The Prediction of Quality Parameters of Craft Beer with FT-MIR and Chemometrics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Samples

2.3. Sample Preparation

2.4. Chemical Analysis

2.5. Statistical Analyses

2.6. FT-MIR Spectra

2.7. Multivariate Analysis

2.7.1. Principal Component Analysis (PCA)

2.7.2. Chemometric Models

- Calibration

- Validation

- Prediction (application)

3. Results

3.1. Chemical Analysis

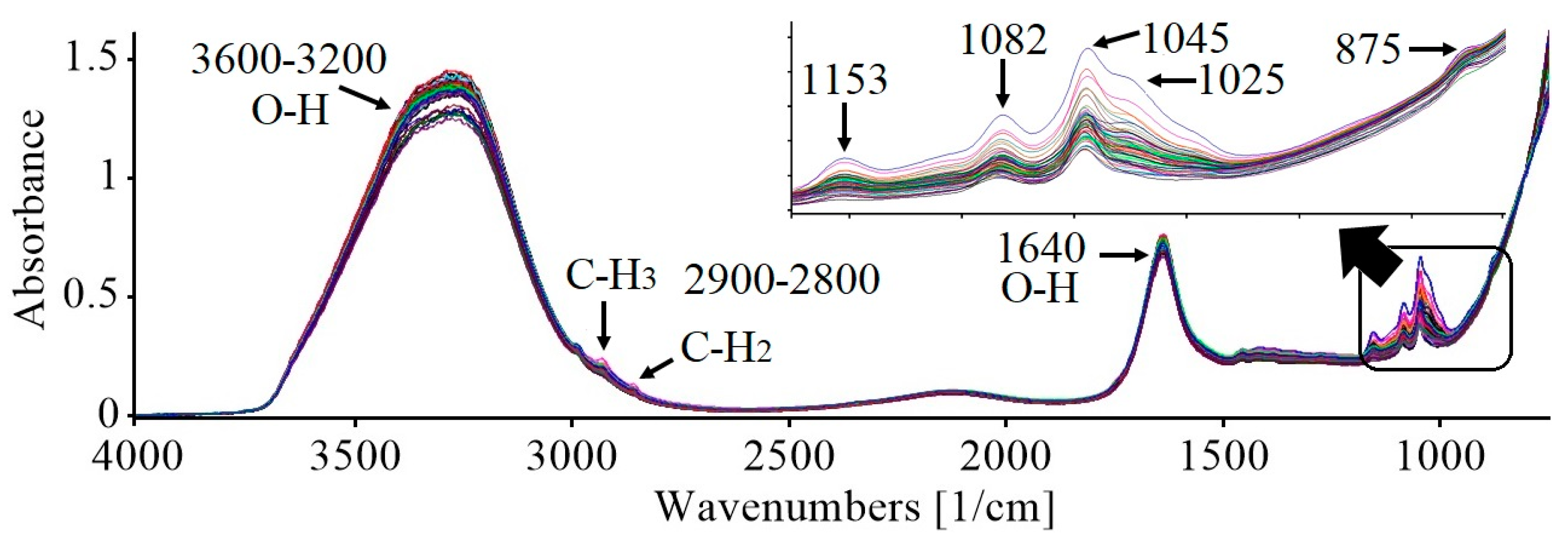

3.2. Spectra FT-MIR

3.3. Multivariate Analysis

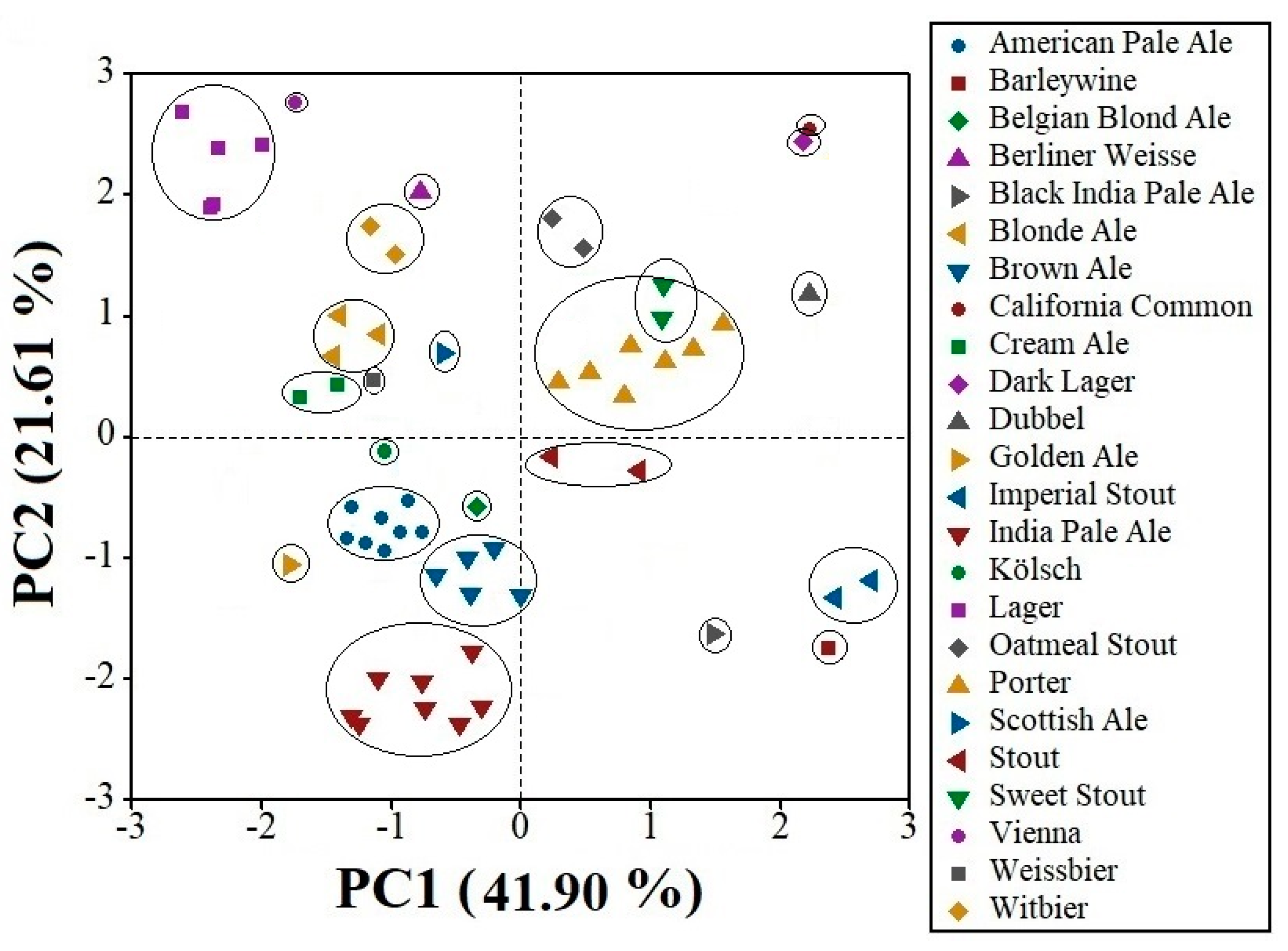

3.3.1. Principal Components Analysis (PCA)

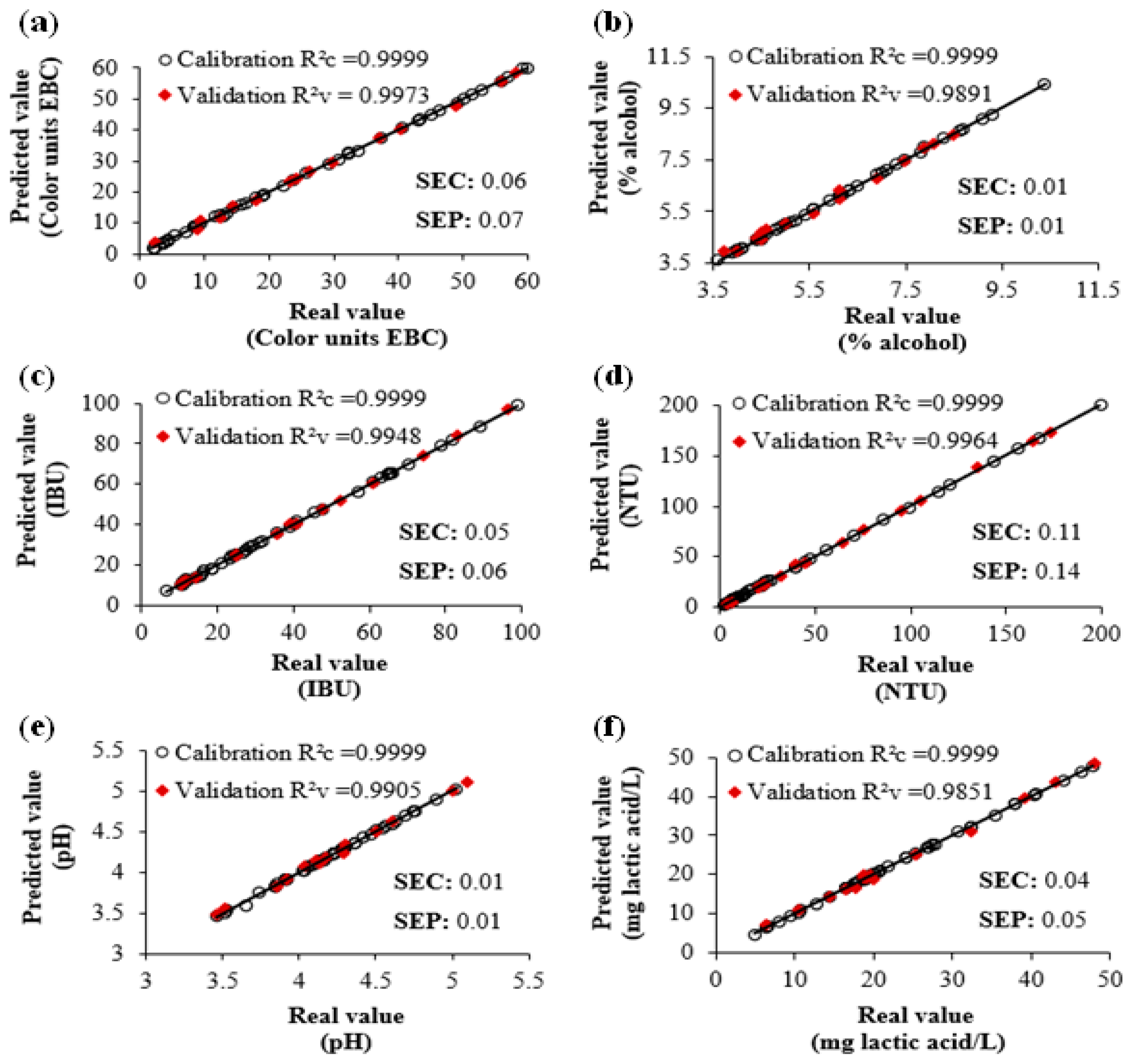

3.3.2. Chemometrics Models

