Rapid Non-Destructive Detection Technology in the Field of Meat Tenderness: A Review

Abstract

1. Introduction

2. Application Progress of the Rapid Non-Destructive Detection Technologies for Meat Tenderness

2.1. Spectroscopy Technology

2.1.1. Visible-Near Infrared (Vis-NIR) Spectroscopy

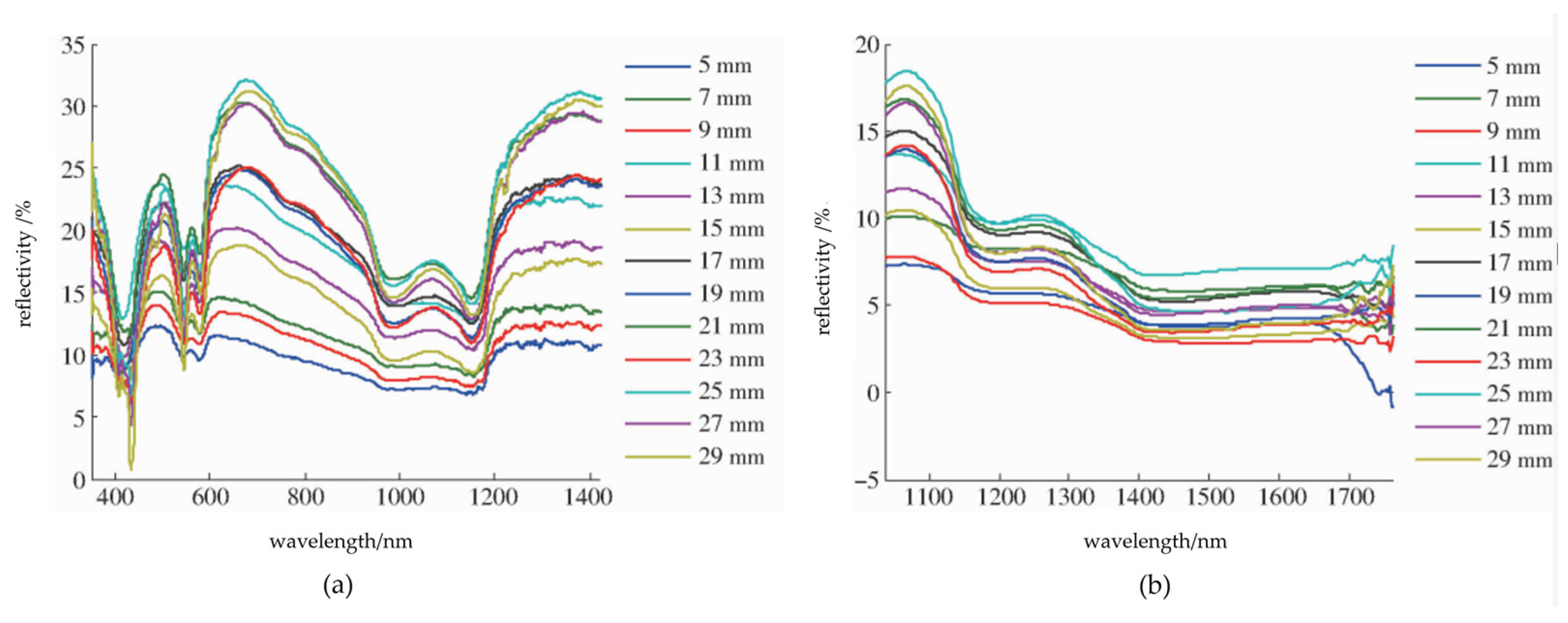

2.1.2. Hyperspectral Imaging (HIS) Technology

2.1.3. Raman Spectroscopy Technology

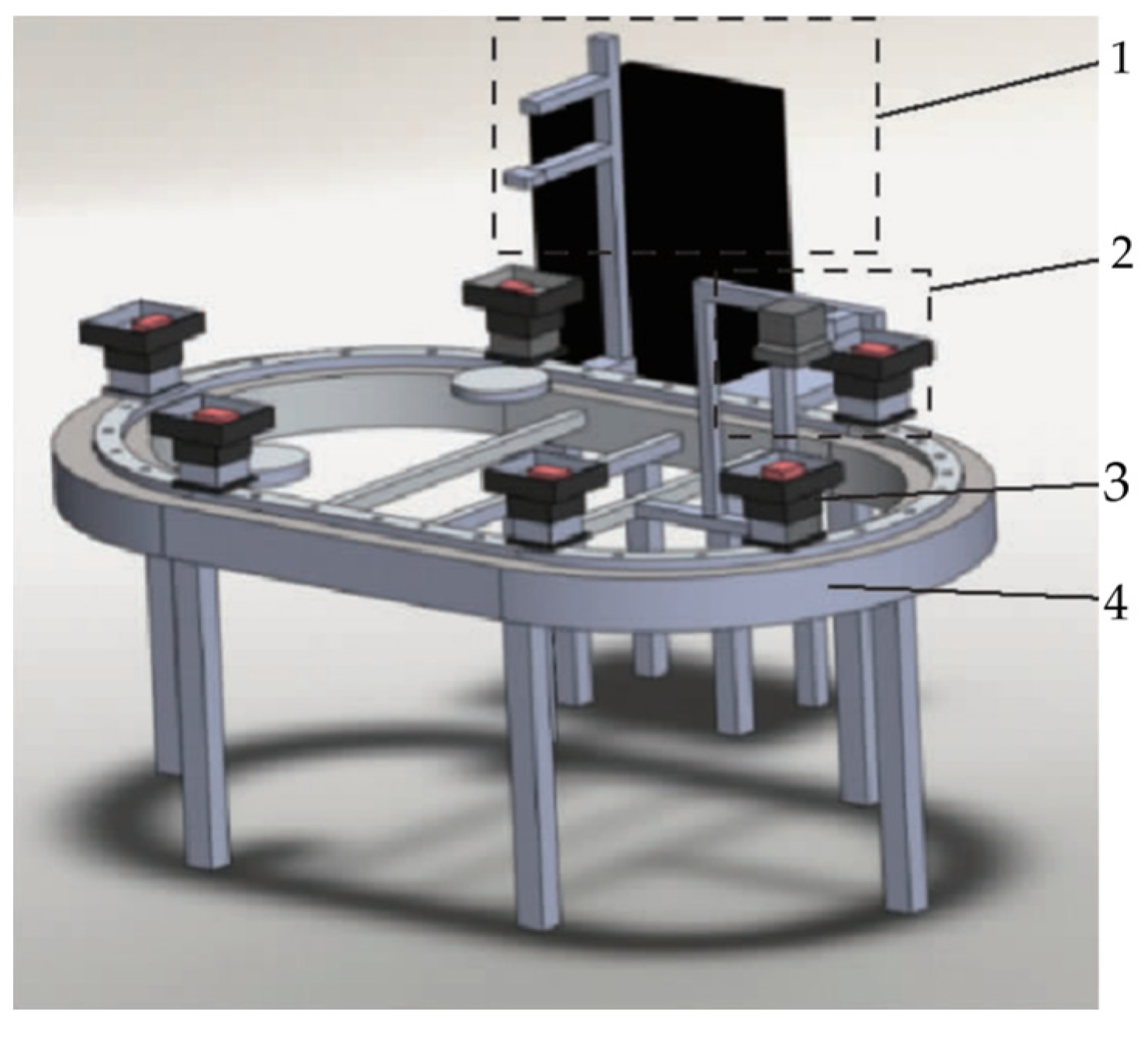

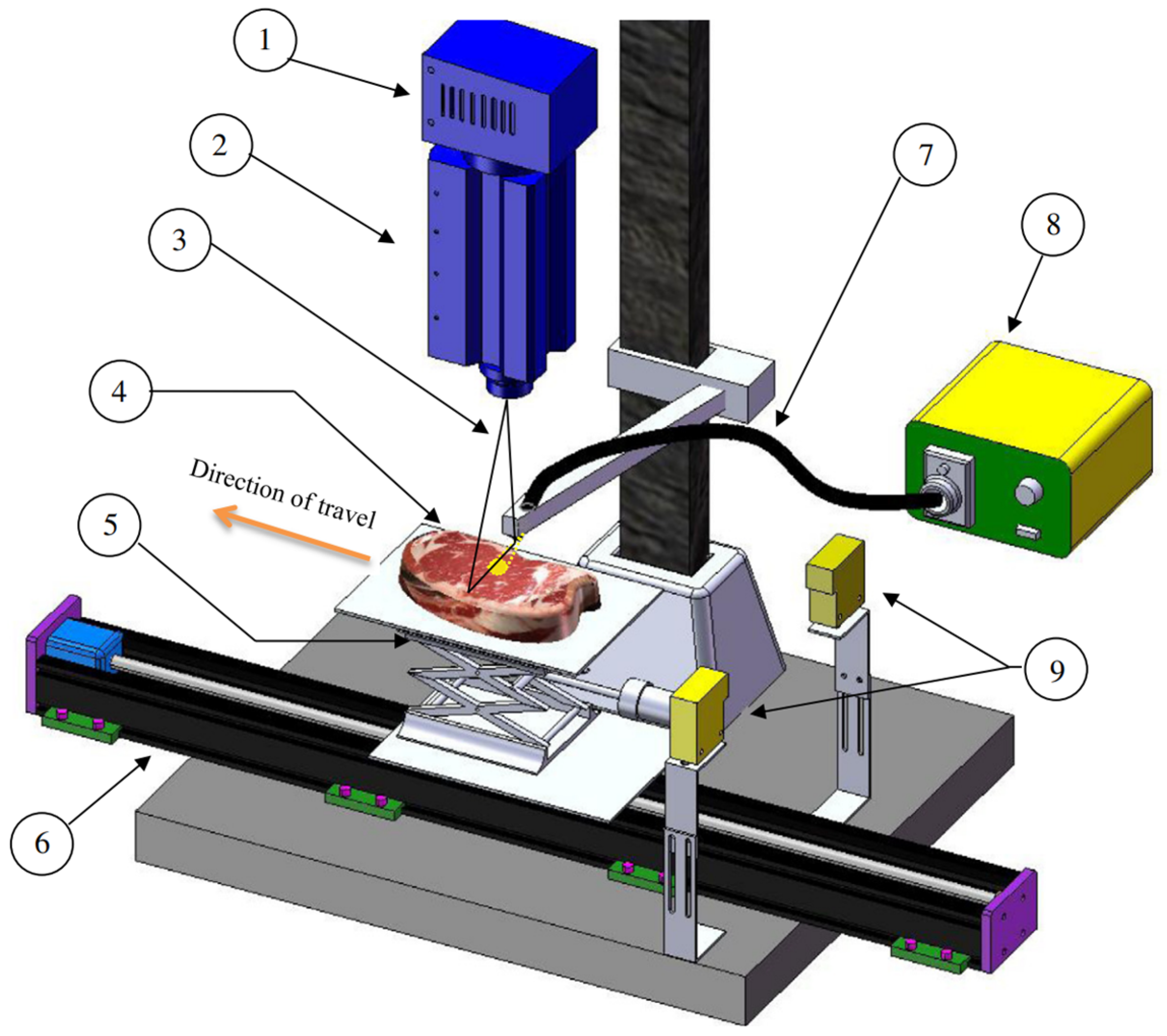

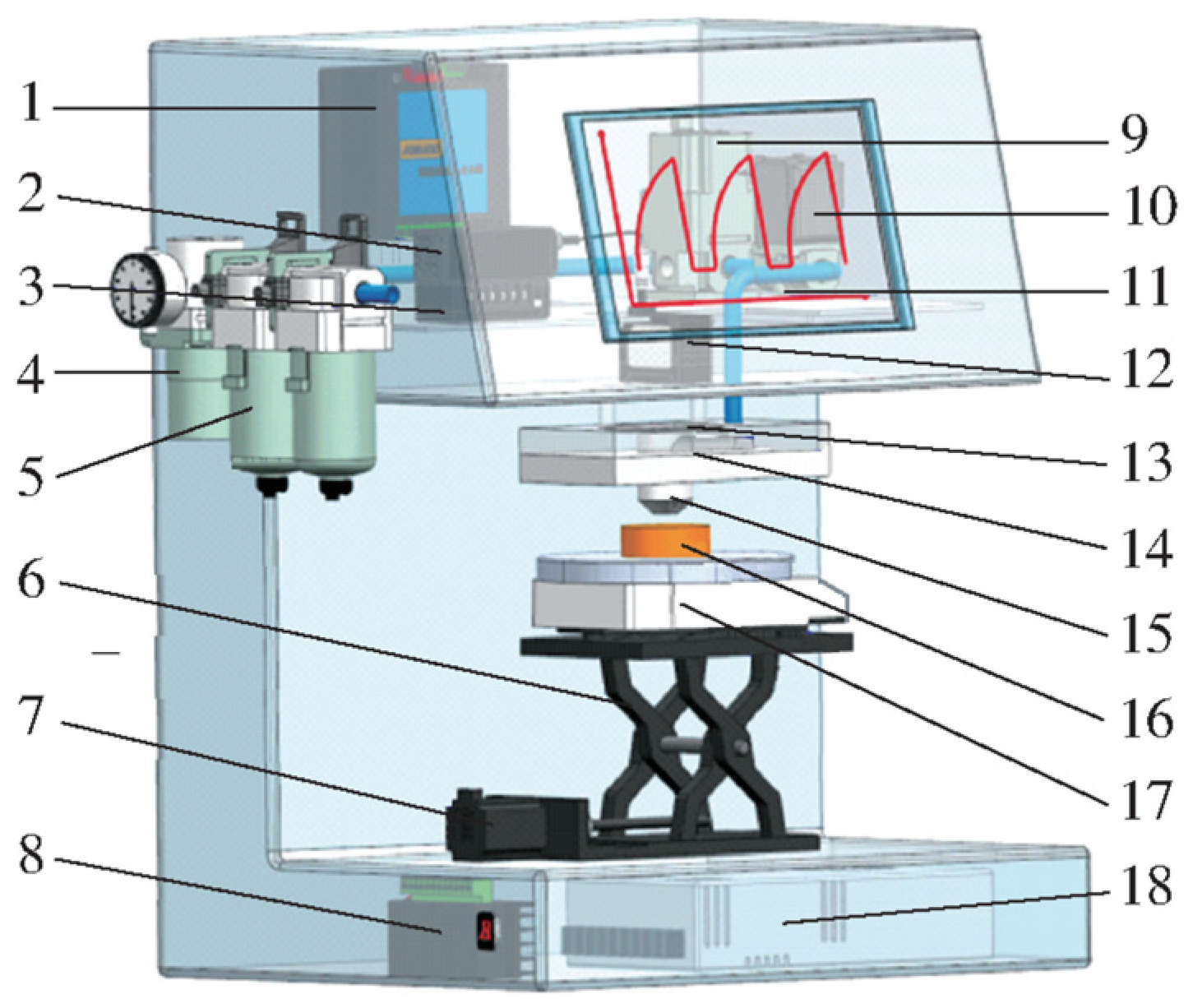

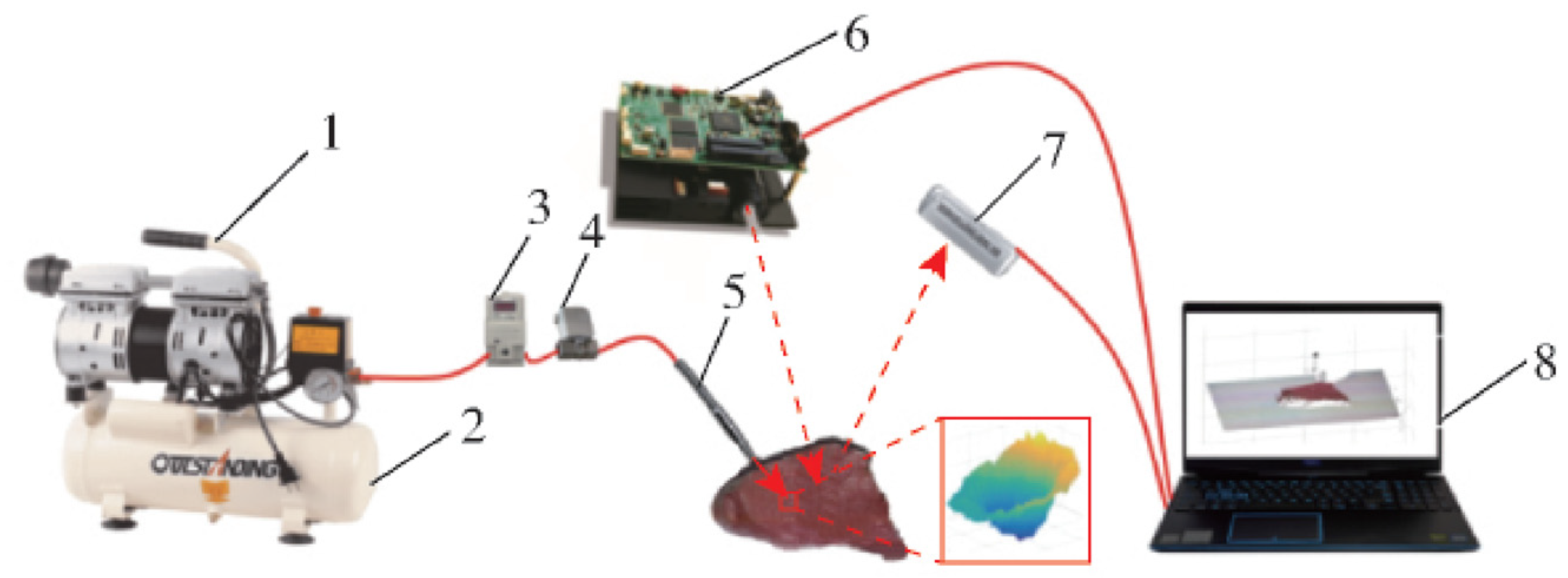

