Characterization of Key Aroma Compounds of Soy Sauce-like Aroma Produced in Ferment of Soybeans by Bacillus subtilis BJ3-2

Abstract

:1. Introduction

2. Materials and Methods

2.1. Strains and Vectors

2.2. Chemicals

2.3. Reverse Transcription-Quantitative Real-Time PCR (RT-qPCR)

2.4. Construction and Transformation of Homologous Recombinant Knockout Vectors

2.5. Soy Sauce-like Aroma Fermentation Experiment

2.6. Sensory Evaluation

2.7. Extraction of Volatile Compounds from Fermentations by HS-SPME

2.8. GC-MS Analysis

2.9. GC–O Analysis

2.10. Qualitative and Quantitative Analyses

2.11. Relative Odor Activity Values (rOAV) Determination

2.12. Adding Experiments

2.13. Data Analysis

3. Results and Discussion

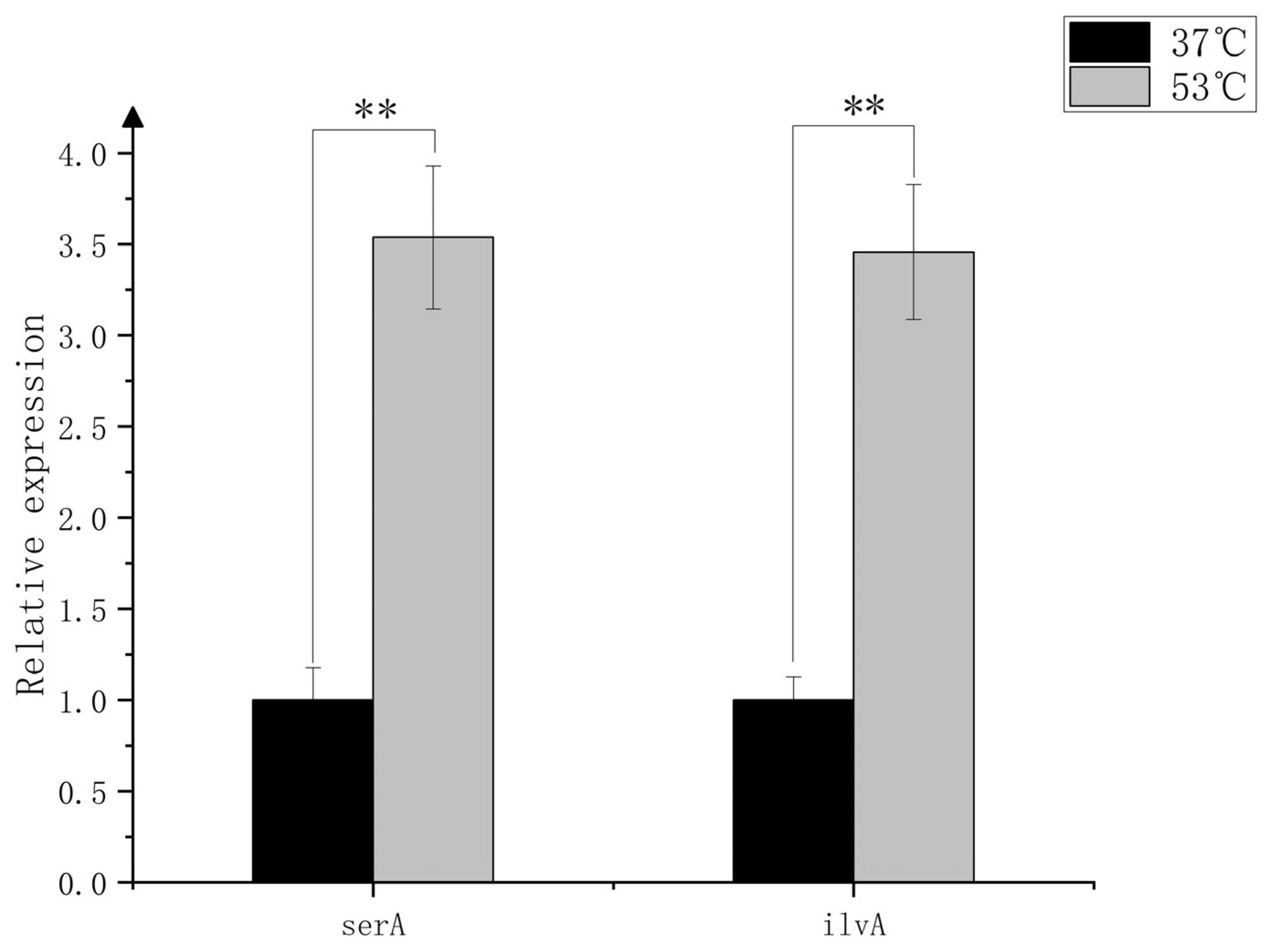

3.1. Expression of ilvA and serA in BJ3-2 Incubated at 37 °C and 53 °C

