Radio Frequency Vacuum Drying Study on the Drying Characteristics and Quality of Cistanche Slices and Analysis of Heating Uniformity

Abstract

1. Introduction

2. Materials and Methods

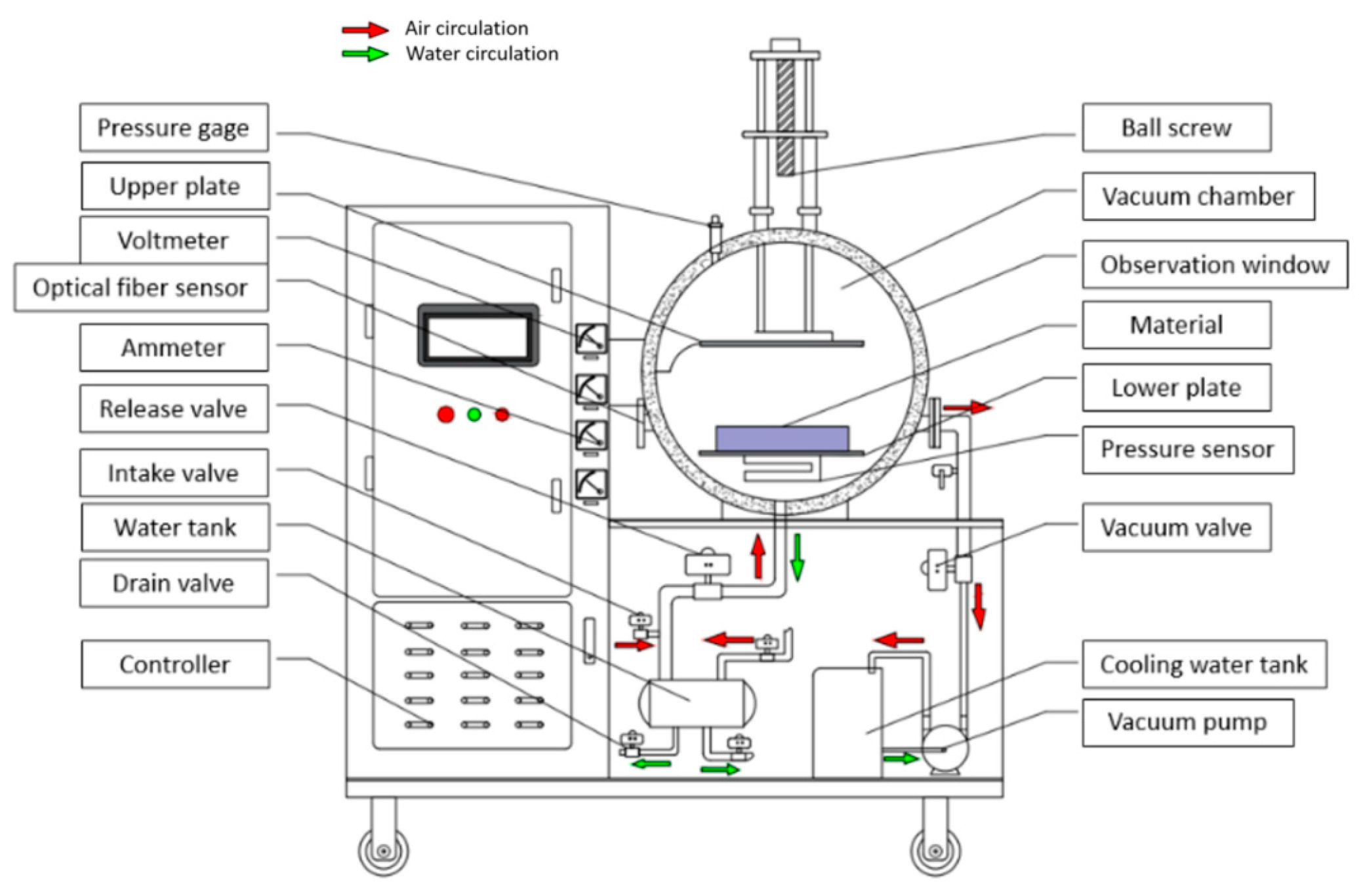

2.1. RF Drying Equipment

2.2. Test Materials and Methods

2.2.1. Testing Material

2.2.2. Test Method

- Hot Air Drying: The Cistanche slices were first spread flat in the hot air drying oven, and the drying temperature was set to 55 °C to quickly raise the surface temperature of the slices. The weight was recorded every 30 min. It was calculated that after 2 h of hot air drying, the moisture ratio reached the optimal transition point for combined drying (53.58 ± 0.2%). The slices were then immediately transferred to the RFV drying equipment for the second stage of drying;

