Characterization of Băbească Neagră Grape Pomace and Incorporation into Jelly Candy: Evaluation of Phytochemical, Sensory, and Textural Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Material and Jelly Candy Preparation

- Aqueous extract (w/v): 1 g of grape pomace with each particle size was mixed with 30 mL of water; the samples were homogenized with an Ultra-Turrax Homogenizer (Daigger Scientific Inc., Vernon Hills, IL, USA) for 5 min and heated for 1 h at 70 °C in a water bath Precisdig (J.P. Selecta, Barcelona, Spain). At the end of the treatment, the samples were centrifuged for 10 min at 5000 rpm; the supernatant was filtered and used for jelly candy formulation.

- Gelatin hydration (w/v): 7, 8.5, and 10 g of gelatin (to make 100 g of jelly) were hydrated with water for 10 min at 40 °C.

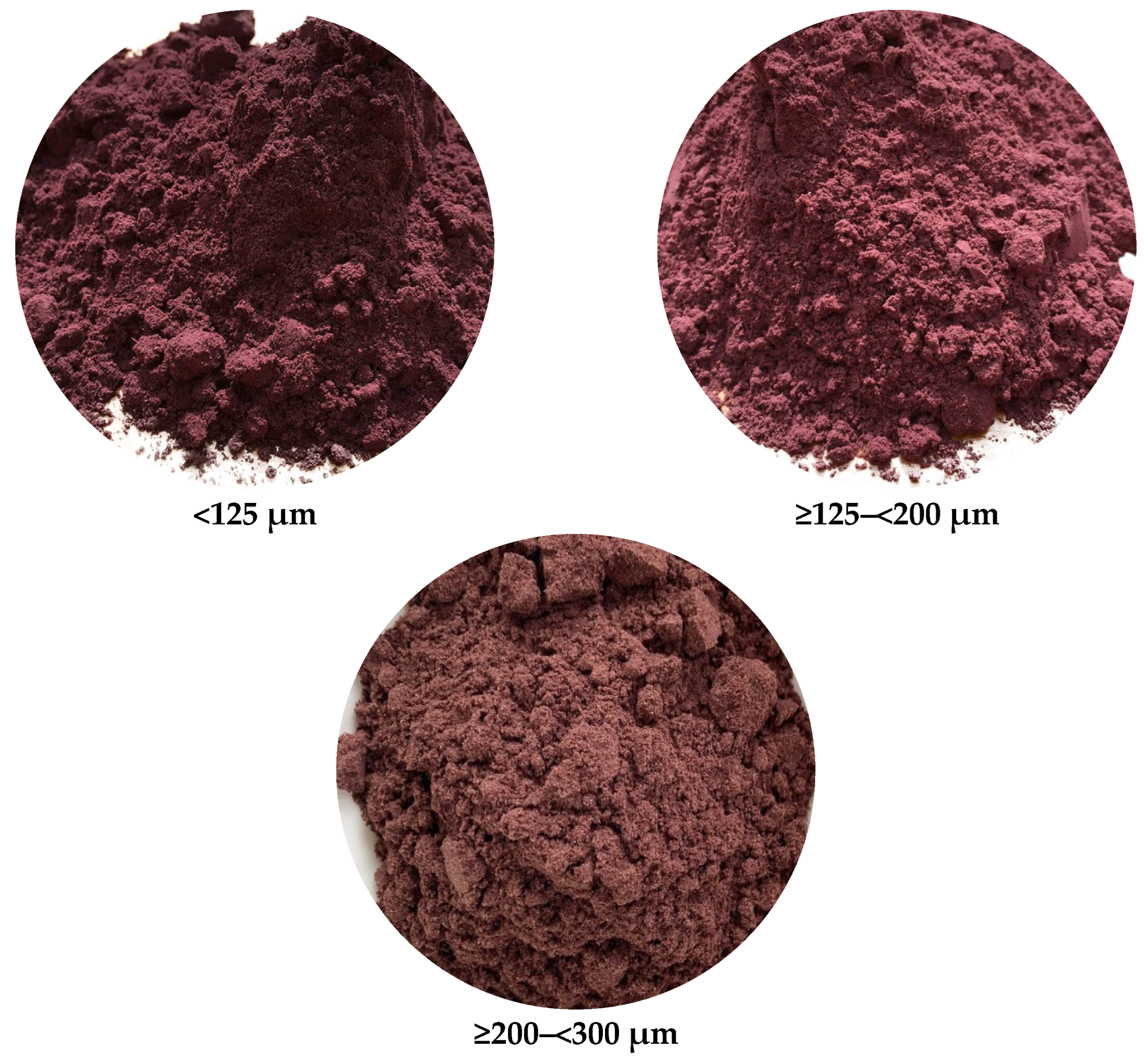

- Heat treatment and homogenization (v/v): the final mixture consisted of 12.5 g sweetener (stevia) and 210 mL of grape pomace extract for the products with 7, 8.5, and 10 g of gelatin, respectively (to make 100 g of jelly). These blends were heated for 5 min at 55 °C in a Thermomix device (Vorwerk, Wuppertal, Germany). Finally, the different formulations were established (F1–7, F1–8.5, F1–10, F2–7, F2–8.5, F2–10, F3–7, F3–8.5, and F3–10; F1—grape pomace extract with the particle size of <125 μm; F2—grape pomace extract with the particle size of ≥125–<200 μm; F3—grape pomace extract with the particle size of ≥200–<300 μm; 7—7 g of gelatin; 8.5—8.5 g of gelatin; 10—10 g of gelatin). The molding and maturation stages were performed at 5 °C for 24 h.

2.2. Methods

2.2.1. Characterization of Grape Pomace and Grape Pomace Aqueous Extract

2.2.2. Functional Properties of Grape Pomace

2.2.3. Color of Grape Pomace and Jelly Candy

2.2.4. Phytochemical Characterization of Grape Pomace Extract

Extract Preparation

Bioactive Compounds and Antioxidant Activity of Grape Pomace Extract

2.2.5. FT-IR Analysis of Grape Pomace

2.2.6. SEM Analysis of Grape Pomace

