Use of Integral Forage Palm Flour as an Innovative Ingredient in New Fettuccine-Type Pasta: Thermomechanical and Technological Properties, and Sensory Acceptance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

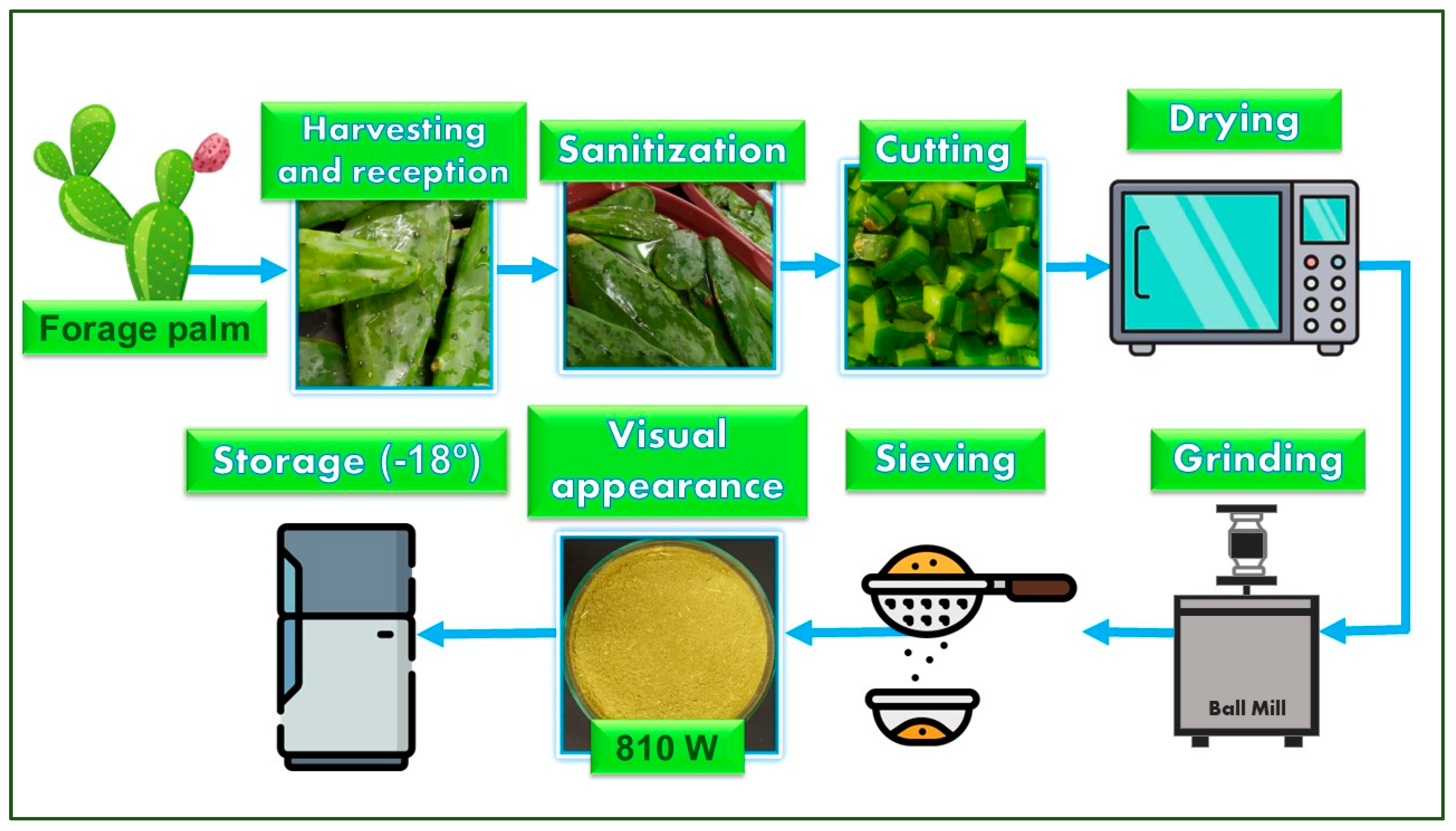

2.2.1. Receiving, Sanitizing, and Processing Cladodes for Analysis and Flour Preparation

2.2.2. Proximate Composition of Integral Forage Palm Cladodes

2.2.3. Microwave Radiation Drying Process

2.2.4. Instrumental Color of Integral Forage Palm Puree and Flour

2.2.5. Total Soluble Phenolic Compounds of Integral Forage Palm Puree and Flour

2.2.6. Experimental Design for Fresh and Dry Extruded Fettuccine-Type Pasta

2.2.7. Thermomechanical Properties of Flour Blends

