Dynamic Viscoelastic Behavior of Maize Kernel: Application of Frequency–Temperature Superposition

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Drying

2.2.1. Combined Hot Air- and Vacuum-Drying (HAVD)

2.2.2. Natural Drying (ND)

2.3. Sample Preparation

2.4. Frequency Dependency

2.5. Frequency–Temperature Superposition

2.6. Statistical Analysis

3. Results and Discussion

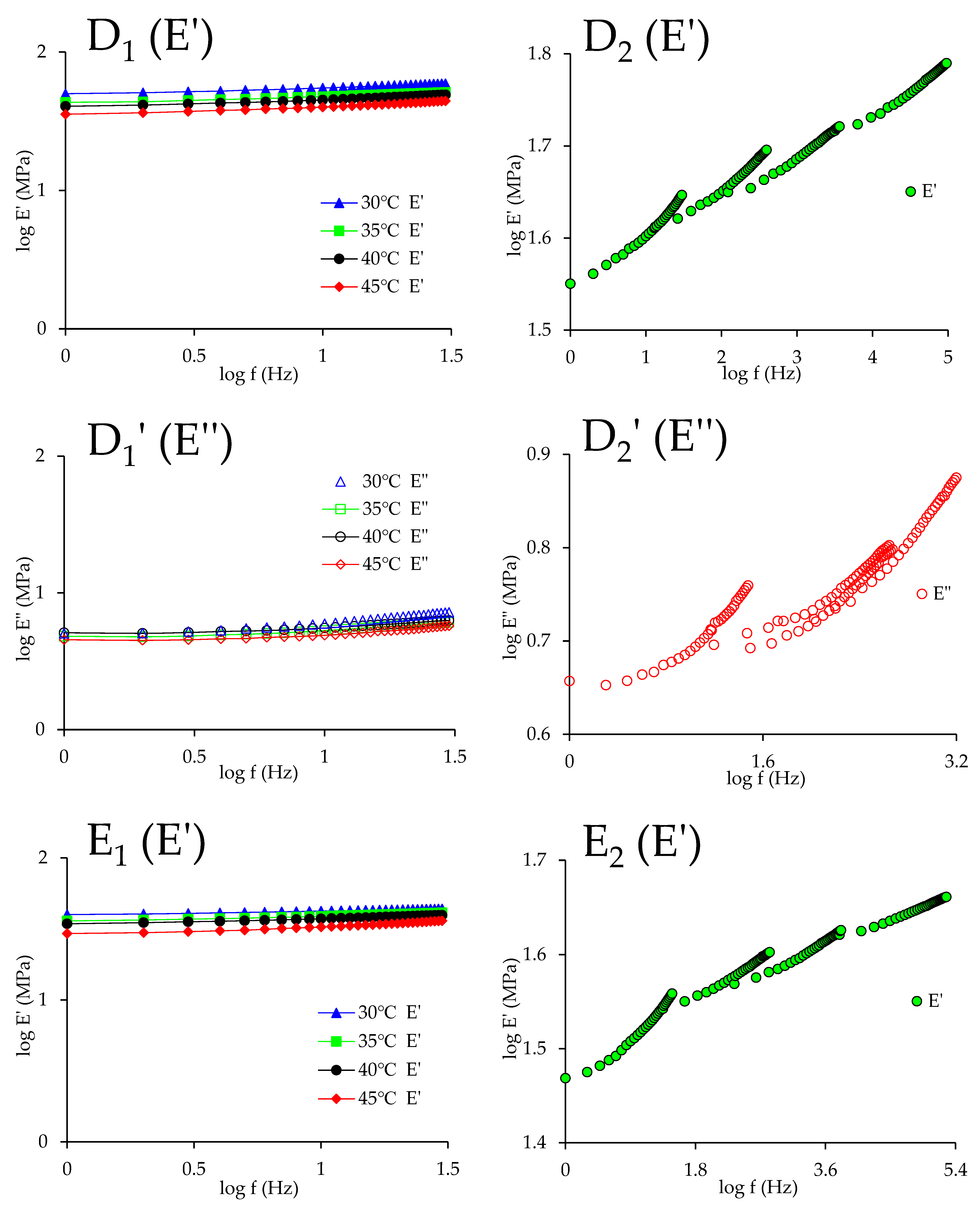

3.1. Frequency Dependency

3.2. Frequency–Temperature Superposition

3.3. Modified Cole–Cole Plot

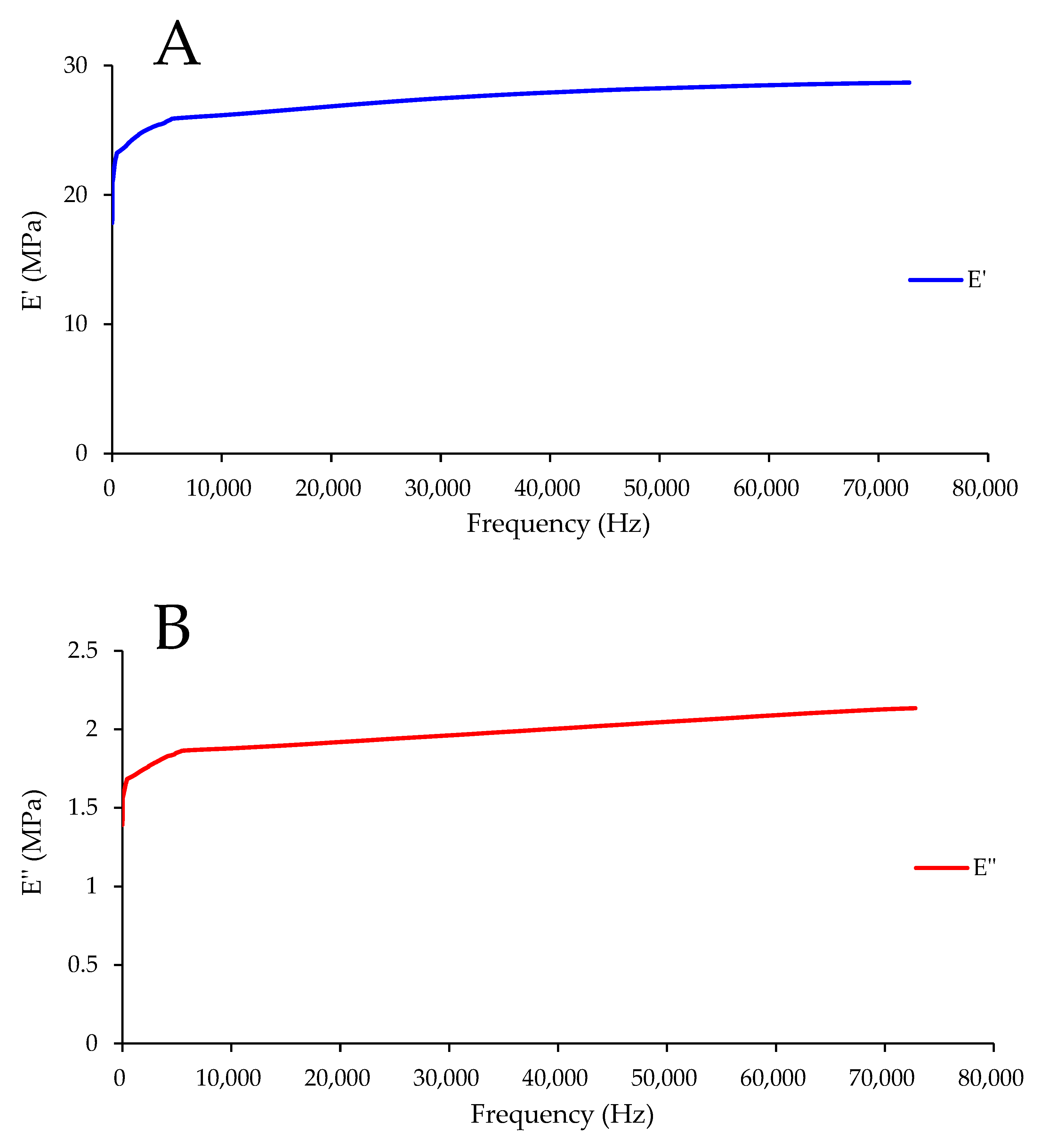

3.4. Wider Frequency Range

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, W.; Miao, X.; Qian, J.; Chen, S.; Jin, Q.; Li, M.; Han, L.; Zhong, W.; Xie, D.; Shang, X.; et al. A translatome-transcriptome multi-omics gene regulatory network reveals the complicated functional landscape of maize. Genome Biol. 2023, 24, 60. [Google Scholar] [CrossRef]

- Lippacher, A.; Müller, R.H.; Mäder, K. Semisolid SLN™ dispersions for topical application: Influence of formulation and production parameters on viscoelastic properties. Eur. J. Pharm. Biopharm. 2002, 53, 155–160. [Google Scholar] [CrossRef]

