Enhancing Gluten-Free Muffins with Milk Thistle Seed Proteins: Evaluation of Physicochemical, Rheological, Textural, and Sensory Characteristics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation of Milk Thistle Protein Isolate

2.2.2. Preparation of Gluten-Free Muffin Samples

2.2.3. Rheological Characteristics of Gluten-Free Muffin Batters

2.2.4. Physicochemical Characteristics of Gluten-Free Muffin Samples

2.2.5. Textural Properties of Gluten-Free Muffin Samples

2.2.6. Oxidative Stability of Muffin Samples

2.2.7. Sensory Analysis

2.2.8. Statistical Analysis

3. Results and Discussion

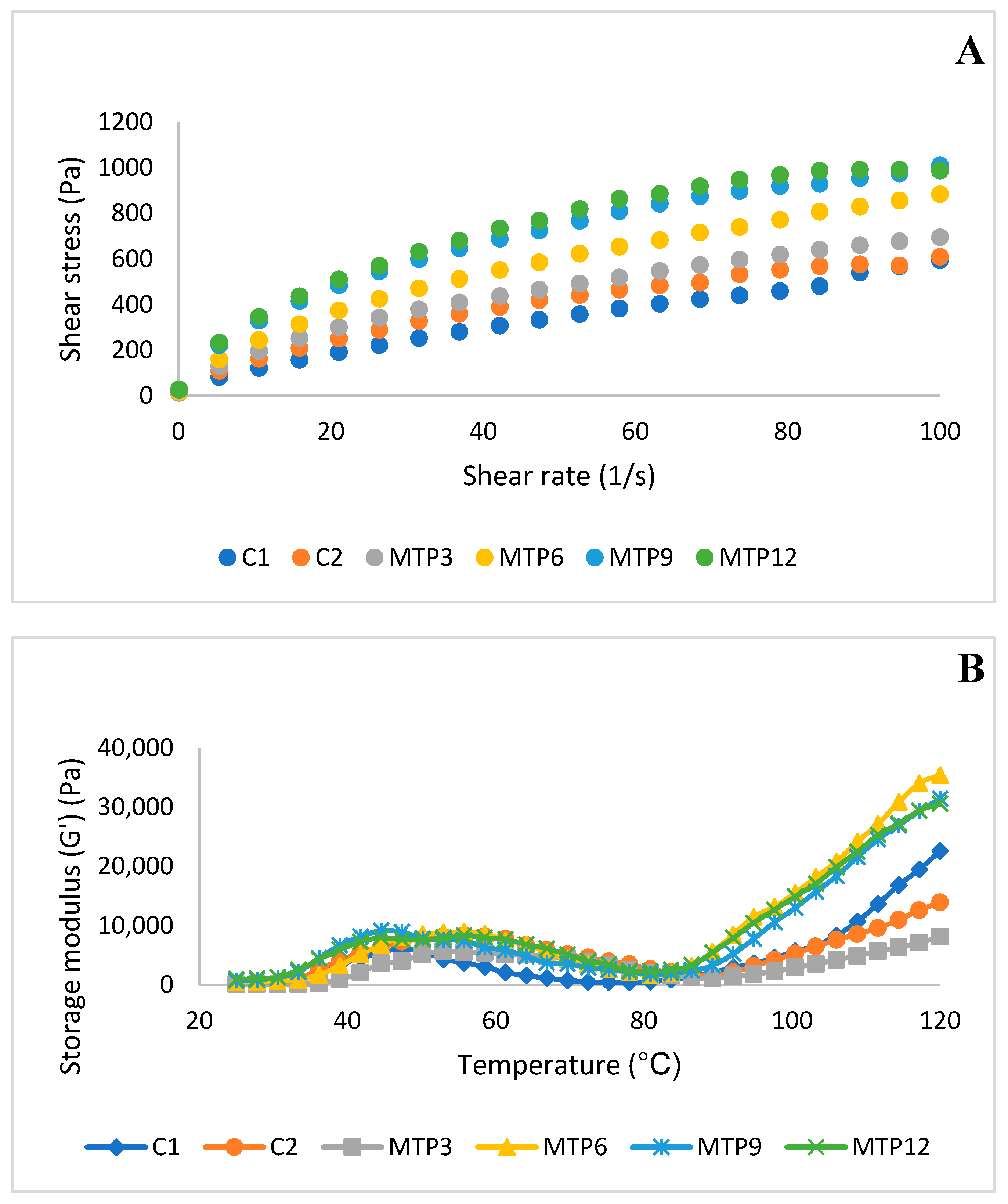

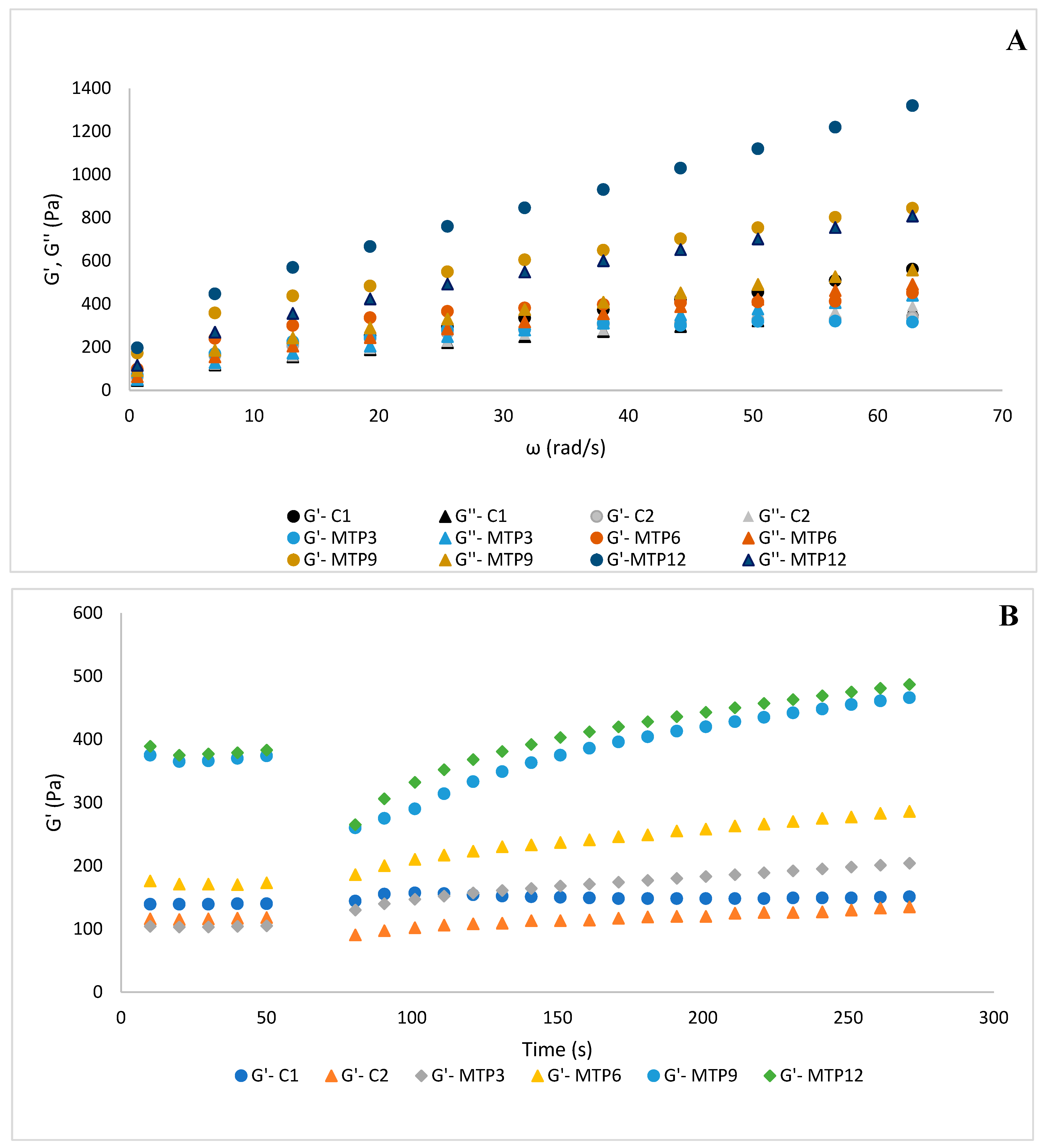

3.1. Rheological Characteristics of Muffin Batters

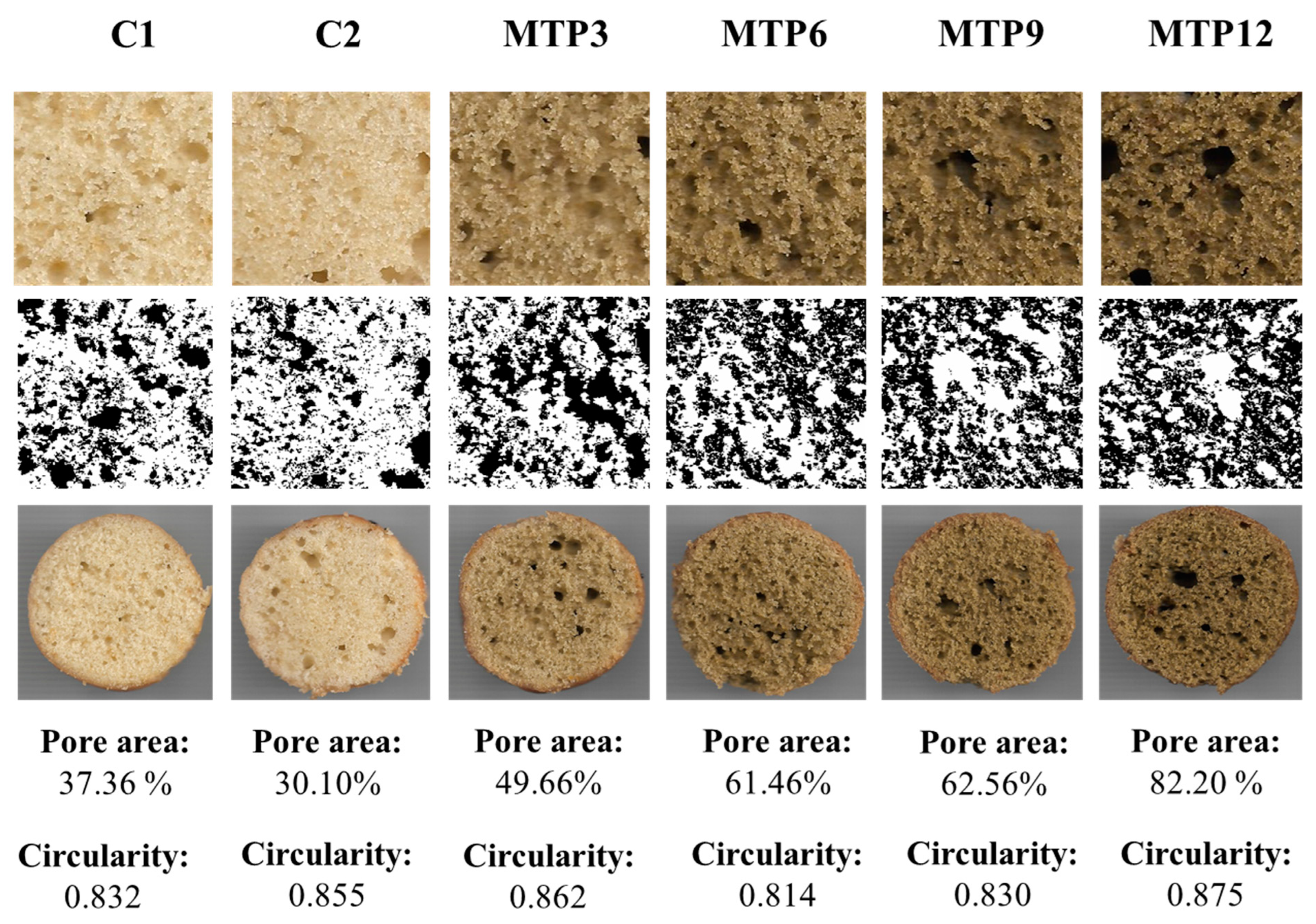

3.2. Physicochemical Characteristics of Muffin Samples

3.3. Textural Properties of Muffin Samples

3.4. Oxidative Stability of Muffin Samples

3.5. Sensory Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choudhry, R.; Yasmin, A.; Aslam, M.A.; Imran, A.; Ahmad, R.S.; Saeed, F.; Islam, F.; Zahoor, T.; Shah, M.A.; Rasool, A. Extraction of protein from apricot kernel oil press cake (AKOPC) through innovative techniques and the formulation of supplemented yogurt. Food Sci. Nutr. 2023, 11, 6085–6095. [Google Scholar] [CrossRef]

- Mamone, G.; Picariello, G.; Ramondo, A.; Nicolai, M.A.; Ferranti, P. Production, digestibility and allergenicity of hemp (Cannabis sativa L.) protein isolates. Food Res. Int. 2019, 115, 562–571. [Google Scholar] [CrossRef] [PubMed]

