Physicochemical, Textural, and Antioxidant Attributes of Yogurts Supplemented with Black Chokeberry: Fruit, Juice, and Pomace

Abstract

:1. Introduction

2. Materials and Methods

2.1. Milk, Starter Culture, Black Chokeberry: Fruit, Juice, and Pomace

2.2. Production of Yogurt Supplemented with Black Chokeberry

2.3. Physicochemical Analysis

2.4. Texture Analysis

2.5. Antioxidant Activity

2.6. Sensory Evaluation

2.7. Statistical Evaluation

3. Results and Discussion

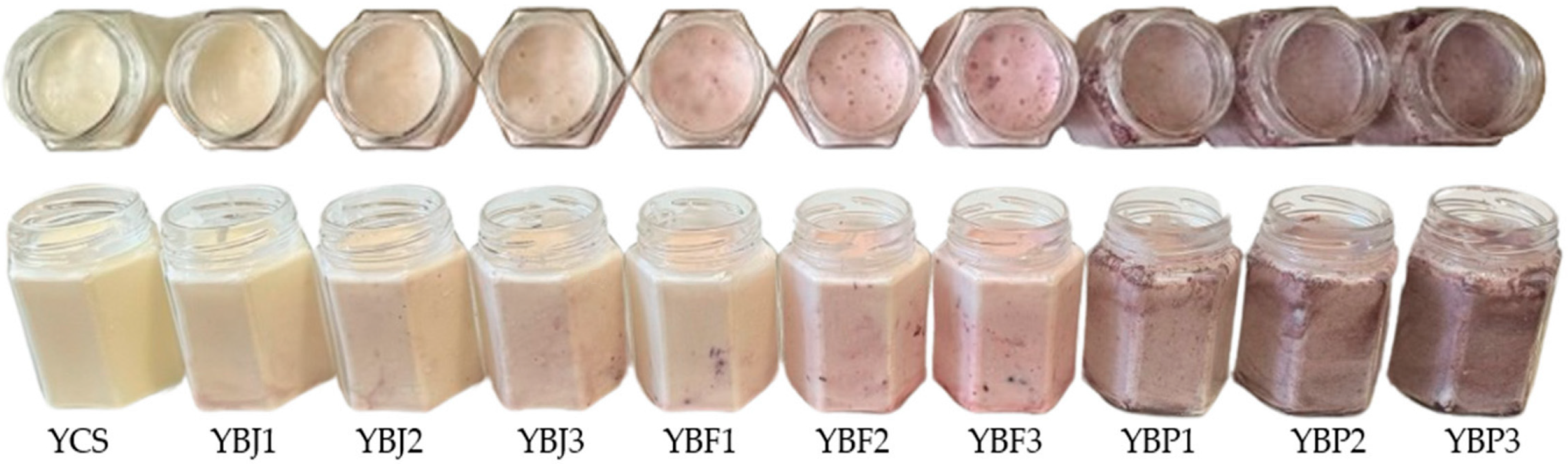

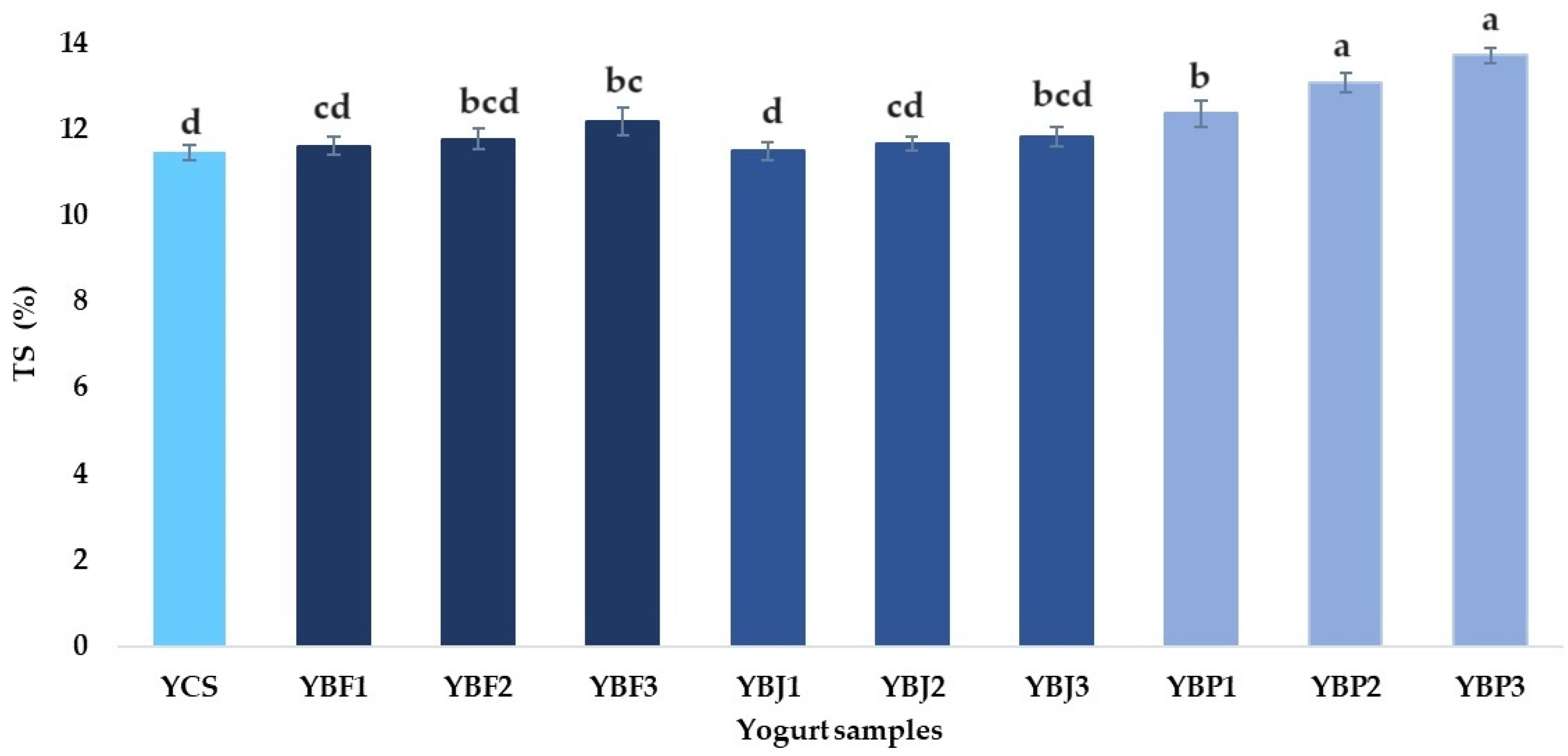

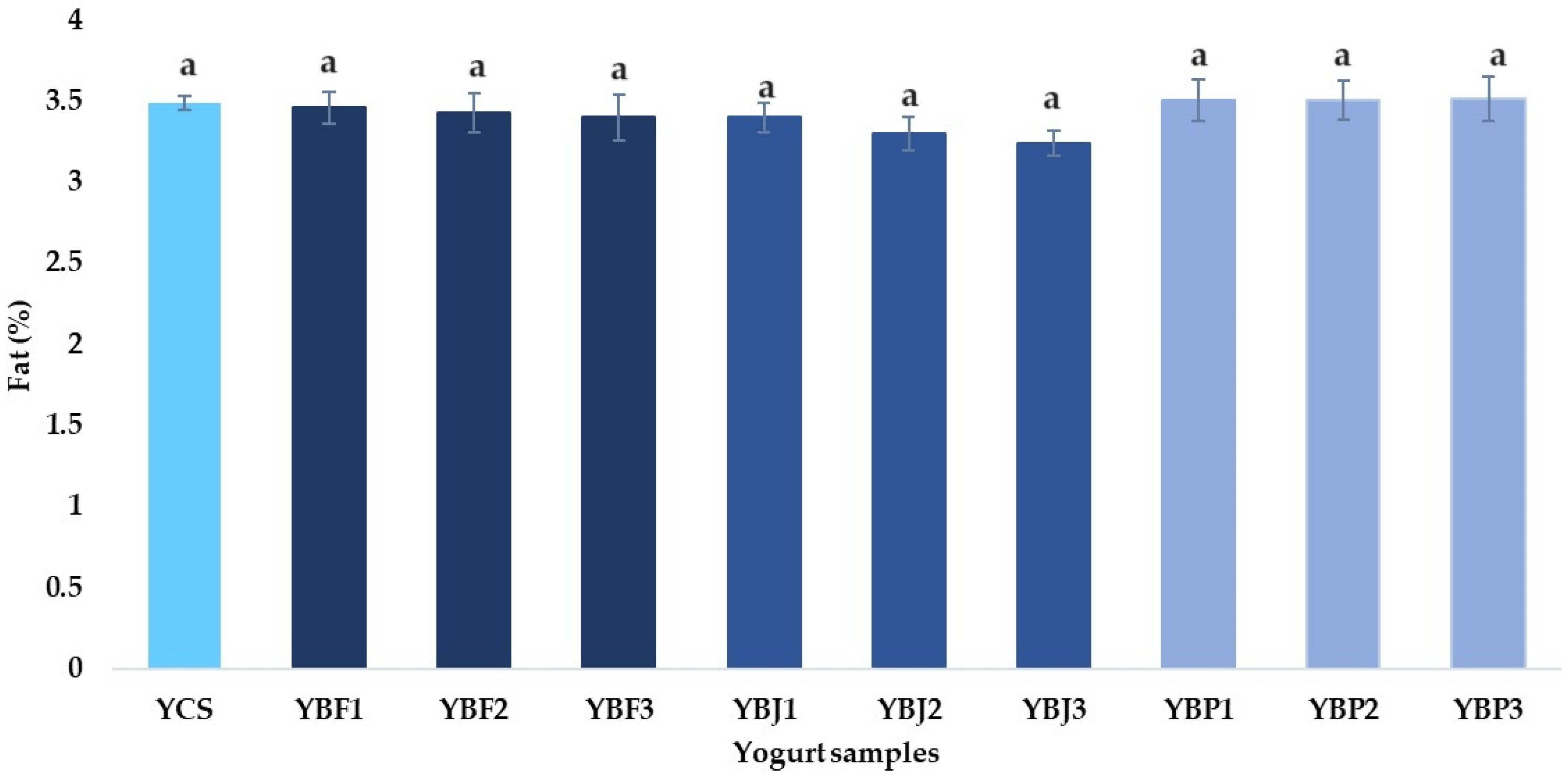

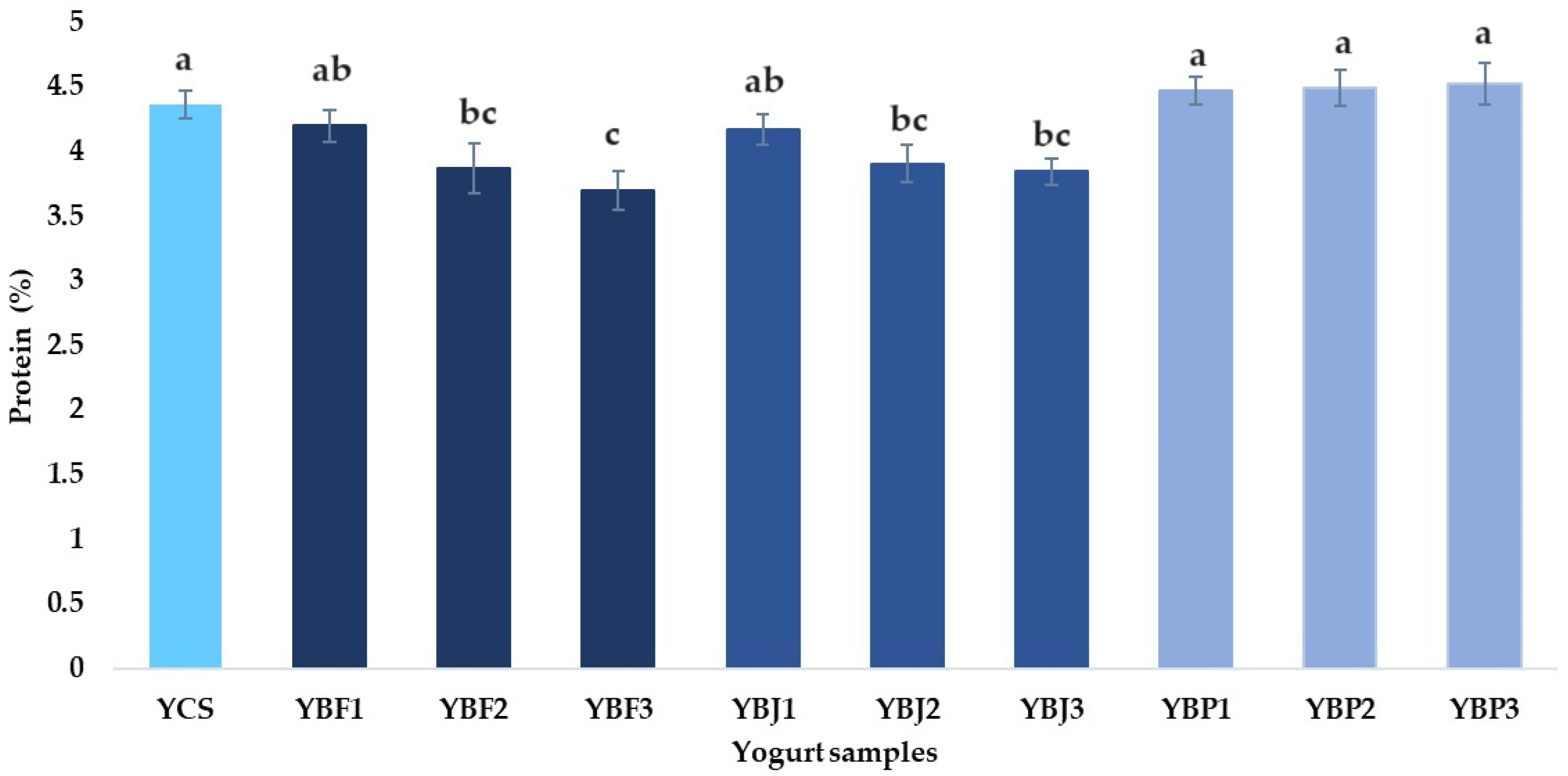

