Technological Evaluation of Fiber Effects in Wheat-Based Dough and Bread

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Flour and Dough Characteristics

2.2.1. Water Retention Capacity

2.2.2. Water Absorption and Kneading Properties

2.2.3. Chopin Alveograph

2.2.4. Pasting Properties

2.2.5. Dough Expansion during Proofing (Yeast Activity and Dough Rise)

2.3. Bread-Making Procedure

2.4. Technological Bread Evaluation

2.5. Statistical Analysis

3. Results and Discussion

3.1. Compositional Information Regarding Featured Fiber Products

3.2. Effect of Fiber Concentration (0–10%) on Dough and Gelatinization Parameters

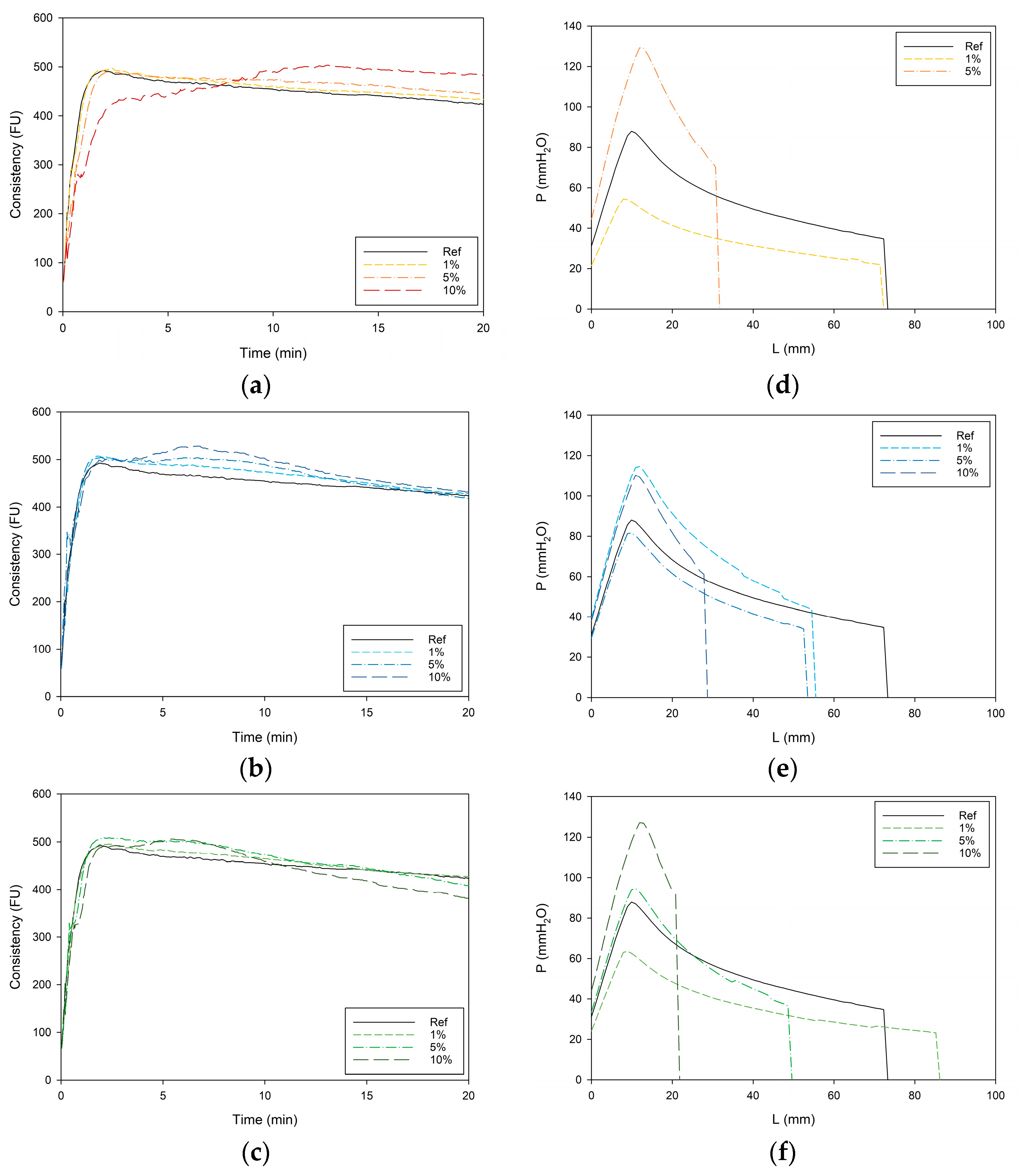

3.2.1. Traditional Dough Analysis

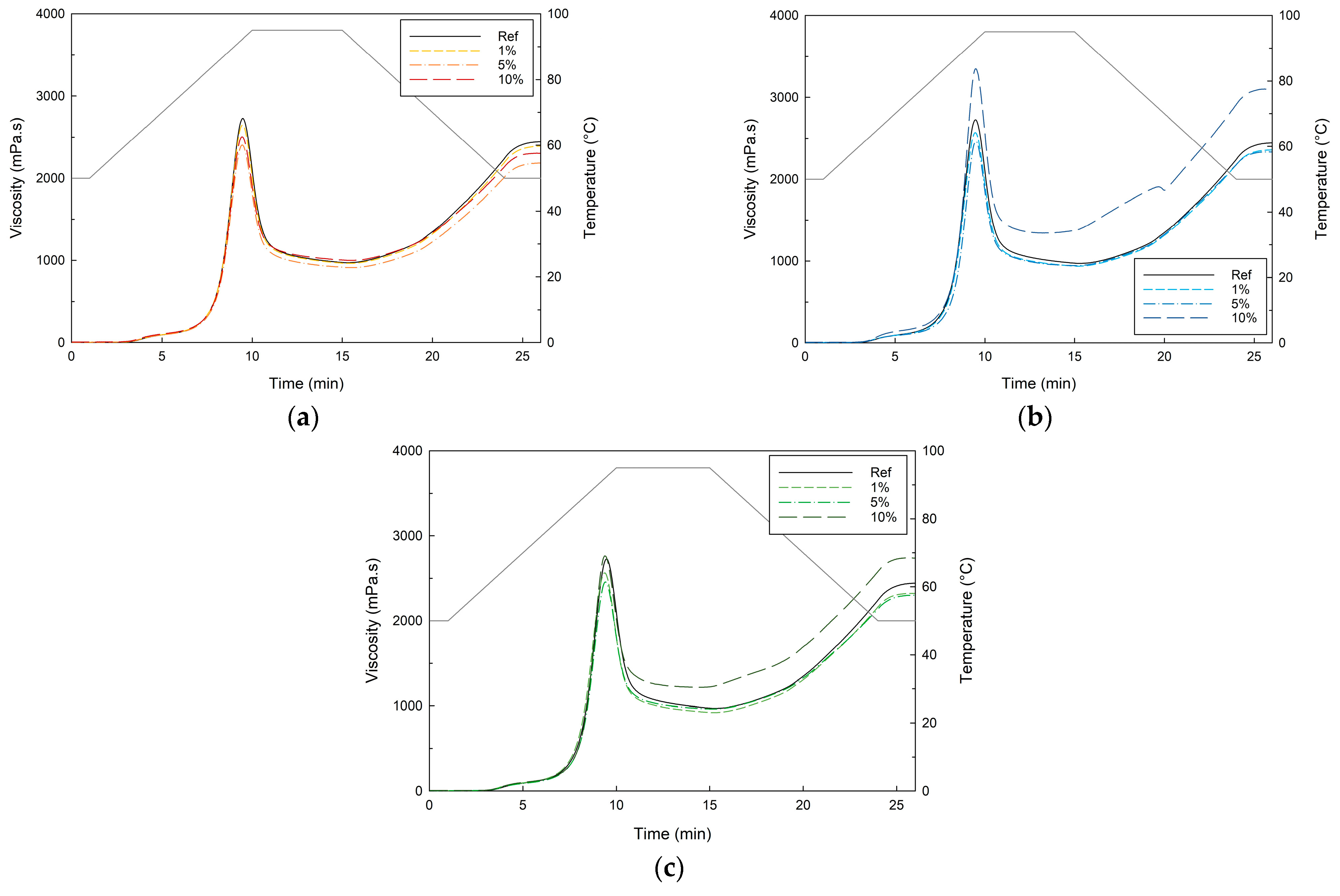

3.2.2. Pasting Analysis

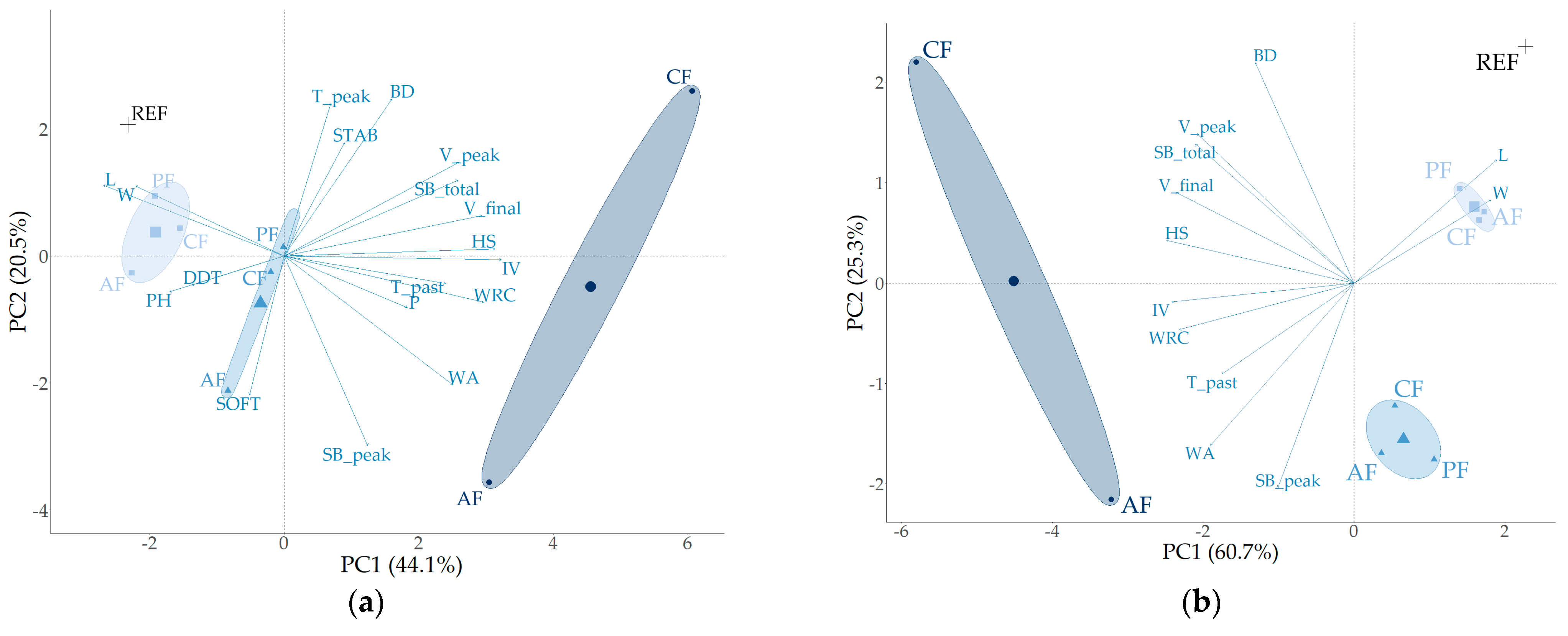

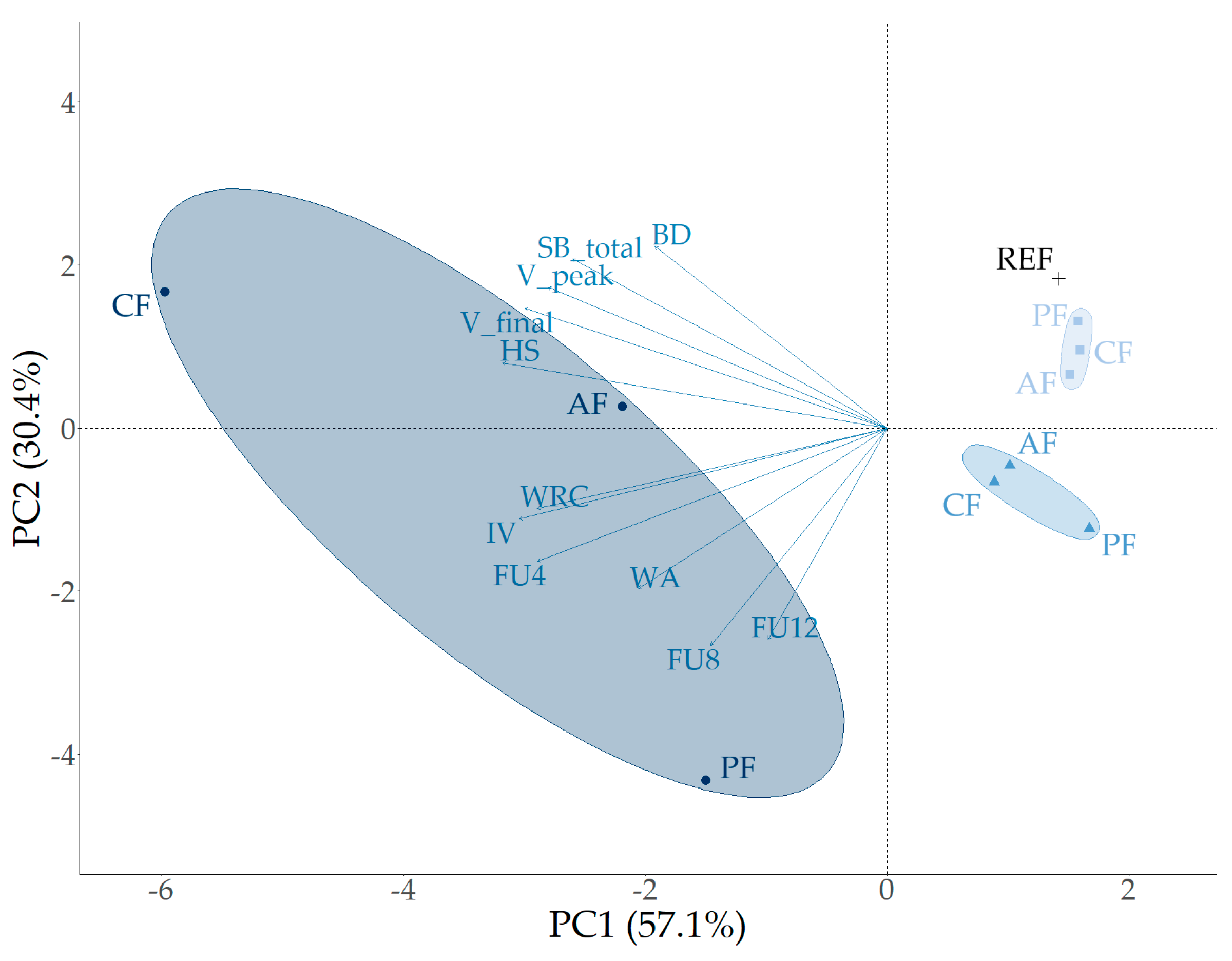

3.2.3. Cluster Analysis

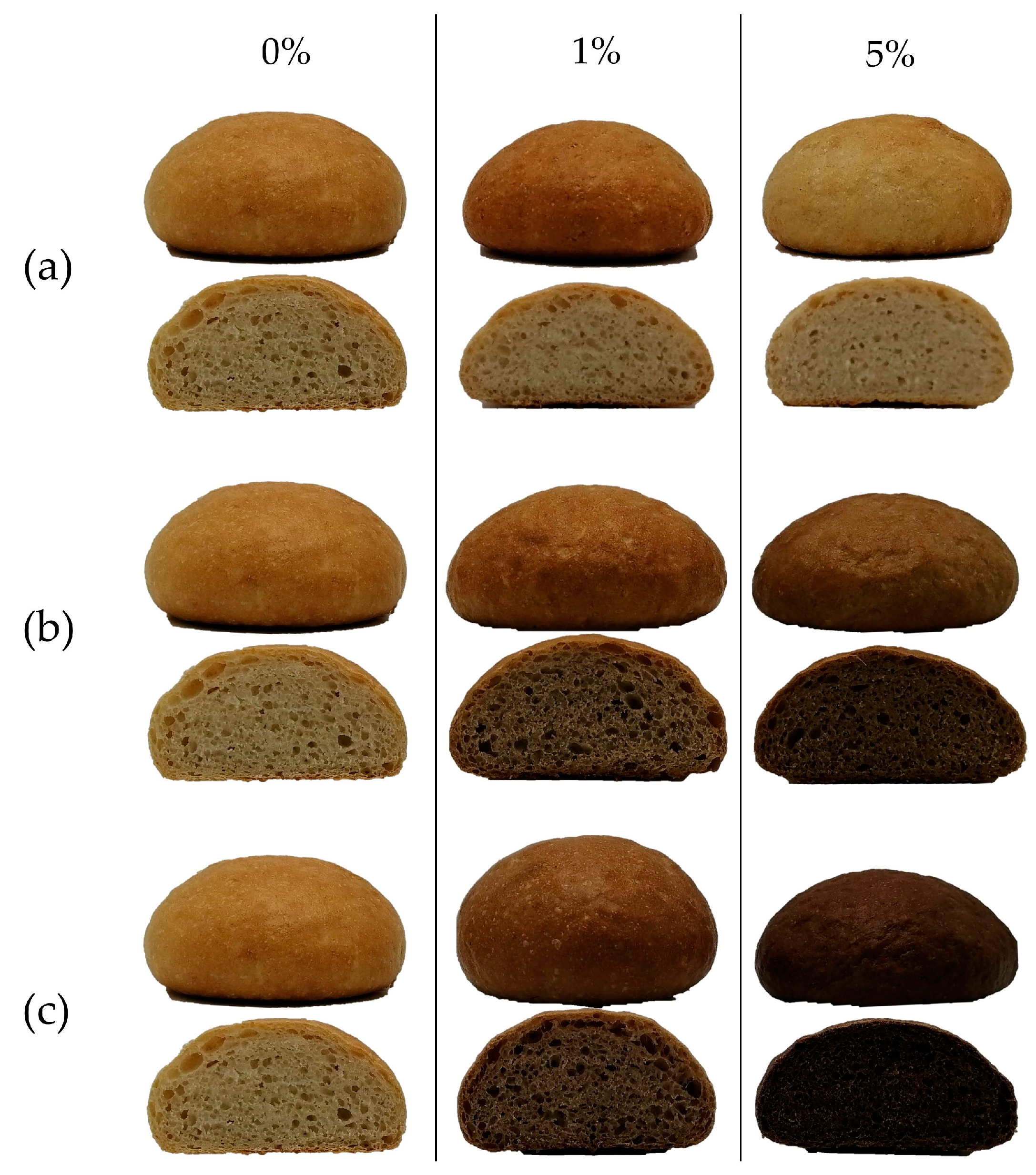

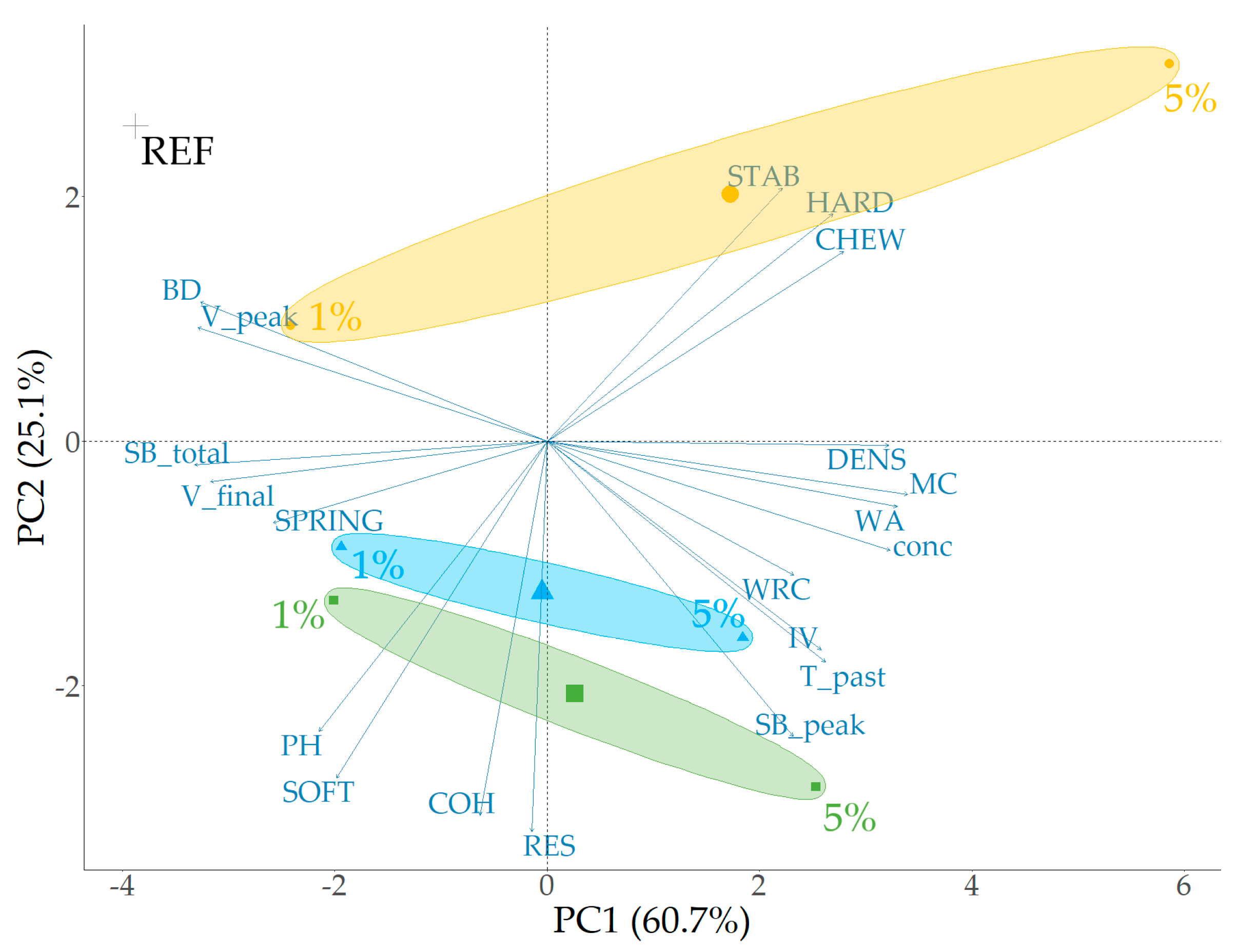

3.3. Effect of Concentration (0–5%) and Type of Fiber on Dough and Bread Quality

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ragaee, S.; Guzar, I.; Dhull, N.; Seetharaman, K. Effects of Fiber Addition on Antioxidant Capacity and Nutritional Quality of Wheat Bread. LWT 2011, 44, 2147–2153. [Google Scholar] [CrossRef]