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anderson, H.; Santos, I.; Hildenbrand, Z.; Schug, K. A review of the analytical methods used for beer ingredient and finished product analysis and quality control. Anal. Chim. Acta 2019, 1085, 1–20. [Google Scholar] [CrossRef]

- Gordon, R.; Chapman, J.; Power, A.; Chandra, S.; Roberts, J.; Cozzolino, D. Unfrazzled by fizziness: Identification of beers using attenuated total reflectance mid-infrared spectroscopy and multivariate analysis. Food Anal. Methods 2018, 11, 2360–2367. [Google Scholar] [CrossRef]

- Argent, N. Heading down to the local? Rural development and the evolving spatiality of the craft beer sector. J. Rural. Stud. 2017, 61, 84–99. [Google Scholar] [CrossRef]

- Aquilani, B.; Laureti, T.; Poponi, S.; Secondi, L. Beer choice and consumption determinants when craft beers are tasted: An exploratory study of consumer preferences. Food Qual. Prefer. 2015, 41, 214–224. [Google Scholar] [CrossRef]

- Giannetti, V.; Boccacci, M.; Torrelli, P.; Marini, F. Flavour component analysis by HS-SPME/GC–MS and chemometric modeling to characterize Pilsner-style Lager craft beers. Microchem. J. 2019, 149, 103991. [Google Scholar] [CrossRef]

- Brewers Association. 2023. Available online: https://www.brewersassociation.org (accessed on 29 September 2023).

