010 a | 0.103 ± 0.007 ab | 0.088 ± 0.001 b | 0.105 ± 0.013 ab | 0.101 ± 0.001 ab | 0.096 ± 0.007 | 0.112 ± 0.010 | 0.083 ± 0.010 | 0.106 ± 0.011 | 0.102 ± 0.003 |

| C10 | 0.362 ± 0.013 | 0.309 ± 0.034 | 0.337 ± 0.010 | 0.326 ± 0.042 | 0.339 ± 0.001 | 0.304 ± 0.008 | 0.329 ± 0.014 | 0.301 ± 0.013 | 0.342 ± 0.036 | 0.317 ± 0.007 |

| C12 | 0.459 ± 0.013 | 0.404 ± 0.037 | 0.419 ± 0.011 | 0.409 ± 0.046 | 0.419 ± 0.001 | 0.396 ± 0.009 b | 0.439 ± 0.024 a | 0.374 ± 0.018 b | 0.426 ± 0.049 ab | 0.401 ± 0.003 b |

| C14 | 1.447 ± 0.045 | 1.275 ± 0.109 | 1.307 ± 0.034 | 1.255 ± 0.146 | 1.302 ± 0.001 | 1.257 ± 0.021 b | 1.376 ± 0.074 a | 1.168 ± 0.044 b | 1.314 ± 0.152 ab | 1.239 ± 0.001 b |

| C14:1 c9 | 0.132 ± 0.006 | 0.120 ± 0.009 | 0.125 ± 0.007 | 0.120 ± 0.015 | 0.127 ± 0.002 | 0.118 ± 0.001 | 0.125 ± 0.007 | 0.109 ± 0.004 | 0.127 ± 0.016 | 0.118 ± <0.001 |

| C15 | 0.149 ± 0.002 | 0.130 ± 0.011 | 0.135 ± 0.003 | 0.128 ± 0.015 | 0.131 ± 0.001 | 0.130 ± 0.004 | 0.140 ± 0.010 | 0.120 ± 0.004 | 0.134 ± 0.015 | 0.125 ± 0.001 |

| C16 | 4.145 ± 0.133 a | 3.623 ± 0.329 b | 3.743 ± 0.111 b | 3.562 ± 0.417 b | 3.694 ± 0.018 b | 3.632 ± 0.053 ab | 3.925 ± 0.203 a | 3.343 ± 0.118 b | 3.743 ± 0.437 ab | 3.531 ± 0.025 b |

| C16:1 c9 | 0.200 ± 0.004 | 0.173 ± 0.015 | 0.188 ± 0.012 | 0.183 ± 0.020 | 0.201 ± 0.006 | 0.183 ± 0.024 | 0.184 ± 0.013 | 0.164 ± 0.009 | 0.196 ± 0.021 | 0.187 ± 0.004 |

| C17 | 0.064 ± 0.003 | 0.055 ± 0.006 | 0.057 ± 0.003 | 0.052 ± 0.006 | 0.056 ± 0.002 | 0.057 ± <0.001 | 0.060 ± 0.003 | 0.051 ± 0.001 | 0.055 ± 0.005 | 0.054 ± <0.001 |

| C18 | 1.329 ± 0.043 a | 1.170 ± 0.118 ab | 1.135 ± 0.044 b | 1.051 ± 0.125 bc | 0.995 ± 0.002 c | 1.208 ± 0.018 a | 1.290 ± 0.058 a | 1.035 ± 0.030 b | 1.100 ± 0.128 ab | 0.956 ± 0.022 b |

| C18:1 c9 | 1.970 ± 0.076 | 1.712 ± 0.179 | 1.840 ± 0.060 | 1.806 ± 0.187 | 1.936 ± 0.014 | 1.873 ± 0.025 | 1.995 ± 0.103 | 1.766 ± 0.081 | 2.027 ± 0.249 | 1.999 ± 0.020 |

| C18:2 c9c12 (LA) | 0.268 ± 0.010 ab | 0.226 ± 0.024 b | 0.246 ± 0.008 b | 0.252 ± 0.019 b | 0.288 ± 0.004 a | 0.258 ± 0.002 b | 0.269 ± 0.011 b | 0.245 ± 0.009 b | 0.289 ± 0.037 ab | 0.299 ± 0.006 a |