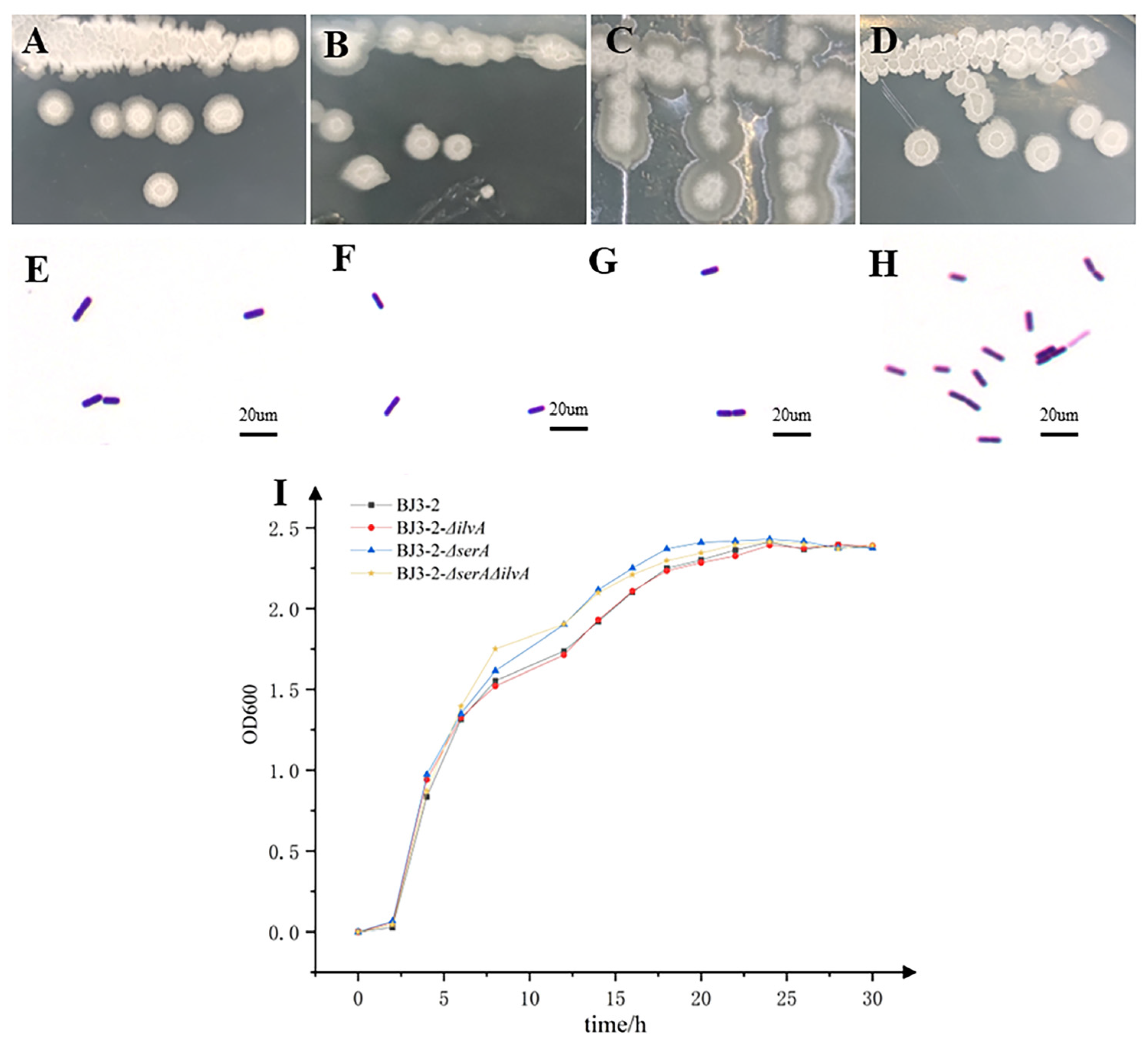

3.2. Generation of Knockout Strains

3.3. Characterisation of Strains

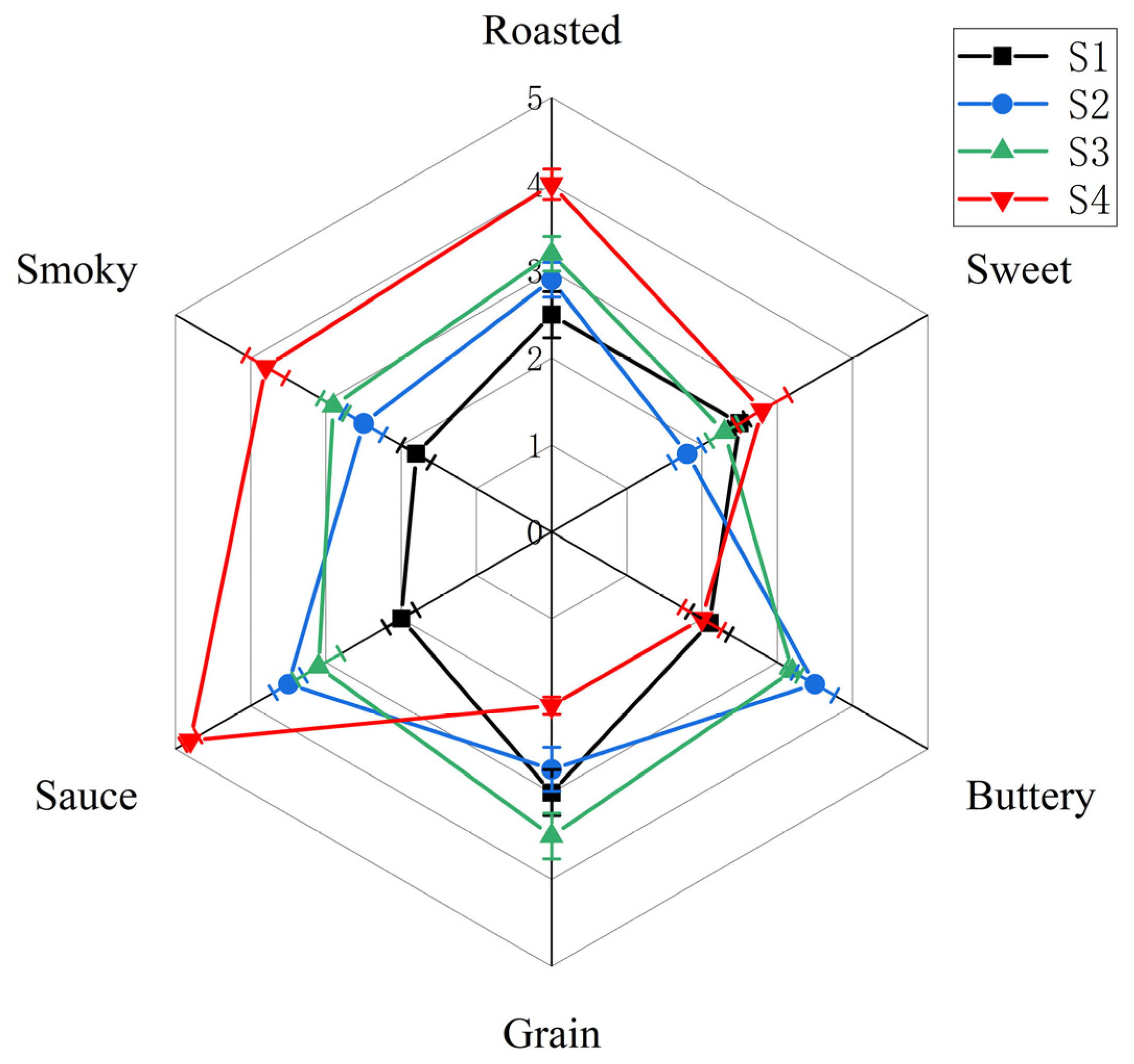

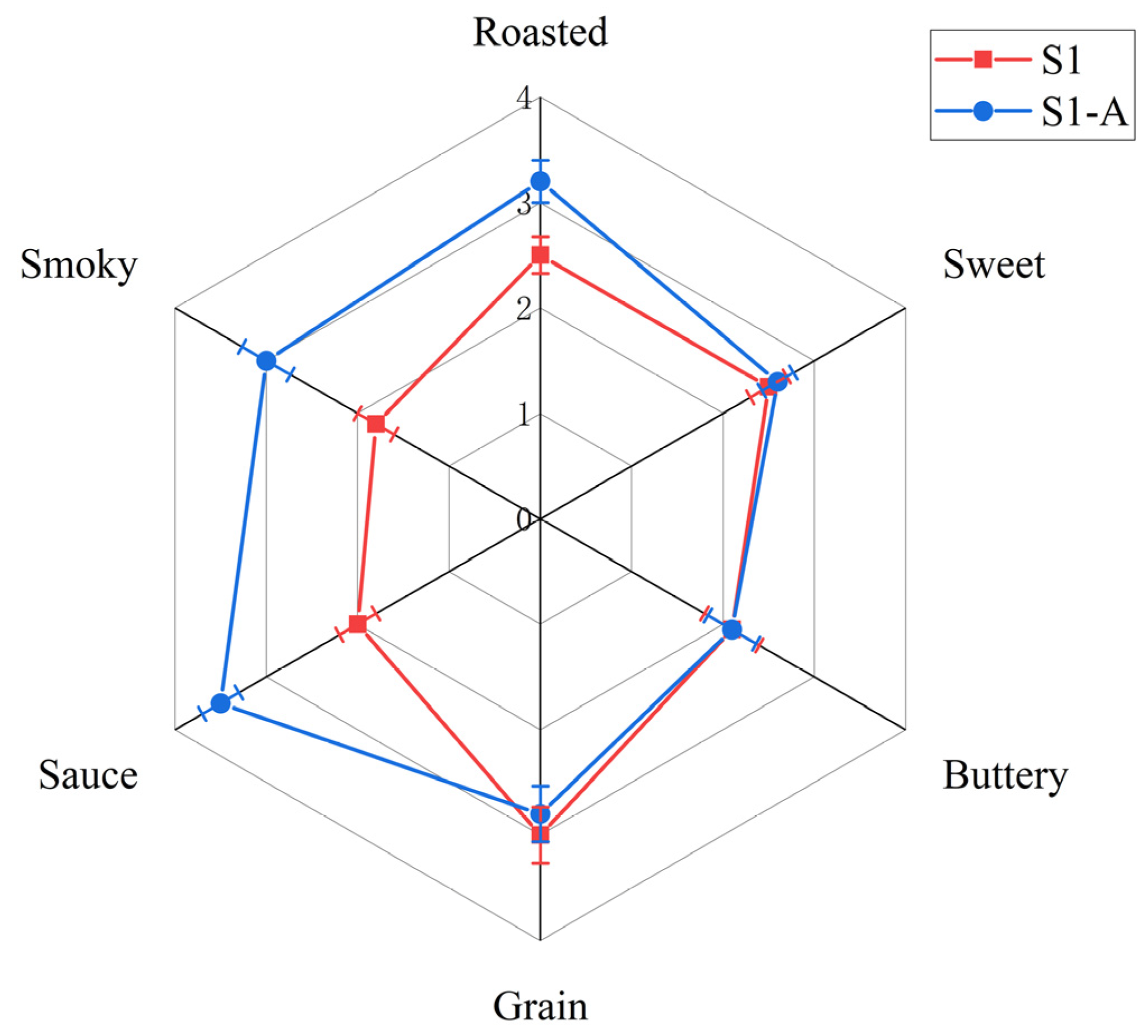

3.4. Sensory Evaluation

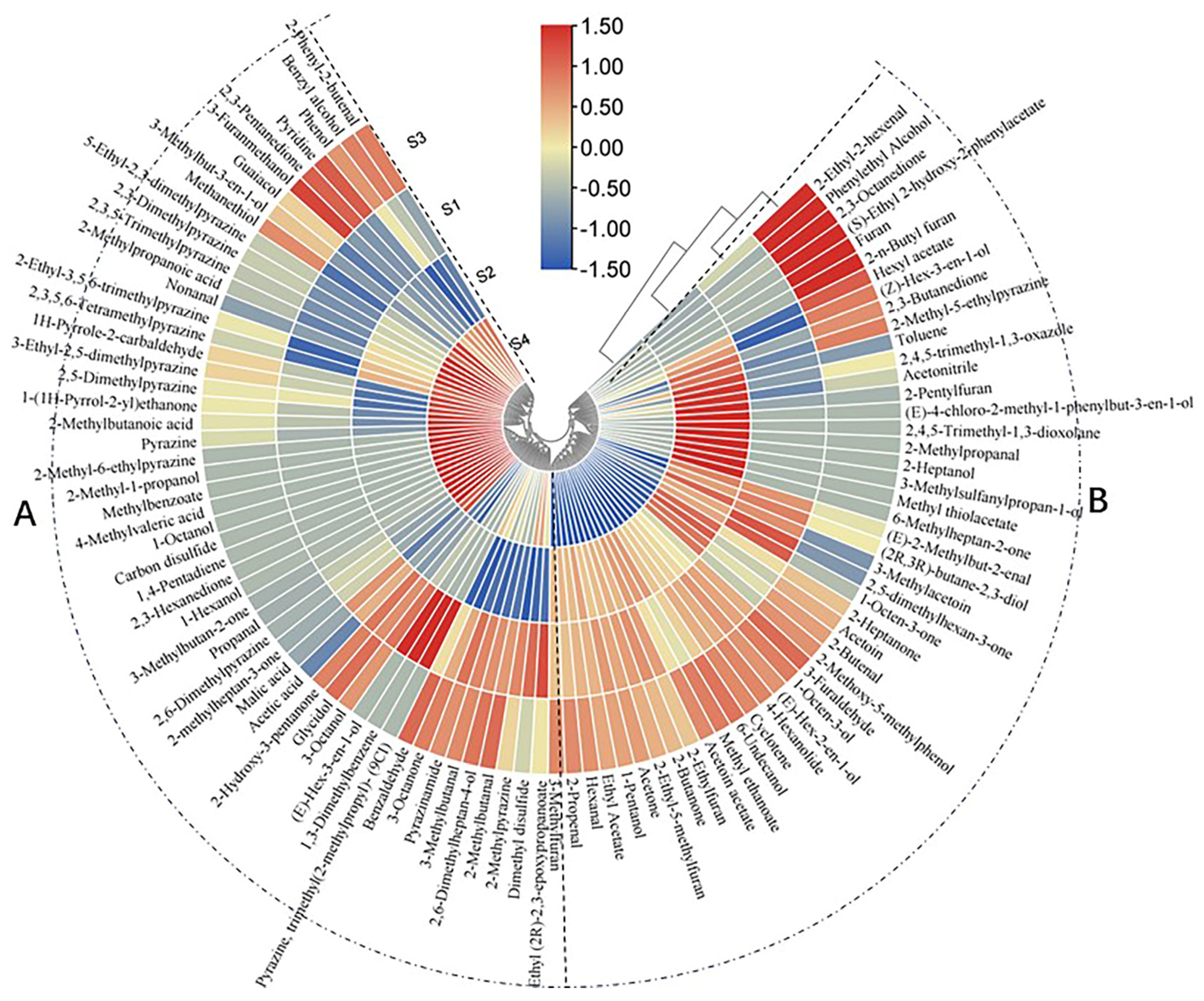

3.5. Qualification and Quantification of Volatile Compounds

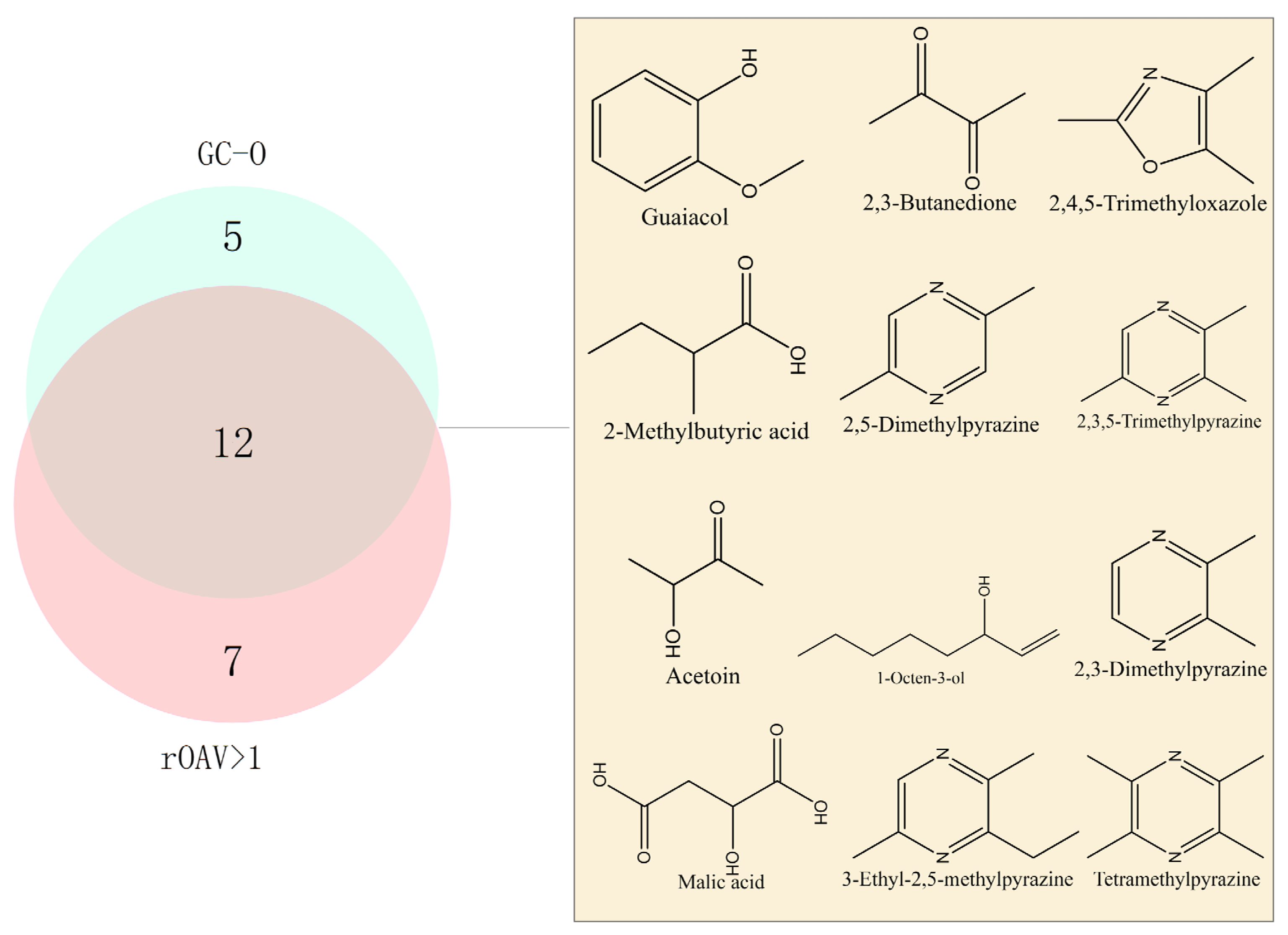

3.6. Characteristic Flavor Substances of Soy Sauce-like Aroma by rOAV and GC-O

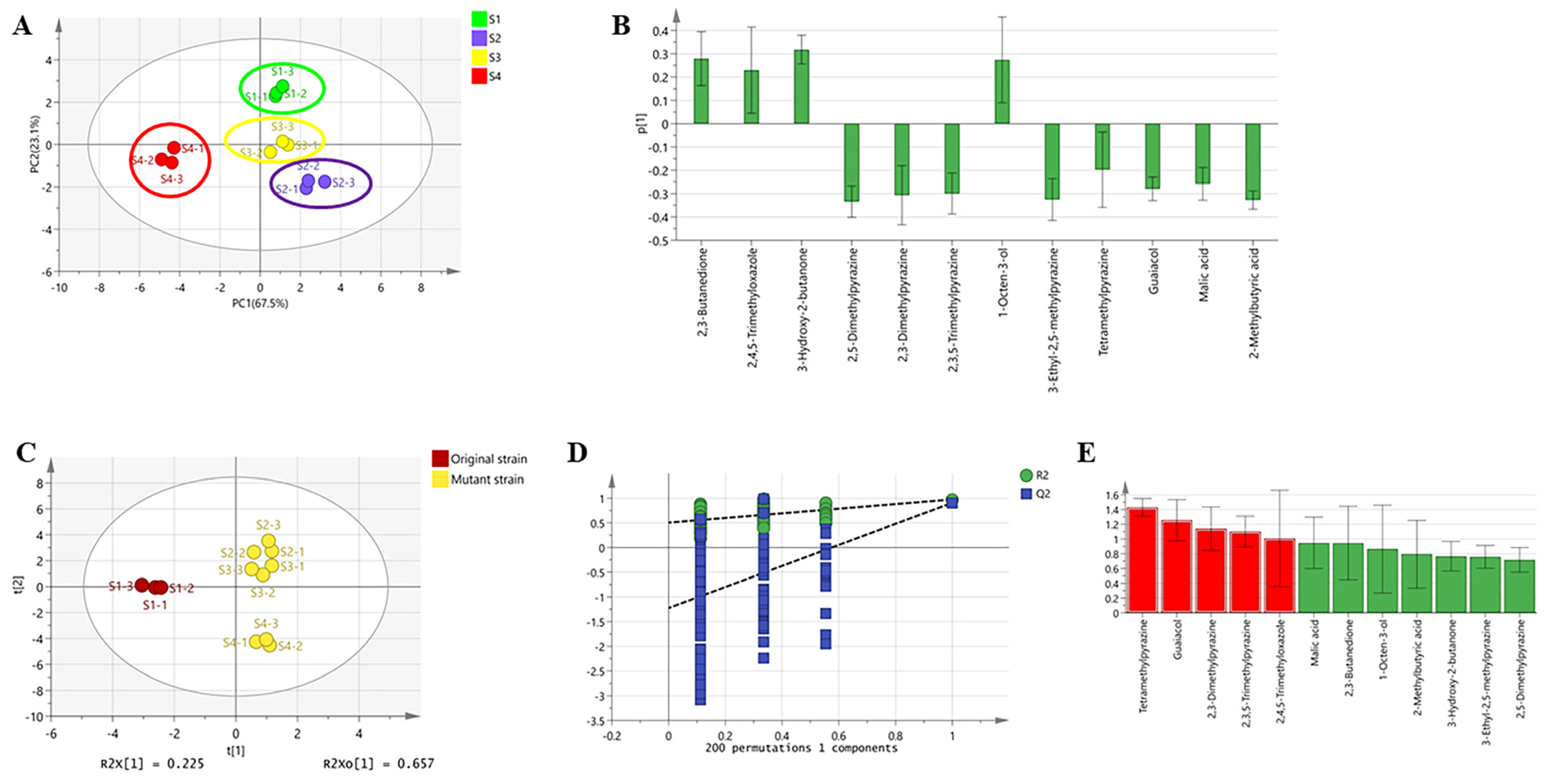

3.7. PCA and OPLS-DA Analyses

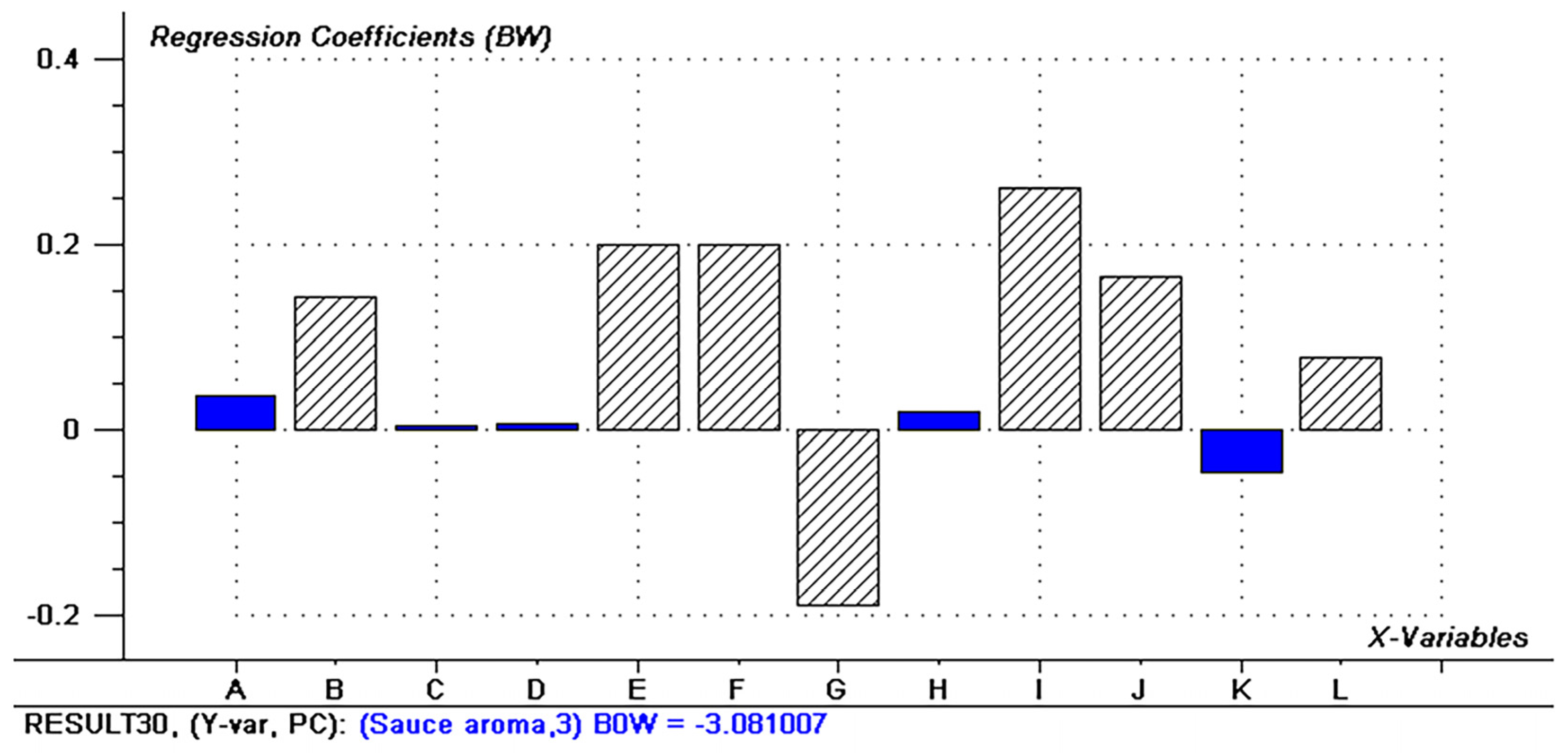

3.8. Correlation between Key Aroma Compounds and Sensory Attributes

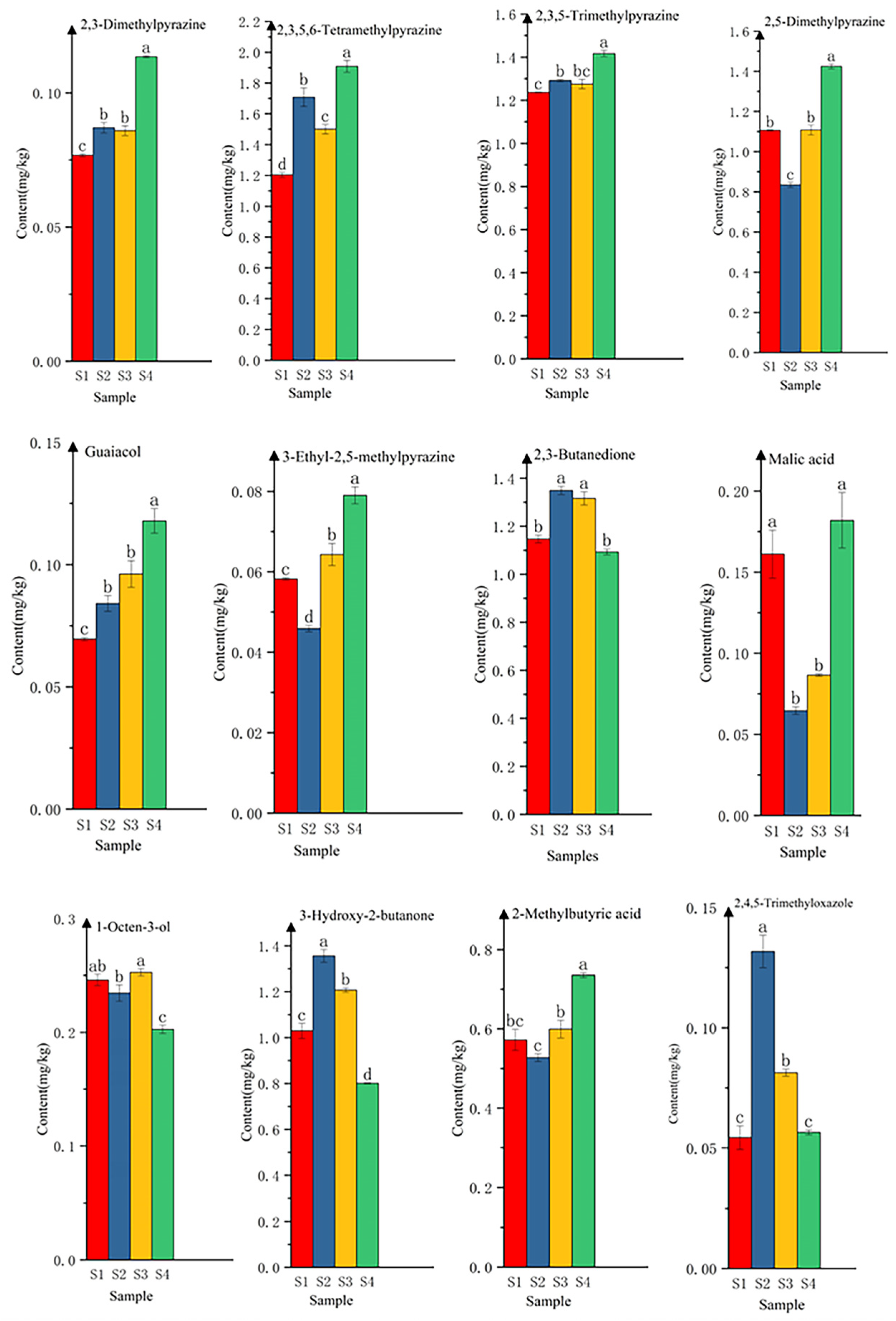

3.9. Changes in Key Aroma Compounds of the Soy Sauce-like Aroma in Fermented Samples between BJ3-2, BJ3-2ΔilvA, BJ3-2ΔserA, and BJ3-2ΔserAΔilvA

