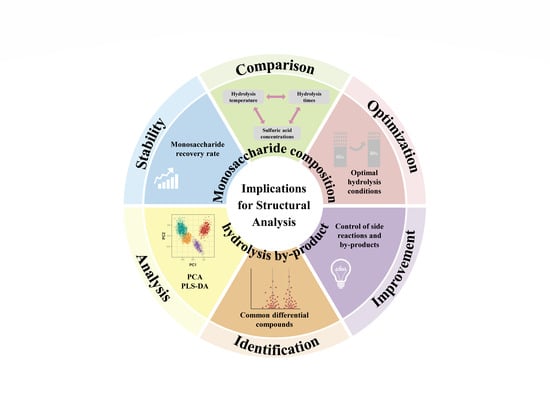

Exploration and Improvement of Acid Hydrolysis Conditions for Inulin-Type Fructans Monosaccharide Composition Analysis: Monosaccharide Recovery and By-Product Identification

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Hydrolysis and Monosaccharide Composition Analysis

2.3. Desalination and Hydrolysis By-Products Identification

2.4. Statistical Analysis

3. Results and Discussion

3.1. Optimization of Acid Hydrolysis Conditions of ITF

3.2. Stability of Monosaccharide Standards under Different Hydrolysis Conditions

3.3. Analysis of Hydrolysis By-Products

3.3.1. Trend of Hydrolysis By-Products of ITF under Different Hydrolysis Conditions

3.3.2. Identification of Characteristic Hydrolysis By-Product

| No | Identification | m/z a | Adducts | Error (ppm) | RT b (min) | Score | Formula | Classification c | References |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 2,5-Furandicarboxaldehyde | 125.02 | [M+H]+ | −3.493 | 3.806 | 46.1 | C6H4O3 | Aldehyde | [16,44,46] |

| 2 | 5-Hydroxymethyl-2-furaldehyde | 109.0285 | [M+H−H2O]+ | 0.419 | 3.660 | 43 | C6H6O3 | ||

| 3 | Furfural | 97.03 | [M+H]+ | −2.110 | 3.101 | 40.4 | C5H4O2 | ||

| 4 | 5-Methyl-2-furaldehyde | 111.0438 | [M+H]+ | −4.408 | 4.007 | 38.7 | C6H6O2 | ||

| 5 | 2-Phenylethanol | 123.0799 | [M+H]+ | −2.350 | 5.077 | 37.3 | C8H10O | ||

| 6 | 2-Hydroxycinnamic acid | 165.05 | [M+H]+ | −0.838 | 3.540 | 41.6 | C9H8O3 | Acid | [44,49,50] |

| 7 | 1,4-Dihydroxy-2-naphthoic acid | 205.05 | [M+H]+ | −2.377 | 4.034 | 38.3 | C11H8O4 | ||

| 8 | 2-Hydroxy-8-methylchromene-2-carboxylate | 207.06 | [M+H]+ | −2.350 | 5.077 | 38.9 | C11H10O4 | Ester | [51,52] |

| 9 | 2-Hydroxy-3-methylbenzalpyruvate | 207.06 | [M+H]+ | −1.987 | 5.699 | 41.1 | C11H10O4 | Ketone | [45,50] |

| 10 | 2-Hydroxy-5-methylquinone | 139.04 | [M+H]+ | −1.921 | 3.819 | 39.7 | C7H6O3 | Others | [38,51,53] |

| 11 | 2-Hydroxy-6-oxo-6-(2-hydroxyphenoxy)-hexa-2,4-dienoate | 273.04 | [M+H]+, [M+Na]+, [M+H−H2O]+ | −0.387 | 4.209 | 39.7 | C12H10O6 | ||

| 12 | (R)-(−)-Mellein | 179.07 | [M+H]+ | −1.985 | 4.847 | 38.6 | C10H10O3 | ||

| 13 | 2-Hydroxyxanthone | 213.0541 | [M+H]+ | −2.367 | 6.092 | 38.5 | C13H8O3 |

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Marie-Luise, P.; de Vos, W.M. Back to the Roots: Revisiting the Use of the Fiber-Rich Cichorium intybus L. Taproots. Adv. Nutr. 2021, 12, 1598. [Google Scholar]