- Lachenmeier, D. Rapid quality control of spirit drinks and beer using multivariate data analysis of Fourier transform infrared spectra. Food Chem. 2007, 101, 825–832. [Google Scholar] [CrossRef]

- Polshin, E.; Aernouts, B.; Saeys, W.; Delvaux, F.; Delvaux, F.R.; Saison, D.; Hertog, M.; Nicolai, B.; Lammertyn, J. Beer quality screening by FT-IR spectrometry: Impact of measurement strategies, data pre-procesings and variable selection algorithms. J. Food Eng. 2011, 106, 188–198. [Google Scholar] [CrossRef]

- Barth, R. The Chemistry of Beer: The Science in the Suds, 20th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Lohumi, S.; Lee, S.; Lee, H.; Cho, B.-K. A review of vibrational spectroscopic techniques for the detection of food authenticity and adulteration. Trends Food Sci. Technol. 2015, 46, 85–98. [Google Scholar] [CrossRef]

- Su, W.-H.; Sun, D.-W. Mid-infrared (MIR) Spectroscopy for Quality Analysis of Liquid Foods. Food Eng. Rev. 2019, 11, 142–158. [Google Scholar] [CrossRef]

- González-Vázquez, M.; Meza-Márquez, O.G.; Gallardo-Velázquez, T.; Osorio-Revilla, G.; Velázquez-Hernández, J.L.; Hernández-Martínez, D.M. Simultaneous determination of caffeine and taurine in energy drinks by FT-MIR spectroscopy coupled with multivariate analysis. J. Spectrosc. 2020, 2020, 8835846. [Google Scholar] [CrossRef]

- Córtes-Estrada, C.E.; Gallardo-Velázquez, T.; Osorio-Revilla, G.; Castañeda-Pérez, E.; Meza-Márquez, O.G.; López-Cortez, M.S.; Hernández-Martínez, D.M. Prediction of total phenolics, ascorbic acid, antioxidant capacities, and total soluble solids of Capsicum annuum L. (bell pepper) juice by FT-MIR and multivariate analysis. LWT-Food Sci. Technol. 2020, 26, 109285. [Google Scholar] [CrossRef]

- Velázquez-Rendón, C.B.; Meza-Márquez, O.G.; Osorio-Revilla, G.; Gallardo-Velázquez, T. Identification of Adulterants (sunflower Oil and Soybean Oil) in Grapeseed Oil (Vitis vinifera L.) and Chia Oil (Salvia hispanica L.) by FT-MIR Spectroscopy and Chemometric. Emir. J. Food Agric. 2022, 34, 620–627. [Google Scholar] [CrossRef]

- Castillejos-Mijangos, L.A.; Meza-Márquez, O.G.; Osorio-Revilla, G.; Jiménez-Martínez, C.; Gallardo-Velázquez, T. Identification of variety and prediction of chemical composition in cocoa beans (Theobroma cacao L.) by FT-MIR spectroscopy and chemometrics. Foods 2023, 12, 4144. [Google Scholar] [CrossRef] [PubMed]

- Duarte, I.; Barros, A.; Almeida, C.; Spraul, M.; Gil, A. Multivariate analysis of NMR and FTIR as potential tool for the quality control of beer. J. Agric. Food Chem. 2004, 52, 1031–1038. [Google Scholar] [CrossRef] [PubMed]

- Iñon, F.; Garrigues, S.; de la Guardia, M. Combination of mid- and near-infrared spectroscopy for the determination of the quality properties of beers. Anal. Chim. Acta 2006, 571, 167–174. [Google Scholar] [CrossRef]