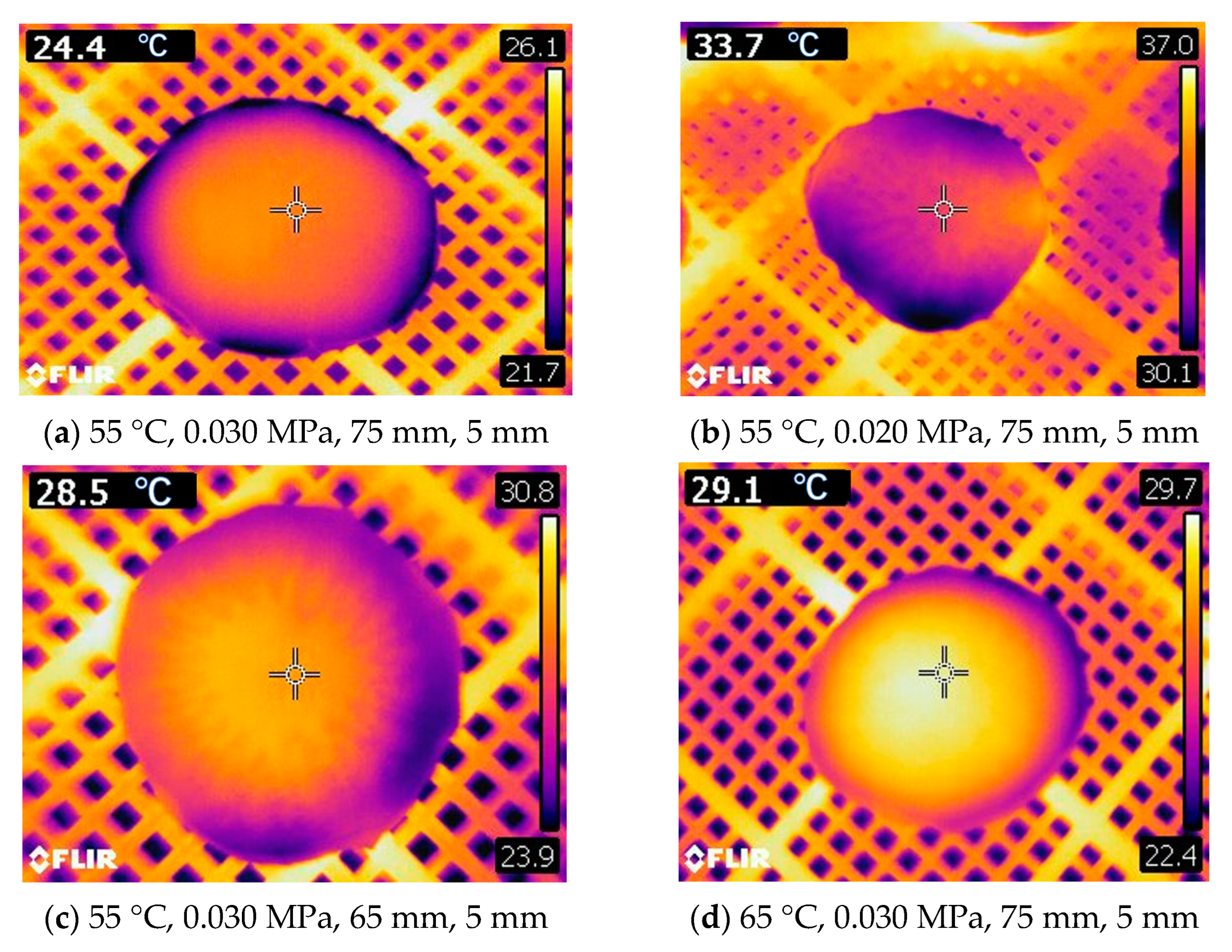

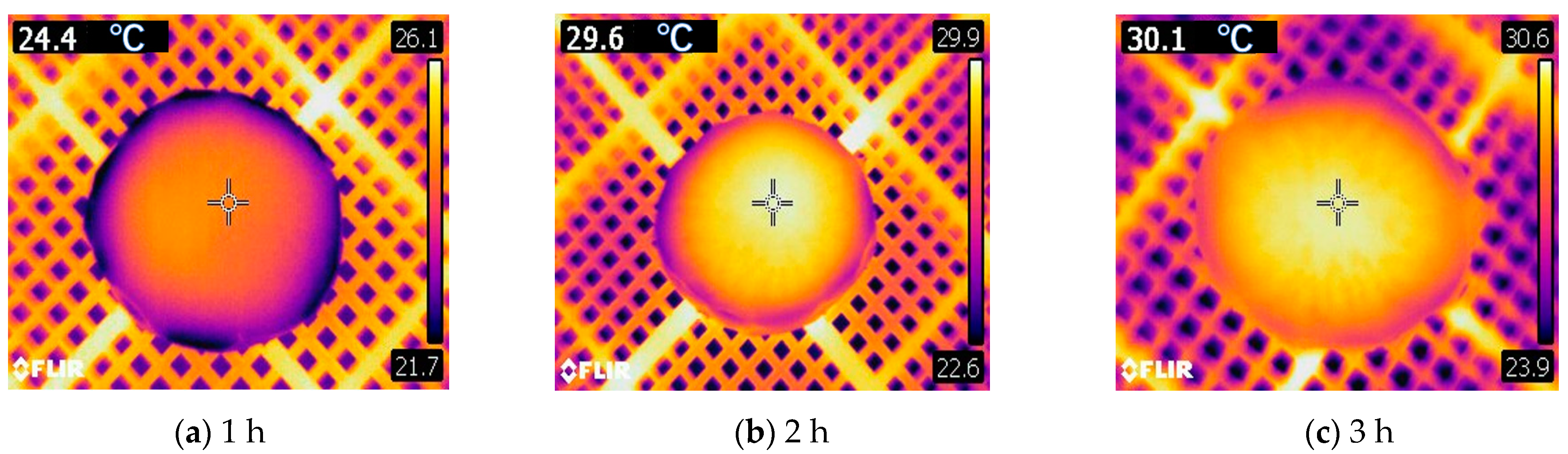

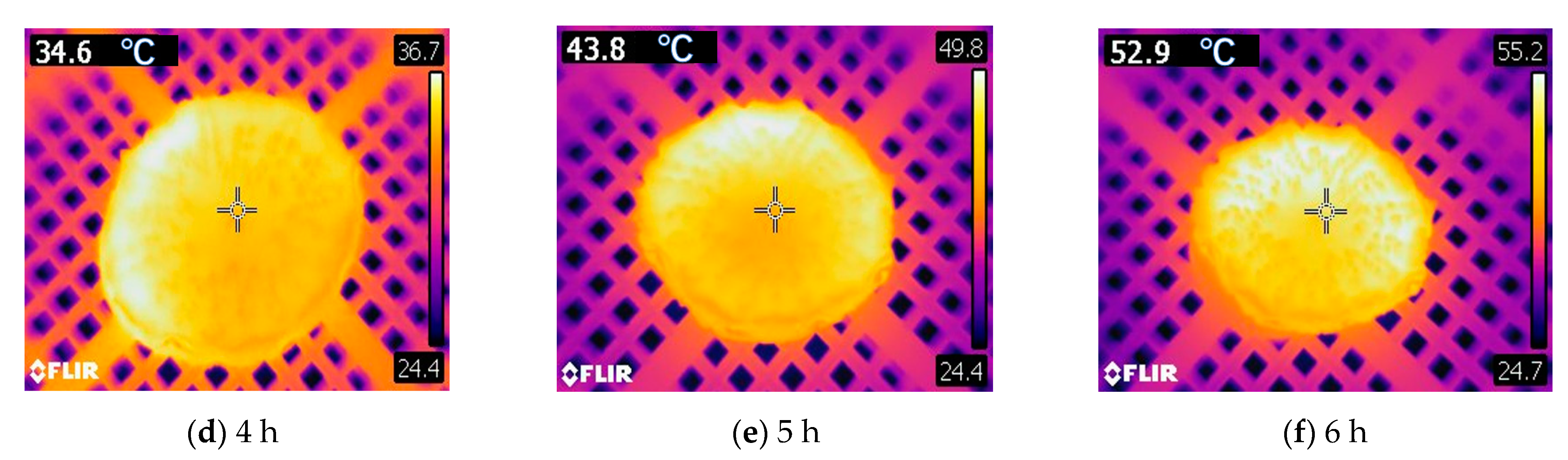

- Radio Frequency Vacuum Drying: To determine the optimal parameters for the second stage of RFV drying of Cistanche slices, the parameter settings of the RF equipment model and the results of previous experiments were considered. It was found that lower vacuum pressures and thinner slice thicknesses led to uneven heating and edge effects in Cistanche. Additionally, too low of plate spacing caused glow discharge within the RF chamber. Therefore, the factor levels for the second stage of RFV drying were selected, as shown in Table 1. The hot air-dried Cistanche slices were placed in perforated rectangular plastic trays made of polystyrene, as shown in Figure 2, and then placed in the RFV dryer. The weight was recorded every 30 min, and the surface temperature was captured using an infrared thermal imager until the moisture content of the material decreased to 10 ± 0.2%, at which point the drying process was concluded.

- Control group:

