Effects of Different Soybean and Coconut Oil Additions on the Physicochemical and Sensory Properties of Soy Protein–Wheat Protein Mixture Subjected to High-Moisture Extrusion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of High-Moisture Extruded Protein

2.3. Color Evaluation

2.4. Textural Analysis and Fiber Degree

2.5. Sensory Evaluation

2.6. Macroscopic and Microscopic Morphology

2.7. SDS-Polyacrylamide Gel Electrophoresis (SDS-PAGE)

2.8. Fourier-Transform Infrared Spectroscopy (FTIR)

2.9. Protein Solubility and Chemical Interactions Analysis

2.10. Differential Scanning Calorimetry (DSC)

2.11. Statistical Analysis

3. Results and Discussion

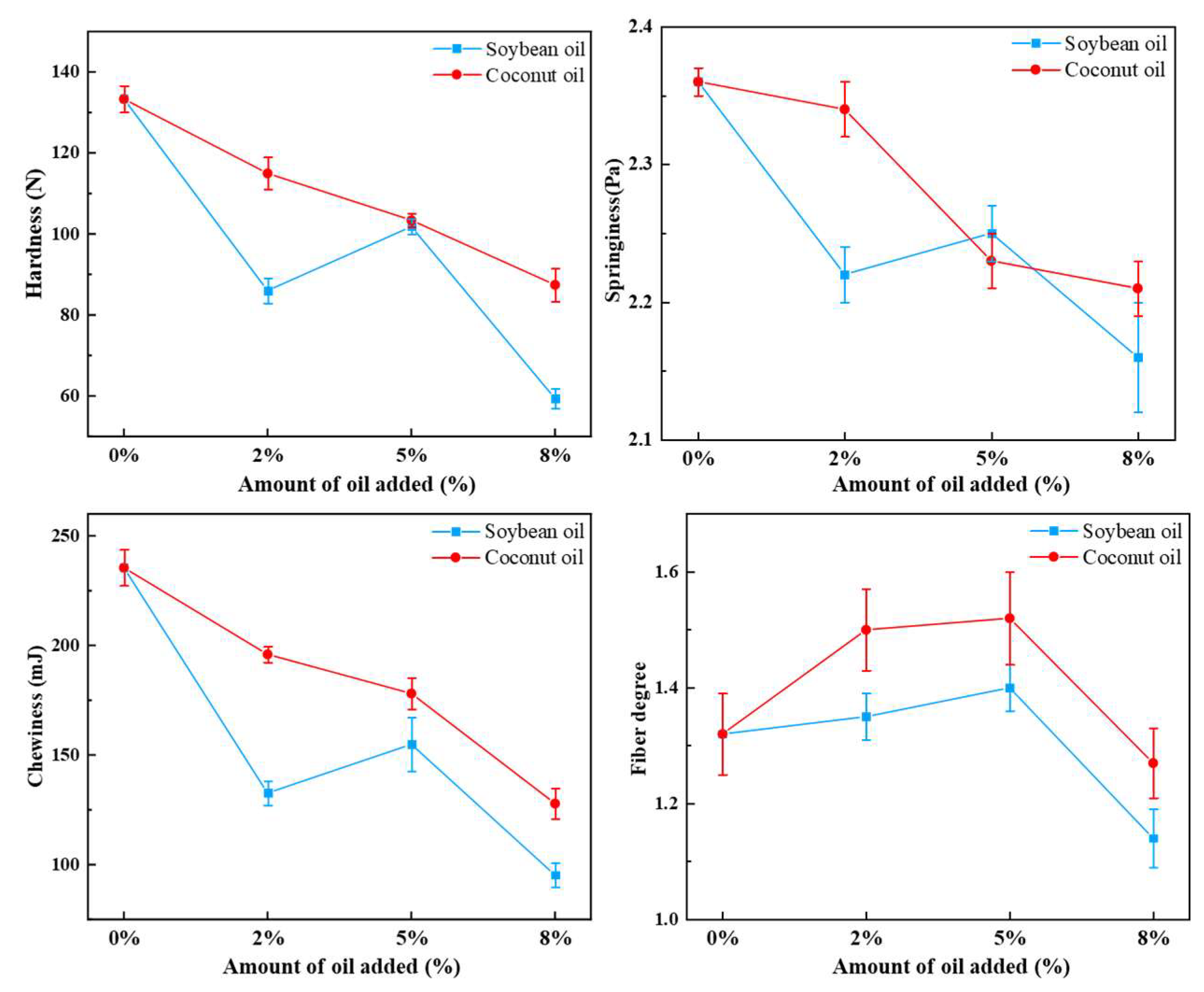

3.1. Textural Properties and Fiber Degree