- Li, Q.; Li, D.; Wang, L.; Özkan, N.; Mao, Z. Dynamic viscoelastic properties of sweet potato studied by dynamic mechanical analyzer. Carbohyd. Polym. 2010, 79, 520–525. [Google Scholar] [CrossRef]

- Ditudompo, S.; Takhar, P.S.; Ganjyal, G.M.; Hanna, M.A. The effect of temperature and moisture on the mechanical properties of extruded cornstarch. J. Texture Stud. 2013, 44, 225–237. [Google Scholar] [CrossRef]

- Shi, A.; Wang, L.; Li, D.; Adhikari, B. Characterization of starch films containing starch nanoparticles. Part 2: Viscoelasticity and creep properties. Carbohyd. Polym. 2013, 96, 602–610. [Google Scholar] [CrossRef] [PubMed]

- Ozturk, O.K.; Takhar, P.S. Selected physical and viscoelastic properties of strawberries as a function of heated-air drying conditions. Dry. Technol. 2019, 37, 1833–1843. [Google Scholar] [CrossRef]

- Ahmed, J. Applicability of time–temperature superposition principle: Dynamic rheology of mung bean starch blended with sodium chloride and sucrose—Part 2. J. Food Eng. 2012, 109, 329–335. [Google Scholar] [CrossRef]

- Altay, F.; Gunasekaran, S. Rheological evaluation of gelatin–xanthan gum system with high levels of co-solutes in the rubber-to-glass transition region. Food Hydrocolloid. 2012, 28, 141–150. [Google Scholar] [CrossRef]

