Optimization of Vitamin B1, B2, and B6 Absorption in Nang Tay Dum Floating Rice Grains

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

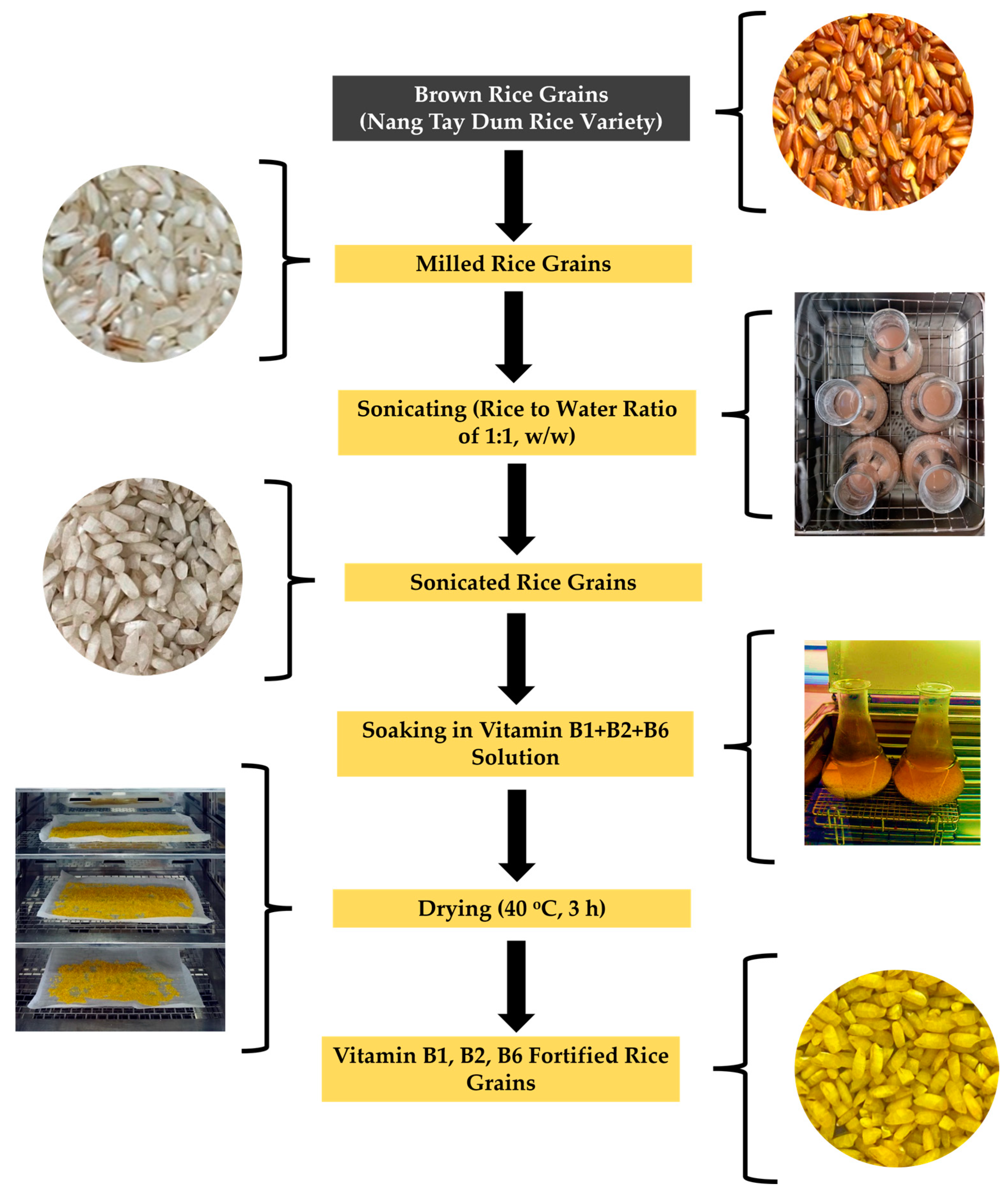

2.2. Sonication of Rice Grains

2.3. Fortification of Rice Grains with Vitamins B1, B2, and B6

2.4. Extraction Method of Vitamins B1, B2, and B6 from Rice Grains

