Determination of Drying Characteristics and Physicochemical Properties of Mint (Mentha spicata L.) Leaves Dried in Refractance Window

Abstract

:1. Introduction

2. Materials and Methods

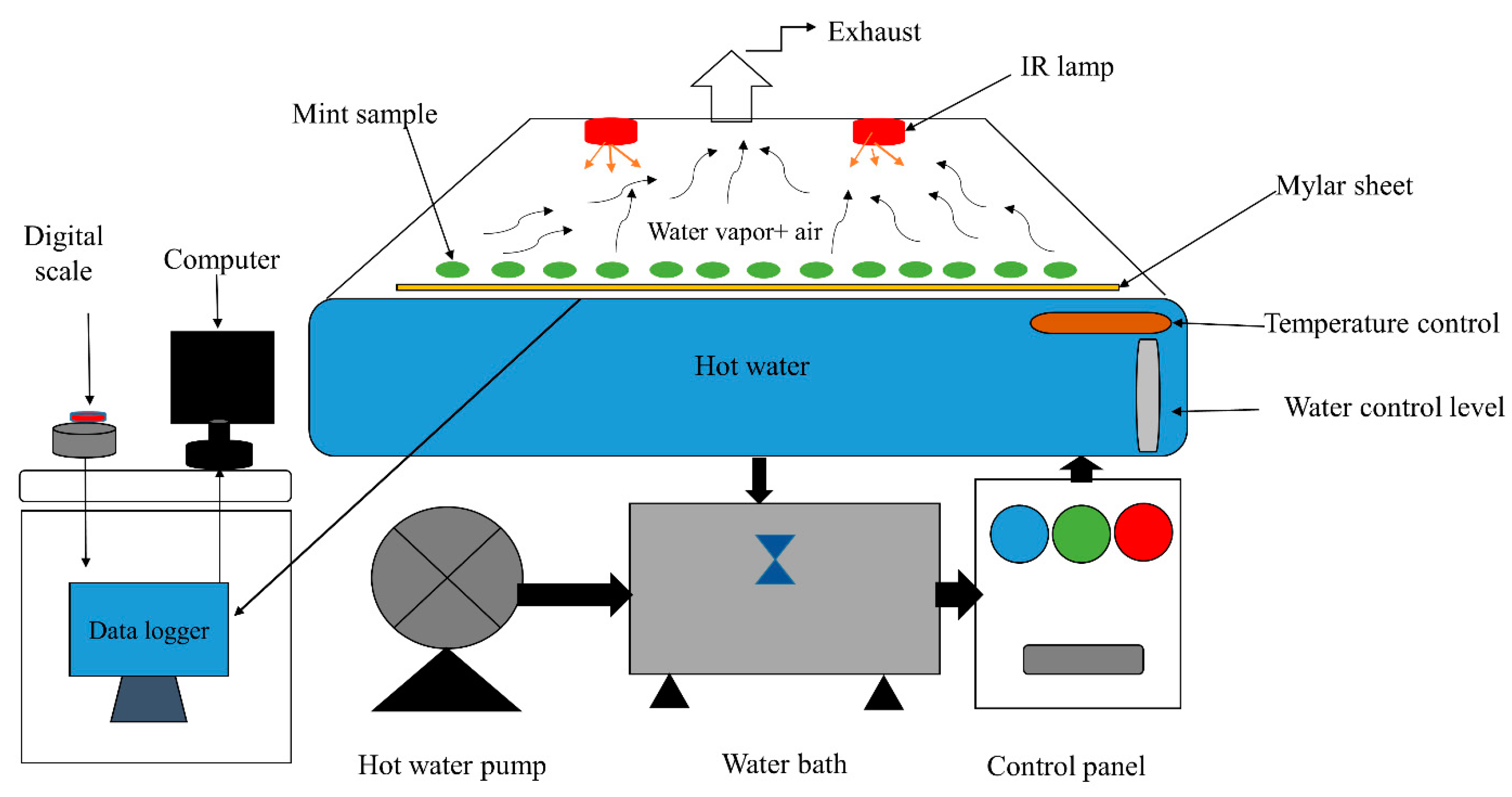

2.1. Refractance Window Dryer

2.2. Drying Kinetics

2.3. Modeling

2.4. Diffusion Coefficient and Activation Energy

2.5. Thermodynamic Properties

2.6. Specific Energy Consumption

2.7. CO2 and NOx

2.8. Color

2.9. Rehydration Ratio

2.10. Measurement of the Total Phenol Content (TPC)

2.11. Measurement of the Total Flavonoid Content (TFC)

2.12. Measurement of Antioxidant Activity (AA) by DPPH Method

2.13. Extraction of Essential Oil (EO) by Distillation with Water

2.14. Artificial Neural Networks

2.15. Statistical Analysis

3. Results and Discussion

3.1. Moisture Ratio

3.2. Values of Deff and Activation Energy

3.3. Thermodynamic Properties

3.4. Specific Energy Consumption

3.5. CO2 and NOx

3.6. Color

3.7. Rehydration Ratio

3.8. Antioxidant Activity (AA)

3.9. Phenol and Flavonoid Content

3.10. Essential Oil Efficiency

3.11. Modeling

3.12. Artificial Neural Network

3.13. Comparison of Mathematical Models and ANN

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| AA | % | Antioxidant activity |

