A Novel Strategy for Mixed Jam Evaluation: Apparent Indicator, Sensory, Metabolomic, and GC-IMS Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

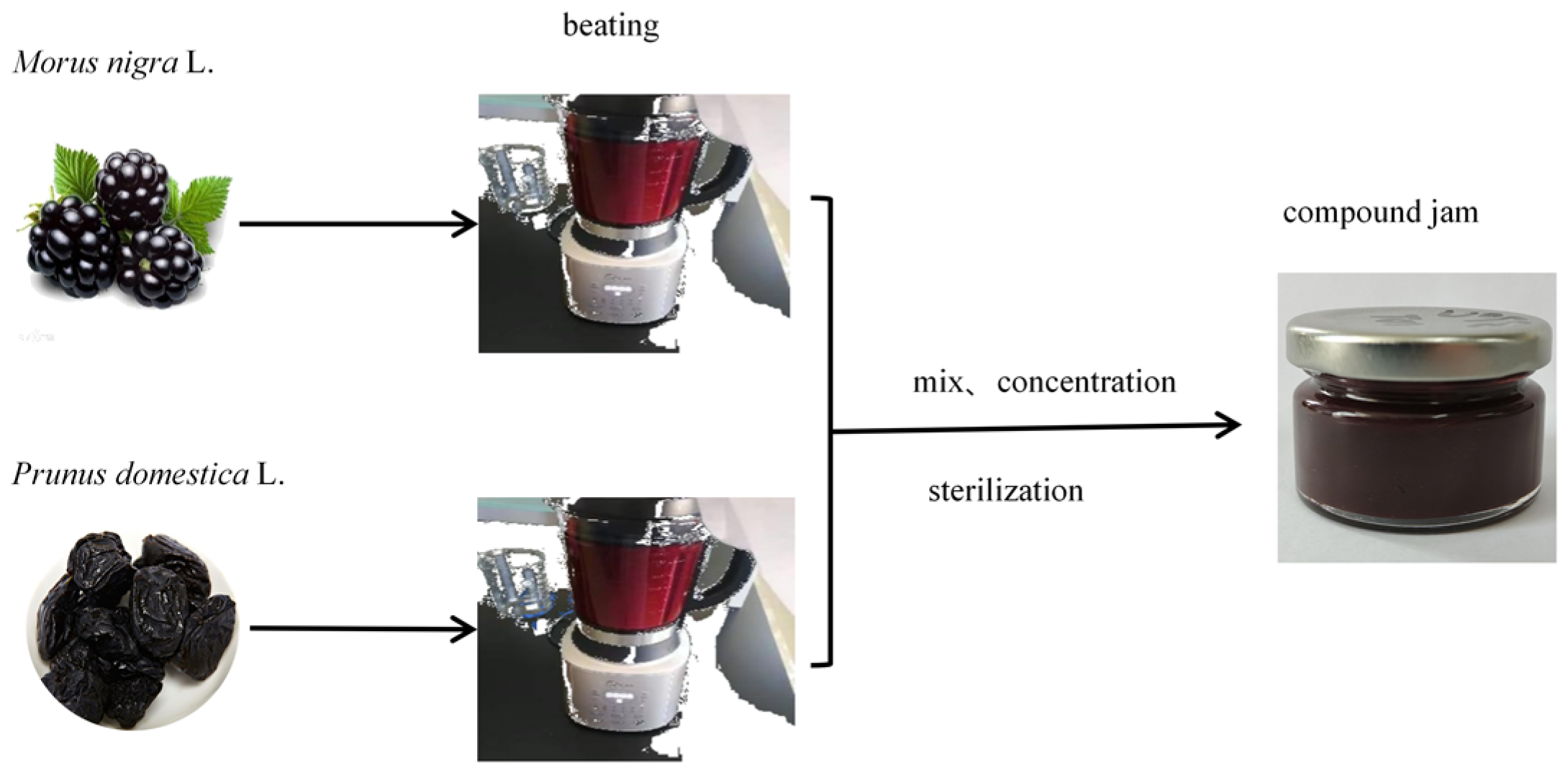

2.2. Mixed Jam Preparation

2.3. Physical and Chemical Indicators Analysis

2.4. Polyphenols and Antioxidants

2.5. Sensory Evaluation

2.6. Metabolite Extraction and Analysis by Liquid Chromatography–Mass Spectrometry

2.7. Analysis of Volatile Aroma Components

2.8. Data Processing and Statistical Analysis

3. Results and Discussion

3.1. Physical and Chemical Indicators

3.2. Antioxidant Activity

3.3. Sensorial Profile

3.4. Metabolome

3.4.1. Multivariate Statistical Analysis of Metabolome

3.4.2. Screening for Differential Metabolites

3.4.3. Dynamic Changes in Polyphenols during Storage

3.5. Fragrance Change

3.5.1. Comparative Analysis of Volatile Constituent Profiles in Single-Fruit and Mixed Jams

3.5.2. Fingerprinting of Volatile Components in Single-Fruit and Mixed Jams

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abid, M.; Yaich, H.; Hidouri, H.; Attia, H.; Ayadi, M.A. Effect of substituted gelling agents from pomegranate peel on colour, textural and sensory properties of pomegranate jam. Food Chem. 2018, 239, 1047–1054. [Google Scholar] [CrossRef]

- Barbieri, S.F.; de Oliveira Petkowicz, C.L.; de Godoy, R.C.B.; de Azeredo, H.C.M.; Franco, C.R.C.; Silveira, J.L.M. Pulp and jam of gabiroba (Campomanesia xanthocarpa Berg): Characterization and Rheological properties. Food Chem. 2018, 263, 292–299. [Google Scholar] [CrossRef] [PubMed]

- TNAU Agritech Portal: Post Harvest Technology. Available online: http://www.agritech.tnau.ac.in/postharvest/fpo_spec.html (accessed on 17 September 2023).