2.2. Airflow–Optical Fusion Detection Technology

2.3. Nuclear Magnetic Resonance (NMR) Technology

3. Research Development Trends and Prospects

| Technology | Object and Indicators | Data Processing | Validation Methods and Parameters |

|---|---|---|---|

| NIR | mutton tenderness | MSC + PLS | The prediction accuracy of the model based on PLS reaches 0.96329 [24]. |

| pork tenderness | MSC, 1st Der + PLS | The PLS model prediction accuracy is 78% [26]. | |

| meat tenderness | SNV, MSC, SG + PLS | The prediction accuracy of the model is average, and the RPD value is only occasionally greater than 2 [27]. | |

| beef tenderness | MLR | The MLR model predicts a correlation coefficient of 0.806 [28]. | |

| HSI | beef tenderness | PCA | The validation set prediction accuracy of the linear discriminant model is 75% [33]. |

| beef tenderness | PLS-DA | The recognition accuracy of the local model based on PLS-DA is 72% [34]. | |

| beef tenderness | GA + PCA-LDA | The recognition accuracy of the PLS-LDA model is 94.44% [35]. | |

| mutton tenderness | SG + PLSR | The correlation coefficient of the PLSR model for predicting the prediction set is 0.89 [36]. | |

| chicken tenderness | SG + PLSR | The constructed PLSR model has the best predictive performance, with a correlation coefficient of 0.94 in the prediction set [37]. | |

| mutton tenderness | MSC + BPNN | The BPNN model has the best predictive performance, with a correlation coefficient of 0.85 for the prediction set [38]. | |

| mutton tenderness | MSC, de rendering, baseline, SNV, normalize, SG + OS-IvISSA-PLSSR | The correlation coefficient of the OS IvISSA-PLSSR tenderness prediction model prediction set is 0.79 [39]. | |