| ASample | - | Absorbance values of the blank |

| Acontrol | - | Absorbance values of the sample |

| Deff | m2/s | Effective moisture diffusivity |

| Ea | J/mol | Activation energy |

| hp | 6.626 × 10−37 m²·kg/s | Planck constant |

| Kb | 1.38 × 10−26 J/K | Boltzmann constant |

| L | m | The thickness of the sliced cantaloupe |

| Me | % d.b | Equilibrium moisture contents |

| MR | - | Moisture ratio |

| Mo | % d.b | Final |

| The moisture content of the sample | ||

| Mt | % d.b | The moisture content at time t |

| - | Experimental moisture fraction | |

| - | Predicted moisture fraction | |

| N | - | Number of observations. |

| R | 8.314 J/mol. K | Universal gas constant |

| RR | - | Rehydration ratio |

| Wr | g | Weight of the rehydrated sample (g) |

| Wd | g | Weight of the dry sample (g) |

| SEC | kWh/kg | Specific energy consumption |

| t | s | Drying time |

| T | K | Absolute temperature |

| ∆H | J/mol | enthalpy |

| ∆G | J/mol | Gibbs free energy |

| ∆S | J/mol. K | Entropy |

| ∆L*, ∆b*, ∆a* | - | The difference between the color of the fresh and dried samples |

References

- Ye, L.; El-Mesery, H.S.; Ashfaq, M.M.; Shi, Y.; Zicheng, H.; Alshaer, W. Analysis of energy and specific energy requirements in various drying process of mint leaves. Case Stud. Therm. Eng. 2021, 26, 10113. [Google Scholar] [CrossRef]

- Eltawil, M.A.; Azam, M.M.; Alghannam, A.O. Energy analysis of hybrid solar tunnel dryer with PV system and solar collector for drying mint (MenthaViridis). J. Clean. Prod. 2018, 181, 352–364. [Google Scholar] [CrossRef]

- Jimenez-Garcia, S.N.; Vazquez-Cruz, M.A.; Ramirez-Gomez, X.S.; Beltran-Campos, V.; Contreras-Medina, L.M.; Garcia-Trejo, J.F.; Feregrino-Pérez, A.A. Changes in the Content of Phenolic Compounds and Biological Activity in Traditional Mexican Herbal Infusions with Different Drying Methods. Molecules 2020, 25, 1601. [Google Scholar] [CrossRef] [PubMed]

- Venkatachalam, S.K.; Thottipalayam Vellingri, A.; Selvaraj, V. Low-temperature drying characteristics of mint leaves in a continuous-dehumidified air drying system. J. Food Process Eng. 2020, 43, e13384. [Google Scholar] [CrossRef]

- Kovacı, T.; Dikmen, E.; Şahin, A. Evaluation of heat mass performances for freeze drying of mint leaves. J. Food Process. Preserv. 2022, 46, e13536. [Google Scholar] [CrossRef]

- Esehaghbeygi, A.; Karimi, Z. Electrohydrodynamic, oven and natural drying of mint leaves and effects on the physiochemical indices of the leaves. Res. Agric. Eng. 2020, 66, 81–88. [Google Scholar] [CrossRef]

- Gürel, A.E.; Ağbulut, Ü.; Ergün, A.; Ceylan, I.; Sözen, A.; Tuncer, A.D.; Khanlari, A. A detailed investigation of the temperature-controlled fluidized bed solar dryer: A numerical, experimental, and modeling study. Sustain. Energy Technol. Assess. 2021, 49, 101703. [Google Scholar] [CrossRef]

- Ertekin, C.; Heybeli, N. Thin-layer infrared drying of mint leaves. J. Food Process. Preserv. 2014, 38, 1480–1490. [Google Scholar] [CrossRef]

- Shafiee, Z.; Samani, B.H.; Rostami, S.; Lorigooini, Z.; Jmashidi-kia, F.; Taki, K. Enhancing the quality attributes of mint medicinal plant (Mentha spicata L.) through simultaneous combined ozone and infrared drying. J. Food Process Eng. 2024, 47, e14529. [Google Scholar] [CrossRef]

- Aktaş, M.; Khanlari, A.; Aktekeli, B.; Amini, A. Analysis of a new drying chamber for heat pump mint leaves dryer. Int. J. Hydrog. Energy 2017, 42, 18034–18044. [Google Scholar] [CrossRef]

- Beigi, M. Drying of mint leaves: Influence of the process temperature on dehydration parameters, quality attributes, and energy consumption. J. Agric. Sci. Technol. 2019, 21, 77–88. [Google Scholar]

- Kovacı, T.; Dikmen, E.; Şahin, A. Mathematical model for mint drying kinetics prediction by freeze-drying process: Gene expression programming. J. Food Process Eng. 2020, 43, e13380. [Google Scholar] [CrossRef]

- Shankar, P.M.; Natarajan, V. Impact of microwave vacuum drying on physicochemical characteristics of mint (Mentha spicata L.) leaves. Pharma Innov. J. 2022, 11, 57–61. [Google Scholar]

- Zalpouri, R.; Singh, M.; Kaur, P.; Singh, S. Refractance Window Drying–a Revisit on Energy Consumption and Quality of Dried Bio-origin Products. Food Eng. Rev. 2022, 14, 257–270. [Google Scholar] [CrossRef]

