Effect of Intermittent Low-Pressure Radiofrequency Helium Cold Plasma Treatments on Rice Gelatinization, Fatty Acid, and Hygroscopicity

Abstract

1. Introduction

2. Materials and Methods

2.1. Plasma Apparatus and Milled Rice Sample

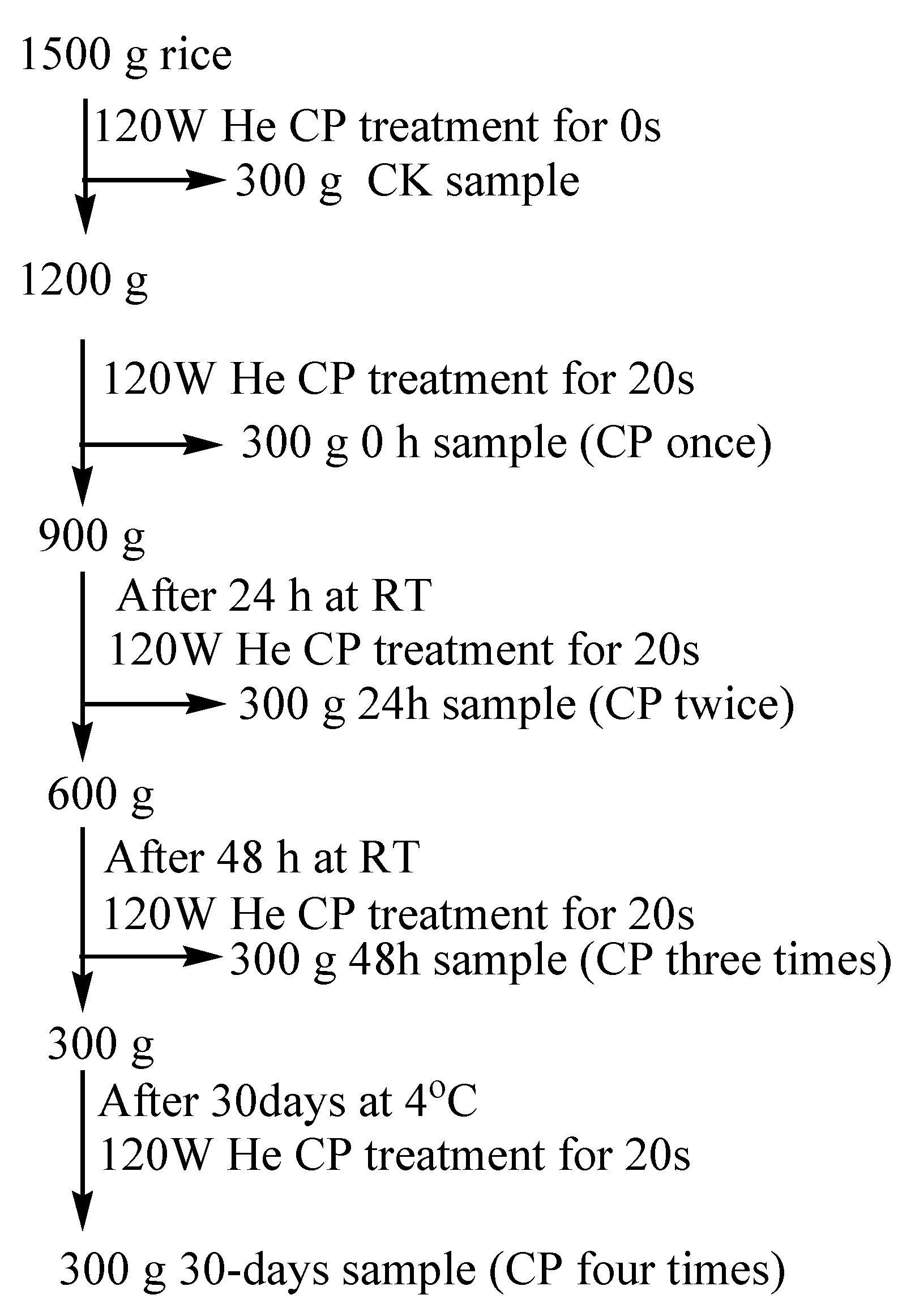

2.2. The Interval Test between Cold Plasma Processing

2.3. The Hydrophilicity, Water Adsorption Rate, and Cooking Time of Milled Rice

2.4. The Freshness Index and pH Value of Rice

2.5. Gelatinization Temperature

2.6. Pasting Property andSolvent Retention Capacity

2.7. Fourier Transform Infrared Spectroscopy

2.8. Fatty Acid Profile Analysis

2.9. Moisture Sorption Isotherms and Solid Surface Area

2.10. Data Analysis

3. Results

3.1. Effect of CP Repeating Treatments on the Water Absorption Rate and Freshness in Rice

3.2. Effect of CP Repeating Treatments on Gelatinization Temperature of Rice

3.3. Effect of CP Repeating Treatments on Pasting Parameters

3.4. Effect of CP Repeating Treatments on Solvent Retention Capacity

3.5. Effect of CP Repeating Treatments on the Deconvoluted IR Spectra

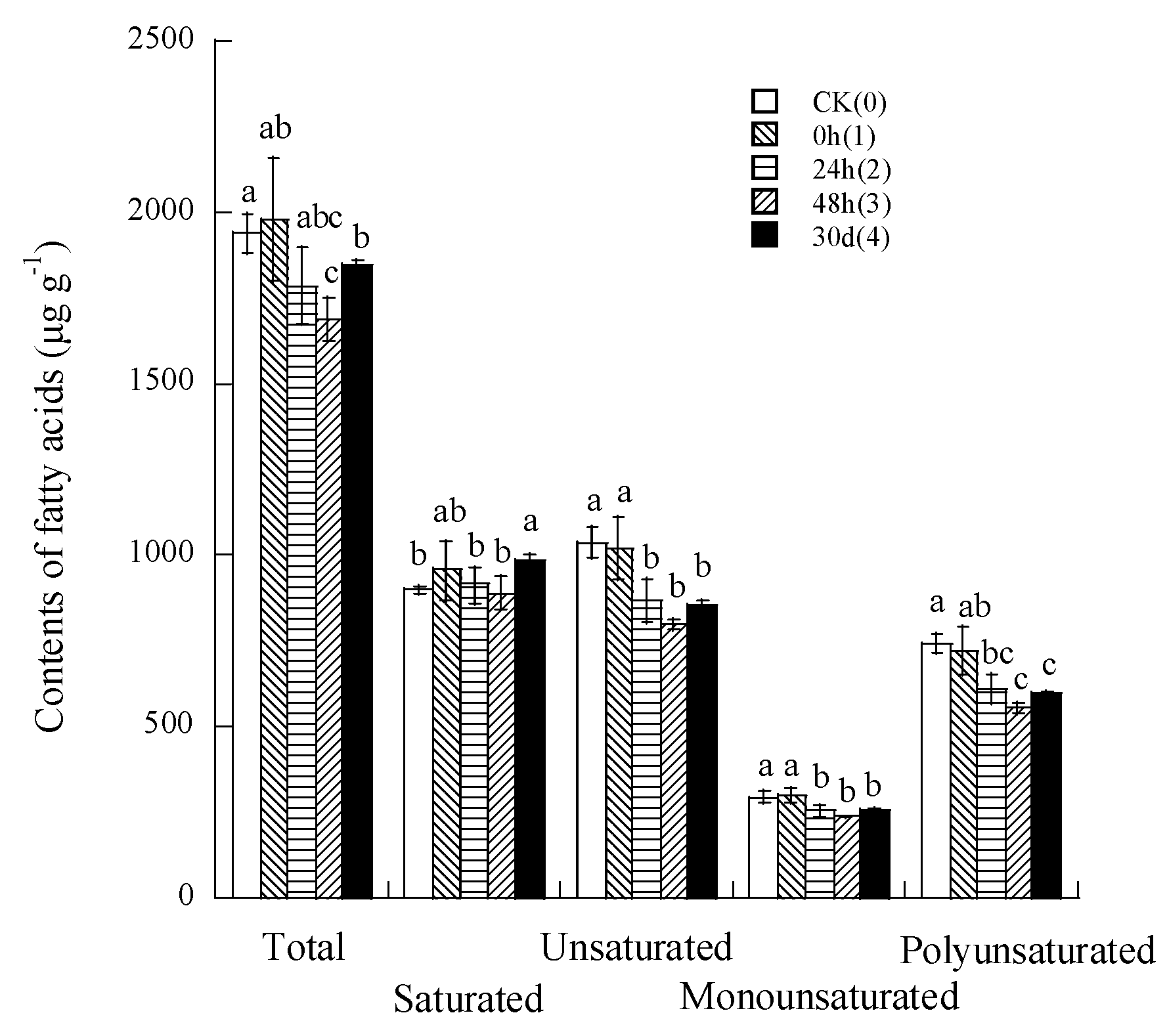

3.6. Effect of CP Repeating Treatments on the Fatty Acid Profile

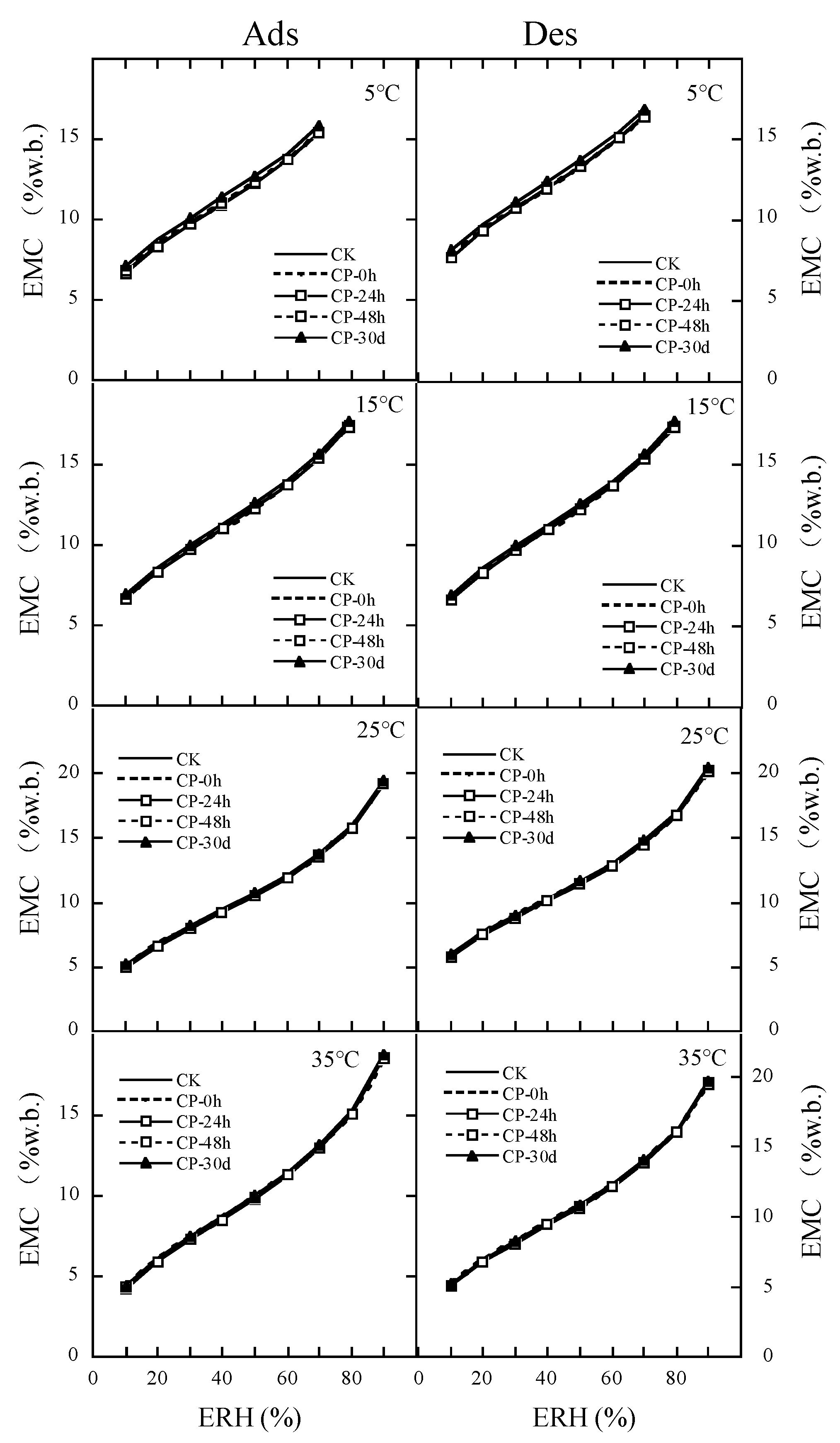