2.3. Calculation of Drying Characteristic Parameters

2.3.1. Calculation of Dry Base Moisture Content

2.3.2. Calculation of Moisture Ratio

2.3.3. Calculation of Drying Rate

2.4. Method for Determining the Active Ingredient of Cistanche

2.4.1. Preparation of Polysaccharides, Total Flavonoids, Total Phenols, and Antioxidant Extracts

2.4.2. Determination of Polysaccharides

2.4.3. Determination of Total Flavonoids

2.4.4. Determination of Total Phenols

2.4.5. Determination of Antioxidant Properties (DPPH Method)

2.4.6. Determination of Phenhexyl Glycosides and Cyclic Ether Terpene Components in Cistanche (HPLC Method)

2.5. Determination of Chromatic Aberration Value

2.6. Rehydration Ratio

2.7. Microstructure

2.8. Statistical Analysis

3. Results and Discussion

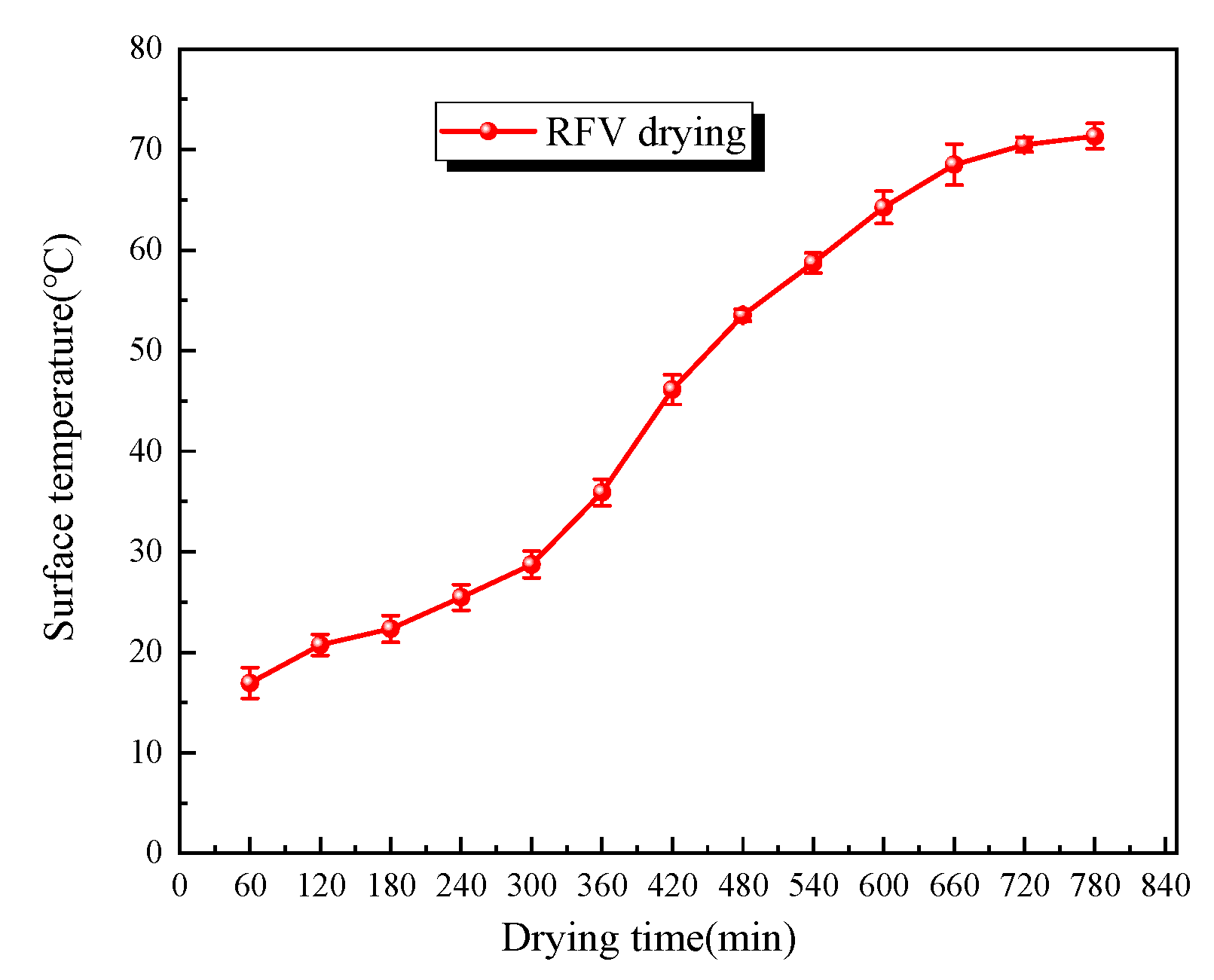

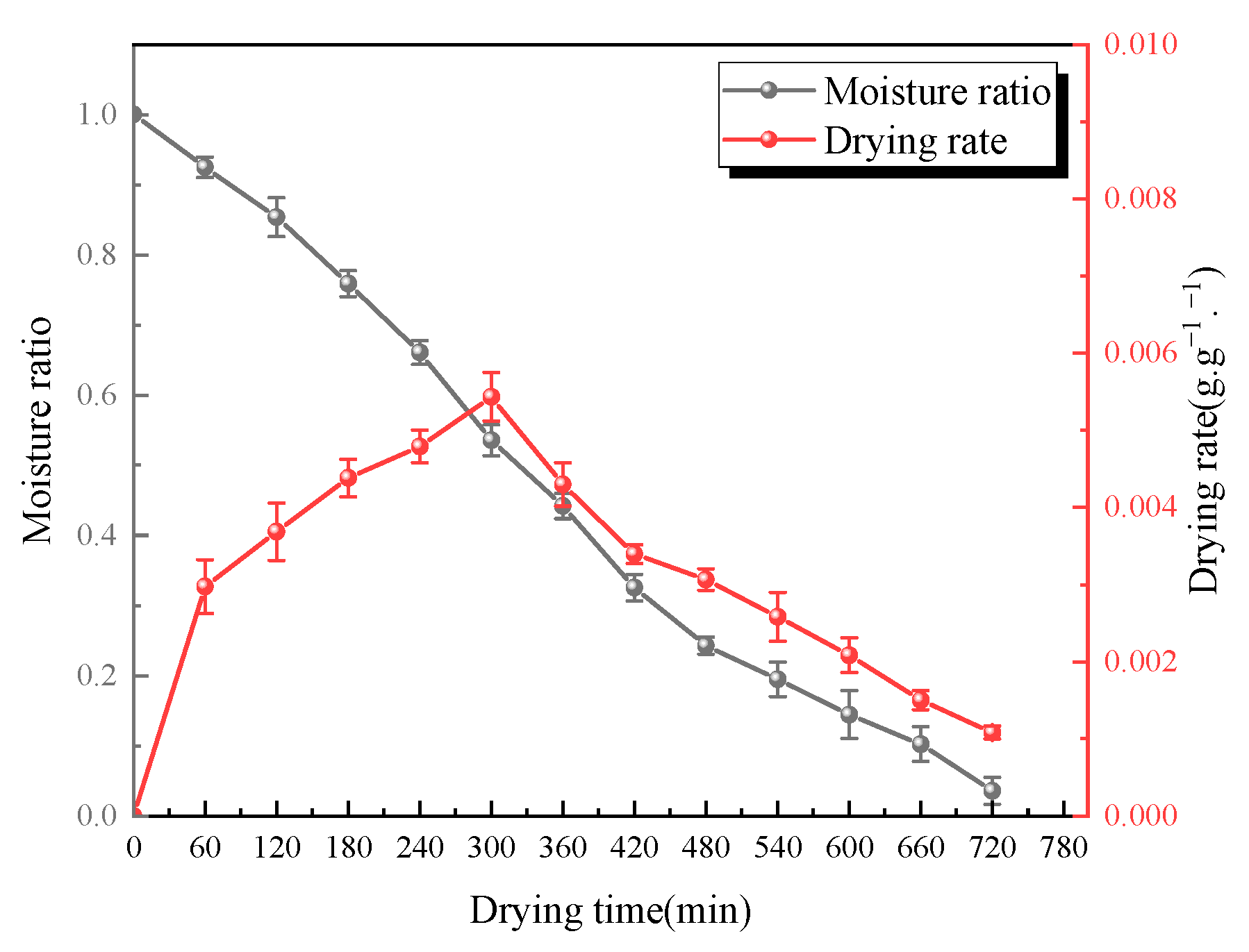