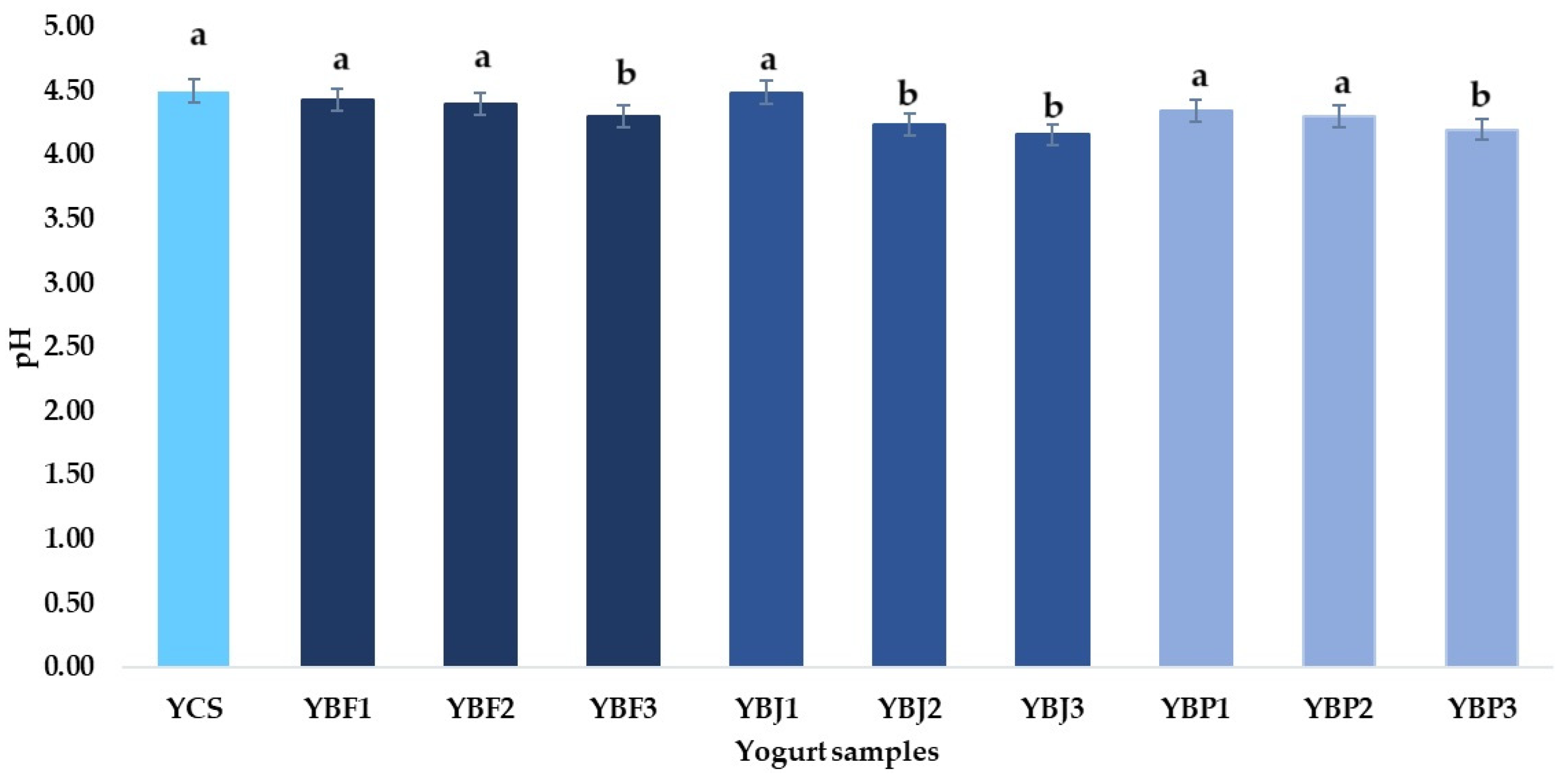

3.1. Physicochemical Characteristics of Yogurts Supplemented with Black Chokeberry

3.2. Texture Analysis of Yogurts Supplemented with Black Chokeberry

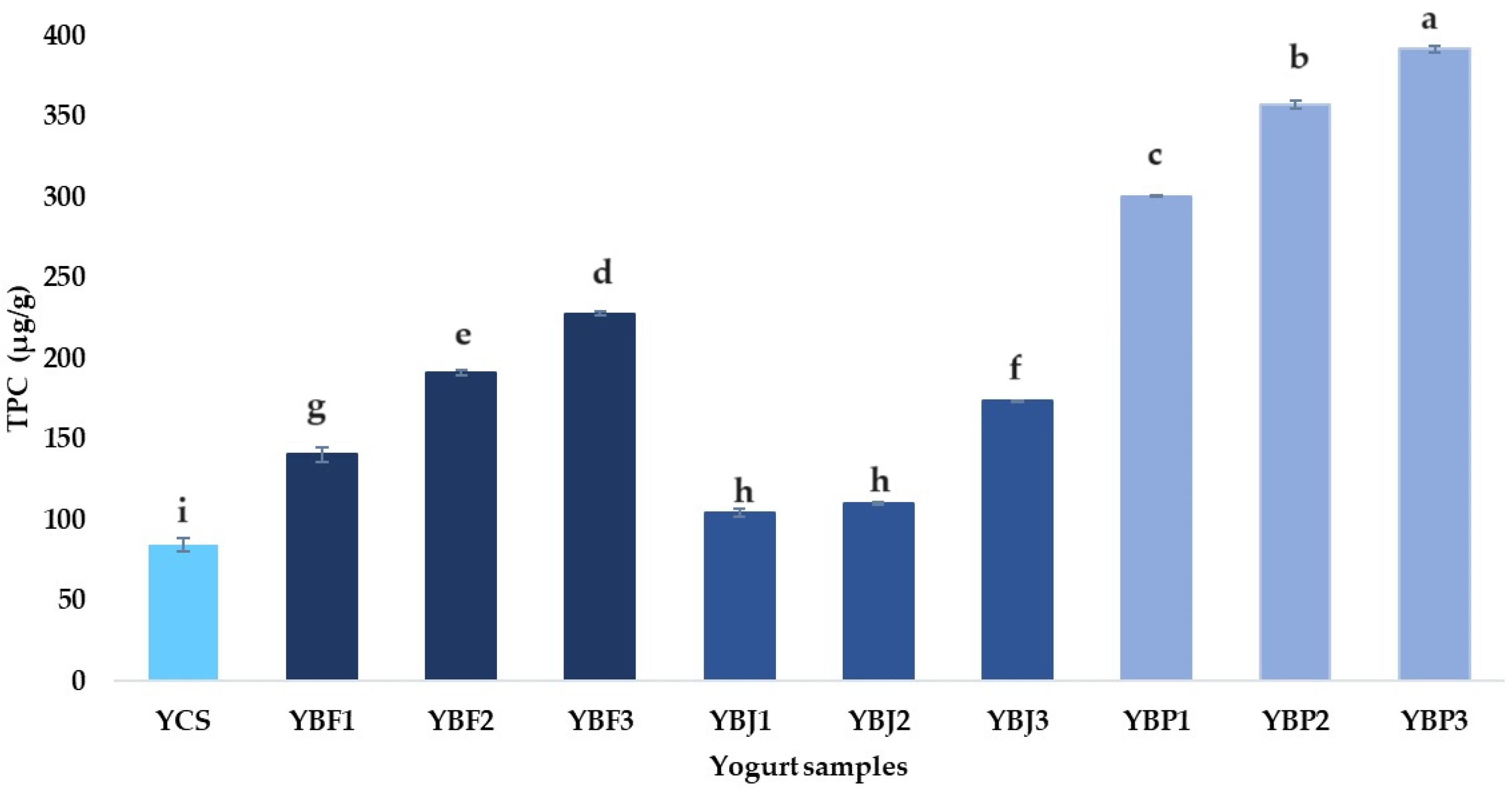

3.3. Evaluation of the Antioxidant Activity of Yogurts Supplemented with Black Chokeberry

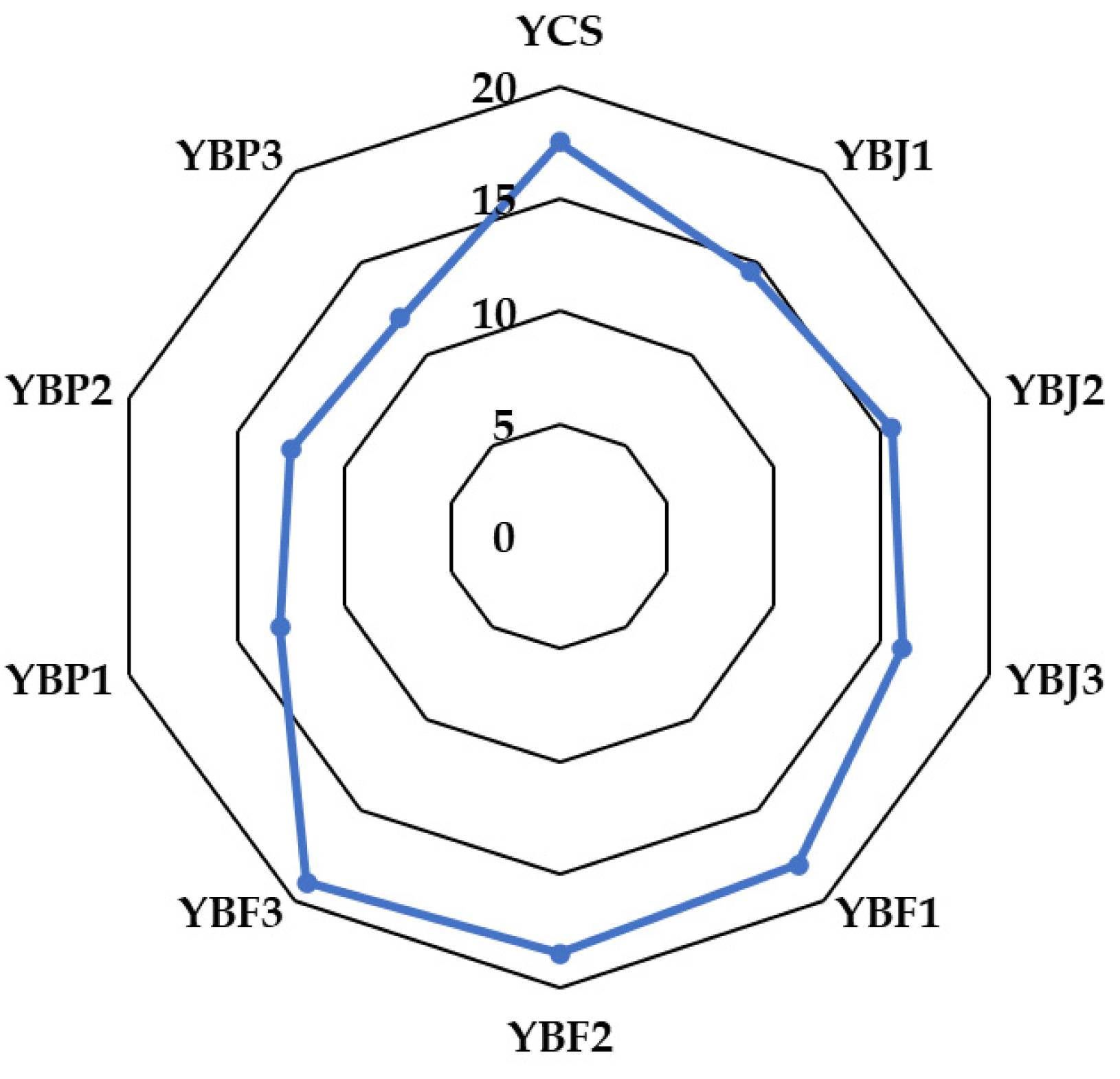

3.4. Sensory Evaluation

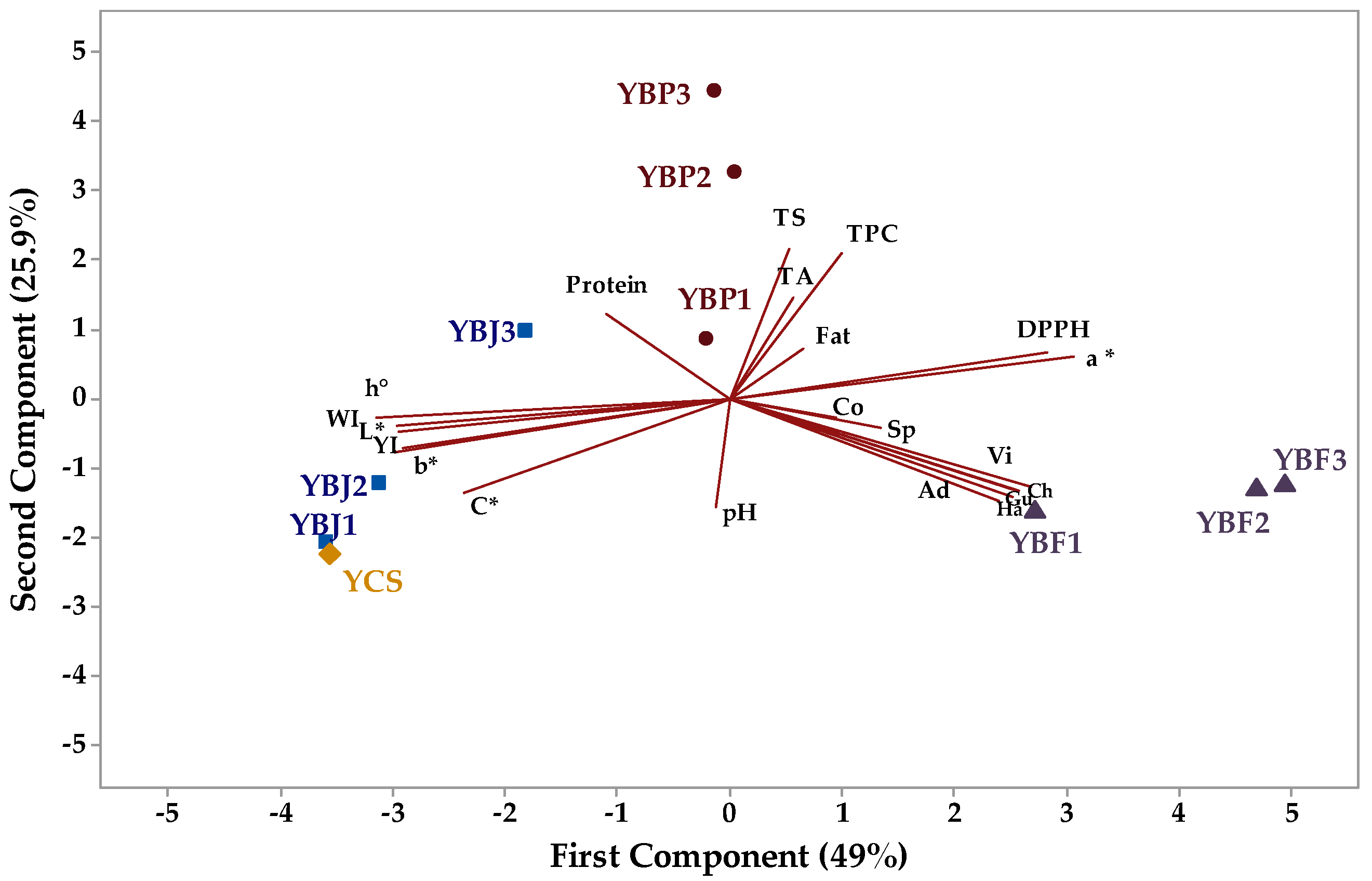

3.5. Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dulf, F.V.; Vodnar, D.C.; Dulf, E.H.; Diaconeasa, Z.; Socaciu, C. Liberation and recovery of phenolic antioxidants and lipids in chokeberry (Aronia