- Razavi, S.M.A.; Alghooneh, A.; Behrouzian, F. Thermo-rheology and thermodynamic analysis of binary biopolymer blend: A case study on sage seed gum-xanthan gum blends. Food Hydrocolloid. 2018, 77, 307–321. [Google Scholar] [CrossRef]

- Baek, D.M.; Han, C.D. Rheological behaviour of binary mixtures of polystyrene-block-polyisoprene copolymers in the disordered state. Polymer 1995, 36, 4833–4839. [Google Scholar] [CrossRef]

- Meza, B.E.; Verdini, R.A.; Rubiolo, A.C. Temperature dependency of linear viscoelastic properties of a commercial low-fat soft cheese after frozen storage. J. Food Eng. 2012, 109, 475–481. [Google Scholar] [CrossRef]

- Ahmed, J.; Auras, R.; Kijchavengkul, T.; Varshney, S.K. Rheological, thermal and structural behavior of poly(ε-caprolactone) and nanoclay blended films. J. Food Eng. 2012, 111, 580–589. [Google Scholar] [CrossRef]

- Wu, Y.; Guo, R.; Cao, N.; Sun, X.; Sui, Z.; Guo, Q. A systematical rheological study of polysaccharide from Sophora alopecuroides L. seeds. Carbohyd. Polym. 2018, 180, 63–71. [Google Scholar] [CrossRef] [PubMed]

- Defraeye, T.; Radu, A.; Derome, D. Recent advances in drying at interfaces of biomaterials. Dry. Technol. 2016, 34, 1904–1925. [Google Scholar] [CrossRef]