3.7. Effect of CP Repeating Treatments on the Hygroscopic Property of Milled Rice

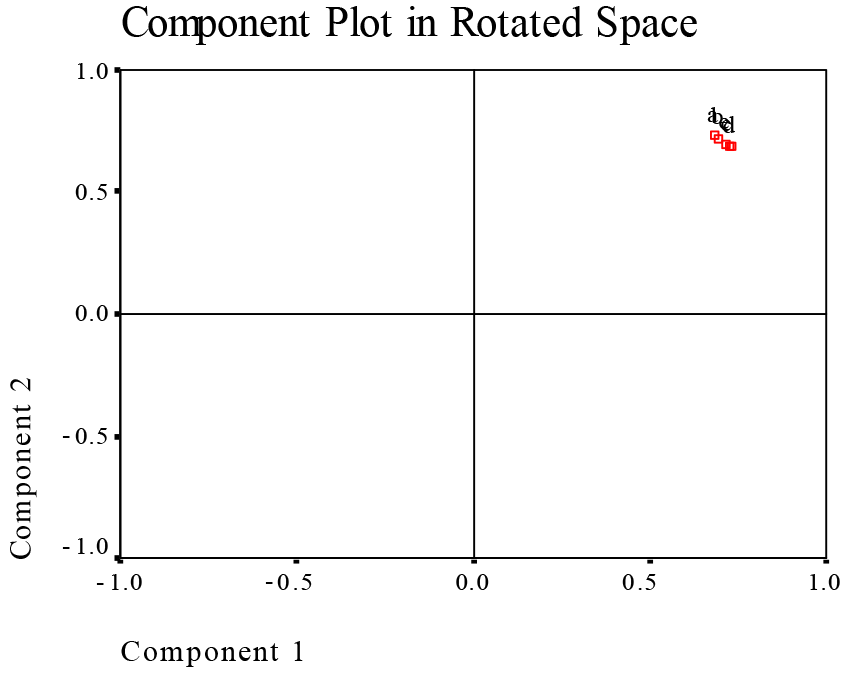

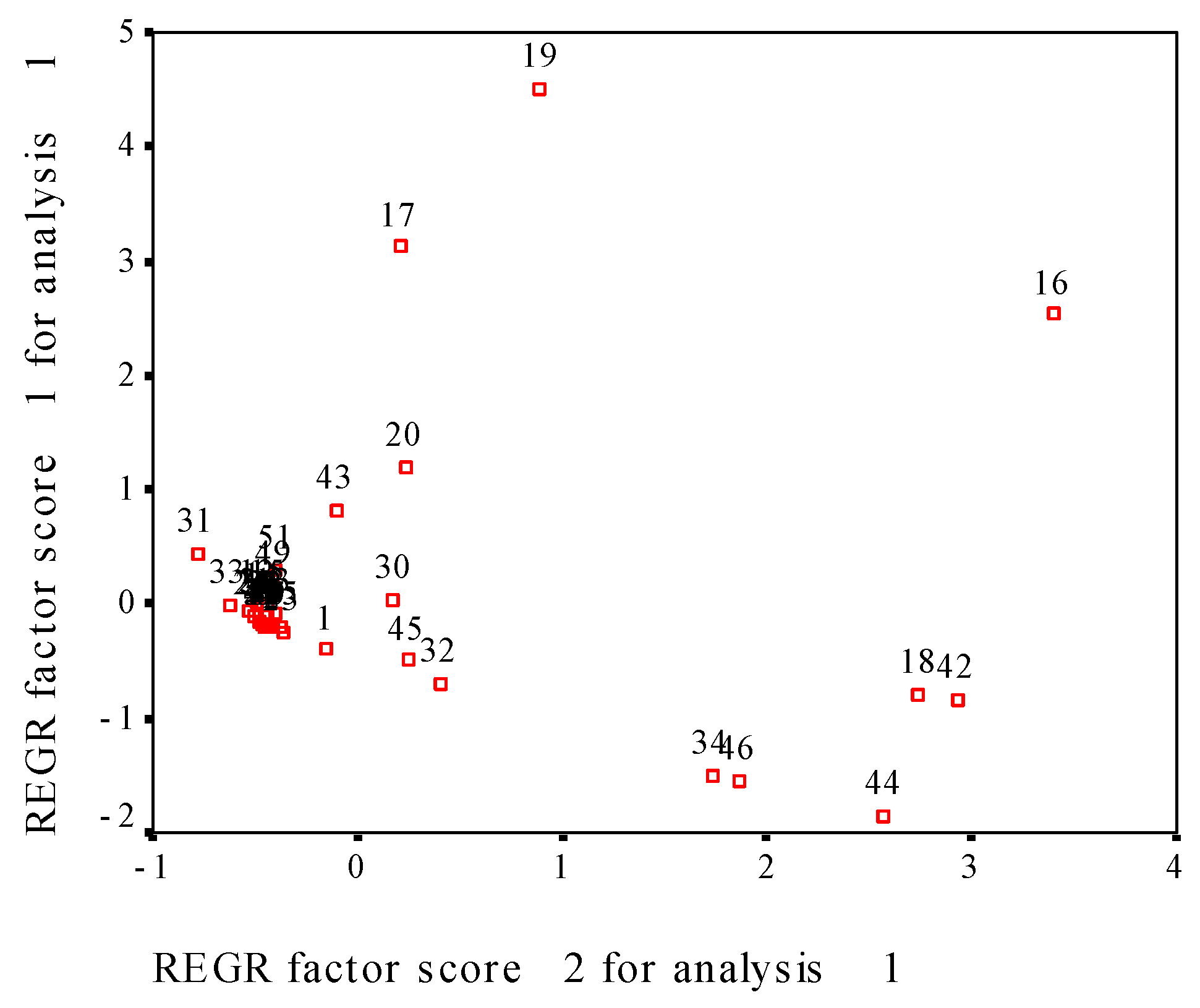

3.8. Evaluation of Effect of CP onMilled Rice Using Principal Component Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zadeh, J.H.; Pazir, F. Invesigation of the potential application of cold plasma technology in food safety. GIDA 2023, 48, 614–626. [Google Scholar] [CrossRef]

- Warne, G.R.; Williams, P.M.; Pho, H.Q.; Tran, N.N.; Hessel, V.; Fisk, I.D. Impact of cold plasma on the biomolecules and organoleptic properties of foods: A review. J. Food Sci. 2021, 86, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Mehr, H.M.; Koocheki, A. Effects of short-term and long-term cold plasma treatment on the color, structure, and pickering foaming properties of grass pea protein particles. Food Hydrocoll. 2023, 143, 108846. [Google Scholar] [CrossRef]

- Ekezie, F.C.; Sun, D.W.; Cheng, J.H. A review on recent advances in cold plasma technology for the food industry: Current applications and future trends. Trends Food Sci. Technol. 2017, 69, 46–58. [Google Scholar] [CrossRef]