- Mensink, M.A.; Frijlink, H.W.; Maarschalk, K.v.d.V.; Hinrichs, W.L. Inulin, a flexible oligosaccharide. II: Review of its pharmaceutical applications. Carbohydr. Polym. 2015, 134, 418–428. [Google Scholar] [CrossRef]

- Apolinário, A.C.; de Lima Damasceno, B.P.G.; de Macêdo Beltrão, N.E.; Pessoa, A.; Converti, A.; da Silva, J.A. Inulin-type fructans: A review on different aspects of biochemical and pharmaceutical technology. Carbohydr. Polym. 2014, 101, 368–378. [Google Scholar] [CrossRef]

- Gupta, N.; Jangid, A.K.; Pooja, D.; Kulhari, H. Inulin: A novel and stretchy polysaccharide tool for biomedical and nutritional applications. Int. J. Biol. Macromol. 2019, 132, 852–863. [Google Scholar] [CrossRef]

- Shoaib, M.; Shehzad, A.; Omar, M.; Rakha, A.; Raza, H.; Sharif, H.R.; Shakeel, A.; Ansari, A.; Niazi, S. Inulin: Properties, health benefits and food applications. Carbohydr. Polym. 2016, 147, 444–454. [Google Scholar] [CrossRef]

- Meyer, D.; Bayarri, S.; Tárrega, A.; Costell, E. Inulin as texture modifier in dairy products. Food Hydrocoll. 2011, 25, 1881–1890. [Google Scholar] [CrossRef]

- Cataldi, T.R.I. Recent advances in carbohydrate analysis by high-performance anion-exchange chromatography coupled with pulsed amperometric detection (HPAEC-PAD). Ann. Chim. 1994, 84, 385–396. [Google Scholar]

- Wang, Q.-C.; Zhao, X.; Pu, J.-H.; Luan, X.-H. Influences of acidic reaction and hydrolytic conditions on monosaccharide composition analysis of acidic, neutral and basic polysaccharides. Carbohydr. Polym. 2016, 143, 296–300. [Google Scholar] [CrossRef]

- Pico, J.; Vidal, N.P.; Widjaja, L.; Falardeau, L.; Albino, L.; Martinez, M.M. Development and assessment of GC/MS and HPAEC/PAD methodologies for the quantification of α-galacto-oligosaccharides (GOS) in dry beans (Phaseolus vulgaris). Food Chem. 2021, 349, 129151. [Google Scholar] [CrossRef]

- Joyce, G.E.; Kagan, I.A.; Flythe, M.D.; Davis, B.E.; Schendel, R.R. Profiling of cool-season forage arabinoxylans via a validated HPAEC-PAD method. Front. Plant Sci. 2023, 14, 1116995. [Google Scholar] [CrossRef]

- Li, K.; Liu, S.; Tan, Y.; Chao, N.; Tian, X.; Qi, L.; Powell, W.A.; Jiang, X.; Gai, Y. Optimized GC-MS Method To Simultaneously Quantify Acetylated Aldose, Ketose, and Alditol for Plant Tissues Based on Derivatization in a Methyl Sulfoxide/1-Methylimidazole System. J. Agric. Food Chem. 2013, 61, 4011–4018. [Google Scholar] [CrossRef]

- Shi, H.; Wan, Y.; Li, O.; Zhang, X.; Xie, M.; Nie, S.; Yin, J. Two-step hydrolysis method for monosaccharide composition analysis of natural polysaccharides rich in uronic acids. Food Hydrocoll. 2020, 101, 105524. [Google Scholar] [CrossRef]

- Zhang, Z.; Khan, N.M.; Nunez, K.M.; Chess, E.K.; Szabo, C.M. Complete monosaccharide analysis by High-performance anion-exchange chromatography with pulsed amperometric detection. Anal. Chem. 2012, 84, 4104–4110. [Google Scholar] [CrossRef]

- Yang, Z.; Hu, J.; Zhao, M. Isolation and quantitative determination of inulin-type oligosaccharides in roots of Morinda officinalis. Carbohydr. Polym. 2011, 83, 1997–2004. [Google Scholar] [CrossRef]

- Rubel, I.A.; Iraporda, C.; Novosad, R.; Cabrera, F.A.; Genovese, D.B.; Manrique, G.D. Inulin rich carbohydrates extraction from Jerusalem artichoke (Helianthus tuberosus L.) tubers and application of different drying methods. Food Res. Int. 2018, 103, 226–233. [Google Scholar] [CrossRef]