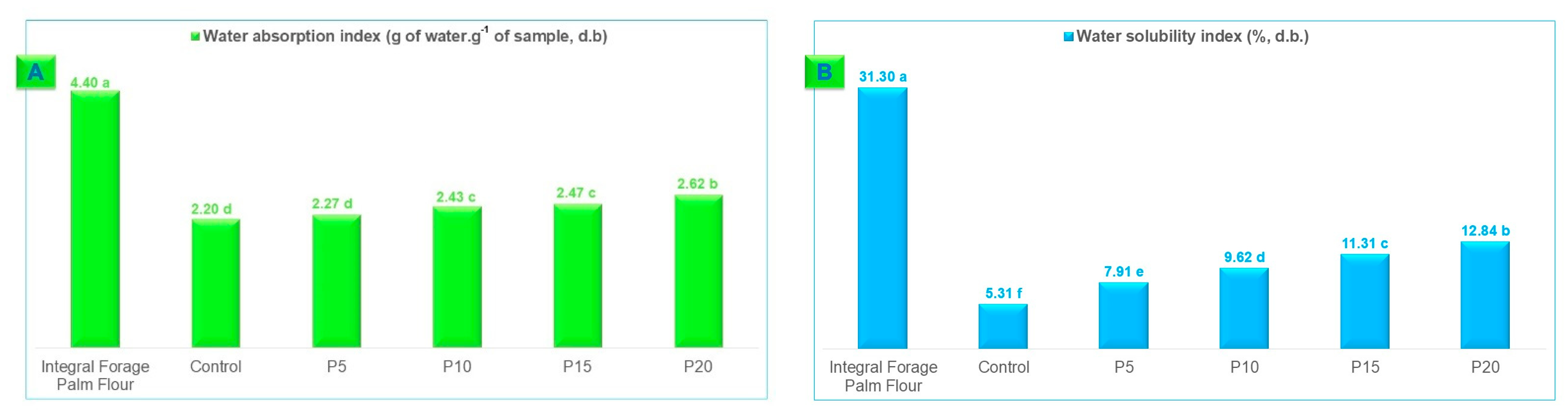

2.2.8. Water Absorption Index and Water Solubility Index

2.2.9. Preparation of Fresh and Dried Extruded Fettuccine-Type Pasta

2.2.10. Moisture Content and Cooking Characteristics of Fettuccine-Type Pasta

2.2.11. Texture Characteristics of Fettuccine-Type Pasta

2.2.12. Sensory Analysis of Unflavored and Flavored (Garlic and Oil) Fettuccine-Type Pasta

2.2.13. Statistical Analysis

3. Results and Discussion

3.1. Proximate Composition of Integral Forage Palm Puree

3.2. Color Parameters and Total Soluble Phenolic Compounds in Integral Forage Palm Puree and Flour

3.3. Thermomechanical Characteristics of Pre-Mixes by Mixolab2