- Mokhtarikhah, G.; Ebadi, M.-T.; Ayyari, M. Qualitative changes of spearmint essential oil as affected by drying methods. Ind. Crops Prod. 2020, 153, 112492. [Google Scholar] [CrossRef]

- Xu, H.; Wu, M.; Wang, B.; Wei, W.; Zhang, T.; Zheng, Z. Changes in water status and microstructure reveal the mechanisms by which tempering affects drying characteristics and quality attributes of medicinal chrysanthemums. Ind. Crops Prod. 2023, 205, 117463. [Google Scholar] [CrossRef]

- Waghmare, R. Refractance window drying: A cohort review on quality characteristics. Trends Food Sci. Technol. 2021, 110, 652–662. [Google Scholar] [CrossRef]

- Setareh, R.; Mohammadi-Ghermezgoli, K.; Ghaffari-Setoubadi, H.; Alizadeh-Salteh, S. The effectiveness of hot-air, infrared and hybrid drying techniques for lemongrass: Appearance acceptability, essential oil yield, and volatile compound preservation. Sci. Rep. 2023, 13, 18820. [Google Scholar] [CrossRef]

- Nalawade, S.A.; Ghiwari, G.K.; Hebbar, H.U. Process efficiency of electromagnetic radiation (EMR)-assisted hybrid drying in spearmint (Mentha spicata L.). J. Food Process. Preserv. 2019, 43, e14190. [Google Scholar] [CrossRef]

- Zamani, S.; Bakhshi, D.; Sahraroo, A.; Ebadi, M. Improvement of phytochemical and quality characteristics of Dracocephalum kotschyi by drying methods. Food Sci. Nutr. 2023, 11, 4246–4262. [Google Scholar] [CrossRef]

- Baeghbali, V.; Niakousari, M.; Ngadi, M.O.; Hadi Eskandari, M. Combined ultrasound and infrared assisted con-ductive hydro-drying of apple slices. Dry. Technol. 2019, 37, 1793–1805. [Google Scholar] [CrossRef]

- Puente-Díaz, L.; Spolmann, O.; Nocetti, D.; Zura-Bravo, L.; Lemus-Mondaca, R. Effects of infrared-assisted Re-fractance Window™ drying on the drying kinetics, microstructure, and color of physalis fruit puree. Foods 2020, 9, 343. [Google Scholar] [CrossRef] [PubMed]

- Zalpouri, R.; Singh, M.; Kaur, P.; Kaur, A.; Gaikwad, K.K.; Singh, A. Drying Kinetics, Physicochemical and Thermal Analysis of Onion Puree Dried Using a Refractance Window Dryer. Processes 2023, 11, 700. [Google Scholar] [CrossRef]

- Kaur, P.; Zalpouri, R.; Modi, R.; Sahota, P.P.; Dhillon, T.S.; Kaur, A. Development and standardization of processing technique for ready-to-use lab fermented Kanji mix using refractance window dried black carrot powder. Sci. Rep. 2023, 13, 185. [Google Scholar] [CrossRef]

- Zhang, Q.; Pertin, O.; Kamdi, H.S.; Durgawati; Xiao, H.W.; Sutar, P.P. Modified refractance window drying of jamun pulp (Syzygium cumini) based on innovative infrared and microwave radiation techniques. Dry. Technol. 2024, 42, 775–794. [Google Scholar] [CrossRef]

- Rajoriya, D.; Bhavya, M.L.; Hebbar, H.U. Far infrared assisted refractance window drying: Influence on drying characteristics and quality of banana leather. Dry. Technol. 2023, 41, 2143–2155. [Google Scholar] [CrossRef]

- Bardakçi, M.S.; Karacabey, E. Drying of Tarhana dough by Refractance Window™ technology under vacuum/atmospheric conditions: Characterization of physical and quality parameters. Food Sci. Nutr. 2024, 12, 971–984. [Google Scholar] [CrossRef]

- Dadhaneeya, H.; Kesavan, R.K.; Inbaraj, B.S.; Sharma, M.; Kamma, S.; Nayak, P.K.; Sridhar, K. Impact of Different Drying Methods on the Phenolic Composition, In Vitro Antioxidant Activity, and Quality Attributes of Dragon Fruit Slices and Pulp. Foods 2023, 12, 1387. [Google Scholar] [CrossRef]

- Subrahmanyam, K.; Gul, K.; Paridala, S.; Sehrawat, R.; More, K.S.; Dwivedi, M.; Jaddu, S. Effect of cold plasma pretreatment on drying kinetics and quality attributes of apple slices in Refractance window drying. Innov. Food Sci. Emerg. Technol. 2024, 92, 103594. [Google Scholar] [CrossRef]

- Durgawati Balasubramanian, P.; Sutar, P.P. Development of a novel non-water infrared refractance window drying method for Malabar spinach: Optimization of process parameters using drying kinetics, mass transfer, and powder characterization. Dry. Technol. 2023, 41, 1620–1635. [Google Scholar] [CrossRef]

- Rajoriya, D.; Bhavya, M.; Hebbar, H.U. Impact of process parameters on drying behaviour, mass transfer and quality profile of refractance window dried banana puree. LWT 2021, 145, 111330. [Google Scholar] [CrossRef]