| C18:3 c9c12c15 (α-LNA) | 0.029 ± 0.001 | 0.025 ± 0.004 | 0.027 ± 0.001 | 0.025 ± 0.004 | 0.032 ± 0.001 | 0.107 ± 0.003 a | 0.091 ± 0.004 ab | 0.079 ± 0.009 b | 0.093 ± 0.020 ab | 0.105 ± 0.005 a |

| C18:2 c9t11 (CLA) | 0.027 ± 0.003 | 0.023 ± 0.002 | 0.025 ± 0.004 | 0.027 ± 0.002 | 0.035 ± 0.001 | 0.028 ± 0.002 | 0.026 ± 0.001 | 0.027 ± 0.001 | 0.032 ± 0.003 | 0.037 ± 0.001 |

| SFA | 8.461 ± 0.266 a | 7.430 ± 0.672 b | 7.582 ± 0.223 b | 7.260 ± 0.863 b | 7.412 ± 0.016 b | 7.433 ± 0.121 b | 8.070 ± 0.418 a | 6.795 ± 0.242 b | 7.612 ± 0.876 ab | 7.082 ± 0.068 b |

| MUFA | 2.302 ± 0.084 a | 2.004 ± 0.202 b | 2.153 ± 0.079 ab | 2.109 ± 0.223 ab | 2.264 ± 0.021 a | 2.175 ± 0.048 | 2.304 ± 0.123 | 2.040 ± 0.093 | 2.351 ± 0.286 | 2.305 ± 0.016 |

| PUFA | 0.324 ± 0.013 ab | 0.274 ± 0.030 b | 0.298 ± 0.013 b | 0.304 ± 0.025 b | 0.355 ± 0.006 a | 0.394 ± 0.004 b | 0.387 ± 0.016 b | 0.350 ± 0.020 b | 0.414 ± 0.058 ab | 0.440 ± 0.002 a |

| Σ FA | 11.086 ± 0.363 | 9.708 ± 0.904 | 10.033 ± 0.315 | 9.673 ± 1.110 | 10.031 ± 0.031 | 10.002 ± 0.173 b | 10.761 ± 0.557 a | 9.184 ± 0.355 b | 10.377 ± 1.217 ab | 9.826 ± 0.086 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fontes, A.L.; Pimentel, L.L.; Monteiro, M.J.P.; Domingues, M.R.; Rodríguez-Alcalá, L.M.; Gomes, A.M. Microbial Conjugated Linolenic Acid-Enriched Fermented Milk Using Lipase-Hydrolyzed Flaxseed Oil: Biochemical, Organoleptic and Storage Traits. Foods 2024, 13, 21. https://doi.org/10.3390/foods13010021

Fontes AL, Pimentel LL, Monteiro MJP, Domingues MR, Rodríguez-Alcalá LM, Gomes AM. Microbial Conjugated Linolenic Acid-Enriched Fermented Milk Using Lipase-Hydrolyzed Flaxseed Oil: Biochemical, Organoleptic and Storage Traits. Foods. 2024; 13(1):21. https://doi.org/10.3390/foods13010021

Chicago/Turabian StyleFontes, Ana Luiza, Lígia L. Pimentel, Maria João P. Monteiro, M. Rosário Domingues, Luis Miguel Rodríguez-Alcalá, and Ana Maria Gomes. 2024. "Microbial Conjugated Linolenic Acid-Enriched Fermented Milk Using Lipase-Hydrolyzed Flaxseed Oil: Biochemical, Organoleptic and Storage Traits" Foods 13, no. 1: 21. https://doi.org/10.3390/foods13010021

APA StyleFontes, A. L., Pimentel, L. L., Monteiro, M. J. P., Domingues, M. R., Rodríguez-Alcalá, L. M., & Gomes, A. M. (2024). Microbial Conjugated Linolenic Acid-Enriched Fermented Milk Using Lipase-Hydrolyzed Flaxseed Oil: Biochemical, Organoleptic and Storage Traits. Foods, 13(1), 21. https://doi.org/10.3390/foods13010021