Food Preservation in the Industrial Revolution Epoch: Innovative High Pressure Processing (HPP, HPT) for the 21st-Century Sustainable Society

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

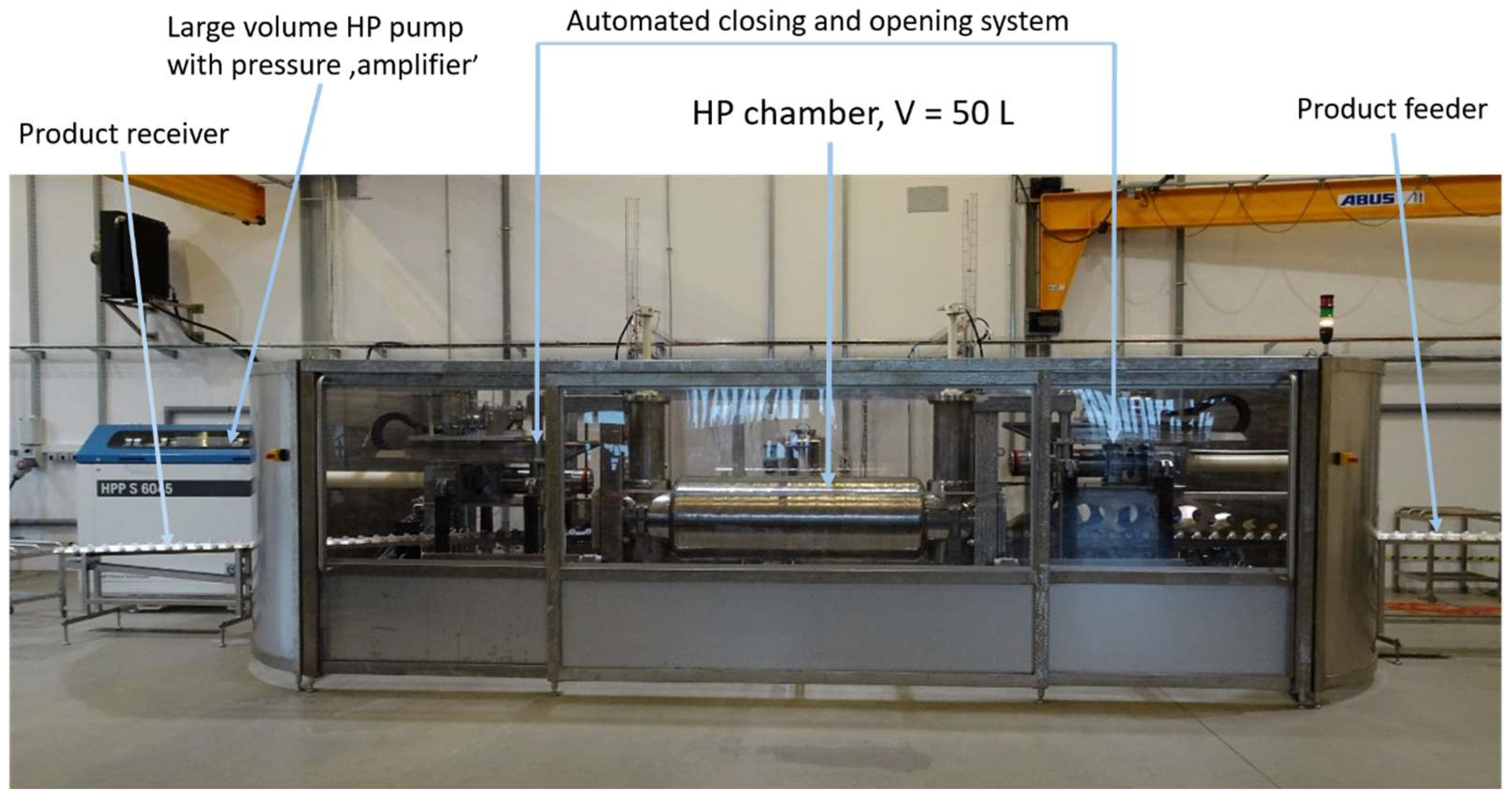

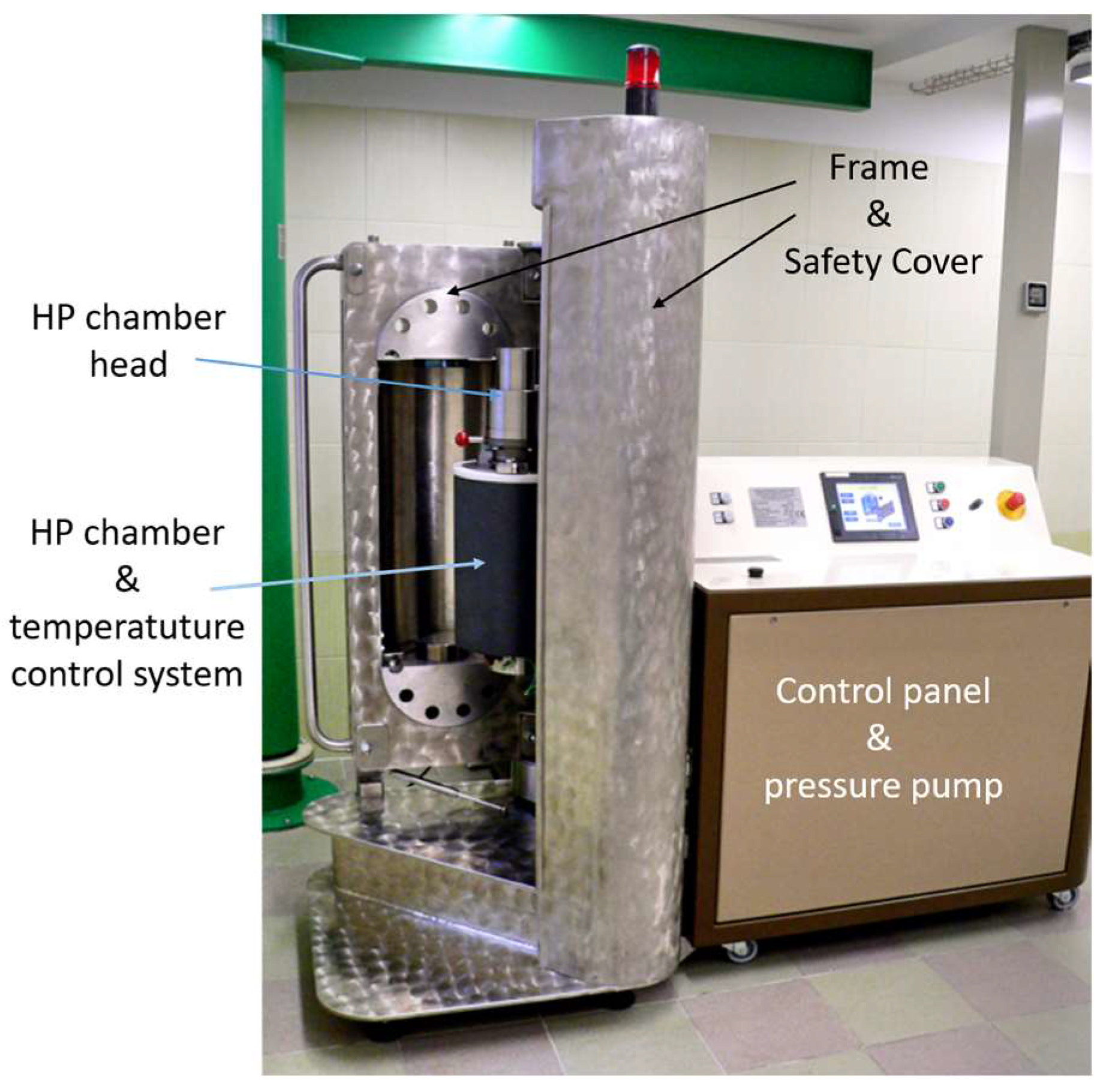

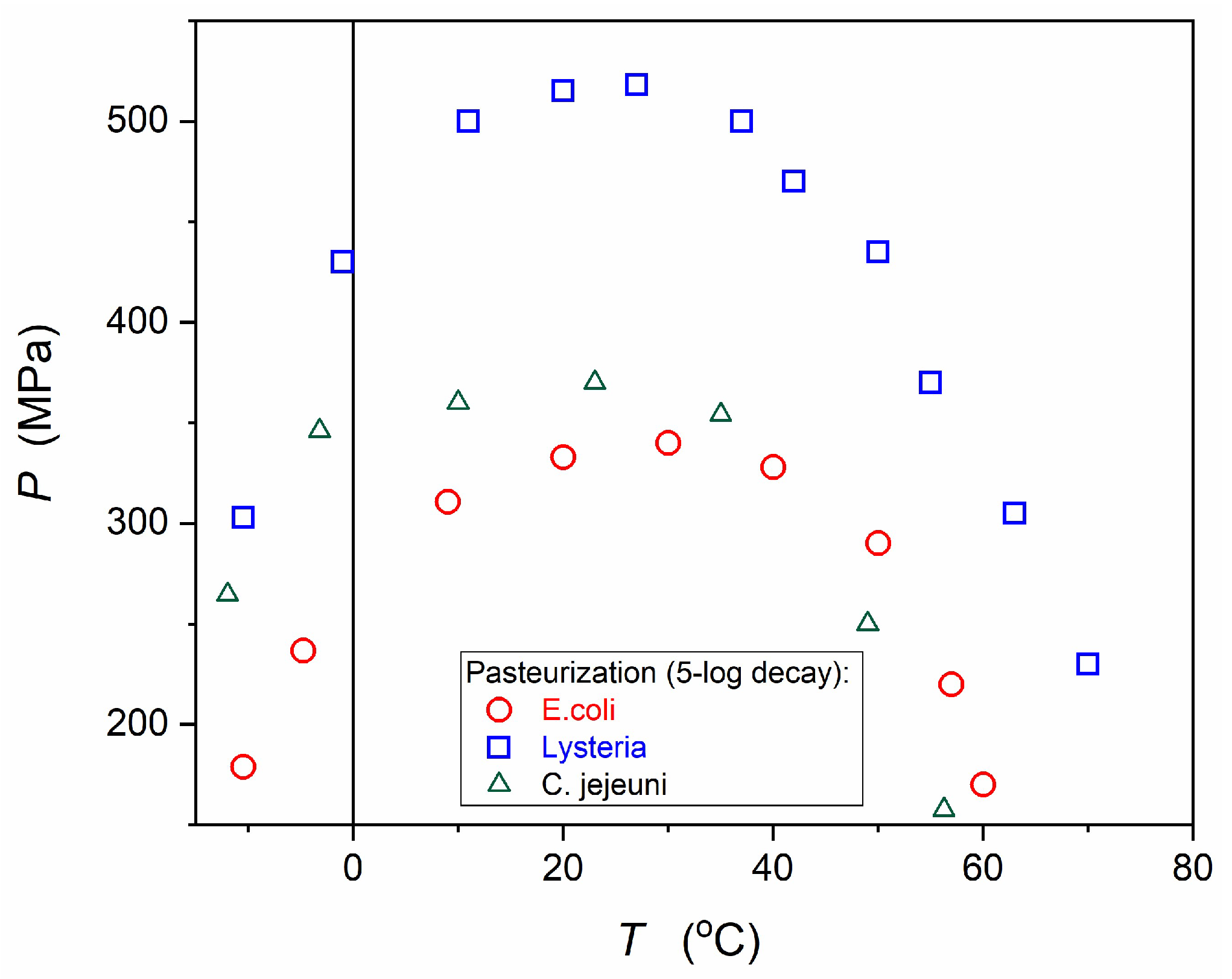

3.1. HPP and HPT Revisted

3.1.1. General HPP Features

- shelf-life extension from 2–3 days to even up to 180 days!