2.5. Analysis of Vitamins B1, B2, and B6 by HPLC

2.6. Data Analysis

3. Results and Discussion

3.1. Nutritional Composition of Brown Rice Grains (Nang Tay Dum Floating Rice Variety)

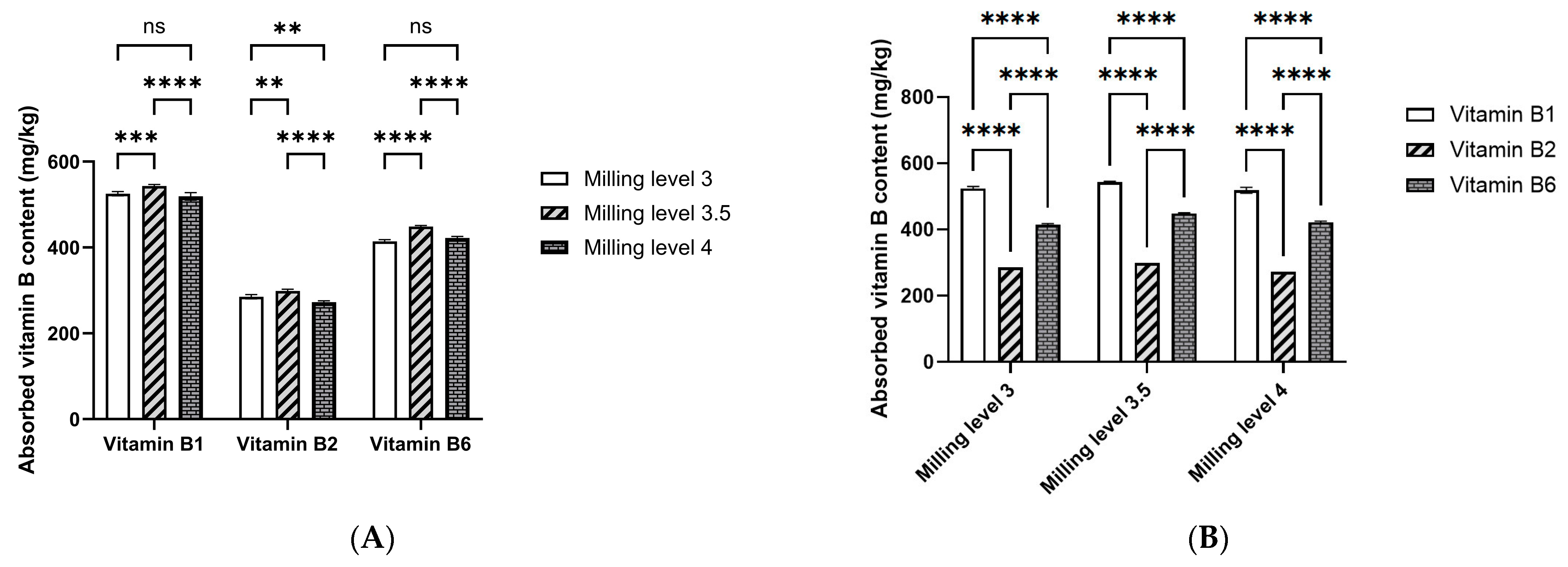

3.2. Effect of Milling Degree on the Absorption of Vitamins B1, B2, and B6 in Nang Tay Dum Floating Rice Grains