| Raman | beef tenderness | PLS | The R2 of the PLS beef tenderness prediction model is 0.65 [45] |

| beef tenderness | EMSC + PLS-DA | The accuracy of the PLS-DA prediction model reaches 80% [46]. | |

| mutton tenderness | SG + PLS | The predictive correlation coefficients (R2) of the PLS model for two sets of data are 0.79 and 0.86, respectively [47]. | |

| Airflow-optical fusion detection | chicken tenderness | OLS, PLS | The accuracy of the detection model is 85% [53]. |

| beef tenderness | ELM | The detection model has good predictive performance, with a correlation coefficient of 0.8356, and a discrimination rate of 92.96% for tender beef [54]. | |

| Airflow-optical fusion detection | chicken tenderness | SG + global variable PLS | The correlation coefficients of the constructed transient modal model in qualitative and quantitative validation sets are 0.95 and 0.913, respectively [55] |

| beef tenderness | GRNN, K-fold | The GRNN neural network based on K-fold cross-validation has a good grading effect on tender beef, with a discrimination effect of 100% [56]. | |

| NMR | mutton tenderness | curve regression | T2 is negatively linked to shear force (R = −0.996, p < 0.01), and A is positively linked (R = 0.960) [61]. |

| beef tenderness | CPMG + PLS | The CPMG tenderness data detection effect is good, with r > 0.65 [62]. |

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, T.Y.; Zhou, X.Y.; Luo, F.; Yang, L.; Li, K.Y.; Qin, M.; Ge, Q.F.; Yu, H.; Wu, M.G.; Liu, R. Research advances in effect of cooking on meat quality and nutrition properties. J. Res. Diet. Sci. Cult. 2022, 39, 44–52. [Google Scholar]

- Han, C.; He, Z.F. Research progress in meat detection technology. Meat Res. 2006, 20, 21–23+32. [Google Scholar]

- NY/T 1180-2006; Determination of Meat Tenderness. Determination of Shear Force. Ministry of Agriculture: Beijing, China, 2006.

- Wang, H.F.; Qu, G.J.; Qin, G.X. The factor of affect meat tenderness and tenderization technology. Jilin Anim. Husb. Vet. Med. 2010, 31, 13–16. [Google Scholar]

- Lepetit, J. A theoretical approach of the relationships between collagen content, collagen cross-links and meat tenderness. Meat Sci. 2007, 76, 147–159. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.J.; Lei, Q.X.; Cao, D.G.; Huang, T.R.; Huang, M. Effects of different ages on the slaughter performance, muscle quality and nutritional characteristics of 817 broilers. J. Nanjing Agric. Univ. 2023, 46, 59–168. [Google Scholar]

- Wei, M.; Zhang, L.; Zhang, Y.M.; Li, S.Z.; Zhao, G.M.; Sun, B.Z. Development status and countermeasures of beef cattle slaughtering and processing industry in China. J. Jilin Agric. Univ. 2023, 45, 429–436. [Google Scholar]

- Liu, Y.M.; Gu, L.W.; Zhou, L. Analysis and research on the transfer trend of pig slaughtering capacity in China. Chin. J. Anim. Sci. 2022, 58, 300–304. [Google Scholar]

- Zhang, Y.L. Application of new non-destructive testing technology in meat quality testing. Mod. Food 2023, 29, 104–106. [Google Scholar]

- Yang, D.; Wang, J.H.; Lu, A.X. Research development on non-destructive determination technology for meat product quality. J. Food Saf. Qual. 2015, 6, 4083–4090. [Google Scholar]

- Jiang, Q. Application of new non-destructive testing technology in meat quality detection. Meat Ind. 2012, 8, 44–47. [Google Scholar]

- Kong, X.Q.; Huang, S.Z. Non-destructive measurement techniques for meat quality detection. Meat Res. 2008, 8, 66–69. [Google Scholar]

- Zaukuu, J.-L.Z.; Tsyawo, E.C. Rapid and non-destructive detection of ponceau 4R red colored pork. Meat Sci. 2024, 209, 109400. [Google Scholar] [CrossRef] [PubMed]

- Fulladosa, E.; Duran-Montgé, P.; Serra, X.; Picouet, P.; Schimmer, O.; Gou, P. Estimation of dry-cured ham composition using dielectric time domain reflectometry. Meat Sci. 2013, 93, 873–879. [Google Scholar] [CrossRef] [PubMed]

- Cheng, L.J.; Liu, G.S.; He, J.G.; Wan, G.L.; Ma, C.; Ban, J.J.; Ma, L.M. Non-destructive assessment of the myoglobin content of Tan sheep using hyperspectral imaging. Meat Sci. 2020, 167, 107988. [Google Scholar] [CrossRef] [PubMed]

- Kamruzzaman, M. Optical sensing as analytical tools for meat tenderness measurements—A review. Meat Sci. 2023, 195, 109007. [Google Scholar] [CrossRef]