- Atzler, J.J.; Sahin, A.W.; Gallagher, E.; Zannini, E.; Arendt, E.K. Investigation of Different Dietary-Fibre-Ingredients for the Design of a Fibre Enriched Bread Formulation Low in FODMAPs Based on Wheat Starch and Vital Gluten. Eur. Food Res. Technol. 2021, 247, 1939–1957. [Google Scholar] [CrossRef]

- Ni, Q.; Ranawana, V.; Hayes, H.E.; Hayward, N.J.; Stead, D.; Raikos, V. Addition of Broad Bean Hull to Wheat Flour for the Development of High-Fiber Bread: Effects on Physical and Nutritional Properties. Foods 2020, 9, 1192. [Google Scholar] [CrossRef] [PubMed]

- Reißner, A.-M.; Beer, A.; Struck, S.; Rohm, H. Pre-Hydrated Berry Pomace in Wheat Bread: An Approach Considering Requisite Water in Fiber Enrichment. Foods 2020, 9, 1600. [Google Scholar] [CrossRef] [PubMed]

- García, P.; Bustamante, A.; Echeverría, F.; Encina, C.; Palma, M.; Sanhueza, L.; Sambra, V.; Pando, M.E.; Jiménez, P. A Feasible Approach to Developing Fiber-Enriched Bread Using Pomegranate Peel Powder: Assessing Its Nutritional Composition and Glycemic Index. Foods 2023, 12, 2798. [Google Scholar] [CrossRef] [PubMed]

- Azadfar, E.; Elhami Rad, A.H.; Sharifi, A.; Armin, M. Effect of Olive Pomace Fiber on the Baking Properties of Wheat Flour and Flat Bread (Barbari Bread) Quality. J. Food Process. Preserv. 2023, 2023, 1405758. [Google Scholar] [CrossRef]

- Ewunetu, M.G.; Atnafu, A.Y.; Fikadu, W. Nutritional Enhancement of Bread Produced from Wheat, Banana, and Carrot Composite Flour. J. Food Qual. 2023, 2023, 1917972. [Google Scholar] [CrossRef]

- Ye, E.Q.; Chacko, S.A.; Chou, E.L.; Kugizaki, M.; Liu, S. Greater Whole-Grain Intake Is Associated with Lower Risk of Type 2 Diabetes, Cardiovascular Disease, and Weight Gain. J. Nutr. 2012, 142, 1304–1313. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Qian, Y.; Pan, Y.; Li, P.; Yang, J.; Ye, X.; Xu, G. Association between Dietary Fiber Intake and Risk of Coronary Heart Disease: A Meta-Analysis. Clin. Nutr. 2015, 34, 603–611. [Google Scholar] [CrossRef] [PubMed]

- Torbica, A.; Radosavljević, M.; Belović, M.; Djukić, N.; Marković, S. Overview of Nature, Frequency and Technological Role of Dietary Fibre from Cereals and Pseudocereals from Grain to Bread. Carbohydr. Polym. 2022, 290, 119470. [Google Scholar] [CrossRef]

- Frølich, W.; Åman, P.; Tetens, I. Whole Grain Foods and Health—A Scandinavian Perspective. Food Nutr. Res. 2013, 57, 18503. [Google Scholar] [CrossRef] [PubMed]

- Prasad, C.R. Barriers and Enablers to the Consumption of Wholegrains. Ph.D. Thesis, University of Auckland, Auckland, New Zealand, 2023. [Google Scholar]

- Cappelli, A.; Cini, E. Challenges and Opportunities in Wheat Flour, Pasta, Bread, and Bakery Product Production Chains: A Systematic Review of Innovations and Improvement Strategies to Increase Sustainability, Productivity, and Product Quality. Sustainability 2021, 13, 2608. [Google Scholar] [CrossRef]

- Betoret, E.; Rosell, C.M. Enrichment of Bread with Fruits and Vegetables: Trends and Strategies to Increase Functionality. Cereals Chem. 2020, 97, 9–19. [Google Scholar] [CrossRef]

- Bernaert, N.; Debonne, E.; De Leyn, I.; Van Droogenbroeck, B.; Van Bockstaele, F. Incorporation of Leek Powder (Allium Ampeloprasum var. Porrum) in Wheat Bread: Technological Implications, Shelf Life and Sensory Evaluation. LWT 2022, 153, 112517. [Google Scholar] [CrossRef]

- Schmidt, H.d.O.; Oliveira, V.R. de Overview of the Incorporation of Legumes into New Food Options: An Approach on Versatility, Nutritional, Technological, and Sensory Quality. Foods 2023, 12, 2586. [Google Scholar] [CrossRef] [PubMed]

- Bojnanska, T.; Frančáková, H.; Líšková, M.; Tokár, M. Legumes-The Alternative Raw Materials for Bread Production. J. Microbiol. Biotechnol. Food Sci. 2012, 1, 876–886. [Google Scholar]

- Nartea, A.; Kuhalskaya, A.; Fanesi, B.; Orhotohwo, O.L.; Susek, K.; Rocchetti, L.; Di Vittori, V.; Bitocchi, E.; Pacetti, D.; Papa, R. Legume Byproducts as Ingredients for Food Applications: Preparation, Nutrition, Bioactivity, and Techno-Functional Properties. Compr. Rev. Food Sci. Food Saf. 2023, 22, 1953–1985. [Google Scholar] [CrossRef] [PubMed]