- Chen, H.H.; Chang, H.C.; Chen, Y.K.; Huang, C.L.; Lin, S.Y.; Chen, Y.S. An improved process for high nutrition of germinated brown rice production: Low-pressure plasma. Food Chem. 2016, 191, 120–127. [Google Scholar] [CrossRef]

- Thirumdas, R.; Deshmukh, R.R.; Annapure, U.S. Effect of low temperature plasma processing on physicochemical properties and cooking quality of basmati rice. Innov. Food Sci. Emerg. Technol. 2015, 31, 83–90. [Google Scholar] [CrossRef]

- Murakam, T.; Niemi, K.; Gans, T.; O’Connell, D.; Graham, W.G. Chemical kinetics and reactive species in atmospheric pressure helium-oxygen plasma with humid air impurities. Plasma Sources Sci. Technol. 2013, 22, 1–29. [Google Scholar] [CrossRef]

- Dong, S.; Gao, A.; Xu, H.; Chen, Y. Effects of dielectric barrier discharge (DBD) cold plasma treatment on physicochemical and structural properties of zein powders. Food Bioprocess Technol. 2017, 10, 434–444. [Google Scholar] [CrossRef]

- Ji, H.; Dong, S.; Han, F.; Li, Y.; Chen, G.; Li, L.; Chen, Y. Effects of dielectric barrier discharge (DBD) cold plasma treatment on physicochemical and functional properties of peanut protein. Food Bioprocess Technol. 2018, 11, 344–354. [Google Scholar] [CrossRef]