- Cáceres-Nevado, J.M.; Garrido-Varo, A.; De Pedro-Sanz, E.; Tejerina-Barrado, D.; Pérez-Marín, D.C. Non-destructive Near Infrared Spectroscopy for the labelling of frozen Iberian pork loins. Meat Sci. 2021, 175, 108440. [Google Scholar] [CrossRef] [PubMed]

- Antequera, T.; Caballero, D.; Grassi, S.; Uttaro, B.; Perez-Palacios, T. Evaluation of fresh meat quality by Hyperspectral Imaging (HSI), Nuclear Magnetic Resonance (NMR) and Magnetic Resonance Imaging (MRI): A review. Meat Sci. 2021, 172, 108340. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.L.; Yang, Z.H.; Wang, W.X.; Wang, X.W.; Zhang, C.Z.; Dong, J.; Bai, M.Y.; Hui, T. Research progress of rapid non-destructive detection technology in the field of apple mold heart disease. Molecules 2023, 28, 7966. [Google Scholar] [CrossRef] [PubMed]

- Luo, D.J.; Wang, M.; Zhang, X.S.; Xiao, X.Q. Vis/NIR based spectral sensing for SSC of table grapes. Spectrosc. Spectral Anal. 2023, 43, 2146–2152. [Google Scholar]

- Guo, Z.M.; Wang, J.Y.; Song, Y.; Zou, X.B.; Cai, J.R. Research progress of sensing detection and monitoring technology for fruit and vegetable quality control. Smart Agric. 2021, 3, 14–28. [Google Scholar]

- Raúl, G.; Antonio, J.S.; Joel, G.; Eugenio, I.; Ana, F.; Jose, M.B. Nondestructive assessment of freshness in packaged sliced chicken breasts using SW-NIR spectroscopy. Food Res. Int. 2011, 44, 331–337. [Google Scholar]

- de Nadai Bonin, M.; da Luz e Silva, S.; BÃnger, L.; Ross, D.; Dias FeijÃ, G.L.; da Costa Gomes, R.; Palma RennÃ, F.; de Almeida Santana, M.H.; Marcondes de Rezende, F.; Vinhas ItÃavo, L.C.; et al. Predicting the shear value and intramuscular fat in meat from Nellore cattle using Vis-NIR spectroscopy. Meat Sci. 2020, 163, 108077. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zhang, X.; Yao, N.; Wang, Y.M. Prediction of tenderness of fresh mutton in South Xinjiang by NIRS. J. Tarim Univ. 2020, 32, 44–49. [Google Scholar]

- Peng, Y.K.; Yang, Q.H.; Wang, W.X. On-line detection and classification of pork moisture based on near-infrared spectra. Trans. Chin. Soc. Agric. Mach. 2018, 49, 347–353. [Google Scholar]

- Balage, J.M.; da Luz e Silva, S.; Gomide, C.A.; Bonin, M.D.N.; Figueira, A.C. Predicting pork quality using Vis/NIR spectroscopy. Meat Sci. 2015, 108, 37–43. [Google Scholar] [CrossRef] [PubMed]

- Wyrwisz, J.; Moczkowska, M.; Kurek, M.; Karp, S.; Atanasov, A.; Wierzbicka, A. Evaluation of WBSF, color, cooking loss of longissimus lumborum muscle with fiber optic near-infrared spectroscopy (FT-NIR), Depending on Aging Time. Molecules 2019, 24, 757. [Google Scholar] [CrossRef] [PubMed]

- Li, S.Q. Application of near-infrared spectroscopy technology in beef tenderness detection. Chin. Food Saf. Mag. 2017, 36, 75. [Google Scholar]

- Sun, J.; Yang, F.Y.; Cheng, J.H.; Wang, S.M.; Fu, L.H. Nondestructive identification of soybean protein in minced chicken meat based on hyperspectral imaging and VGG16-SVM. J. Food Compos. Anal. 2024, 125, 105713. [Google Scholar] [CrossRef]

- Tang, X.; Rao, L.; Xie, L.; Yan, M.; Chen, Z.Q.; Liu, S.Y.; Chen, L.Q.; Xiao, S.J.; Ding, N.S.; Zhang, Z.Y.; et al. Quantification and visualization of meat quality traits in pork using hyperspectral imaging. Meat Sci. 2023, 196, 109052. [Google Scholar] [CrossRef]

- Hitchman, S.; Loeffen, M.P.F.; Reis, M.M.; Craigie, C.R. Robustness of hyperspectral imaging and PLSR model predictions of intramuscular fat in lamb M. longissimus lumborum across several flocks and years. Meat Sci. 2021, 179, 108492. [Google Scholar] [CrossRef]

- Cheng, J.H.; Sun, J.; Yao, K.S.; Xu, M.; Dai, C.X. Multi-task convolutional neural network for simultaneous monitoring of lipid and protein oxidative damage in frozen-thawed pork using hyperspectral imaging. Meat Sci. 2023, 201, 109196. [Google Scholar] [CrossRef]