3.1. Drying Characterization of Radio Frequency Vacuum-Dried Cistanche Slices in the Second Segment

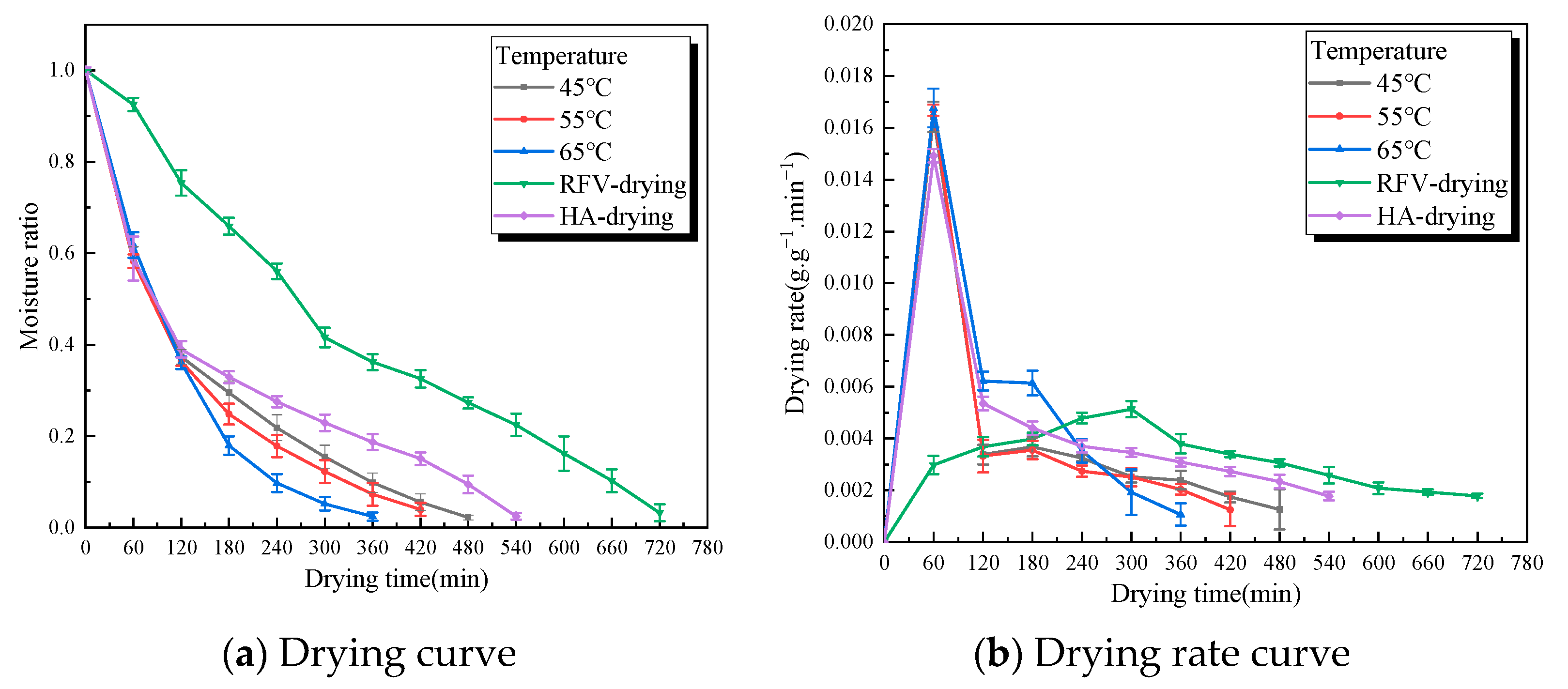

3.1.1. Effect of Temperature on Drying Characteristics of Cistanche

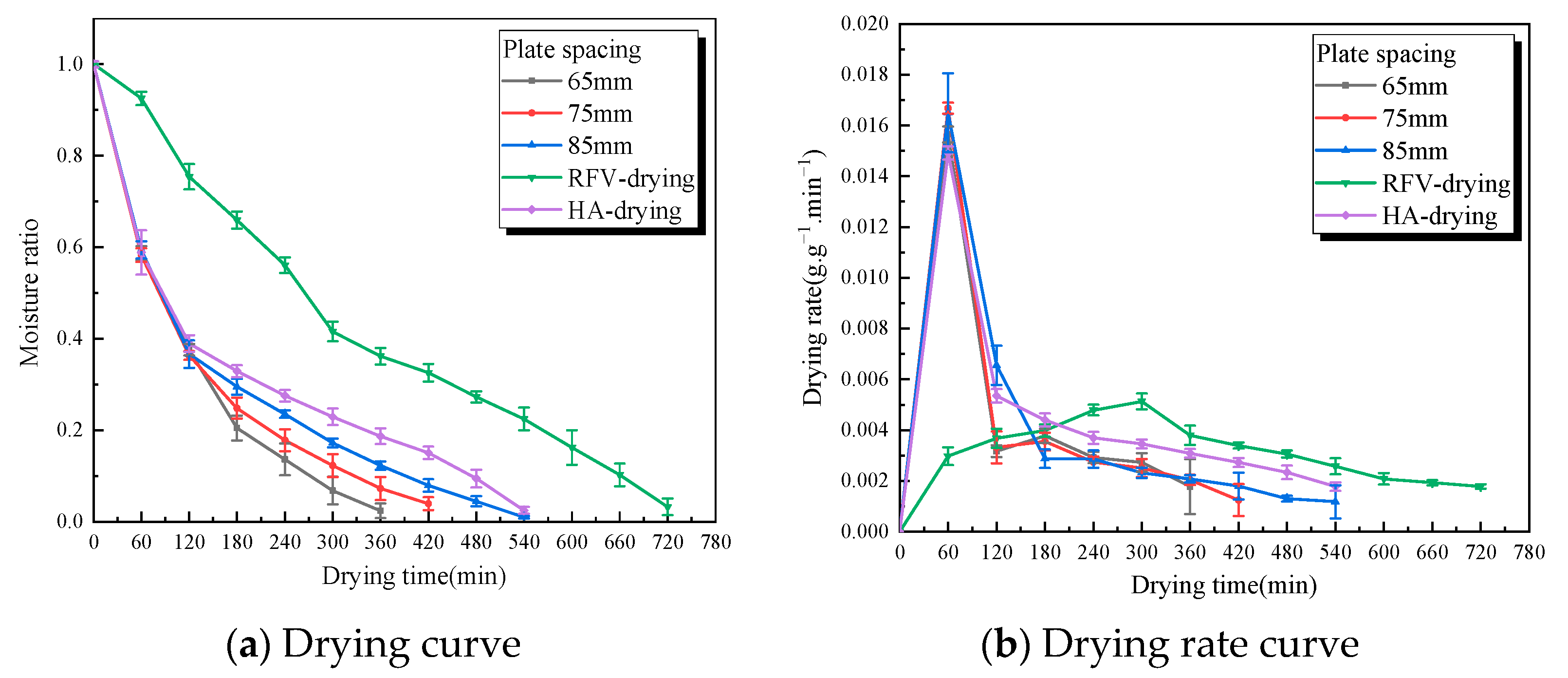

3.1.2. Effect of Plate Spacing on Drying Characteristics of Cistanche

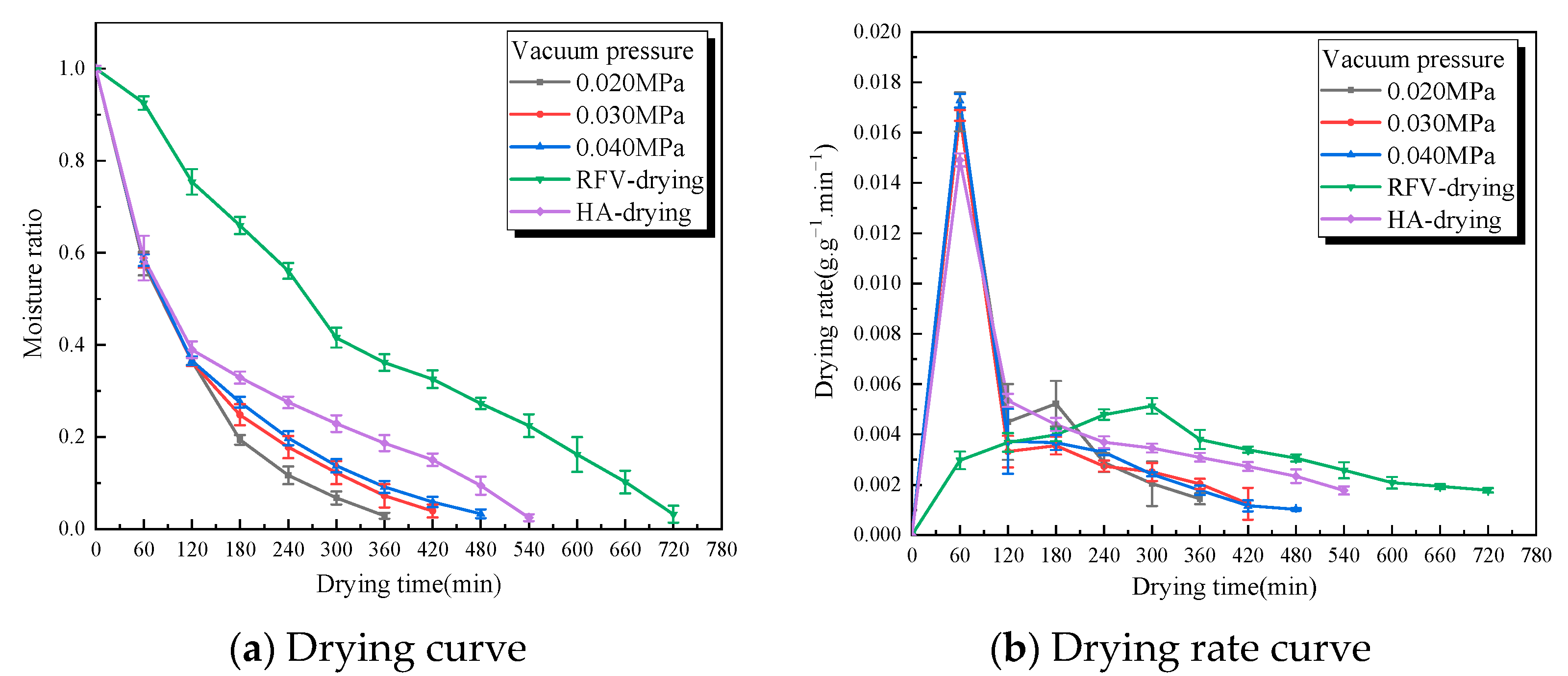

3.1.3. Effect of Vacuum on Drying Characteristics of Cistanche

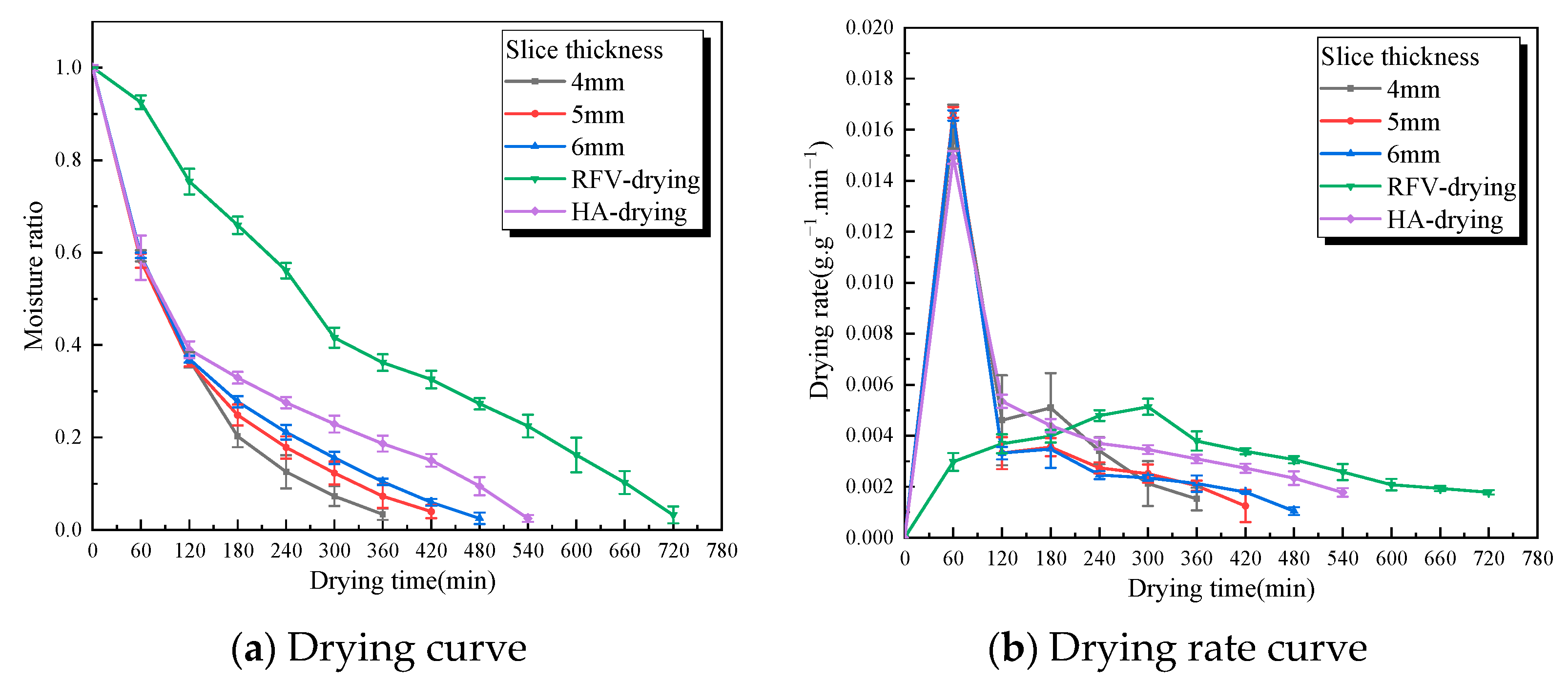

3.1.4. Effect of Slice Thickness on Drying Characteristics of Cistanche

3.2. Computer Vision and Uniformity Analysis

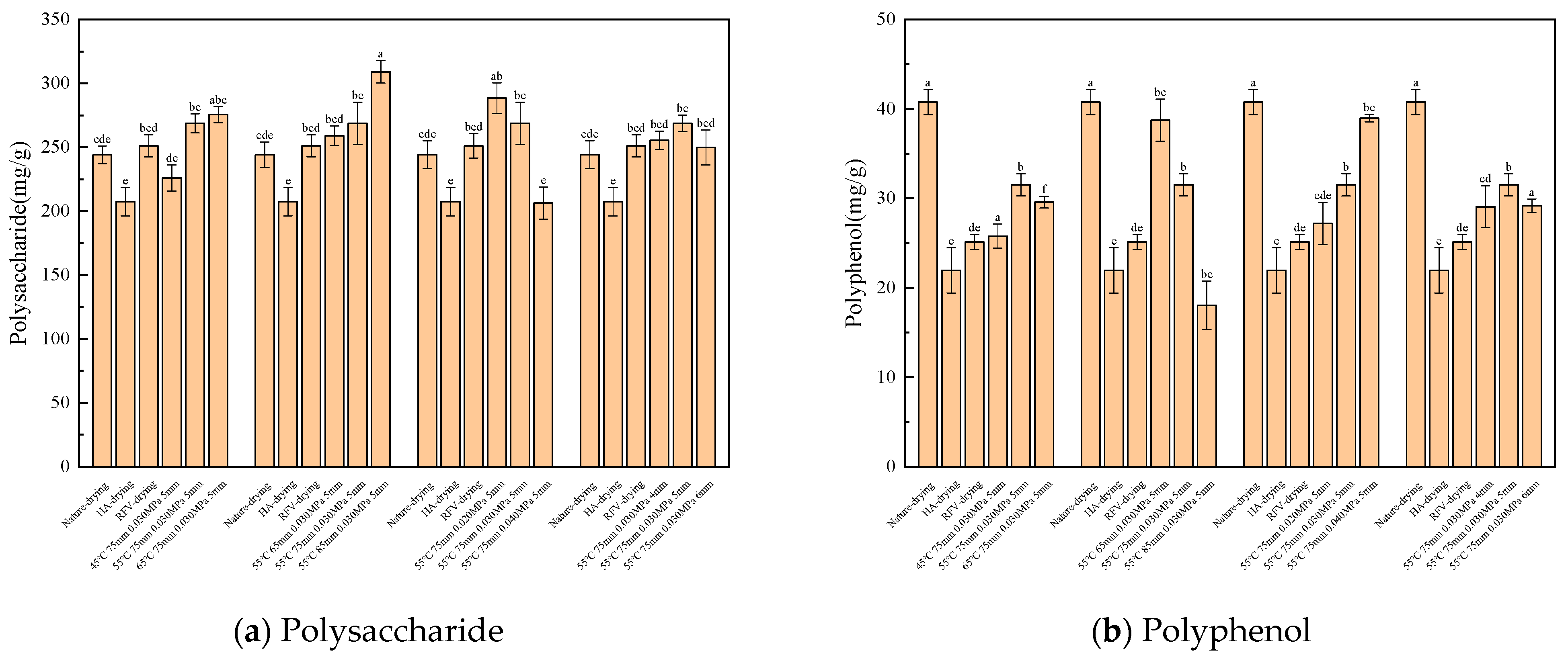

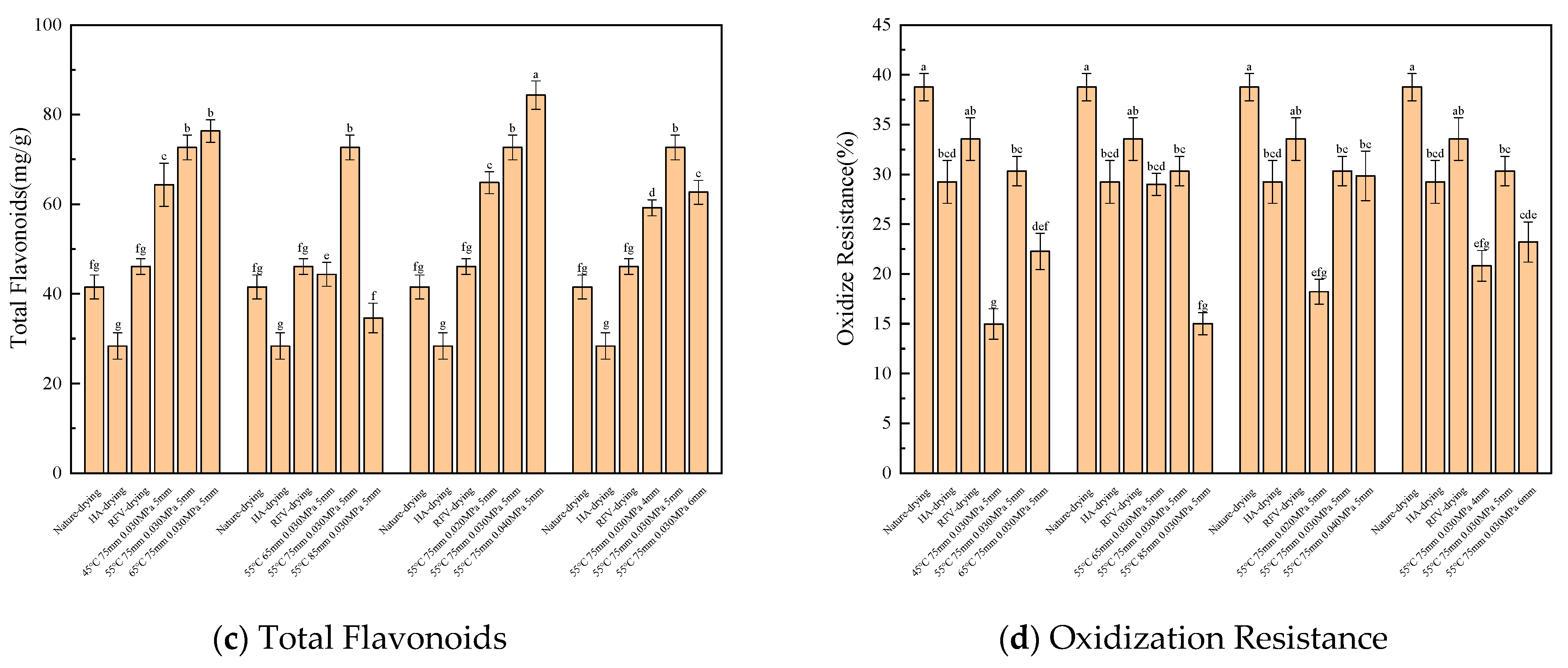

3.3. Quality Analysis of Cistanche Slices by Radio Frequency Vacuum Drying Parameters in the Second Segment

3.3.1. Effects of Different RFV Drying Conditions on Polysaccharides Content