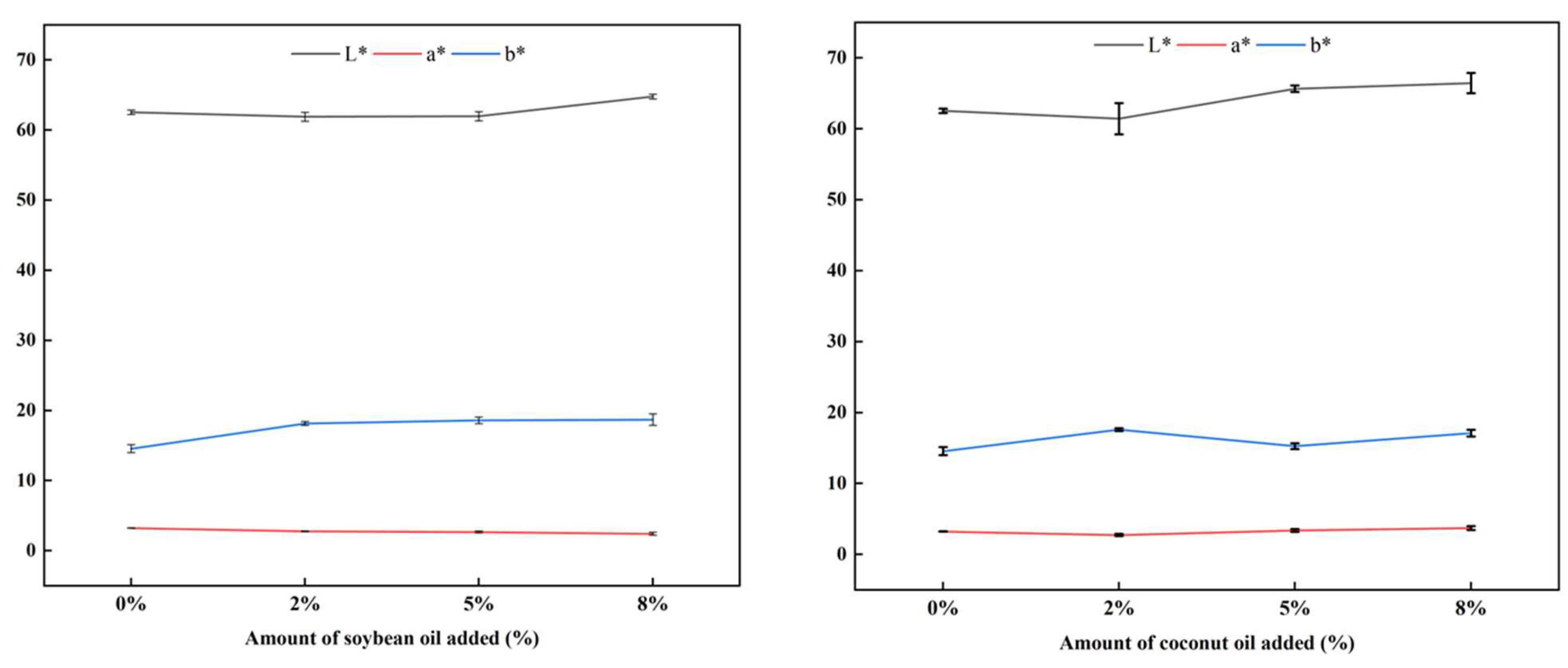

3.2. Color of the Extrudates

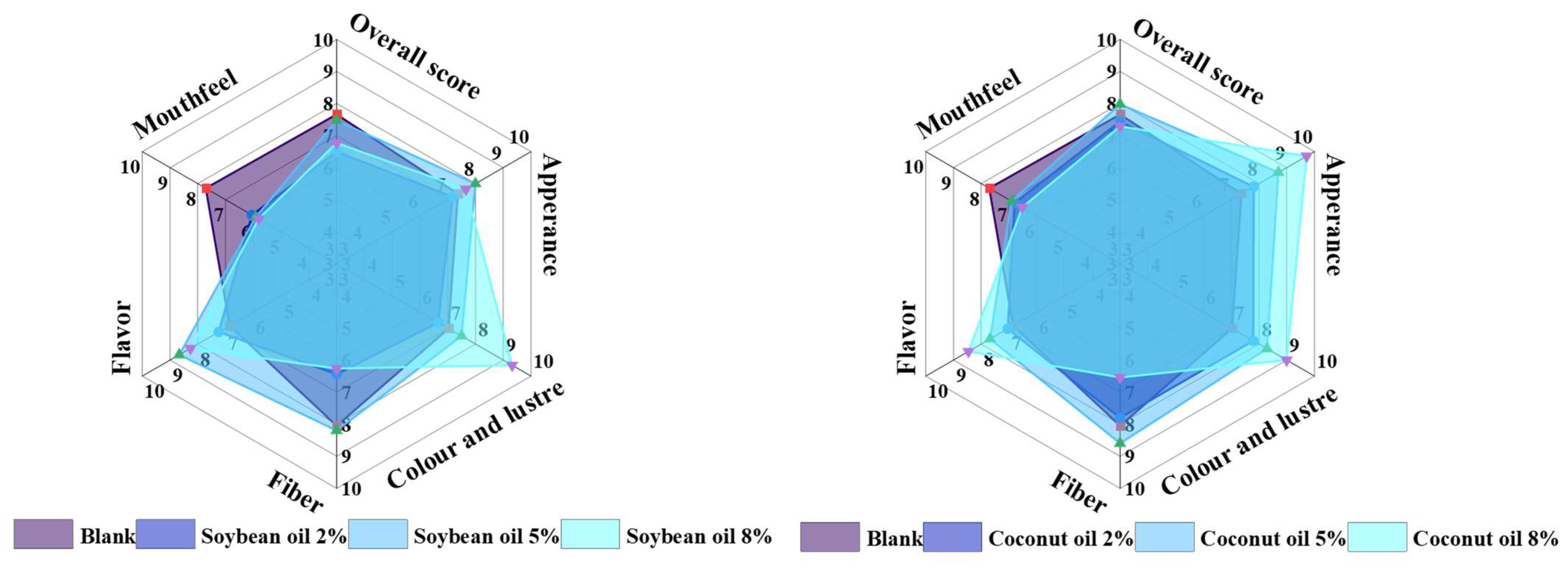

3.3. Sensory Evaluation

3.4. Macroscopic and Microscopic Morphology

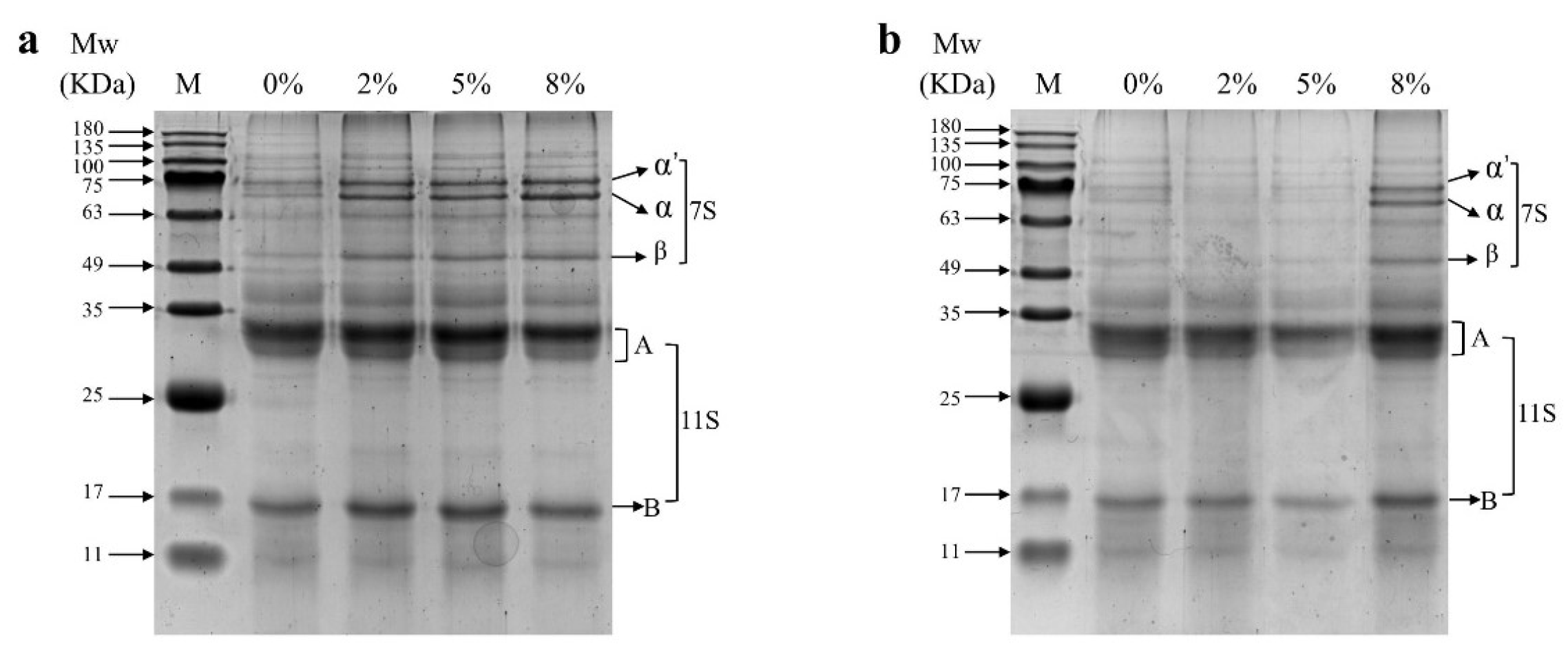

3.5. SDS-PAGE

3.6. Secondary Structure

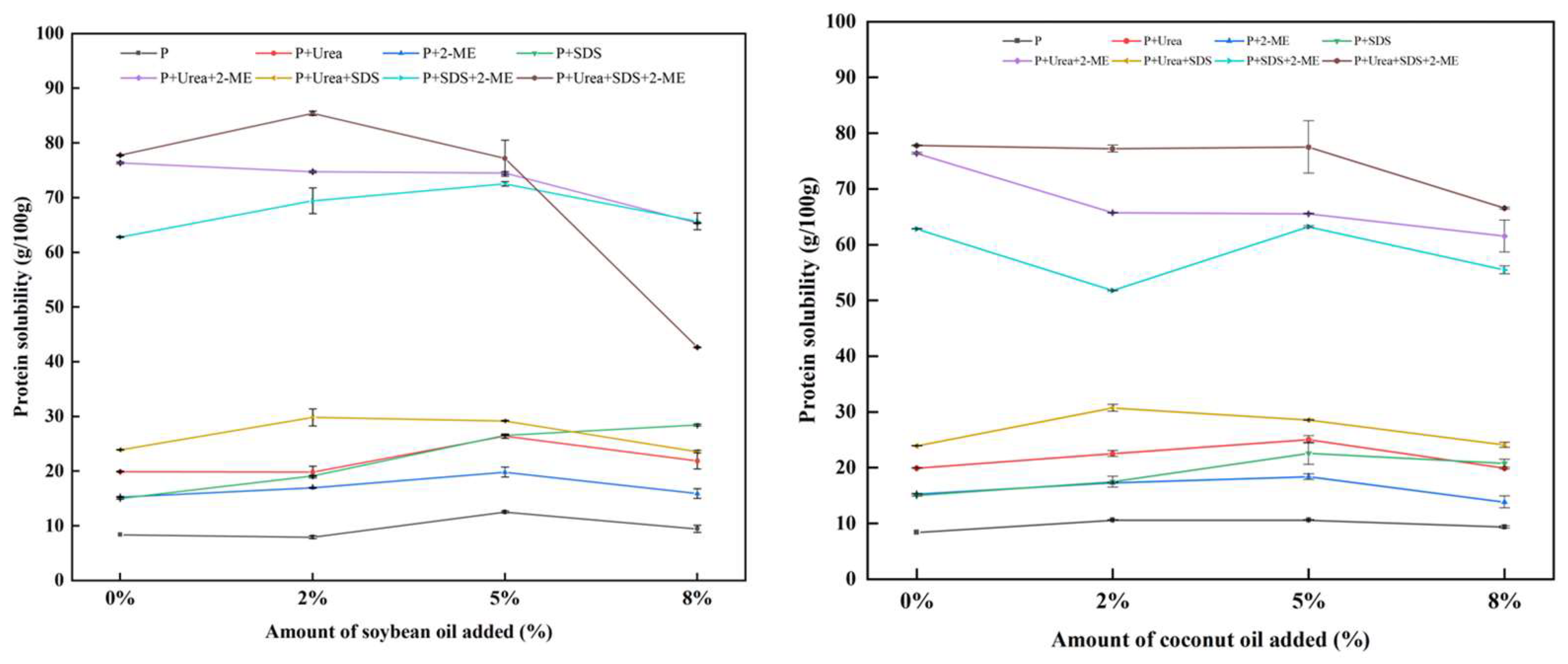

3.7. Protein Solubility and Chemical Cross-Linking

3.8. Thermal Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mattick, C.; Allenby, B. The future of meat. Issues Sci. Technol. 2013, 30, 64–70. [Google Scholar]

- Ou, M.J.; Lou, J.M.; Lao, L.F.; Guo, Y.X.; Pan, D.D.; Yang, H.; Wu, Z. Plant-based meat analogue of soy proteins by the multi-strain solid-state mixing fermentation. Food Chem. 2023, 414, 135671. [Google Scholar] [CrossRef]