- Antal, M.J., Jr.; Mok, W.S.L.; Richards, G.N. Mechanism of formation of 5-(hydroxymethyl)-2-furaldehyde from D-fructose and sucrose. Carbohydr. Res. 1990, 199, 91–109. [Google Scholar] [CrossRef]

- Madani-Tonekaboni, M.; Kamankesh, M.; Mohammadi, A. Determination of furfural and hydroxymethyl furfural from baby formula using dispersive liquid–liquid microextraction coupled with high performance liquid chromatography and method optimization by response surface methodology. J. Food Compos. Anal. 2015, 40, 1–7. [Google Scholar] [CrossRef]

- Kamalabadi, M.; Ghaemi, E.; Mohammadi, A.; Alizadeh, N. Determination of furfural and hydroxymethylfurfural from baby formula using headspace solid phase microextraction based on nanostructured polypyrrole fiber coupled with ion mobility spectrometry. Food Chem. 2015, 181, 72–77. [Google Scholar] [CrossRef]

- Rocklin, R.D.; Christopher, A.P.E. Determination of carbohydrates by anion exchange chromatography with pulsed amperometric detection. J. Liq. Chromatogr. 1983, 9, 1577–1590. [Google Scholar] [CrossRef]

- Amelung, W.; Cheshire, M.V.; Guggenberger, G. Determination of neutral and acidic sugars in soil by capillary gas-liquid chromatography after trifluoroacetic acid hydrolysis. Soil Biol. Biochem. 1996, 28, 1631–1639. [Google Scholar] [CrossRef]

- Amin, E.S. Action of dilute sulfuric acid on D-fructose. Carbohydr. Res. 1967, 4, 96–98. [Google Scholar] [CrossRef]

- Shaw, P.E.; Tatum, J.H.; Berry, R.E. Acid-catalyzed degradation of D-fructose. Carbohydr. Res. 1967, 5, 266–273. [Google Scholar] [CrossRef]

- Cataldi, T.R.I.; Campa, C.; De Benedetto, G.E. Carbohydrate analysis by high-performance anion-exchange chromatography with pulsed amperometric detection: The potential is still growing. Anal. Bioanal. Chem. 2000, 368, 739–758. [Google Scholar] [CrossRef]

- Bai, W.; Fang, X.; Zhao, W.; Huang, S.; Zhang, H.; Qian, M. Determination of oligosaccharides and monosaccharides in Hakka rice wine by precolumn derivation high-performance liquid chromatography. J. Food Drug Anal. 2015, 23, 645–651. [Google Scholar] [CrossRef]

- Liu, Y.; Lei, F.; He, L.; Xu, W.; Jiang, J. Comparative study on the monosaccharides of three typical galactomannans hydrolyzed by different methods. Ind. Crops Prod. 2020, 157, 112895. [Google Scholar] [CrossRef]

- Adeogun, A.I.; Idowu, M.A.; Oladeji, O.B.; Ofudje, E.A.; Akinloye, A.O. Kinetic, thermodynamic and optimization studies of dilute acid hydrolysis of Manihot esculenta peels for glucose production. Waste Biomass Valorization 2020, 11, 817–826. [Google Scholar] [CrossRef]

- Silva, V.G.; Aguilar, M.S.C.; Ascanio, G.; Aguayo, J.P.; Pérez-Salas, K.Y.; Notario, A.d.C.S. Acid Hydrolysis of Pectin and Mucilage from Cactus (Opuntia ficus) for Identification and Quantification of Monosaccharides. Molecules 2022, 27, 5830. [Google Scholar] [CrossRef]

- Świątek, K.; Gaag, S.; Klier, A.; Kruse, A.; Sauer, J.; Steinbach, D. Acid hydrolysis of Lignocellulosic biomass: Sugars and furfurals formation. Catalysts 2020, 10, 437. [Google Scholar] [CrossRef]

- Chong, J.; Soufan, O.; Li, C.; Caraus, I.; Li, S.; Bourque, G.; Wishart, D.S.; Xia, J. MetaboAnalyst 4.0: Towards more transparent and integrative metabolomics analysis. Nucleic Acids Res. 2018, 46, W486–W494. [Google Scholar] [CrossRef]