- Llario, R.; Iñón, F.; Garrigues, S.S.; de la Guardia, M. Determination of quality parameters of beer by the use of attenuated total Reflectance-Fourier transform infrared spectroscopy. Talanta 2006, 69, 469–480. [Google Scholar] [CrossRef] [PubMed]

- Castritius, S.; Geier, M.; Jochims, G.; Stahl, U.; Harms, D. Rapid determination of the attenuation limit of beer using middle infrared (MIR) spectroscopy and multivariate Model. J. Agric. Chem. 2012, 60, 6341–6348. [Google Scholar] [CrossRef]

- Biancolillo, A.; Bucci, R.; Magrì, A.L.; Magrì, A.D.; Marini, F. Data-fusion for multiplataform characterization of an italian craft beer aimed at its authentication. Anal. Chim. Acta 2014, 820, 23–31. [Google Scholar] [CrossRef]

- Program, B.J.C. 2017 Style Guidelines. Beer Judge Certification Program: St. Louis Park, MN, USA, 2018. [Google Scholar]

- EBC Analytica. 9.6—Colour of Beer: Spectrophotometric Method (IM). 2000. Available online: https://brewup.eu/ebc-analytica/beer/colour-of-beer-spectrophotometric-method-im/9.6 (accessed on 29 September 2023).

- EBC Analytica. 9.43.1—Specific Gravity of Beer using a Pyknometer. 2004. Available online: https://brewup.eu/ebc-analytica/beer/specific-gravity-of-beer-using-a-pyknometer/9.43.1 (accessed on 29 September 2023).

- EBC Analytica. 9.2.3—Alcohol in Beer by Refractometry. 2007. Available online: https://brewup.eu/ebc-analytica/beer/alcohol-in-beer-by-refractometry/9.2.3 (accessed on 29 September 2023).

- EBC Analytica. 9.8—Bitterness of Beer (IM). 2020. Available online: https://brewup.eu/ebc-analytica/beer/bitterness-of-beer-im/9.8 (accessed on 29 September 2023).

- EBC Analytica. 9.29—Haze in Beer: Calibration of Haze Meters. 2015. Available online: https://brewup.eu/ebc-analytica/beer/haze-in-beer-calibration-of-haze-meters/9.29 (accessed on 29 September 2023).

- EBC Analytica. 9.35—pH of Beer. 2004. Available online: https://brewup.eu/ebc-analytica/beer/ph-of-beer-formerly-published-as-iob-method-9-42/9.35 (accessed on 29 September 2023).

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis, 20th ed.; Association of Official Analytical Chemists: Arlington, VA, USA, 2016. [Google Scholar]

- Tamaki, Y.; Mazza, G. Rapid determination of lignin content of straw using Fourier mid-infrared spectroscopy. J. Agric. Food Chem. 2011, 59, 504–519. [Google Scholar] [CrossRef]

- Beebe, K.R.; Pell, R.J.; Deascholtz, M.B. Chemometrics: A Practical Guide, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1998. [Google Scholar]

- Granato, D.; Ares, G. Mathematical and Statistical Methods in Food Science and Technology; Wiley Blackwell: New York, NY, USA, 2014. [Google Scholar]

- Liu, F.; Jiang, Y.; He, Y. Variable selection in visible/near spectra for linear and nonlinear calibration: A case study to determine soluble solids content of beer. Anal. Chim. Acta 2009, 635, 45–52. [Google Scholar] [CrossRef]

- Cheiran, K.P.; Raimundo, V.P.; Manfroi, V.; Anzanello, M.J.; Kahmann, A.; Rodrigues, E.; Frazzon, J. Simultaneous identification of low-molecular weight phenolic and nitrogen compounds in craft beers by HPLC-ESI-MS/MS. Food Chem. 2019, 15, 113–122. [Google Scholar] [CrossRef] [PubMed]

- Palmer, J. How to Brew; Brewers Publishing: New York, NY, USA, 2006. [Google Scholar]