3.4. Water Absorption Index and Water Solubility Index

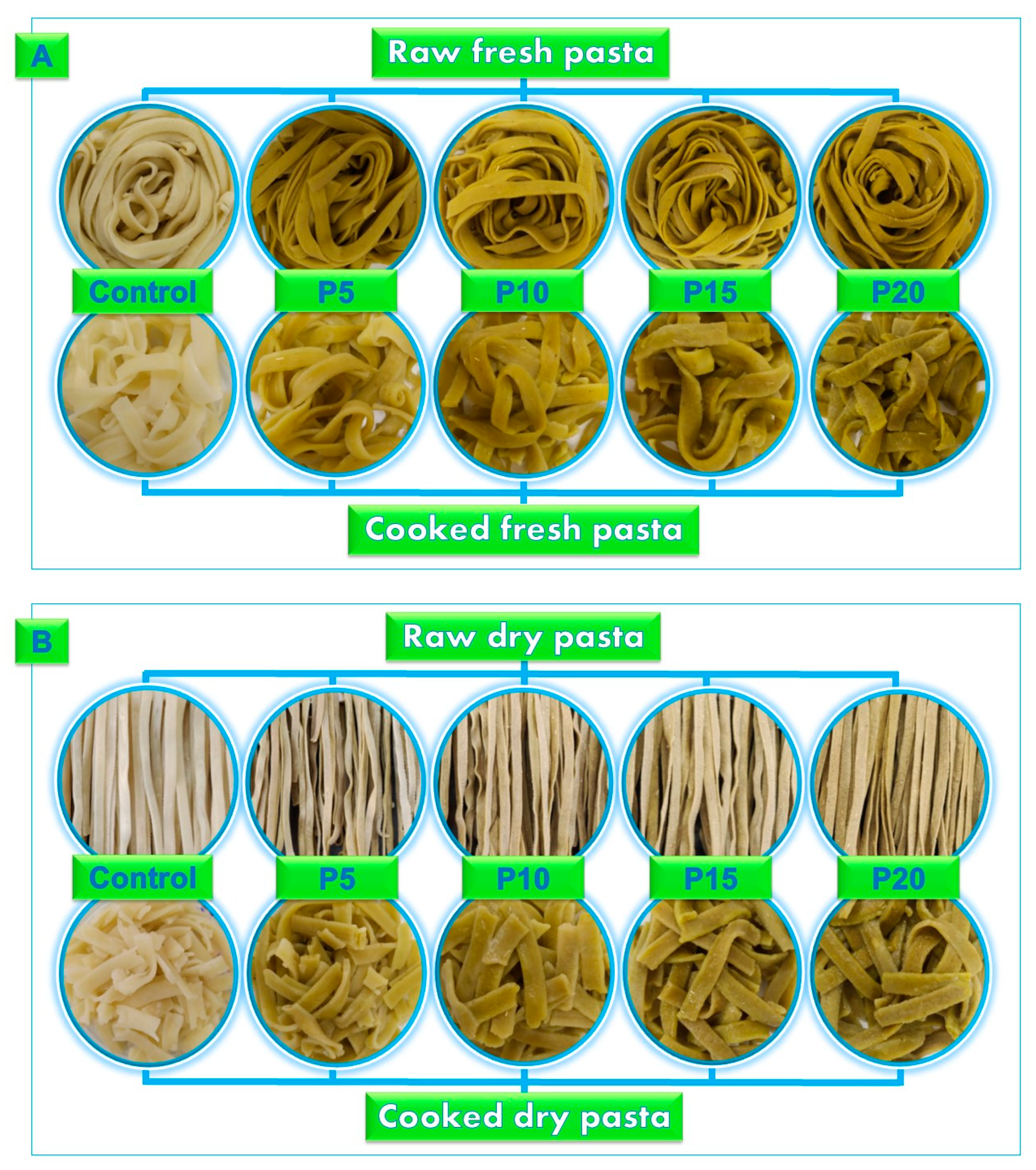

3.5. Technological Evaluation of Fettuccine-Type Pasta Quality

3.5.1. Moisture Content and Cooking Characteristics

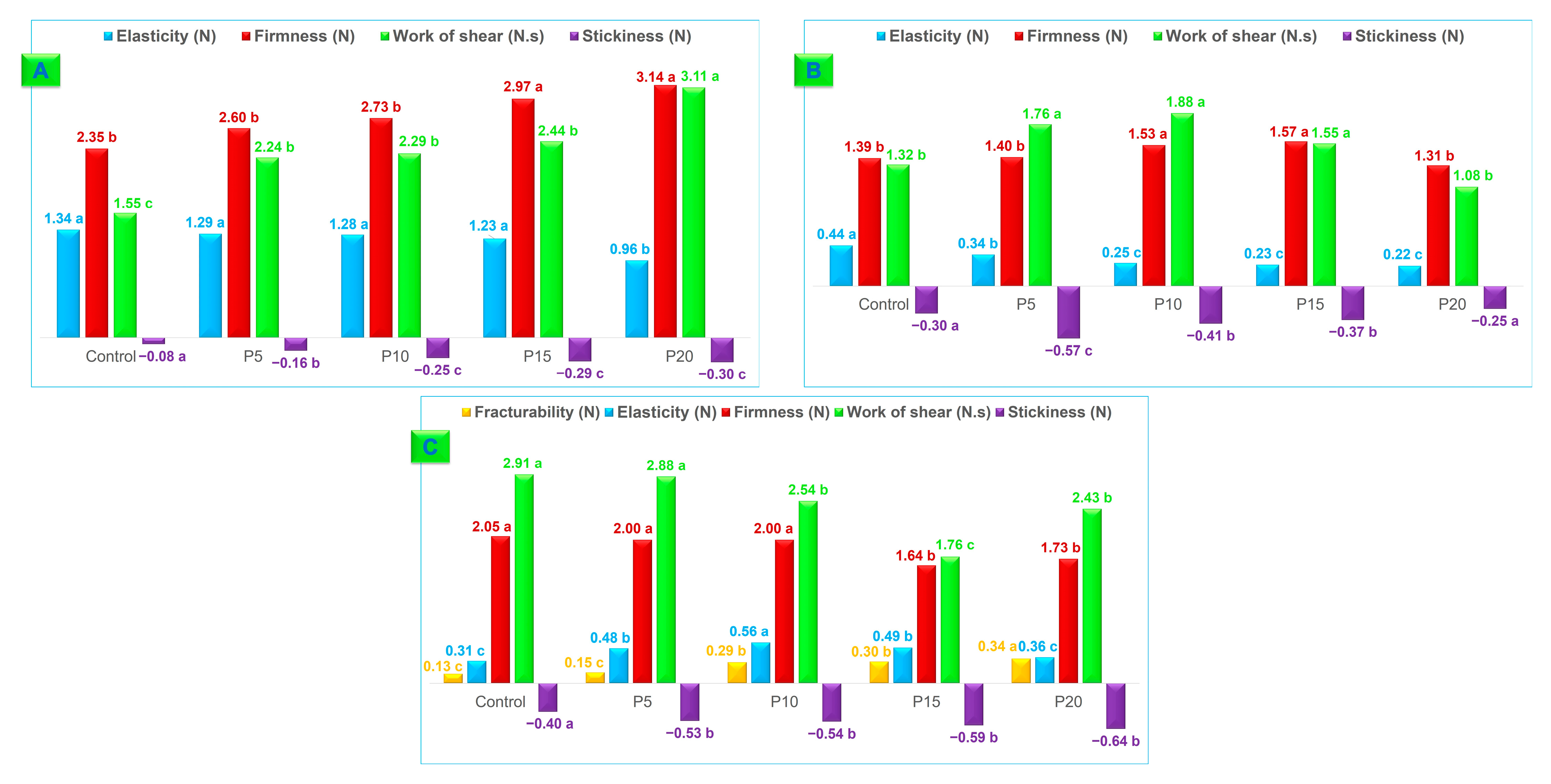

3.5.2. Texture Characteristics

3.6. Sensory Evaluation of Fettuccine-Type Pasta Quality

3.6.1. Cooked Fresh and Dry Fettuccine-Type Pasta

3.6.2. Ready-to-Eat Garlic and Oil Fettuccine-Type Pasta

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Giraldo-Silva, L.; Ferreira, B.; Rosa, E.; Dias, A.C.P. Opuntia ficus-indica fruit: A systematic review of its phytochemicals and pharmacological activities. Plants 2023, 12, 543. [Google Scholar] [CrossRef]