- Aimin, M.; Xiaoquan, Q. Mining plant metabolomes: Methods, applications and perspectives. Plant Commun. 2021, 2, 10028. [Google Scholar]

- Hu, S.; Liu, C.; Liu, X. Innovative application of metabolomics on bioactive ingredients of Foods. Foods 2022, 11, 2974. [Google Scholar] [CrossRef] [PubMed]

- Panseri, S.; Arioli, F. Impact of irradiation on metabolomics profile of ground meat and its implications toward food safety. LWT 2022, 161, 113305. [Google Scholar] [CrossRef]

- Wang, T.; Wei, G. Integrated metabolomics and peptidomics to delineate characteristic metabolites in milk fermented with novel Lactiplantibacillus plantarum L3. Food Chem. 2023, 18, 100732. [Google Scholar] [CrossRef]

- Moing, A.; Pétriacq, P.; Osorio, S. Special Issue on “Fruit Metabolism and Metabolomics”. Metabolites 2022, 10, 230. [Google Scholar] [CrossRef]

- Liu, H.; Wen, J.; Xu, Y.; Wu, J.; Yu, Y.; Yang, J.; Liu, H.; Fu, M. Evaluation of dynamic changes and formation regularity in volatile flavor compounds in Citrus reticulata ‘chachi’ peel at different collection periods using gas chromatography-ion mobility spectrometry. LWT 2022, 171, 114126. [Google Scholar] [CrossRef]

- Kwan, C.; Snyder, A.P.; Erickson, R.P.; Smith, P.A.; Maswadeh, W.M.B.; Ayhan, J.L.; Jensen, J.L.; Jensen, J.O.; Tripathi, A. Chemical Agent Detection Using GC-IMS: A Comparative Study. IEEE Sens. J. 2010, 10, 451–460. [Google Scholar] [CrossRef]

- Wang, S.; Chen, H.; Sun, B. Recent progress in food flavor analysis using gas chromatography–ion mobility spectrometry (GC-IMS). Food Chem. 2020, 315, 126158. [Google Scholar] [CrossRef] [PubMed]

- Geng, D.; Chen, X.; Lu, D.; Chen, B. Discrimination of different edible vegetable oils based on GC-IMS and SIMCA. CyTA J. Food 2023, 21, 49–56. [Google Scholar] [CrossRef]