- Johnson, J.; Claverie, M.; Wooton, D. The Color and Turbidity of Beer; Beverage Industries: Arlington, VA, USA, 2010. [Google Scholar]

- Kunze, W. Tecnología Para Cerveceros y Malteros; VLB Berlin: Berlin, Germany, 2006. [Google Scholar]

- Boulton, C.; Quain, D. Brewing Yeast and Fermentation; Blackwell Publishing: London, UK, 2001. [Google Scholar]

- Giovenzana, V.; Beghi, R.; Guidetti, R. Rapid evaluation of craft beer quality during fermentation process by vis/NIR spectroscopy. J. Food Eng. 2014, 142, 80–86. [Google Scholar] [CrossRef]

- NOM-199-SCFI-2017; Bebidas Alcohólicas-Denominación, Especificaciones Fisicoquímicas, Información Comercial y Métodos de Prueba (Alcoholic Beverages-Denomination, Physicochemical Specifications, Commercial Information and Test Methods). Diario Oficial de la Federación: Ciudad de México, México, 2017.

- Castritius, S.; Kron, A.; Schäfer, T.; Rädle, M.; Harms, D. Determination of alcohol and extract concentration in beer samples using a combined method of near-infrared (NIR) spectroscopy and refractometry. J. Agric. Food Chem. 2010, 58, 12634–12641. [Google Scholar] [CrossRef]

- Rojano, B. Cómo Hacer Cerveza en Casa; Panorama: Ciudad de México, México, 2015. [Google Scholar]

- Keukeleire, D. Fundamentals of Beer and Hop Chemistry. Química Nova 2000, 23, 108–112. [Google Scholar] [CrossRef]

- Fermun, D.; Catells, I.; Sarries, N. Guía Para Descubrir las Mejores Cervezas Artesanas; Planeta: Madrid, España, 2013. [Google Scholar]

- Grazia, A.; Ciaccheri, L.; Mencaglia, A.; Ottovaere, H.; Samano, E.; Thienpont, H. Optical measurements and pattern-recognition techniques for identifying the characteristics of beer and distinguishing Belgian beers. Sens. Actuators B Chem. 2013, 179, 140–149. [Google Scholar]

- Steiner, E.; Becker, T.; Gastl, M. Turbidity and haze formation in beer. J. Inst. Brew. 2010, 116, 360–368. [Google Scholar] [CrossRef]

- Almeida, A.; Duarte, I.; Barros, A.; Rodrigues, J.; Spraul, M.; Gil, A. Composition of Beer by 1H NMR spectroscopy: Effects of brewing site and date of production. J. Agric. Food Chem. 2006, 54, 700–706. [Google Scholar] [CrossRef] [PubMed]

- Grassi, S.; Amigo, J.; Lyndgaard, C.; Foschino, R.; Casiraghi, E. Beer fermentation: Monitoring of process parameters by FT-NIR and multivariate data analysis. Food Chem. 2014, 155, 279–286. [Google Scholar] [CrossRef]

- Lachenmeier, D.; Frank, W.; Humpfer, E.; Schäfer, H.; Keller, S.; Mörtter, M.; Spraul, M. Quality control of beer using high-resolution nuclear magnetic resonance spectroscopy and multivariate analysis. Eur. Food Res. Technol. 2005, 220, 215–221. [Google Scholar] [CrossRef]

| CALIBRATION (n = 45) | VALIDATION (n = 15) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Algorithm | Parameter | Units | Factors | R2c | SEC | R2v | SEP | MD | RR | %RD | RPD |

| PCR | Color | EBC | 1 | 0.2403 | 16.93 | - | 16.96 | - | - | - | - |

| Alcohol | %(v/v) | 4 | 0.7102 | 1.03 | - | 1.08 | - | - | - | - | |

| Bitterness | IBU | 2 | 0.4386 | 16.84 | - | 16.82 | - | - | - | - | |

| Turbidity | NTU | 3 | 0.3172 | 16.51 | - | 16.47 | - | - | - | - | |

| pH | - | 1 | 0.5648 | 0.24 | - | 0.25 | - | - | - | - | |

| Acidity | mg/L | 2 | 0.2909 | 8.38 | - | 8.72 | - | - | - | - | |

| PLS1 | Color | EBC | 10 | 0.9999 | 0.06 | 0.9973 | 0.07 | 0.15–0.74 | 0.59–0.99 | 2.22–6.57 | 14.39–18.62 |