melanocarpa) pomace by solid-state bioprocessing using Aspergillus niger and Rhizopus oligosporus strains. LWT 2018, 87, 241–249. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Y.; Liu, X.; Chen, X.; Ding, C.; Dong, L.; Zhang, J.; Sun, S.; Ding, O.; Khatoom, S.; et al. Chokeberry (Aronia melanocarpa) as a new functional food relationship with health: An overview. J. Future Foods 2021, 1, 168–178. [Google Scholar] [CrossRef]

- Dinu, M.D.; Mazilu, I.E.; Cosmulescu, S. Influence of Climatic Factors on the Phenology of Chokeberry Cultivars Planted in the Pedoclimatic Conditions of Southern Romania. Sustainability 2022, 14, 4991. [Google Scholar] [CrossRef]

- Lei, W.A.N.G.; Rui, W.A.N.G.; Jinxu, D.O.N.G.; Yikai, W.A.N.G.; Huang, X.; Changbao, C.H.E.N. Research on the extraction, purification and determination of chemical components, biological activities, and applications in diet of black chokeberry (Aronia melanocarpa). Chin. J. Anal. Chem. 2023, 51, 100301. [Google Scholar]

- Saracila, M.; Untea, A.E.; Oancea, A.G.; Varzaru, I.; Vlaicu, P.A. Comparative Analysis of Black Chokeberry (Aronia melanocarpa L.) Fruit, Leaves, and Pomace for Their Phytochemical Composition, Antioxidant Potential, and Polyphenol Bioaccessibility. Foods 2024, 13, 1856. [Google Scholar] [CrossRef]