- He, S.; Wang, Q.; Ayinuer, B.; Liu, M.; Shen, J.; Li, W.; Xiao, H. Total flavonoid content and antioxidant activity of mulberries from Xinjiang. Shaan Xi J. Agric. Sci. 2023, 69, 13–21. [Google Scholar]

- Ma, Y.; Zhang, X.; Li, L.; Yang, W.; Zhang, W.; Cheng, S.; Guo, M.; Chen, G. Delaying fruit softening of ‘France’ prune (Prunus domestica L.) using near-freezing temperature storage. LWT 2022, 172, 114165. [Google Scholar] [CrossRef]

- Chen, M.; Wang, Z.; Yu, J.; Wang, J.; Xu, H.; Yue, X. Effects of electron beam irradiation and ultrahigh-pressure treatments on the physicochemical properties, active components, and flavor volatiles of jujube jam. LWT 2023, 187, 115292. [Google Scholar] [CrossRef]

- GB 12456-2021; Determination of Total Acid in Food of National Standard for Food Safety. National Health Commission of the People’s Republic of China, State Administration for Market Regulation: Beijing, China, 2021.

- Culetu, A.; Manolache, F.A.; Duta, D.E. Exploratory study of physicochemical, textural and sensory characteristics of sugar-free traditional plum jams. J. Texture Stud. 2014, 45, 138–147. [Google Scholar] [CrossRef]

- Miao, H.Y.; Wang, M.Y.; Chang, J.Q.; Tao, H.; Sun, B.; Wang, Q.M. Effects of glucose and gibberellic acid on glucosinolate content and antioxidant properties of Chinese kale sprouts. J. Zhejiang Univ. Sci. B 2017, 18, 1093–1100. [Google Scholar] [CrossRef] [PubMed]

- Amorim, F.L.; Cerqueira Silva, M.B.d.; Cirqueira, M.G.; Oliveira, R.S.; Machado, B.A.S.; Gomes, R.G.; Souza, C.O.d.; Druzian, J.I.; Souza Ferreira, E.d.; Umsza-Guez, M.A. Grape peel (Syrah var.) jam as a polyphenol-enriched functional food ingredient. Food Sci. Nutr. 2019, 7, 1584–1594. [Google Scholar] [CrossRef] [PubMed]

- Banaś, A.; Korus, A.; Tabaszewska, M. Quality assessment of low-sugar jams enriched with plant raw materials exhibiting health-promoting properties. J. Food Sci. Technol. 2017, 55, 408–417. [Google Scholar] [CrossRef] [PubMed]

- GB/T 22474-2008; Jam. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2008.

- Nistor, O.V.; Bolea, C.A.; Andronoiu, D.G.; Cotârleț, M.; Stănciuc, N. Attempts for developing novel sugar-based and sugar-free sea buckthorn marmalades. Molecules 2021, 26, 3073. [Google Scholar] [CrossRef] [PubMed]

- T/CNFIA 001-2017; General Guideline for Food Shelf Life. China National Food Industry Association: Beijing, China, 2017.

- Seo, C.S.; Shin, H.K. Simultaneous Determination of 12 Marker Components in Yeonkyopaedok-san Using HPLC–PDA and LC–MS/MS. Appl. Sci. 2020, 10, 1713. [Google Scholar] [CrossRef]

- Publisher of Peer-Reviewed Articles in Open Access Journals. Available online: https://www.frontiersin.org/ (accessed on 10 November 2023).

- National Center for Biotechnology Information. Available online: https://www.ncbi.nlm.nih.gov/ (accessed on 25 November 2023).

- Publishing Open Access Research Journals & Papers. Available online: https://www.hindawi.com/ (accessed on 20 November 2023).