- Segat, A.; Misra, N.N.; Cullen, P.J.; Innocente, N. Atmospheric pressure cold plasma (ACP) treatment of whey protein isolate model solution. Innov. Food Sci. Emerg. Technol. 2015, 29, 247–254. [Google Scholar] [CrossRef]

- Rowan, N.J.; Espie, S.; Harrower, J.; Anderson, J.G.; Marsili, L.; MacGregor, S.J. Pulsed-plasma gas-discharge inactivation of microbial pathogens in chilled poultry wash water. J. Food Prot. 2007, 70, 2805–2810. [Google Scholar] [CrossRef] [PubMed]

- Pal, P.; Kaur, P.; Singh, N.; Misra, N.N.; Tiwari, B.K.; Cullen, P.J.; Virdi, A.S. Effect of nonthermal plasma on physicochemical, amino acid composition, pasting and protein characteristics of short and long grain rice flour. Food Res. Int. 2016, 81, 50–57. [Google Scholar] [CrossRef]

- Muhammad, A.I.; Liao, X.J.; Cullen, P.J.; Liu, D.; Xiang, Q.; Wang, J.; Chen, S.; Ye, X.; Ding, T. Effects of nonthermal plasma technology on functional food components. Compr. Rev. Food Sci. Food Saf. 2018, 17, 1379–1394. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Oh, J.K.; Cisneros-Zevallos, L.; Akbulut, M. Bactericidal effects of nonthermal low-pressure oxygen plasma S. typhimurium LT2 attached to fresh produce surfaces. J. Food Eng. 2013, 119, 425–432. [Google Scholar] [CrossRef]