- Silva, M.A.; Albuquerque, T.G.; Pereira, P.; Ramalho, R.; Vicente, F.; Oliveira, M.B.P.P.; Costa, H.S. Opuntia ficus-indica (L.) Mill.: A multi-benefit potential to be exploited. Molecules 2021, 26, 951. [Google Scholar] [CrossRef]

- da Silva, L.M.; Fagundes, J.L.; Viegas, P.A.A.; Muniz, E.N.; de Albuquerque Rangel, J.H.; Moreira, A.L.; Backes, A.A. Cactus pear forage production under different plant densities. Cienc. Rural 2014, 44, 2064–2071. [Google Scholar] [CrossRef]

- Skalkos, D. Scientific Advancements for an innovative agri-food supply chain towards the 2030 Sustainable Development Goals III. Sustainability 2024, 16, 5693. [Google Scholar] [CrossRef]

- Manzoor, S.; Fayaz, U.; Dar, A.H.; Dash, K.K.; Shams, R.; Bashir, I.; Pandey, V.K.; Abdi, G. Sustainable Development Goals through reducing food loss and food waste: A comprehensive review. Future Foods 2024, 9, 100362. [Google Scholar] [CrossRef]

- Shoukat, R.; Cappai, M.; Pia, G.; Pilia, L. An updated review: Opuntia ficus indica (OFI) chemistry and its diverse applications. Appl. Sci. 2023, 13, 7724. [Google Scholar] [CrossRef]

- Amaral, S.M.B.; de Almeida, A.P.F.; Marinho, R.M.O.; Silva, Y.Y.V.; Frota, M.M.; Damaceno, M.N. Use of forage palm in the preparation of food products: A review. Holos 2022, 1, 1–9. [Google Scholar] [CrossRef]

- Gordiano, I.; Bezerra, P.Q.M.; Pinto, L.C.; de Matos, M.F.R. Brazilian cacti potential in the gastronomy: A review. Res. Soc. Dev. 2022, 11, e7611729617. [Google Scholar] [CrossRef]

- Ullah, A.; Munir, S.; Badshah, S.L.; Khan, N.; Ghani, L.; Poulson, B.G.; Emwas, A.-H.; Jaremko, M. Important flavonoids and their role as a therapeutic agent. Molecules 2020, 25, 5243. [Google Scholar] [CrossRef] [PubMed]

- Jucá, M.M.; Cysne Filho, F.M.S.; Almeida, J.C.; Mesquita, D.D.S.; Barriga, J.R.D.M.; Dias, K.C.F.; Barbosa, T.M.; Vasconcelor, L.C.; Leal, L.K.A.M.; Honório Junior, J.E.R.; et al. Flavonoids: Biological activities and therapeutic potential. Nat. Prod. Res. 2020, 34, 692–705. [Google Scholar] [CrossRef] [PubMed]

- Barba, F.J.; Garcia, C.; Fessard, A.; Munekata, P.E.S.; Lorenzo, J.M.; Aboudia, A.; Ouadia, A.; Remize, F. Opuntia ficus indica edible parts: A food and nutritional security perspective. Food Rev. Int. 2022, 38, 930–952. [Google Scholar] [CrossRef]

- Santos, D.; Lopes da Silva, J.A.; Pintado, M. Fruit and vegetable by-products’ flours as ingredients: A review on production process, health benefits and technological functionalities. LWT Food Sci. Technol. 2022, 154, 112707. [Google Scholar] [CrossRef]

- Larrosa, A.P.Q.; Otero, D.M. Flour made from fruit by-products: Characteristics, processing conditions, and applications. J. Food Process. Preserv. 2021, 45, e15398. [Google Scholar] [CrossRef]

- Gomes, L.R.; Araújo, M.A.; Schmiele, M. Técnicas de Secagem de Cactaceas—Uma Abordagem Geral. In Proceedings of the III Simpósio de Ciência e Tecnologia de Alimentos: “Compostos Bioativos do Bioma Brasileiro: Aplicações Nutricionais e Industriais”, Diamantina, Brazil, 7–9 May 2024; Available online: https://www.even3.com.br/iii-simposio-de-ciencia-e-tecnologia-de-alimentos-sicital-398288/ (accessed on 31 July 2024).

- Brahmi, F.; Mateos-Aparicio, I.; Mouhoubi, K.; Guemouni, S.; Sahki, T.; Dahmoune, F.; Belmehdi, F.; Bessai, C.; Madani, K.; Boulekbache-Makhlouf, L. Kinetic modeling of convective and microwave drying of potato peels and their effects on antioxidant content and capacity. Antioxidants 2023, 12, 638. [Google Scholar] [CrossRef]

- Menon, A.; Stojceska, V.; Tassou, S.A. A systematic review on the recent advances of the energy efficiency improvements in non-conventional food drying technologies. Trends Food Sci. Technol. 2020, 100, 67–76. [Google Scholar] [CrossRef]

- Kgonothi, D.; Mehlomakulu, N.N.; Emmambux, M.N. Effects of combining microwave with infrared energy on the drying kinetics and technofunctional properties of orange-fleshed sweet potato. J. Food Process. Preserv. 2024, 1, 6336446. [Google Scholar] [CrossRef]