- Acar, C.; Dincer, I.; Mujumdar, A. A comprehensive review of recent advances in renewable-based drying technologies for a sustainable future. Dry. Technol. 2022, 40, 1029–1050. [Google Scholar] [CrossRef]

- Baeghbali, V.; Niakousari, M.; Farahnaky, A. Refractance Window drying of pomegranate juice: Quality retention and energy efficiency. LWT 2016, 66, 34–40. [Google Scholar] [CrossRef]

- Puente, L.; Vega-Gálvez, A.; Ah-Hen, K.S.; Rodríguez, A.; Pasten, A.; Poblete, J.; Pardo-Orellana, C.; Muñoz, M. Refractance Window drying of goldenberry (Physalis peruviana L.) pulp: A comparison of quality characteristics with respect to other drying techniques. LWT 2020, 131, 109772. [Google Scholar] [CrossRef]

- Preethi, R.; Deotale, S.M.; Moses, J.A.; Anandharamakrishnan, C. Conductive hydro drying of beetroot (Beta vulgaris L) pulp: Insights for natural food colorant applications. J. Food Process Eng. 2020, 43, e13557. [Google Scholar] [CrossRef]

- Uribe, E.; Gómez-Pérez, L.S.; Pasten, A.; Pardo, C.; Puente, L.; Vega-Galvez, A. Assessment of refractive window drying of physalis (Physalis peruviana L.) puree at different temperatures: Drying kinetic prediction and retention of bioactive components. J. Food Meas. Charact. 2022, 16, 2605–2615. [Google Scholar] [CrossRef]

- Seyfi, A.; Asl, A.R.; Motevali, A. Comparison of the energy and pollution parameters in solar refractance window (photovoltaic-thermal), conventional refractance window, and hot air dryer. Sol. Energy 2021, 229, 162–173. [Google Scholar] [CrossRef]

- El-Mesery, H.S.; Qenawy, M.; Li, J.; El-Sharkawy, M.; Du, D. Predictive Modeling of Garlic Quality in Hybrid Infrared-Convective Drying Using Artificial Neural Networks. Food Bioprod. Process. 2024, 145, 226–238. [Google Scholar] [CrossRef]

- Zalpouri, R.; Singh, M.; Kaur, P.; Singh, S.; Kumar, S.; Kaur, A. Mathematical and artificial neural network modelling for refractance window drying kinetics of coriander (Coriandrum sativum L.) followed by the determination of energy consumption, mass transfer parameters and quality. Biomass Convers. Biorefinery 2023. [Google Scholar] [CrossRef]

- Mahesh, J.S.; Rengaraju, B.; Selvakumarasamy, S. Effect of ANN and semi-empirical models on dried Annona muricata leaves. Biomass Convers. Biorefinery 2024. [Google Scholar] [CrossRef]

- Selvakumarasamy, S.; Kulathooran, R.; Rengaraju, B. Effect of Drying on Insulin Plant Leaves for Its Sustainability and Modeling the Drying Kinetics by Mathematical Models and Artificial Neural Network. Environ. Model. Assess. 2024, 29, 901–914. [Google Scholar] [CrossRef]

- Kalsi, B.S.; Singh, S.; Alam, M.S.; Sidhu, G.K. Comparison of ANN and ANFIS modeling for predicting drying kinetics of Stevia rebaudiana leaves in a hot-air dryer and characterization of dried powder. Int. J. Food Prop. 2023, 26, 3356–3375. [Google Scholar] [CrossRef]

- Kannan, V.S.; Arjunan, T.V.; Vijayan, S. Drying characteristics of mint leaves (Mentha arvensis) dried in a solid desiccant dehumidifier system. J. Food Sci. Technol. 2020, 58, 777–786. [Google Scholar] [CrossRef] [PubMed]

- El-Mesery, H.S.; Huang, H.; Hu, Z.; Kaveh, M.; Qenawy, M. Experimental performance analysis of an infrared heating system for continuous applications of drying. Case Stud. Therm. Eng. 2024, 59, 104522. [Google Scholar] [CrossRef]

- Kaveh, M.; Abbaspour-Gilandeh, Y.; Nowacka, M.; Kalantari, D.; El-Mesery, H.S.; Taghinezhad, E. Energy and exergy analysis of drying terebinth in a far infrared-rotary dryer using response surface methodology. Heat Transf. 2024, Early View. [Google Scholar] [CrossRef]

- Akhoundzadeh Yamchi, A.; Sharifian, F.; Khalife, E.; Kaveh, K. Drying kinetic, thermodynamic and quality analyses of infrared drying of truffle slices. J. Food Sci. 2024, 89, 3666–3686. [Google Scholar] [CrossRef] [PubMed]

- Crank, J. The Mathematics of Diffusion; Oxford University Press: Oxford, UK, 1979. [Google Scholar]

- Kalantari, D.; Naji-Tabasi, S.; Kaveh, M.; Azadbakht, M.; Majnooni, M.; Khorshidi, Y.; Asghari, A.; Khalife, E. Drying kinetics and shrinkage rate of thin-sliced pears in different drying stages. J. Food Process Eng. 2022, 46, e14264. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, Y.; Huang, D.; Zhao, H.; Huang, S.; Zhang, L.; Gong, G.; Li, L. Infrared drying characteristics and optimization of ginseng. Case Stud. Therm. Eng. 2024, 57, 104334. [Google Scholar] [CrossRef]