3.3.2. Effects of Different RFV Drying Conditions on Polyphenols in Cistanche Slices

3.3.3. Effects of Different RFV Drying Conditions on Total Flavonoids in Cistanche Slices

3.3.4. Effects of Different RFV Drying Conditions on the Oxidation Resistance of Cistanche Slices

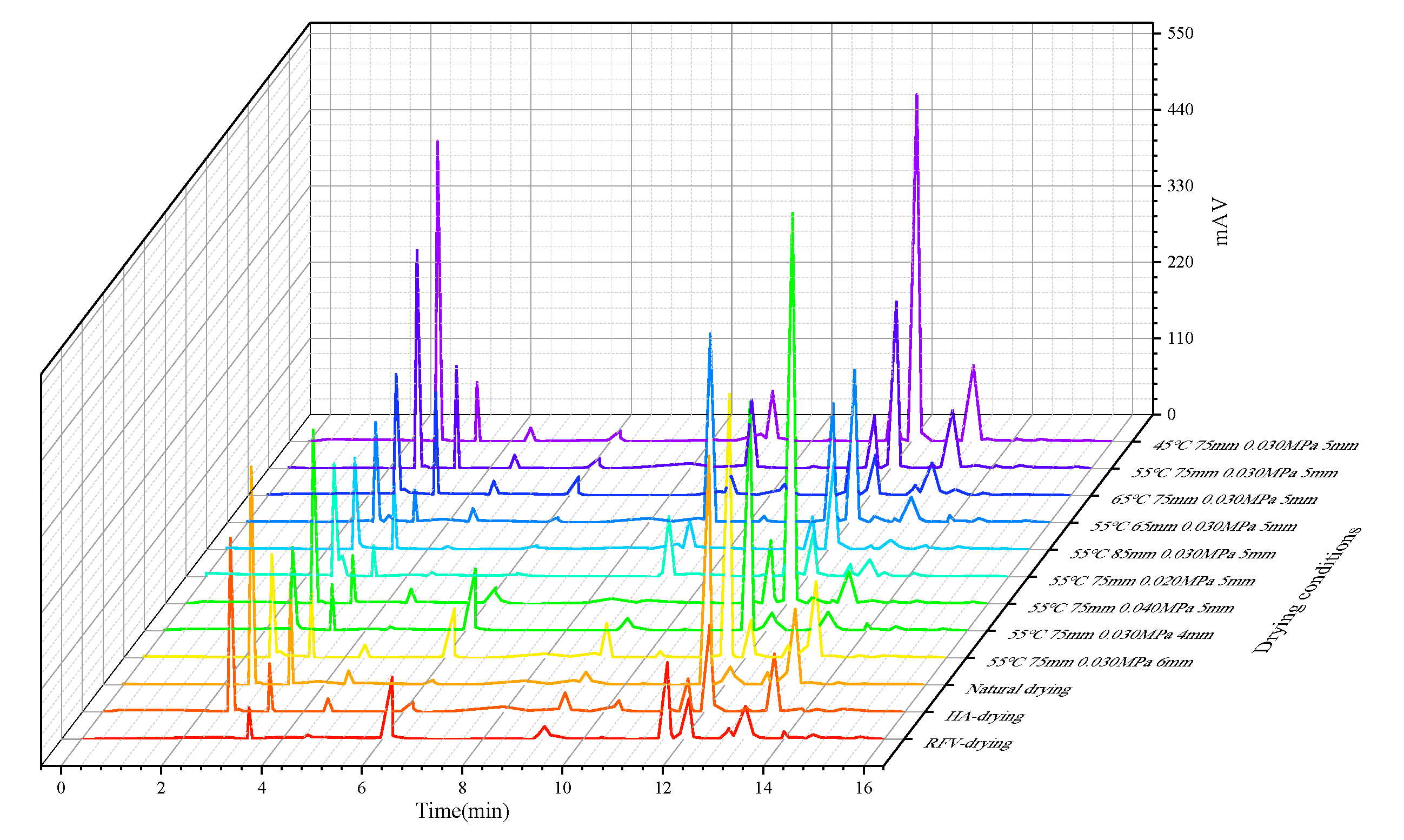

3.3.5. Effects of Different RFV Drying Conditions on Phenylethanol Glycosides and Cyclic Ether Terpenes in Cistanche Slices

3.3.6. Effects of Different RFV Drying Conditions on the Color and Rehydration Ratio of Cistanche

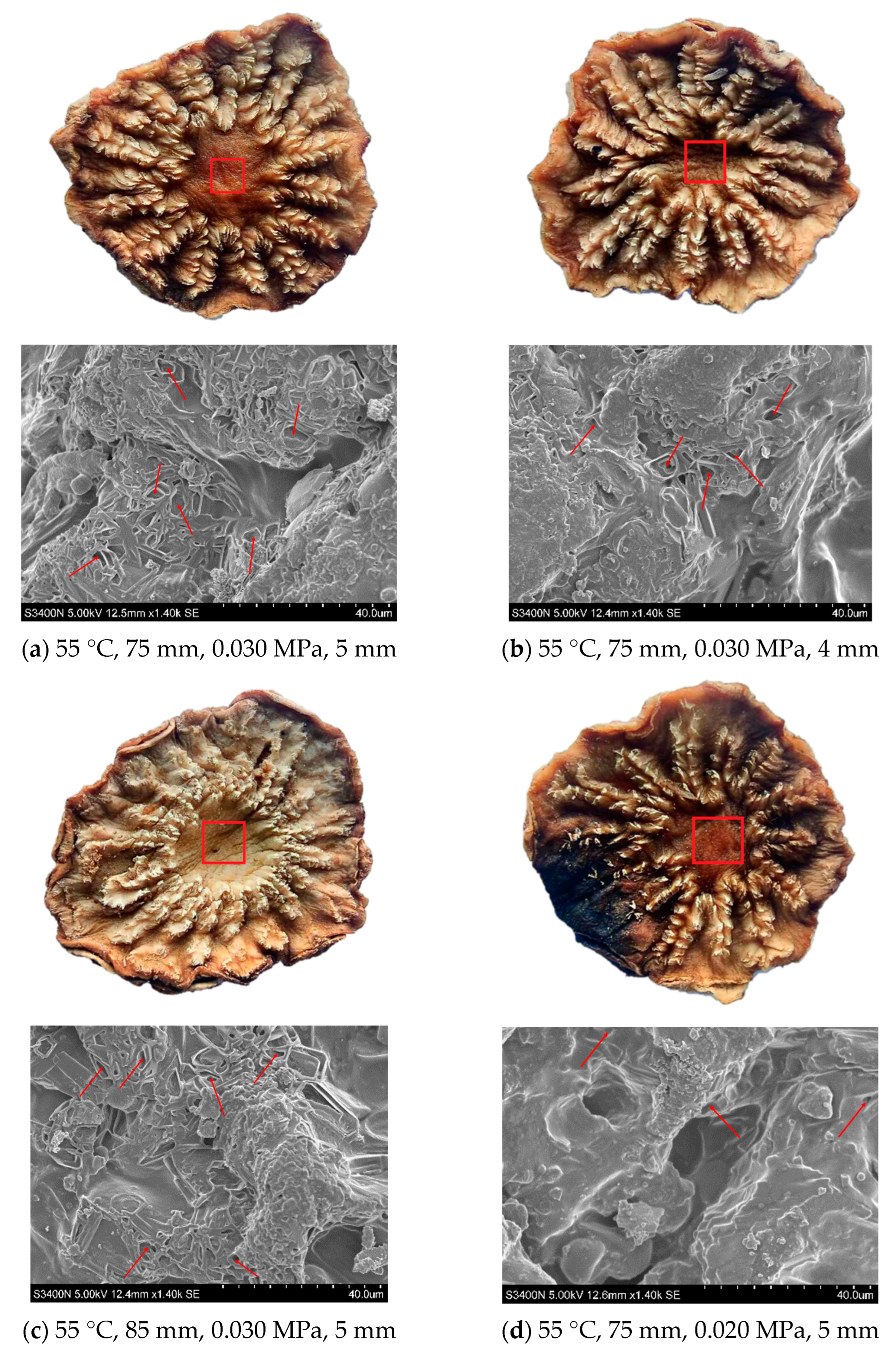

3.3.7. Effects on the Microstructure of Cistanche Slices under Different RFV Drying Conditions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, S.; Feng, D.; Zhou, Y.; Duan, H.; Jiang, Y.; Yan, W. Analysis of the active ingredients and health applications of cistanche. Front. Nutr. 2023, 10, 1101182. [Google Scholar] [CrossRef] [PubMed]

- Cheng, N.; Wang, H.; Hao, H.; Rahman, F.-U.; Zhang, Y. Research progress on polysaccharide components of Cistanche deserticola as potential pharmaceutical agents. Eur. J. Med. Chem. 2023, 245, 114892. [Google Scholar] [CrossRef] [PubMed]

- Boateng, I.D. Recent processing of fruits and vegetables using emerging thermal and non-thermal technologies. A critical review of their potentialities and limitations on bioactives, structure, and drying performance. Crit. Rev. Food Sci. Nutr. 2022, 64, 4240–4274. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, L.; Li, Q.; Zhao, C.; He, P.; Ma, X. Enhancement of Kidney Invigorating Function in Mouse Model by Cistanches Herba Dried Rapidly at a Medium High Temperature. J. Med. Food 2019, 22, 1246–1253. [Google Scholar] [CrossRef]