- high microbiological safety

- taste, flavor, and appearance of a fresh product

- vitamin composition of the fresh product

- maintaining bioactive properties

- limited or even no chemical preservatives

- activation/deactivation of selected enzymes

- salt-free products

- application to fluids and “soft, solid” food

- application to packed food, reducing the risk of secondary contamination

- environment-friendly technology, namely: (i) requirements for electric energy notably lesser than for thermal pasteurization; (ii) practical lack of waste during processing

- reduction of the number of expired products and, therefore also, disposal costs

- for some consumers, important can be a ‘clean label’ and innovative technology

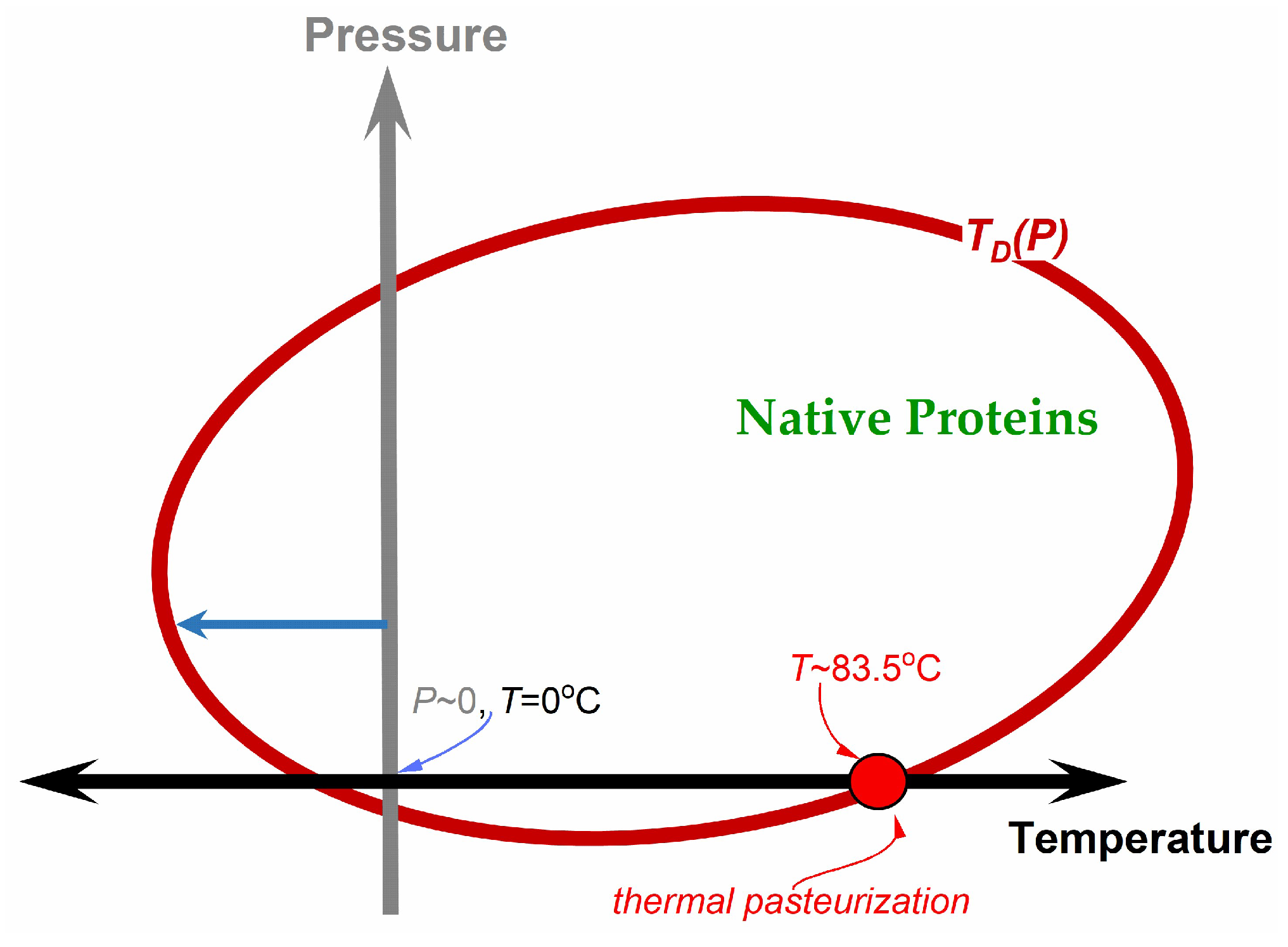

3.1.2. Food as a Soft Matter System

- membrane disruptions, most often explained by local shear forces, but local differences in compressibility also can be important

- proteins denaturation

- proteins deformation and local volume changes within

- destruction of intracellular elements

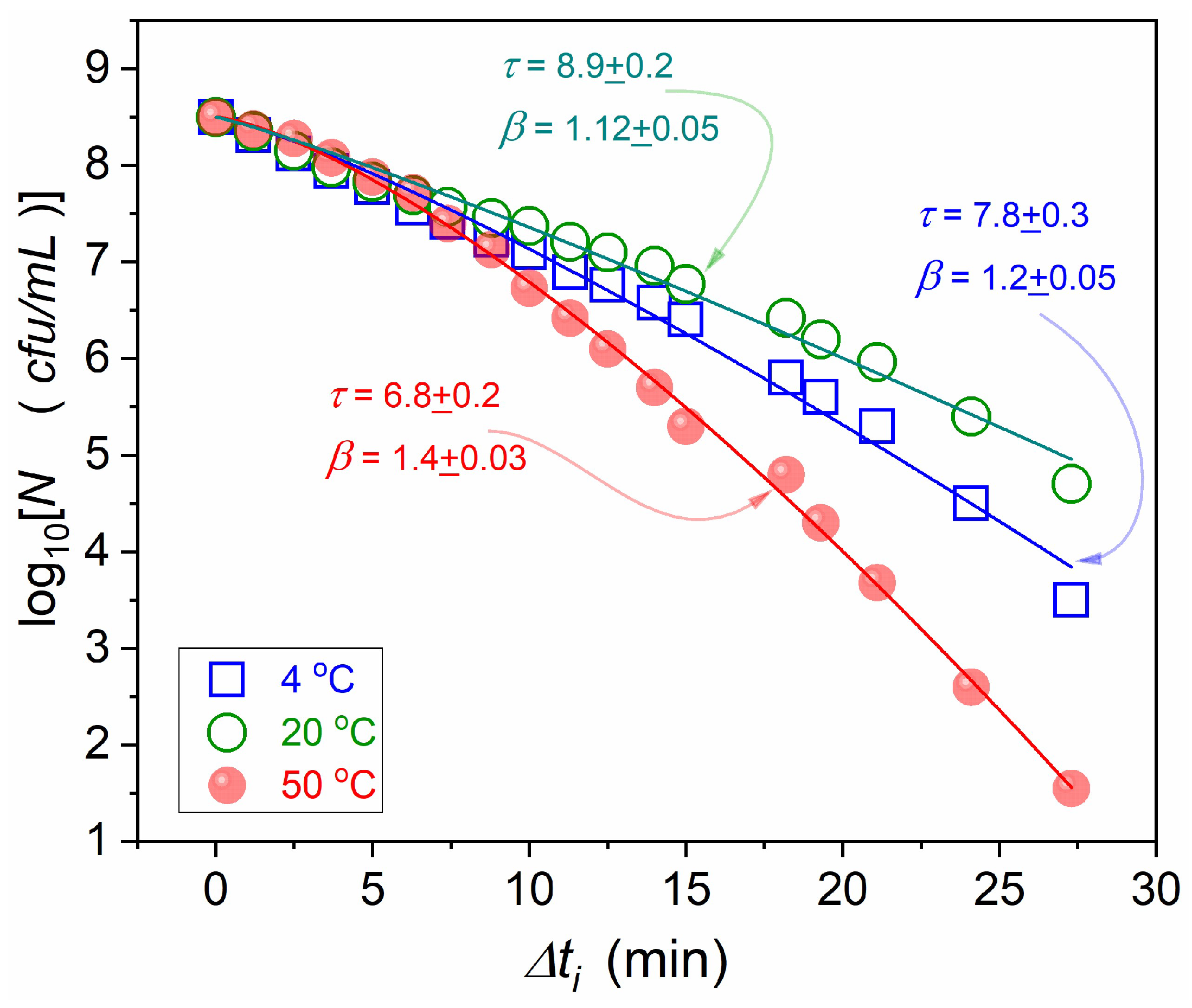

3.1.3. The Decay in the Number of Microorganisms after HPP Treatment and the Distortions-Sensitive Analysis

- (a)

- There is a limited number of data: usually, tests are carried out for 4–6 time periods of tested high pressure pulses. Nevertheless,, a nonlinear pattern of changes is commonly observed, indicating the non-Malthusian behavior, i.e., beyond Equation (6).

- (b)

- Non-Malthusian behavior is analyzed via the empowered exponential function (see below), with a heuristic recalling the Weibull model. However, the graphical presentation of fitting results, essential for the validation, is hardly presented.

- (c)

- Fitting results are typically given only in tables, with questionable estimations of parameter errors and fitting quality parameters, in the opinion of the authors.

- (d)

- Generally, the number of experimental data points in nonlinear fitting should be a decade larger than the number of fitted parameters. For the empowered exponential/Weibull equation, there are three adjustable parameters. Hence, the formally correct analysis requires at least 20 data points. Such results are (very) hardly reported.

- (e)

- The meaning of parameters derived via nonlinear fittings is usually not discussed.

- (a)

- Usually, results of fitting via Equation (8) or Equation (9) are not presented in plots but only given in a table.

- (b)

- Experimental data are only linked by straight lines to facilitate the view.

- (c)

- Usually, post-HPP decay experimental data are related to 4–5 tested lengths of high-pressure pulses related to data points in the plot.

- (d)

- The errors of fitted parameters presented in the tables are usually significantly lower than those given in Figure 4.

- (i)

- HPP technology does not lead to food sterilization.