- Bahrami, N.; Bayliss, D.; Chope, G.; Penson, S.; Perehinec, T.; Fisk, I.D. Cold plasma: A new technology to modify wheat flour functionality. Food Chem. 2016, 202, 247–253. [Google Scholar] [CrossRef]

- Yepez, X.V.; Baykara, H.; Xu, L.; Keener, K.M. Cold plasma treatment of soybean oil with hydrogen gas. J. Am. Oil Chem. Soc. 2021, 98, 103–113. [Google Scholar] [CrossRef]

- Zhang, J.; Du, Q.; Yang, Y.; Zhang, J.; Han, R.; Wang, J. Research prgress and future trends of low temperature plasma application in food industry: A review. Molecules 2023, 28, 4714. [Google Scholar] [CrossRef]

- Usman, I.; Afzaal, M.; Imran, A.; Saeed, F.; Afzal, A.; Ashfaq, I.; Ahah, Y.A.; Islam, F.; Azam, I.; Tariq, I.; et al. Recent updates and perspectives of plasma in food processing: A review. Int. J. Food Prop. 2023, 26, 552–566. [Google Scholar] [CrossRef]

- Misnal, M.F.I.; Redzuan, N.; Zainal, M.N.F.; Ahmad, N.; Ibrahim, K.R.; Agun, L. Cold plasma: A potential alternative for rice grain postharvest treatment management in Malaysia. Rice Sci. 2022, 29, 1–15. [Google Scholar] [CrossRef]

- Liu, J.J.; Wang, R.L.; Chen, Z.T.; Li, X.J. Effect of cold plasma treatment on cooking, thermomechanical and surface structural properties of Chinese milled rice. Food Bioprocess Technol 2021, 14, 866–886. [Google Scholar] [CrossRef]

- Chen, Z.T.; Wang, R.L.; Li, X.J.; Zhu, J.; Xu, Y.N.; Liu, J.J. Sorption equilibrium moisture and isosteric heat of cold plasma treated milled rice. Innov. Food Sci. Emerg. Technol. 2019, 55, 35–47. [Google Scholar] [CrossRef]

- Gao, G.B.; Wu, J.Z.; Wei, Z.; Li, X.J. Effects of low-pressure radio-frequency cold plasma on the biochemical parameters and fatty acid profile of wheat flours. Cereal Chem. 2023, 110, 393–413. [Google Scholar] [CrossRef]

- Tao, L.S.; Qin, W.; Wei, Z.; Li, X.J.; Zhang, H.Q. Effect of small-scale storage on the cooking property and fatty acid profile. Appl. Food Res. 2022, 2, 100175. [Google Scholar] [CrossRef]

- Takashi, M.; Koji, K.; Tatsuhiko, O. Method of Measuring Freshness of Cereals and Beans and Apparatus Therafor. EP 1612542A1. 1 April 2006.

- AACC International Approved Methods of Analysis, 11th ed.; Methods: 54-21.01 (Rheological Behaviour of Flour by Farinograph), 56-11.02 (Solvent Retention Capacity Profile); American Association of Cereal Chemists International: St. Paul, MN, USA, 2012.

- Li, X.J.; Han, X.; Tao, L.S.; Jiang, P.; Qin, W. Sorption equilibrium moisture and isosteric heats of Chinese wheat bran products added to rice to increase its dietary fiber content. Grain Oil Sci. Technol. 2021, 4, 149–161. [Google Scholar] [CrossRef]

- SPSS Inc. SPSS for Windows; Release 17.0.1; SPSS Inc.: Chicago, IL, USA, 2017. [Google Scholar]

- Moraes, M.A.; Rosa, G.S.; Pinto, L.A. Moisture sorption isotherms and thermodynamic properties of apple Fuji and garlic. Int. J. Food Sci. Technol. 2008, 43, 1824–1831. [Google Scholar] [CrossRef]

- Surowsky, B.; Fischer, A.; Schlueter, O.; Knorr, D. Cold plasma effects on enzyme activity in a model food system. Innov. Food Sci. Emerg. Technol. 2013, 19, 146–152. [Google Scholar] [CrossRef]

- Gurol, C.; Ekinci, F.Y.; Aslan, N.; Korachi, M. Low temperature plasma for decontamination of E. coli in milk. Int. J. Food Microbiol. 2012, 157, 1–5. [Google Scholar] [CrossRef]

- Yan, Y.H.; Feng, X.P.; Tang, X.L.; Xie, H.K. The basic character of emission spectra of He plasma from normal pressure to ultra-low pressure. Chin. J. Light Scatt. 2004, 16, 242–245. (In Chinese) [Google Scholar] [CrossRef]

- Franchina, F.A.; Maimone, M.; Sciarrone, D.; Purcaro, G.; Tranchida, P.Q.; Mondello, L. Evaluation of a novel helium ionization detector within the context of (low-)flow modulation comprehensive two-dimensional gas chromatography. J. Chromatogr. A. 2015, 1402, 102–109. [Google Scholar] [CrossRef]

- Wang, S.J.; Li, C.L.; Copeland, L.; Niu, Q.; Wang, S. Starch retrogradation: A comprehensive review. Compr. Rev. Food Sci. Food Safety. 2015, 14, 568–584. [Google Scholar] [CrossRef]

- Thirumdas, R.; Kadam, D.; Annapure, U.S. Cold plasma: An alternative technology for the starch modification. Food Biophys. 2017, 12, 129–139. [Google Scholar] [CrossRef]

- Chaiwat, W.; Wongsagonsup, R.; Tangpanichyanon, N.; Jariyaporn, T.; Deeyai, P.; Suphantharika, M.; Fuongfuchat, A.; Nisoa, M.; Dangtip, S. Argon plasma treatment of tapioca starch using a semi-continuous downer reactor. Food Bioprocess Technol. 2016, 9, 1125–1134. [Google Scholar] [CrossRef]