- Bresciani, A.; Pagani, M.A.; Marti, A. Pasta-making process: A narrative review on the relation between process variables and pasta quality. Foods 2022, 11, 256. [Google Scholar] [CrossRef] [PubMed]

- Bianchi, F.; Tolve, R.; Rainero, G.; Bordiga, M.; Brennan, C.S.; Simonato, B. Technological, nutritional and sensory properties of pasta fortified with agro-industrial by-products: A review. Int. J. Food Sci. Technol. 2021, 56, 4356–4366. [Google Scholar] [CrossRef]

- Mildner-Szkudlarz, S.; Siger, A.; Szwengiel, A.; Bajerska, J. Natural compounds from grape by-products enhance nutritive value and reduce formation of CML in model muffins. Food Chem. 2015, 172, 78–85. [Google Scholar] [CrossRef]

- AOAC. Approved Methods of Analysis of AOAC International, 22nd ed.; Methods 934.01, 920.152, 920.39, 942.05, 982.14 and 978.10; The Association of Official Analysis AOAC International: Gaithersburg, MD, USA, 2023. [Google Scholar]

- dos Santos, A.A.; Deoti, J.R.; Müller, G.; Dário, M.G.; Stambuk, B.U.; Alves Junior, S.L. Microwell plate-based method for the determination of reducing sugars with the DNS reagent. Braz. J. Food Technol. 2017, 20, e2015113. [Google Scholar] [CrossRef]

- Pico, J.; Pismag, R.Y.; Laudouze, M.; Martinez, M.M. Systematic evaluation of the Folin–Ciocalteu and fast blue BB reactions during the analysis of total phenolics in legumes, nuts and plant seeds. Food Funct. 2020, 11, 9868–9880. [Google Scholar] [CrossRef]

- AACCI. Approved Methods of AACCI, 11th ed.; Methods 54-60.01, 44-15.02, 66-50.01, and 66-50.01; The American Association of Cereal Chemists International: St. Paul, MN, USA, 2010. [Google Scholar]

- Schmiele, M.; Ferrari Felisberto, M.H.; Pedrosa Silva Clerici, M.T.; Chang, Y.K. MixolabTM for rheological evaluation of wheat flour partially replaced by soy protein hydrolysate and fructooligosaccharides for bread production. LWT Food Sci. Technol. 2017, 76, 259–269. [Google Scholar] [CrossRef]

- Schmiele, M.; Jaekel, L.Z.; Ishida, P.M.G.; Chang, Y.K.; Steel, C.J. Gluten-free pasta with high protein content obtained by conventional processing. Cienc. Rural 2013, 43, 908–914. [Google Scholar] [CrossRef]

- Ungureanu-Iuga, M.; Dimian, M.; Mironeasa, S. Development and quality evaluation of gluten-free pasta with grape peels and whey powders. LWT Food Sci. Technol. 2020, 130, 109714. [Google Scholar] [CrossRef]

- Jaekel, L.Z.; Schmiele, M.; Chang, Y.K. Impacts of resistant starch and the enzyme transglutaminase on the technological characteristics of spaghetti. Res. Soc. Dev. 2020, 9, e891986219. [Google Scholar] [CrossRef]

- Meilgaard, M.C.; Civille, G.V.; Carr, T. Sensory Evaluation Techniques, 5th ed.; CRC Press: Boca Raton, FL, USA, 2017; p. 632. [Google Scholar]

- Feugang, J.M. Nutritional and medicinal use of cactus pear (Opuntia spp.) cladodes and fruits. Front. Biosci. 2006, 11, 2574. [Google Scholar] [CrossRef]

- López-Cervantes, J.; Sánchez-Machado, D.I.; Campas-Baypoli, O.N.; Bueno-Solano, C. Functional properties and proximate composition of cactus pear cladodes flours. Food Sci. Technol. 2011, 31, 654–659. [Google Scholar] [CrossRef]

- Palumbo, M.; Attolico, G.; Capozzi, V.; Cozzolino, R.; Corvino, A.; de Chiara, M.L.V.; Pace, B.; Pelosi, S.; Ricci, I.; Romaniello, R.; et al. Emerging postharvest technologies to enhance the shelf-life of fruit and vegetables: An overview. Foods 2022, 11, 3925. [Google Scholar] [CrossRef]

- da Silva, A.P.G.; de Souza, C.C.E.; Ribeiro, J.E.S.; dos Santos, M.C.G.; Pontes, A.L.d.S.; Madruga, M.S. Physical, chemical and bromatological characteristics of the giant forage cactus (Opuntia ficus-indica) and small forage cactus (Nopalea cochenillifera) from Paraíba State (Brazil). Rev. Bras. Tecnol. Agroind. 2015, 9, 1810–1820. [Google Scholar] [CrossRef]

- Mounir, B.; Younes, E.-G.; Asmaa, M.; Abdeljalil, Z.; Abdellah, A. Physico-chemical changes in cladodes of Opuntia ficus-indica as a function of the growth stage and harvesting areas. J. Plant Physiol. 2020, 251, 153196. [Google Scholar] [CrossRef]

- Lima, A.K.V.O.; Gomes, J.P.; Silva, F.L.H.; Santana, M.F.S.; Pereira, F.C. Physicochemical characterization of the umbuzadas formulated with spineless cactus. Rev. Bras. Tecnol. Agroind. 2012, 14, 397–405. [Google Scholar] [CrossRef]