- Silva, E.T.d.V.; de Queiroz, A.J.M.; de Figueirêdo, R.M.F.; Moura, H.V.; Silva, A.P.d.F.; dos Santos, F.S.; Paiva, Y.F.; Palma, C.F.C.; Saraiva, M.M.T.; Junior, N.d.M.A. Enhancing mangosteen peel drying: Impact of ethanol pre-treatment, vacuum pulsing, and blaching on process efficiency and bioactive compound levels. LWT 2024, 198, 115981. [Google Scholar] [CrossRef]

- Darvishi, H.; Khodaei, J.; Behroozi-Khazaei, N.; Salami, P.; Akhijahani, H.S. Greenhouse gas emission reduction potential, energy and exergy analysis of combined microwave-convective dryer. Energy 2023, 285, 128772. [Google Scholar] [CrossRef]

- Nazari, S.; Shahhoseini, O.; Sohrabi-Kashani, A.; Davari, S.; Paydar, R.; Delavar-Moghadam, Z. Experimental de-termination and analysis of CO2, SO2 and NOx emission factors in Iran’s thermal power plants. Energy 2010, 35, 2992–2998. [Google Scholar] [CrossRef]

- Motevali, A.; Jafari, H.; Molkabadi, E.Z.; Zhu, S.; Koloor, R.T.; Taghizadeh-Alisaraei, A. Comparison of environ-mental pollution and social cost analyses in different drying technologies. Int. J. Glob. Warm. 2020, 22, 1–29. [Google Scholar] [CrossRef]

- Shahdadi, F.; Mirzaei, H.O.; Garmakhany, A.D. Study of phenolic compound and antioxidant activity of date fruit as a function of ripening stages and drying process. J. Food Sci. Technol. 2013, 52, 1814–1819. [Google Scholar] [CrossRef] [PubMed]

- Torki-Harchegani, M.; Ghanbarian, D.; Pirbalouti, A.G.; Sadeghi, M. Dehydration behaviour, mathematical modelling, energy efficiency and essential oil yield of peppermint leaves undergoing microwave and hot air treatments. Renew. Sustain. Energy Rev. 2016, 58, 407–418. [Google Scholar] [CrossRef]

- Cunha, N.; da Silva, L.H.M.; da Cruz Rodrigues, A.M. Drying of Curcuma longa L. slices by refractance window: Effect of temperature on thermodynamic properties and mass transfer parameters. Heat Mass Transf. 2024, 60, 617–626. [Google Scholar] [CrossRef]

- Korese, J.K.; Chikpah, S.K. Understanding infrared drying behavior of shea (Vitellaria paradoxa) fruit by-product for the production of value-added products. Biomass Convers. Biorefinery 2022, 13, 15001–15015. [Google Scholar] [CrossRef]

- Kant, R.; Kushwah, A.; Kumar, A.; Kumar, M. Solar drying of peppermint leave: Thermal characteristics, drying kinetics, and quality assessment. J. Stored Prod. Res. 2023, 100, 102068. [Google Scholar] [CrossRef]

- Motevali, A.; Chayjan, R.A.; Salari, K.; Taghizadeh, A. Studying the effect of different drying bed on drying characteristic of mint leaves. Chem. Prod. Process Model. 2016, 11, 231–239. [Google Scholar] [CrossRef]

- Santos, N.C.; Almeida, R.L.J.; Brito, A.C.D.O.; Silva, V.M.D.A.; Albuquerque, J.C.; Saraiva, M.M.T.; Santos, R.M.S.; De Sousa, F.M.; Ribeiro, V.H.D.A.; Carvalho, R.D.O.; et al. Effect of pulse electric field (PEF) intensity combined with drying temperature on mass transfer, functional properties, and in vitro digestibility of dehydrated mango peels. J. Food Meas. Charact. 2023, 17, 5219–5233. [Google Scholar] [CrossRef]

- Santos, S.d.J.L.; da Silva, L.H.M.; Rodrigues, A.M.d.C. Prediction of mass transfer parameters and thermodynamic properties using the refractance Window TM technique for drying of Yam (Dioscorea trifida) paste. Food Sci. Technol. 2022, 42, e67021. [Google Scholar] [CrossRef]

- Almeida, R.L.J.; Santos, N.C.; Alves, I.L.; André, A.M.M.C.N. Evaluation of thermodynamic properties and antioxidant activities of Achachairu (Garcinia humilis) peels under drying process. Flavour Fragr. J. 2020, 36, 213–222. [Google Scholar] [CrossRef]

- Gomes, F.P.; Resende, O.; de Sousa, E.P.; Célia, J.A.; de Oliveira, K.B. Application of Mathematical Models and Thermodynamic Properties in the Drying of Jambu Leaves. Agriculture 2022, 12, 1252. [Google Scholar] [CrossRef]

- Xing, T.; Luo, X.; Li, M.; Wang, Y.; Deng, Z.; Yao, M.; Zhang, W.; Zhang, Z.; Gao, M. Study on drying characteristics of Gentiana macrophylla under the interaction of temperature and relative humidity. Energy 2023, 273, 127261. [Google Scholar] [CrossRef]