- Zaidul, I.S.; Norulaini, N.A.; Omar, A.K.; Yamauchi, H.; Noda, T. RVA analysis of mixtures of wheat flour and potato, sweet potato, yam, and cassava starches. Carbohydr. Polym. 2007, 69, 784–791. [Google Scholar] [CrossRef]

- Kweon, M.; Slade, L.; Levine, H. Solvent retention capacity (SRC) testing of wheat flour: Principles and value in predicting flour functionality in different wheat-based food processes and in wheat breeding—A review. Cereal Chem. 2011, 88, 537–552. [Google Scholar] [CrossRef]

- Sifuentes-Nieves, I.; Mendez-Montealvo, G.; Flores-Silva, P.C.; Nieto-Pérez, M.; Neira-Velazquez, G.; Rodriguez-Fernandez, O.; Hernández-Hernández, E.; Velazquez, G. Dielectric barrier discharge and radiofrequency plasma effect on structural properties of starches with different amylose content. Innov. Food Sci. Emerg. Technol. 2021, 68, 102630. [Google Scholar] [CrossRef]

- Li, R.H.; Li, X.Y.; Tu, A.; Jing, C.T.; Dong, S.; Chen, S.F.; Guo, P. Effects of dielectric barrier discharge plasma treatment on the structural orders and functional properties of chickpea starch. Int. J. Food Sci. Technol. 2022, 1–13. [Google Scholar] [CrossRef]

- Albertos, I.; Martin-Diana, A.; Cullen, P.; Brijesh-Kumar, T.; Ojha, S.; Bourke, P.; Álvarez, C.; Rico, D. Effects of dielectric barrier discharge (DBD) generated plasma on microbial reduction and quality parameters of fresh mackerel (Scomber scombrus) fillets. Innov. Food Sci. Emerg. Technol. 2017, 44, 117–122. [Google Scholar] [CrossRef]

- Thirumdas, R. Partial hydrogenation of oils using cold plasma technology and its effect on lipid oxidation. J. Food Sci. Technol. 2023, 60, 1674–1680. [Google Scholar] [CrossRef]

- China Nation Standard, GB 28050-2011; Food Safety Nation Standard–General Rules for Nutrition Labeling of Prepackaged Foods. China National Standardization Administration: Beijing, China, 2011.

| CP Treatments | Water Contact Angle (°) | Water Absorption Rate (%) | Cooking Time (min) | Freshness Index (0.01) | pH Value |

|---|---|---|---|---|---|

| CK (0) | 79.7 ± 2.90 a | 29.1 ± 1.39 d | 20.0 ± 0.52 a | 3.79 ± 0.36 d | 6.59 ± 0.03 a |

| 0 h (1) | 73.8 ± 1.98 b | 30.9 ± 0.19 c | 14.5 ± 0.42 c | 4.75 ± 0.73 cd | 6.61 ± 0.03 a |

| 24 h (2) | 60.8 ± 1.43 c | 36.6 ± 1.40 a | 15.5 ± 0.43 b | 5.59 ± 0.05 b | 6.59 ± 0.03 a |

| 48 h (3) | 55.2 ± 4.42 cd | 34.8 ± 0.20 b | 15.0 ± 0.50 bc | 4.51 ± 0.04 c | 6.57 ± 0.01 a |

| 30 d (4) | 53.6 ± 1.94 d | 37.1 ± 0.45 a | 15.5 ± 0.40 b | 10.25 ± 2.06 a | 6.57 ± 0.02 a |

| CP Treatments | ΔH (J/g) | To (°C) | Tp (°C) | Tc (°C) | Tc–To (°C) | Peak Width(°C) | Peak Enthalpy (0.01 mW/mg) |

|---|---|---|---|---|---|---|---|

| CK (0) | 1.94 ± 0.00 a | 62.13 ± 0.15 c | 66.47 ± 0.32 cd | 70.50 ± 0.44 a | 8.37 ± 0.50 a | 5.30 ± 0.00 a | 5.46 ± 0.02 c |

| 0 h (1) | 1.82 ± 0.01 b | 62.37 ± 0.31 bc | 66.53 ± 0.06 d | 70.33 ± 0.86 a | 7.97 ± 0.76 a | 5.00 ± 0.10 b | 5.47 ± 0.07 c |

| 24 h (2) | 1.82 ± 0.05 b | 63.03 ± 0.42 ab | 66.83 ± 0.15 bc | 70.53 ± 1.19 a | 7.50 ± 1.05 a | 4.83 ± 0.21 b | 5.65 ± 0.18 bc |

| 48 h (3) | 1.93 ± 0.03 a | 62.93 ± 0.38 ab | 67.07 ± 0.12 b | 70.73 ± 0.81 a | 7.80 ± 0.52 a | 4.97 ± 0.06 b | 5.83 ± 0.10 ab |

| 30 d (4) | 1.93 ± 0.02 a | 63.77 ± 0.49 a | 67.53 ± 0.15 a | 71.07 ± 0.84 a | 7.30 ± 1.11 a | 4.77 ± 0.15 b | 6.04 ± 0.20 a |

| CP Treatments | PV (cp) | TV (cp) | BD (cp) | FV (cp) | SB (cp) | Peak Time (min) | PT (°C) |

|---|---|---|---|---|---|---|---|

| CK | 4597 ± 32 a | 2661 ± 91 ab | 1937 ± 72 a | 4106 ± 93 ab | 1445 ± 7 a | 5.89 ± 0.03 c | 70.93 ± 0.06 a |

| 0 h | 4595 ± 5 a | 2783 ± 45 a | 1812 ± 48 b | 4189 ± 29 a | 1407 ± 17 b | 5.98 ± 0.04 b | 70.65 ± 0.43 a |