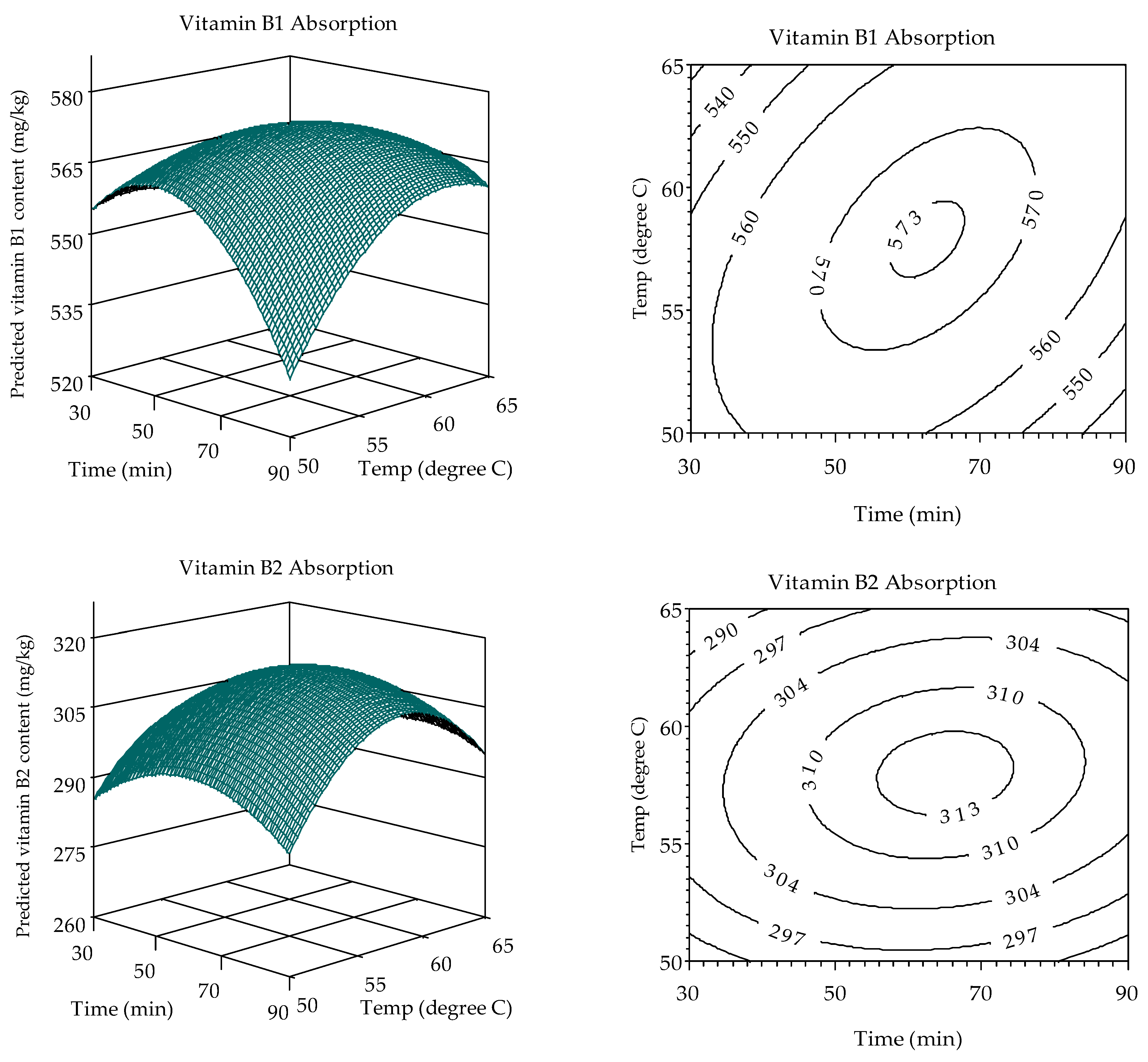

3.3. Effect of Soaking Time and Temperature on the Absorption of Vitamins B1, B2, and B6 in Rice Grains

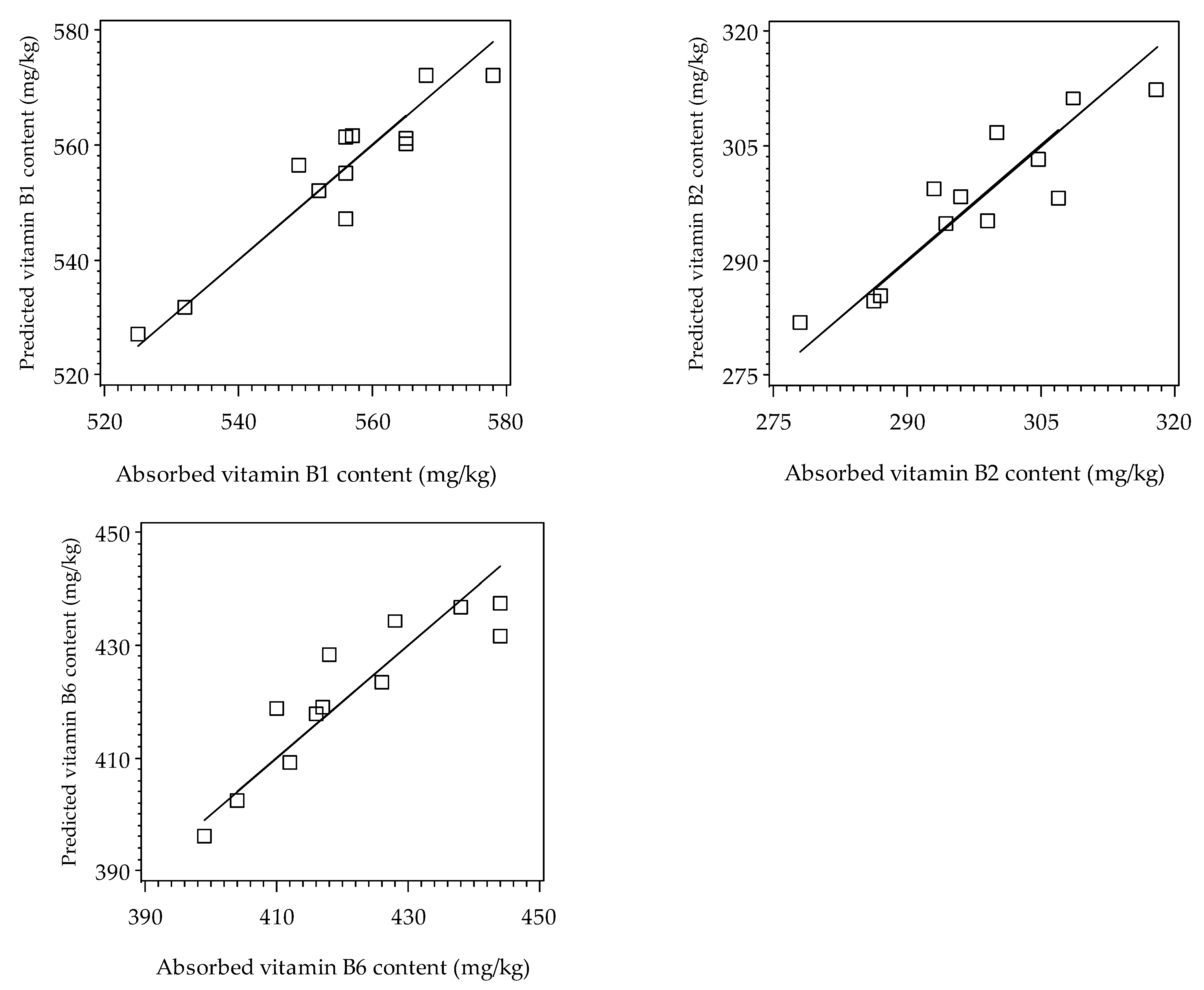

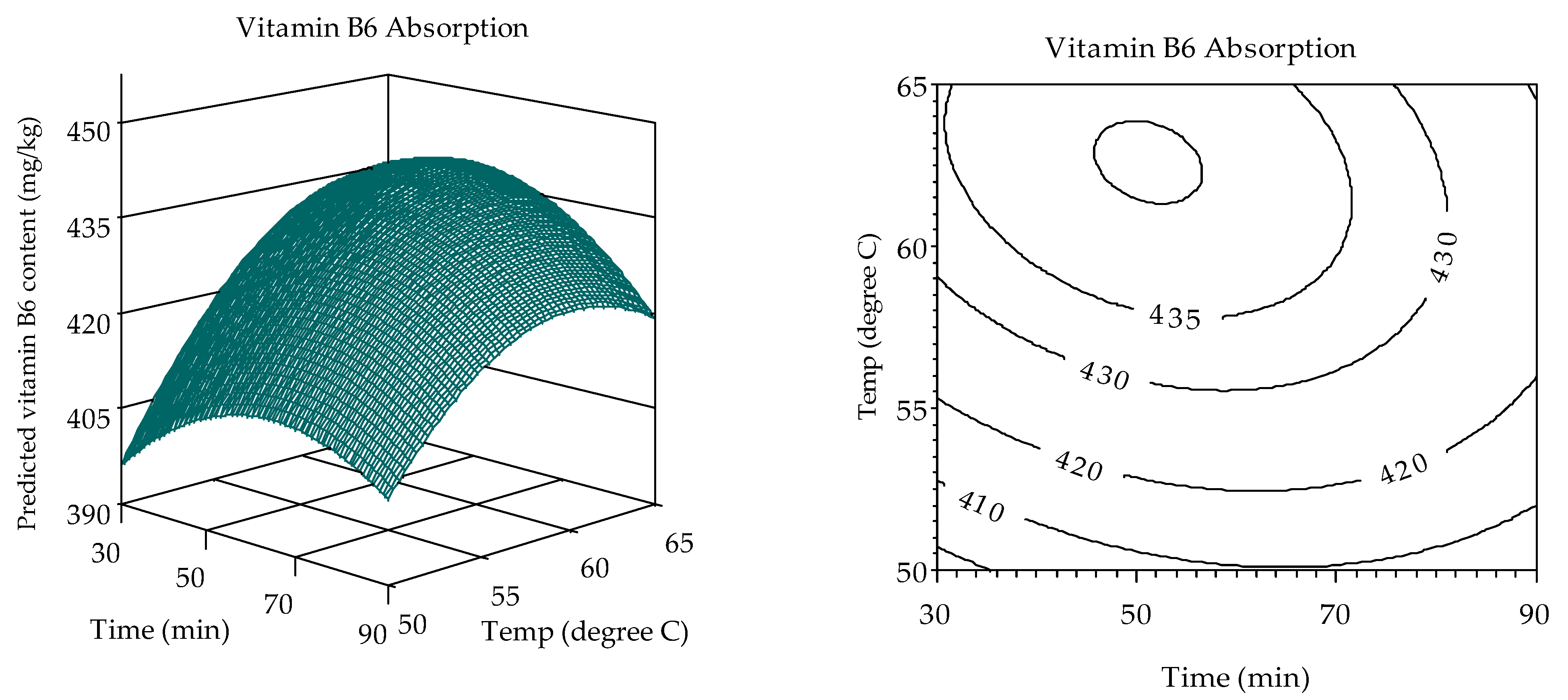

3.4. Modeling the Combined Effect of Soaking Time and Temperature on the Absorption of Vitamins B1, B2, and B6 in Rice Grains