- Kaveh, M.; Çetin, N.; Gilandeh, Y.A.; Sharifian, F.; Szymanek, M. Comparative evaluation of greenhouse gas emissions and specific energy consumption of different drying techniques in pear slices. Eur. Food Res. Technol. 2023, 249, 3027–3041. [Google Scholar] [CrossRef]

- Kripanand, S.; Guruguntla, S. Effect of various drying methods on quality and flavor characteristics of mint leaves (Mentha spicata L.). J. Food Pharm. Sci. 2015, 3, 38–45. [Google Scholar]

- Tan, S.; Miao, Y.; Zhou, C.; Luo, Y.; Lin, Z.; Xie, R.; Li, W. Effects of Hot Air Drying on Drying Kinetics and Anthocyanin Degradation of Blood-Flesh Peach. Foods 2022, 11, 1596. [Google Scholar] [CrossRef]

- Ayala-Aponte, A.A.; Cárdenas-Nieto, J.D.; Tirado, D.F. Aloe vera Gel Drying by Refractance Window®: Drying Kinetics and High-Quality Retention. Foods 2021, 10, 1445. [Google Scholar] [CrossRef]

- Lal, A.N.; Krishnamurthy, S.; Girinandagopal, M.; Kothakota, A.; Kumar, R.; Venugopalan, V.; Ishwarya, S.P.; Venkatesh, T. A comparison of the Refrigerated Adsorption Drying of Daucus carota with fluidized bed drying. LWT 2022, 154, 112749. [Google Scholar] [CrossRef]

- Vega-Gálvez, A.; Notte-Cuello, E.; Lemus-Mondaca, R.; Zura, L.; Miranda, M. Mathematical modelling of mass transfer during rehydration process of Aloe vera (Aloe barbadensis Miller). Food Bioprod. Process. 2009, 87, 254–260. [Google Scholar] [CrossRef]

- Rekik, C.; Hajji, W.; Gliguem, H.; Allaf, K.; Bellagha, S. Energy saving and quality preservation through modulating time related conditions during interval drying of pumpkin (Cucurbita maxima). Food Bioprod. Process. 2024, 144, 220–233. [Google Scholar] [CrossRef]

- López-Vidaña, E.C.; Figueroa, I.P.; Cortés, F.B.; Rojano, B.A.; Ocaña, A.N. Effect of temperature on antioxidant capacity during drying process of mortiño (Vaccinium meridionale Swartz). Int. J. Food Prop. 2016, 20, 294–305. [Google Scholar] [CrossRef]

- Harboune, N.; Marete, E.; Jacquier, J.C.; O’Riordan, D. Effect of drying methods on the phenolic constituents of meadowsweet (Filipendula ulmaria) and willow (Salix alba). Food Chem. 2009, 42, 1468–1473. [Google Scholar]

- Rakic, S.; Petrovic, S.; Kukic, J.; Jadranin, M.; Tesevic, V.; Povrenovic, D.; Šiler-Marinković, S. Influence of thermal treatment on phenolic compounds and antioxidant properties of oak acorns from Serbia. Food Chem. 2007, 104, 830–834. [Google Scholar] [CrossRef]

- Nguyen, T.-V.; Nguyen, Q.-D.; Nguyen, P.-B. Drying Kinetics and Changes of Total Phenolic Content, Antioxidant Activity and Color Parameters of Mango and Avocado Pulp in Refractance Window Drying. Pol. J. Food Nutr. Sci. 2022, 72, 27–38. [Google Scholar] [CrossRef]

- Sellami, I.H.; Rebey, I.B.; Sriti, J.; Rahali, F.Z.; Limam, F.; Marzouk, B. Drying Sage (Salvia officinalis L.) Plants and Its Effects on Content, Chemical Composition, and Radical Scavenging Activity of the Essential Oil. Food Bioprocess Technol. 2011, 5, 2978–2989. [Google Scholar] [CrossRef]

- Asiimwe, A.; Kigozi, J.; Baidhe, E.; Muyonga, J. Optimization of refractance window drying conditions for passion fruit puree. LWT 2022, 154, 112742. [Google Scholar] [CrossRef]

- Ciric, A.; Krajnc, B.; Heath, D.; Ogrinc, N. Response surface methodology and artificial neural network approach for the optimization of ultrasound-assisted extraction of polyphenols from garlic. Food Chem. Toxicol. 2019, 135, 110976. [Google Scholar] [CrossRef]

| Model Name | Model Formula | Reference |

|---|---|---|

| Logarithmic | [41] | |

| Page | [6] | |

| Wang and Singh | [40] | |

| Henderson and Pabis | [42] | |

| Newton | [45] | |

| Two-term | [46] |

| S.O.V | Time | SEC | Deff | CO2 | NOx | ΔH | ΔS | ΔG |

|---|---|---|---|---|---|---|---|---|

| df | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Sum Sq | 17,802 | 14.92 | 4.43 × 10−15 | 6.60 | 2.41 × 10−4 | 0.20 | 4 1.78 × 10−4 | 106.4 |

| Mean Sq | 4451 | 3.73 | 1.10 × 10−15 | 1.65 | 6.04 × 10−5 | 0.051 | 4.46 × 10−5 | 26.61 |