3.10. Adding Experiments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, S.H.; Lee, S.; Lee, S.H.; Kim, H.J.; Singh, D.; Lee, C.H. Integrated Metabolomics and Volatolomics for Comparative Evaluation of Fermented Soy Products. Foods 2021, 10, 2516. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Sun, C.; Zhang, M.; He, J.; Shen, Z.; Geng, L.; Yuan, L.; Wang, S.; Wang, C. Study on the factors affecting the sauce-flavor compounds of soybean paste in fermentation. Food Biosci. 2024, 59, 103872. [Google Scholar] [CrossRef]

- Gao, L.H.; Liu, T.; An, X.J.; Zhang, J.L.; Ma, X.R.; Cui, J.M. Analysis of volatile flavor compounds influencing Chinese-type soy sauces using GC-MS combined with HS-SPME and discrimination with electronic nose. J. Food Sci. Technol. Mysore 2017, 54, 130–143. [Google Scholar] [CrossRef] [PubMed]

- An, F.Y.; Wu, J.R.; Feng, Y.Z.; Pan, G.Y.; Ma, Y.Y.; Jiang, J.H.; Yang, X.M.; Xue, R.X.; Wu, R.A.; Zhao, M.M. A systematic review on the flavor of soy-based fermented foods: Core fermentation microbiome, multisensory flavor substances, key enzymes, and metabolic pathways. Compr. Rev. Food Sci. Food Saf. 2023, 22, 2773–2801. [Google Scholar] [CrossRef]

- Fan, W.; Qian, M.C. Headspace solid phase microextraction and gas chromatography-olfactometry dilution analysis of young and aged Chinese “Yanghe Daqu” liquors. J. Agric. Food Chem. 2005, 53, 7931–7938. [Google Scholar] [CrossRef]

- Fan, W.; Qian, M.C. Characterization of aroma compounds of chinese “Wuliangye” and “Jiannanchun” liquors by aroma extract dilution analysis. J. Agric. Food Chem. 2006, 54, 2695–2704. [Google Scholar] [CrossRef] [PubMed]