- Cluff, K.; Naganathan, G.K.; Subbiah, J.; Samal, A.; Calkins, C.R. Optical scattering with hyperspectral imaging to classify longissimus dorsi muscle based on beef tenderness using multivariate modeling. Meat Sci. 2013, 95, 42–50. [Google Scholar] [CrossRef] [PubMed]

- Balage, J.M.; Amigo, J.M.; Antonelo, D.S.; Mazon, M.R.; da Luz e Silva, S. Shear force analysis by core location in Longissimus steaks from Nellore cattle using hyperspectral images—A feasibility study. Meat Sci. 2018, 143, 30–38. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Peng, Y.K. Distribution of beef tenderness grading based on texture features by hyperspectral image analysis. Trans. Chin. Soc. Agric. Eng. 2015, 31, 279–286. [Google Scholar]

- Wang, S.L.; Wu, L.G.; Kang, N.B.; Li, H.Y.; Wang, J.Y.; He, X.G. Study on Tan-lamb mutton tenderness by using the fusion of hyperspectral spectrum and image information. J. Optoelectron. Laser 2016, 27, 987–995. [Google Scholar]

- Wang, H.; He, H.J.; Zhang, H.M.; Liu, X.; Ma, H.J.; Zhu, M.M.; Gao, H.Y.; Zeng, J. Rapid prediction of chicken tenderness by hyperspectral imaging technique. J. Hainan Norm. Univ. (Nat. Sci.) 2018, 31, 164–170. [Google Scholar]

- Yu, Y.; Zhang, J.; Tian, H.Q.; Wang, D.; Wang, K.; Zhang, H.Q. Detection method for tenderness of chilled fresh lamb based on hyperspectral imaging technology. J. Agric. Sci. Technol. 2021, 23, 101–108. [Google Scholar]

- Liu, G.S.; Zhang, C.; Fan, N.Y.; Cheng, L.J.; Yu, J.Y.; Yuan, R.R. Hyperspectral model optimization for tenderness of chilled tan-sheep mutton based on IVISSA. Spectrosc. Spectral Anal. 2020, 40, 2558–2563. [Google Scholar]

- Qu, C.; Li, Y.Z.; Du, S.S.; Geng, Y.C.; Su, M.K.; Liu, H.L. Raman spectroscopy for rapid fingerprint analysis of meat quality and security: Principles, progress and prospects. Food Res. Int. 2022, 161, 111805. [Google Scholar] [CrossRef]

- Robert, C.; Fraser-Miller, S.J.; Jessep, W.T.; Bain, W.E.; Hicks, T.M.; Ward, J.F.; Craigie, C.R.; Loeffen, M.; Gordon, K.C. Rapid discrimination of intact beef, venison and lamb meat using Raman spectroscopy. Food Chem. 2021, 343, 128441. [Google Scholar] [CrossRef]

- Chen, Q.M.; Xie, Y.F.; Yu, H.; Guo, Y.H.; Yao, W.R. Non-destructive prediction of colour and water-related properties of frozen/thawed beef meat by Raman spectroscopy coupled multivariate calibration. Food Chem. 2023, 413, 135513. [Google Scholar] [CrossRef]

- Sun, H.R.; Song, C.; Lin, X.M.; Gao, X. Identification of meat species by combined laser-induced breakdown and Raman spectroscopies. Spectrochim. Acta Part B 2022, 194, 106456. [Google Scholar] [CrossRef]

- Hu, W.Y.; Xia, L.; Hu, Y.F.; Li, G.K. Fe3O4-WO3−X@AuNPs for magnetic separation, enrichment and surface-enhanced Raman scattering analysis all-in-one of albendazole and streptomycin in meat samples. Sens. Actuators B 2024, 402, 135131. [Google Scholar] [CrossRef]

- Rene, J.B.; Steven, J.B.; Linda, J.F.; Bruce, W.M.; Desmond, P. Preliminary investigation of the application of Raman spectroscopy to the prediction of the sensory quality of beef silverside. Meat Sci. 2004, 66, 903–913. [Google Scholar]

- Bauer, A.; Scheier, R.; Eberle, T.; Schmidt, H. Assessment of tenderness of aged bovine gluteus medius muscles using Raman spectroscopy. Meat Sci. 2016, 115, 27–33. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, H.; Scheier, R.; Hopkins, D.L. Preliminary investigation on the relationship of Raman spectra of sheep meat with shear force and cooking loss. Meat Sci. 2013, 93, 138–143. [Google Scholar] [CrossRef]

- Cama-Moncunill, R.; Cafferky, J.; Augier, C.; Sweeney, T.; Allen, P.; Ferragina, A.; Sullivan, C.; Cromie, A.; Hamill, R.M. Prediction of Warner-Bratzler shear force, intramuscular fat, drip-loss and cook-loss in beef via Raman spectroscopy and chemometrics. Meat Sci. 2020, 167, 108157. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.L.; Tang, X.Y.; Shen, Z.X.; Dong, J. Prediction of Total Volatile Basic Nitrogen (TVB-N) Content of Chilled Beef for Freshness Evaluation by Using Viscoelasticity Based on Airflow and Laser Technique. Food Chem. 2019, 287, 126–132. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.L.; Wang, W.J.; Long, Y.; Peng, Y.K.; Li, Y.Y.; Chao, K.L.; Tang, X.Y. A feasibility study of rapid nondestructive detection of total volatile basic nitrogen (TVB-N) content in beef based on airflow and laser ranging technique. Meat Sci. 2018, 145, 367–374. [Google Scholar] [CrossRef]