- (ii)

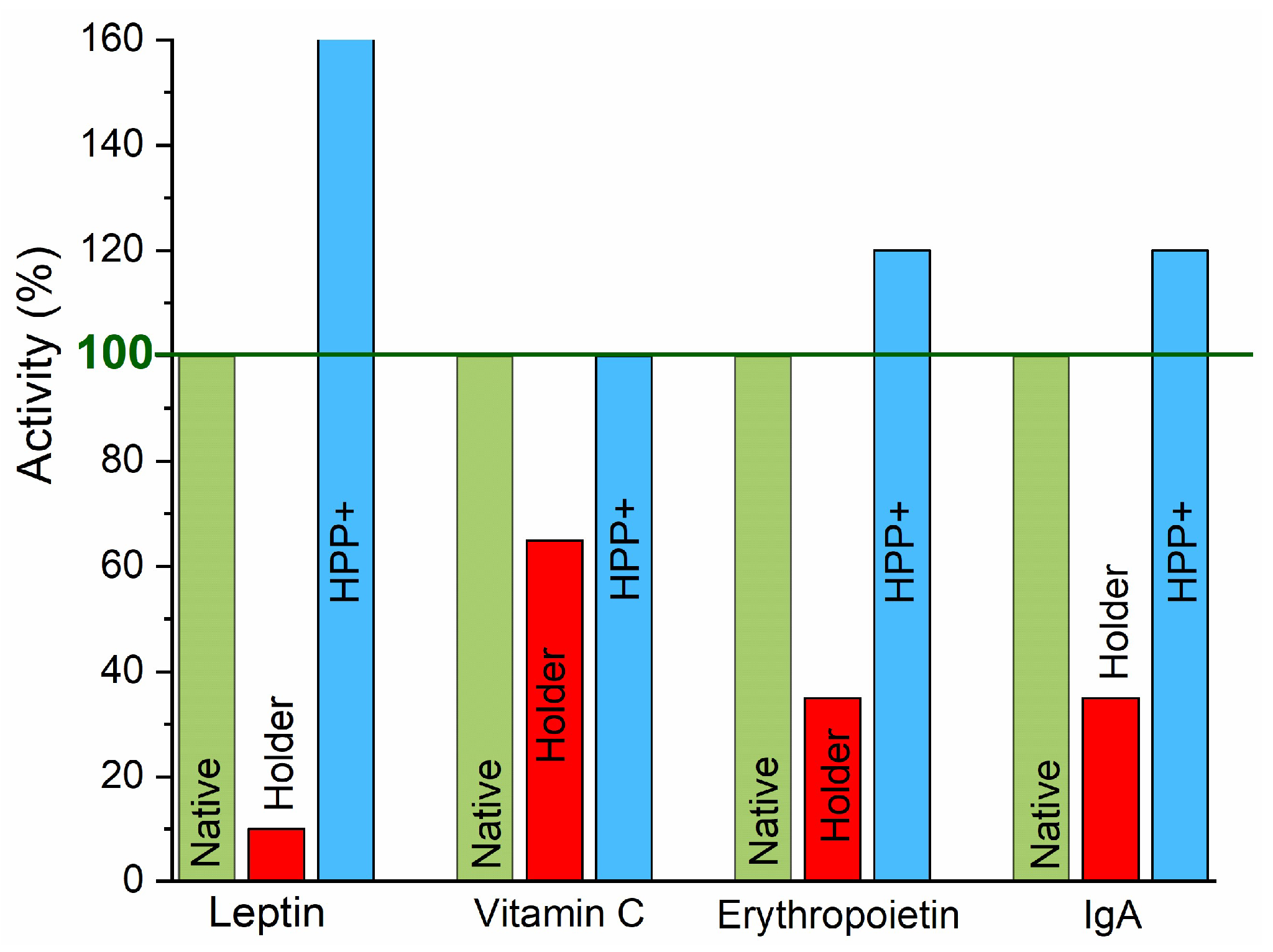

- HPP rarely deactivates undesirable enzymes and often even increases their activity. However, for the last several years, research on high pressure and high temperature (HPHT, HPT) technology has been carried out, which allows for overcoming the above problems.

3.2. High Pressure and High Temperature Sterilization Technology (HPT, HPHT)

3.2.1. HPT Basics

- Spores inactivation—efficiently inactivating spores to enable shelf-stable products.

- Nutrient preservation—preserving nutrition and flavor better than standard heat methods.

- Reducing newly formed contaminants such as heterocyclic aromatic amines, acrylamide, and n-nitroso- compounds.

- Efficiency: less operating energy than for classic thermal pasteurization can be needed

- Reaching technological sterilization under ‘softer’ conditions than for the classic thermal pasteurization, regarding the treatment temperature and the time of its application.

- The reduction of enzyme activity

- (i)

- The pre-heating product up to ca. is placed in a thermally isolated container;

- (ii)

- The container is shifted to the standard HPP pressure chamber;

- (iii)

- The adiabatic compression up to further increases the temperature of the product up to ca. 120–130 °C. Such conditions are preserved for ca. ;

- (iv)

- Decompressing and returning to the ambient conditions;

- (v)