- Sheng, S.; Wang, L.; Li, D.; Mao, Z.; Adhikari, B. Viscoelastic behavior of maize kernel studied by dynamic mechanical analyzer. Carbohyd. Polym. 2014, 112, 350–358. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, X.; Sun, G.; Li, D.; Pan, Z. A comparison of dynamic mechanical properties of processing-tomato peel as affected by hot lye and infrared radiation heating for peeling. J. Food Eng. 2014, 126, 27–34. [Google Scholar] [CrossRef]

- Zhu, H.; Yang, L.; Fang, X.; Wang, Y.; Li, D.; Wang, L. Effects of intermittent radio frequency drying on structure and gelatinization properties of native potato flour. Food Res. Int. 2021, 139, 109807. [Google Scholar] [CrossRef] [PubMed]

- Quintana, S.E.; Torregroza-Fuentes, E.; García Zapateiro, L.A. Development of dressing-type emulsion with hydrocolloids from butternut squash seed: Effect of additives on emulsion stability. Gels 2022, 8, 209. [Google Scholar] [CrossRef] [PubMed]

- Cespi, M.; Bonacucina, G.; Mencarelli, G.; Casettari, L.; Palmieri, G.F. Dynamic mechanical thermal analysis of hypromellose 2910 free films. Eur. J. Pharm. Biopharm. 2011, 79, 458–463. [Google Scholar] [CrossRef]

- Hundal, J.; Takhar, P.S. Dynamic viscoelastic properties and glass transition behavior of corn kernels. Int. J. Food Prop. 2009, 12, 295–307. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Li, D.; Xue, J.; Mao, Z. Effects of drying methods on rheological properties of flaxseed gum. Carbohyd. Polym. 2009, 78, 213–219. [Google Scholar] [CrossRef]

- Li, M.; Li, D.; Wang, L.; Adhikari, B. Creep behavior of starch-based nanocomposite films with cellulose nanofibrils. Carbohyd. Polym. 2015, 117, 957–963. [Google Scholar] [CrossRef] [PubMed]

- Ferry, J.D. Viscoelastic Properties of Polymers, 3rd ed.; John Wiley & Sons: New York, NY, USA, 1980; p. 672. [Google Scholar]

- Zhu, Y.; Fu, N.; Li, D.; Wang, L.; Chen, X.D. Physical and viscoelastic properties of different moisture content highland barley kernels. Int. J. Food Eng. 2017, 13, 20170186. [Google Scholar] [CrossRef]

- Ahmed, J. Effect of pressure, concentration and temperature on the oscillatory rheology of guar gum dispersions: Response surface methodology approach. Food Hydrocolloid. 2021, 113, 106554. [Google Scholar] [CrossRef]

- Van Gurp, M.; Palmen, J. Time–temperature superposition for polymeric blends. Rheol. Bull. 1998, 67, 5–8. [Google Scholar]

- Subramanian, R.; Muthukumarappan, K.; Gunasekaran, S. Linear viscoelastic properties of regular- and reduced-fat pasteurized process cheese during heating and cooling. Int. J. Food Prop. 2006, 9, 377–393. [Google Scholar] [CrossRef]

- Sheng, S.; Shi, A.; Xing, J. A systematical rheological study of maize kernel. Foods 2023, 12, 738. [Google Scholar] [CrossRef]

- Nickerson, M.T.; Paulson, A.T. Time–temperature studies of κ-carrageenan gelation in the presence of high levels of co-solutes. Carbohyd. Polym. 2005, 61, 231–237. [Google Scholar] [CrossRef]

- Han, C.D.; Kim, J.K. On the use of time–temperature superposition in multicomponent/multiphase polymer systems. Polymer 1993, 34, 2533–2539. [Google Scholar] [CrossRef]

- Mours, M.; Winter, H.H. Mechanical spectroscopy of polymers. In Experimental Methods in Polymer Science: Modern Methods in Polymer Research and Technology; Tanaka, T., Ed.; Academic Press: San Diego, CA, USA, 2000; pp. 495–546. [Google Scholar]