- Dai, H.H.; An, H.Z.; Ma, Y.X.; Guo, Y.T.; Du, Y.; Zhu, X.Q.; Luo, Q. Effects of lysine on the physiochemical properties of plant-protein high-moisture extrudates. LWT–Food Sci. Technol. 2023, 173, 114410. [Google Scholar] [CrossRef]

- Murillo, J.S.; Osen, R.; Hiermaier, S.; Ganzenmüller, G. Towards understanding the mechanism of fibrous texture formation during high-moisture extrusion of meat substitutes. J. Food Eng. 2019, 242, 8–20. [Google Scholar] [CrossRef]

- Zhang, J.C.; Liu, L.; Jiang, Y.R.; Shah, F.; Xu, Y.J.; Wang, Q. High-moisture extrusion of peanut protein-/carrageenan/sodium alginate/wheat starch mixtures: Effect of different exogenous polysaccharides on the process forming a fibrous structure. Food Hydrocoll. 2020, 99, 105311. [Google Scholar] [CrossRef]

- Zasypkin, D.V.; Lee, T.C. Extrusion of soybean and wheat flour as affected by moisture content. J. Food Sci. 1998, 63, 1058–1061. [Google Scholar] [CrossRef]

- Lin, S.; Huff, H.E.; Hsieh, F. Extrusion process parameters, sensory characteristics, and structural properties of a high moisture soy protein meat analog. J. Food Sci. 2002, 67, 1066–1072. [Google Scholar] [CrossRef]

- Li, R.L.; Xue, H.; Gao, B.H.; Liu, H.L.; Han, T.F.; Hu, X.B.; Tu, Y.G.; Zhao, Y. Study on the enhancement effect and mechanism of heat-induced gel strength of duck egg white by emulsified lipids. LWT–Food Sci. Technol. 2002, 160, 113146. [Google Scholar] [CrossRef]

- Devi, A.; Khatkar, B.S. Effects of fatty acids composition and microstructure properties of fats and oils on textural properties of dough and cookie quality. J. Food Sci. Technol. 2018, 55, 321–330. [Google Scholar] [CrossRef]

- Kendler, C.; Duchardt, A.; Karbstein, H.P.; Emin, M.A. Effect of oil content and oil addition point on the extrusion processing of wheat gluten-based meat analogues. Foods 2021, 10, 697. [Google Scholar] [CrossRef]

- Guo, X.N.; Gao, F.; Zhu, K.X. Effect of fresh egg white addition on the quality characteristics and protein aggregation of oat noodles. Food Chem. 2020, 330, 127319. [Google Scholar] [CrossRef]

- Xiao, Z.G.; Li, H.; Wang, Z.; Tian, J.J.; Zhu, W.G.; Jin, Z.Y.; He, D.; Wang, N.; Zhu, M.P. Extrusion preparation and quality characteristics of high moisture textured compound protein. J. Chin. Cereals Oils Assoc. 2022, 37, 72–88. [Google Scholar]

- Chen, Q.L.; Zhang, J.C.; Zhang, Y.J.; Wang, Q. Effect of fatty acid saturation degree on the rheological properties of pea protein and its high-moisture extruded product quality. Food Chem. 2022, 390, 133139. [Google Scholar] [CrossRef]

- Chen, F.L.; Wei, Y.M.; Zhang, B. Chemical cross-linking and molecular aggregation of soybean protein during extrusion cooking at low and high moisture content. LWT–Food Sci. Technol. 2011, 44, 957–962. [Google Scholar] [CrossRef]

- Grabowska, K.J.; Tekidou, S.; Boom, R.M.; van der Goot, A.J. Shear structuring as a new method to make anisotropic structures from soy–gluten blends. Food Res. Int. 2014, 64, 743–751. [Google Scholar] [CrossRef]

- Chen, Y.; Liang, Y.; Jia, F.; Chen, D.; Zhang, X.; Wang, Q.; Wang, J.S. Effect of extrusion temperature on the protein aggregation of wheat gluten with the addition of peanut oil during extrusion. Int. J. Biol. Macromol. 2021, 166, 1377–1386. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, R.C.; Zhang, L.T.; Zhang, W.; Bakalis, S.; Li, Y.; Lametsch, R. Physicochemical properties, texture, and in vitro protein digestibility in high-moisture extrudate with different oil/water ratio. Food Res. Int. 2023, 163, 112286. [Google Scholar] [CrossRef]

- Afizah, M.N.; Rizvi, S.S. Functional properties of whey protein concentrate texturized at acidic pH: Effect of extrusion temperature. LWT–Food Sci. Technol. 2014, 57, 290–298. [Google Scholar] [CrossRef]