| Alcohol | %(v/v) | 10 | 0.9999 | 0.01 | 0.9890 | 0.01 | 0.13–0.68 | 0.63–1.04 | 0.76–5.33 | 13.01–17.93 | |

| Bitterness | IBU | 10 | 0.9999 | 0.05 | 0.9948 | 0.06 | 0.11–0.79 | 0.57–1.15 | 1.61–6.25 | 9.01–15.32 | |

| Turbidity | NTU | 10 | 0.9999 | 0.11 | 0.9964 | 0.14 | 0.16–0.68 | 0.55–1.36 | 1.35–4.68 | 11.02–16.97 | |

| pH | - | 10 | 0.9999 | 0.01 | 0.9905 | 0.01 | 0.09–0.81 | 0.44–1.28 | 1.98–4.87 | 10.48–18.89 | |

| Acidity | mg/L | 10 | 0.9999 | 0.04 | 0.9851 | 0.05 | 0.18–0.80 | 0.54–1.45 | 2.01–6.19 | 8.32–14.35 | |

| PLS2 | Color | EBC | 5 | 0.7198 | 10.64 | - | 10.95 | - | - | - | - |

| Alcohol | %(v/v) | 1 | 0.8604 | 1.53 | - | 1.56 | - | - | - | - | |

| Bitterness | IBU | 7 | 0.7371 | 11.54 | - | 12.95 | - | - | - | - | |

| Turbidity | NTU | 1 | 0.9240 | 10.11 | - | 10.11 | - | - | - | - | |

| pH | - | 1 | 0.7488 | 0.46 | - | 0.47 | - | - | - | - | |

| Acidity | mg/L | 7 | 0.7197 | 8.58 | - | 8.58 | - | - | - | - | |

| Non-Craft Beer | Parameter | Units | MD | RR |

|---|---|---|---|---|

| 1–15 | Color | EBC | 0.16–0.85 | 1.95–2.68 |

| Alcohol | % | 0.05–0.62 | 0.25–1.36 | |

| Bitterness | IBU | 0.28–0.37 | 1.37–1.99 | |

| Turbidity | NTU | 0.67–0.89 | 0.89–2.14 | |

| pH | - | 0.31–0.78 | 0.46–2.38 | |

| Acidity | mg/L | 0.47–0.66 | 1.48–1.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meza-Márquez, O.G.; Rodríguez-Híjar, A.R.; Gallardo-Velázquez, T.; Osorio-Revilla, G.; Ramos-Monroy, O.A. The Prediction of Quality Parameters of Craft Beer with FT-MIR and Chemometrics. Foods 2024, 13, 1157. https://doi.org/10.3390/foods13081157

Meza-Márquez OG, Rodríguez-Híjar AR, Gallardo-Velázquez T, Osorio-Revilla G, Ramos-Monroy OA. The Prediction of Quality Parameters of Craft Beer with FT-MIR and Chemometrics. Foods. 2024; 13(8):1157. https://doi.org/10.3390/foods13081157

Chicago/Turabian StyleMeza-Márquez, Ofelia Gabriela, Andrés Ricardo Rodríguez-Híjar, Tzayhri Gallardo-Velázquez, Guillermo Osorio-Revilla, and Oswaldo Arturo Ramos-Monroy. 2024. "The Prediction of Quality Parameters of Craft Beer with FT-MIR and Chemometrics" Foods 13, no. 8: 1157. https://doi.org/10.3390/foods13081157

APA StyleMeza-Márquez, O. G., Rodríguez-Híjar, A. R., Gallardo-Velázquez, T., Osorio-Revilla, G., & Ramos-Monroy, O. A. (2024). The Prediction of Quality Parameters of Craft Beer with FT-MIR and Chemometrics. Foods, 13(8), 1157. https://doi.org/10.3390/foods13081157