| 24 h | 4420 ± 34 b | 2729 ± 27 a | 1691 ± 29 c | 4165 ± 41 ab | 1437 ± 62 ab | 6.05 ± 0.04 ab | 71.22 ± 0.55 a |

| 48 h | 4485 ± 32 b | 2738 ± 38 a | 1748 ± 57 bc | 4136 ± 40 a | 1398 ± 3 b | 6.02 ± 0.04 ab | 71.48 ± 0.51 a |

| 30 d | 4220 ± 54 c | 2625 ± 64 b | 1595 ± 16 d | 3965 ± 59 b | 1340 ± 7 c | 6.07 ± 0.01 a | 71.17 ± 0.46 a |

| CP Treatments | Water SRC (%) | NaHCO3 SRC (%) | Lactic Acid SRC (%) | Sucrose SRC (%) |

|---|---|---|---|---|

| CK (0) | 105.95 ± 0.90 c | 113.66 ± 1.72 b | 110.47 ± 1.26 b | 131.25 ± 0.67 c |

| 0 h (1) | 110.09 ± 1.40 b | 118.90 ± 0.88 a | 108.01 ± 1.91 b | 135.33 ± 0.94 a |

| 24 h (2) | 110.97 ± 1.71 b | 112.50 ± 1.80 b | 110.07 ± 0.77 b | 132.77 ± 0.47 b |

| 48 h (3) | 114.77 ± 0.90 a | 114.98 ± 1.32 b | 115.43 ± 1.60 a | 135.71 ± 0.06 a |

| 30 d (4) | 106.65 ± 0.91 c | 114.68 ± 1.67 b | 109.77 ± 0.16 b | 131.88 ± 0.40 c |

| CP Treatments | IR Ratios | ||

|---|---|---|---|

| R1022/995 | R1047/1022 | R1068/1022 | |

| CK (0) | 1.056 ± 0.008 a | 0.910 ± 0.006 a | 0.759 ± 0.011 a |

| 0 h (1) | 1.054 ± 0.021 a | 0.914 ± 0.008 a | 0.762 ± 0.012 a |

| 24 h (2) | 1.065 ± 0.012 a | 0.904 ± 0.010 a | 0.739 ± 0.017 a |

| 48 h (3) | 1.045 ± 0.013 a | 0.916 ± 0.007 a | 0.769 ± 0.013 a |

| 30 d (4) | 1.059 ± 0.014 a | 0.912 ± 0.012 a | 0.760 ± 0.014 a |

| CP Treatments | C6:0 | C10:0 | C12:0 | C14:0 | C14:1 |

|---|---|---|---|---|---|

| CK (0) | 33.0 ± 1.0 a | 26.8 ± 0.8 b | 27.7 ± 0.2 c | 22.1 ± 0.2 b | 3.8 ± 0.1 c |

| 0 h (1) | 32.7 ± 1.5 a | 27.4 ± 0.2 b | 29.9 ± 2.5 bc | 23.6 ± 3.6 ab | 4.3 ± 0.3 ab |

| 24 h (2) | 28.4 ± 0. 6 c | 27.7 ± 4.1 b | 27.5 ± 1.5 bc | 21.7 ± 2.1 ab | 4.1 ± 0.2 b |

| 48 h (3) | 24.4 ± 1.2 d | 32.1 ± 4.9 ab | 33.9 ± 5.8 ab | 20.8 ± 1.6 b | 4.6 ± 0.4 ab |

| 30 d (4) | 30.7 ± 0. 4 b | 34.9 ± 2.1 a | 39.2 ± 1.1 a | 23.2 ± 0.6 a | 4.8 ± 0.3 a |

| CP Treatments | C15:0 | C15:1 | C16:0 | C18:0 | C18:1n9c |

| CK (0) | 4.6 ± 0.2 c | 6.1 ± 0.4 b | 585.3 ± 11.2 a | 175.3 ± 2.5 c | 271.1 ± 17.3 a |

| 0 h (1) | 5.3 ± 0.3 ab | 6.4 ± 0.3 b | 613.6 ± 60.1 ab | 197.1 ± 19.1 b | 267.7 ± 23.2 a |

| 24 h (2) | 4.8 ± 0.6 bc | 6.3 ± 0.2 b | 573.1 ± 34.1 ab | 208.1 ± 9.7 b | 222.1 ± 15.9 bc |

| 48 h (3) | 5.7 ± 0.1 a | 6.7 ± 0.4 ab | 543.2 ± 22.2 b | 205.9 ± 10.2 b | 204.5 ± 3.1 c |

| 30 d (4) | 5.8 ± 0.3 a | 7.1 ± 0.2 a | 594.8 ± 5.9 a | 231.7 ± 4.1 a | 217.5 ± 3.1 b |

| CP Treatments | C18:1n9t | C18:2n6c | C18:3n3 | C20:0 | C20:1 |

| CK (0) | 0.1 ± 0.1e | 677.2 ± 28.7 a | 60.2 ± 0.5 a | 11.4 ± 0.3 c | 2.7 ± 0.4 a |

| 0 h (1) | 9.5 ± 0.7 d | 657.1 ± 64.1 a | 59.4 ± 3.1 ab | 12.7 ± 0.7 ab | 1.6 ± 0.2 b |

| 24 h (2) | 14.2 ± 0.4 c | 551.3 ± 41.4 b | 55.3 ± 1.6 bc | 11.1 ± 0.4 c | 0.5 ± 0.1 c |

| 48 h (3) | 15.6 ± 0.6 b | 498.4 ± 13.1 b | 54.1 ± 0.6 c | 11.1 ± 1.2 bc | 1.3 ± 0.3 b |

| 30 d (4) | 17.7 ± 1.1 a | 548.3 ± 4.9 b | 55.1 ± 0.3 c | 13.5 ± 0.1 a | 0.1 ± 0.1 d |