- Dubey, A.; Kumar, A.; Rao, P.S. Development and storage study of reduced calorie aloe vera (Aloe barbadensis Miller) based pineapple fruit jam. J. Food Meas. Charact. 2020, 15, 961–975. [Google Scholar] [CrossRef]

- Chawafambira, A. Extraction and characterization of pectin from snot apple (Azanza garckeana) fruits with potential use in Zimbabwe. Int. J. Fruit Sci. 2021, 21, 791–803. [Google Scholar] [CrossRef]

- Picot-Allain, M.C.N.; Ramasawmy, B.; Emmambux, M.N. Extraction, characterisation, and application of pectin from tropical and sub-tropical Fruits: A review. Food Rev. Int. 2020, 38, 282–312. [Google Scholar] [CrossRef]

- Xie, J.; Peng, G.; Hu, X.; Xie, J.; Chen, Y.; Dong, R.; Si, J.; Yang, C.; Yu, Q. Physicochemical characteristics of soluble dietary fiber obtained from grapefruit peel insoluble dietary fiber and its effects on blueberry jam. Foods 2022, 11, 3735. [Google Scholar] [CrossRef] [PubMed]

- Popov, S.V.; Ovodova, R.G.; Golovchenko, V.V.; Khramova, D.S.; Markov, P.A.; Smirnov, V.V.; Shashkov, A.S.; Ovodov, Y.S. Pectic polysaccharides of the fresh plum Prunus domestica L. isolated with a simulated gastric fluid and their anti-inflammatory and antioxidant activities. Food Chem. 2013, 143, 106–113. [Google Scholar] [CrossRef]

- Hao, J.; Gao, Y.; Xue, J.; Yang, Y.; Yin, J.; Wu, T.; Zhang, M. Phytochemicals, pharmacological effects and molecular mechanisms of mulberry. Foods 2022, 11, 1170. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Bao, T.; Chen, W. Comparison of the protective effect of black and white mulberry against ethyl carbamate-induced cytotoxicity and oxidative damage. Food Chem. 2018, 243, 65–73. [Google Scholar] [CrossRef] [PubMed]

- Erden, Y. Sour black mulberry (Morus nigra L.) causes cell death by decreasing mutant p53 expression in HT-29 human colon cancer cells. Food Biosci. 2021, 42, 101113. [Google Scholar] [CrossRef]

- Emelike, N.J.T.; Akusu, O.M. Quality Attributes of Jams and Marmalades Produced from Some Selected Tropical Fruits. J. Food Proc. Technol. 2019, 10, 1000790. [Google Scholar]

- Ai, J.; Wu, Q.; Battino, M.; Bai, W.; Tian, L. Using untargeted metabolomics to profile the changes in roselle (Hibiscus sabdariffa L.) anthocyanins during wine fermentation. Food Chem. 2021, 364, 130425. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Fan, X.; Zhang, S.; Yu, M.; Wu, T.; Liang, Y.; Wang, C.; Yang, H. Effect of thermal processing on the metabolic components of black beans on ultra-high-performance liquid chromatography coupled with high-field quadrupole-orbitrap high-resolution mass spectrometry. Molecules 2022, 27, 3919. [Google Scholar] [CrossRef] [PubMed]

- Meiji Service Network—Meiji Biological One-Stop Scientific Research Service Platform. Available online: https://www.majorbio.com/web/www/index (accessed on 26 December 2023).

- Li, M.; Zhang, J.; Li, L.; Wang, S.; Liu, Y.; Gao, M. Effect of enzymatic hydrolysis on volatile flavor compounds of Monascus-fermented tartary buckwheat based on headspace gas chromatography-ion mobility spectrometry. Food Res. Int. 2022, 163, 112180. [Google Scholar] [CrossRef] [PubMed]

- Gao, L.; Zhang, L.; Liu, J.; Zhang, X.; Lu, Y. Analysis of the volatile flavor compounds of pomegranate seeds at different processing temperatures by GC-IMS. Molecules 2023, 28, 2717. [Google Scholar] [CrossRef] [PubMed]

| Item | Trait Performance | Score |

|---|---|---|

| Spreadability (15 points) | Easy to apply, even, continuous, smooth coating, no faults | 10.1–15 |

| Easier to apply, more even coating, some consistency | 5.1–10 | |

| Not suitable for application, uneven coating, not easy to push away | 0–5 | |

| Odor (15 points) | Rich in odor, with fruity notes of Morus nigra L. or Prunus domestica L. | 10.1–15 |

| Morus nigra L. or Prunus domestica L. are less fruity | 6.1–10 | |

| Strong irritating odor, no Morus nigra L. or Prunus domestica L. fruit aroma | 0–6 | |