- Jiang, C.; Wan, F.; Zang, Z.; Zhang, Q.; Xu, Y.; Huang, X. Influence of far-infrared vacuum drying on drying kinetics and quality characteristics of Cistanche slices. J. Food Process. Preserv. 2022, 46, e17144. [Google Scholar] [CrossRef]

- Ai, Z.; Xie, Y.; Li, X.; Zhu, G.; Peng, Z.; Liu, Y.; Mowafy, S.; Guo, J. Mechanism of freezing treatment to improve the efficiency of hot air impingement drying of steamed Cistanche deserticola and the quality attribute of the dried product. Ind. Crop. Prod. 2023, 195, 116472. [Google Scholar] [CrossRef]

- Li, C.; Ren, G.; Zhang, L.; Duan, X.; Wang, Z.; Ren, X.; Chu, Q.; He, T. Effects of different drying methods on the drying characteristics and drying quality of Cistanche deserticola. LWT 2023, 184, 115000. [Google Scholar] [CrossRef]

- Yin, C.; Li, J.; Liu, B. Research progress on the application of radio frequency heating technology in food thawing. Cold Storage 2023, 46, 72–77. [Google Scholar] [CrossRef]

- Sosa-Morales, M.; Valerio-Junco, L.; López-Malo, A.; García, H. Dielectric properties of foods: Reported data in the 21st Century and their potential applications. J. LWT Food Sci. Technol. 2010, 43, 1169–1179. [Google Scholar] [CrossRef]

- Ling, B.; Tiwari, G.; Wang, S. Pest control by microwave and radio frequency energy: Dielectric properties of stone fruit. Agron. Sustain. Dev. 2015, 35, 233–240. [Google Scholar] [CrossRef]

- Wason, S.; Verma, T.; Irmak, S.; Subbiah, J. In-package pasteurization of dried basil leaves using radiofrequency heating. Food Control. 2022, 141, 109179. [Google Scholar] [CrossRef]

- Jiang, H.; Gu, Y.; Gou, M.; Xia, T.; Wang, S. Radio frequency pasteurization and disinfestation techniques applied on low-moisture foods. Crit. Rev. Food Sci. Nutr. 2020, 60, 1417–1430. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Jia, Y.; Song, M.; Liu, Y.; Xin, L.; Chen, X.; Fu, H.; Wang, Y.; Wang, Y. Effects of radio frequency thawing on the quality characteristics of frozen mutton. J. Food Bioprod. Process. 2023, 139, 24–33. [Google Scholar] [CrossRef]

- Birla, S.; Wang, S.; Tang, J. Computer simulation of radio frequency heating of model fruit immersed in water. J. Food Eng. 2008, 84, 270–280. [Google Scholar] [CrossRef]

- Xu, Y.; Zang, Z.; Zhang, Q.; Wang, T.; Shang, J.; Huang, X.; Wan, F. Characteristics and Quality Analysis of Radio Frequency-Hot Air Combined Segmented Drying of Wolfberry (Lycium barbarum). Foods 2022, 11, 1645. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.; Wei, X.; Wu, D.; Dai, J.; Liu, S.; Qin, W. Effect of radio frequency-assisted hot-air drying on drying kinetics and quality of Sichuan pepper (Zanthoxylum bungeanum maxim.). J. LWT 2021, 147, 111572. [Google Scholar] [CrossRef]

- Ai, Z.; Zhu, G.; Zheng, Z.; Xiao, H.; Mowafy, S.; Liu, Y. Successive Two-Stage Hot Air-Drying with Humidity Control Combined Radio Frequency Drying Improving Drying Efficiency and Nutritional Quality of Amomi fructus. Food Bioprocess Technol. 2023, 16, 149–166. [Google Scholar] [CrossRef]

- Peng, J.; Yin, X.; Jiao, S.; Wei, K.; Tu, K.; Pan, L. Air jet impingement and hot air-assisted radio frequency hybrid drying of apple slices. LWT 2019, 116, 108517. [Google Scholar] [CrossRef]

- Zhang, H.; Gong, C.; Wang, X.; Liao, M.; Yue, J.; Jiao, S. Application of hot air-assisted radio frequency as second stage drying method for mango slices. J. Food Process. Eng. 2019, 42, e12974. [Google Scholar] [CrossRef]

- Gong, C.; Liao, M.; Zhang, H.; Xu, Y.; Miao, Y.; Jiao, S. Investigation of Hot Air–Assisted Radio Frequency as a Final-Stage Drying of Pre-dried Carrot Cubes. J. Food Bioprocess Technol. 2020, 13, 419–429. [Google Scholar] [CrossRef]

- Krishnamurthy, K.; Khurana, H.K.; Soojin, J.; Irudayaraj, J.; Demirci, A. Infrared heating in food processing: An overview. J. Compr. Rev. Food Sci. Food Saf. 2008, 7, 2–13. [Google Scholar] [CrossRef]

- Xiao, H.; Wei, G.Z.J.; Lin, H.A.I.; Yang, W.X. Air impingement drying characteristics and quality of carrot cubes. J. Food Process Eng. 2010, 33, 899–918. [Google Scholar] [CrossRef]

- DuBois, M.; Gilles, K.A.; Hamilton, J.K.; Rebers, P.A.; Smith, F. Colorimetric method for determination of sugars and related substances. Anal. Chem. 1956, 28, 350–356. [Google Scholar] [CrossRef]

- Zeng, C.; Ye, G.; Li, G.; Cao, H.; Wang, Z.; Ji, S. RID serve as a more appropriate measure than phenol sulfuric acid method for natural water-soluble polysaccharides quantification. J. Carbohydr. Polym. 2021, 278, 118928. [Google Scholar] [CrossRef]

- Gull, T.; Sultana, B.; Anwar, F.; Nouman, W.; Mehmood, T.; Sher, M. Characterization of phenolics in different parts of selected Capparis species harvested in low and high rainfall season. J. Food Meas. Charact. 2018, 12, 1539–1547. [Google Scholar] [CrossRef]

- Nencini, C.; Menchiari, A.; Franchi, G.G.; Micheli, L. In vitro Antioxidant Activity of Aged Extracts of some Italian Allium Species. J. Plant Foods Hum. Nutr. 2011, 66, 11–16. [Google Scholar] [CrossRef]

- Ai, Z.; Zhang, Y.; Li, X.; Sun, W.; Liu, Y. Widely Targeted Metabolomics Analysis to Reveal Transformation Mechanism of Cistanche Deserticola Active Compounds During Steaming and Drying Processes. J. Front. Nutr. 2021, 8, 742511. [Google Scholar] [CrossRef]

- Sabancı, S.; Icier, F. Effects of Vacuum Ohmic Evaporation on Some Quality Properties of Sour Cherry Juice Concentrates. Int. J. Food Eng. 2019, 15, 20190055. [Google Scholar] [CrossRef]

- Boateng, I.D.; Yang, X. Osmotic, osmovacuum, sonication, and osmosonication pretreatment on the infrared drying of Ginkgo seed slices: Mass transfer, mathematical modeling, drying, and rehydration kinetics and energy consumption. J. Food Sci. 2021, 86, 4577–4593. [Google Scholar] [CrossRef]

- Alolga, R.N.; Osae, R.; Essilfie, G.; Saalia, F.K.; Akaba, S.; Chikari, F. Sonication, osmosonication and vacuum-assisted osmosonication pretreatment of Ghanaian garlic slices: Effect on physicochemical properties and quality characteristics. J. Food Chem. 2021, 343, 128535. [Google Scholar] [CrossRef]

- Zhang, Q.; Wan, F.; Zang, Z.; Jiang, C.; Xu, Y.; Huang, X. Effect of ultrasonic far-infrared synergistic drying on the characteristics and qualities of wolfberry (Lycium barbarum L.). J. Ultrason. Sonochemistry 2022, 89, 106134. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Yang, Y.; Li, Z.; Wang, X.; Liu, Y. Moisture transfer and microstructure change of banana slices during contact ultrasound strengthened far-infrared radiation drying. Innov. Food Sci. Emerg. Technol. 2020, 66, 102537. [Google Scholar] [CrossRef]

- Mahmood, N.; Liu, Y.; Munir, Z.; Zhang, Y.; Niazi, B.M.K. Effects of hot air assisted radio frequency drying on heating uniformity, drying characteristics and quality of paddy. LWT 2022, 158, 113131. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, R.; Zhang, B.; Pei, S.; Liu, Q.; Ramaswamy, H.S.; Wang, S. Radio Frequency-Vacuum Drying of Kiwifruits: Kinetics, Uniformity, and Product Quality. Food Bioprocess Technol. 2018, 11, 2094–2109. [Google Scholar] [CrossRef]