- Aldughpassi, A.; Alkandari, S.; Alkandari, D.; Al-Hassawi, F.; Sidhu, J.S.; Al-Amiri, H.A.; Al-Salem, E. Effect of Psyllium Fiber Addition on the Quality of Arabic Flatbread (Pita) Produced in a Commercial Bakery. Ann. Agric. Sci. 2021, 66, 115–120. [Google Scholar] [CrossRef]

- Ma, S.; Wang, Z.; Liu, H.; Li, L.; Zheng, X.; Tian, X.; Sun, B.; Wang, X. Supplementation of Wheat Flour Products with Wheat Bran Dietary Fiber: Purpose, Mechanisms, and Challenges. Trends Food Sci. Technol. 2022, 123, 281–289. [Google Scholar] [CrossRef]

- Djordjević, M.; Djordjević, M.; Šoronja-Simović, D.; Nikolić, I.; Šereš, Z. Delving into the Role of Dietary Fiber in Gluten-Free Bread Formulations: Integrating Fundamental Rheological, Technological, Sensory, and Nutritional Aspects. Polysaccharides 2022, 3, 59–82. [Google Scholar] [CrossRef]

- Verbeke, C.; Debonne, E.; Van Leirsberghe, H.; Van Bockstaele, F.; Eeckhout, M. An Impact Assessment of Par-Baking and Storage on the Quality of Wheat, Whole Wheat, and Whole Rye Breads. Foods 2024, 13, 224. [Google Scholar] [CrossRef] [PubMed]

- Culetu, A.; Duta, D.E.; Papageorgiou, M.; Varzakas, T. The Role of Hydrocolloids in Gluten-Free Bread and Pasta; Rheology, Characteristics, Staling and Glycemic Index. Foods 2021, 10, 3121. [Google Scholar] [CrossRef] [PubMed]

- Correa, M.J.; Arp, C.G.; Ferrero, C. Chapter 8—Hydrocolloids in Wheat Breadmaking: Traditional and Novel Uses. In Trends in Wheat and Bread Making; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2021; pp. 227–254. ISBN 978-0-12-821048-2. [Google Scholar]

- Guarda, A.; Rosell, C.M.; Benedito, C.; Galotto, M.J. Different Hydrocolloids as Bread Improvers and Antistaling Agents. Food Hydrocoll. 2004, 18, 241–247. [Google Scholar] [CrossRef]

- Ferrero, C. Hydrocolloids in Wheat Breadmaking: A Concise Review. Food Hydrocoll. 2017, 68, 15–22. [Google Scholar] [CrossRef]

- Bárcenas, M.E.; Benedito, C.; Rosell, C.M. Use of Hydrocolloids as Bread Improvers in Interrupted Baking Process with Frozen Storage. Food Hydrocoll. 2004, 18, 769–774. [Google Scholar] [CrossRef]

- Regulation (EC) No 1333/2008 of the European Parliament and of the Council of 16 December 2008 on Food Additives. Available online: https://eur-lex.europa.eu/eli/reg/2008/1333/oj (accessed on 5 July 2024).

- Kajzer, M.; Diowksz, A. The Clean Label Concept: Novel Approaches in Gluten-Free Breadmaking. Appl. Sci. 2021, 11, 6129. [Google Scholar] [CrossRef]

- Vargas, M.C.A.; Simsek, S. Clean Label in Bread. Foods 2021, 10, 2054. [Google Scholar] [CrossRef] [PubMed]

- Fratelli, C.; Santos, F.G.; Muniz, D.G.; Habu, S.; Braga, A.R.C.; Capriles, V.D. Psyllium Improves the Quality and Shelf Life of Gluten-Free Bread. Foods 2021, 10, 954. [Google Scholar] [CrossRef] [PubMed]

- Torres-Pérez, R.; Martínez-García, E.; Siguero-Tudela, M.M.; García-Segovia, P.; Martínez-Monzó, J.; Igual, M. Enhancing Gluten-Free Bread Production: Impact of Hydroxypropyl Methylcellulose, Psyllium Husk Fiber, and Xanthan Gum on Dough Characteristics and Bread Quality. Foods 2024, 13, 1691. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, F.; Shiri, A.; Tahmouzi, S.; Mollakhalili-Meybodi, N.; Nematollahi, A. Application of Inulin in Bread: A Review of Technological Properties and Factors Affecting Its Stability. Food Sci. Nutr. 2023, 11, 639–650. [Google Scholar] [CrossRef] [PubMed]

- Królak, M.; Górska-Warsewicz, H.; Mądra-Sawicka, M.; Rejman, K.; Żakowska-Biemans, S.; Szlachciuk, J.; Czeczotko, M.; Kwiatkowski, B.; Zaremba, R.; Wojtaszek, M. Towards Sustainable Innovation in the Bakery Sector—An Example of Fibre-Enriched Bread. Sustainability 2022, 14, 2743. [Google Scholar] [CrossRef]

- De Bock, P.; Daelemans, L.; Selis, L.; Raes, K.; Vermeir, P.; Eeckhout, M.; Van Bockstaele, F. Comparison of the Chemical and Technological Characteristics of Wholemeal Flours Obtained from Amaranth (Amaranthus sp.), Quinoa (Chenopodium quinoa) and Buckwheat (Fagopyrum sp.) Seeds. Foods 2021, 10, 651. [Google Scholar] [CrossRef] [PubMed]

- Cereal & Grains Association. AACC International Method 76-21.02. General Pasting Method for Wheat or Rye Flour of Starch Using the Rapid Visco Analyser. In AACC Approved Methods of Analysis; American Association of Cereal Chemists International: St. Paul, MN, USA, 1999. [Google Scholar]