| F value | 84.72 | 61.29 | 77.08 | 101.6 | 79.77 | 44.69 | 69.96 | 51.13 |

| Pr (>F) | 1.13 × 10−7 ** | 5.36 × 10−7 ** | 1.79 × 10−7 ** | 4.71 × 10−8 ** | 1.52 × 10−7 ** | 2.39 × 10−6 ** | 2.85 × 10−7 ** | 1.27 × 10−6 ** |

| C.V | 6.94 | 5.83 | 8.92 | 4.39 | 4.94 | 0.01 | −0.7 | 1.16 |

| T (°C) | Drying Time (min) | Deff (m2/s) | SEC (kWh/kg) | CO2 (kg/kg Water) | NOx (kg/kg Water) |

|---|---|---|---|---|---|

| 50 | 156 ± 4.02 a | 2.48 × 10−8 ± 9.90 × 10−10 d | 5.66 ± 0.14 a | 3.80 ± 0.08 a | 0.023 ± 0.0004 a |

| 60 | 124.33 ± 4.25 b | 2.94 × 10−8 ± 1.93 × 10−9 d | 4.91 ± 0.08 b | 3.39 ± 0.04 b | 0.020 ± 0.0004 b |

| 70 | 105.00 ± 2.35 c | 3.67 × 10−8 ± 1.75 × 10−9 c | 4.20 ± 0.12 c | 2.91 ± 0.04 c | 0.017 ± 0.0004 c |

| 80 | 80.00 ± 2.35 d | 4.87 × 10−8 ± 2.40 × 10−9 b | 3.55 ± 0.11 d | 2.43 ± 0.07 d | 0.014 ± 0.0003 d |

| 90 | 56.66 ± 3.60 e | 7.28 × 10−8 ± 2.12 × 10−9 a | 2.81 ± 0.09 e | 1.94 ± 0.03 e | 0.011 ± 0.0003 e |

| T (°C) | ΔH (kJ/mol) | ΔΣ (kJ/mol K) | ΔΓ (kJ/mol) |

|---|---|---|---|

| 50 | 23.12 ± 0.014 a | −0.1077 ± −0.0002 a | 57.90 ± 0.37 e |

| 60 | 23.03 ± 0.079 b | −0.1103 ± 0.0003 b | 59.78 ± 0.25 d |

| 70 | 22.93 ± 0.024 c | −0.1128 ± 0.0004 c | 61.67 ± 0.31 c |

| 80 | 22.89 ± 0.030 d | −0.1152 ± 0.0004 d | 63.55 ± 0.23 b |

| 90 | 22.77 ± 0.017 e | −0.1175 ± 0.0003 e | 65.43 ± 0.47 a |

| S.O.V | L* | a* | b* | TPC | TFC | AA |

|---|---|---|---|---|---|---|

| df | 5 | 5 | 5 | 5 | 5 | 5 |

| Sum Sq | 175.63 | 16.29 | 94.21 | 610.4 | 522.6 | 1720.4 |

| Mean Sq | 35.13 | 3.25 | 18.84 | 122.09 | 104.5 | 344.1 |

| F value | 28.23 | 7.53 | 68.93 | 6.05 | 5.17 | 15.8 |

| Pr (>F) | 3.05 × 10−6 ** | 0.002 ** | 2.04 × 10−8 ** | 0.005 ** | 0.009 ** | 6.44 × 10−5 ** |

| C.V | 2.97 | −7.66 | 2.12 | 10.74 | 13.39 | 6.52 |

| T (°C) | L* | a* | b* | ΔE | C |

|---|---|---|---|---|---|

| Fresh | 42.89 ± 0.86 a | −10.80 ± 0.73 d | 27.87 ± 0.69 a | - | 29.65 ± 0.83 a |

| 50 | 32.75 ± 0.47 e | −7.18 ± 0.23 a | 21.28 ± 0.09 e | 13.00 ± 0.03 a | 22.46 ± 0.16 e |

| 60 | 35.46 ± 0.56 d | −8.50 ± 0.24 bc | 23.35 ± 0.09 d | 11.56 ± 0.04 b | 24.85 ± 0.17 d |

| 70 | 39.03 ± 0.47 b | −9.13 ± 0.17 cd | 26.93 ± 0.09 b | 9.96 ± 0.07 d | 28.43 ± 0.14 b |

| 80 | 37.77 ± 0.41 bc | −8.72 ± 0.19 bc | 25.32 ± 0.09 c | 10.23 ± 0.04 d | 26.78 ± 0.15 c |

| 90 | 36.90 ± 0.51cd | −7.77 ± 0.20 ab | 23.12 ± 0.09 d | 10.78 ± 0.01 c | 24.39 ± 0.15 d |