- Özbek, H.N. Radio frequency-assisted hot air drying of carrots for the production of carrot powder: Kinetics and product quality. LWT 2021, 152, 112332. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Li, X.; Zhu, J.; Wang, X.; Ma, L. Drying characteristics, quality changes, parameters optimization and flavor analysis for microwave vacuum drying of garlic (Allium sativum L.) slices. LWT 2023, 173, 114372. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Johnson, J.; Gao, M.; Tang, J.; Powers, J.R.; Wang, S. Developing Hot Air-Assisted Radio Frequency Drying for In-shell Macadamia Nuts. J. Food Bioprocess Technol. 2014, 7, 278–288. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, Y.; Zeng, S.; Zheng, Y.; Chen, F.; Guo, Z.; Lin, Y.; Zheng, B. Optimization of microwave vacuum drying of lotus (Nelumbo nucifera Gaertn.) seeds by response surface methodology. J. Food Sci. Technol. Int. 2012, 18, 477–488. [Google Scholar] [CrossRef]

- Villa-Corrales, L.; Flores-Prieto, J.; Xamán-Villaseñor, J.; García-Hernández, E. Numerical and experimental analysis of heat and moisture transfer during drying of Ataulfo mango. J. Food Eng. 2010, 98, 198–206. [Google Scholar] [CrossRef]

- Hongyue, L.I.; Qingluan, L.I.; Jianjun, Z.; Bo, L.; Shaojin, W. Recent advances on application of radio frequency heating in the research of post-harvest grain storage and processing. J. Smart Agric. 2021, 3, 1. [Google Scholar]

- Zhou, L.; Ling, B.; Zheng, A.; Zhang, B.; Wang, S. Developing radio frequency technology for postharvest insect control in milled rice. J. Stored Prod. Res. 2015, 62, 22–31. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, H.; Lim, R.-X. Recent Developments in Microwave-Assisted Drying of Vegetables, Fruits, and Aquatic Products—Drying Kinetics and Quality Considerations. J. Dry. Technol. 2010, 28, 1307–1316. [Google Scholar] [CrossRef]

- Kipcak, A.S. Microwave drying kinetics of mussels (Mytilus edulis). J. Res. Chem. Intermed. 2017, 43, 1429–1445. [Google Scholar] [CrossRef]

- Zhang, C.; Wei, A.; Yue, M. Effects of different drying methods on the content and antioxidant activity of truffle polysaccharides. J. Food Ind. 2020, 41, 214–218. [Google Scholar]

- Liu, Y.; Sun, C.; Lei, Y.; Yu, H.; Xi, H.; Duan, X. Contact ultrasound strengthened far-infrared radiation drying on pear slices: Effects on drying characteristics, microstructure, and quality attributes. J. Dry. Technol. 2019, 37, 745–758. [Google Scholar] [CrossRef]

- Chen, W.H.; Xu, C.M.; Zeng, J.L.; Zhao, B.; Wang, X.D.; Wang, Y.C. Improvement of echinacoside and acteoside production by two-stage elicitation in cell suspension culture of Cistanche deserticola. J. World J. Microbiol. Biotechnol. 2007, 23, 1451–1458. [Google Scholar] [CrossRef]

- Peng, F.; Xu, R.; Wang, X.; Xu, C.; Liu, T.; Chen, J. Effect of the Steaming Process on Quality of Postharvest Cistanche deserticola for Medicinal Use during Sun Drying. J. Biol. Pharm. Bull. 2016, 39, 2066–2070. [Google Scholar] [CrossRef]

- Chu, Q.; Li, L.; Duan, X.; Zhao, M.; Wang, Z.; Wang, Z.; Ren, X.; Li, C.; Ren, G. Effect mechanism of different drying methods on the quality and browning for daylily. J. LWT 2023, 182, 114862. [Google Scholar] [CrossRef]

- Mothibe, K.J.; Zhang, M.; Nsor-Atindana, J.; Wang, Y.-C. Use of Ultrasound Pretreatment in Drying of Fruits: Drying Rates, Quality Attributes, and Shelf Life Extension. J. Dry. Technol. 2011, 29, 1611–1621. [Google Scholar] [CrossRef]

- Luo, X.; Zhang, S.; Zhang, W. The effect of different drying methods on the quality of golden ear slices after color protection. J. Food Ferment. Ind. 2022, 48, 227–232. [Google Scholar] [CrossRef]

- Zhang, Z.; Guo, C.; Gao, T.; Fu, H.; Chen, Q.; Wang, Y. Pilot-scale radiofrequency blanching of potato cuboids: Heating uniformity. J. Sci. Food Agric. 2018, 98, 312–320. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Jiang, S.; Miao, S.; Zhang, L.; Deng, K.; Zheng, B. Effects of drying on the quality characteristics and release of umami substances of Flammulina velutipes. J. Food Biosci. 2023, 51, 102338. [Google Scholar] [CrossRef]

| Test Serial Number | Temperature (°C) | Vacuum Pressure (MPa) | Plate Spacing (mm) | Slice Thickness (mm) |

|---|---|---|---|---|

| 1 | 45 | 0.030 | 75 | 5 |

| 2 | 55 | 0.030 | 75 | 5 |

| 3 | 65 | 0.030 | 75 | 5 |

| 4 | 55 | 0.020 | 75 | 5 |

| 5 | 55 | 0.040 | 75 | 5 |

| 6 | 55 | 0.030 | 65 | 5 |

| 7 | 55 | 0.030 | 85 | 5 |

| 8 | 55 | 0.030 | 75 | 4 |

| 9 | 55 | 0.030 | 75 | 6 |

| Drying Conditions | Phenylethanoid Glycoside (mg/mL) | Iridoids (mg/mL) | |||||

|---|---|---|---|---|---|---|---|

| Echinacoside | Salidroside | Jinshi Sericin | Verbascoside | Isoacteoside | Catalpol | Leonurus Japonicus Glycoside | |

| 45 °C 75 mm 0.030 MPa 5 mm | |||||||

| 55 °C 75 mm 0.030 MPa 5 mm | |||||||

| 65 °C 75 mm 0.030 MPa 5 mm | |||||||

| 55 °C 65 mm 0.030 MPa 5 mm | |||||||

| 55 °C 85 mm 0.030 MPa 5 mm | |||||||

| 55 °C 75 mm 0.020 MPa 5 mm | |||||||

| 55 °C 75 mm 0.040 MPa 5 mm | |||||||

| 55 °C 75 mm 0.030 MPa 4 mm | |||||||

| 55 °C 75 mm 0.030 MPa 6 mm | |||||||

| Natural drying | |||||||

| HA drying | |||||||

| RFV drying | |||||||

| Drying Conditions | Color | Rehydration Ratio | |||

|---|---|---|---|---|---|

| R (%) | |||||

| Fresh sample | |||||

| 45 °C 75 mm 0.030 MPa 5 mm | |||||

| 55 °C 75 mm 0.030 MPa 5 mm | |||||

| 65 °C 75 mm 0.030 MPa 5 mm | |||||

| 55 °C 65 mm 0.030 MPa 5 mm | |||||

| 55 °C 85 mm 0.030 MPa 5 mm | |||||

| 55 °C 75 mm 0.020 MPa 5 mm | |||||

| 55 °C 75 mm 0.040 MPa 5 mm | |||||

| 55 °C 75 mm 0.030 MPa 4 mm | |||||

| 55 °C 75 mm 0.030 MPa 6 mm | |||||

| Natural drying | |||||

| HA drying | |||||

| RFV drying | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, A.; Wan, F.; Ma, G.; Ma, J.; Xu, Y.; Zang, Z.; Ying, X.; Jia, H.; Huang, X. Radio Frequency Vacuum Drying Study on the Drying Characteristics and Quality of Cistanche Slices and Analysis of Heating Uniformity. Foods 2024, 13, 2672. https://doi.org/10.3390/foods13172672

Chen A, Wan F, Ma G, Ma J, Xu Y, Zang Z, Ying X, Jia H, Huang X. Radio Frequency Vacuum Drying Study on the Drying Characteristics and Quality of Cistanche Slices and Analysis of Heating Uniformity. Foods. 2024; 13(17):2672. https://doi.org/10.3390/foods13172672

Chicago/Turabian StyleChen, Ao, Fangxin Wan, Guojun Ma, Junmin Ma, Yanrui Xu, Zepeng Zang, Xinyu Ying, Haiwen Jia, and Xiaopeng Huang. 2024. "Radio Frequency Vacuum Drying Study on the Drying Characteristics and Quality of Cistanche Slices and Analysis of Heating Uniformity" Foods 13, no. 17: 2672. https://doi.org/10.3390/foods13172672

APA StyleChen, A., Wan, F., Ma, G., Ma, J., Xu, Y., Zang, Z., Ying, X., Jia, H., & Huang, X. (2024). Radio Frequency Vacuum Drying Study on the Drying Characteristics and Quality of Cistanche Slices and Analysis of Heating Uniformity. Foods, 13(17), 2672. https://doi.org/10.3390/foods13172672