2.2.7. Total Phenolic Content and Antioxidant Activity of Jelly Candy

2.2.8. Textural Profile of Jelly Candy

2.2.9. Sensorial Analysis of Jelly Candy

2.2.10. Microbiological Analysis of Jelly Candy

2.3. Statistical Analysis

3. Results and Discussion

3.1. Influence of the Particle Size on the Proximate Composition of Grape Pomace

3.2. Influence of the Particle Size on the Functional Properties of Grape Pomace

3.3. Influence of the Particle Size on the Color of Grape Pomace

3.4. Phytochemical Characterization of Grape Pomace Extract

3.5. FT-IR Spectra of Grape Pomace

3.6. Microstructural Analysis by SEM

3.7. Phytochemical Parameters and Proximate Composition of Grape Pomace Aqueous Extract

3.8. Physicochemical Parameters of Jelly Candy

3.9. Textural Parameters of Jelly Candy

3.10. Sensorial Analysis of Jelly Candy

3.11. Microbiological Analysis

3.12. Principal Component Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Spinei, M.; Oroian, M. The Potential of Grape Pomace Varieties as a Dietary Source of Pectic Substances. Foods 2021, 10, 867. [Google Scholar] [CrossRef] [PubMed]

- Kokkinomagoulos, E.; Kandylis, P. Grape Pomace, an Undervalued By-Product: Industrial Reutilization within a Circular Economy Vision. Rev. Environ. Sci. Bio/Technol. 2023, 22, 739–773. [Google Scholar] [CrossRef]

- Markus, K. The Science of Grapevines; Elsevier: Amsterdam, The Netherlands, 2020; ISBN 9780128163658. [Google Scholar]

- Castellanos-Gallo, L.; Ballinas-Casarrubias, L.; Espinoza-Hicks, J.C.; Hernández-Ochoa, L.R.; Muñoz-Castellanos, L.N.; Zermeño-Ortega, M.R.; Borrego-Loya, A.; Salas, E. Grape Pomace Valorization by Extraction of Phenolic Polymeric Pigments: A Review. Processes 2022, 10, 469. [Google Scholar] [CrossRef]

- Pisciotta, A.; Barone, E.; Di Lorenzo, R. Table-Grape Cultivation in Soil-Less Systems: A Review. Horticulturae 2022, 8, 553. [Google Scholar] [CrossRef]

- Alston, J.M.; Sambucci, O. Grapes in the World Economy. In The Grape Genome; Springer: Cham, Switzerland, 2019; pp. 1–24. [Google Scholar]