- Fan, W.; Xu, Y.; Qian, M.C. Identification of Aroma Compounds in Chinese “Moutai” and “Langjiu” Liquors by Normal Phase Liquid Chromatography Fractionation Followed by Gas Chromatography/Olfactometry. In Flavor Chemistry of Wine and Other Alcoholic Beverages; American Chemical Society: Washington, DC, USA, 2012. [Google Scholar]

- Lin, H.B.; Liu, Y.; He, Q.; Liu, P.; Che, Z.M.; Wang, X.M.; Huang, J.Q. Characterization of odor components of Pixian Douban (broad bean paste) by aroma extract dilute analysis and odor activity values. Int. J. Food Prop. 2019, 22, 1223–1234. [Google Scholar] [CrossRef]

- Duan, J.W.; Cheng, W.; Lv, S.L.; Deng, W.Y.; Hu, X.J.; Li, H.H.; Sun, J.Y.; Zheng, F.P.; Sun, B.G. Characterization of key aroma compounds in soy sauce flavor baijiu by molecular sensory science combined with aroma active compounds reverse verification method. Food Chem. 2024, 443, 138487. [Google Scholar] [CrossRef]

- Zhao, G.Z.; Feng, Y.X.; Hadiatullah, H.; Zheng, F.P.; Yao, Y.P. Chemical Characteristics of Three Kinds of Japanese Soy Sauce Based on Electronic Senses and GC-MS Analyses. Front. Microbiol. 2021, 11, 579808. [Google Scholar] [CrossRef]

- Cai, W.C.; Wang, Y.R.; Wang, W.P.; Shu, N.; Hou, Q.C.; Tang, F.X.; Shan, C.H.; Yang, X.Q.; Guo, Z. Insights into the Aroma Profile of Sauce-Flavor Baijiu by GC-IMS Combined with Multivariate Statistical Analysis. J. Anal. Methods Chem. 2022, 2022, 4614330. [Google Scholar] [CrossRef]

- Duan, J.W.; Yang, S.Q.; Li, H.H.; Qin, D.; Shen, Y.; Li, H.H.; Sun, J.Y.; Zheng, F.P.; Sun, B.G. Why the key aroma compound of soy sauce aroma type baijiu has not been revealed yet? Lwt-Food Sci. Technol. 2022, 154, 112735. [Google Scholar] [CrossRef]