- Product removal from the chamber

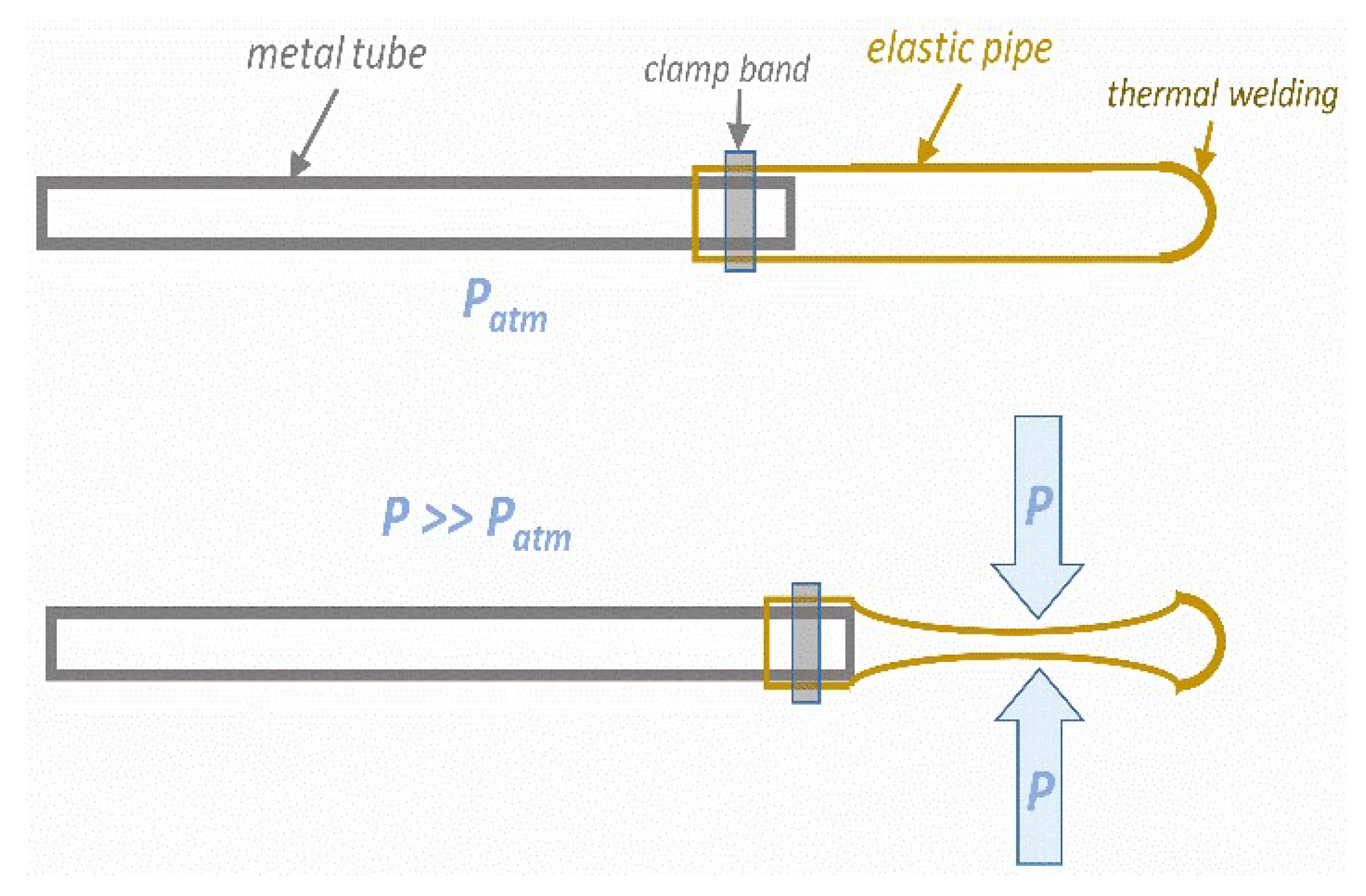

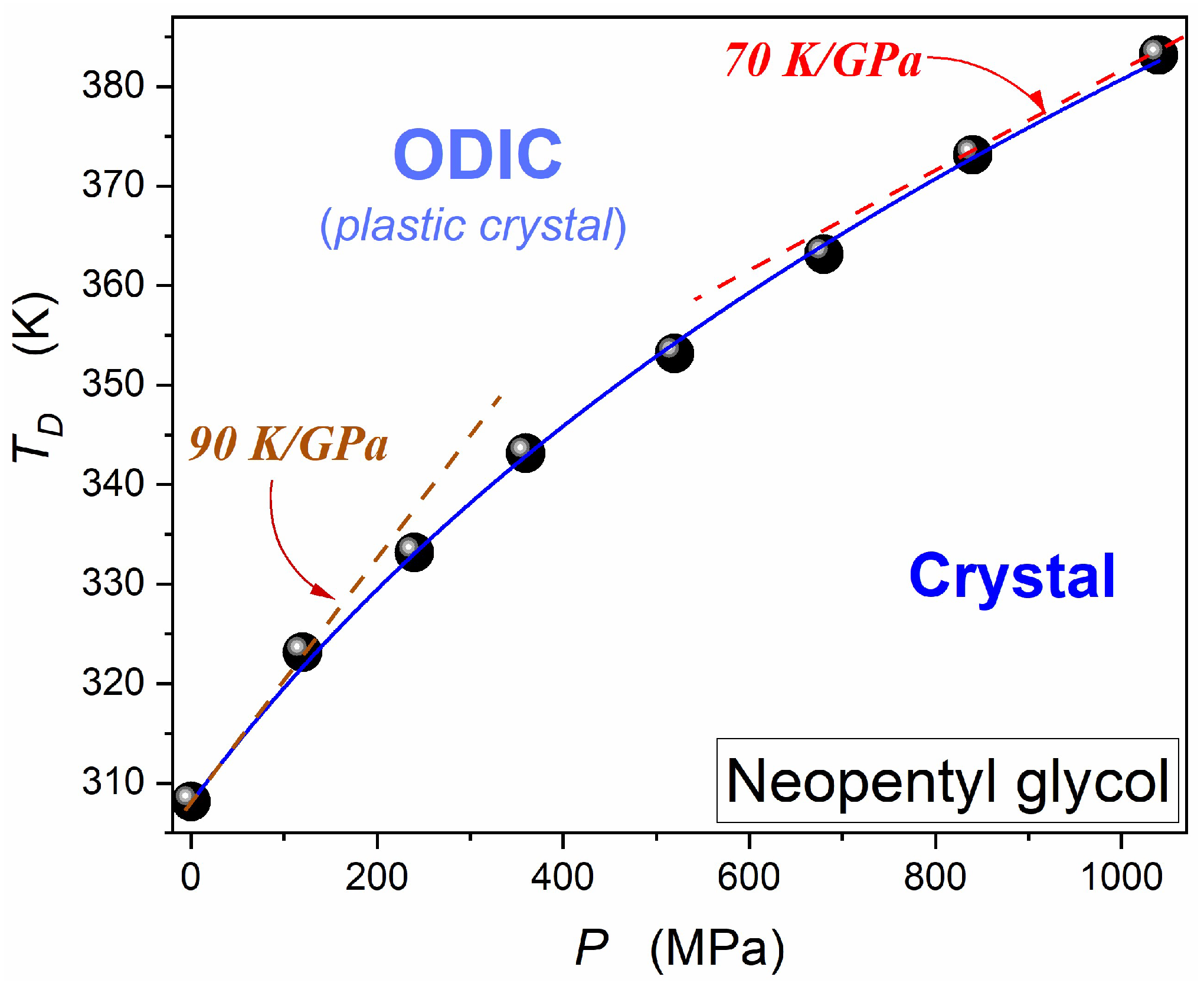

3.2.2. Barocaloric Effect-Based Innovative Solution for HPT Sterilization

- The standard HPP processors can be used for the innovative HPT-barocaloric concept, but the surface of the pressure chamber interior should be covered by a layer of thermo-isolated material, for instance Teflon. It ensures near-adiabatic conditions within the chamber.

- The processed food product is placed in standard containers used for HPP technology, supplemented (‘mixed’) with the barocaloric effect exploring elements, for instance, as shown in Figure 6 (see comment below).

- The compression/decompression, as for the standard HPP processing, starts.

- However, when passing the ‘designed’ pressure, the interior of the chamber and the product are heated due to the barocaloric heat effect freed on compressing.

- Additional heating is associated with general adiabatic heating. It is effective due to adiabatic conditions.

- “Designed” thermal parameters are maintained for the time when the planned high pressure value acts.

- Decompression: the product is cooled due to the barocaloric effect on decompressing and the adiabatic cooling on decompressing.

- A relatively ‘cool’ product is shifted from the chamber to the product transporter. It can be immediately placed in a chilling room if necessary.

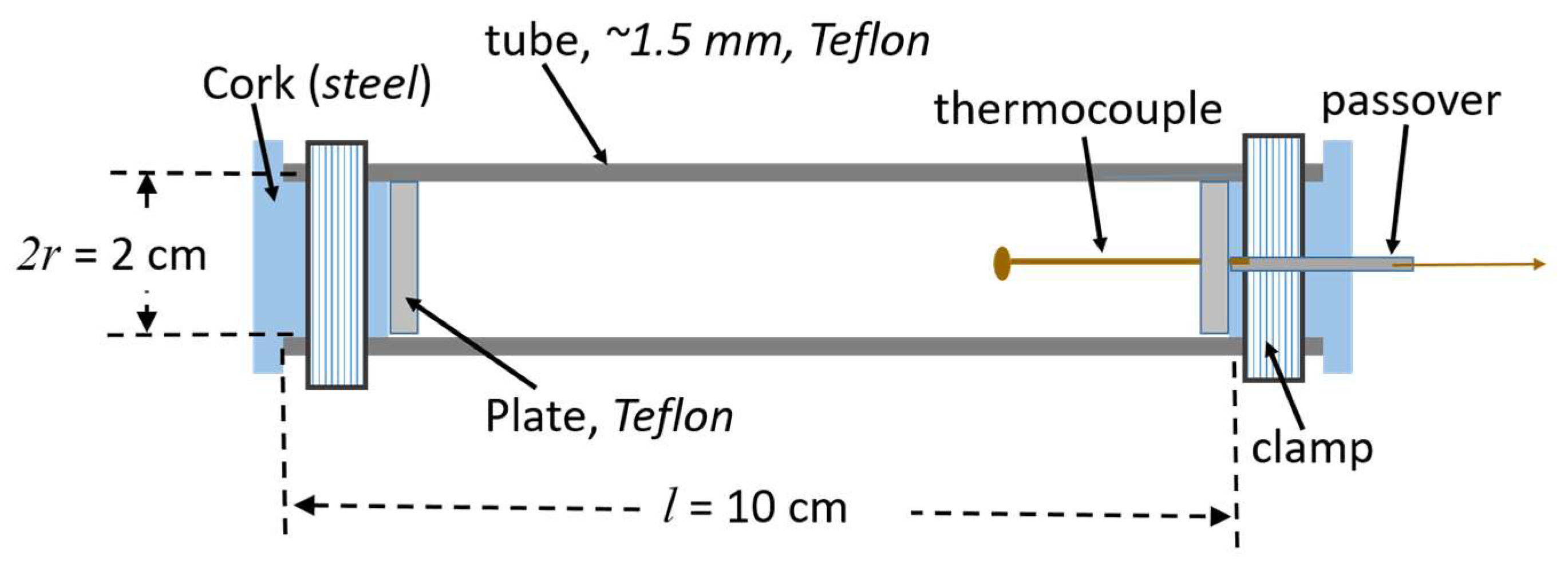

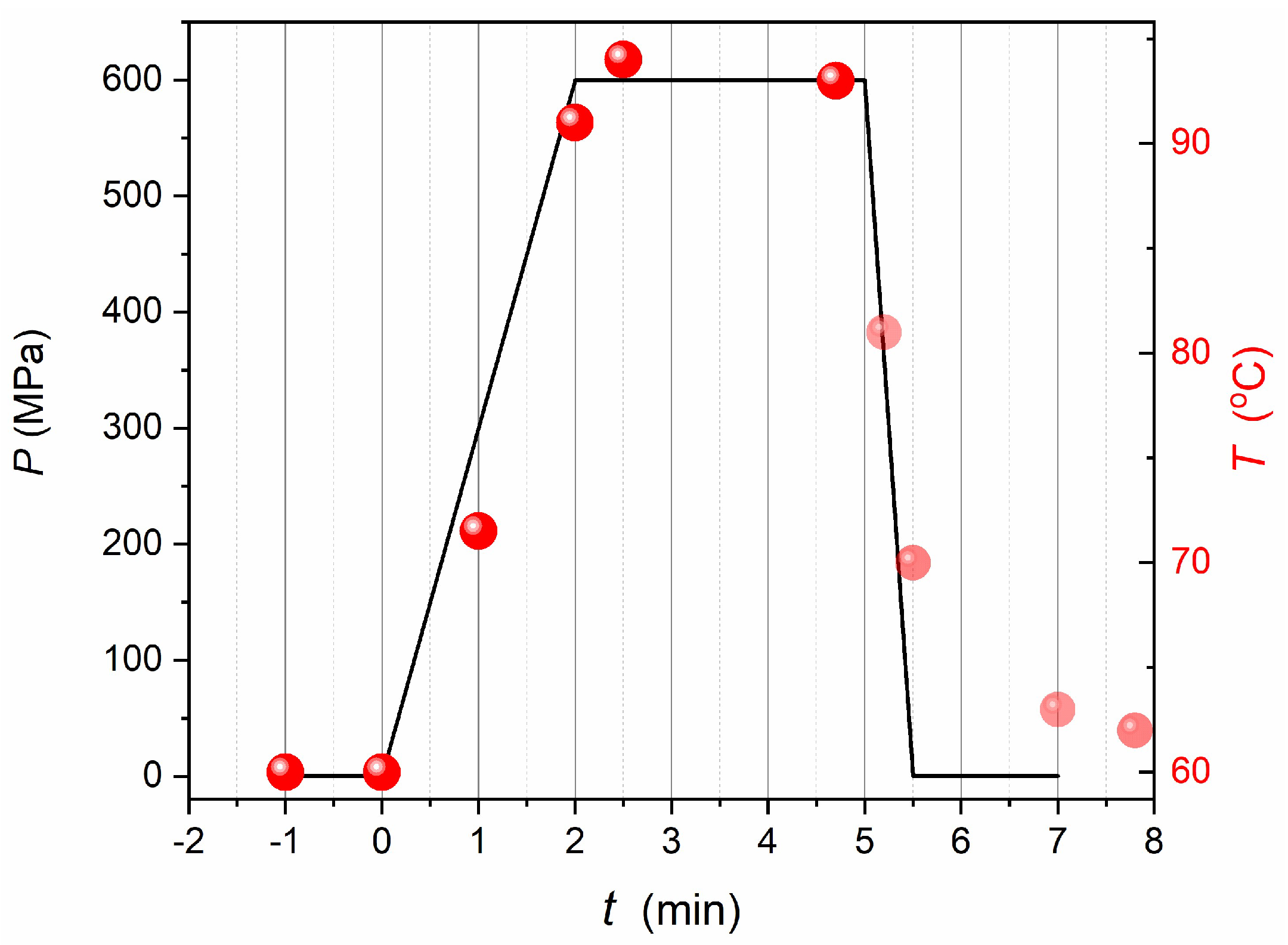

3.2.3. Preliminary Feasibility Test for the ‘HPT-Barocaloric’ Innovative Solutions

- Only the adiabatic heating associated with compressing was tested in the experiment’s first stage.