- OIV. State of the World Vine and Wine Sector in 2022; OIV: Paris, France, 2022. [Google Scholar]

- OIV. Managing By-Products of Vitivinicultural Origin; OIV: Paris, France, 2018. [Google Scholar]

- Antonić, B.; Jančíková, S.; Dordević, D.; Tremlová, B. Grape Pomace Valorization: A Systematic Review and Meta-Analysis. Foods 2020, 9, 1627. [Google Scholar] [CrossRef] [PubMed]

- Rashad, M.; Mahgoub, R.; Abedelmaksoud, T.G. Functional Strawberry and Red Beetroot Jelly Candies Rich in Fibers and Phenolic Compounds. Food Syst. 2021, 4, 82–88. [Google Scholar]

- Nicolescu, C.M.; Bumbac, M.; Radulescu, C.; Buruleanu, L.C.; Olteanu, R.L.; Gorghiu, L.M.; Teodorescu, G.; Holban, C.G. Romanian Organic and Conventional Red Grapes Vineyards as Potential Sources of High Value-Added Products, in a Circular Economy Approach. In Grapes and Wine; IntechOpen: London, UK, 2022; ISBN 978-1-83969-642-8. [Google Scholar]

- Indreaş, A.; Vişan, L. Principalele Soiuri de Struguri de Vin Cultivate În România; Ceres: Bucharest, Romania, 2001. [Google Scholar]

- MARD Operational Data Portal of Ministry of Agriculture and Rural Development, Romania. Available online: https://www.madr.ro/horticultura/viticultura-vinificatie.html (accessed on 20 October 2023).

- Capanoglu, E.; Tomás-Barberán, F.A. Introduction to Novel Approaches in the Valorization of Agricultural Wastes and Their Applications. J. Agric. Food Chem. 2022, 70, 6785–6786. [Google Scholar] [CrossRef]

- Altınok, E.; Palabiyik, I.; Gunes, R.; Toker, O.S.; Konar, N.; Kurultay, S. Valorisation of Grape By-Products as a Bulking Agent in Soft Candies: Effect of Particle Size. LWT 2020, 118, 108776. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of the AOAC International; AOAC: Gaithersburg, MD, USA, 2006. [Google Scholar]

- Spinei, M.; Oroian, M. The Influence of Osmotic Treatment Assisted by Ultrasound on the Physico-Chemical Characteristics of Blueberries (Vaccinium Myrtillus L.). Ultrasonics 2021, 110, 106298. [Google Scholar] [CrossRef]

- Zhang, Z.; Song, H.; Peng, Z.; Luo, Q.; Ming, J.; Zhao, G. Characterization of Stipe and Cap Powders of Mushroom (Lentinus edodes) Prepared by Different Grinding Methods. J. Food Eng. 2012, 109, 406–413. [Google Scholar] [CrossRef]

- Gao, W.; Chen, F.; Zhang, L.; Meng, Q. Effects of Superfine Grinding on Asparagus Pomace. Part I: Changes on Physicochemical and Functional Properties. J. Food Sci. 2020, 85, 1827–1833. [Google Scholar] [CrossRef] [PubMed]

- Spinei, M.; Oroian, M. The Influence of Extraction Conditions on the Yield and Physico-Chemical Parameters of Pectin from Grape Pomace. Polymers 2022, 14, 1378. [Google Scholar] [CrossRef] [PubMed]

- Guiné, R.P.F.; Correia, P.M.R.; Reis, C.; Florença, S.G. Evaluation of Texture in Jelly Gums Incorporating Berries and Aromatic Plants. Open Agric. 2020, 5, 450–461. [Google Scholar] [CrossRef]

- Figueroa, L.E.; Genovese, D.B. Fruit Jellies Enriched with Dietary Fibre: Development and Characterization of a Novel Functional Food Product. LWT 2019, 111, 423–428. [Google Scholar] [CrossRef]

- Milincic, D.; Kostic, A.; Spirovic-Trifunovic, B.; Tesic, Z.; Tosti, T.; Dramicanin, A.; Barac, M.; Pesic, M. Grape Seed Flour of Different Grape Pomaces: Fatty Acid Profile, Soluble Sugar Profile and Nutritional Value. J. Serb. Chem. Soc. 2020, 85, 305–319. [Google Scholar] [CrossRef]