| Texture (20 points) | Good gelation, no layering, no liquid precipitation on the surface | 15.1–20 |

| Basic gel formation, flow feeling, slight water precipitation | 8.1–15 | |

| No gel formation, strong flow sensation, layering phenomenon | 0–8 | |

| Color (20 points) | Uniform color and high color brightness | 15.1–20 |

| More uniform color, lower color brightness | 8.1–15 | |

| Uneven color, dark color brightness | 0–8 | |

| Taste (30 points) | Moderately tart or sweet, fruity, and smooth | 20.1–30 |

| Tart or sweet, less fruity, and smoother in texture | 10.1–20 | |

| Excessive acidity or sweetness, off-flavor, sticky and uneven texture | 0–10 |

| Morus nigra L. to Prunus domestica L. in Jam (w/w) | 0:5 | 1:4 | 2:3 | 3:2 | 4:1 | 5:0 |

|---|---|---|---|---|---|---|

| pH | 4.13 ± 0.005 a | 3.99 ± 0.015 b | 3.84 ± 0.050 c | 3.61 ± 0.010 d | 3.41 ± 0.006 e | 3.25 ± 0.006 f |

| Total acid (%) | 3.30 ± 0.004 f | 6.74 ± 0.005 e | 10.45 ± 0.007 d | 13.62 ± 0.004 c | 15.37 ± 0.002 b | 18.09 ± 0.003 a |

| Morus nigra L. to Prunus domestica L. in Jam (w/w) | L* | a* | b* | ∆E |

|---|---|---|---|---|

| 0:5 | 31.85 ± 0.03 a | 2.51 ± 0.10 c | 2.56 ± 0.33 a | 68.15 ± 0.04 b |

| 1:4 | 29.37 ± 0.20 b | 3.37 ± 0.04 ab | −0.16 ± 0.31 b | 70.63 ± 0.20 a |

| 2:3 | 28.73 ± 0.13 bc | 3.45 ± 0.11 a | −0.54 ± 0.26 b | 71.27 ± 0.13 a |

| 3:2 | 28.70 ± 0.06 bc | 3.09 ± 0.41 d | −1.00 ± 0.16 c | 71.30 ± 0.05 a |

| 4:1 | 28.73 ± 0.11 bc | 3.03 ± 0.19 b | −1.01 ± 0.22 c | 71.27 ± 0.13 a |

| 5:0 | 28.14 ± 1.58 c | 2.28 ± 0.02 cd | −1.01 ± 0.06 c | 71.86 ± 1.56 a |

| Morus nigra L. to Prunus domestica L. in Jam (w/w) | Hardness | Adhesiveness | Chewiness | Cohesiveness |

|---|---|---|---|---|

| 0:5 | 47.76 ± 0.75 a | −726.58 ± 21.17 a | 36.70 ± 1.39 a | 0.84 ± 0.021 b |

| 1:4 | 43.34 ± 2.06 b | −603.90 ± 2.76 b | 33.23 ± 2.34 b | 0.83 ± 0.006 b |

| 2:3 | 38.20 ± 0.94 c | −473.91 ± 12.99 c | 27.17 ± 0.74 c | 0.80 ± 0.002 c |

| 3:2 | 36.66 ± 0.92 cd | −375.14 ± 6.37 d | 26.83 ± 1.25 c | 0.81 ± 0.013 bc |

| 4:1 | 34.56 ± 1.66 e | −351.49 ± 0.78 e | 25.85 ± 1.88 c | 0.83 ± 0.013 bc |

| 5:0 | 19.10 ± 0.73 f | −29.59 ± 2.83 f | 14.38 ± 0.78 d | 0.89 ± 0.002 a |

| Morus nigra L. to Prunus domestica L. in Jam (w/w) | Total Antioxidant Capacity (U/mL) | OH (%) | DPPH (mM TE /g FW) | ABTS (mM TE/g FW) | Total Polyphenol (mgGAE/100 g FW) |

|---|---|---|---|---|---|

| 0:5 | 205.73 ± 12.58 e | 0.08 ± 0.002 d | 0.84 ± 0.021 b | 2.77 ± 0.27 d | 381.00 ± 26.60 d |