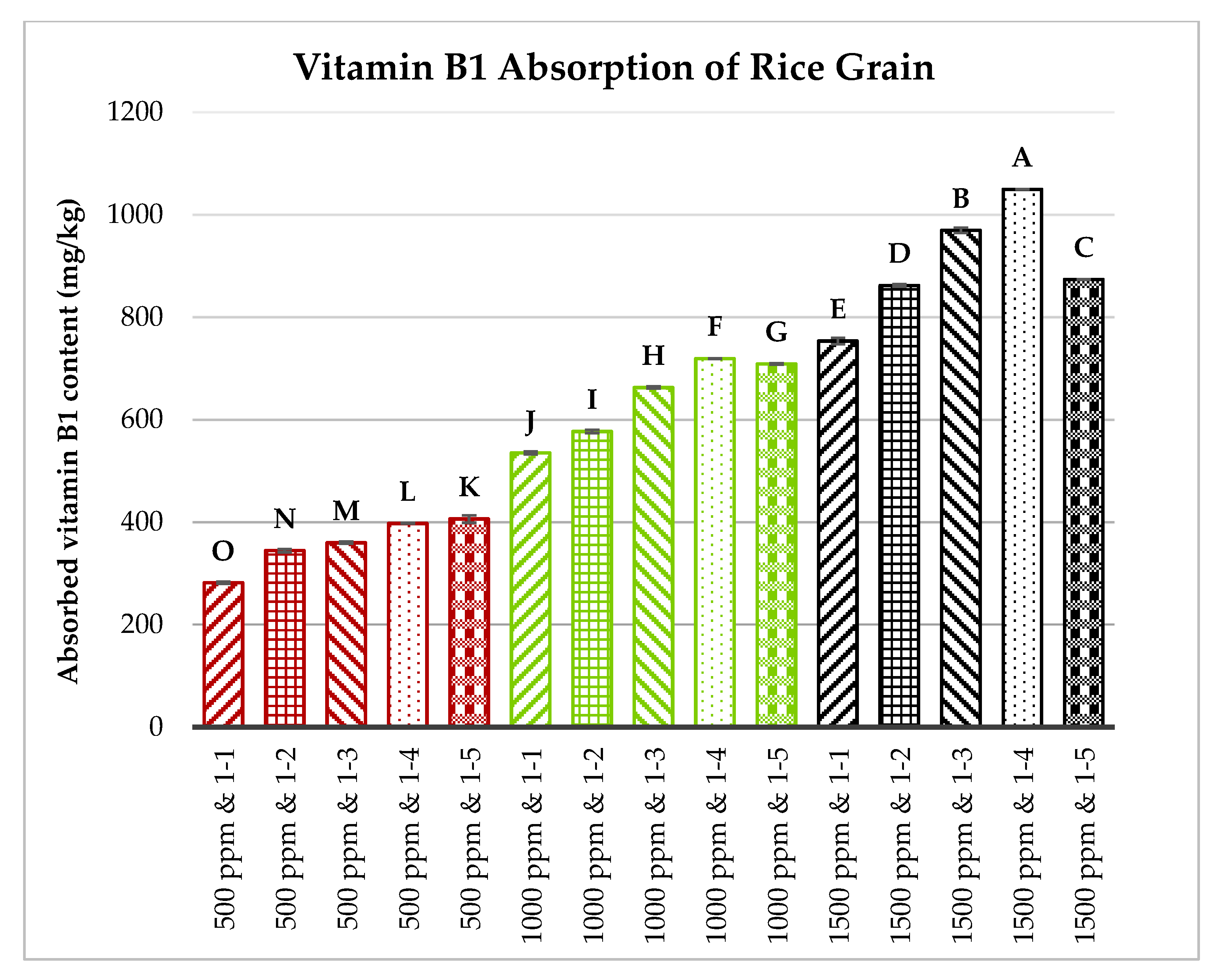

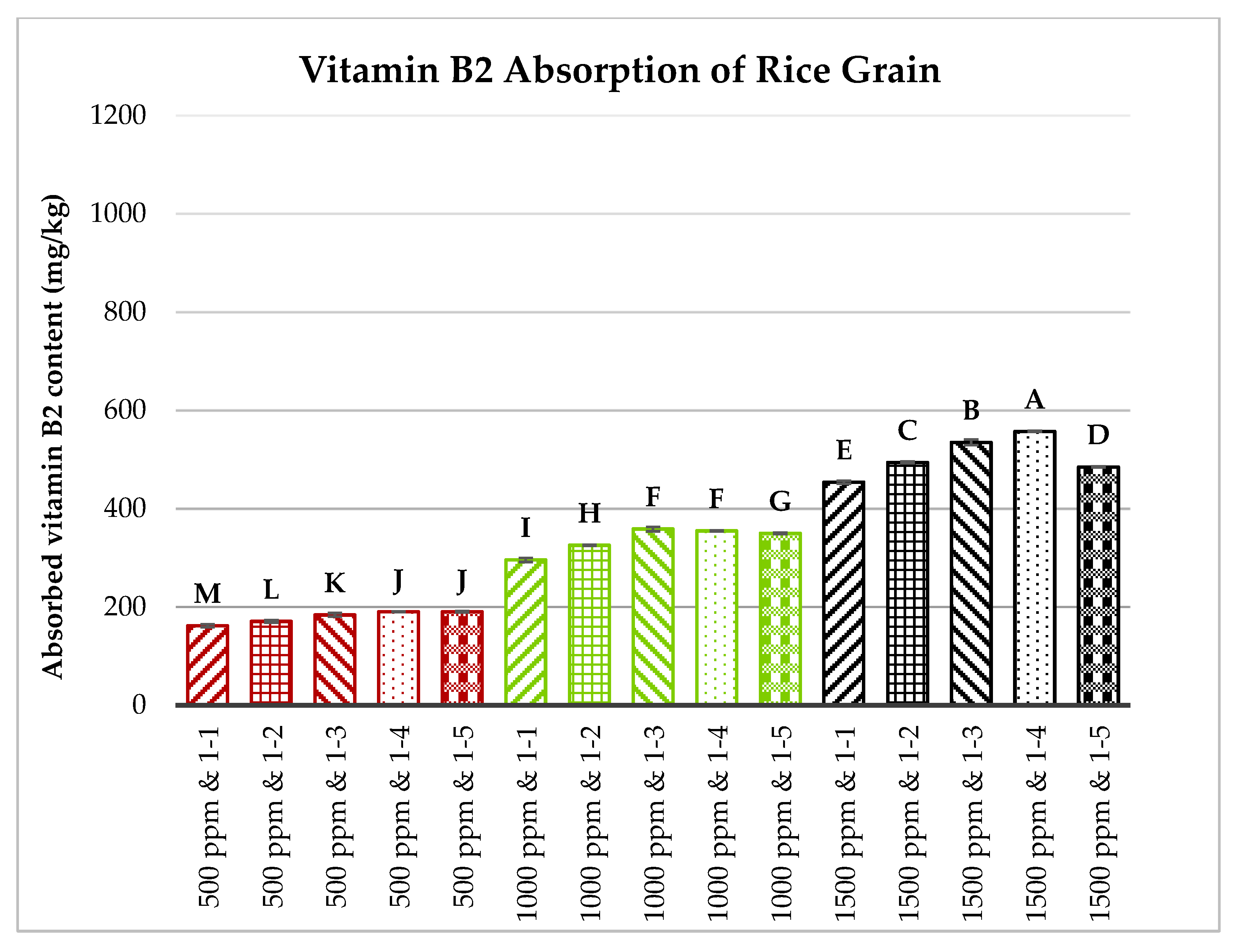

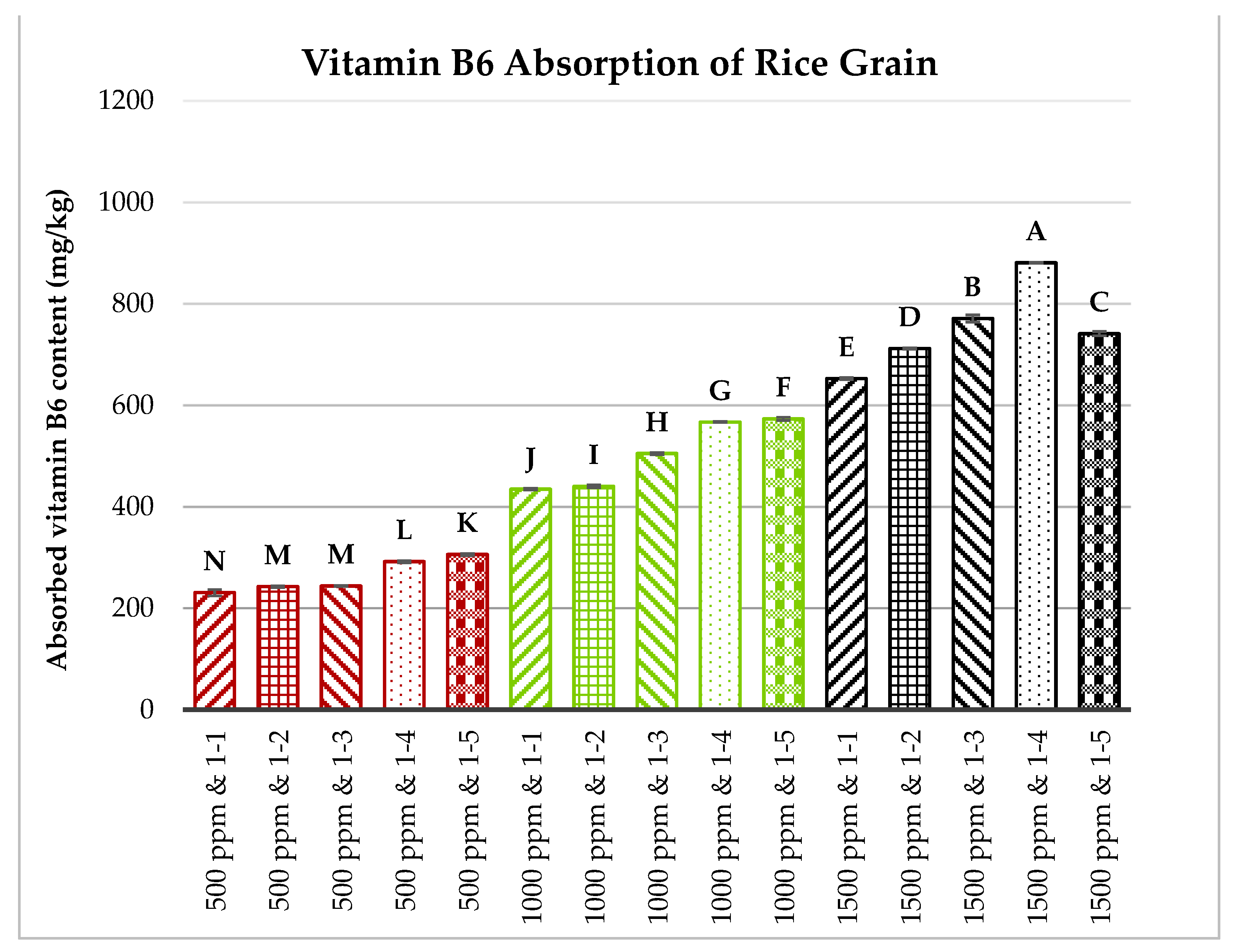

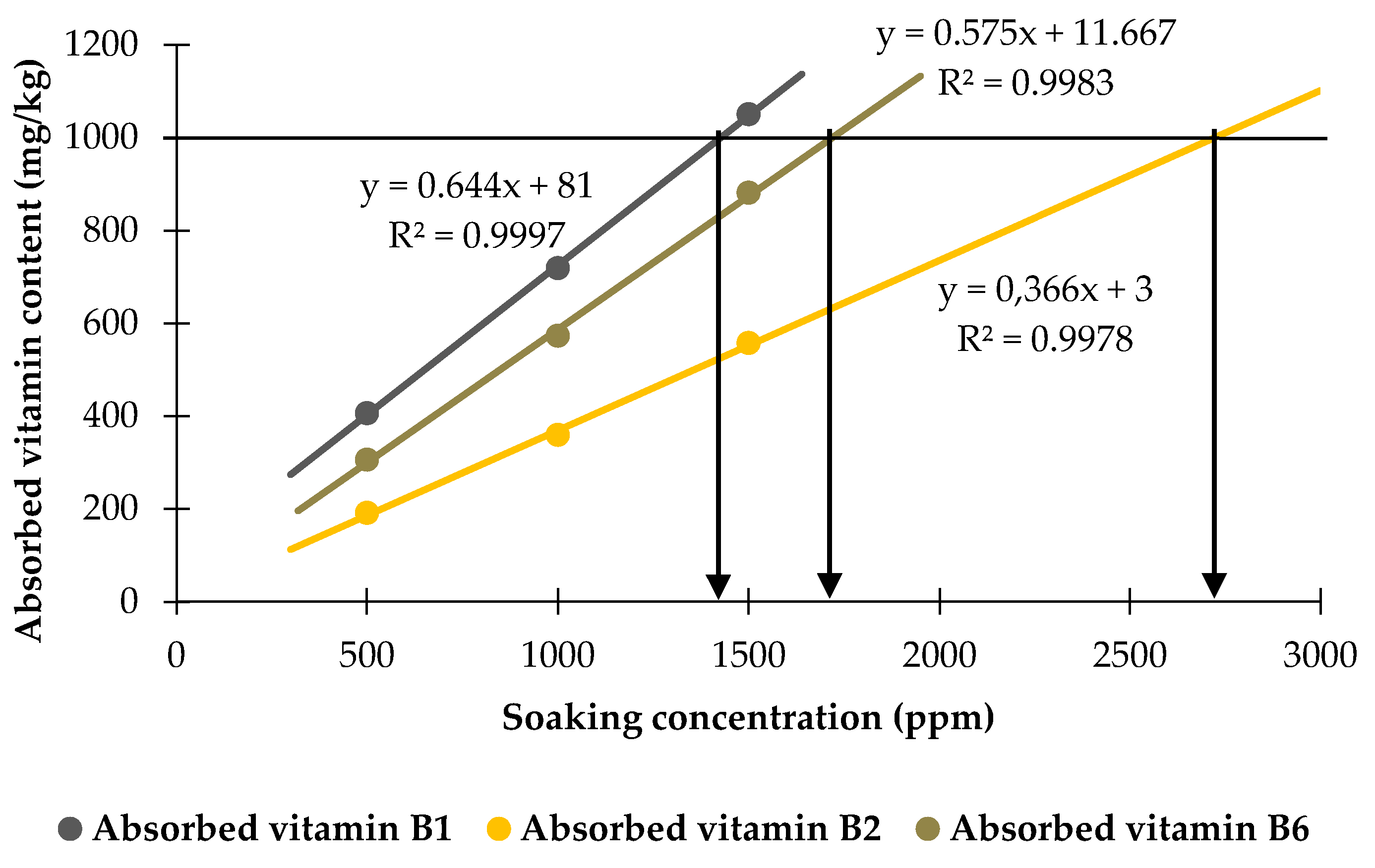

3.5. Effects of Vitamin Concentration and Rice-to-Solution Ratio on the Absorption of Vitamins B1, B2, and B6 in Rice Grains

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO; IFAD; UNICEF; WFP; WHO. The State of Food Security and Nutrition in the World 2023. In Urbanization, Agrifood Systems Transformation and Healthy Diets across the Rural-Urban Continuum; FAO: Rome, Italy, 2023. [Google Scholar] [CrossRef]

- Peña-Rosas, J.P.; Mithra, P.; Unnikrishnan, B.; Kumar, N.; De-Regil, L.M.; Nair, N.S.; Garcia-Casal, M.N.; Solon, J.A. Fortification of rice with vitamins and minerals for addressing micronutrient malnutrition. Cochrane Database Syst. Rev. 2019, CD009902. [Google Scholar] [CrossRef]

- Biebinger, R.; Hurrell, R.F. Vitamin and mineral fortification of foods. In Food Fortification and Supplementation: Technological, Safety and Regulatory Aspects; Ottaway, P.B., Ed.; Woodhead Publishing Limited: Sawston, UK, 2008; pp. 27–40. [Google Scholar] [CrossRef]

- Williams, L.J.; Rasmussen, S.A.; Flores, A.; Kirby, R.S.; Edmonds, L.D. Decline in the prevalence of spina bifida and anencephaly by race/ethnicity: 1995–2002. Pediatrics 2005, 116, 580–586. [Google Scholar] [CrossRef]