- Konuskan, D.B.; Kamiloglu, O.; Demirkeser, O. Fatty Acid Composition, Total Phenolic Content and Antioxidamt Activity of Grape Seed Oils Obtained by Cold-Pressed and Solvent Extraction. Indian J. Pharm. Educ. Res. 2019, 53, 144–150. [Google Scholar] [CrossRef]

- Tolve, R.; Simonato, B.; Rainero, G.; Bianchi, F.; Rizzi, C.; Cervini, M.; Giuberti, G. Wheat Bread Fortification by Grape Pomace Powder: Nutritional, Technological, Antioxidant, and Sensory Properties. Foods 2021, 10, 75. [Google Scholar] [CrossRef]

- Bender, A.B.B.; Speroni, C.S.; Moro, K.I.B.; Morisso, F.D.P.; dos Santos, D.R.; da Silva, L.P.; Penna, N.G. Effects of Micronization on Dietary Fiber Composition, Physicochemical Properties, Phenolic Compounds, and Antioxidant Capacity of Grape Pomace and Its Dietary Fiber Concentrate. LWT 2020, 117, 108652. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, M.; Shi, T.; Guo, C.; Huang, Y.; Chen, Y.; Xie, M. Recovery of Dietary Fiber and Polyphenol from Grape Juice Pomace and Evaluation of Their Functional Properties and Polyphenol Compositions. Food Funct. 2017, 8, 341–351. [Google Scholar] [CrossRef]

- Ma, M.; Mu, T. Effects of Extraction Methods and Particle Size Distribution on the Structural, Physicochemical, and Functional Properties of Dietary Fiber from Deoiled Cumin. Food Chem. 2016, 194, 237–246. [Google Scholar] [CrossRef]

- Jurevičiūtė, I.; Keršienė, M.; Bašinskienė, L.; Leskauskaitė, D.; Jasutienė, I. Characterization of Berry Pomace Powders as Dietary Fiber-Rich Food Ingredients with Functional Properties. Foods 2022, 11, 716. [Google Scholar] [CrossRef] [PubMed]

- Dimitriu, L.; Preda, D.; Constantinescu-Aruxandei, D.; Oancea, F. Quince Pomace: A Source of Fiber Products and Polyphenols. In Proceedings of the NeXT-Chem 2023. Chem. Proc. 2023, 13, 6. [Google Scholar]

- Liu, W.; Jing, H.; Ma, C.; Liu, C.; Lv, W.; Wang, H. Microstructure, Physicochemical and Functional Properties of Dendrobium officinale Pomace and Its Total Dietary Fiber. J. Food Meas. Charact. 2023, 17, 3927–3937. [Google Scholar] [CrossRef]

- Jagelaviciute, J.; Basinskiene, L.; Cizeikiene, D.; Syrpas, M. Technological Properties and Composition of Enzymatically Modified Cranberry Pomace. Foods 2022, 11, 2321. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Liu, Y.; Yang, G.; Sun, L.; Song, X.; Chen, Q.; Bao, Y.; Luo, T.; Wang, J. Microstructure, Physicochemical Properties, and Adsorption Capacity of Deoiled Red Raspberry Pomace and Its Total Dietary Fiber. LWT 2022, 153, 112478. [Google Scholar] [CrossRef]

- Oladiran, D.A.; Emmambux, N.M. Nutritional and Functional Properties of Extruded Cassava-soy Composite with Grape Pomace. Starch—Stärke 2018, 70, 1700298. [Google Scholar] [CrossRef]

- Wang, L.; Xu, H.; Yuan, F.; Pan, Q.; Fan, R.; Gao, Y. Physicochemical Characterization of Five Types of Citrus Dietary Fibers. Biocatal. Agric. Biotechnol. 2015, 4, 250–258. [Google Scholar] [CrossRef]

- Wojdyło, A.; Samoticha, J.; Chmielewska, J. Effect of Different Pre-Treatment Maceration Techniques on the Content of Phenolic Compounds and Color of Dornfelder Wines Elaborated in Cold Climate. Food Chem. 2021, 339, 127888. [Google Scholar] [CrossRef]