- Panahabadi, R.; Ahmadikhah, A.; Farrokhi, N. Genetic dissection of monosaccharides contents in rice whole grain using genome-wide association study. Plant Genome 2023, 16, e20292. [Google Scholar] [CrossRef]

- Thani, N.M.; Kamal, S.M.M.; Taip, F.S.; Sulaiman, A.; Omar, R.; Siajam, S.I. Hydrolysis and characterization of sugar recovery from bakery waste under optimized subcritical water conditions. J. Food Sci. Technol. 2020, 57, 3108–3118. [Google Scholar] [CrossRef]

- Liu, D.; Tang, W.; Yin, J.-Y.; Nie, S.-P.; Xie, M.-Y. Monosaccharide composition analysis of polysaccharides from natural sources: Hydrolysis condition and detection method development. Food Hydrocoll. 2021, 116, 106641. [Google Scholar] [CrossRef]

- Xie, B.; Yi, L.; Zhu, Y.; Chang, X.; Hao, J.; Pang, L.; Ouyang, Y.; Yuan, S.; Zhang, Z. Structural elucidation of a branch-on-branch β-glucan from Hericium erinaceus with A HPAEC-PAD-MS system. Carbohydr. Polym. 2021, 251, 117080. [Google Scholar] [CrossRef]

- Wang, S.; Li, G.; Zhang, X.; Wang, Y.; Qiang, Y.; Wang, B.; Zou, J.; Niu, J.; Wang, Z. Structural characterization and antioxidant activity of Polygonatum sibiricum polysaccharides. Carbohydr. Polym. 2022, 291, 119524. [Google Scholar] [CrossRef]

- Zong, X.; Wang, Z.; Chen, S.; Li, S.; Xie, M.; Nie, S.; Yin, J. Optimized acid hydrolysis conditions for better characterization the structure of inulin-type fructan from Polygonatum sibiricum. Int. J. Biol. Macromol. 2024, 256, 128030. [Google Scholar] [CrossRef]

- Moreau, C.; Durand, R.; Razigade, S.; Duhamet, J.; Faugeras, P.; Rivalier, P.; Ros, P.; Avignon, G. Dehydration of fructose to 5-hydroxymethylfurfural over H-mordenites. Appl. Catal. A Gen. 1996, 145, 211–224. [Google Scholar] [CrossRef]

- Uhliariková, I.; Matulová, M.; Capek, P. Optimizing acid hydrolysis for monosaccharide compositional analysis of Nostoc cf. linckia acidic exopolysaccharide. Carbohydr. Res. 2021, 508, 108400. [Google Scholar] [CrossRef]

- Philip, E.S.; James, H.T.; Robert, E.B. 2,3-Dihydro-3,5-dihydroxy-6-methyl-4H-pyran-4-one, a degradation product of a hexose. Carbohydr. Res. 1971, 16, 207–211. [Google Scholar]

- Cordella, C.; Militão, J.S.; Clément, M.-C.; Drajnudel, P.; Cabrol-Bass, D. Detection and quantification of honey adulteration via direct incorporation of sugar syrups or bee-feeding: Preliminary study using high-performance anion exchange chromatography with pulsed amperometric detection (HPAEC-PAD) and chemometrics. Anal. Chim. Acta 2005, 531, 239–248. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Choi, J.; Lee, G.; Lee, K.-G. Analysis of furan and monosaccharides in various coffee beans. J. Food Sci. Technol. 2021, 58, 862–869. [Google Scholar] [CrossRef]

- Miller, R.E.; Cantor, S.M. 2-Hydroxyacetylfuran from sugars. J. Am. Chem. Soc. 1952, 20, 5236–5237. [Google Scholar] [CrossRef]

- Brown, D.W.; Floyd, A.J.; Kinsman, R.G.; Roshan-Ali, Y. Dehydration reactions of fructose in non-aqueous media. J. Chem. Technol. Biotechnol. 1982, 32, 920–924. [Google Scholar] [CrossRef]

- Asghari, F.S.; Yoshida, H. Acid-catalyzed production of 5-hydroxymethyl furfural from D-fructose in subcritical water. Ind. Eng. Chem. Res. 2013, 45, 2163–2173. [Google Scholar] [CrossRef]