- Song, D.H.; Chun, B.H.; Lee, S.; Son, S.Y.; Reddy, C.K.; Mun, H.I.; Jeon, C.O.; Lee, C.H. Comprehensive Metabolite Profiling and Microbial Communities of Doenjang (Fermented Soy Paste) and Ganjang (Fermented Soy Sauce): A Comparative Study. Foods 2021, 10, 641. [Google Scholar] [CrossRef]

- Gao, Y.X.; Hu, M.; Meng, W.M.; Wen, W.; Zhang, P.F.; Fan, B.; Wang, F.Z.; Li, S.Y. Study on the quality of soybean proteins fermented by Bacillus subtilis BSNK-5: Insights into nutritional, functional, safety, and flavor properties. Food Chem. 2024, 443, 138523. [Google Scholar] [CrossRef] [PubMed]

- Van Dijl, J.M.; Hecker, M. Bacillus subtilis: From soil bacterium to super-secreting cell factory. Microb. Cell Factories 2013, 12, 3. [Google Scholar] [CrossRef] [PubMed]

- Schallmey, M.; Singh, A.; Ward, O.P. Developments in the use of Bacillus species for industrial production. Can. J. Microbiol. 2004, 50, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Tao, Y.; Jin, J.; Tong, S.; Li, S.; Zhang, L. Multi-omics analyses of the mechanism for the formation of soy sauce-like and soybean flavor in Bacillus subtilis BJ3-2. BMC Microbiol. 2022, 22, 142. [Google Scholar] [CrossRef]

- Rosenberg, J.; Müller, P.; Lentes, S.; Thiele, M.J.; Zeigler, D.R.; Tödter, D.; Paulus, H.; Brantl, S.; Stülke, J.; Commichau, F.M. ThrR, a DNA-binding transcription factor involved in controlling threonine biosynthesis in Bacillus subtilis. Mol. Microbiol. 2016, 101, 879–893. [Google Scholar] [CrossRef]

- Révora, V.; Marchesini, M.I.; Comerci, D.J. Brucella abortus Depends on l-Serine Biosynthesis for Intracellular Proliferation. Infect. Immun. 2020, 88, 10–1128. [Google Scholar] [CrossRef]

- Liu, Z.L.; Wu, Y.J.; Zhang, L.C.; Tong, S.Q.; Jin, J.; Gong, X.; Zhong, J. rocF affects the production of tetramethylpyrazine in fermented soybeans with Bacillus subtilis BJ3-2. BMC Biotechnol. 2022, 22, 18. [Google Scholar] [CrossRef]

- Zhang, L.J.; Cao, Y.L.; Tong, J.N.; Xu, Y. An Alkylpyrazine Synthesis Mechanism Involving L-Threonine-3-Dehydrogenase Describes the Production of 2,5-Dimethylpyrazine and 2,3,5-Trimethylpyrazine by Bacillus subtilis. Appl. Environ. Microbiol. 2019, 85, e01807-19. [Google Scholar] [CrossRef]

- Zhao, S.S.; Sai, Y.; Liu, W.T.; Zhao, H.W.; Bai, X.; Song, W.Y.; Zheng, Y.; Yue, X.Q. Flavor Characterization of Traditional Fermented Soybean Pastes from Northeast China and Korea. Foods 2023, 12, 3294. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.X.; Xia, D.Z.; Li, T.H.; Wei, Y.M.; Feng, W.Z.; Xiong, Z.C.; Huang, J.L.; Deng, W.W.; Ning, J.M. Effects of different over-fired drying methods on the aroma of Lu’an Guapian tea. Food Res. Int. 2023, 173, 113224. [Google Scholar] [CrossRef] [PubMed]

- Jia, D.; Wu, Y.; Li, Y.; Xu, W. Screening and Identification of Bacillus for Lobster Sauce Fermentation. Food Science 2009, 30, 217–221. [Google Scholar]

- Liu, L.; Zhang, L.C.; Yang, L.H.; Zheng, J.H.; Jin, J.; Tong, S.Q.; Wu, Y.J. Genome-wide characterization and expression analysis of the HD-Zip II gene family in response to drought and GA3 stresses in Nicotiana tabacum. Mol. Biol. Rep. 2024, 51, 581. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.-Z.; Cui, Z.-L.; Hong, Q.; Li, S.-P. High-level expression and secretion of methyl parathion hydrolase in Bacillus subtilis WB800. Appl. Environ. Microbiol. 2005, 71, 4101–4103. [Google Scholar] [CrossRef]

- Phan, T.T.P.; Nguyen, H.D.; Schumann, W. Novel plasmid-based expression vectors for intra- and extracellular production of recombinant proteins in Bacillus subtilis. Protein Expr. Purif. 2006, 46, 189–195. [Google Scholar] [CrossRef]

- Li, W.; Xie, H. Effect of tdh gene of Bacillus subtilis on Maotai-flavor. Food Ferment. Ind. 2021, 47, 116–123. [Google Scholar] [CrossRef]

- Zhang, L.; Qin, Z.; Zhang, L.; Jiang, Y.; Zhu, J. Dynamic changes of quality and flavor characterization of Zhejiang rosy vinegar during fermentation and aging based on untargeted metabolomics. Food Chem. 2023, 404, 134702. [Google Scholar] [CrossRef]

- Peng, X.; Li, X.; Shi, X.; Guo, S. Evaluation of the aroma quality of Chinese traditional soy paste during storage based on principal component analysis. Food Chem. 2014, 151, 532–538. [Google Scholar] [CrossRef]

- Nuzzi, M.; Lo Scalzo, R.; Testoni, A.; Rizzolo, A. Evaluation of Fruit Aroma Quality: Comparison Between Gas Chromatography-Olfactometry (GC-O) and Odour Activity Value (OAV) Aroma Patterns of Strawberries. Food Anal. Methods 2008, 1, 270–282. [Google Scholar] [CrossRef]

- Zhao, M.; Li, T.; Yang, F.; Cui, X.Y.; Zou, T.T.; Song, H.L.; Liu, Y. Characterization of key aroma-active compounds in Hanyuan Zanthoxylum bungeanum by GC-O-MS and switchable GC x GC-O-MS. Food Chem. 2022, 385, 132659. [Google Scholar] [CrossRef]

- Leo, V. Compilations of Odour Threshold Values in Air, Water and Other Media; Science Press Ltd.: Beijing, China, 2015. [Google Scholar]

- Boch, J.; Kempf, B.; Schmid, R.; Bremer, E. Synthesis of the osmoprotectant glycine betaine in Bacillus subtilis: Characterization of the gbsAB genes. J. Bacteriol. 1996, 178, 5121–5129. [Google Scholar] [CrossRef] [PubMed]