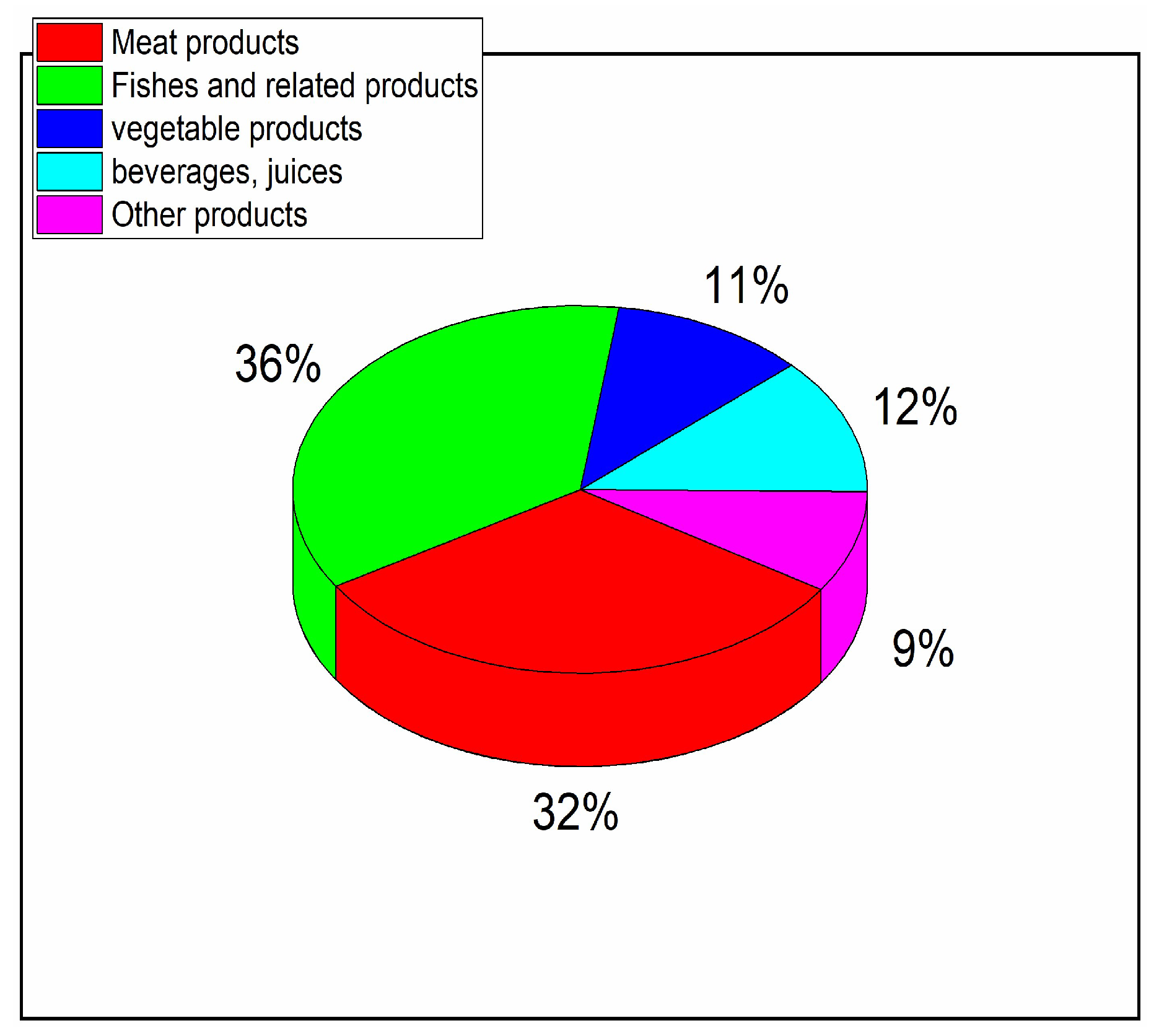

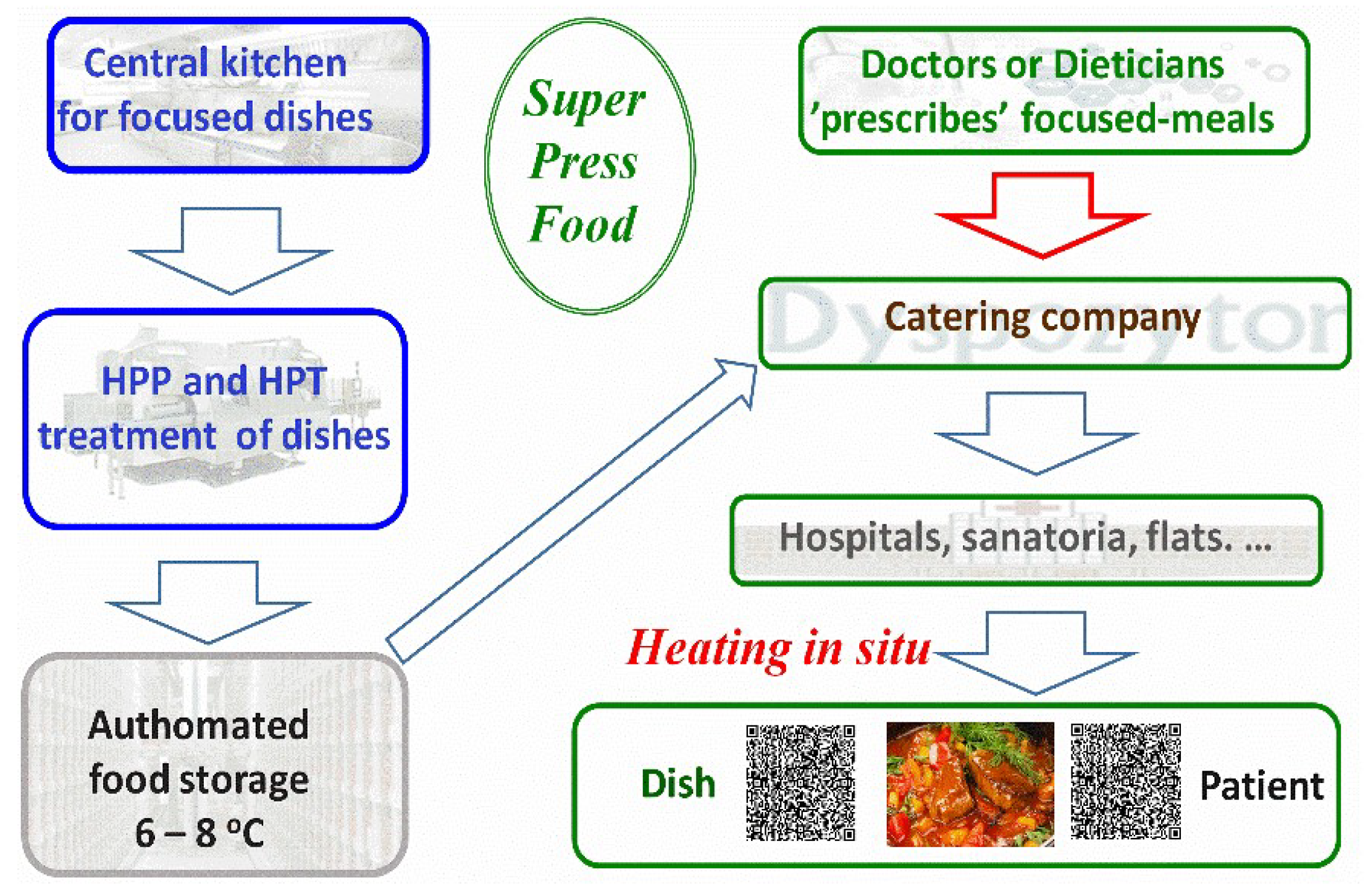

3.3. High Pressure Processing: Socio-Economic Aspects and New Challenges

3.3.1. Comments on HPP Market Development

3.3.2. New Innovative Products, New Markets

- (i)

- When HPP technology is used for raw meats, there is a problem for beef or pork related to reducing their characteristic reddish color. It is not the desired view of the product by the consumer. However, it results from the process occurring evenly in the entire volume. The degree of activation of the process depends on the value of the maximum pressure, the time of its application, and the temperature. Therefore, the product can be ‘pressurized’ (‘pre-cooked’) to a different extent defined by the parameters . It is a possibility of qualitative extension of the ‘low-temperature cooking’ technology. Here, additional opportunities are opened by applying the innovative HPT technology described in the previous section.

- (ii)

- A few years ago, a patent was issued for the possibility of quickly and evenly soaking various food products in an appropriately prepared marinade, but also, for example, beetroot juice, orange juice, … or even appropriately diluted chocolate. It can be supplemented by the ‘cold precooking’, solely by compressing. The patents [126,127], in which one of the authors of this work participates, show an application for vegetables and, above all, meats. The effective action has already been obtained for for a few minutes at room temperature.

- (iii)

- Extraordinary pro-health features of green parsley-based nectars are widely known [128], but rapid biodegradation and separation into two layers were major problems.

- (iv)

- Another known option is the possibility of pressure ‘cold’ cooking of eggs, to a varying extent depending on the parameters of the HPP process.

- (v)

- One of the features of food products after HPP technology is often a velvety structure and taste, which has already been noted for the first market products using this technology in 1990/1991. The structure of many products, such as jams or hummus, is wholly homogenized, related to the new taste values mentioned above [130].

- (vi)

- For ground coffee, coffee beans or coarsely granulated coffee beans placed in water at a temperature of to (HPP) or even up to (HPT) led to the creation of a new generation of beverages with a variety of flavors with different pressure-time implementation scenarios, as has been tested by the authors of the given report. It can create new generations of beverages using cocoa, tea, and herbs placed in ‘cold’ water and compressed using an HPP processor.

- (vii)

- The elements of the system presented in Figure 16 could be used in some branches of the catering business, for example, in popular eateries selling meals ‘by weight’. The significant problem of such restaurants is associated with losses that occur with unpredictable changes in the number of customers or the utilization of remaining foods, resulting in significant losses and costs. The aforementioned use of products based on HPP technology, ready to eat even after 3 min, solves this problem.

- HPP and HPT technologies open up qualitatively new possibilities for creative gourmet chefs. The implementation of high pressures opens up a new dimension of food preparation. It could be an innovative option for haute cuisine restaurants. For such applications, HPP processors with a pressure chamber volume L could be sufficient. Such a volume means a reasonable price and simple operations and services. It is worth emphasizing the possibility of extending such a processor to the HPT option using the barocaloric effect-based innovation presented above.

- There is a wide range of local, traditional products and dishes with excellent quality, pro-health, and taste values. Usually, they are unavailable outside their traditional regions. They are based on locally available products with exceptional qualities. Local implementation of HPP and HPT technologies for these products and dishes could open broad markets, benefiting local communities and producers greatly. This can also be a qualitatively new offer for a global customer.

3.3.3. HPP Market and Consumers’ Economic Constraints

4. Conclusions

- The innovative HPHT (HPT) technology is based on the barocaloric effect, which allows for action at high temperatures only when maximal stationary pressure acts on the product. The high-pressure value controls the triggering and termination of the high-temperature simultaneous operation stage.

- Proposal for using HPP processors as a base for cold sterilization, particularly for removing biofilms from fools or other equipment important for medicine, the pharmaceutical industry, and the food industry. It can be essential for elements built from metal and ‘plastic’ elements.

- There is a new discussion regarding the post-HPP decay of microorganisms, particularly the introduction of the innovative distortion-sensitive analysis.