- Mozafarpour, R.; Koocheki, A.; Milani, E.; Varidi, M. Extruded soy protein as a novel emulsifier: Structure, interfacial activity and emulsifying property. Food Hydrocoll. 2019, 93, 361–373. [Google Scholar] [CrossRef]

- Chen, Q.L.; Zhang, J.C.; Zhang, Y.J.; Meng, S.; Wang, Q. Rheological properties of pea protein isolate-amylose/amylopectin mixtures and the application in the high-moisture extruded meat substitutes. Food Hydrocoll. 2021, 117, 106732. [Google Scholar] [CrossRef]

- Mohammad, A.; Olcott, H.S.; Fraenkel-Conrat, H. The reaction of proteins with acetaldehyde. Arch. Biochem. 1949, 24, 270–280. [Google Scholar]

- Liu, K.; Hsieh, F.H. Protein–protein interactions during high-moisture extrusion for fibrous meat analogues and comparison of protein solubility methods using different solvent systems. J. Agric. Food Chem. 2008, 56, 2681–2687. [Google Scholar] [CrossRef]

- Nishinari, K.; Fang, Y.; Guo, S.; Phillips, G.O. Soy proteins: A review on composition, aggregation and emulsification. Food Hydrocoll. 2014, 39, 301–318. [Google Scholar] [CrossRef]

- Sun, F.W.; Li, B.L.; Guo, Y.A.; Wang, Y.C.; Cheng, T.F.; Yang, Q.Y.; Liu, J.; Fan, Z.J.; Guo, Z.W.; Wang, Z.J. Effects of ultrasonic pretreatment of soybean protein isolate on the binding efficiency, structural changes, and bioavailability of a protein-luteolin nanodelivery system. Ultrason. Sonochem. 2022, 88, 106075. [Google Scholar] [CrossRef]

- Zhou, L.Y.; Zhang, Y.; Zhao, C.B.; Lin, H.J.; Wang, Z.J.; Wu, F. Structural and functional properties of rice bran protein oxidized by peroxyl radicals. Int. J. Food Prop. 2017, 20, 1456–1467. [Google Scholar] [CrossRef]

- Guo, Z.W.; Teng, F.; Huang, Z.X.; Lv, B.; Lv, X.Q.; Babich, O.; Yu, W.H.; Li, Y.; Wang, Z.J.; Jiang, L.Z. Effects of material characteristics on the structural characteristics and flavor substances retention of meat analogs. Food Hydrocoll. 2020, 105, 105752. [Google Scholar] [CrossRef]

- Beck, S.M.; Knoerzer, K.; Arcot, J. Effect of low moisture extrusion on a pea protein isolate’s expansion, solubility, molecular weight distribution and secondary structure as determined by Fourier Transform Infrared Spectroscopy (FTIR). J. Food Eng. 2017, 214, 166–174. [Google Scholar]

- Wang, K.Q.; Li, C.; Wang, B.Z.; Yang, W.; Luo, S.Z.; Zhao, Y.Y.; Jiang, S.T.; Mu, D.D.; Zheng, Z. Formation of macromolecules in wheat gluten/starch mixtures during twin-screw extrusion: Effect of different additives. J. Sci. Food Agric. 2017, 97, 5131–5138. [Google Scholar] [CrossRef]

- Guo, X.Y.; Peng, Z.Q.; Zhang, Y.W.; Liu, B.; Cui, Y.Q. The solubility and conformational characteristics of porcine myosin as affected by the presence of L-lysine and L-histidine. Food Chem. 2015, 170, 212–217. [Google Scholar] [CrossRef]

- Zhao, G.L.; Liu, Y.; Zhao, M.M.; Ren, J.Y.; Yang, B. Enzymatic hydrolysis and their effects on conformational and functional properties of peanut protein isolate. Food Chem. 2011, 127, 1438–1443. [Google Scholar] [CrossRef]

- Chávez-Murillo, C.E.; Veyna-Torres, J.I.; Cavazos-Tamez, L.M.; de la Rosa-Millán, J.; Serna-Saldívar, S.O. Physicochemical characteristics, ATR-FTIR molecular interactions and in vitro starch and protein digestion of thermally-treated whole pulse flours. Food Res. Int. 2018, 105, 371–383. [Google Scholar] [CrossRef] [PubMed]

| Attribute (Weight) | Quality Description and Scoring Criteria | |||

|---|---|---|---|---|

| 1–3 Points | 4–6 Points | 7–9 Points | 10 Points | |

| Appearance (0.1) | Unshaped, loose, and rough surface | Minimally shaped, surface with fractures and granules | Adequately shaped, smooth surface, moderate texture | Perfectly shaped, smooth surface, uniform texture |