- Ni, R.J.; Wang, P.; Zhan, P.; Tian, H.L.; Li, T. Effects of different frying temperatures on the aroma profiles of fried mountain pepper (Litsea cubeba (Lour.) Pers.) oils and characterization of their key odorants. Food Chem. 2021, 357, 129786. [Google Scholar] [CrossRef]

- Fan, W.; Xu, Y.; Zhang, Y. Characterization of pyrazines in some Chinese liquors and their approximate concentrations. J. Agric. Food Chem. 2007, 55, 9956–9962. [Google Scholar] [CrossRef] [PubMed]

- Vidal, A.M.; Alcalá, S.; De Torres, A.; Moya, M.; Espínola, J.M.; Espínola, F. Fresh and Aromatic Virgin Olive Oil Obtained from Arbequina, Koroneiki, and Arbosana Cultivars. Molecules 2019, 24, 3587. [Google Scholar] [CrossRef] [PubMed]

- Tan, F.L.; Wang, P.; Zhan, P.; Tian, H.L. Characterization of key aroma compounds in flat peach juice based on gas chromatography-mass spectrometry-olfactometry (GC-MS-O), odor activity value (OAV), aroma recombination, and omission experiments. Food Chem. 2022, 366, 130604. [Google Scholar] [CrossRef]

- Niu, Y.W.; Yao, Z.M.; Xiao, Z.B.; Zhu, G.Y.; Zhu, J.C.; Chen, J.Y. Sensory evaluation of the synergism among ester odorants in light aroma type liquor by odor threshold, aroma intensity and flash GC electronic nose. Food Res. Int. 2018, 113, 102–114. [Google Scholar] [CrossRef]

- Xie, J.L.; Wang, L.L.; Deng, Y.L.; Yuan, H.B.; Zhu, J.Y.; Jiang, Y.W.; Yang, Y.Q. Characterization of the key odorants in floral aroma green tea based on GC-E-Nose, GC-IMS, GC-MS and aroma recombination and investigation of the dynamic changes and aroma formation during processing. Food Chem. 2023, 427, 136641. [Google Scholar] [CrossRef]

- Feng, Y.; Cai, Y.; Fu, X.; Zheng, L.; Xiao, Z.; Zhao, M. Comparison of aroma-active compounds in broiler broth and native chicken broth by aroma extract dilution analysis (AEDA), odor activity value (OAV) and omission experiment. Food Chem. 2018, 265, 274–280. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, B.; Fu, Y.; Shi, Y.G.; Chen, F.L.; Guan, H.N.; Liu, L.L.; Zhang, C.Y.; Zhu, P.Y.; Liu, Y.; et al. HS-GC-IMS with PCA to analyze volatile flavor compounds across different production stages of fermented soybean whey tofu. Food Chem. 2021, 346, 128880. [Google Scholar] [CrossRef]

- Krstić, G.; Anđelković, B.; Choi, Y.H.; Vajs, V.; Stević, T.; Tešević, V.; Gođevac, D. Metabolic changes in Euphorbia palusrtis latex after fungal infection. Phytochemistry 2016, 131, 17–25. [Google Scholar] [CrossRef]

- Khalil, M.N.A.; Fekry, M.I.; Farag, M.A. Metabolome based volatiles profiling in 13 date palm fruit varieties from Egypt via SPME GC-MS and chemometrics. Food Chem. 2017, 217, 171–181. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Song, S.Q.; Zhang, X.M.; Tan, C.; Karangwa, E. Effect of sterilization methods on ginger flavor beverage assessed by partial least squares regression of descriptive sensory analysis and gas chromatography-mass spectrometry. Eur. Food Res. Technol. 2014, 238, 247–257. [Google Scholar] [CrossRef]

- Grant, G.A.; Xu, X.L.; Hu, Z. Role of an interdomain Gly-Gly sequence at the regulatory-substrate domain interface in the regulation of Escherichia coli. D-3-phosphoglycerate dehydrogenase. Biochemistry 2000, 39, 7316–7319. [Google Scholar] [CrossRef]

- Zalán, Z.; Hudáček, J.; Tóth-Markus, M.; Husová, E.; Solichová, K.; Hegyi, F.; Plocková, M.; Chumchalová, J.; Halász, A. Sensorically and antimicrobially active metabolite production of Lactobacillus strains on Jerusalem artichoke juice. J. Sci. Food Agric. 2011, 91, 672–679. [Google Scholar] [CrossRef] [PubMed]

| No. | Compounds | Odor Description a | Related Sample b |

|---|---|---|---|

| Group 1 | |||

| 2,3,5-trimethylpyrazine | roasted peanut, cocoa | all | |

| 2,5-dimethylpyrazine | woody grass medical | all | |

| 2,3,5,6-tetramethylpyrazine | chocolate, nutty | all | |

| 3-ethyl-2,5-methylpyrazine | roasted potato | all | |

| 2,3-dimethylpyrazine | nutty, coffee | S4 | |

| Group 2 | |||

| 2.3-butanedione | strong butter, yoghurt | all | |

| 3-hydroxy-2-butanone | buttery, creamy | all | |

| malic acid | caramel, popcorn | all | |

| Group 3 | |||

| guaiacol | smoky, woody | all | |

| 2,4,5-trimethyloxazole | earthy, cucumbers | all | |

| Group 4 | |||

| 2-methylbutyric acid | stinky feet, cheese | all | |

| 1-octen-3-ol | mushroom. | all |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Q.; Wu, Y.; Li, C.; Jin, J.; Zhang, L.; Tong, S.; Chen, Z.; Ran, L.; Huang, L.; Zuo, Z. Characterization of Key Aroma Compounds of Soy Sauce-like Aroma Produced in Ferment of Soybeans by Bacillus subtilis BJ3-2. Foods 2024, 13, 2731. https://doi.org/10.3390/foods13172731

Tan Q, Wu Y, Li C, Jin J, Zhang L, Tong S, Chen Z, Ran L, Huang L, Zuo Z. Characterization of Key Aroma Compounds of Soy Sauce-like Aroma Produced in Ferment of Soybeans by Bacillus subtilis BJ3-2. Foods. 2024; 13(17):2731. https://doi.org/10.3390/foods13172731

Chicago/Turabian StyleTan, Qibo, Yongjun Wu, Cen Li, Jing Jin, Lincheng Zhang, Shuoqiu Tong, Zhaofeng Chen, Li Ran, Lu Huang, and Zeyan Zuo. 2024. "Characterization of Key Aroma Compounds of Soy Sauce-like Aroma Produced in Ferment of Soybeans by Bacillus subtilis BJ3-2" Foods 13, no. 17: 2731. https://doi.org/10.3390/foods13172731