| S.O.V | RR | ΔE | Chroma | EO |

|---|---|---|---|---|

| df | 4 | 4 | 4 | 4 |

| Sum Sq | 2.59 | 17.89 | 63.21 | 3.08 |

| Mean Sq | 0.64 | 4.47 | 15.80 | 0.77 |

| F value | 21.64 | 91.81 | 141.6 | 74.28 |

| Pr (>F) | 6.54 × 10−5 ** | 7.68 × 10−8 ** | 9.28 × 10−9 ** | 2.14 × 10−7 ** |

| C.V | 3.88 | 1.98 | 1.31 | 6.59 |

| T (°C) | RR | TPC (mg GAE/100g DW) | TFC (mg QE/100 g DW) | AA (%) | EO (%) |

|---|---|---|---|---|---|

| Fresh | - | 48.51 ± 4.90 a | 42.57 ± 2.95 a | 89.61 ± 4.95 a | - |

| 50 | 3.79 ± 0.06 d | 31.18 ± 0.70 c | 26.52 ± 0.46 c | 58.55 ± 0.90 d | 0.82 ± 0.03 d |

| 60 | 4.25 ± 0.08 c | 40.72 ± 0.86 ab | 28.62 ± 0.61 bc | 64.92 ± 0.82 cd | 1.23 ± 0.04 c |

| 70 | 4.50 ± 0.05 bc | 46.42 ± 0.40 ab | 36.81 ± 0.82 ab | 75.31 ± 1.41 b | 1.93 ± 0.07 a |

| 80 | 5.01 ± 0.10 a | 45.19 ± 0.66 ab | 35.47 ± 0.71 ab | 73.52 ± 0.73 bc | 2.01 ± 0.04 a |

| 90 | 4.72 ± 0.08 ab | 38.52 ± 0.70 bc | 31.34 ± 0.78 bc | 67.50 ± 0.70 bc | 1.73 ± 0.01 b |

| Model | T (C) | R2 | MSE |

|---|---|---|---|

| Logarithmic | 50 | 0.9958 | 0.0302 |

| 60 | 0.9972 | 0.0263 | |

| 70 | 0.9944 | 0.0315 | |

| 80 | 0.9969 | 0.0244 | |

| 90 | 0.9981 | 0.0199 | |

| Average | 0.9964 | 0.0264 | |

| Page | 50 | 0.9996 | 0.0124 |

| 60 | 0.9990 | 0.0148 | |

| 70 | 0.9995 | 0.0130 | |

| 80 | 0.9988 | 0.0169 | |

| 90 | 0.9984 | 0.0178 | |

| Average | 0.9990 | 0.0149 | |

| Newton | 50 | 0.9696 | 0.0710 |

| 60 | 0.9858 | 0.0515 | |

| 70 | 0.9803 | 0.0595 | |

| 80 | 0.9900 | 0.0415 | |

| 90 | 0.9729 | 0.0677 | |

| Average | 0.9797 | 0.0582 | |

| Wang and Singh | 50 | 0.9965 | 0.0268 |

| 60 | 0.9908 | 0.0411 | |

| 70 | 0.9952 | 0.0299 | |

| 80 | 0.9798 | 0.0622 | |

| 90 | 0.9868 | 0.0496 | |

| Average | 0.9898 | 0.0419 | |

| Two-term | 50 | 0.9867 | 0.0488 |

| 60 | 0.9893 | 0.0424 | |

| 70 | 0.9811 | 0.0611 | |

| 80 | 0.9659 | 0.0722 | |

| 90 | 0.9903 | 0.0418 | |

| Average | 0.9826 | 0.0532 | |

| Henderson and Pabis | 50 | 0.9985 | 0.0173 |

| 60 | 0.9968 | 0.0245 | |

| 70 | 0.9970 | 0.0242 | |

| 80 | 0.9860 | 0.0512 | |

| 90 | 0.9862 | 0.0511 | |

| Average | 0.9929 | 0.0336 |

| Threshold Function | Number of Layers and Neurons | MSE | R2 | Epoch |

|---|---|---|---|---|

| Tansig-Tansig-Tansig | 2-10-10-1 | 0.000312 | 0.9975 | 12 |

| Tansig-Purelin-Tansig | 2-10-10-1 | 1.73 × 10−6 | 0.9999 | 147 |

| Tansig-Purelin, | 2-10-1 | 2.45 × 10−6 | 0.9998 | 120 |

| Tansig-Logsig-purelin, | 2-15-14-1 | 8.77 × 10−7 | 0.9999 | 15 |

| Tansig-Tansig | 2-15-1 | 0.0041 | 0.9828 | 15 |

| Model | MSE | R2 |

|---|---|---|

| ANN | 8.77 × 10−7 | 0.9999 |

| Page | 0.0124–0.0178 | 0.9984–9996 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaveh, M.; Zomorodi, S.; Mariusz, S.; Dziwulska-Hunek, A. Determination of Drying Characteristics and Physicochemical Properties of Mint (Mentha spicata L.) Leaves Dried in Refractance Window. Foods 2024, 13, 2867. https://doi.org/10.3390/foods13182867

Kaveh M, Zomorodi S, Mariusz S, Dziwulska-Hunek A. Determination of Drying Characteristics and Physicochemical Properties of Mint (Mentha spicata L.) Leaves Dried in Refractance Window. Foods. 2024; 13(18):2867. https://doi.org/10.3390/foods13182867

Chicago/Turabian StyleKaveh, Mohammad, Shahin Zomorodi, Szymanek Mariusz, and Agata Dziwulska-Hunek. 2024. "Determination of Drying Characteristics and Physicochemical Properties of Mint (Mentha spicata L.) Leaves Dried in Refractance Window" Foods 13, no. 18: 2867. https://doi.org/10.3390/foods13182867