- Ribeiro, E.M.D.O.; Silva, N.H.D.; Lima Filho, J.L.D.; Brito, J.Z.D.; Silva, M.D.P.C.D. Study of carbohydrates present in the cladodes of Opuntia ficus-indica (Fodder Palm), according to age and season. Food Sci. Technol. 2010, 30, 933–939. [Google Scholar] [CrossRef]

- Di Bella, G.; Vecchio, G.L.; Albergamo, A.; Nava, V.; Bartolomeo, G.; Macrì, A.; Bacchetta, L.; Lo Turco, V.; Potortì, A.G. Chemical characterization of sicilian dried nopal [Opuntia ficus-indica (L.) Mill.]. J. Food Compos. Anal. 2022, 106, 104307. [Google Scholar] [CrossRef]

- Miranda, A.V.S.; Schmiele, M. Non-digestible carbohydrates as an alternative to improve the technological and nutritional quality of meat products and potential application in fish burgers. Res. Soc. Dev. 2020, 9, e87691110490. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, S.; Nie, Q.; He, H.; Tan, H.; Geng, F.; Ji, H.; Hu, J.; Nie, S. Gut firmicutes: Relationship with dietary fiber and role in host homeostasis. Crit. Rev. Food Sci. Nutr. 2022, 63, 12073–12088. [Google Scholar] [CrossRef]

- Messina, C.M.; Arena, R.; Morghese, M.; Santulli, A.; Liguori, G.; Inglese, P. Seasonal characterization of nutritional and antioxidant properties of Opuntia ficus-indica [(L.) Mill.] mucilage. Food Hydrocoll. 2021, 111, 106398. [Google Scholar] [CrossRef]

- Osório, C.; Machado, S.; Peixoto, J.; Bessada, S.; Pimentel, F.B.C.; Alves, R.; Oliveira, M.B.P.P. Pigments content (chlorophylls, fucoxanthin and phycobiliproteins) of different commercial dried algae. Separations 2020, 7, 33. [Google Scholar] [CrossRef]

- Chen, K.; Roca, M. Cooking effects on chlorophyll profile of the main edible seaweeds. Food Chem. 2018, 266, 368–374. [Google Scholar] [CrossRef]

- Chahdoura, H.; Ben Hsouna, A.; Ali Boujbiha, M.; Mnif, W.; Snoussi, M.; Khemiss, M.; El Bok, S.; Ben M’hadheb, M.; Garzoli, S.; Mosbah, H. Phytochemical characterization and biological activities evaluation of Opuntia sp. cladodes. S. Afr. J. Bot. 2024, 168, 246–252. [Google Scholar] [CrossRef]

- Dick, M.; Limberger, C.; Cruz Silveira Thys, R.; de Oliveira Rios, A.; Hickmann Flôres, S. Mucilage and cladode flour from cactus (Opuntia monacantha) as alternative ingredients in gluten-free crackers. Food Chem. 2020, 314, 126178. [Google Scholar] [CrossRef]

- Alves, S.D.A.; Constant, P.B.L.; Teles, A.R.S. Physical-chemical and sensory evaluation of bread made with forage palm flour (Opuntia ficus-indica). Res. Soc. Dev. 2021, 10, e14101119433. [Google Scholar] [CrossRef]

- Mena, P.; Tassotti, M.; Andreu, L.; Nuncio-Jáuregui, N.; Legua, P.; Del Rio, D.; Hernández, F. Phytochemical characterization of different prickly pear (Opuntia ficus-indica (L.) Mill.) cultivars and botanical parts: UHPLC-ESI-MSn metabolomics profiles and their chemometric analysis. Food Res. Int. 2018, 108, 301–308. [Google Scholar] [CrossRef]

- Calderón, A.; Bonilla, S.; Schmiele, M.; Navarrete, D.; Vernaza, M.G. Study of Lupinus mutabilis sweet flour incorporation on the rheological, physical, chemical, and sensory properties of wheat bread. J. Food Process. Preserv. 2022, 46, e17027. [Google Scholar] [CrossRef]

- Dick, M.; Magro, L.D.; Rodrigues, R.C.; de Oliveira Rios, A.; Flôres, S.H. Valorization of Opuntia monacantha (Willd.) Haw. cladodes to obtain a mucilage with hydrocolloid features: Physicochemical and functional performance. Int. J. Biol. Macromol. 2019, 123, 900–909. [Google Scholar] [CrossRef]

- Mironeasa, S.; Codină, G.G. The Mixolab rheological properties and dough microstructure of defatted mustard seed-wheat composite flours. J. Food Process. Preserv. 2017, 41, e13130. [Google Scholar] [CrossRef]

- Freire, C.D.; Pinto, F.R.; Almeida, D.; Gil, M.M. Linseed and xanthan gum in algae pasta: Textural, sensory and antioxidant characteristics. Int. J. Food Sci. Technol. 2024, 59, 5477–5489. [Google Scholar] [CrossRef]

- Szydłowska-Tutaj, M.; Złotek, U.; Combrzyński, M. Influence of addition of mushroom powder to semolina on proximate composition, physicochemical properties and some safety parameters of material for pasta production. LWT Food Sci. Technol. 2021, 151, 112235. [Google Scholar] [CrossRef]