- Xiao, Q.; Tong, Q.; Zhou, Y.; Deng, F. Rheological properties of pullulan-sodium alginate based solutions during film formation. Carbohyd. Polym. 2015, 130, 49–56. [Google Scholar] [CrossRef] [PubMed]

| Drying Treatment | Sample Size (Thickness × D *) | T (°C) | E′ = K′·fn′ | E″ = K″·fn” | ||||

|---|---|---|---|---|---|---|---|---|

| n′ | K′ (MPa·sn) | R2 | n″ | K″ (MPa·sn) | R2 | |||

| ND | 3.848 mm × 8.789 mm | 30 | 0.064 | 72.476 | 0.979 | 0.148 | 10.709 | 0.927 |

| 3.848 mm × 8.789 mm | 35 | 0.083 | 60.005 | 0.982 | 0.152 | 8.422 | 0.926 | |

| 3.848 mm × 8.789 mm | 40 | 0.103 | 51.683 | 0.977 | 0.146 | 8.389 | 0.917 | |

| 3.848 mm × 8.789 mm | 45 | 0.121 | 42.506 | 0.984 | 0.174 | 6.609 | 0.917 | |

| HAVD 35 °C | 4.073 mm × 8.755 mm | 30 | 0.049 | 31.068 | 0.969 | 0.115 | 2.330 | 0.916 |

| 4.073 mm × 8.755 mm | 35 | 0.056 | 28.296 | 0.976 | 0.098 | 2.318 | 0.901 | |

| 4.073 mm × 8.755 mm | 40 | 0.065 | 25.627 | 0.980 | 0.084 | 2.304 | 0.891 | |

| 4.073 mm × 8.755 mm | 45 | 0.066 | 21.432 | 0.964 | 0.101 | 1.831 | 0.874 | |

| HAVD 45 °C | 4.388 mm × 9.144 mm | 30 | 0.035 | 16.331 | 0.994 | 0.069 | 1.147 | 0.905 |

| 4.388 mm × 9.144 mm | 35 | 0.030 | 15.901 | 0.996 | 0.052 | 1.177 | 0.874 | |

| 4.388 mm × 9.144 mm | 40 | 0.051 | 13.598 | 0.992 | 0.038 | 1.186 | 0.769 | |

| 4.388 mm × 9.144 mm | 45 | 0.045 | 13.036 | 0.996 | 0.052 | 1.103 | 0.843 | |

| HAVD 55 °C | 4.588 mm × 9.313 mm | 30 | 0.056 | 48.636 | 0.980 | 0.132 | 4.504 | 0.951 |

| 4.588 mm × 9.313 mm | 35 | 0.055 | 42.159 | 0.984 | 0.092 | 4.382 | 0.924 | |

| 4.588 mm × 9.313 mm | 40 | 0.063 | 39.313 | 0.977 | 0.080 | 4.700 | 0.915 | |

| 4.588 mm × 9.313 mm | 45 | 0.071 | 34.325 | 0.972 | 0.090 | 4.100 | 0.886 | |

| HAVD 65 °C | 4.647 mm × 9.117 mm | 30 | 0.030 | 39.577 | 0.990 | 0.070 | 2.195 | 0.956 |

| 4.647 mm × 9.117 mm | 35 | 0.043 | 35.440 | 0.981 | 0.072 | 1.934 | 0.890 | |

| 4.647 mm × 9.117 mm | 40 | 0.045 | 33.877 | 0.985 | 0.046 | 2.131 | 0.832 | |

| 4.647 mm × 9.117 mm | 45 | 0.070 | 28.119 | 0.963 | 0.066 | 1.952 | 0.876 | |

| HAVD 75 °C | 3.979 mm × 8.845 mm | 30 | 0.042 | 23.725 | 0.976 | 0.078 | 1.549 | 0.940 |