- The indication of the feedback interactions between research, technological, and socio-economic issues is a characteristic feature of the Industrial Revolution’s epoch.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Allen, R.C. The Industrial Revolution: A Very Short Introduction; OUP Oxford: Oxford, UK, 2017. [Google Scholar]

- Gauch, H.G. Scientific Method in Brief; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Anstey, P.R. The methodological origins of Newton’s queries. Stud. History Philos. Sci. Part A 2004, 35, 247–269. [Google Scholar] [CrossRef]

- Crump, T. A Brief History of the Age of Steam. The Power that Drove Industrial Revolution; Robinson: London, UK, 2007. [Google Scholar]

- Martin, A. Industry 5.0. Introductory Guide to the 5th Industrial Revolution; Editoriale Delfino: Milano, Italy, 2023. [Google Scholar]

- Sojecka, A.A.; Drozd-Rzoska, A. Global population: From Super-Malthus behavior to Doomsday criticality. Sci. Rep. 2024, 14, 9853. [Google Scholar] [CrossRef]

- Malthus, T. An Essay on the Principle of Population (first published in 1798). In Winch; Malthus, D., Ed.; Oxford Univ. Press: Oxford, UK, 1987. [Google Scholar]

- Galor, O. Population, Technology, and growth: From malthusian stagnation to the demographic transition and beyond. Am. Econom. Rev. 2000, 90, 816–828. [Google Scholar] [CrossRef]

- Markert, J. The Malthusian fallacy: Prophecies of doom and the crisis of social security. Soc. Sci. J. 2005, 42, 555–568. [Google Scholar] [CrossRef]

- Weil, D.N.; Wilde, J. How relevant is Malthus for economic development today? Am. Econ. Rev. 2010, 100, 378–382. [Google Scholar] [CrossRef]

- Kaack, L.H.; Katul, G.G. Fifty years to prove Malthus right. Proc. Natl. Acad. Sci. USA 2013, 110, 4161–4416. [Google Scholar] [CrossRef]

- Smith, P. Malthus is still wrong: We can feed a world of 9-10 billion, but only by reducing food demand. Proc. Nutr. Soc. 2015, 74, 187–190. [Google Scholar] [CrossRef]

- Zheng, Y. Malthus’ population theory is still wrong. Chin. Sci. Bull. 2017, 2335–2345. [Google Scholar] [CrossRef][Green Version]

- Kallis, G. Limits: Why Malthus Was Wrong and Why Environmentalists Should Care; Stanford Univ. Press: Stanford, CA, USA, 2019. [Google Scholar]

- Montano, B.; Garcia-López, M.S. Malthusianism of the 21st century. Environ. Sustain. Indicator 2020, 6, 100032. [Google Scholar] [CrossRef]

- Valenze, D. The Invention of Scarcity: Malthus and the Margins of History; Yale University Press: New Heaven, CT, USA, 2023. [Google Scholar]

- Verhulst, P.F. Deuxieme memoire sur la loi d’accroissement de la population. Mem. De L’academie R. Des Sci. Des Lett. Et Des Beaux-Arts De Belg. 1847, 20, 1–32. [Google Scholar] [CrossRef]

- Pearl, R. The growth of populations. Quater. Rev. Biol. 1927, 2, 532–548. [Google Scholar] [CrossRef]

- Iskender, C. Mathematical study of the Verhulst and Gompertz growth functions and their contemporary applications. Ekoist J. Econom. Stat. 2021, 34, 73–102. [Google Scholar] [CrossRef]

- Von Foerster, H.; Mora, P.M.; Amiot, L.W. Doomsday: Friday, 13th November, A.D. 2026. Science 1960, 132, 1291–1295. [Google Scholar] [CrossRef]

- Taagapera, R. People, skills, and resources: An interaction model for world population growth. Technol. Forecast. Soc. Change 1979, 13, 13–40. [Google Scholar] [CrossRef]

- Kendall, B.E.; Fox, G.A.; Fujiwara, M.; Nogeire, T.M. Demographic heterogeneity, cohort selection, and population growth. Ecology 2011, 92, 1985–1995. [Google Scholar] [CrossRef]

- Lima, M.; Berryman, A.A. Positive and negative feedbacks in human population dynamics: Future equilibrium or collapse? Oikos 2011, 120, 1301–1310. [Google Scholar] [CrossRef]

- Lueddeke, G.R. Global Population Health and Well- Being in The 21st Century: Toward New Paradigms, Policy, and Practice; Springer: Berlin, Germany, 2015. [Google Scholar]

- Dias, A.; D’Hombres, M.; Ghisetti, B.; Pontarollo, C.; Dijkstra, N. The Determinants of Population Growth: Literature Review an Empirical Analysis. Working Papers-10; Joint Research Centre, European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Broadberry, S.; Campbell, B.M.S.; Klein, A.; Overton, M.; van Keeuven, B. British Economic Growth, 1270–1870; Cambridge Univ. Press: Cambridge, UK, 2015. [Google Scholar]

- Our World in Data: GDP per Capita in England. Available online: https://ourworldindata.org/grapher/gdp-per-capita-in-the-uk-since-1270 (accessed on 11 August 2024).

- Clark, G. The Condition of the Working-Class in England, 1200–2000: Magna Carta to Tony Blair; 2003; Available online: https://www.researchgate.net/publication/247816806 (accessed on 10 June 2024).

- Huxley, A. Brave New World; Vintage Books: New York, NY, USA, 2004. [Google Scholar]

- Driggers, E.A. The voice of the stomach’: The mind, hypochondriasis and theories of dyspepsia in the nineteenth century. Hist. Psychiatry 2021, 32, 5–99. [Google Scholar] [CrossRef]

- Kirsner, J.B. Blossoming of gastroenterology during the twentieth century. World J. Gastroenterol. 2004, 10, 1541–1542. [Google Scholar] [CrossRef]

- Bulgakov, M. The Master and Margarita; written in years 1928–1940 (in Soviet Union); first limited publication in 1966 (in Soviet Union); Vintage: New York, NY, USA, 1996. [Google Scholar]

- Zumwalt, B. Ketchup, Pickles, Sauces: Nineteenth Century Food in Glass; West Group: Berkeley, CA, USA, 1980. [Google Scholar]

- Thorne, S. The History of Food Preservation; Barnes & Noble: Boston, MA, USA, 1986. [Google Scholar]

- Hunter, N. Luis Pasteur; Raintree Publishers: Oxford, UK, 2014. [Google Scholar]

- Rahman, M.S. Handbook of Food Preservation; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Sun, D.-W. Thermal Food Processing: New Technologies and Quality Issues; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Sen, M. Food Chemistry: The Role of Additives, Preservatives and Adulteration; Wiley and Sons: Hoboken, NJ, USA, 2022. [Google Scholar]

- Muhsin, N.M.B.; Ghafil, R.A.; Hussein, K.M.; Alasady, D. Review on the Impact of Chemical Preservatives on Health. J. Clin. Trials Regul. 2022, 4, 26–32. [Google Scholar]

- Anand, S.P.; Sati, N. Artificial preservatives and their harmful effects: Looking toward nature for safer alternatives. Int. J. Pharm. Sci. Res. 2013, 7, 2496–2501. [Google Scholar]

- Reardon, S. Food preservatives linked to obesity and gut disease. Nature 2015. [Google Scholar] [CrossRef]

- Kobets, T.; Smith, B.P.C.; Williams, G.M. Food-borne chemical carcinogens and the evidence for human cancer risk. Foods 2022, 11, 2828. [Google Scholar] [CrossRef] [PubMed]

- Simmons, A.L.; Schlezinger, J.J.; Corkey, B.E. What are we putting in our food that is making us fat? Food Additives, contaminants, and other putative contributors to obesity. Curr. Obes. Rep. 2014, 3, 273–285. [Google Scholar] [CrossRef]

- Nyambok, E.; Robinson, C. The role of food additives and chemicals in food allergy. Ann. Food Proces. Preserv. 2016, 1, 1006. [Google Scholar]

- Bald, W.B. Food Freezing: Today and Tomorrow; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Evans, J.A. Frozen Food Science and Technology; Wiley-Blackwell: Hoboken, NJ, USA, 2008. [Google Scholar]

- Li, B.; Kawakita, Y.; Ohira-Kawamura, S.; Sugahara, T.; Wang, H.; Wang, J.; Chen, Y.; Kawaguchi, S.I.; Kawaguchi, S.; Ohara, K.; et al. Colossal barocaloric effects in plastic crystals. Nature 2019, 567, 506–510. [Google Scholar] [CrossRef] [PubMed]

- Lloveras, P.; Aznar, A.; Barrio, M.; Negrier, P.; Popescu, C.; Planes, A.; Mañosa, L.; Stern-Taulats, E.; Avramenko, A.; Mathur, N.D.; et al. Colossal barocaloric effects near room temperature in plastic crystals of neopentylglycol. Nat. Commun. 2019, 10, 1803. [Google Scholar] [CrossRef]

- Houška, M.; Silva, F.V.M.; Evelyn; Buckow, R.; Terefe, N.S.; Tonello, C. High pressure processing applications in plant foods. Foods 2022, 11, 223. [Google Scholar] [CrossRef]

- Amsasekar, A.; Mor, R.S.; Kishore, A.; Singh, A.; Sid, S. Impact of high pressure processing on microbiological, nutritional and sensory properties of food: A review. Nutr. Food Sci. 2022, 52, 996–1017. [Google Scholar] [CrossRef]

- Nema, P.K.; Sehrawat, R.; Ravichandran, C.; Kaur, B.P.; Kumar, A.; Tarafdar, A. Inactivating food microbes by high-pressure processing and combined nonthermal and thermal treatment: A review. J. Food Qual. 2022, 2022, 5797843. [Google Scholar] [CrossRef]

- Roobab, U.; Fidalgo, L.G.; Arshad, R.N.; Khan, A.W.; Zeng, X.A.; Bhat, Z.F.; Bekhit, A.E.; Batool, Z.; Aadil, R.M. High-pressure processing of fish and shellfish products: Safety, quality, and research prospects. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3297–3325. [Google Scholar] [CrossRef]

- Nath, K.G.; Pandiselvam, R.; Sunil, C.K. High-pressure processing: Effect on textural properties of food—A review. J. Food Engn. 2023, 351, 111521. [Google Scholar] [CrossRef]

- Silva, F.V. Pasteurization of food and beverages by high pressure processing (hpp) at room temperature: Inactivation of Staphylococcus aureus, Escherichia coli, Listeria monocytogenes, Salmonella, and other microbial pathogens. Appl. Sci. 2023, 13, 1193. [Google Scholar] [CrossRef]

- Ganjeh, A.M.; Moreira, N.; Pinto, C.A.; Casal, S.; Saraiva, J.A. The effects of high-pressure processing on biogenic amines in food: A review. Food Humanit. 2024, 2, 100252. [Google Scholar] [CrossRef]

- Patel, Y.K.; Patel, K.K. High pressure processing. In Novel Technologies in Food Science; Chhikara, N., Panghal, A., Chaudhary, G., Eds.; Wiley: Hoboken, NJ, USA, 2022; Chapter 13. [Google Scholar]

- Lim, S.H.; Chin, N.L.; Sulaiman, A.; Tay, C.H.; Wong, T.H. Microbiological, physicochemical and nutritional properties of fresh cow milk treated with industrial high-pressure processing (hpp) during storage. Foods 2023, 12, 592. [Google Scholar] [CrossRef]