- Fernandes, M.D.S.; Sehn, G.A.R.; Leoro, M.G.V.; Chang, Y.K.; Steel, C.J. Effect of adding unconventional raw materials on the technological properties of rice fresh pasta. Food Sci. Technol. 2013, 33, 257–264. [Google Scholar] [CrossRef]

- Silva, L.E.P.; Rodrigues, S.M.; Lima, C.T.; Neves, N.A.; Schmiele, M. Farinha de palma (Opuntia ficus-indica (L.) Miller) liofilizada aplicada em massas alimentícias tipo talharim. In Proceedings of the I Simpósio Online Sulamericano de Tecnologia, Engenharia e Ciência de Alimentos, Diamantina, Brazil, 2 May 2022. [Google Scholar] [CrossRef]

- Silva, L.E.P.; Rodrigues, S.M.; Santos, T.M.; Nascimento, G.K.S.; Lima, C.T.; Andressa, I.; Schmiele, M. Propriedades de cozimento de massas alimentícias elaboradas com adição parcial de farinha de sabugo branco de milho. In Proceedings of the II CBCP—Congresso Brasileiro de Tecnologia de Cereais e Panificação, Sete Lagoas, Brazil, 23 September 2022; Available online: https://www.even3.com.br/anais/cbcp2022/519833/ (accessed on 31 July 2024).

- Ferreira, A.R.; Felisberto, M.H.F.; Neves, E.C.A.; Behrens, J.H.; Clerici, M.T.P.S. Comparative study of the partial replacement of triticum durum semolina in fettuccine pasta by bamboo fiber and young bamboo culm flour. Res. Soc. Dev. 2022, 11, e37811225728. [Google Scholar] [CrossRef]

- Shiozawa, S.; Prestes, L.E.L.; de Souza, R.D.S.; Bezerra, V.V.A. Produção de caracterização de massas alimentícias com substituição parcial de semolina de trigo durum por farinha de feijão fradinho e de arroz. In Proceedings of the II CBCP—Congresso Brasileiro de Tecnologia de Cereais e Panificação, Sete Lagoas, Brazil, 24 February 2022. [Google Scholar] [CrossRef]

- Bruneel, C.; Pareyt, B.; Brijs, K.; Delcour, J.A. The impact of the protein network on the pasting and cooking properties of dry pasta products. Food Chem. 2010, 120, 371–378. [Google Scholar] [CrossRef]

- Vasile, C.; Baican, M. Progresses in food packaging, food quality, and safety—Controlled-release antioxidant and/or antimicrobial packaging. Molecules 2021, 26, 1263. [Google Scholar] [CrossRef] [PubMed]

- Franco, M.; Spotti, M.J.; Gomez, M.; Martinez, M.M. Understanding the influence of the arabinoxylan-rich psyllium (Plantago ovata) husk on dough elasticity and bread staling: Interplay between biopolymer and water dynamics. Food Hydrocoll. 2024, 154, 110099. [Google Scholar] [CrossRef]

- Quinaud, B.E.R.; Monteiro, P.L.; Pires, C.R.F.; dos Santos, V.F.; Kato, H.C.A.; Sousa, D.N. Elaboration and nutritional characterization of enriched food pasta with soybean waste. Res. Soc. Dev. 2020, 9, e718974724. [Google Scholar] [CrossRef]

- Silva, M.L.T.; Brinques, G.B.; Gurak, P.D. Use of sprouts byproduct flour for fresh pasta production. Braz. J. Food Technol. 2019, 22. [Google Scholar] [CrossRef]

- Rodrigues, D.S.; Cavalcanti, M.T.; Gomes, C.A.; Araújo, J.S.; Lima, R.P.; Moreira, I.D.S.; Monteiro, S.S.; Pereira, E.M. Partial substitution of wheat flour with palm flour in pasta preparation. Appl. Sci. 2023, 13, 12123. [Google Scholar] [CrossRef]

- Zhang, Z.-H.; Wang, Y.; Ho, C.-T.; Patiguli, M.; Zhang, Y.; Yu, B.; Zhang, C.; Aadil, R.M.; Qu, W.; Xiao, R.; et al. Addition of chlorophyll microcapsules to improve the quality of fresh wheat noodles. LWT Food Sci. Technol. 2023, 183, 114940. [Google Scholar] [CrossRef]

- Rousta, L.K.; Yazdi, A.P.G.; Amini, M. Optimization of athletic pasta formulation by D-optimal Mixture Design. Food Sci. Nutr. 2020, 8, 4546–4554. [Google Scholar] [CrossRef]

| Component | Integral Forage Palm Puree (Wet Basis) | Integral Forage Palm Puree (Dry Basis) |

|---|---|---|

| Moisture (%) | 92.04 ± 1.82 | - |

| Proteins (%) | 1.88 ± 0.17 | 15.80 |

| Lipids (%) | 0.14 ± <0.01 | 1.18 |

| Ashes (%) | 1.80 ± 0.06 | 15.13 |

| Non-reducing sugars (mg of sucrose·100 g−1) | 4.25 ± 4.06 | 35.71 |

| Reducing sugars (mg of glucose·100 g−1) | 63.47 ± 3.51 | 533.36 |

| Glucose (mg·100 g−1) | 2.49 ± 0.34 | 20.92 |

| Total dietary fiber (%) * | 4.08 ± 5.39 | 67.30 |

| Other Parameters | Integral Forage Palm Puree | Integral Forage Palm Flour |

|---|---|---|

| L* | 42.14 ± 0.09 | 60.18 ± 0.05 |

| a* | −5.57 ± 0.01 | 3.32 ± 0.04 |

| b* | 29.09 ± 0.12 | 27.46 ± 0.01 |

| Total soluble phenolic compounds (mg GAE·100 g−1, d.b) | 359.70 ± 13.55 | 250.81 ± 8.86 |