- Kotecka-Majchrzak, K.; Sumara, A.; Fornal, E.; Montowska, M. Oilseed proteins—Properties and application as a food ingredient. Trends Food Sci. Technol. 2020, 106, 160–170. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, O.; Cai, S.; Zhao, L.; Zhao, L. Composition, functional properties, health benefits and applications of oilseed proteins: A systematic review. Food Res. Int. 2023, 171, 113061. [Google Scholar] [CrossRef]

- Arooj, A.; Rabail, R.; Naeem, M.; Goksen, G.; Xu, B.; Aadil, R.M. A comprehensive review of the bioactive components of sesame seeds and their impact on bone health issues in postmenopausal women. Food Funct. 2023, 14, 4966–4980. [Google Scholar] [CrossRef] [PubMed]

- Jung, S.-J.; Jung, E.-S.; Ha, K.-C.; Baek, H.-I.; Park, Y.-K.; Han, S.-K.; Chae, S.-W.; Lee, S.-O.; Chung, Y.-C. Efficacy and safety of sesame oil cake extract on memory function improvement: A 12-week, randomized, double-blind, placebo-controlled pilot study. Nutrients 2021, 13, 2606. [Google Scholar] [CrossRef]

- Jozinović, A.; Ačkar, D.; Jokić, S.; Babić, J.; Balentić, J.P.; Banožić, M.; Šubarić, D. Optimisation of Extrusion Variables for the Production of Corn Snack Products Enriched with Defatted Hemp Cake. Czech J. Food Sci. 2017, 35, 507–516. [Google Scholar] [CrossRef]

- Usman, I.; Saif, H.; Imran, A.; Afzaal, M.; Saeed, F.; Azam, I.; Afzal, A.; Ateeq, H.; Islam, F.; Shah, Y.A.; et al. Innovative applications and therapeutic potential of oilseeds and their by-products: An eco-friendly and sustainable approach. Food Sci. Nutr. 2023, 11, 2599–2609. [Google Scholar] [CrossRef] [PubMed]

- Czaja-Bulsa, G. Non coeliac gluten sensitivity—A new disease with gluten intolerance. Clin. Nutr. 2015, 34, 189–194. [Google Scholar] [CrossRef]

- Fu, W.; Yano, H. Development of “new” bread and cheese. Processes 2020, 8, 1541. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. Hemp (Cannabis sativa subsp. sativa) flour and protein preparation as natural nutrients and structure forming agents in starch based gluten-free bread. LWT 2017, 84, 143–150. [Google Scholar] [CrossRef]

- Hager, A.-S.; Wolter, A.; Jacob, F.; Zannini, E.; Arendt, E.K. Nutritional properties and ultra-structure of commercial gluten free flours from different botanical sources compared to wheat flours. J. Cereal Sci. 2012, 56, 239–247. [Google Scholar] [CrossRef]

- Akcicek, A.; Ozgolet, M.; Tekin-Cakmak, Z.H.; Karasu, S.; Duran, E.; Sagdic, O. Cold-Pressed Okra Seed Oil Byproduct as an Ingredient for Muffins to Decrease Glycemic Index, Maillard Reaction, and Oxidation. ACS Omega 2024, 9, 7491–7501. [Google Scholar] [CrossRef]

- Brites, L.T.G.F.; Rebellato, A.P.; Meinhart, A.D.; Godoy, H.T.; Steel, C.J. Antioxidant-enriched gluten-free bread made with buckwheat flour: Evaluation of technological and nutritional quality. Cereal Chem. 2022, 99, 995–1006. [Google Scholar] [CrossRef]

- Matos, M.E.; Sanz, T.; Rosell, C.M. Establishing the function of proteins on the rheological and quality properties of rice based gluten free muffins. Food Hydrocoll. 2014, 35, 150–158. [Google Scholar] [CrossRef]

- Shevkani, K.; Kaur, A.; Kumar, S.; Singh, N. Cowpea protein isolates: Functional properties and application in gluten-free rice muffins. LWT 2015, 63, 927–933. [Google Scholar] [CrossRef]

- Monfared, M.R.; Nouri, L.; Nafchi, A.M. The effects of sesame protein isolate and transglutaminase enzyme on the quality characteristics of gluten-free batter and cake. J. Food Meas. Charact. 2023, 17, 4881–4891. [Google Scholar] [CrossRef]

- Ozgolet, M.; Cakmak, Z.H.T.; Bozkurt, F.; Sagdic, O.; Karasu, S. Optimization of extraction parameters of protein isolate from milk thistle seed: Physicochemical and functional characteristics. Food Sci. Nutr. 2024, 12, 3346–3359. [Google Scholar] [CrossRef]