- Makris, D.P.; Kefalas, P. Characterization of Polyphenolicphytochemicals in Red Grape Pomace. Int. J. Waste Resour. 2013, 3, 126. [Google Scholar] [CrossRef]

- Dhua, S.; Kumar, K.; Sharanagat, V.S.; Nema, P.K. Bioactive Compounds and Its Optimization from Food Waste: Review on Novel Extraction Techniques. Nutr. Food Sci. 2022, 52, 1270–1288. [Google Scholar] [CrossRef]

- Barriga-Sánchez, M.; Hiparraguirre, H.C.; Rosales-Hartshorn, M. Chemical Composition and Mineral Content of Black Borgoña (Vitis Labrusca L.) Grapes, Pomace and Seeds, and Effects of Conventional and Non-Conventional Extraction Methods on Their Antioxidant Properties. Food Sci. Technol. 2022, 42, e120021. [Google Scholar] [CrossRef]

- Xu, Y.; Burton, S.; Kim, C.; Sismour, E. Phenolic Compounds, Antioxidant, and Antibacterial Properties of Pomace Extracts from Four Virginia-grown Grape Varieties. Food Sci. Nutr. 2016, 4, 125–133. [Google Scholar] [CrossRef] [PubMed]

- Carmona-Jiménez, Y.; García-Moreno, M.V.; García-Barroso, C. Effect of Drying on the Phenolic Content and Antioxidant Activity of Red Grape Pomace. Plant Foods Hum. Nutr. 2018, 73, 74–81. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Zhu, H.; Zhang, G.; Tang, W. Effect of Superfine Grinding on the Physicochemical Properties and Antioxidant Activity of Red Grape Pomace Powders. Powder Technol. 2015, 286, 838–844. [Google Scholar] [CrossRef]

- Fu, C.; Yang, X.; Lai, S.; Liu, C.; Huang, S.; Yang, H. Structure, Antioxidant and α-Amylase Inhibitory Activities of Longan Pericarp Proanthocyanidins. J. Funct. Foods 2015, 14, 23–32. [Google Scholar] [CrossRef]

- Lucarini, M.; Durazzo, A.; Kiefer, J.; Santini, A.; Lombardi-Boccia, G.; Souto, E.; Romani, A.; Lampe, A.; Ferrari Nicoli, S.; Gabrielli, P.; et al. Grape Seeds: Chromatographic Profile of Fatty Acids and Phenolic Compounds and Qualitative Analysis by FTIR-ATR Spectroscopy. Foods 2019, 9, 10. [Google Scholar] [CrossRef] [PubMed]

- Mohammed, A.; Avin, A. Scanning Electron Microscopy (SEM): A Review. In Proceedings of the 2018 International Conference on Hydraulics and Pneumatics—HERVEX, Băile Govora, Romania, 7–9 November 2018; pp. 77–85. [Google Scholar]

- Pala, M.; Kantarli, I.C.; Buyukisik, H.B.; Yanik, J. Hydrothermal Carbonization and Torrefaction of Grape Pomace: A Comparative Evaluation. Bioresour. Technol. 2014, 161, 255–262. [Google Scholar] [CrossRef]

- Gowman, A.C.; Picard, M.C.; Rodriguez-Uribe, A.; Misra, M.; Khalil, H.; Thimmanagari, M.; Mohanty, A.K. Physicochemical Analysis of Apple and Grape Pomaces. BioResources 2019, 14, 3210–3230. [Google Scholar] [CrossRef]

- Baldán, Y.; Riveros, M.; Fabani, M.P.; Rodriguez, R. Grape Pomace Powder Valorization: A Novel Ingredient to Improve the Nutritional Quality of Gluten-Free Muffins. Biomass Convers. Biorefinery 2023, 13, 9997–10009. [Google Scholar] [CrossRef]

- Drevelegka, I.; Goula, A.M. Recovery of Grape Pomace Phenolic Compounds through Optimized Extraction and Adsorption Processes. Chem. Eng. Process.—Process Intensif. 2020, 149, 107845. [Google Scholar] [CrossRef]

- Cano-Lamadrid, M.; Calín-Sánchez, Á.; Clemente-Villalba, J.; Hernández, F.; Carbonell-Barrachina, Á.A.; Sendra, E.; Wojdyło, A. Quality Parameters and Consumer Acceptance of Jelly Candies Based on Pomegranate Juice “Mollar de Elche”. Foods 2020, 9, 516. [Google Scholar] [CrossRef] [PubMed]