| CP Treatments | C20:5n3 | C22:6n3 | C24:0 | C24:1 | Ratio |

| CK (0) | 2.5 ± 0.1 ab | 5.2 ± 0.2 a | 14.1 ± 0.8 a | 9.1 ± 0.1 bc | 1.15 ± 0.04 a |

| 0 h (1) | 2.6 ± 0.2 ab | 3.7 ± 0.3 bc | 12.9 ± 0.7 ab | 9.5 ± 0.4 b | 1.07 ± 0.01 b |

| 24 h (2) | 2.3 ± 0.1 b | 3.1 ± 0.2 d | 13.1 ± 1.4 ab | 8.7 ± 0.3 c | 0.95 ± 0.95 c |

| 48 h (3) | 2.4 ± 0.1 ab | 3.2 ± 0.6 cd | 12.1 ± 0.7 b | 9.7 ± 0.5 ab | 0.91 ± 0.03 cd |

| 30 d (4) | 2.7 ± 0.2 a | 4.1 ± 0.1 b | 13.1 ± 0.6 ab | 10.3 ± 0.1 a | 0.87 ± 0.02 d |

| Sorption | Cp Treatments | Mcpe | Coefficients | Statistic | Parameters | |||

|---|---|---|---|---|---|---|---|---|

| A | B | C | RSS | SE | R2 | MRE (%) | ||

| Ads. | CK (0) | 439.522 ± 49.717 a | 38.236 ± 6.122 a | 0.221 ± 0.006 a | 18.4802 | 0.4620 | 0.9747 | 6.0734 |

| 0 h (1) | 449.323 ± 49.701 a | 39.451 ± 6.127 a | 0.219 ± 0.005 a | 17.3578 | 0.4339 | 0.9766 | 6.2175 | |

| 24 h (2) | 426.744 ± 46.921 a | 38.849 ± 6.041 a | 0.215 ± 0.005 a | 18.1666 | 0.4542 | 0.9763 | 6.6199 | |

| 48 h (3) | 427.376 ± 46.286 a | 37.201 ± 5.739 a | 0.218 ± 0.005 a | 17.9984 | 0.4499 | 0.9761 | 6.3093 | |

| 30 d (4) | 414.708 ± 41.339 a | 33.343 ± 4.846 a | 0.216 ± 0.005 a | 17.2339 | 0.4309 | 0.9774 | 6.1359 | |

| Des. | CK (0) | 482.952 ± 41.797 a | 35.951 ± 4.389 a | 0.216 ± 0.004 a | 12.0133 | 0.2930 | 0.9834 | 3.6602 |

| 0 h (1) | 502.329 ± 44.104 a | 36.613 ± 4.502 a | 0.216 ± 0.004 a | 12.0893 | 0.2949 | 0.9834 | 3.6179 | |

| 24 h (2) | 482.612 ± 43.177 a | 35.693 ± 4.507 a | 0.213 ± 0.004 a | 13.2659 | 0.3236 | 0.9822 | 3.7853 | |

| 48 h (3) | 481.107 ± 41.317 a | 34.809 ± 4.236 a | 0.215 ± 0.004 a | 12.3237 | 0.3006 | 0.9833 | 3.6594 | |

| 30 d (4) | 466.352 ± 36.156 a | 30.724 ± 3.457 a | 0.214 ± 0.004 a | 11.3338 | 0.2763 | 0.9848 | 3.549 |

| CP Treatment (Times) | Adsorption | Desorption | ||

|---|---|---|---|---|

| Mm (% Dry Basis) | Surface Area (m2/g Solid) | Mm (% Dry Basis) | Surface Area (m2/g Solid) | |

| CK | 7.02 ± 0.51 a | 266.7 ± 18.0 a | 9.46 ± 0.82 a | 369.3 ± 29.4 a |

| 0 h (1) | 7.13 ± 0.50 a | 271.1 ± 17.9 a | 9.59 ± 0.81 a | 374.9 ± 28.9 a |

| 24 h (2) | 7.17 ± 0.53 a | 272.8 ± 18.8 a | 9.68 ± 0.86 a | 378.7 ± 30.6 a |

| 48 h (3) | 7.05 ± 0.50 a | 267.9 ± 17.9 a | 9.49 ± 0.53 a | 370.9 ± 29.4 a |

| 30 d (4) | 7.23 ± 0.52 a | 275.2 ± 18.6 a | 9.76 ± 0.88 a | 382.1 ± 31.3 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, Z.; Li, X.; Song, H.; Jie, Y.; Liu, C. Effect of Intermittent Low-Pressure Radiofrequency Helium Cold Plasma Treatments on Rice Gelatinization, Fatty Acid, and Hygroscopicity. Foods 2024, 13, 1056. https://doi.org/10.3390/foods13071056

Cao Z, Li X, Song H, Jie Y, Liu C. Effect of Intermittent Low-Pressure Radiofrequency Helium Cold Plasma Treatments on Rice Gelatinization, Fatty Acid, and Hygroscopicity. Foods. 2024; 13(7):1056. https://doi.org/10.3390/foods13071056

Chicago/Turabian StyleCao, Ziyi, Xingjun Li, Hongdong Song, Yu Jie, and Chang Liu. 2024. "Effect of Intermittent Low-Pressure Radiofrequency Helium Cold Plasma Treatments on Rice Gelatinization, Fatty Acid, and Hygroscopicity" Foods 13, no. 7: 1056. https://doi.org/10.3390/foods13071056

APA StyleCao, Z., Li, X., Song, H., Jie, Y., & Liu, C. (2024). Effect of Intermittent Low-Pressure Radiofrequency Helium Cold Plasma Treatments on Rice Gelatinization, Fatty Acid, and Hygroscopicity. Foods, 13(7), 1056. https://doi.org/10.3390/foods13071056