- Dragomir, D.; Dogaru, M.; Călinită, C.; Hoza, D.; Stănică, F.; Peticilă, A.G.; Ion, L. Preliminary results regarding the behavior of some chokeberry cultivars (Aronia melanocarpa) in organic system. Sci. Pap. Ser. B Hortic. 2022, 66, 80–84. [Google Scholar]

- Sidor, A.; Drożdżyńska, A.; Gramza-Michałowska, A. Black chokeberry (Aronia melanocarpa) and its products as potential health-promoting factors—An overview. Trends Food Sci. Technol. 2019, 89, 45–60. [Google Scholar] [CrossRef]

- Gao, N.; Shu, C.; Wang, Y.; Tian, J.; Lang, Y.; Jin, C.; Cui, X.; Jiang, H.; Liu, S.; Li, Z.; et al. Polyphenol components in black chokeberry (Aronia melanocarpa) as clinically proven diseases control factors—An overview. Food Sci. Hum. Wellness 2024, 13, 1152–1167. [Google Scholar] [CrossRef]

- Buda, V.; Brezoiu, A.-M.; Berger, D.; Pavel, I.Z.; Muntean, D.; Minda, D.; Dehelean, C.A.; Soica, C.; Diaconeasa, Z.; Folescu, R.; et al. Biological Evaluation of Black Chokeberry Extract Free and Embedded in Two Mesoporous Silica-Type Matrices. Pharmaceutics 2020, 12, 838. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Combrzyński, M.; Biernacka, B.; Różyło, R.; Bąkowski, M.; Wojtunik-Kulesza, K.; Mołdoch, J.; Kowalska, I. Fresh Chokeberry (Aronia melanocarpa) Fruits as Valuable Additive in Extruded Snack Pellets: Selected Nutritional and Physiochemical Properties. Plants 2023, 12, 3276. [Google Scholar] [CrossRef]

- Oziembłowski, M.; Trenka, M.; Czaplicka, M.; Maksimowski, D.; Nawirska-Olszańska, A. Selected Properties of Juices from Black Chokeberry (Aronia melanocarpa L.) Fruits Preserved Using the PEF Method. Appl. Sci. 2022, 12, 7008. [Google Scholar] [CrossRef]

- Grunovaitė, L.; Pukalskienė, M.; Pukalskas, A.; Venskutonis, P.R. Fractionation of black chokeberry pomace into functional ingredients using high pressure extraction methods and evaluation of their antioxidant capacity and chemical composition. J. Funct. Foods 2016, 24, 85–96. [Google Scholar] [CrossRef]

- D’Alessandro, L.G.; Dimitrov, K.; Vauchel, P.; Nikov, I. Kinetics of ultrasound assisted extraction of anthocyanins from Aronia melanocarpa (black chokeberry) wastes. Chem. Eng. Res. Des. 2014, 92, 1818–1826. [Google Scholar] [CrossRef]

- Cacak-Pietrzak, G.; Dziki, D.; Gawlik-Dziki, U.; Parol-Nadłonek, N.; Kalisz, S.; Krajewska, A.; Stępniewska, S. Wheat Bread Enriched with Black Chokeberry (Aronia melanocarpa L.) Pomace: Physicochemical Properties and Sensory Evaluation. Appl. Sci. 2023, 13, 6936. [Google Scholar] [CrossRef]

- Babaoğlu, A.S.; Unal, K.; Dilek, N.M.; Poçan, H.B.; Karakaya, M. Antioxidant and antimicrobial effects of blackberry, black chokeberry, blueberry, and red currant pomace extracts on beef patties subject to refrigerated storage. Meat Sci. 2022, 187, 108765. [Google Scholar] [CrossRef]

- Schmid, V.; Mayer-Miebach, E.; Behsnilian, D.; Briviba, K.; Karbstein, H.P.; Emin, M.A. Enrichment of starch-based extruded cereals with chokeberry (Aronia melanocarpa) pomace: Influence of processing conditions on techno-functional and sensory related properties, dietary fibre and polyphenol content as well as in vitro digestibility. LWT 2022, 154, 112610. [Google Scholar] [CrossRef]

- Nemetz, N.J.; Schieber, A.; Weber, F. Application of crude pomace powder of chokeberry, bilberry, and elderberry as a coloring foodstuff. Molecules 2021, 26, 2689. [Google Scholar] [CrossRef]

- Ghinea, C.; Leahu, A. Life cycle assessment of fermented milk: Yogurt production. Ovidius Univ. Ann. Chem. 2020, 31, 49–54. [Google Scholar] [CrossRef]

- Iqbal, A.; Schulz, P.; Rizvi, S.S. Valorization of bioactive compounds in fruit pomace from agro-fruit industries: Present Insights and future challenges. Food Biosci. 2021, 44, 101384. [Google Scholar] [CrossRef]

- Amal, A.; Eman, A.; Nahla, S.Z. Fruit flavored yogurt: Chemical, functional and rheological properties. Int. J. Environ. Agric. Res. 2016, 2, 57–66. [Google Scholar]

- Raikos, V.; Ni, H.; Hayes, H.; Ranawana, V. Antioxidant properties of a yogurt beverage enriched with salal (Gaultheria shallon) berries and blackcurrant (Ribes nigrum) pomace during cold storage. Beverages 2018, 5, 2. [Google Scholar] [CrossRef]

- Dimitrellou, D.; Solomakou, N.; Kokkinomagoulos, E.; Kandylis, P. Yogurts supplemented with juices from grapes and berries. Foods 2020, 9, 1158. [Google Scholar] [CrossRef] [PubMed]

- Plessas, S.; Mantzourani, I.; Terpou, A.; Bekatorou, A. Assessment of the Physicochemical, Antioxidant, Microbial, and Sensory Attributes of Yogurt-Style Products Enriched with Probiotic-Fermented Aronia melanocarpa Berry Juice. Foods 2024, 13, 111. [Google Scholar] [CrossRef]

- Predescu, C.; Ștefan, G.; Papuc, C. Impact of the addition of different forest berry fruits on functional, physicochemical and sensory properties of yogurt shelf life. Sci. Works Ser. C Vet. Med. 2022, 68, 43–49. [Google Scholar]

- Nguyen, L.; Hwang, E.S. Quality characteristics and antioxidant activity of yogurt supplemented with aronia (Aronia melanocarpa) juice. Prev. Nutr. Food Sci. 2016, 21, 330. [Google Scholar] [CrossRef]

- AOAC International. Official Methods of Analysis of AOAC International; AOAC International: Alrington, VA, USA, 1995. [Google Scholar]

- ISO 20483:2013; Cereals and Pulses—Determination of the Nitrogen Content and Calculation of the Crude Protein Content—Kjeldahl Method. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 659:2009; Oilseeds—Determination of Oil Content (Reference Method). International Organization for Standardization: Geneva, Switzerland, 2009.

- AOAC 985.29; Total Dietary Fibre in Foods. Enzymatic-Gravimetric Method. Official Methods of Analysis. 14th ed. Association of Official Analytical Chemists: Washington, DC, USA, 1985.

- AOAC. Official Methods of Food Analysis, 17th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 2010. [Google Scholar]

- Denev, P.N.; Kratchanov, C.G.; Ciz, M.; Lojek, A.; Kratchanova, M.G. Bioavailability and antioxidant activity of black chokeberry (Aronia melanocarpa) polyphenols: In vitro and in vivo evidences and possible mechanisms of action: A review. Compr. Rev. Food Sci. Food Saf. 2012, 11, 471–489. [Google Scholar] [CrossRef]

- Nour, V. Quality characteristics, anthocyanin stability and antioxidant activity of apple (Malus domestica) and black chokeberry (Aronia melanocarpa) juice blends. Plants 2022, 11, 2027. [Google Scholar] [CrossRef]

- Konić Ristić, A.; Srdić-Rajić, T.; Kardum, N.; Glibetić, M. Biological activity of Aronia melanocarpa antioxidants pre-screening in an intervention study design. J. Serb. Chem. Soc. 2013, 78, 429–443. [Google Scholar] [CrossRef]

- Tolić, M.T.; Landeka Jurčević, I.; Panjkota Krbavčić, I.; Marković, K.; Vahčić, N. Phenolic content, antioxidant capacity and quality of chokeberry (Aronia melanocarpa) products. Food Technol. Biotechnol. 2015, 53, 171–179. [Google Scholar] [CrossRef]

- ISO 13580:2005 IDF 151; Yogurt—Determination of Total Solids Content (Reference Method). International Organization for Standardization: Geneva, Switzerland, 2005.