- Tacsan, L.; Fabrizio, C.; Smit, J. Rice fortification in Costa Rica—Case study. In Scaling Up Rice Fortification in Latin America and the Caribbean; Irizarry, L., Prost, M.-A., Murillo, D., Eds.; World Food Programme Regional Bureau for Latin America and the Caribbean: Panama City, Panama, 2017; pp. 217–222. [Google Scholar] [CrossRef]

- Burlingame, B.; Charrondiere, R.; Mouille, B. Food composition is fundamental to the cross-cutting initiative on biodiversity for food and nutrition. J. Food Compos. Anal. 2009, 22, 361–365. [Google Scholar] [CrossRef]

- Müller, A.; Nunes, M.T.; Maldaner, V.; Coradi, P.C.; de Moraes, R.S.; Martens, S.; Leal, A.F.; Pereira, V.F.; Marin, C.K. Rice drying, storage and processing: Effects of post-harvest operations on grain quality. Rice Sci. 2022, 29, 16–30. [Google Scholar] [CrossRef]

- Liu, K.; Zheng, J.; Wang, X.; Chen, F. Effects of household cooking processes on mineral, vitamin B, and phytic acid contents and mineral bioaccessibility in rice. Food Chem. 2019, 280, 59–64. [Google Scholar] [CrossRef]

- Muthayya, S.; Hall, J.; Bagriansky, J.; Sugimoto, J.; Gundry, D.; Matthias, D.; Prigge, S.; Hindle, P.; Moench-Pfanner, R.; Maberly, G. Rice fortification: An emerging opportunity to contribute to the elimination of vitamin and mineral deficiency worldwide. Food Nutr. Bull. 2012, 33, 296–307. [Google Scholar] [CrossRef]