- Goraya, R.K.; Singla, M.; Kaura, R.; Singh, C.B.; Singh, A. Exploring the impact of high pressure on the characteristics of processed fruit and vegetable products: A comprehensive review. Crit. Rev. Food Sci. Nutr. 2024, 1–24. [Google Scholar] [CrossRef]

- Xiao, T.; Li, Y.; Zheng, Z.; Hu, l.; Zhu, S.; Ramaswamy, H.S.; Yu, Y. High pressure sub-zero temperature concept for improving microbial safety and maintaining food quality: Background fundamentals, equipment issues and applications. Food. Rev. Int. 2024, 1–21. [Google Scholar] [CrossRef]

- Keyata, E.O.; Bikila, A.M. Effect of high-pressure processing on nutritional composition, microbial safety, shelf life and sensory properties of perishable food products: A review. J. Agric. Food. Nat. Res. 2024, 2, 69–78. [Google Scholar]

- Kateh, A.-A.; Purnomo, E.H.; Hasanah, U. Meta-analysis: Microbial inactivation in milk using high-pressure processing (HPP). Int. J. Food Sci. Technol. 2024, 59, 4185–4193. [Google Scholar] [CrossRef]

- Waghmare, R. High pressure processing of fruit beverages: A recent trend. Food Humanit. 2024, 2, 100232. [Google Scholar] [CrossRef]

- Bai, C.; Chen, R.; Chen, Y.; Bai, H.; Sun, H.; Li, D.; Wu, W.; Wang, Y.; Gong, M. Plant polysaccharides extracted by high pressure: A review on yields, physicochemical, structure properties, and bioactivities. Int. J. Biol. Macromol. Part 2 2024, 263, 129939. [Google Scholar] [CrossRef]

- Braspaiboon, S.; Laokuldilok, T. High hydrostatic pressure: Influences on allergenicity, bioactivities, and structural and functional properties of proteins from diverse food sources. Foods 2024, 13, 922. [Google Scholar] [CrossRef] [PubMed]

- Russo, G.L.; Langelolotti, A.L.; Torrieri, E.; Masi, P. Emerging technologies in seafood processing: An overview of innovations reshaping the aquatic food industry. Compr. Rev. Food Sci. Food Saf. 2024, 23, e13281. [Google Scholar] [CrossRef] [PubMed]

- Gazda, P.; Glibowski, P. Advanced technologies in food processing—Development perspective. Appl. Sci. 2024, 14, 3617. [Google Scholar] [CrossRef]

- Yang, P.; Liao, X. High pressure processing plus technologies: Enhancing the inactivation of vegetative microorganisms. Adv. Food Nutr. Rev. 2024, 110, 145–195. [Google Scholar]

- Zuo, H.; Wang, B.; Zhang, J.; Zhong, Z.; Tang, Z. Research progress on bacteria-reducing pretreatment technology of meat. Foods 2024, 13, 2361. [Google Scholar] [CrossRef]

- Windyga, B.; Rutkowska, M.; Sokołowska, B.; Skąpska, S.; Wesołowska, A.; Wilińska, M.; Fonberg-Broczek, M.; Rzoska, S.J. Inactivation of Staphylococcus aureus and native microflora in human milk by high pressure processing. High Press. Res. 2015, 36, 181–188. [Google Scholar] [CrossRef]

- Rzoska, S.J.; Musiał, F.; Rutkowska, M.; Fonberg-Broczek, M.; Sokołowska, B.; Drozd-Rzoska, A.; Nowakowska, J. Simultaneous impact of high pressures and pulsed electric field on Saccharomyces cerevisiae model system. J. Food Process. Technol. 2015, 6, 1000518. [Google Scholar]

- Martinez-Garcia, J.C.; Rzoska, S.J.; Drozd-Rzoska, A.; Martinez-Garcia, J. A universal description of ultraslow glass dynamics. Nat. Comm. 2013, 4, 1823. [Google Scholar] [CrossRef]

- Drozd-Rzoska, A. Universal behavior of the apparent fragility in ultraslow glass forming systems. Sci. Rep. 2019, 9, 6816. [Google Scholar] [CrossRef] [PubMed]

- Hite, B.H. The effect of pressure in the preservation of milk. West Va. Agric. Exp. Stn. Bull. 1899, 58. Available online: https://researchrepository.wvu.edu/wv_agricultural_and_forestry_experiment_station_bulletins/58/?utm_source=researchrepository.wvu.edu%2Fwv_agricultural_and_forestry_experiment_station_bulletins%2F58&utm_medium=PDF&utm_campaign=PDFCoverPages (accessed on 10 June 2024).

- Bridgeman, P.W. The coagulation of albumen by pressure. J. Biol. Chem. 1912, 19, 511–512. [Google Scholar] [CrossRef]

- Bridgeman, P.W. General Survey of Certain Results in the Field of High-Pressure Physics. Nobel Prize in Physics Lecture. 1946. Available online: https://www.nobelprize.org/uploads/2018/06/bridgman-lecture.pdf (accessed on 20 June 2024).

- Suzuki, A. High pressure-processed foods in Japan and the world. In Progress in Biotechnology; Hayashi, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2002; pp. 365–374. [Google Scholar]

- Farkas, D.F. A Short history of research and development efforts leading to the commercialization of high-pressure processing of food. In High Pressure Processing of Food; Food Engineering Series; Balasubramaniam, V., Barbosa-Cánovas, G., Lelieveld, H., Eds.; Springer: New York, NY, USA, 2016. [Google Scholar]

- Cognitive Market Research. Food Processing Food Market Report 2024. Available online: https://www.cognitivemarketresearch.com/food-processing-food-market-report (accessed on 15 August 2024).

- Sokołowska, B.; Skąpska, S.; Niezgoda, J.; Rutkowska, M.; Dekowska, A.; Rzoska, S.J. Inactivation and sublethal injury of Escherichia coli and Listeria innocua by high hydrostatic pressure in model suspensions and beetroot juice. High Press. Res. 2014, 34, 147–155. [Google Scholar] [CrossRef]

- Starzonek, S.; Rutkowska, M.; Rzoska, S.J.; Drozd-Rzoska, A.; Fonberg-Broczek, M.; Sokołowska, B.; Martinez-Garcia, J.C. Dielectric spectroscopy of pressurized Saccharomyces cerevisiae. Food Biophys. 2014, 140, 229–234. [Google Scholar] [CrossRef] [PubMed]

- Rzoska, S.J.; Rosiak, E.; Rutkowska, M.; Drozd-Rzoska, A.; Wesołowska, A.; Borszewska-Kornacka, M.K. Comments on the high pressure preservation of human milk. Food Sci. Nutr. Stud. 2017, 1, 17. [Google Scholar] [CrossRef]

- Wesołowska, A.; Sinkiewicz-Darol, E.; Barbarska, O.; Strom, K.; Rutkowska, M.; Karzel, K.; Rosiak, E.; Olędzka, G.; Orczyk-Pawiłowicz, M.; Rzoska, S.J.; et al. New achievements in high-pressure processing to preserve human milk bioactivity. Front. Pediatr. 2018, 6, 323. [Google Scholar] [CrossRef]

- Heinz, V.; Buckow, R. Food preservation by high pressure. J. Verbr. Lebensm. 2010, 5, 73–81. [Google Scholar] [CrossRef]

- Koutchma, T.; Guo, B.; Patazca, E.; Parisi, B. High pressure-high temperature sterilization: From kinetic analysis to process verification. J. Food Proc. Eng. 2005, 28, 610–629. [Google Scholar] [CrossRef]

- The Authors Personal Discussions with Eng. Jacek Arabas, the Head of Unipress Equipment (Unit IHPP PAS), One of Leading Producers of Laboratory High Pressure Equipment in EU (Non-Published). Available online: https://ue.unipress.waw.pl/ (accessed on 20 July 2024).

- Juliano, P.; Koutchma, T.; Sui, Q.; Barbosa-Cánovas, G.V.; Sadler, G. Polymeric-based food packaging for high-pressure processing. Food Eng. Rev. 2010, 2, 274–297. [Google Scholar] [CrossRef]

- Rzoska, S.J.; Mazur, V.; Drozd-Rzoska, A. Metastable Systems under Pressure; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- de Gennes, P.G. Soft Matter. Nobel Prize for Physics Lecture. 1991. Available online: https://www.nobelprize.org/prizes/physics/1991/gennes/lecture/ (accessed on 10 June 2024).

- Mezzenga, R.; Schurtenberger, P.; Burbidge, A.; Michel, M. Understanding foods as soft materials. Nat. Mater. 2005, 4, 729–740. [Google Scholar] [CrossRef]

- Teixeira, A.A. Thermal food preservation techniques (pasteurization, sterilization, canning and blanching. In Conventional and Advanced Food Processing Technologies; Bhattacharya, S., Ed.; Wiley: New York, NY, USA, 2014; Chapter 6. [Google Scholar]

- Smeller, L.; Heremans, K. Some thermodynamic and kinetic consequences of the phase diagram of protein denaturation. In High Pressure Research in Bioscience and Biotechnology; Heremans, K., Ed.; Leuven Univ. Press: Leuven, Belgium, 1997; pp. 55–58. [Google Scholar]

- Heremans, K.; Smeller, L. Proteins in structure and dynamics at high pressure. Biochim. Biophys. Acta (BBA) Protein Struct. Molec. Enzymol. 1998, 1386, 353–370. [Google Scholar] [CrossRef]

- Stanley, H.E. Introduction to Phase Transitions; Oxford Univ. Press: Oxford, UK, 1987. [Google Scholar]

- Imre, A.R.; Drozd-Rzoska, A.; Kraska, T.; Rzoska, S.J.; Yelas, L.V. Liquids under absolute negative pressure. In Complex Systems in Natural and Social Sciences; Hideg, E., Martinas, K., Moreau, M., Meyer, D., Eds.; ELFT: Budapest, Hungary, 2003. [Google Scholar]

- Imre, A.R.; Drozd-Rzoska, A.; Horvath, A.; Kraska, T.; Rzoska, S.J. Solid-fluid phase transitions under extreme pressures including negative ones. J. Non-Cryst. Solids 2008, 354, 4157–4162. [Google Scholar] [CrossRef]

- Debenedetti, P.G. Metastable Liquids: Concepts and Principle; Cambridge Univ. Press: Cambridge, UK, 1997. [Google Scholar]

- Drozd-Rzoska, A. Pressure dependence of the glass temperature in supercooled liquids. Phys. Rev. E 2005, 72, 041505. [Google Scholar] [CrossRef] [PubMed]

- Drozd-Rzoska, A.; Rzoska, S.J.; Kalabiński, J. The impact of pressure on low molecular weight near-critical mixtures of limited miscibility. ACS Omega 2020, 5, 20141–20152. [Google Scholar] [CrossRef] [PubMed]

- Rzoska, S.J.; Drozd-Rzoska, A.; Kalabiński, J. Critical concentration in binary mixtures of limited miscibility. Fluid Phase Equilibria 2021, 540, 112979. [Google Scholar] [CrossRef]

- Drozd-Rzoska, A.; Rzoska, S.J.; Łoś, J. Supercriticality, glassy dynamics, and the new insight into melting/freezing discontinuous transition in linseed oil. Biophysica 2024, 4, 34–57. [Google Scholar] [CrossRef]

- Brouwer, A.F.; Eisenberg, M.C.; Remais, J.V.; Collender, P.A.; Meza, R.; Eisenberg, J.N.S. Modeling Biphasic environmental decay of pathogens and implications for risk analysis. Environ. Sci. Technol. 2017, 51, 2186–2196. [Google Scholar] [CrossRef]

- Mújica-Paz, H.; Valdez-Fragoso, A.; Samson, C.T.; Welti-Chanes, J.; Torres, J.A. High-pressure processing technologies for the pasteurization and sterilization of foods. Food Bioprocess. Technol. 2011, 4, 969–985. [Google Scholar] [CrossRef]

- Govaris, A.; Pexara, A. Inactivation of foodborne viruses by high-pressure processing (HPP). Foods 2021, 10, 215. [Google Scholar] [CrossRef]

- Meyer, R.S.; Cooper, K.L.; Knorr, D.; Lelieveld, H.L.M. High-Pressure Sterilization of Foods. Food Technol. Mag. 2000. Available online: https://www.ift.org/news-and-publications/food-technology-magazine/issues/2000/november/features/high-pressure-sterilization-of-foods (accessed on 10 June 2024).