- ISO 11870:2009 IDF 152:2009; Milk and Milk Products Determination of Fat Content General Guidance on the Use of Butyrometric Methods. International Organization for Standardization: Geneva, Switzerland, 2009.

- Andrade, E.H.P.; da Fonseca, L.M.; de Souza, M.R.; Penna, C.F.D.A.M.; Cerqueira, M.M.O.P.; de Oliveira Leite, M. Fat content in fermented milk beverages: Determination by the Gerber method. Semin. Ciênc. Agrár. 2022, 43, 441–448. [Google Scholar] [CrossRef]

- ISO 8968-1:2014 IDF 20-1; Milk and Milk Products—Determination of Nitrogen Content—Part 1: Kjeldahl Principle and Crude Protein Calculation. International Organization for Standardization: Geneva, Switzerland, 2014.

- Vieira, E.D.; Styles, D.; Sousa, S.; Santos, C.; Gil, A.M.; Gomes, A.M.; Vasconcelos, M.W. Nutritional, rheological, sensory characteristics and environmental impact of a yogurt-like dairy drink for children enriched with lupin flour. Int. J. Gastron. Food Sci. 2022, 30, 100617. [Google Scholar] [CrossRef]

- ISO/TS 11869 IDF/RM150; Fermented Milks—Determination of Titratable Acidity—Potentiometric Method. International Organization for Standardization: Geneva, Switzerland, 2012.

- Pădureţ, S. The effect of fat content and fatty acids composition on color and textural properties of butter. Molecules 2021, 26, 4565. [Google Scholar] [CrossRef] [PubMed]

- Milovanovic, B.; Djekic, I.; Miocinovic, J.; Djordjevic, V.; Lorenzo, J.M.; Barba, F.J.; Mörlein, D.; Tomasevic, I. What Is the Color of Milk and Dairy Products and How Is It Measured? Foods 2020, 9, 1629. [Google Scholar] [CrossRef] [PubMed]

- Oroian, M.; Paduret, S.; Gutt, G. Influence of citrus fibre addition on textural and rheological properties of yogurt. Food Environ. Saf. J. 2016, 13, 335–341. [Google Scholar]

- Saleh, A.; Mohamed, A.A.; Alamri, M.S.; Hussain, S.; Qasem, A.A.; Ibraheem, M.A. Effect of Different Starches on the Rheological, Sensory and Storage Attributes of Non-fat Set Yogurt. Foods 2020, 9, 61. [Google Scholar] [CrossRef]

- Kose, Y.E.; Altun, I.; Kose, S. Determination of texture profile analysis of yogurt produced by industrial and traditional method. Int. J. Sci. Technol. Res. 2018, 4, 66–70. [Google Scholar]

- Mousavi, M.; Heshmati, A.; Daraei Garmakhany, A.; Vahidinia, A.; Taheri, M. Texture and sensory characterization of functional yogurt supplemented with flaxseed during cold storage. Food Sci. Nutr. 2019, 7, 907–917. [Google Scholar] [CrossRef]

- Moldovan, B.; Iasko, B.; David, L. Antioxidant activity and total phenolic content of some commercial fruit-flavoured yogurts. Stud. Univ. Babes-Bolyai Chem. 2016, 61, 101–108. [Google Scholar]

- El-Din, H.F.; Haggag, H.; Farahat, A.; El-Said, M. Production of healthy fermented milk supplemented with natural sources of antioxidants. Int. J. Dairy Sci. 2017, 12, 52–63. [Google Scholar] [CrossRef]

- Karaaslan, M.; Ozden, M.; Vardin, H.; Turkoglu, H. Phenolic fortification of yogurt using grape and callus extracts. LWT—Food Sci. Technol. 2011, 44, 1065–1072. [Google Scholar] [CrossRef]

- Arfaoui, L. Total polyphenol content and radical scavenging activity of functional yogurt enriched with dates. Czech J. Food Sci. 2020, 38, 287–292. [Google Scholar] [CrossRef]

- Pădureţ, S.; Amariei, S.; Gutt, G.; Piscuc, B. The evaluation of dandelion (Taraxacum officinale) properties as a valuable food ingredient. Rom. Biotechnol. Lett. 2016, 21, 11569–11575. [Google Scholar]

- ASRO SR 6345:1995; Milk and Dairy Products: Sensory Analysis Standard. Emerald Publishing: Bingley, UK, 1995.

- Ibrahim, A.; Naufalin, R.; Muryatmo, E.; Dwiyanti, H. Comparative study between cow and goat milk yogurt based on composition and sensory evaluation. IOP Conf. Ser. Earth Environ. Sci. 2021, 746, 012001. [Google Scholar] [CrossRef]

- Dudal, P.S.; Salunkhe, D.D.; Chavan, K.D.; Waghulde, G.K. Studies on quality of yoghurt prepared from blend of goat and cow milk. J. Dairy. Foods Home Sci. 2009, 28, 89–94. [Google Scholar]

- Alqahtani, N.K.; Alnemr, T.M.; Alsalem, A.K.; Alotaibi, M.M.; Mohammed, M. Experimental Investigation and Modeling for the Influence of Adding Date Press Cake on Drinkable Yogurt Quality. Foods 2023, 12, 1219. [Google Scholar] [CrossRef]

- Wang, X.; Kristo, E.; LaPointe, G. Adding apple pomace as a functional ingredient in stirred-type yogurt and yogurt drinks. Food Hydrocoll. 2020, 100, 105453. [Google Scholar] [CrossRef]

- Popescu, L.; Ceșco, T.; Gurev, A.; Ghendov-Mosanu, A.; Sturza, R.; Tarna, R. Impact of Apple Pomace Powder on the Bioactivity, and the Sensory and Textural Characteristics of Yogurt. Foods 2022, 11, 3565. [Google Scholar] [CrossRef]

- Varnaitė, L.; Keršienė, M.; Šipailienė, A.; Kazernavičiūtė, R.; Venskutonis, P.R.; Leskauskaitė, D. Fiber-Rich Cranberry Pomace as Food Ingredient with Functional Activity for Yogurt Production. Foods 2022, 11, 758. [Google Scholar] [CrossRef]

- Du, H.; Yang, H.; Wang, X.; Zhu, F.; Tang, D.; Cheng, J.; Liu, X. Effects of mulberry pomace on physicochemical and textural properties of stirred-type flavored yogurt. J. Dairy Sci. 2021, 104, 12403–12414. [Google Scholar] [CrossRef]

- CXS 243–2003; CODEX Standard for Fermented Milks. FAO: Rome, Italy; WHO: Geneva, Switzerland, 2003. Available online: https://www.fao.org/fao-who-codexalimentarius/sh-proxy/en/?lnk=1&url=https%253A%252F%252Fworkspace.fao.org%252Fsites%252Fcodex%252FStandards%252FCXS%2B243-2003%252FCXS_243e.pdf (accessed on 26 June 2024).