- Jalal, C.S.B.; De-Regil, L.M.; Pike, V.; Mithra, P. Fortification of condiments and seasonings with iron for preventing anaemia and improving health. Cochrane Database Syst. Rev. 2023, CD009604. [Google Scholar] [CrossRef]

- Steiger, G.; Müller-Fischer, N.; Cori, H.; Conde-Petit, B. Fortification of rice: Technologies and nutrients. Ann. N. Y. Acad. Sci. 2014, 1324, 29–39. [Google Scholar] [CrossRef]

- Camacho, D.H. Vitamin fortification of milled rice: A new approach to address micronutrient malnutrition. Policy Brief AKI Res. Grants Food Stud. 2018, 8, 1–4. [Google Scholar]

- Kyritsi, A.; Tzia, C.; Karathanos, V.T. Vitamin fortified rice grain using spraying and soaking methods. LWT 2011, 44, 312–320. [Google Scholar] [CrossRef]

- Montgomery, S.; Rosenzweig, J.; Smit, J. Technology for rice fortification. In Scaling Up Rice Fortification in Latin America and the Caribbean; Irizarry, L., Prost, M.-A., Murillo, D., Eds.; World Food Programme Regional Bureau for Latin America and the Caribbean: Panama City, Panama, 2017; pp. 159–164. [Google Scholar] [CrossRef]

- FAO. State of the World’s Plant Genetic Resources for Food and Agriculture; FAO: Rome, Italy, 1997. [Google Scholar]

- Narciso, J.O.; Nyström, L. Breathing new life to ancient crops: Promoting the ancient Philippine grain “Kabog Millet” as an alternative to rice. Foods 2020, 9, 1727. [Google Scholar] [CrossRef] [PubMed]