- Gökşen, G.; Ekiz, H.I. Use of aniseed cold-pressed by-product as a food ingredient in muffin formulation. LWT 2021, 148, 111722. [Google Scholar] [CrossRef]

- Toker, O.S.; Karasu, S.; Yilmaz, M.T.; Karaman, S. Three interval thixotropy test (3ITT) in food applications: A novel technique to determine structural regeneration of mayonnaise under different shear conditions. Food Res. Int. 2015, 70, 125–133. [Google Scholar] [CrossRef]

- Aranibar, C.; Aguirre, A.; Borneo, R. Utilization of a by-product of chia oil extraction as a potential source for value addition in wheat muffins. J. Food Sci. Technol. 2019, 56, 4189–4197. [Google Scholar] [CrossRef] [PubMed]

- Sahin, M.; Ozgolet, M.; Cankurt, H.; Dertli, E. Harnessing the Role of Three Lactic Acid Bacteria (LAB) Strains for Type II Sourdough Production and Influence of Sourdoughs on Bread Quality and Maillard Reaction Products. Foods 2024, 13, 1801. [Google Scholar] [CrossRef]

- Aksoy, F.S.; Tekin-Cakmak, Z.H.; Karasu, S.; Aksoy, A.S. Oxidative stability of the salad dressing enriched by microencapsulated phenolic extracts from cold-pressed grape and pomegranate seed oil by-products evaluated using OXITEST. Food Sci. Technol. 2022, 42, e57220. [Google Scholar] [CrossRef]

- Alvarez, M.D.; Herranz, B.; Fuentes, R.; Cuesta, F.J.; Canet, W. Replacement of wheat flour by chickpea flour in muffin batter: Effect on rheological properties. J. Food Process Eng. 2017, 40, e12372. [Google Scholar] [CrossRef]

- Ghaemi, P.; Arabshahi-Delouee, S.; Aalami, M.; Hosseini Ghaboos, S.H. The Effect of Whey Protein Concentrate, Soy Protein Isolate, and Xanthan Gum on Textural and Rheological Characteristics of Gluten-Free Batter and Cake. J. Food Process. Preserv. 2024, 2024, 5571107. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, B.; Kaur, A. Influence of different oilseed cake incorporation on batter rheology, proximate composition, texture, antioxidant and sensory properties of wheat flour muffins. Int. J. Food Sci. Technol. 2022, 57, 7107–7115. [Google Scholar] [CrossRef]

- Shevkani, K.; Singh, N. Influence of kidney bean, field pea and amaranth protein isolates on the characteristics of starch-based gluten-free muffins. Int. J. Food Sci. Technol. 2014, 49, 2237–2244. [Google Scholar] [CrossRef]

- Noisuwan, A.; Hemar, Y.; Wilkinson, B.; Bronlund, J. Adsorption of milk proteins onto rice starch granules. Carbohydr. Polym. 2011, 84, 247–254. [Google Scholar] [CrossRef]

- Wang, S.; Chao, C.; Cai, J.; Niu, B.; Copeland, L.; Wang, S. Starch–lipid and starch–lipid–protein complexes: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1056–1079. [Google Scholar] [CrossRef]

- Singh, J.P.; Kaur, A.; Singh, N. Development of eggless gluten-free rice muffins utilizing black carrot dietary fibre concentrate and xanthan gum. J. Food Sci. Technol. 2016, 53, 1269–1278. [Google Scholar] [CrossRef]

- Marco, C.; Rosell, C.M. Functional and rheological properties of protein enriched gluten free composite flours. J. Food Eng. 2008, 88, 94–103. [Google Scholar] [CrossRef]

- Bala, M.; Kumar, T.V.A.; Tushir, S.; Nanda, S.K.; Gupta, R.K. Quality protein maize based muffins: Influence of non-gluten proteins on batter and muffin characteristics. J. Food Sci. Technol. 2019, 56, 713–723. [Google Scholar] [CrossRef]

- Sopotenska, I.; Chonova, V. Image analysis of gluten free muffins’ porosity. Sci. Work. Univ. Food Technol. 2019, 66, 43–48. [Google Scholar]

- Kuang, J.; Huang, J.; Ma, W.; Min, C.; Pu, H.; Xiong, Y.L. Influence of reconstituted gluten fractions on the short-term and long-term retrogradation of wheat starch. Food Hydrocoll. 2022, 130, 107716. [Google Scholar] [CrossRef]