| 3.979 mm × 8.845 mm | 35 | 0.045 | 21.469 | 0.968 | 0.076 | 1.432 | 0.919 | |

| 3.979 mm × 8.845 mm | 40 | 0.054 | 19.106 | 0.978 | 0.065 | 1.362 | 0.908 | |

| 3.979 mm × 8.845 mm | 45 | 0.063 | 17.147 | 0.972 | 0.070 | 1.271 | 0.853 | |

| Drying Treatment | T (°C) | logαT (E′) | logαT (E″) |

|---|---|---|---|

| ND | 30 | 2.868 | 2.868 |

| 35 | 1.628 | 1.628 | |

| 40 | 1.004 | 1.004 | |

| 45 | 0.000 | 0.000 | |

| HAVD 35 °C | 30 | 3.217 | 3.217 |

| 35 | 2.358 | 2.358 | |

| 40 | 1.457 | 1.457 | |

| 45 | 0.000 | 0.000 | |

| HAVD 45 °C | 30 | 2.717 | 2.717 |

| 35 | 1.997 | 1.997 | |

| 40 | 0.915 | 0.915 | |

| 45 | 0.000 | 0.000 | |

| HAVD 55 °C | 30 | 3.503 | 1.722 |

| 35 | 2.087 | 1.195 | |

| 40 | 1.121 | 1.168 | |

| 45 | 0.000 | 0.000 | |

| HAVD 65 °C | 30 | 3.795 | 2.171 |

| 35 | 2.338 | 1.278 | |

| 40 | 1.351 | 1.174 | |

| 45 | 0.000 | 0.000 | |

| HAVD 75 °C | 30 | 3.385 | 3.385 |

| 35 | 2.264 | 2.264 | |

| 40 | 1.147 | 1.147 | |

| 45 | 0.000 | 0.000 |

| Drying Treatment | Ea (kJ/mol) | R2 |

|---|---|---|

| ND | 341.049 | 0.987 |

| HAVD 35 °C | 388.955 | 0.978 |

| HAVD 45 °C | 340.723 | 0.993 |

| HAVD 55 °C | 424.109 (for E′), 191.014 (for E″) | 0.995 (for E′), 0.844 (for E″) |

| HAVD 65 °C | 457.004 (for E′), 244.030 (for E″) | 0.996 (for E′), 0.917 (for E″) |

| HAVD 75 °C | 416.221 | 0.999 |

| Drying Treatment | E′ = K′·fn′ | E″ = K″·fn″ | ||||

|---|---|---|---|---|---|---|

| n′ | K′ (MPa·sn) | R2 | n″ | K″ (MPa·sn) | R2 | |

| HAVD 75 °C | 0.042 | 17.871 | 0.995 | 0.038 | 1.338 | 0.979 |

| x | λi (s) | Ei (MPa) |

|---|---|---|

| 1 | 2.186 × 10−6 | 3.473 |

| 2 | 1.544 × 10−5 | 1.733 |

| 3 | 4.590 × 10−5 | 1.125 |

| 4 | 1.237 × 10−4 | 1.033 |

| 5 | 4.065 × 10−4 | 0.579 |

| 6 | 4.090 × 10−4 | 0.894 |

| 7 | 1.536 × 10−3 | 1.257 |

| 8 | 6.213 × 10−3 | 1.509 |

| 9 | 0.026 | 1.240 |

| 10 | 0.159 | 2.248 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheng, S.; Wu, M.; Lv, W. Dynamic Viscoelastic Behavior of Maize Kernel: Application of Frequency–Temperature Superposition. Foods 2024, 13, 976. https://doi.org/10.3390/foods13070976

Sheng S, Wu M, Lv W. Dynamic Viscoelastic Behavior of Maize Kernel: Application of Frequency–Temperature Superposition. Foods. 2024; 13(7):976. https://doi.org/10.3390/foods13070976

Chicago/Turabian StyleSheng, Shaoyang, Min Wu, and Weiqiao Lv. 2024. "Dynamic Viscoelastic Behavior of Maize Kernel: Application of Frequency–Temperature Superposition" Foods 13, no. 7: 976. https://doi.org/10.3390/foods13070976