- Vo, H.T.; Kopp, S.W.; Nguyen, T.T.; Kontoleon, A.; Yabe, M. UK consumers’ preferences for ethical attributes of floating rice: Implications for environmentally friendly agriculture in Vietnam. Sustainability 2021, 13, 8354. [Google Scholar] [CrossRef]

- Bonto, A.P.; Camacho, K.S.I.; Camacho, D.H. Increased vitamin B5 uptake capacity of ultrasonic treated milled rice: A new method for rice fortification. LWT 2018, 95, 32–39. [Google Scholar] [CrossRef]

- Tiozon, R.N.; Camacho, D.H.; Bonto, A.P.; Oyong, G.G.; Sreenivasulu, N. Dataset on the folic acid uptake and the effect of sonication-based fortification on the color, pasting and textural properties of brown and milled rice. Data Brief 2020, 32, 106198. [Google Scholar] [CrossRef] [PubMed]

- Bonto, A.P.; Tiozon, R.N.; Sreenivasulu, N.; Camacho, D.H. Impact of ultrasonic treatment on rice starch and grain functional properties: A review. Ultrason. Sonochem. 2021, 71, 105383. [Google Scholar] [CrossRef] [PubMed]

- Le, H.P.; Hong, D.T.N.; Nguyen, T.T.L.; Le, T.M.H.; Koseki, S.; Ho, T.B.; Ly-Nguyen, B. Thermal stability of fructooligosaccharides extracted from defatted rice bran: A kinetic study using liquid chromatography-tandem mass spectrometry. Foods 2022, 11, 2054. [Google Scholar] [CrossRef] [PubMed]

- Melini, V.; Melini, F. Modelling and optimization of ultrasound-assisted extraction of phenolic compounds from black quinoa by response surface methodology. Molecules 2021, 26, 3616. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Gao, Y.-T.; Wei, J.-W.; Chen, Y.-F.; Liu, Q.-L.; Liu, H.-M. Optimization of ultrasonic cellulase-assisted extraction and antioxidant activity of natural polyphenols from passion fruit. Molecules 2021, 26, 2494. [Google Scholar] [CrossRef]

- Shaik, L.; Chakraborty, S. Sequential pulsed light and ultrasound treatments for the inactivation of Saccharomyces cerevisiae and PPO and the retention of bioactive compounds in sweet lime juice. Foods 2024, 13, 1996. [Google Scholar] [CrossRef]

- Li, X.L.; Yuan, S.L.; Piao, X.S.; Lai, C.H.; Zang, J.J.; Ding, Y.H.; Han, L.J.; Han, I.K. The nutritional value of brown rice and maize for growing pigs. Asian-Aust. J. Anim. Sci. 2006, 19, 892–897. [Google Scholar] [CrossRef]

- Pandey, S.; Lijini, K.R.; Jayadeep, A. Medicinal and health benefits of brown rice. In Brown Rice; Manickavasagan, A., Santhakumar, C., Venkatachalapathy, N., Eds.; Springer International Publishing: New York, NY, USA, 2017; pp. 111–122. [Google Scholar] [CrossRef]

- Ascheri, D.P.R.; Boêno, J.A.; Bassinello, P.Z.; Ascheri, J.L.R. Correlation between grain nutritional content and pasting properties of pre-gelatinized red rice flour. Rev. Ceres 2012, 59, 16–24. [Google Scholar] [CrossRef]

- Müller, C.P.; Hoffmann, J.F.; Ferreira, C.D.; Diehl, G.W.; Rossi, R.C.; Ziegler, V. Effect of germination on nutritional and bioactive properties of red rice grains and its application in cupcake production. Int. J. Gastron. Food Sci. 2021, 25, 100379. [Google Scholar] [CrossRef]

- Duong, T.N.H.; Nguyen, M.T. The use of α-amylase enzyme in starch hydrolysis from red rice. CTU J. Sci. 2014, 1, 61–67. Available online: https://ctujsvn.ctu.edu.vn/index.php/ctujsvn/article/view/2075/1744 (accessed on 11 June 2024).

- Saleh, A.S.M.; Wang, P.; Wang, N.; Yang, L.; Xiao, Z. Brown rice versus white rice: Nutritional quality, potential health benefits, development of food products, and preservation technologies. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1070–1096. [Google Scholar] [CrossRef] [PubMed]

- Rathna Priya, T.S.; Eliazer Nelson, A.R.L.; Ravichandran, K.; Antony, U. Nutritional and functional properties of coloured rice varieties of South India: A review. J. Ethn. Foods 2019, 6, 11. [Google Scholar] [CrossRef]

- Zahra, N.; Jabeen, S. Brown rice as useful nutritional source. Pakistan J. Agri. Res. 2020, 33, 445–453. [Google Scholar] [CrossRef]

- Doesthale, Y.G.; Devara, S.; Rao, S.; Belavady, B. Effect of milling on mineral and trace element composition of raw and parboiled rice. J. Sci. Food Agri. 1979, 30, 40–46. [Google Scholar] [CrossRef]

- Wahengbam, E.D.; Green, B.D.; Hazarika, M.K. Fortification of zinc in a parboiled low-amylose rice: Effects of milling and cooking. J. Sci. Food Agric. 2019, 99, 3434–3442. [Google Scholar] [CrossRef]

- Bhattacharya, K.R. (Ed.) Degree of milling (DM) of rice and its effect. In Rice Quality; Woodhead Publishing Limited: Sawston, UK, 2013; pp. 100–115. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhou, S.; Peng, Y.; Wen, X.; Ni, Y.; Li, M. Effect of milling on nutritional components in common and zinc-biofortified wheat. Nutrients 2023, 15, 833. [Google Scholar] [CrossRef]

- Reddy, C.K.; Kimi, L.; Haripriya, S.; Kang, N. Effects of polishing on proximate composition, physico-chemical characteristics, mineral composition and antioxidant properties of pigmented rice. Rice Sci. 2017, 24, 241–252. [Google Scholar] [CrossRef]

- Tiozon, R.N.; Camacho, D.H.; Bonto, A.P.; Oyong, G.G.; Sreenivasulu, N. Efficient fortification of folic acid in rice through ultrasonic treatment and absorption. Food Chem. 2021, 335, 127629. [Google Scholar] [CrossRef]

- Bonto, A.P.; Jearanaikoon, N.; Sreenivasulu, N.; Camacho, D.H. High uptake and inward diffusion of iron fortificant in ultrasonicated milled rice. LWT 2020, 128, 109459. [Google Scholar] [CrossRef]

- Bello, M.O.; Tolaba, M.P.; Suarez, C. Water absorption and starch gelatinization in whole rice grain during soaking. LWT 2007, 40, 313–318. [Google Scholar] [CrossRef]