| Color (0.1) | Abnormal color | Dark and burnt color | Uniform color, slightly shiny | Uniform color, shiny |

| Texture (0.4) | Without fibrous structure | Poor fibrous structure, nonuniform arrangement, layered structure | Clear fibrous structure, relatively uniform arrangement, without layered structure | Clear fibrous structure, uniform arrangement, without layered structure |

| Flavor (0.1) | Poor flavor, heavy soybean odor | Moderate flavor, slight unpleasant odor | Good flavor, moderate meat aroma and taste, very slight unpleasant odor | Abundant meat aroma and taste, without unpleasant odor |

| Mouthfeel (0.3) | Without springiness, rough mouthfeel, low chewiness | Moderate springiness, hard mouthfeel, low chewiness | High springiness, good mouthfeel, moderate chewiness | High springiness, good mouthfeel, high chewiness |

| Plant Oil Content | 76 kDa | 70 kDa | 53 kDa | 7S | 41 kDa | 35 kDa | 21.4 kDa | 17.8 kDa | 11S | 7S/11S |

|---|---|---|---|---|---|---|---|---|---|---|

| Control | 4.52 ± 0.10 d | 3.67 ± 0.12 c | 3.48 ± 0.15 cd | 11.66 ± 0.13 d | 16.28 ± 0.69 a | 51.55 ± 0.29 bc | 1.98 ± 0.77 a | 18.54 ± 1.63 a | 88.34 ± 0.13 b | 0.13 ± 0.00 d |

| Soybean oil (2%) | 10.75 ± 0.13 a | 8.96 ± 0.39 b | 5.14 ± 0.90 ab | 24.85 ± 1.42 ab | 8.44 ± 2.37 d | 44.97 ± 3.43 d | 0.79 ± 0.55 a | 20.96 ± 0.90 a | 75.16 ± 1.42 de | 0.34 ± 0.03 b |

| Soybean oil (5%) | 8.84 ± 0.09 b | 8.25 ± 0.53 b | 5.92 ± 0.16 ab | 23.00 ± 0.59 bc | 9.62 ± 0.04 cd | 46.53 ± 1.52 cd | 1.35 ± 0.15 a | 19.50 ± 1.11 a | 77.00 ± 0.59 cd | 0.30 ± 0.01 b |

| Soybean oil (8%) | 9.94 ± 0.03 a | 12.51 ± 0.36 a | 6.45 ± 0.13 a | 28.89 ± 0.21 a | 8.53 ± 1.18 d | 42.24 ± 1.50 d | 1.03 ± 0.22 a | 19.31 ± 2.67 a | 71.11 ± 0.21 e | 0.41 ± 0.00 a |

| Coconut oil (2%) | 2.51 ± 0.44 e | 2.23 ± 0.42 c | 2.31 ± 0.56 d | 7.05 ± 1.42 e | 15.09 ± 1.31 ab | 54.37 ± 0.29 ab | 1.89 ± 1.33 a | 21.61 ± 1.15 a | 92.96 ± 1.42 a | 0.08 ± 0.02 d |

| Coconut oil (5%) | 3.21 ± 0.68 e | 3.67 ± 2.04 c | 2.15 ± 0.29 d | 9.03 ± 2.43 de | 13.12 ± 0.15 abc | 59.44 ± 2.09 a | 1.14 ± 0.64 a | 17.28 ± 5.01 a | 90.97 ± 2.43 ab | 0.10 ± 0.03 d |

| Coconut oil (8%) | 7.12 ± 0.15 c | 7.74 ± 0.76 b | 4.77 ± 0.06 bc | 19.63 ± 0.67 c | 12.00 ± 0.21 bcd | 42.78 ± 1.59 d | 1.45 ± 0.21 a | 24.15 ± 0.50 a | 80.37 ± 0.68 c | 0.24 ± 0.01 c |

| Plant Oil Content | β-Sheet (%) | Random Coil (%) | α-Helix (%) | β-Turn (%) |

|---|---|---|---|---|

| Control | 27.99 ± 1.23 d | 20.65 ± 0.41 d | 21.94 ± 0.06 a | 29.41 ± 0.88 a |

| Soybean oil (2%) | 30.69 ± 0.25 bc | 21.28 ± 0.10 c | 21.41 ± 0.18 a | 26.62 ± 0.02 b |

| Soybean oil (5%) | 31.60 ± 0.18 ab | 21.82 ± 0.16 b | 20.14 ± 0.34 b | 26.44 ± 0.68 b |

| Soybean oil (8%) | 29.56 ± 1.31 cd | 22.76 ± 0.15 a | 18.97 ± 0.07 c | 28.71 ± 1.09 a |