| Sample | Control | P5 | P10 | P15 | P20 |

|---|---|---|---|---|---|

| Water absorption (%) | 58.00 | 58.00 | 58.00 | 58.00 | 59.7 |

| Stability (min) | 9.40 ± 0.42 ns | 8.85 ± 0.21 ns | 9.10 ± 0.14 ns | 9.75 ± 0.07 ns | 9.75 ± 0.64 ns |

| C1 (Nm) | 1.097 ± 0.006 ns | 1.091 ± 0.040 ns | 1.123 ± 0.007 ns | 1.128 ± 0.018 ns | 1.129 ± 0.005 ns |

| C2 (Nm) | 0.592 ± 0.001 a | 0.457 ± 0.016 b | 0.464 ± 0.004 b | 0.484 ± 0.013 b | 0.480 ± 0.013 b |

| C3 (Nm) | 1.811 ± 0.002 a | 1.648 ± 0.031 b | 1.598 ± 0.010 bc | 1.537 ± 0.024 c | 1.415 ± 0.024 d |

| C4 (Nm) | 1.595 ± 0.028 a | 1.506 ± 0.031 a | 1.278 ± 0.081 b | 0.323 ± 0.023 c | 0.312 ± 0.001 c |

| C5 (Nm) | 2.361 ± 0.015 c | 2.564 ± 0.015 a | 2.489 ± 0.011 b | nd | nd |

| Slope-α | −0.072 ± 0.023 ab | −0.125 ± 0.007 b | −0.086 ± 0.025 ab | −0.065 ± 0.007 ab | −0.031 ± 0.0267 a |

| Slope-β | 0.454 ± 0.040 a | 0.296 ± 0.014 b | 0.288 ± 0.014 b | 0.282 ± 0.090 ab | 0.228 ± 0.059 b |

| Slope-γ | −0.056 ± 0.025 ns | −0.056 ± 0.020 ns | −0.013 ± 0.024 ns | nd | nd |

| C2-C1 (Nm) | −0.505 ± 0.007 a | −0.634 ± 0.024 b | −0.659 ± 0.011 b | −0.644 ± 0.006 b | −0.649 ± 0.018 b |

| C3-C2 (Nm) | 1.219 ± 0.003 a | 1.190 ± 0.015 a | 1.134 ± 0.006 b | 1.053 ± 0.011 c | 0.934 ± 0.011 d |

| C4-C3 (Nm) | −0.216 ± 0.030 ab | −0.142 ± 0.001 a | −0.320 ± 0.090 b | nd | nd |

| C5-C4 (Nm) | 0.765 ± 0.012 c | 1.058 ± 0.016 b | 1.211 ± 0.070 a | nd | nd |

| Attributes | Fresh Pasta | Dry Pasta |

|---|---|---|

| Aroma ns | 5.74 ± 1.72 | 5.85 ± 1.74 |

| Appearance ns | 5.75 ± 1.77 | 5.54 ± 1.67 |

| Color ns | 5.82 ± 1.70 | 5.62 ± 1.65 |

| Texture | 6.88 ± 1.71 * | 6.31 ± 1.90 * |

| Taste ns | 6.16 ± 1.96 | 5.78 ± 1.94 |

| Overall impression ns | 6.25 ± 1.75 | 5.96 ± 1.62 |

| Purchase intention ns | 3.28 ± 1.09 | 3.09 ± 0.98 |

| Acceptability index (%) | 69.44 | 66.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, L.E.P.d.; Moreira, S.R.; Neves, N.d.A.; Aguiar, E.V.d.; Caprilles, V.D.; Amaral, T.N.; Schmiele, M. Use of Integral Forage Palm Flour as an Innovative Ingredient in New Fettuccine-Type Pasta: Thermomechanical and Technological Properties, and Sensory Acceptance. Foods 2024, 13, 2683. https://doi.org/10.3390/foods13172683

Silva LEPd, Moreira SR, Neves NdA, Aguiar EVd, Caprilles VD, Amaral TN, Schmiele M. Use of Integral Forage Palm Flour as an Innovative Ingredient in New Fettuccine-Type Pasta: Thermomechanical and Technological Properties, and Sensory Acceptance. Foods. 2024; 13(17):2683. https://doi.org/10.3390/foods13172683

Chicago/Turabian StyleSilva, Luiz Eliel Pinheiro da, Sander Rodrigues Moreira, Nathalia de Andrade Neves, Etiene Valéria de Aguiar, Vanessa Dias Caprilles, Tatiana Nunes Amaral, and Marcio Schmiele. 2024. "Use of Integral Forage Palm Flour as an Innovative Ingredient in New Fettuccine-Type Pasta: Thermomechanical and Technological Properties, and Sensory Acceptance" Foods 13, no. 17: 2683. https://doi.org/10.3390/foods13172683