- Luo, X.Z.; Sun, Q.M.; Yang, T.X.; He, K.; Tang, X.Y. Nondestructive determination of common indicators of beef for freshness assessment using airflow-three dimensional (3D) machine vision technique and machine learning. J. Food Eng. 2023, 340, 111305. [Google Scholar] [CrossRef]

- He, K.; Luo, X.Z.; Sun, Q.M.; Tang, X.Y. Development of beef freshness detection device based on air flow and multi-point laser technique. Trans. Chin. Soc. Agric. Eng. 2021, 37, 278–286. [Google Scholar]

- Lee, Y.S.; Owens, C.M.; Meullenet, J.F. A Novel Laser Air Puff and Shape Profile Method for Predicting Tenderness of Broiler Breast Meat. Poult. Sci. 2008, 87, 1451–1457. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.Z.; Xiong, L.J.; Gao, X.; Hou, Y.X.; He, M.; Tang, X.Y. Determination of beef tenderness based on airflow pressure combined with structural light three-dimensional (3D) vision technology. Meat Sci. 2023, 202, 109206. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.B.; Zhao, Q.L.; He, K.; Li, Y.Y.; Peng, Y.K.; Tang, X.Y. Evaluation of chicken tenderness based on controlled air-flow laser detection technique. Trans. Chin. Soc. Agric. Mach. 2020, 51, 457–465. [Google Scholar]

- Lu, W.; Hu, Q.Y.; Dai, D.J.; Zhang, C.Y.; Deng, Y.M. Beef Tenderness detection based on pulse air-puff combined with structural light 3D imaging. Trans. Chin. Soc. Agric. Mach. 2020, 51, 324–331. [Google Scholar]

- John, W.B.; Dmitry, B.; Andreas, T. Lower than low: Perspectives on zero- to ultralow-field nuclear magnetic resonance. J. Magn. Reson. 2021, 323, 106886. [Google Scholar]

- Leng, T.; Hu, X.Y.; Chen, Y.; Gan, B.; Xie, J.H.; Yu, Q. Rapid identification and quantitation of pork and duck meat of binary and ternary adulteration in minced beef by 1H NMR combined with multivariate data fusion. Food Control 2023, 154, 110018. [Google Scholar] [CrossRef]

- Xu, J.M.; Yang, F.; Lin, Q.; Wang, J.H.; Ai, Z.J. Establishment of detection model of water-injected meat based on low field nuclear magnetic resonance transverse relaxation spectroscopy. Sci. Technol. Food Ind. 2021, 42, 226–232. [Google Scholar]

- Kelly, L.P.; Katja, R.; Henrik, J.A.; David, L.H. Water distribution and mobility in meat during the conversion of muscle to meat and ageing and the impacts on fresh meat quality attributes—A review. Meat Sci. 2011, 89, 111–124. [Google Scholar]

- Ma, T.L.; Wu, L.G.; Wang, S.L.; He, X.G.; He, J.G. Detection of tan-sheep meat tenderness based on low-field nuclear magnetic resonance. Sci. Technol. Food Ind. 2017, 38, 69–74. [Google Scholar]

- Fabíola, M.V.P.; Sérgio, B.P.; Thaísa, G.; Carolina, L.G.; Pedro, E.D.F.; Luiz, A.C. Fast determination of beef quality parameters with time-domain nuclear magnetic resonance spectroscopy and chemometrics. Talanta 2013, 108, 88–91. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Wang, H.; Yang, Z.; Wang, X.; Wang, W.; Hui, T. Rapid Non-Destructive Detection Technology in the Field of Meat Tenderness: A Review. Foods 2024, 13, 1512. https://doi.org/10.3390/foods13101512

Li Y, Wang H, Yang Z, Wang X, Wang W, Hui T. Rapid Non-Destructive Detection Technology in the Field of Meat Tenderness: A Review. Foods. 2024; 13(10):1512. https://doi.org/10.3390/foods13101512

Chicago/Turabian StyleLi, Yanlei, Huaiqun Wang, Zihao Yang, Xiangwu Wang, Wenxiu Wang, and Teng Hui. 2024. "Rapid Non-Destructive Detection Technology in the Field of Meat Tenderness: A Review" Foods 13, no. 10: 1512. https://doi.org/10.3390/foods13101512

APA StyleLi, Y., Wang, H., Yang, Z., Wang, X., Wang, W., & Hui, T. (2024). Rapid Non-Destructive Detection Technology in the Field of Meat Tenderness: A Review. Foods, 13(10), 1512. https://doi.org/10.3390/foods13101512