- Debonne, E.; De Leyn, I.; Verwaeren, J.; Moens, S.; Devlieghere, F.; Eeckhout, M.; Van Bockstaele, F. The Influence of Natural Oils of Blackcurrant, Black Cumin Seed, Thyme and Wheat Germ on Dough and Bread Technological and Microbiological Quality. LWT 2018, 93, 212–219. [Google Scholar] [CrossRef]

- Debonne, E.; Van Bockstaele, F.; Philips, E.; De Leyn, I.; Eeckhout, M. Impact of Par-Baking and Storage Conditions on the Quality of Par-Baked and Fully Baked Bread. LWT 2017, 78, 16–22. [Google Scholar] [CrossRef]

- Cereal & Grains Association. AACC International Method 44-15.02. Moisture—Air-Oven Methods. In AACC Approved Methods of Analysis; American Association of Cereal Chemists International: St. Paul, MN, USA, 1999. [Google Scholar]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2021. [Google Scholar]

- Kassambara, A.; Mundt, F. Factoextra: Extract and Visualize the Results of Multivariate Data Analyses. R Package, 2020. Available online: https://rpkgs.datanovia.com/factoextra/ (accessed on 15 July 2024).

- Wickham, H.; Chang, W.; Henry, L.; Pedersen, T.L.; Takahashi, K.; Wilke, C.; Woo, K.; Yutani, H.; Dunnington, D.; Brand, T.; et al. Ggplot2: Create Elegant Data Visualisations Using the Grammar of Graphics; R Package. 2024. Available online: https://search.r-project.org/CRAN/refmans/ggplot2/html/ggplot2-package.html (accessed on 15 July 2024).

- Khorasaniha, R.; Olof, H.; Voisin, A.; Armstrong, K.; Wine, E.; Vasanthan, T.; Armstrong, H. Diversity of Fibers in Common Foods: Key to Advancing Dietary Research. Food Hydrocoll. 2023, 139, 108495. [Google Scholar] [CrossRef]

- Pfoertner, H.P.; Fischer, J. Dietary Fibres of Lupins and Other Grain Legumes. In Advanced Dietary Fibre Technology; John Wiley & Sons: Hoboken, NJ, USA, 2000; pp. 361–366. ISBN 978-0-470-99961-5. [Google Scholar]

- Meuser, F. Technological Aspects of Dietary Fibre. In Advanced Dietary Fibre Technology; John Wiley & Sons: Hoboken, NJ, USA, 2000; pp. 248–269. ISBN 978-0-470-99961-5. [Google Scholar]

- Bchir, B.; Rabetafika, H.N.; Paquot, M.; Blecker, C. Effect of Pear, Apple and Date Fibres from Cooked Fruit By-Products on Dough Performance and Bread Quality. Food Bioprocess Technol. 2014, 7, 1114–1127. [Google Scholar] [CrossRef]

- Sudha, M.L.; Baskaran, V.; Leelavathi, K. Apple Pomace as a Source of Dietary Fiber and Polyphenols and Its Effect on the Rheological Characteristics and Cake Making. Food Chem. 2007, 104, 686–692. [Google Scholar] [CrossRef]

- Lecumberri, E.; Mateos, R.; Izquierdo-Pulido, M.; Rupérez, P.; Goya, L.; Bravo, L. Dietary Fibre Composition, Antioxidant Capacity and Physico-Chemical Properties of a Fibre-Rich Product from Cocoa (Theobroma Cacao L.). Food Chem. 2007, 104, 948–954. [Google Scholar] [CrossRef]

- Redgwell, R.; Trovato, V.; Merinat, S.; Curti, D.; Hediger, S.; Manez, A. Dietary Fibre in Cocoa Shell: Characterisation of Component Polysaccharides. Food Chem. 2003, 81, 103–112. [Google Scholar] [CrossRef]

- Miś, A.; Nawrocka, A.; Dziki, D. Behaviour of Dietary Fibre Supplements During Bread Dough Development Evaluated Using Novel Farinograph Curve Analysis. Food Bioprocess Technol. 2017, 10, 1031–1041. [Google Scholar] [CrossRef]

- Miś, A.; Grundas, S.; Dziki, D.; Laskowski, J. Use of Farinograph Measurements for Predicting Extensograph Traits of Bread Dough Enriched with Carob Fibre and Oat Wholemeal. J. Food Eng. 2012, 108, 1–12. [Google Scholar] [CrossRef]

- Struck, S.; Straube, D.; Zahn, S.; Rohm, H. Interaction of Wheat Macromolecules and Berry Pomace in Model Dough: Rheology and Microstructure. J. Food Eng. 2018, 223, 109–115. [Google Scholar] [CrossRef]

- Huang, G.; Guo, Q.; Wang, C.; Ding, H.H.; Cui, S.W. Fenugreek Fibre in Bread: Effects on Dough Development and Bread Quality. LWT 2016, 71, 274–280. [Google Scholar] [CrossRef]

- Nawrocka, A.; Miś, A.; Szymańska-Chargot, M. Characteristics of Relationships Between Structure of Gluten Proteins and Dough Rheology—Influence of Dietary Fibres Studied by FT-Raman Spectroscopy. Food Biophys. 2016, 11, 81–90. [Google Scholar] [CrossRef]

- Alba, K.; Rizou, T.; Paraskevopoulou, A.; Campbell, G.M.; Kontogiorgos, V. Effects of Blackcurrant Fibre on Dough Physical Properties and Bread Quality Characteristics. Food Biophys. 2020, 15, 313–322. [Google Scholar] [CrossRef]

- Collar, C.; Rosell, C.M.; Muguerza, B.; Moulay, L. Breadmaking Performance and Keeping Behavior of Cocoa-Soluble Fiber-Enriched Wheat Breads. Food Sci. Technol. Int. 2009, 15, 79–87. [Google Scholar] [CrossRef]

- Rosell, C.M.; Santos, E.; Collar, C. Physical Characterization of Fiber-Enriched Bread Doughs by Dual Mixing and Temperature Constraint Using the Mixolab®. Eur. Food Res. Technol. 2010, 231, 535–544. [Google Scholar] [CrossRef]

- Schmidt, U.S.; Schmidt, K.; Kurz, T.; Endreß, H.-U.; Schuchmann, H.P. Pectins of Different Origin and Their Performance in Forming and Stabilizing Oil-in-Water-Emulsions. Food Hydrocoll. 2015, 46, 59–66. [Google Scholar] [CrossRef]

- Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on Nutrition and Health Claims Made on Foods. Available online: https://eur-lex.europa.eu/eli/reg/2006/1924/oj (accessed on 5 July 2024).