- De Nishiyama-Hortense, Y.P.O.; Rossi, M.J.d.P.; Shimizu-Marin, V.D.; Janzantti, N.S.; Gómez-Alonso, S.; Da-Silva, R.; Lago-Vanzela, E.S. Jelly Candy Enriched with BRS Violeta Grape Juice: Anthocyanin Retention and Sensory Evaluation. Future Foods 2022, 6, 100179. [Google Scholar] [CrossRef]

- Hani, N.M.; Romli, S.R.; Ahmad, M. Influences of Red Pitaya Fruit Puree and Gelling Agents on the Physico-mechanical Properties and Quality Changes of Gummy Confections. Int. J. Food Sci. Technol. 2015, 50, 331–339. [Google Scholar] [CrossRef]

- Shahu, R.; Jobby, R.; Patil, S.; Bhori, M.; Tungare, K.; Jha, P. Phytochemical Content and Antioxidant Activity of Different Varieties of Stevia rebaudiana. Hortic. Environ. Biotechnol. 2022, 63, 935–948. [Google Scholar] [CrossRef]

- Garrido, J.I.; Lozano, J.E.; Genovese, D.B. Effect of Formulation Variables on Rheology, Texture, Colour, and Acceptability of Apple Jelly: Modelling and Optimization. LWT—Food Sci. Technol. 2015, 62, 325–332. [Google Scholar] [CrossRef]

- Akesowan, A. Optimization of Textural Properties of Konjac Gels Formed with κ-Carrageenan or Xanthan and Xylitol as Ingredients in Jelly Drink Processing. J. Food Process. Preserv. 2015, 39, 1735–1743. [Google Scholar] [CrossRef]

- Rios de Souza, V.; Aparecida Pimenta Pereira, P.; Carla Marques Pinheiro, A.; Carlos de Oliveira Lima, L.; Pio, R.; Queiroz, F. Analysis of the Subtropical Blackberry Cultivar Potential in Jelly Processing. J. Food Sci. 2014, 79, S1776–S1781. [Google Scholar] [CrossRef]

- Mutlu, C.; Tontul, S.A.; Erbaş, M. Production of a Minimally Processed Jelly Candy for Children Using Honey Instead of Sugar. LWT 2018, 93, 499–505. [Google Scholar] [CrossRef]

- Curi, P.N.; de Sousa Tavares, B.; de Almeida, A.B.; Pio, R.; Peche, P.M.; de Souza, V.R. Influence of Subtropical Region Strawberry Cultivars on Jelly Characteristics. J. Food Sci. 2016, 81, S1515–S1520. [Google Scholar] [CrossRef]

- Thompson, S. Microbiological Spoilage of High-Sugar Products. In Compendium of the Microbiological Spoilage of Foods and Beverages; Sperber, W.H., Doyle, M.P., Eds.; Springer: New York, NY, USA, 2009; pp. 301–324. [Google Scholar]

- Ismawati, R.; Romadhoni, I.F.; Nurul, Q.T.; Ratna, S.T. Storability of Seaweed Jelly Candy Based on Chemical, Physical and Microbiology Characteristics. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP: Bristol, UK, 2019; Volume 347, p. 012021. [Google Scholar]

| Parameter | Particle Size (µm) | p-Value | ||

|---|---|---|---|---|

| <125 | ≥125–<200 | ≥200–<300 | ||

| Proximate composition | ||||

| Moisture (g/100 g ODPP) | 12.0 (0.34) a | 11.9 (0.26) b | 11.5 (0.29) c | p < 0.0001 |

| Crude protein (g/100 g ODPP) | 7.7 (0.28) c | 8.0 (0.33) b | 8.4 (0.42) a | p < 0.0001 |

| Crude fat (g/100 g ODPP) | 18.3 (0.22) c | 19.4 (0.25) b | 20.1 (0.18) a | p < 0.0001 |

| Ash (g/100 g ODPP) | 1.9 (0.14) a | 1.8 (0.19) b | 1.6 (0.27) c | p < 0.0001 |

| Carbohydrates A (g/100 g ODPP) | 60.0 (0.27) a | 58.8 (0.21) b | 58.2 (0.34) c | p < 0.0001 |