- Fachri, B.A.; Abdilla, R.M.; van de Bovenkamp, H.H.; Rasrendra, C.B.; Heeres, H.J. Experimental and kinetic modeling studies on the sulfuric acid catalyzed conversion of d-fructose to 5-Hydroxymethylfurfural and levulinic acid in water. ACS Sustain. Chem. Eng. 2015, 3, 3024–3034. [Google Scholar] [CrossRef]

- Perez, G.P.; Mukherjee, A.; Dumont, M.J. Insights into HMF catalysis. J. Ind. Eng. Chem. 2019, 70, 1–34. [Google Scholar] [CrossRef]

- Swift, T.D.; Bagia, C.; Choudhary, V.; Peklaris, G.; Nikolakis, V.; Vlachos, D.G. Kinetics of homogeneous bronsted acid catalyzed fructose dehydration and 5-Hydroxymethyl furfural rehydration: A combined experimental and computational study. ACS Catal. 2014, 4, 259–267. [Google Scholar] [CrossRef]

- Antonetti, C.; Melloni, M.; Licursi, D.; Fulignati, S.; Ribechini, E.; Rivas, S.; Parajó, J.C.; Cavani, F.; Galletti, A.M.R. Microwave-assisted dehydration of fructose and inulin to HMF catalyzed by niobium and zirconium phosphate catalysts. Appl. Catal. B Environ. 2017, 206, 364–377. [Google Scholar] [CrossRef]

- Ruan, Y.; Niu, C.; Zhang, P.; Qian, Y.; Li, X.; Wang, L.; Ma, B. Acid-catalyzed water extraction of two polysaccharides from Artemisia argyi and their physicochemical properties and antioxidant activities. Gels 2022, 8, 5. [Google Scholar] [CrossRef]

- Rice, F.H.; Fishbein, L. Effect of Aqueous Sulfuric Acid on Sugars. II. Spectrophotometric Studies on the Hexoses; Identification of the Ether-soluble Products Formed. J. Am. Chem. Soc. 1956, 78, 3731–3734. [Google Scholar] [CrossRef]

- James, C.G.; John, E.H.; David, W. Preparation and structure of an unusual dimeric furan from the acid decomposition of isomaltol. Carbohydr. Res. 1986, 146, 107–116. [Google Scholar]

- Akien, G.R.; Qi, L.; Horváth, I.T. Molecular mapping of the acid catalysed dehydration of fructose. Chem. Commun. 2012, 47, 5850–5852. [Google Scholar] [CrossRef] [PubMed]

- Rice, F.A.H.; Fishbein, L. Spectrophotometric Studies on the Action of Sulfuric Acid on Reducing Sugars and the Isolation and Identification of the Ether-soluble Substances Produced from Pentoses under Acid Conditions. J. Am. Chem. Soc. 1956, 78, 1005–1009. [Google Scholar] [CrossRef]

- Hoang, T.M.C.; van Eck, E.R.H.; Bula, W.P.; Gardeniers, J.G.E.; Lefferts, L.; Seshan, K. Humin based by-products from biomass processing as a potential carbonaceous source for synthesis gas production. Green Chem. 2015, 17, 959–972. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zong, X.; Lei, N.; Yin, J.; He, W.; Nie, S.; Xie, M. Exploration and Improvement of Acid Hydrolysis Conditions for Inulin-Type Fructans Monosaccharide Composition Analysis: Monosaccharide Recovery and By-Product Identification. Foods 2024, 13, 1241. https://doi.org/10.3390/foods13081241

Zong X, Lei N, Yin J, He W, Nie S, Xie M. Exploration and Improvement of Acid Hydrolysis Conditions for Inulin-Type Fructans Monosaccharide Composition Analysis: Monosaccharide Recovery and By-Product Identification. Foods. 2024; 13(8):1241. https://doi.org/10.3390/foods13081241

Chicago/Turabian StyleZong, Xinyan, Ningyu Lei, Junyi Yin, Weiwei He, Shaoping Nie, and Mingyong Xie. 2024. "Exploration and Improvement of Acid Hydrolysis Conditions for Inulin-Type Fructans Monosaccharide Composition Analysis: Monosaccharide Recovery and By-Product Identification" Foods 13, no. 8: 1241. https://doi.org/10.3390/foods13081241