- Jødal, A.-S.S.; Larsen, K.L. Investigation of the Relationships between the Alveograph Parameters. Sci. Rep. 2021, 11, 5349. [Google Scholar] [CrossRef]

- Lucas, T. Baking. In Bakery Products: Science and Technology; Zhou, W., Hui, Y.H., De Leyn, I., Pagani, M.A., Rosell, C.M., Selman, J.D., Therdthai, N., Eds.; Wiley Blackwell: Chichester, UK, 2014; pp. 335–354. ISBN 978-1-119-96715-6. [Google Scholar]

- Li, S.; Chen, W.; Zongo, A.W.-S.; Chen, Y.; Liang, H.; Li, J.; Li, B.; Li, S.; Chen, W.; Zongo, A.W.-S.; et al. Effects of Non-Starch Polysaccharide on Starch Gelatinization and Digestibility: A Review. Food Innov. Adv. 2023, 2, 302–312. [Google Scholar] [CrossRef]

| REF | Pea | Apple | Cocoa | ||||

| 1% | 5% | 1% | 5% | 1% | 5% | ||

| Flour/Fiber * | 60.8 | 59.8 | 58.0 | 60.3 | 58.8 | 60.1 | 58.3 |

| Flour | 60.8 | 59.2 | 55.1 | 59.7 | 55.9 | 59.5 | 55.4 |

| Fiber | 0 | 0.60 | 2.90 | 0.60 | 2.94 | 0.60 | 2.92 |

| Yeast | 0.63 | 0.62 | 0.60 | 0.62 | 0.61 | 0.62 | 0.60 |

| Malt | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 |

| Salt | 0.94 | 0.92 | 0.90 | 0.94 | 0.91 | 0.93 | 0.91 |

| Vitamin C | 0.0016 | 0.0015 | 0.0015 | 0.0016 | 0.0015 | 0.0015 | 0.0015 |

| Water ** | 37.6 | 38.6 | 40.4 | 38.1 | 39.6 | 38.3 | 40.1 |

| Supplier | Literature | ||

|---|---|---|---|

| Pea | [44] | [45] | |

| Total DF | Approx. 65 | 60.0 | 76.3 |

| Apple | [46] | [47] | |

| Total DF | 51.0–60.0 | 51.1 | 82.0 |

| Insoluble DF | 47.0–52.0 | 36.5 | 77.8 |

| Soluble DF | 4.0–8.0 | 14.6 | 4.2 |

| Cocoa | [48] | [49] | |

| Total DF | 56.0–62.0 | 28.1 a (60.5 *) | 35.7 a (63.6 *) |

| Insoluble DF | 47.0–50.0 | 18.0 a (50.4 *) | 24.0 a (51.9 *) |

| Soluble DF | 9.0–12.0 | 10.1 | 11.7 |

| Per 100 g | 0% REF | 1% | 5% | ||||

|---|---|---|---|---|---|---|---|

| PF | CF | AF | PF | CF | AF | ||

| Energy (kJ) | 1024 | 1023 | 1004 | 1000 | 944 | 947 | 953 |

| Energy (kcal) | 252 | 251 | 247 | 246 | 233 | 233 | 235 |

| Fats (%) | 0.9 | 0.9 | 0.9 | 0.9 | 0.8 | 0.9 | 0.9 |

| Saturates (%) | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.2 |

| Carbohydrates (%) | 49.1 | 48.8 | 48.0 | 47.7 | 44.3 | 44.1 | 44.9 |

| Sugars (%) | 1.0 | 1.0 | 1.0 | 1.1 | 1.0 | 1.0 | 1.3–1.6 |

| Protein (%) | 8.6 | 8.6 | 8.5 | 8.4 | 8.0 | 8.2–8.5 | 7.8–8.0 |

| Salt (%) | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 |

| Fibers (%) | 2.3 | 2.7 | 2.7 | 2.6–2.7 | 4.1 | 4.0–4.2 | 3.8–4.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Verbeke, C.; Debonne, E.; Versele, S.; Van Bockstaele, F.; Eeckhout, M. Technological Evaluation of Fiber Effects in Wheat-Based Dough and Bread. Foods 2024, 13, 2582. https://doi.org/10.3390/foods13162582

Verbeke C, Debonne E, Versele S, Van Bockstaele F, Eeckhout M. Technological Evaluation of Fiber Effects in Wheat-Based Dough and Bread. Foods. 2024; 13(16):2582. https://doi.org/10.3390/foods13162582

Chicago/Turabian StyleVerbeke, Celeste, Els Debonne, Stien Versele, Filip Van Bockstaele, and Mia Eeckhout. 2024. "Technological Evaluation of Fiber Effects in Wheat-Based Dough and Bread" Foods 13, no. 16: 2582. https://doi.org/10.3390/foods13162582

APA StyleVerbeke, C., Debonne, E., Versele, S., Van Bockstaele, F., & Eeckhout, M. (2024). Technological Evaluation of Fiber Effects in Wheat-Based Dough and Bread. Foods, 13(16), 2582. https://doi.org/10.3390/foods13162582