- Al-Neshawy, A.; Al-Eid, S. Improving the quality and oxidative stability of vegetable oil shortening using fermented dairy products and wheat gluten. Food Chem. 2000, 71, 57–60. [Google Scholar] [CrossRef]

- Mastrocola, D.; Munari, M.; Cioroi, M.; Lerici, C.R. Interaction between Maillard reaction products and lipid oxidation in starch-based model systems. J. Sci. Food Agric. 2000, 80, 684–690. [Google Scholar] [CrossRef]

- González-Mateo, S.; González-SanJosé, M.; Muñiz, P. Presence of Maillard products in Spanish muffins and evaluation of colour and antioxidant potential. Food Chem. Toxicol. 2009, 47, 2798–2805. [Google Scholar] [CrossRef] [PubMed]

- Marinopoulou, A.; Papastergiadis, E.; Raphaelides, S.N.; Kontominas, M.G. Morphological characteristics, oxidative stability and enzymic hydrolysis of amylose-fatty acid complexes. Carbohydr. Polym. 2016, 141, 106–115. [Google Scholar] [CrossRef] [PubMed]

- Wendin, K.; Höglund, E.; Andersson, M.; Rothenberg, E. Protein enriched foods and healthy ageing: Effects of protein fortification on muffin characteristics. Agro Food Ind. Hi-Tech 2017, 28, 16–18. [Google Scholar]

- Sahagún, M.; Bravo-Núñez, Á.; Báscones, G.; Gómez, M. Influence of protein source on the characteristics of gluten-free layer cakes. LWT 2018, 94, 50–56. [Google Scholar] [CrossRef]

| K | n | R2 | K′ | n′ | R2 | K″ | n″ | R2 | |

|---|---|---|---|---|---|---|---|---|---|

| C1 | 21.00 ± 1.15 f | 0.72 ± 0.06 a | 0.997 | 130.79 ± 3.75 c | 0.61 ± 0.02 a | 0.992 | 39.35 ± 2.01 d | 0.54 ± 0.03 ab | 0.998 |

| C2 | 46.46 ± 1.37 e | 0.56 ± 0.04 b | 0.998 | 86.52 ± 2.22 e | 0.34 ± 0.03 cd | 0.996 | 37.92 ± 2.27 d | 0.56 ± 0.03 ab | 0.997 |

| MTP3 | 55.58 ± 1.87 d | 0.55 ± 0.02 b | 0.999 | 103.53 ± 3.16 d | 0.29 ± 0.02 d | 0.985 | 38.01 ± 2.20 d | 0.58 ± 0.02 a | 0.997 |

| MTP6 | 67.79 ± 2.07 c | 0.56 ± 0.03 b | 0.999 | 142.47 ± 2.69 b | 0.28 ± 0.04 d | 0.989 | 50.03 ± 3.13 c | 0.55 ± 0.04 ab | 0.996 |

| MTP9 | 112.79 ± 2.52 b | 0.48 ± 0.04 b | 0.998 | 158.44 ± 3.82 a | 0.40 ± 0.04 c | 0.994 | 66.67 ± 3.27 b | 0.51 ± 0.02 ab | 0.994 |

| MTP12 | 128.15 ± 3.62 a | 0.46 ± 0.05 b | 0.994 | 150.66 ± 3.95 ab | 0.51 ± 0.04 b | 0.992 | 99.51 ± 2.84 a | 0.50 ± 0.03 b | 0.997 |

| Sample | G0 | Ge | Ge/G0 | k × 1000 | R2 | %Def | %Rec | Rtime (s) |

|---|---|---|---|---|---|---|---|---|

| C1 | 143.47 ± 2.95 c | 154.35 ± 3.00 e | 1.08 | 6.20 ± 0.20 b | 0.995 | - | 111.4 | - |

| C2 | 87.32 ± 2.37 d | 160.39 ± 1.76 e | 1.85 | 7.17 ± 0.35 b | 0.988 | 23.2 | 89.8 | 95.5 |

| MTP3 | 90.71 ± 2.39 d | 251.85 ± 4.40 d | 2.74 | 3.57 ± 0.35 c | 0.998 | - | 144.8 | - |

| MTP6 | 176.40 ± 6.60 b | 359.31 ± 6.36 c | 2.03 | 6.42 ± 0.24 b | 0.994 | - | 125.4 | - |

| MTP9 | 235.89 ± 3.51 a | 631.51 ± 5.56 a | 2.69 | 2.79 ± 0.19 c | 0.994 | 30.5 | 84.0 | 69.7 |