- King, E.S.; Bolling, B.W. Composition, polyphenol bioavailability, and health benefits of aronia berry: A review. J. Food Bioact. 2020, 11, 13–30. [Google Scholar] [CrossRef]

- Rashwan, A.K.; Osman, A.I.; Chen, W. Natural nutraceuticals for enhancing yogurt properties: A review. Environ. Chem. Lett. 2023, 21, 1907–1931. [Google Scholar] [CrossRef]

- Trenka, M.; Nawirska-Olszańska, A.; Oziembłowski, M. Analysis of Selected Properties of Fruits of Black Chokeberry (Aronia melanocarpa L.) from Organic and Conventional Cultivation. Appl. Sci. 2020, 10, 9096. [Google Scholar] [CrossRef]

- Reißner, A.M.; Al-Hamimi, S.; Quiles, A.; Schmidt, C.; Struck, S.; Hernando, I.; Turner, C.; Rohm, H. Composition and physicochemical properties of dried berry pomace. J. Sci. Food Agric. 2019, 99, 1284–1293. [Google Scholar] [CrossRef] [PubMed]

- Demirkol, M.; Tarakci, Z. Effect of grape (Vitis labrusca L.) pomace dried by different methods on physicochemical, microbiological and bioactive properties of yoghurt. LWT Food Sci. Technol. 2018, 97, 770–777. [Google Scholar] [CrossRef]

- De Toledo, N.M.V.; De Camargo, A.C.; Ramos, P.B.M.; Button, D.C.; Granato, D.; Canniatti-Brazaca, S.G. Potentials and Pitfalls on the Use of Passion Fruit By-Products in Drinkable Yogurt: Physicochemical, Technological, Microbiological, and Sensory Aspects. Beverages 2018, 4, 47. [Google Scholar] [CrossRef]

- Ścibisz, I.; Ziarno, M.; Mitek, M. Color stability of fruit yogurt during storage. J. Food Sci. Technol. 2019, 56, 1997–2009. [Google Scholar] [CrossRef]

- Machado, K.R.D.; Tulini, F.L.; Guimarães, J.d.G.L.; Moraes, I.C.F.; Ditchfield, C.; Lima, C.G.d.; Silva, V.L.d.S.; Favaro-Trindade, C.S. Production and Evaluation of Yogurt Colored with Anthocyanin-Rich Pigment Prepared from Jabuticaba (Myrciaria cauliflora Mart.) Skin. Processes 2023, 11, 526. [Google Scholar] [CrossRef]

- Aydinol Sonmez, P.; Ozcan, T. Assessment of structure and sensory characteristics of reduced fat yoghurt manufactured with carob bean gum polysaccharides. Food Sci. Technol. 2021, 42, e61220. [Google Scholar] [CrossRef]

- Scalisi, A.; O’Connell, M.G.; Islam, M.S.; Goodwin, I. A Fruit Colour Development Index (CDI) to Support Harvest Time Decisions in Peach and Nectarine Orchards. Horticulturae 2022, 8, 459. [Google Scholar] [CrossRef]

- Lisak Jakopović, K.; Repajić, M.; Rumora Samarin, I.; Božanić, R.; Blažić, M.; Barukčić Jurina, I. Fortification of Cow Milk with Moringa oleifera Extract: Influence on Physicochemical Characteristics, Antioxidant Capacity and Mineral Content of Yoghurt. Fermentation 2022, 8, 545. [Google Scholar] [CrossRef]

- Mudgil, D.; Barak, S.; Khatkar, B.S. Texture profile analysis of yogurt as influenced by partially hydrolyzed guar gum and process variables. J. Food Sci. Technol. 2017, 54, 3810–3817. [Google Scholar] [CrossRef] [PubMed]

- Jurendić, T.; Ščetar, M. Aronia melanocarpa products and by-products for health and nutrition: A review. Antioxidants 2021, 10, 1052. [Google Scholar] [CrossRef] [PubMed]

- Olszowy-Tomczyk, M. How to express the antioxidant properties of substances properly? Chem. Pap. 2021, 75, 6157–6167. [Google Scholar] [CrossRef]

- Krasnova, I.; Seglina, D.; Lācis, G.; Āboltiņš, A.; Viškelis, J. The impact of additives on the quality indices of different black chokeberry products, developed using waste-free processing technology. Braz. J. Food Technol. 2023, 26, e2023047. [Google Scholar] [CrossRef]

- Marjanovic, A.; Djedjibegovic, J.; Lugusic, A.; Sober, M.; Saso, L. Multivariate analysis of polyphenolic content and in vitro antioxidant capacity of wild and cultivated berries from Bosnia and Herzegovina. Sci. Rep. 2021, 11, 19259. [Google Scholar] [CrossRef]

- Petrov Ivanković, A.; Ćorović, M.; Milivojević, A.; Simović, M.; Banjanac, K.; Veljković, M.; Bezbradica, D. Berries Pomace Valorization: From Waste to Potent Antioxidants and Emerging Skin Prebiotics. Int. J. Fruit Sci. 2024, 24, 85–101. [Google Scholar] [CrossRef]

- Okur, Ö.D. Determination of antioxidant activity and total phenolic contents in yogurt added with black cumin (Nigella sativa L.) honey. Ovidius Univ. Ann. Chem. 2021, 32, 1–5. [Google Scholar] [CrossRef]

- Baniasadi, M.; Azizkhani, M.; Saris, P.E.J.; Tooryan, F. Comparative antioxidant potential of kefir and yogurt of bovine and non-bovine origins. J. Food Sci. Technol. 2022, 59, 1307–1316. [Google Scholar] [CrossRef]

- Helal, A.; Cattivelli, A.; Conte, A.; Tagliazucchi, D. In Vitro Bioaccessibility and Antioxidant Activity of Phenolic Compounds in Coffee-Fortified Yogurt. Molecules 2022, 27, 6843. [Google Scholar] [CrossRef]

- Sik, B.; Székelyhidi, R.; Lakatos, E.; Kapcsándi, V.; Ajtony, Z. Analytical procedures for determination of phenolics active herbal ingredients in fortified functional foods: An overview. Eur. Food Res. Technol. 2022, 248, 329–344. [Google Scholar] [CrossRef]

- Kapci, B.; Neradová, E.; Čížková, H.; Voldřich, M.; Rajchl, A.; Capanoglu, E. Investigating the antioxidant potential of chokeberry (Aronia melanocarpa) products. J. Food Nutr. Res. 2013, 52, 219–229. [Google Scholar]

- Ren, L.; Chen, Y. Influence of Color Perception on Consumer Behavior. In HCI in Business, Government, and Organizations; Nah, F.H., Xiao, B., Eds.; HCIBGO 2018; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2018; Volume 10923, pp. 413–421. [Google Scholar]

| Sample Coding | Main Sample Ingredients |

|---|---|

| YCS | Pasteurized cow milk, lactic cultures |

| YBF1 | Pasteurized cow milk, lactic cultures, black chokeberry fruit (1%) |

| YBF2 | Pasteurized cow milk, lactic cultures, black chokeberry fruit (2%) |

| YBF3 | Pasteurized cow milk, lactic cultures, black chokeberry fruit (3%) |

| YBJ1 | Pasteurized cow milk, lactic cultures, black chokeberry juice (1%) |

| YBJ2 | Pasteurized cow milk, lactic cultures, black chokeberry juice (2%) |

| YBJ3 | Pasteurized cow milk, lactic cultures, black chokeberry juice (3%) |

| YBP1 | Pasteurized cow milk, lactic cultures, black chokeberry pomace (1%) |

| YBP2 | Pasteurized cow milk, lactic cultures, black chokeberry pomace (2%) |

| YBP3 | Pasteurized cow milk, lactic cultures, black chokeberry pomace (3%) |

| Yogurt Samples | Cow Milk (%) | Black Chokeberry Fruit (%) | Black Chokeberry Juice (%) | Black Chokeberry Pomace (%) | Lactic Cultures (U) |

|---|---|---|---|---|---|

| YCS | 100 | - | - | - | 20 |

| YBF1 | 99 | 1 | - | - | 20 |

| YBF2 | 98 | 2 | - | - | 20 |

| YBF3 | 97 | 3 | - | - | 20 |

| YBJ1 | 99 | - | 1 | - | 20 |

| YBJ2 | 98 | - | 2 | - | 20 |

| YBJ3 | 97 | - | 3 | - | 20 |

| YBP1 | 99 | - | - | 1 | 20 |

| YBP2 | 98 | - | - | 2 | 20 |

| YBP3 | 97 | - | - | 3 | 20 |

| Yogurt Samples | L* | a* | b* | C* | YI | WI | h° |

|---|---|---|---|---|---|---|---|

| YCS | 74.6 ± 0.1 c | −6.4 ± 0.1 j | 11.1 ± 0.1 b | 12.8 ± 0.1 a | 21.4 ± 0.1 a | 71.6 ± 0.03 c | 119.7 ± 0.1 a |