- Hyperbaric Company: HPP Blog. High Pressure Thermal Processing (HPTP). 2014. Available online: https://www.hiperbaric.com/en/high-pressure-thermal-processing-hptp/ (accessed on 10 June 2024).

- Strässle, T.; Furrer, A.; Müller, K.A. Cooling by adiabatic application of pressure—The barocaloric effect. Phys. B Cond. Matt. 2000, 276–278, 944–945. [Google Scholar] [CrossRef]

- Dai, Z.; She, X.; Shao, B.; Yin, E.; Ding, Y.; Li, Y.; Zhang, X.; Zhao, D. Plastic crystal neopentyl glycol/multiwall carbon nanotubes composites for highly efficient barocaloric refrigeration system. J. Therm. Sci. 2024, 33, 383–393. [Google Scholar] [CrossRef]

- Zhu, L.; Dai, Z.; Gao, Y. Barocaloric material with high thermal conductivity for room-temperature refrigeration. J. Therm. Sci. 2022, 32, 2115–2125. [Google Scholar] [CrossRef]

- Lin, J.; Tong, P.; Zhang, K.; Tao, K.; Lu, W.; Wang, X.; Zhang, X.; Song, W.; Sun, Y. Colossal and reversible barocaloric effect in liquid-solid-transition materials n-alkanfes. Nat. Commun. 2022, 13, 596. [Google Scholar] [CrossRef]

- The Presentation of X-PressMatter Lab for Pressurized Foods and Soft Matter. Available online: https://young4softmatter.pl/ (accessed on 10 June 2024).

- Drozd-Rzoska, A.; Kalabiński, J.; Rzoska, S.J. Critical model-insight into broadband dielectric properties of neopentyl glycol (NPG). Materials 2014, 17, 4144. [Google Scholar] [CrossRef]

- Drozd-Rzoska, A.; Rzoska, S.J.; Imre, A.R. On the pressure evolution of the melting temperature and the glass transition temperature. J. Non-Cryst. Solids 2007, 353, 3915–3923. [Google Scholar] [CrossRef]

- Łoś, J.; Drozd-Rzoska, A.; Rzoska, S.J.; Starzonek, S.; Czupryński, K.; Mukherjee, P.K. Near-continuous isotropic—Nematic transition in compressed rod-like liquid crystal based nanocolloid. J. Mol. Liq. 2023, 382, 121884. [Google Scholar] [CrossRef]

- Sawale, M.; Benyathiar, P.; Coronel, P.; Rawat, A.; Simunovic, J.; Ozadali, F.; Mishra, D.K. Aseptic microwave sterilization and validation of food containing particles. Food Bioprod. Process. 2024, 143, 28–35. [Google Scholar] [CrossRef]

- Astráin-Redín, L.; Ospina, S.; Cebrián, G.; Álvarez-Lanzarote, I. Ohmic heating technology for food applications, from ohmic systems to moderate electric fields and pulsed electric fields. Food Eng. Rev. 2024, 16, 225–251. [Google Scholar] [CrossRef]

- Global Trends in High Pressure Processing (HPP) for 2019. Available online: https://www.hiperbaric.com/en/global-trends-in-hpp-for-2019/ (accessed on 10 June 2024).

- The Future of High-Pressure Processing. Available online: https://www.refrigeratedfrozenfood.com/articles/94091-the-future-of-high-pressure-processing (accessed on 10 June 2024).

- Iqbal, A.; Murtaza, A.; Pinto, C.A.; Saraiva, J.A.; Liu, X.; Zhu, Z.; Lorenzo, J.M.; Marszałek, K. High-pressure processing for food preservation. In Innovative and Emerging Technologies in the Bio-Marine Food Sector; Garcia-Vaquero, M., Rajauria, G., Eds.; Academic Press: New York, NY, USA, 2022; Chapter 22. [Google Scholar]

- Tao, Y.; Sun, D.-.W.; Hogan, E.; Kelly, A.L. High-pressure processing of foods: An overview. In Emerging Technologies for Food Processing; Sun, D.-W., Ed.; Academic Press: New York, NY, USA, 2014; Chapter I. [Google Scholar]

- Pinto, C.A.; Moreira, S.A.; Fidalgo, L.G.; Inácio, R.S.; Barba, F.J.; Saraiva, J.A. Effects of high-pressure processing on fungi spores: Factors affecting spore germination and inactivation and impact on ultrastructure. Comp. Rev. Food Sci. Food Saf. 2020, 19, 553–573. [Google Scholar] [CrossRef]

- Khan, A.W.; Roobab, U.; Wang, Z.; Raza, M.M.; Nawazish, H.; Islam, F.; Aadil, R.M. Salt reduction in food products: A systematic review of clean-label ingredients and non-thermal technologies. Trends Food Sci. Technol. 2024, 153, 104695. [Google Scholar] [CrossRef]

- European Commission: An Agenda for a Climate-Smart and Sustainable Food System for a Healthy Europe Recipe for Change: Recipe for Change & An Agenda for a Climate-Smart and Sustainable Food System for a Healthy Europe. In European Commission Report of the FOOD 2030 Expert Group; European Commission: Brussels, Belgium. [CrossRef]

- Available online: https://www.linkedin.com/pulse/2032-high-pressure-processing-hpp-equipment-yyxpf/ (accessed on 10 June 2024).

- Global High Pressure Procesing Food Market. Available online: https://www.imrmarketreports.com/reports/high-pressure-processing-hpp-food-market (accessed on 10 June 2024).

- Lerouge, S. Sterilisation of Biomaterials and Medical Devices; Woodheard Publ.: Cambridge, UK, 2012. [Google Scholar]

- Dzwolak, W.; Smoleń, B.; Klein, E.; Dzięcielewski, I.; Rzoska, S.J.; Wierezbki, M. Method of Food Modification. Patent WO2017090008A1, 9 June 2017. [Google Scholar]

- Dzwolak, W.; Smoleń, B.; Klein, E.; Dzięcielewski, I.; Rzoska, S.J.; Wierezbki, M. Sposób Modyfikacji Pokarmu. Patent 234231, 6 May 2017. [Google Scholar]

- Ganea, M.; Vicaș, L.G.; Gligor, O.; Sarac, I.; Onisan, E.; Nagy, C.; Moisa, C.; Ghotea, T.C. Exploring the therapeutic efficacy of parsley (Petroselinum crispum mill.) as a functional food: Implications in immunological tolerability, reduction of muscle cramps, and treatment of dermatitis. Molecules 2024, 29, 608. [Google Scholar] [CrossRef] [PubMed]

- Rzoska, S.J.; Drozd-Rzoska, A.; Windyga, B. ‘Wysokociśnieniowy koktajl z zielonej natki pietruszki’ (Eng.: High Pressure Coctail from Green Parsley). Patent 230318, 18 July 2014. [Google Scholar]

- Sokołowska, B.; Nasiłowska, J.; Rutkowska, M.; Fonberg-Broczek, M.; Rzoska, S.J. The usage of high hydrostatic pressure, (HPP) to control food-borne pathogens in hummus. High Press. Res. 2019, 39, 525–532. [Google Scholar] [CrossRef]

- Knudsen, J.C.; Skibsted, L.H. High pressure effects on the structure of casein micelles in milk as studied by cryo-transmission electron microscopy. Food Chem. 2010, 119, 202–208. [Google Scholar] [CrossRef]

- Serna-Hernandez, S.O.; Escobedo-Avellaneda, Z.; García-García, R.; de Jesús Rostro-Alanis, M.; Welti-Chanes, J. Microscopical Evaluation of the Effects of High-Pressure Processing on Milk Casein Micelles. Molecules 2022, 27, 7179. [Google Scholar] [CrossRef] [PubMed]

- Wegener, G. ‘Let food be thy medicine, and medicine be thy food’. Hippocrates revisted. Acta Neuropsych. 2014, 26, 103. [Google Scholar] [CrossRef]

- Płace Rekordowo Wysokie, ale Zatrudnienie Spada Coraz Szybciej. Available online: https://www.bankier.pl/wiadomosc/Przecietne-wynagrodzenie-i-zatrudnienie-w-Polsce-w-marcu-2024-8732945.html (accessed on 20 July 2024).

- Int. Monetary Fund, Statista. Available online: https://x.com/StateOfPoland/status/1698949868494979454/photo/1 (accessed on 10 August 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sojecka, A.A.; Drozd-Rzoska, A.; Rzoska, S.J. Food Preservation in the Industrial Revolution Epoch: Innovative High Pressure Processing (HPP, HPT) for the 21st-Century Sustainable Society. Foods 2024, 13, 3028. https://doi.org/10.3390/foods13193028

Sojecka AA, Drozd-Rzoska A, Rzoska SJ. Food Preservation in the Industrial Revolution Epoch: Innovative High Pressure Processing (HPP, HPT) for the 21st-Century Sustainable Society. Foods. 2024; 13(19):3028. https://doi.org/10.3390/foods13193028

Chicago/Turabian StyleSojecka, Agata Angelika, Aleksandra Drozd-Rzoska, and Sylwester J. Rzoska. 2024. "Food Preservation in the Industrial Revolution Epoch: Innovative High Pressure Processing (HPP, HPT) for the 21st-Century Sustainable Society" Foods 13, no. 19: 3028. https://doi.org/10.3390/foods13193028

APA StyleSojecka, A. A., Drozd-Rzoska, A., & Rzoska, S. J. (2024). Food Preservation in the Industrial Revolution Epoch: Innovative High Pressure Processing (HPP, HPT) for the 21st-Century Sustainable Society. Foods, 13(19), 3028. https://doi.org/10.3390/foods13193028