| MTP12 | 237.05 ± 4.75 a | 587.77 ± 4.01 b | 2.48 | 11.46 ± 0.65 a | 0.998 | 30.8 | 91.9 | 51.5 |

| Sample | Specific Volume (cm3) | Height (cm) | Baking Loss (%) | Porosity (%) | Circularity | Protein (%) | 1st Day | Aw 4th Day | 7th Day | IP (h:min) |

|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 2.02 ± 0.03 cd | 45.3 ± 0.2 c | 9.74 ± 0.26 d | 37.66 ± 1.37 d | 0.832 ± 0.005 c | 5.39 ± 0.07 bc | 0.782 ± 0.003 c | 0.754 ± 0.003 cd | 0.746 ± 0.002 abc | 10:54 ± 0.49 a |

| C2 | 1.95 ± 0.03 d | 45.2 ± 0.2 c | 9.88 ± 0.14 cd | 30.39 ± 2.06 e | 0.856 ± 0.003 b | 3.63 ± 0.06 e | 0.788 ± 0.002 b | 0.758 ± 0.003 bc | 0.753 ± 0.003 a | 11:08 ± 0.32 a |

| MTP3 | 2.17 ± 0.04 a | 45.0 ± 0.2 c | 10.14 ± 0.13 cd | 50.31 ± 3.11 c | 0.861 ± 0.003 ab | 4.11 ± 0.07 d | 0.794 ± 0.002 a | 0.774 ± 0.001 a | 0.751 ± 0.002 ab | 8:40 ± 0.49 b |

| MTP6 | 2.07 ± 0.03 bc | 45.4 ± 0.2 c | 10.31 ± 0.23 bc | 60.73 ± 1.92 b | 0.813 ± 0.007 d | 5.22 ± 0.11 c | 0.789 ± 0.001 ab | 0.763 ± 0.003 b | 0.738 ± 0.002 d | 9:32 ± 0.21 b |

| MTP9 | 2.10 ± 0.03 ab | 48.3 ± 0.5 a | 11.03 ± 0.10 a | 62.69 ± 1.35 b | 0.830 ± 0.006 c | 5.57 ± 0.07 b | 0.788 ± 0.002 bc | 0.751 ± 0.002 d | 0.745 ± 0.004 bc | 9:07 ± 0.17 b |

| MTP12 | 2.06 ± 0.04 bc | 47.0 ± 0.5 b | 10.75 ± 0.27 ab | 79.88 ± 2.64 a | 0.872 ± 0.003 a | 6.13 ± 0.10 a | 0.784 ± 0.002 bc | 0.749 ± 0.003 d | 0.741 ± 0.002 cd | 9:19 ± 0.19 b |

| Parameters | Storage Day | C1 | C2 | MTP3 | MTP6 | MTP9 | MTP12 |

|---|---|---|---|---|---|---|---|

| Hardness (N) | 1 | 6.96 ± 0.18 b | 7.81 ± 0.21 a | 7.92 ± 0.14 a | 7.98 ± 0.09 a | 6.70 ± 0.19 b | 6.81 ± 0.13 b |

| 4 | 13.76 ± 0.13 c | 23.58 ± 0.34 a | 23.65 ± 0.64 a | 23.27 ± 0.47 a | 20.45 ± 0.60 b | 19.42 ± 0.42 b | |

| 7 | 19.50 ± 0.38 c | 28.65 ± 0.92 a | 29.16 ± 1.26 a | 30.58 ± 0.51 a | 26.44 ± 0.71 b | 24.37 ± 0.62 b | |

| Springiness | 1 | 0.914 ± 0.005 b | 0.925 ± 0.006 b | 0.951 ± 0.009 a | 0.953 ± 0.005 a | 0.950 ± 0.005 a | 0.962 ± 0.004 a |

| 4 | 0.888 ± 0.004 b | 0.826 ± 0.006 d | 0.871 ± 0.010 c | 0.869 ± 0.004 c | 0.904 ± 0.004 a | 0.895 ± 0.004 ab | |

| 7 | 0.846 ± 0.004 b | 0.796 ± 0.004 c | 0.783 ± 0.006 c | 0.850 ± 0.008 b | 0.870 ± 0.011 a | 0.841 ± 0.008 b | |

| Cohesiveness | 1 | 0.692 ± 0.003 b | 0.664 ± 0.006 c | 0.719 ± 0.015 a | 0.714 ± 0.007 ab | 0.731 ± 0.011 a | 0.729 ± 0.005 a |