| TDF (g/100 g ODPP) | 48.2 (0.36) c | 55.0 (0.32) b | 57.0 (0.26) a | p < 0.0001 |

| IDF (g/100 g ODPP) | 41.4 (0.19) c | 47.1 (0.23) b | 49.4 (0.28) a | p < 0.0001 |

| SDF (g/100 g ODPP) | 6.9 (0.23) b | 7.8 (0.15) a | 7.6 (0.19) a | p < 0.0001 |

| Functional properties | ||||

| WHC (g/g ODPP) | 4.0 (0.13) c | 5.1 (0.17) b | 7.8 (0.19) a | p < 0.0001 |

| OBC (g/g ODPP) | 2.7 (0.08) a | 2.1 (0.12) b | 1.9 (0.07) c | p < 0.0001 |

| SC (mL/g ODPP) | 4.1 (0.28) c | 6.9 (0.32) b | 10.1 (0.37) a | p < 0.0001 |

| WSI (% ODPP) | 9.4 (0.11) a | 8.3 (0.18) b | 5.2 (0.09) c | p < 0.0001 |

| Color parameters | ||||

| L* | 17.6 (0.14) b | 25.1 (0.11) a | 29.9 (0.09) a | p > 0.05 |

| h*ab | 39.9 (0.21) a | 38.1 (0.28) b | 38.7 (0.34) ab | p > 0.05 |

| C*ab | 11.2 (0.17) b | 14.3 (0.12) ab | 14.9 (0.07) a | p > 0.05 |

| Phytochemical characteristics | ||||

| TPC (mg GAE/g ODPP) | 146 (0.22) a | 136 (0.32) b | 135 (0.37) b | p < 0.0001 |

| TMA content (mg C3G/g ODPP) | 11.4 (0.46) a | 9.2 (0.41) b | 6.9 (0.38) c | p < 0.0001 |

| TFC (mg QE/g ODPP) | 19.0 (0.13) b | 21.4 (0.26) a | 17.5 (0.17) c | p < 0.0001 |

| DPPH (% inhibition ODPP) | 67.1 (0.19) a | 50.4 (0.54) b | 48.6 (0.68) c | p < 0.0001 |

| Parameter | Particle Size (µm) | p-Value | ||

|---|---|---|---|---|

| <125 | ≥125–<200 | ≥200–<300 | ||

| Proximate composition | ||||

| Moisture (% ODPP) | 84.1 (0.13) c | 86.7 (0.16) b | 89.3 (0.14) a | p < 0.0001 |

| Crude protein (g/100 mL ODPP) * | n.d. | n.d. | 0.23 (0.01) a | p < 0.0001 |

| Crude fat (g/100 mL ODPP) * | n.d. | n.d. | n.d. | – |

| Ash (g/100 mL ODPP) * | 0.02 (0.02) c | 0.05 (0.02) b | 0.12 (0.01) a | p < 0.0001 |

| Carbohydrates A (g/100 mL ODPP) * | 15.9 (0.06) a | 13.2 (0.08) b | 10.3 (0.11) c | p < 0.0001 |

| TDF (g/100 mL ODPP) * | 12.4 (0.11) c | 10.6 (0.12) b | 9.7 (0.16) a | p < 0.0001 |

| Phytochemical characteristics | ||||

| TPC (mg GAE/mL ODPP) | 126 (0.22) a | 107 (0.32) c | 109 (0.37) b | p < 0.0001 |

| DPPH (% inhibition ODPP) | 60.8 (0.17) a | 49.6 (0.25) b | 42.5 (0.32) c | p < 0.0001 |

| Parameter | Samples | p-Value | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| F1–7 | F1–8.5 | F1–10 | F2–7 | F2–8.5 | F2–10 | F3–7 | F3–8.5 | F3–10 | ||

| Color parameters | ||||||||||

| L* | 29.9 (0.13) d | 32.5 (0.17) c | 39.4 (0.16) ab | 29.2 (0.14) d | 33.4 (0.19) c | 40.2 (0.19) ab | 33.1 (0.12) c | 36.2 (0.08) b | 42.7 (0.11) a | p < 0.0001 |