| 1:4 | 229.89 ± 8.15 d | 0.08 ± 0.006 d | 0.83 ± 0.006 b | 3.35 ± 0.29 d | 403.35 ± 2.34 cd |

| 2:3 | 250.86 ± 1.48 c | 0.09 ± 0.004 cd | 0.80 ± 0.002 c | 4.68 ± 0.31 c | 422.25 ± 3.75 c |

| 3:2 | 265.81 ± 13.70 c | 0.10 ± 0.008 bc | 0.81 ± 0.013 bc | 5.46 ± 0.87 c | 428.95 ± 7.46 c |

| 4:1 | 319.95 ± 5.92 b | 0.11 ± 0.005 b | 0.83 ± 0.013 bc | 6.67 ± 0.41 b | 550.40 ± 13.76 b |

| 5:0 | 375.55 ± 14.43 a | 0.12 ± 0.009 a | 0.89 ± 0.002 a | 8.08 ± 0.38 a | 649.31 ± 7.37 a |

| Morus nigra L. to Prunus domestica L. in Jam (w/w) | Spreadability | Odor | Texture | Color | Taste | Total Sensory Score |

|---|---|---|---|---|---|---|

| 0:5 | 8.88 ± 2.57 b | 11.53 ± 2.91 a | 17.37 ± 0.82 a | 8.45 ± 2.11 c | 12.45 ± 4.51 d | 59.08 ± 10.74 c |

| 1:4 | 9.30 ± 2.58 b | 11.48 ± 2.76 a | 17.45 ± 0.69 a | 11.63 ± 2.64 b | 15.62 ± 4.59 cd | 65.48 ± 9.10 bc |

| 2:3 | 10.08 ± 2.52 ab | 11.40 ± 2.12 a | 18.22 ± 0.63 a | 14.72 ± 2.31 a | 15.22 ± 2.14 cd | 69.63 ± 5.66 ab |

| 3:2 | 12.30 ± 2.98 a | 10.77 ± 3.19 a | 18.02 ± 0.67 a | 15.62 ± 1.42 a | 20.98 ± 4.62 ab | 77.68 ± 9.95 a |

| 4:1 | 11.22 ± 1.99 ab | 12.33 ± 2.14 a | 14.77 ± 1.03 b | 16.62 ± 1.17 a | 22.97 ± 3.71 a | 77.90 ± 6.69 a |

| 5:0 | 11.03 ± 1.49 ab | 11.70 ± 3.16 a | 10.73 ± 2.38 c | 15.57 ± 2.01 a | 19.02 ± 4.82 bc | 68.05 ± 10.12 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maimaitiyiming, R.; Zhang, H.; Wang, J.; Wang, L.; Zhao, L.; Liu, B.; Chen, K.; Aihaiti, A. A Novel Strategy for Mixed Jam Evaluation: Apparent Indicator, Sensory, Metabolomic, and GC-IMS Analysis. Foods 2024, 13, 1104. https://doi.org/10.3390/foods13071104

Maimaitiyiming R, Zhang H, Wang J, Wang L, Zhao L, Liu B, Chen K, Aihaiti A. A Novel Strategy for Mixed Jam Evaluation: Apparent Indicator, Sensory, Metabolomic, and GC-IMS Analysis. Foods. 2024; 13(7):1104. https://doi.org/10.3390/foods13071104

Chicago/Turabian StyleMaimaitiyiming, Ruxianguli, Huimin Zhang, Jiayi Wang, Liang Wang, Lei Zhao, Bingze Liu, Keping Chen, and Aihemaitijiang Aihaiti. 2024. "A Novel Strategy for Mixed Jam Evaluation: Apparent Indicator, Sensory, Metabolomic, and GC-IMS Analysis" Foods 13, no. 7: 1104. https://doi.org/10.3390/foods13071104

APA StyleMaimaitiyiming, R., Zhang, H., Wang, J., Wang, L., Zhao, L., Liu, B., Chen, K., & Aihaiti, A. (2024). A Novel Strategy for Mixed Jam Evaluation: Apparent Indicator, Sensory, Metabolomic, and GC-IMS Analysis. Foods, 13(7), 1104. https://doi.org/10.3390/foods13071104