| 4 | 0.553 ± 0.008 a | 0.383 ± 0.012 e | 0.461 ± 0.010 cd | 0.454 ± 0.012 d | 0.485 ± 0.005 bc | 0.493 ± 0.006 b | |

| 7 | 0.471 ± 0.009 a | 0.327 ± 0.012 d | 0.328 ± 0.003 d | 0.371 ± 0.009 c | 0.377 ± 0.008 c | 0.410 ± 0.010 b | |

| Chewiness | 1 | 4.410 ± 0.114 c | 4.795 ± 0.056 b | 5.407 ± 0.036 a | 5.432 ± 0.137 a | 4.660 ± 0.180 bc | 4.787 ± 0.076 b |

| 4 | 6.755 ± 0.180 c | 7.454 ± 0.380 c | 9.498 ± 0.163 a | 9.179 ± 0.102 ab | 8.958 ± 0.325 ab | 8.572 ± 0.315 b | |

| 7 | 7.772 ± 0.030 c | 7.474 ± 0.536 c | 7.493 ± 0.340 c | 9.639 ± 0.296 a | 8.675 ± 0.309 b | 8.303 ± 0.085 bc | |

| Resilience | 1 | 0.337 ± 0.005 c | 0.356 ± 0.006 b | 0.378 ± 0.010 a | 0.374 ± 0.006 ab | 0.375 ± 0.005 a | 0.377 ± 0.008 a |

| 4 | 0.245 ± 0.005 a | 0.177 ± 0.007 c | 0.228 ± 0.008 ab | 0.217 ± 0.005 b | 0.231 ± 0.006 ab | 0.228 ± 0.007 ab | |

| 7 | 0.199 ± 0.007 a | 0.174 ± 0.004 b | 0.157 ± 0.007 c | 0.177 ± 0.007 b | 0.178 ± 0.003 b | 0.185 ± 0.004 ab |

| Appearance | Taste/Flavor | Smell/Odor | Texture/Mouthfeel | Sweetness | Overall Quality | |

|---|---|---|---|---|---|---|

| C1 | 4.69 ± 0.48 a | 4.39 ± 0.77 a | 4.15 ± 0.69 a | 4.46 ± 0.66 a | 4.38 ± 0.77 a | 4.46 ± 0.66 a |

| C2 | 4.38 ± 0.77 ab | 4.00 ± 1.00 ab | 4.23 ± 0.73 a | 3.77 ± 1.09 ab | 4.15 ± 0.90 a | 4.15 ± 0.80 ab |

| MTP3 | 4.23 ± 0.73 ab | 3.92 ± 0.76 ab | 4.15 ± 0.56 a | 3.69 ± 0.63 ab | 3.92 ± 0.86 a | 3.85 ± 0.69 ab |

| MTP6 | 4.08 ± 0.76 ab | 3.77 ± 0.60 ab | 4.08 ± 0.64 a | 3.69 ± 0.63 ab | 4.00 ± 0.91 a | 3.92 ± 0.64 ab |

| MTP9 | 3.85 ± 0.69 b | 3.31 ± 0.95 b | 3.92 ± 0.76 a | 3.62 ± 0.51 ab | 3.69 ± 1.11 a | 3.39 ± 0.65 b |

| MTP12 | 3.77 ± 0.73 b | 3.31 ± 1.03 b | 3.77 ± 0.60 a | 3.54 ± 0.78 b | 3.46 ± 1.20 a | 3.46 ± 0.78 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozgolet, M.; Kasapoglu, M.Z.; Avcı, E.; Karasu, S. Enhancing Gluten-Free Muffins with Milk Thistle Seed Proteins: Evaluation of Physicochemical, Rheological, Textural, and Sensory Characteristics. Foods 2024, 13, 2542. https://doi.org/10.3390/foods13162542

Ozgolet M, Kasapoglu MZ, Avcı E, Karasu S. Enhancing Gluten-Free Muffins with Milk Thistle Seed Proteins: Evaluation of Physicochemical, Rheological, Textural, and Sensory Characteristics. Foods. 2024; 13(16):2542. https://doi.org/10.3390/foods13162542

Chicago/Turabian StyleOzgolet, Muhammed, Muhammed Zahid Kasapoglu, Esra Avcı, and Salih Karasu. 2024. "Enhancing Gluten-Free Muffins with Milk Thistle Seed Proteins: Evaluation of Physicochemical, Rheological, Textural, and Sensory Characteristics" Foods 13, no. 16: 2542. https://doi.org/10.3390/foods13162542