| Coconut oil (2%) | 32.06 ± 0.42 ab | 21.30 ± 0.10 c | 20.53 ± 0.26 b | 26.12 ± 0.05 b |

| Coconut oil (5%) | 32.37 ± 0.95 ab | 21.92 ± 0.09 b | 20.44 ± 0.75 b | 25.27 ± 0.10 bc |

| Coconut oil (8%) | 32.90 ± 0.11 a | 22.17 ± 0.48 b | 20.53 ± 0.15 b | 24.40 ± 0.04 c |

| Plant Oil Content | Hydrogen Bond (A) | Disulfide Bond (B) | Hydrophobic Interactions (C) | A + B | A + C | C + B | A + B + C |

|---|---|---|---|---|---|---|---|

| Control | 11.55 ± 0.12 bc | 6.90 ± 0.12 b | 6.65 ± 0.24 c | 49.54 ± 0.24 a | −2.66 ± 0.01 b | 40.90 ± 0.24 a | −43.47 ± 0.35 b |

| Soybean oil (2%) | 11.93 ± 1.87 bc | 9.04 ± 0.22 a | 11.23 ± 0.22 b | 45.84 ± 1.98 a | −1.25 ± 0.44 ab | 41.24 ± 3.20 a | −40.54 ± 3.09 b |

| Soybean oil (5%) | 13.87 ± 0.35 ab | 7.31 ± 1.51 ab | 14.04 ± 0.12 b | 40.80 ± 0.58 b | −11.25 ± 0.58 d | 38.67 ± 1.97 a | −38.75 ± 3.72 b |

| Soybean oil (8%) | 12.45 ± 1.13 abc | 4.47 ± 1.26 c | 19.01 ± 0.72 a | 36.99 ± 2.47 bc | −17.33 ± 1.03 e | 30.73 ± 1.65 b | −55.12 ± 0.31 c |

| Coconut oil (2%) | 11.25 ± 0.59 c | 6.33 ± 0.01 bc | 6.50 ± 1.18 c | 34.41 ± 0.59 cd | 1.25 ± 1.06 a | 25.99 ± 1.18 c | −22.91 ± 0.12 a |

| Coconut oil (5%) | 14.46 ± 0.85 a | 7.79 ± 0.85 ab | 11.98 ± 2.66 b | 32.69 ± 0.24 d | −8.47 ± 3.75 cd | 32.86 ± 1.69 b | −24.39 ± 3.75 a |

| Coconut oil (8%) | 10.54 ± 0.01 c | 6.48 ± 0.31 bc | 11.44 ± 1.26 b | 37.17 ± 2.53 bc | −7.24 ± 0.38 c | 30.20 ± 0.76 bc | −29.39 ± 4.17 a |

| Plant Oil Content | Tp (°C) | ΔH (J/g) |

|---|---|---|

| Control | 163.89 ± 0.62 a | 25.96 ± 0.65 e |

| Soybean oil (2%) | 119.26 ± 3.75 b | 138.48 ± 6.70 ab |

| Soybean oil (5%) | 111.96 ± 0.21 c | 135.73 ± 3.05 b |

| Soybean oil (8%) | 113.65 ± 3.07 bc | 144.17 ± 3.04 a |

| Coconut oil (2%) | 111.07 ± 5.29 c | 113.42 ± 1.04 c |

| Coconut oil (5%) | 111.19 ± 1.67 c | 131.62 ± 3.01 b |

| Coconut oil (8%) | 111.05 ± 3.07 c | 99.30 ± 0.97 d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Hui, B.; Li, X.; Guo, Z.; Ma, J.; Li, J. Effects of Different Soybean and Coconut Oil Additions on the Physicochemical and Sensory Properties of Soy Protein–Wheat Protein Mixture Subjected to High-Moisture Extrusion. Foods 2024, 13, 2263. https://doi.org/10.3390/foods13142263

Zhang W, Hui B, Li X, Guo Z, Ma J, Li J. Effects of Different Soybean and Coconut Oil Additions on the Physicochemical and Sensory Properties of Soy Protein–Wheat Protein Mixture Subjected to High-Moisture Extrusion. Foods. 2024; 13(14):2263. https://doi.org/10.3390/foods13142263

Chicago/Turabian StyleZhang, Wentao, Bowen Hui, Xuejie Li, Zengwang Guo, Jian Ma, and Jian Li. 2024. "Effects of Different Soybean and Coconut Oil Additions on the Physicochemical and Sensory Properties of Soy Protein–Wheat Protein Mixture Subjected to High-Moisture Extrusion" Foods 13, no. 14: 2263. https://doi.org/10.3390/foods13142263