| h*ab | 40.7 (0.14) d | 42.1 (0.17) cd | 43.6 (0.17) c | 41.3 (0.13) cd | 44.7 (0.14) c | 46.3 (0.15) bc | 45.6 (0.18) bc | 47.1 (0.13) b | 48.9 (0.15) a | p < 0.0001 |

| C*ab | 15.1 (0.30) c | 16.2 (0.22) bc | 16.8 (0.23) bc | 15.9 (0.17) c | 16.9 (0.21) bc | 17.2 (0.16) b | 16.8 (0.24) bc | 17.5 (0.29) b | 18.1 (0.27) a | p < 0.0001 |

| Phytochemical characteristics | ||||||||||

| TPC (mg GAE/g ODPP) | 156 (1.42) a | 148 (1.29) b | 138 (2.01) c | 130 (2.13) d | 129 (1.08) d | 127 (1.37) d | 120 (1.23) e | 118 (0.99) e | 115 (1.14) e | p < 0.0001 |

| DPPH (% inhibition ODPP) | 65.8 (0.98) a | 63.3 (1.10) ab | 58.3 (2.18) b | 48.1 (1.15) c | 46.4 (0.57) c | 46.4 (0.69) c | 30.1 (1.77) d | 30.0 (2.13) d | 29.9 (2.27) d | p < 0.0001 |

| Textural parameters | ||||||||||

| H (N) | 6.3 (0.13) c | 11.1 (2.13) b | 16.7 (1.10) a | 6.5 (0.27) c | 10.8 (1.08) b | 17.1 (0.98) a | 6.1 (0.24) c | 10.7 (1.37) b | 16.5 (0.46) a | p < 0.0001 |

| Co (adim.) | 0.23 (0.02) a | 0.24 (0.02) a | 0.24 (0.01) a | 0.23 (0.06) a | 0.24 (0.06) a | 0.25 (0.05) a | 0.23 (0.01) a | 0.24 (0.03) a | 0.25 (0.07) a | p > 0.05 |

| Ad (N × s) | −2.9 (0.08) a | −2.9 (0.10) a | −3.0 (0.06) a | −3.0 (0.13) a | −3.0 (0.08) a | −3.1 (0.07) a | −3.2 (0.07) ab | −3.2 (0.11) ab | −3.3 (0.06) b | p < 0.01 |

| S (adim.) | 0.85 (0.03) b | 0.84 (0.01) b | 0.83 (0.01) b | 0.88 (0.01) a | 0.85 (0.01) b | 0.84 (0.02) b | 0.85 (0.03) b | 0.86 (0.02) b | 0.89 (0.01) a | p < 0.01 |

| G (N) | 48.9 (0.12) d | 54.2 (0.18) b | 54.0 (0.17) b | 53.1 (0.15) c | 54.2 (0.12) b | 54.4 (0.16) b | 55.1 (0.18) a | 55.2 (0.12) a | 49.6 (0.11) d | p < 0.001 |

| Microbiological tests | ||||||||||

| TP count (CFU/mL) | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | 69.3 (0.14) c | 74.6 (0.17) b | 95.3 (0.23) a | p < 0.0001 |

| MY counts (CFU/mL) | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | 51.6 (0.13) c | 53.3 (0.18) b | 74.1 (0.21) a | p < 0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spinei, M.; Oroian, M. Characterization of Băbească Neagră Grape Pomace and Incorporation into Jelly Candy: Evaluation of Phytochemical, Sensory, and Textural Properties. Foods 2024, 13, 98. https://doi.org/10.3390/foods13010098

Spinei M, Oroian M. Characterization of Băbească Neagră Grape Pomace and Incorporation into Jelly Candy: Evaluation of Phytochemical, Sensory, and Textural Properties. Foods. 2024; 13(1):98. https://doi.org/10.3390/foods13010098

Chicago/Turabian StyleSpinei, Mariana, and Mircea Oroian. 2024. "Characterization of Băbească Neagră Grape Pomace and Incorporation into Jelly Candy: Evaluation of Phytochemical, Sensory, and Textural Properties" Foods 13, no. 1: 98. https://doi.org/10.3390/foods13010098

APA StyleSpinei, M., & Oroian, M. (2024). Characterization of Băbească Neagră Grape Pomace and Incorporation into Jelly Candy: Evaluation of Phytochemical, Sensory, and Textural Properties. Foods, 13(1), 98. https://doi.org/10.3390/foods13010098