- Fischer, M.; Bacher, A. Biosynthesis of vitamin B2: Structure and mechanism of riboflavin synthase. Arch. Biochem. Biophys. 2008, 474, 252–265. [Google Scholar] [CrossRef]

- Saha, S.; Roy, A. Whole grain rice fortification as a solution to micronutrient deficiency: Technologies and need for more viable alternatives. Food Chem. 2020, 326, 127049. [Google Scholar] [CrossRef]

- Institute of Medicine (US). Dietary Reference Intakes for Thiamin, Riboflavin, Niacin, Vitamin B6, Folate, Vitamin B12, Pantothenic Acid, Biotin, and Choline; National Academies Press: Washington, DC, USA, 1998. [Google Scholar] [CrossRef]

- Rice Consumption by Country 2024. World Population Review. Available online: https://worldpopulationreview.com/country-rankings/rice-consumption-by-country (accessed on 21 July 2024).

| Nutritional Composition 1 | Unit | Content |

|---|---|---|

| Moisture | % | 11.67 ± 0.01 |

| Crude protein | g/100 g | 9.20 ± 0.07 |

| Lipid | g/100 g | 1.79 ± 0.03 |

| Carbohydrate | g/100 g | 73.3 |

| Vitamin B1 | mg/100 g | 0.413 |

| Vitamin B2 | mg/100 g | 0.154 |

| Vitamin B6 | mg/100 g | 0.112 |

| Mean of Absorbed Vitamin B1 Content 2 | ||||

| Soaking Time (min) | ||||

| Temperature (°C) | 30 | 60 | 90 | Group mean |

| 50 | 556.3 ± 0.9 | 565.0 ± 0.1 | 532.0 ± 0.3 | 551.1 ± 15.4 AB |

| 55 | 549.0 ± 0.1 | 568.0 ± 0.8 | 552.3 ± 0.6 | 556.4 ± 9.4 AB |

| 60 | 556.0 ± 0.1 | 577.8 ± 1.0 | 557.0 ± 0.6 | 563.6 ± 11.2 A |

| 65 | 525.0 ± 0.6 | 556.0 ± 0.6 | 565.0 ± 0.4 | 548.7 ± 18.3 B |

| Group mean | 546.6 ± 14.8 b | 566.7 ± 9.0 a | 551.6 ± 14.1 b | 555.0 ± 10.5 |

| Mean of absorbed vitamin B2 content 2 | ||||

| Soaking Time (min) | ||||

| Temperature (°C) | 30 | 60 | 90 | Group mean |

| 50 | 287.0 ± 0.5 | 294.3 ± 0.7 | 286.3 ± 0.4 | 289.2 ± 5.3 B |

| 55 | 293.0 ± 0.4 | 308.7 ± 0.2 | 304.7 ± 0.3 | 302.1 ± 7.5 A |

| 60 | 307.0 ± 0.6 | 318.0 ± 0.1 | 300.0 ± 0.4 | 308.3 ± 8.1 A |

| 65 | 278.0 ± 0.3 | 296.0 ± 0.6 | 299.0 ± 0.6 | 291.0 ± 9.9 B |

| Group mean | 291.3 ± 12.2 b | 304.3 ± 11.2 a | 297.5 ± 7.8 ab | 297.7 ± 6.5 |

| Mean of Absorbed Vitamin B6 Content 2 | ||||

| Soaking Time (min) | ||||

| Temperature (°C) | 30 | 60 | 90 | Group mean |

| 50 | 399.3 ± 0.5 | 412.0 ± 0.5 | 404.0 ± 0.5 | 405.1 ± 7.9 D |

| 55 | 410.0 ± 0.6 | 418.0 ± 0.2 | 416.0 ± 0.5 | 414.7 ± 4.8 C |

| 60 | 444.0 ± 0.8 | 444.0 ± 0.6 | 426.0 ± 0.7 | 438.0 ± 9.9 A |

| 65 | 428.0 ± 0.5 | 438.0 ± 0.2 | 417.0 ± 0.2 | 427.7 ± 9.3 B |

| Group mean | 420.3 ± 19.7 a | 428.0 ± 15.4 a | 415.8 ± 9.0 a | 421.4 ± 6.2 |

| Parameter | Vitamin B1 (Equation (2)) | Vitamin B2 (Equation (1)) | Vitamin B6 (Equation (1)) |

|---|---|---|---|

| β0 | - | −692.7 ± 247.4 | −450.3 ± 337.5 |

| β1 (X1: time) | 1.1613 ± 0.9069 | 0.5315 ± 0.9377 | 2.6383 ± 1.2792 |

| β2 (X2: temp) | 21.0620 ± 0.9789 | 34.1107 ± 8.5372 | 26.2667 ± 11.6456 |

| β11 (X12: time2) | −0.0198 ± 0.0043 | −0.0110 ± 0.0044 | −0.0111 ± 0.0059 |

| β22 (X22: temp2) | −0.2159 ± 0.0153 | −0.3027 ± 0.0738 | −0.2000 ± 0.1007 |

| β12 (X1 × X2: time × temp) | 0.0629 ± 0.0130 | 0.0155 ± 0.0135 | −0.0240 ± 0.0184 |

| Corrected R2 | 0.99 | 0.81 | 0.80 |

| Standard Deviation (SD) | 6.29 | 1.65 | 2.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, T.T.L.; Pham, T.M.N.; Ho, T.B.; Ly-Nguyen, B. Optimization of Vitamin B1, B2, and B6 Absorption in Nang Tay Dum Floating Rice Grains. Foods 2024, 13, 2650. https://doi.org/10.3390/foods13172650

Nguyen TTL, Pham TMN, Ho TB, Ly-Nguyen B. Optimization of Vitamin B1, B2, and B6 Absorption in Nang Tay Dum Floating Rice Grains. Foods. 2024; 13(17):2650. https://doi.org/10.3390/foods13172650

Chicago/Turabian StyleNguyen, Thi Thao Loan, Thi Mong Nghi Pham, Thanh Binh Ho, and Binh Ly-Nguyen. 2024. "Optimization of Vitamin B1, B2, and B6 Absorption in Nang Tay Dum Floating Rice Grains" Foods 13, no. 17: 2650. https://doi.org/10.3390/foods13172650

APA StyleNguyen, T. T. L., Pham, T. M. N., Ho, T. B., & Ly-Nguyen, B. (2024). Optimization of Vitamin B1, B2, and B6 Absorption in Nang Tay Dum Floating Rice Grains. Foods, 13(17), 2650. https://doi.org/10.3390/foods13172650