| YBF1 | 55.2 ± 0.1 g | 3.9 ± 0.1 c | 4.8 ± 0.1 f | 6.2 ± 0.1 e | 12.4 ± 0.1 de | 54.8 ± 0.1 g | 50.8 ± 0.2 h |

| YBF2 | 39. 8 ± 0. 2 i | 5.4 ± 0.1 b | 2.8 ± 0.1 g | 6.1 ± 0.1 e | 10 ± 0.1 f | 39.5 ± 0.1 i | 26.9 ± 0.2 i |

| YBF3 | 40.2 ± 0.10 i | 6.4 ± 0.1 a | 3.2 ± 0.4 g | 7.2 ± 0.1 c | 11.6 ± 0.7 e | 39.7 ± 0.1 i | 26.8 ± 0.1 i |

| YBJ1 | 87.6 ± 0.3 a | −6.1 ± 0.1 i | 11.1 ± 0.6 b | 12.7 ± 0.5 a | 18.2 ± 1.0 b | 82.3 ± 0.6 a | 119 ± 1b |

| YBJ2 | 84 ± 1 b | −4.7 ± 0.1 h | 12.2 ± 0.4 a | 13.1 ± 0.3 a | 20.8 ± 0.8 a | 79.1 ± 0.8 b | 111.2 ± 1. c |

| YBJ3 | 65.1 ± 0.1 e | −1.8 ± 0.1 g | 7.9 ± 0.1 c | 8.2 ± 0.1 b | 17.4 ± 0.1 b | 64.1 ± 0.2 e | 103 ± 0.1 d |

| YBP1 | 69.5 ± 0.1 d | 0.2 ± 0.1 f | 6.8 ± 0.1 d | 6.8 ± 0.1 d | 13.9 ± 0.1 c | 68.70 ± 0.1 d | 88.34 ± 0.04 e |

| YBP2 | 49.5 ± 0.1 h | 0.9 ± 0.1 e | 4.8 ± 0.1 f | 5 ± 0.1 f | 14 ± 0.1 c | 49.2 ± 0.1 h | 78.8 ± 0.1 f |

| YBP3 | 61.9 ± 0.1 f | 3.6 ± 0.1 d | 5.4 ± 0.1 e | 6.2 ± 0.1 e | 12.6 ± 0.1 d | 61.4 ± 0.1 f | 60.70 ± 0.10 g |

| p-value | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 | p < 0.001 |

| F-value | 7324.36 | 28346.50 | 437.09 | 485.49 | 166.01 | 4274.91 | 8935.8 |

| Yogurt Samples | YCS | YBJ1 | YBJ2 | YBJ3 | YBP1 | YBP2 | YBP3 | YBF1 | YBF2 | YBF3 |

|---|---|---|---|---|---|---|---|---|---|---|

| YCS | - | 12.99 | 9.35 | 10.96 | 9.35 | 26.88 | 16.73 | 22.76 | 37.67 | 37.52 |

| YBJ1 | - | - | 4.20 | 23.10 | 19.66 | 39.26 | 27.82 | 34.43 | 49.86 | 49.64 |

| YBJ2 | - | - | - | 19.34 | 16.04 | 35.51 | 24.12 | 30.68 | 46.08 | 45.84 |

| YBJ3 | - | - | - | - | 4.96 | 16.17 | 6.34 | 11.83 | 26.84 | 26.66 |

| YBP1 | - | - | - | - | - | 20.10 | 8.17 | 14.82 | 30.39 | 30.14 |

| YBP2 | - | - | - | - | - | - | 12.64 | 6.48 | 10.87 | 10.89 |

| YBP3 | - | - | - | - | - | - | - | 6.77 | 22.42 | 22.11 |

| YBF1 | - | - | - | - | - | - | - | - | 15.66 | 15.35 |

| YBF2 | - | - | - | - | - | - | - | - | - | 1.14 |

| YBF3 | - | - | - | - | - | - | - | - | - | - |

| Yogurt Samples | Hardness | Viscosity | Adhesiveness | Cohesiveness | Springiness | Gumminess | Chewiness |

|---|---|---|---|---|---|---|---|

| YCS | 0.70 ± 0.2 b | 0.36 ± 0.03 d | 1.48 ± 0.3 bcd | 54.00 ± 0.1 f | 0.72 ± 0.02 c | 0.38 ± 0.01 e | 0.27 ± 0.01 cd |

| YBF1 | 1.4 ± 0.3 a | 0.72 ± 0.05 b | 2.84 ± 0.1 a | 55.04 ± 0.1 e | 0.83 ± 0.03 ab | 0.77 ± 0.03 c | 0.64 ± 0.06 b |

| YBF2 | 1.5 ± 0.2 a | 0.74 ± 0.01 b | 2.84 ± 0.2 a | 58.70 ± 0.3 c | 0.87 ± 0.04 a | 0.88 ± 0.05 b | 0.76 ± 0.02 a |

| YBF3 | 1.7 ± 0.3 a | 0.84 ± 0.03 a | 2.97 ± 0.1 a | 59.23 ± 0.2 c | 0.75 ± 0.01 bc | 1.01 ± 0.02 a | 0.76 ± 0.03 a |

| YBJ1 | 0.74 ± 0.2 b | 0.40 ± 0.01 cd | 1.73 ± 0.1 b | 52.28 ± 0.1 g | 0.57 ± 0.05 e | 0.39 ± 0.01 e | 0.26 ± 0.01 cd |

| YBJ2 | 0.70 ± 0.2 b | 0.36 ± 0.02 d | 1.57 ± 0.2 bc | 52.34 ± 0.4 g | 0.66 ± 0.05 cde | 0.39 ± 0.00 e | 0.22 ± 0.05 de |

| YBJ3 | 0.5 ± 0.4 b | 0.24 ± 0.01 e | 0.99 ± 0.1 de | 56.06 ± 0.2 d | 0.69 ± 0.01 cd | 0.25 ± 0.05 f | 0.17 ± 0.03 ef |

| YBP1 | 0.8 ± 0.1 b | 0.44 ± 0.03 c | 1.86 ± 0.2 b | 64.32 ± 0.1 a | 0.61 ± 0.04 de | 0.50 ± 0.01 d | 0.31 ± 0.02 c |

| YBP2 | 0.40 ± 0.3 b | 0.26 ± 0.01 e | 1.09 ± 0.2 cde | 62.86 ± 0.2 b | 0.55 ± 0.02 e | 0.23 ± 0.04 f | 0.17 ± 0.01 ef |

| YBP3 | 0.4 ± 0.3 b | 0.24 ± 0.01 e | 0.88 ± 0.3 e | 60.31 ± 0.3 b | 0.41 ± 0.02 f | 0.17 ± 0.04 f | 0.09 ± 0.01 f |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pădureţ, S.; Ghinea, C.; Prisacaru, A.E.; Leahu, A. Physicochemical, Textural, and Antioxidant Attributes of Yogurts Supplemented with Black Chokeberry: Fruit, Juice, and Pomace. Foods 2024, 13, 3231. https://doi.org/10.3390/foods13203231

Pădureţ S, Ghinea C, Prisacaru AE, Leahu A. Physicochemical, Textural, and Antioxidant Attributes of Yogurts Supplemented with Black Chokeberry: Fruit, Juice, and Pomace. Foods. 2024; 13(20):3231. https://doi.org/10.3390/foods13203231

Chicago/Turabian StylePădureţ, Sergiu, Cristina Ghinea, Ancuta Elena Prisacaru, and Ana Leahu. 2024. "Physicochemical, Textural, and Antioxidant Attributes of Yogurts Supplemented with Black Chokeberry: Fruit, Juice, and Pomace" Foods 13, no. 20: 3231. https://doi.org/10.3390/foods13203231